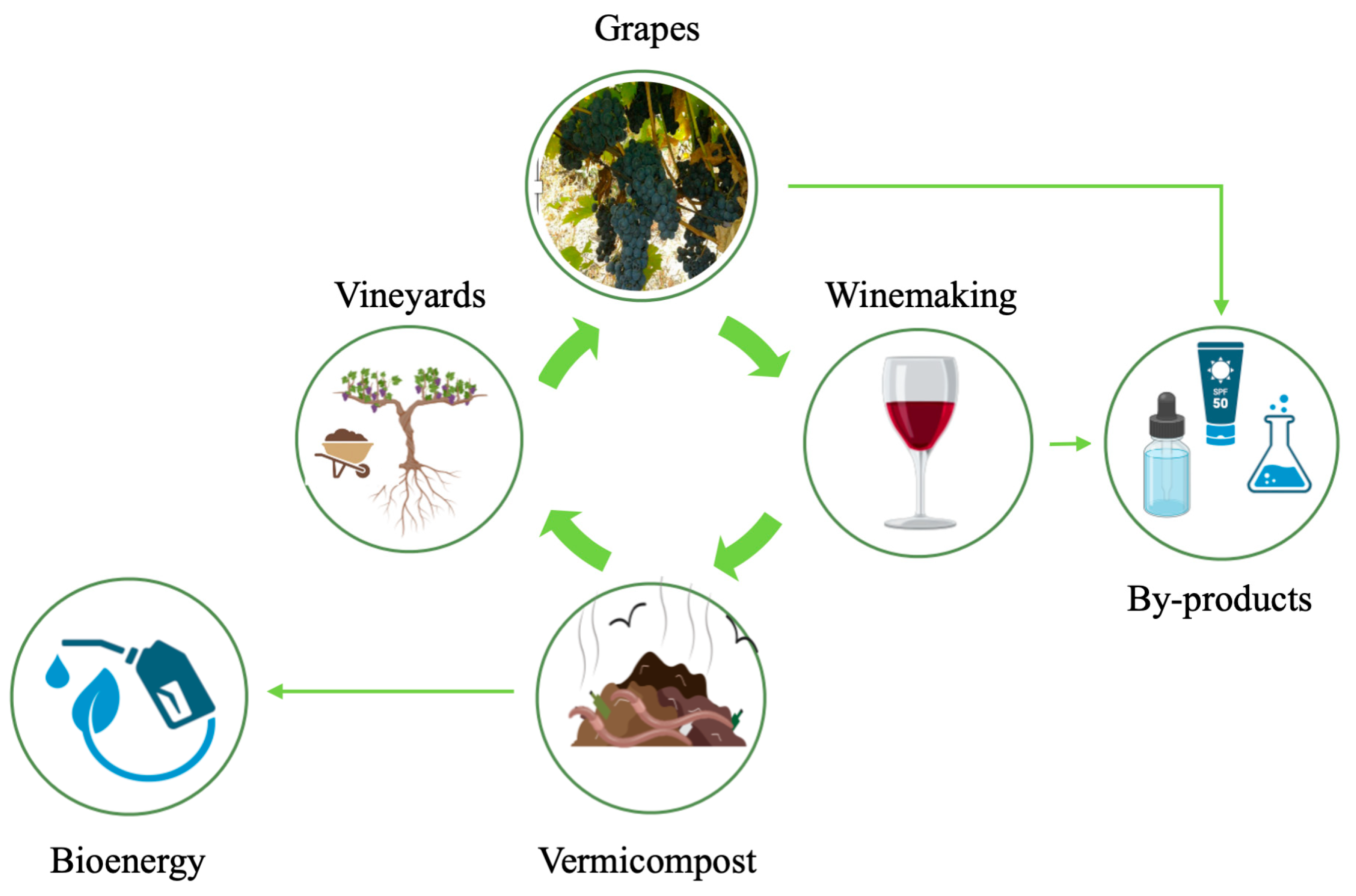

From Waste to Value in Circular Economy: Valorizing Grape Pomace Waste through Vermicomposting

Abstract

:1. Introduction

2. Methodology

- (a)

- Relevant international databases and information sources. Bibliometric sources such as Elsevier (Science Direct), MDPI, PubMed, Frontiers, Springer, and Wiley Online databases were used to retrieve articles, book chapters, and international proceedings articles. International databases of the European Commission were used for the selection of directives or reports related to the relevant keywords.

- (b)

- Relevant keywords for the topics of interest were considered: “grape pomace”, “grape marc”, “winemaking by-products”, “circular economy”, “vermicompost”, “valorisation of grape pomace”, “advantages of vermicompost”, “environmental”, “vineyards management”, “biofertilizers”.

- (c)

- Period of publication: articles between 2009 and 2024 were selected, published in the English language.

- (d)

- Selection of the references cited in this review based on content analysis. More than 139 articles were identified as interesting based on their abstracts, and 111 publications/reports were included, based on a thorough analysis of their content.

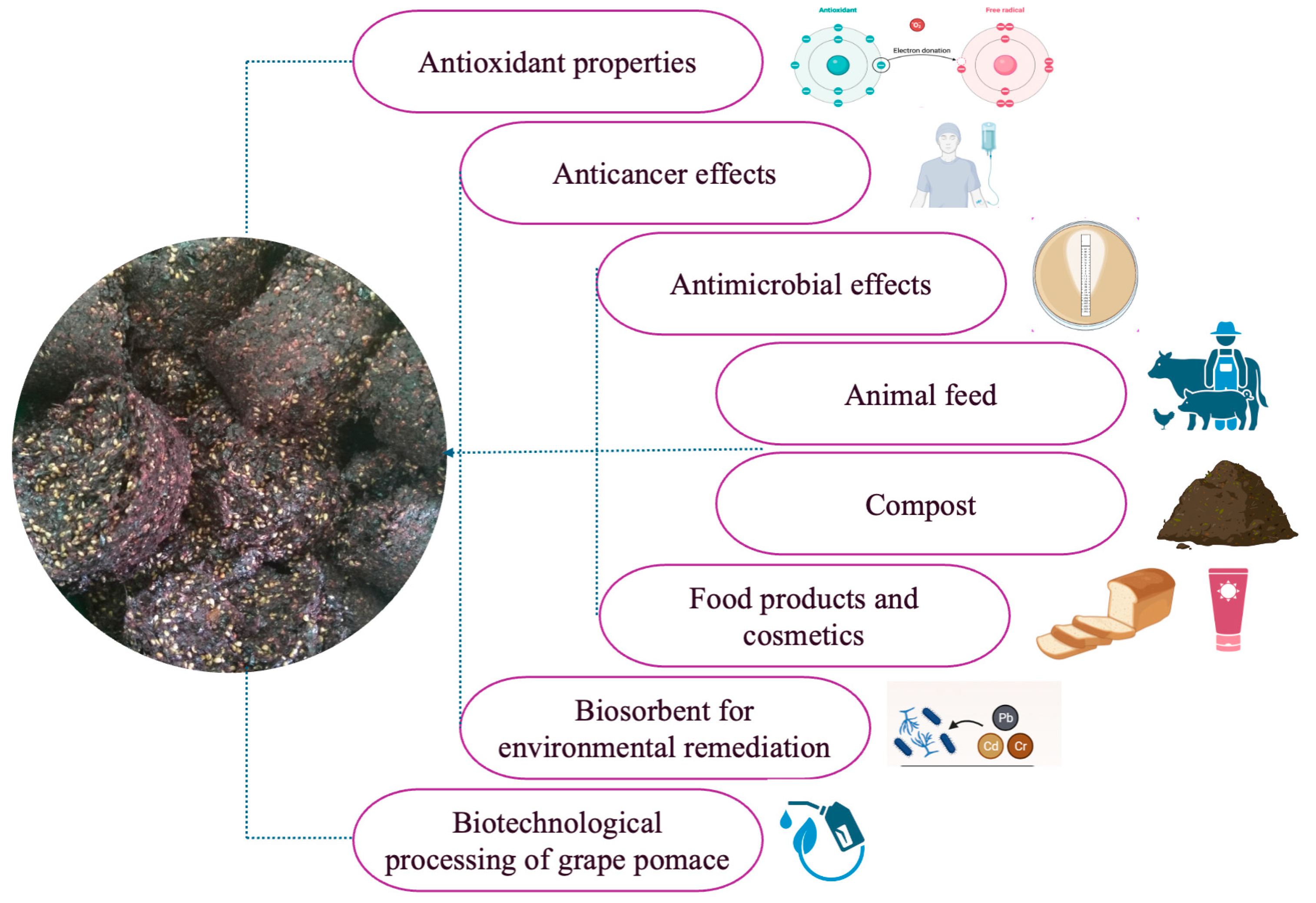

3. Valorization of By-Products and Wastes from Winemaking Process

| Waste | Composition (w/w) | Percentage (%) | References |

|---|---|---|---|

| Grape pomace/grape marc/grape bagasse | Cellulose | 10–75 | [23,24,25,26] |

| Hemicellulose | 6.1 | ||

| Lignin | 34–41 | ||

| Moisture content | 50–70 | ||

| Proteins | <4 | ||

| Condensed tannins (insoluble) | 15 | ||

| Pectin substances | 20 | ||

| Neutral polysaccharides | 30 | ||

| Grape stalks/grape stems | Cellulose | 20–30 | [23] |

| Hemicellulose | 15–20 | ||

| Lignin | 17–26 | ||

| Condensed tannins (insoluble) | 6–16 | ||

| Proteins | 6 | ||

| Ashes | 6–9 | ||

| Soluble polyphenols | 1–3 | ||

| Seeds | Lipids (oils and fatty acids) | 13–15 | [27] |

| Dietary fibers | 48 | ||

| Proteins | 11.5 | ||

| Polyphenolic compounds | 5–8 | ||

| Carbohydrates | 60–70 | ||

| Lees | Dead yeast | N/A | [28] |

| Grape pulp | |||

| Inorganic matter | |||

| Phenolics | |||

| Tartaric acid | |||

| Ethanol | |||

| Vine shoots | Cellulose | 34 | [24,29] |

| Hemicellulose | 20–30 | ||

| Lignin | 20–27 | ||

| Tannin | 1.25 | ||

| Proteins | 5 | ||

| Ashes | 3–4 |

3.1. Antimicrobial Effects

3.2. Antioxidant Properties

3.3. Anticancer Effects

3.4. Animal Feed

3.5. Compost

3.6. Food Products and Cosmetics

3.7. Biosorbents for Environmental Remediation

3.8. Biotechnological Processing of Grape Pomace to Produce Value-Added Products

4. Overview of the Vermicompost Production

5. Advantages and Disadvantages of Vermicompost

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Commission of European Communities. Closing the Loop—An EU Action Plan for the Circular Economy; Communication No. 614; (COM (2015), 614); Commission of European Communities: Brussels, Belgium, 2015; Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:8a8ef5e8-99a0-11e5-b3b7-01aa75ed71a1.0012.02/DOC_1&format=PDF (accessed on 30 June 2024).

- OIV. State of the World Vine and Wine Sector in 2022. Available online: https://www.oiv.int/sites/default/files/documents/OIV_State_of_the_world_Vine_and_Wine_sector_in_2022_2.pdf (accessed on 3 March 2024).

- Zabaniotou, A.; Kamaterou, P.; Pavlou, A.; Panayiotou, C. Sustainable bioeconomy transitions: Targeting value capture by integrating pyrolysis in a winery waste biorefinery. J. Clean. Prod. 2017, 172, 3387–3397. [Google Scholar] [CrossRef]

- Poveda, J.M.; Loarce, L.; Alarcón, M.; Díaz-Maroto, M.C.; Alañón, M.E. Revalorization of winery by-products as source of natural preservatives obtained by means of green extraction techniques. Ind. Crops Prod. 2018, 112, 617–625. [Google Scholar] [CrossRef]

- European Parliament and the Council of the European Union. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; European Parliament and the Council of the European Union: Strasbourg, France, 2018; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32008L0098&from=EL (accessed on 20 April 2024).

- Barbera, A.C.; Maucieri, C.; Cavallaro, V.; Ioppolo, A.; Spagna, G. Effects of spreading olive mill wastewater on soil properties and crops, a review. Agric. Water Manag. 2013, 119, 43–53. [Google Scholar] [CrossRef]

- Flavel, T.C.; Murphy, D.V.; Lalor, B.M.; Fillery, I.R.P. Gross N mineralization rates after application of composted grape marc to soil. Soil Biol. Biochem. 2005, 37, 1397–1400. [Google Scholar] [CrossRef]

- Gόmez-Brandόn, M.; Lazcano, C.; Lores, M.; Domínguez, J. Short-term stabilization of grape marc through earthworms. J. Hazard. Mat. 2011, 187, 291–295. [Google Scholar] [CrossRef]

- Cebrián-Tarancón, C.; Fernández-Roldán, F.; Sánchez-Gómez, R.; Salinas, R.; Llorens, S. Vine-Shoots as Enological Additives. A Study of Acute Toxicity and Cytotoxicity. Foods 2021, 10, 1267. [Google Scholar] [CrossRef]

- Sánchez−Gómez, R.; Alonso, G.L.; Salinas, M.R.; Zalacain, A. Reuse of Vine−Shoots Wastes for Agricultural Purposes. In Handbook of Grape Processing By-Products; Galanakis, C.M., Ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2017; pp. 79–104. ISBN 9780128098707. [Google Scholar]

- Publications Office of the European Union. Council Regulation (EEC) No 337/79 of 5 February 1979 on the Common Organization of the Market in Wine, CELEX1. Available online: https://op.europa.eu/en/publication-detail/-/publication/c908ef22-1fb5-49ee-bb41-ab65eb608bad/language-en (accessed on 24 April 2024).

- Jara-Palacios, M.J. Wine Lees as a Source of Antioxidant Compounds. Antioxidants 2019, 8, 45. [Google Scholar] [CrossRef]

- Oliveira, M.; Duarte, E. Integrated approach to winery waste: Waste generation and data consolidation. Front. Environ. Sci. Eng. 2016, 10, 168–176. [Google Scholar] [CrossRef]

- Sancho-Galán, P.; Amores-Arrocha, A.; Jiménez-Cantizano, A.; Palacios, V. Physicochemical and Nutritional Characterization of Winemaking Lees: A New Food Ingredient. Agronomy 2020, 10, 996. [Google Scholar] [CrossRef]

- Goyal, S.; Esposito, M.; Kapoor, A. Circular economy business models in developing economies: Lessons from India on reduce, recycle, and reuse paradigms. Thunderbird Int. Bus. Rev. 2016, 60, 729–740. [Google Scholar] [CrossRef]

- Bimbo, F.; Bonanno, A.; Nocella, G.; Viscecchia, R.; Nardone, G.; De Devitiis, B.; Carlucci, D. Consumers’ acceptance and preferences for nutrition-modified and functional dairy products: A systematic review. Appetite 2017, 113, 141–154. [Google Scholar] [CrossRef] [PubMed]

- Cortés, A.; Moreira, M.T.; Feijoo, G. Integrated evaluation of wine lees valorization to produce value-added products. Waste Manag. 2019, 95, 70–77. [Google Scholar] [CrossRef]

- Rogiers, S.Y.; Greer, D.H.; Liu, Y.; Baby, T.; Xiao, Z. Impact of climate change on grape berry ripening: An assessment of adaptation strategies for the Australian vineyard. Front Plant Sci. 2022, 13, 1094633. [Google Scholar] [CrossRef] [PubMed]

- Chedea, V.; Dragulinescu, A.-M.; Tomoiaga, L.; Balaceanu, C.; Iliescu, M. Climate Change and Internet of Things Technologies—Sustainable Premises of Extending the Culture of the Amurg Cultivar in Transylvania—A Use Case for Târnave Vineyard. Sustainability 2021, 13, 8170. [Google Scholar] [CrossRef]

- Muhlack, R.A.; Potumarthi, R.; Jefery, D.W. Sustainable wineries through waste valorisation: A review of grape marc utilisation for value-added products. Waste Manag. 2018, 72, 99–118. [Google Scholar] [CrossRef]

- Gómez-Brandón, M.; Lores, M.; Insam, H.; Domínguez, J. Strategies for recycling and valorization of grape marc. Crit. Rev. Biotechnol. 2019, 39, 437–450. [Google Scholar] [CrossRef]

- Council Regulation (EC) No 479/2008 of 29 April 2008 on the Common Organisation of the Market in Wine, Amending Regulations (EC) No 1493/1999, (EC) No 1782/2003, (EC) No 1290/2005, (EC) No 3/2008 and Repealing Regulations (EEC) No 2392/86 and (EC) No 1493/1999 (Repealed). Available online: https://www.legislation.gov.uk/eur/2008/479/contents/adopted (accessed on 20 May 2024).

- Rani, J.; Indrajeet, Y.; Rautela, A.; Kumar, S. Biovalorization of winery industry waste to produce value-added products. In Biovalorisation of Wastes to Renewable Chemicals and Biofuels; Elsevier: Amsterdam, The Netherlands, 2020; pp. 63–85. ISBN 9780128179512. [Google Scholar]

- David, G.; Vannini, M.; Sisti, L.; Marchese, P.; Celli, A.; Gontard, N.; Angellier-Coussy, H. Eco-Conversion of Two Winery Lignocellulosic Wastes into Fillers for Biocomposites: Vine Shoots and Wine Pomaces. Polymers 2020, 12, 1530. [Google Scholar] [CrossRef]

- González-Centeno, M.; Rosselló, C.; Simal, S.; Garau, M.; López, F.; Femenia, A. Physico-chemical properties of cell wall materials obtained from ten grape varieties and their byproducts: Grape pomaces and stems. LWT-Food Sci. Technol. 2010, 43, 1580–1586. [Google Scholar] [CrossRef]

- Minjares-Fuentes, R.; Femenia, A.; Garau, M.; Meza-Velázquez, J.; Simal, S.; Rosselló, C. Ultrasound-assisted extraction of pectins from grape pomace using citric acid: A response surface methodology approach. Carbohydr. Polym. 2014, 106, 179–189. [Google Scholar] [CrossRef]

- Rombaut, N.; Savoire, R.; Thomasset, B.; Castello, J.; Van Hecke, E.; Lanoisellé, J.-L. Optimization of oil yield and oil total phenolic content during grape seed cold screw pressing. Ind. Crop. Prod. 2015, 63, 26–33. [Google Scholar] [CrossRef]

- Dimou, C.; Kopsahelis, N.; Papadaki, A.; Papanikolaou, S.; Kookos, I.K.; Mandala, I.; Koutinas, A.A. Wine lees valorization: Biorefinery development including production of a generic fermentation feedstock employed for poly (3-hydroxybutyrate) synthesis. Food Res. Int. 2015, 73, 81–87. [Google Scholar] [CrossRef]

- Dávila, I.; Gordobil, O.; Labidi, J.; Gullón, P. Assessment of suitability of vine shoots for hemicellulosic oligosaccharides production through aqueous processing. Bioresour. Technol. 2016, 211, 636–644. [Google Scholar] [CrossRef]

- Lazcano, C.; Domınguez, J. The use of vermicompost in sustainable agriculture: Impact on plant growth and soil fertility. In Soil Nutrients; Nova Science Publishers: New York, NY, USA, 2011; pp. 230–254. [Google Scholar]

- Niculescu, V.-C.; Ionete, R.-E. An Overview on Management and Valorisation of Winery Wastes. Appl. Sci. 2023, 13, 5063. [Google Scholar] [CrossRef]

- Ioannidou, S.P.; Margellou, A.G.; Petala, M.D.; Triantafyllidis, K.S. Pretreatment/Fractionation and Characterization of Winery Waste Streams within an Integrated Biorefinery Concept. Sustain. Chem. Pharm. 2022, 27, 100670. [Google Scholar] [CrossRef]

- Egüés, I.; Serrano, L.; Amendola, D.; De Faveri, D.M.; Spigno, G.; Labidi, J. Fermentable Sugars Recovery from Grape Stalks for Bioethanol Production. Renew. Energy 2013, 60, 553–558. [Google Scholar] [CrossRef]

- Requejo, M.I.; Fernandez-Rubın de Felis, M.; Martınez Caro, R. Winery and distillery derived materials as phosphorus source in calcareous soils. Catena 2016, 141, 30–38. [Google Scholar] [CrossRef]

- Christ, K.L.; Burritt, R.L. Critical environmental concerns in wine production: An integrative review. J. Clean Prod. 2013, 53, 232–242. [Google Scholar] [CrossRef]

- Gazzola, D.; Vincenzi, S.; Marangon, M.; Pasini, G.; Curioni, A. Grape seed extract: The first protein-based fining agent endogenous to grapes. Aust. J. Grape Wine Res. 2017, 23, 215–225. [Google Scholar] [CrossRef]

- Bordiga, M.; Coısson, J.D.; Locatelli, M.; Arlorio, M.; Travaglia, F. Pyrogallol: An alternative trapping agent in proanthocyanidins analysis. Food Anal. Methods 2013, 6, 148–156. [Google Scholar] [CrossRef]

- Bordiga, M.; Travaglia, F.; Locatelli, M.; Arlorio, M.; Coısson, J.D. Spent grape pomace as a still potential by-product. Int. J. Food Sci. Technol. 2015, 50, 2022–2031. [Google Scholar] [CrossRef]

- Sanhueza, M.; Zechini, L.; Gillespie, T.; Pennetta, G. Gain-of-function mutations in the ALS8 causative gene VAPB have detrimental effects on neurons and muscles. Biol. Open 2014, 3, 59–71. [Google Scholar] [CrossRef] [PubMed]

- Sateriale, D.; Forgione, G.; Di Rosario, M.; Pagliuca, C.; Colicchio, R.; Salvatore, P.; Paolucci, M.; Pagliarulo, C. Vine-Winery Byproducts as Precious Resource of Natural Antimicrobials: In Vitro Antibacterial and Antibiofilm Activity of Grape Pomace Extracts against Foodborne Pathogens. Microorganisms 2024, 12, 437. [Google Scholar] [CrossRef] [PubMed]

- Kabir, F.; Mosammad, S.S.; Heri, K. Antimicrobial activities of grape (Vitis vinifera L.) pomace polyphenols as a source of naturally occurring bioactive components. Afr. J. Biotechnol. 2015, 14, 2157–2161. [Google Scholar] [CrossRef]

- Dumitriu, D.; Peinado, R.A.; Peinado, J.; de Lerma, N.L. Grape pomace extract improves the in vitro and in vivo antioxidant properties of wines from sun light dried Pedro Ximénez grapes. J. Funct. Foods 2015, 17, 380–387. [Google Scholar] [CrossRef]

- Dumitriu, G.D.; López de Lerma, N.; Cotea, V.V.; Peinado, R.A. Antioxidant activity, phenolic compounds and colour of red wines treated with new fining agents. Vitis 2018, 57, 61–68. [Google Scholar]

- Dumitriu, G.-D.; Teodosiu, C.; Gabur, I.; Cotea, V.V.; Peinado, R.A.; López de Lerma, N. Alternative Winemaking Techniques to Improve the Content of Phenolic and Aromatic Compounds in Wines. Agriculture 2021, 11, 233. [Google Scholar] [CrossRef]

- Dinicola, S.; Pasqualato, A.; Cucina, A.; Coluccia, P.; Ferranti, F.; Canipari, R.; Catizone, A.; Proietti, S.; D’Anselmi, F.; Ricci, G.; et al. Grape seed extract suppresses MDA-MB231 breast cancer cell migration and invasion. Eur. J. Nutr. 2014, 53, 421–431. [Google Scholar] [CrossRef] [PubMed]

- Del Pino-García, R.; González-SanJosé, M.L.; Rivero-Pérez, M.D.; García-Lomillo, J.; Muñiz, P. Total antioxidant capacity of new natural powdered seasonings after gastrointestinal and colonic digestion. Food Chem. 2016, 211, 707–714. [Google Scholar] [CrossRef]

- Elejalde, E.; Villarán, M.C.; Esquivel, A. Bioaccessibility and Antioxidant Capacity of Grape Seed and Grape Skin Phenolic Compounds After Simulated In Vitro Gastrointestinal Digestion. Plant Foods Hum. Nutr. 2024, 79, 432–439. [Google Scholar] [CrossRef]

- Dwyer, K.; Hosseinian, F.; Rod, M. The market potential of grape waste alternatives. J. Food Res. 2014, 3, 91–106. [Google Scholar] [CrossRef]

- Brenes, A.; Viveros, A.; Saura, C.; Arija, I. Use of polyphenol-rich grape by- products in monogastric nutrition. Anim. Feed Sci. Technol. 2016, 1, 1–17. [Google Scholar] [CrossRef]

- Taranu, I.; Habeanu, M.; Gras, M.A.; Pistol, G.C.; Lefter, N.; Palade, M.; Ropota, M.; Sanda Chedea, V.; Marin, D.E. Assessment of the effect of grape seed cake inclusion in the diet of healthy fattening finishing pigs. J. Anim. Physiol. Anim. Nutr. 2017, 102, 30. [Google Scholar] [CrossRef]

- Commission Implementing Regulation (EU) No 2017/307 of 21 February 2017 Concerning the Authorisation of Dry Grape Extract of Vitis vinifera subsp. vinifera as a Feed Additive for All Animal Species Except for Dogs. OJ L 44/1. 22 February 2017, p. 5. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=OJ:L:2017:044:FULL (accessed on 28 August 2024).

- Marin, D.E.; Bulgaru, C.V.; Anghel, C.A.; Pistol, G.C.; Dore, M.I.; Palade, M.L.; Taranu, I. Grape Seed Waste Counteracts Aflatoxin B1 Toxicity in Piglet Mesenteric Lymph Nodes. Toxins 2020, 12, 800. [Google Scholar] [CrossRef]

- Kafantaris, I.; Stagos, D.; Kotsampasi, B.; Hatzis, A.; Kypriotakis, A.; Gerasopoulos, K.; Makri, S.; Goutzourelas, N.; Mitsagga, C.; Giavasis, I.; et al. Grape pomace improves performance, antioxidant status, fecal microbiota and meat quality of piglets. Animal 2018, 12, 246–255. [Google Scholar] [CrossRef] [PubMed]

- Alipour, D.; Rouzbehan, Y. Effects of ensiling grape pomace and addition of polyethylene glycol on in vitro gas production and microbial biomass yield. Anim. Feed. Sci. Technol. 2007, 137, 138–149. [Google Scholar] [CrossRef]

- Ebrahimzadeh, S.K.; Navidshad, B.; Farhoomand, P.; Aghjehgheshlagh, F.M. Effects of grape pomace and vitamin E on performance, antioxidant status, immune response, gut morphology and histopathological responses in broiler chickens. S. Afr. J. Anim. Sci. 2018, 48, 324–336. [Google Scholar] [CrossRef]

- Martínez, M.M.; Blu, R.O.; Janssens, M.; Fincheira, P. Grape pomace compost as a source of organic matter: Evolution of quality parameters to evaluate maturity and stability. J. Clean. Prod. 2019, 216, 56–63. [Google Scholar] [CrossRef]

- Bambeni, T.; Tayengwa, T.; Chikwanha, O.C.; Manley, M.; Gouws, P.A.; Marais, J.; Fawole, O.A.; Mapiye, C. Biopreservative efficacy of grape (Vitis vinifera) and clementine mandarin orange (Citrus reticulata) by-product extracts in raw ground beef patties. Meat Sci. 2021, 181, 108609. [Google Scholar] [CrossRef]

- Ryu, K.S.; Shim, K.S.; Shin, D. Effect of grape pomace pow- der addition on TBARS and color of cooked pork sausages during storage. Korean J. Food Sci. Anim. Resour. 2014, 34, 200. [Google Scholar] [CrossRef]

- Saberi, M.; Saremnezhad, S.; Soltani, M.; Faraji, A. Functional stirred yogurt manufactured using co-microencapsulated or free forms of grape pomace and flaxseed oil as bioactive ingredients: Physicochemical, antioxidant, rheological, microstructural, and sensory properties. Food Sci. Nutr. 2023, 11, 3989–4001. [Google Scholar] [CrossRef]

- Sagdic, O.; Ozturk, I.; Cankurt, H.; Tornuk, F. Interaction between some phenolic compounds and probiotic bacterium in functional ice cream production. Food Bioproc. Technol. 2012, 5, 2964–2971. [Google Scholar] [CrossRef]

- Smith, I.N.; Yu, J. Nutritional and sensory quality of bread containing different quantities of grape pomace from different grape cultivars. EC Nutr. 2015, 2, 291–301. [Google Scholar]

- Fontana, M.; Murowaniecki Otero, D.; Pereira, A.M.; Santos, R.B.; Gularte, M.A. Grape pomace flour for incorporation into cookies: Evaluation of nutritional, sensory and technological characteristics. J. Culin. Sci. Technol. 2022, 1, 1–20. [Google Scholar] [CrossRef]

- Gaita, C.; Alexa, E.; Moigradean, D.; Conforti, F.; Poiana, M.A. Designing of high value-added pasta formulas by incorporation of grape pomace skins. Rom. Biotechnol. Lett. 2020, 25, 1607–1614. [Google Scholar] [CrossRef]

- Lavelli, V.; Harsha, P.S.; Torri, L.; Zeppa, G. Use of winemaking by-products as an ingredient for tomato puree: The effect of particle size on product quality. Food Chem. 2014, 152, 162–168. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, D.M.; Marques, D.R.; Kwiatkowski, A.; Monteiro, A.R.G.; Clemente, E. Sensory analysis and chemical characterization of cereal enriched with grape peel and seed flour. Acta Sci. Technol. 2013, 35, 427–431. [Google Scholar] [CrossRef]

- Wittenauer, J.; Mäckle, S.; Sußmann, D.; Schweiggert-Weisz, U.; Carle, R. Inhibitory effects of polyphenols from grape pomace extract on collagenase and elastase activity. Fitoterapia 2015, 101, 179–187. [Google Scholar] [CrossRef]

- Glampedaki, P.; Dutschk, V. Stability studies of cosmetic emulsions prepared from natural products such as wine, grape seed oil and mastic resin. Colloids Surf. Physicochem. Eng. Asp. 2014, 460, 306–311. [Google Scholar] [CrossRef]

- Ferreira, S.M.; Santos, L. A potential valorization strategy of wine industry by-products and their application in cosmetics—Case study: Grape pomace and grapeseed. Molecules 2022, 27, 969. [Google Scholar] [CrossRef]

- Arvanitoyannis, I.S.; Ladas, D.; Mavromatis, A. Potential uses and applications of treated wine waste: A review. Int. J. Food Sci. Technol. 2006, 41, 475–487. [Google Scholar] [CrossRef]

- Rodríguez-Cruz, M.S.; Herrero-Hernández, E.; Ordax, J.M.; Marín-Benito, J.M.; Draoui, K.; Sánchez-Martín, M.J. Adsorption of pesticides by sewage sludge, grape marc, spent mushroom substrate and by amended soils. Int. J. Environ. Anal. Chem. 2012, 92, 933–948. [Google Scholar] [CrossRef]

- Perez-Ameneiro, M.; Vecino, X.; Vega, L.; Devesa-Rey, R.; Cruz, J.; Moldes, A. Elimination of micronutrients from winery wastewater using entrapped grape marc in alginate beads. CyTA J. Food 2014, 12, 73–79. [Google Scholar] [CrossRef]

- Dumitriu Gabur, G.-D.; Gabur, I.; Cucolea, E.I.; Costache, T.; Rambu, D.; Cotea, V.V.; Teodosiu, C. Investigating Six Common Pesticides Residues and Dietary Risk Assessment of Romanian Wine Varieties. Foods 2022, 11, 2225. [Google Scholar] [CrossRef] [PubMed]

- Devi, V.; Sumathy, V.J.H. Production of biofertilizer from fruit waste. Eur. J. Pharm. Med. Res. 2017, 4, 436–443. [Google Scholar]

- Braide, W.; Kanu, I.; Oranusi, U.; Adeleye, S. Production of bioethanol from agricultural waste. J. Fundam. Appl. Sci. 2016, 8, 372. [Google Scholar] [CrossRef]

- Gil-Muñoz, R.; Jiménez-Martínez, M.D.; Bautista-Ortín, A.B.; Gómez-Plaza, E. Effect of the Use of Purified Grape Pomace as a Fining Agent on the Volatile Composition of Monastrell Wines. Molecules 2019, 24, 2423. [Google Scholar] [CrossRef]

- Solfrizzo, M.; Avantaggiato, G.; Panzarini, G.; Visconti, A. Removal of ochratoxin A from contaminated red wines by repassage over grape pomaces. J. Agric. Food Chem. 2010, 58, 317–323. [Google Scholar] [CrossRef]

- da Silva, A.P.; Silva, A.O.; Lima, F.R.; Benedet, L.; Franco, A.; Souza, J.K. Potentially toxic elements in iron mine tailings: Effects of reducing soil ph on available concentrations of toxic elements. Environ. Res. 2022, 215, 114321. [Google Scholar] [CrossRef]

- Kinigopoulou, V.; Hatzigiannakis, E.; Stefanou, S.; Guitonas, A.; Oikonomou, E.K. Utilization of Vermicompost Sludge Instead of Peat in Olive Tree Nurseries in the Frame of Circular Economy and Sustainable Development. AgriEngineering 2023, 5, 1630–1643. [Google Scholar] [CrossRef]

- Mazur-Pączka, A.; Butt, K.R.; Garczyńska, M.; Jaromin, M.; Hajduk, E.; Kostecka, J.; Pączka, G. Comparative Effects of No-dig and Conventional Cultivation with Vermicompost Fertilization on Earthworm Community Parameters and Soil Physicochemical Condition. Agriculture 2024, 14, 870. [Google Scholar] [CrossRef]

- Romero, E.; Castillo, J.M.; Nogales, R. Field-scale assessment of vermicompost amendments for diuron-contaminated soil: Implications for soil quality and pesticide fate. Appl. Soil Ecol. 2024, 201, 105516. [Google Scholar] [CrossRef]

- Santana, N.A.; Jacques, R.J.S.; Antoniolli, Z.I.; Martínez-Cordeiro, H.; Domínguez, J. Changes in the chemical and biological characteristics of grape marc vermicompost during a two-year production period. Appl. Soil Ecol. 2020, 154, 103587. [Google Scholar] [CrossRef]

- Domínguez, J.; Martínez-Cordeiro, H.; Álvarez-Casas, M.; Lores, M. Vermicomposting grape marc yields high quality organic biofertiliser and bioactive polyphenols. Waste Manag. Res. 2014, 32, 1235–1240. [Google Scholar] [CrossRef] [PubMed]

- Kolbe, A.R.; Aira, M.; Gόmez-Brandόn, M.; Pérez-Losada, M.; Domínguez, J. Bacterial succession and functional diver- sity during vermicomposting of the white grape marc Vitis vinifera v. Albariño. Sci. Rep. 2019, 9, 7472. [Google Scholar] [CrossRef]

- Gόmez-Brandόn, M.; Aira, M.; Kolbe, A.R.; de Andrade, N.; Pérez- Losada, M.; Domínguez, J. Rapid bacterial community changes during vermicomposting of grape marc derived from red winemaking. Microorganisms 2019, 7, 473. [Google Scholar] [CrossRef] [PubMed]

- Gόmez-Brandόn, M.; Fornasier, F.; de Andrade, N.; Domínguez, J. Influence of earthworms on the microbial properties and extracellular enzyme activities during vermicomposting of raw and distilled marc. J. Environ. Manag. 2022, 319, 115654. [Google Scholar] [CrossRef]

- Gómez-Brandón, M.; Martínez-Cordeiro, H.; Domínguez, J. Changes in the nutrient dynamics and microbiological properties of grape marc in a continuous-feeding vermicomposting system. Waste Manag. 2021, 135, 1–10. [Google Scholar] [CrossRef]

- Gόmez-Brandόn, M.; Aira, M.; Santana, N.; Pérez-Losada, M.; Domínguez, J. Temporal dynamics of bacterial communities in a pilot-scale vermireactor fed with distilled grape marc. Microorganisms 2020, 8, 642. [Google Scholar] [CrossRef]

- Nogales, R.; Fernández-Gόmez, M.J.; Delgado-Moreno, L.; Castillo- Díaz, J.M.; Romero, E. Eco-friendly vermitechnological winery waste management: A pilot-scale study. Appl. Sci. 2020, 2, 653. [Google Scholar] [CrossRef]

- Hanc, A.; Hrebeckova, T.; Pliva, P.; Cajthaml, T. Vermicomposting of sludge from a malt house. Waste Manag. 2020, 118, 232–240. [Google Scholar] [CrossRef]

- Fernández-Bayo, J.D.; Nogales, R.; Romero, E. Assessment of three vermicomposts as organic amendments used to enhance diuron sorption in soils with low organic carbon content. Eur. J. Soil Sci. 2009, 60, 935–944. [Google Scholar] [CrossRef]

- Edwards, C.A.; Arancon, N.Q. The Role of Earthworms in Organic Matter and Nutrient Cycles. In Biology and Ecology of Earthworms; Springer: New York, NY, USA, 2022; pp. 233–274. [Google Scholar] [CrossRef]

- Medina-Sauza, R.; Álvarez-Jiménez, M.; Delhal, A.; Reverchon, F.; Blouin, M.; Guerrero-Analco, J.A.; Cerdán, C.R.; Guevara, R.; Villain, L.; Barois, I. Earthworms building up soil microbiota, a review. Front. Environ. Sci. 2019, 7, 81. [Google Scholar]

- Lawton, J.H. What do species do in ecosystems? Oikos 1994, 71, 367–374. [Google Scholar] [CrossRef]

- Goswami, L.; Nath, A.; Sutradhar, S.; Bhattacharya, S.S.; Kalamdhad, A.; Vellingiri, K.; Kim, K.-H. Application of drum compost and vermicompost to improve soil health, growth, and yield parameters for tomato and cabbage plants. J. Environ. Manag. 2017, 200, 243–252. [Google Scholar] [CrossRef] [PubMed]

- Riaz, U.; Mehdi, S.M.; Iqbal, S.; Khalid, H.I.; Qadir, A.A.; Anum, W.; Ahmad, M.; Murtaza, G. Bio-fertilizers: Eco-friendly approach for plant and soil environment. In Bioremediation and Biotechnology: Sustainable Approaches to Pollution Degradation; Hakeem, K., Bhat, R., Qadri, H., Eds.; Springer: Cham, Switzerland, 2020; pp. 189–213. [Google Scholar] [CrossRef]

- Sinha, R.K.; Herat, S.; Bharambe, G.; Patil, S.; Bapat, P.; Chauhan, K.; Valani, D. Human waste-apotential resource: Converting trash into treasure by embracing the 5 r’s philosophy for safe and sustainable waste management. Environ. Res. J. 2009, 3, 143. [Google Scholar]

- Das, S.; Lee, S.H.; Kumar, P.; Kim, K.H.; Lee, S.S.; Bhattacharya, S.S. Solid waste management: Scope and the challenge of sustainability. J. Clean. Prod. 2019, 228, 658–678. [Google Scholar] [CrossRef]

- Urmi, T.A.; Rahman, M.M.; Islam, M.M.; Islam, M.A.; Jahan, N.A.; Mia, M.A.B.; Akhter, S.; Siddiqui, M.H.; Kalaji, H.M. Integrated Nutrient Management for Rice Yield, Soil Fertility, and Carbon Sequestration. Plants 2022, 11, 138. [Google Scholar] [CrossRef]

- Varjani, S.; Shah, A.V.; Vyas, S.; Srivastava, V.K. Processes and prospects on valorizing solid waste for the production of valuable products employing bio-routes: A systematic review. Chemosphere 2021, 282, 130954. [Google Scholar] [CrossRef]

- Ayilara, M.S.; Olanrewaju, O.S.; Babalola, O.O.; Odeyemi, O. Waste management through composting: Challenges and potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

- Singh, K.; Bhartiya, D.K. Heavy metal accumulation by earthworm Eisenia fetida from animal waste, soil and wheat (Triticum aestivum) for protection of human health. Res. J. Pharm. Technol. 2020, 13, 3205–3210. [Google Scholar] [CrossRef]

- Lin, J.; Yuan, Q. A novel technology for separating live earthworm from vermicompost: Experiment, mechanism analysis, and simulation. Waste Manag. 2021, 131, 50–60. [Google Scholar] [CrossRef] [PubMed]

- Rostami, R. Vermicomposting, Integrated Waste Management—Volume II; IntechOpen: London, UK, 2011. [Google Scholar] [CrossRef]

- Wang, F.; Wang, X.; Song, N. Biochar and vermicompost improve the soil properties and the yield and quality of cucumber (Cucumis sativus L.) grown in plastic shed soil continuously cropped for different years. Agric. Ecosyst. Environ. 2021, 315, 107425. [Google Scholar] [CrossRef]

- Zuo, Y.; Zhang, J.; Zhao, R.; Dai, H.; Zhang, Z. Application of vermicompost improves strawberry growth and quality through increased photosynthesis rate, free radical scavenging and soil enzymatic activity. Sci. Hortic. 2018, 233, 132–140. [Google Scholar] [CrossRef]

- Raimondo, M.; Simeone, G.; Coppola, G.P.; Zaccardelli, M.; Caracciolo, F.; Rao, M.A. Economic benefits and soil improvement: Impacts of vermicompost use in spinach production through industrial symbiosis. J. Agric. Food Res. 2023, 14, 100845. [Google Scholar] [CrossRef]

- Paradelo, R.; Moldes, A.B.; Barral, M.A.T. Utilization of a factorial design to study the composting of hydrolyzed grape marc and vinification lees. J. Agric. Food Chem. 2010, 58, 3085–3092. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Brandón, M.; Lores, M.; Domínguez, J. Recycling and valorization of distilled grape marc through vermicomposting: A pilot-scale study. J. Mater. Cycles Waste Manag. 2023, 25, 1509–1518. [Google Scholar] [CrossRef]

- Palenzuela, M.d.V.; López de Lerma, N.; Sánchez-Suárez, F.; Martínez-García, R.; Peinado, R.A.; Rosal, A. Aroma Composition of Wines Produced from Grapes Treated with Organic Amendments. Appl. Sci. 2023, 13, 8001. [Google Scholar] [CrossRef]

- Rosado, D.; Ramos-Tapia, I.; Crandall, K.A.; Pérez-Losada, M.; Domínguez, J. Grapevine treatment with bagasse vermicompost changes the microbiome of Albariño must and wine and improves wine quality. OENO One 2022, 56, 219–230. [Google Scholar] [CrossRef]

| Component | Grape Pomace |

|---|---|

| Dry matter (g kg−1 FM) | 329–490 |

| Ash (g kg−1 FM) | 18–24 |

| Organic matter (g kg−1 DM) | 827–959 |

| Total sugars (g kg−1 FM) | 150–330 |

| Neutral detergent fiber (g kg−1 DM) | 569–626 |

| Acid detergent fiber (g kg−1 DM) | 480–543 |

| Acid detergent lignin (g kg−1 DM) | 320–388 |

| Total dietary fiber (g kg−1 FM) | 190–380 |

| Total nitrogen (g kg−1 DM) | 10–17 |

| Lipids (g kg−1 FM) | 4–10 |

| Condensed tannins (g kg−1 DM) | |

| Free | 16–38 |

| Fiber-bound | 19–34 |

| Protein-bound | 56–131 |

| Total | 91–203 |

| Parameter | Units | Vermicompost 1 [78] | Vermicompost 2 [79] | Vermicompost 3 [80] |

|---|---|---|---|---|

| Organic carbon | mg kg−1 | - | 98,153 | - |

| Total nitrogen | 37,000 | 4911 | - | |

| P | 623 | 274 | 3700 | |

| K | 1300 | 3563 | 1500 | |

| Na | 8400 | - | 114 | |

| Mg | 4430 | 288 | 4800 | |

| Ca | 15,670 | 1989 | 38,000 | |

| Fe | 304 | - | 1100 | |

| Cu | 42.4 | - | 87 | |

| Mn | 304 | - | 95 | |

| Zn | 492 | - | 99 | |

| Cd | - | 0.8 | - | |

| Pb | - | 0.7 | - | |

| C/N ratio | - | 7.5 | 19.98 | 11 |

| pH | - | 5.6 | 6.33 | 7.6 |

| Materials | Grape Variety | Set-Up Conditions | Days | References |

|---|---|---|---|---|

| Grape pomace | White grape pomace (Vitis vinifera cv. Albariño) | Laboratory scale | 720 | [81] |

| Grape pomace | White grape pomace (Vitis vinifera cv. Albariño) | Pilot scale | 112 | [82] |

| Grape pomace | White grape pomace (Vitis vinifera cv. Albariño) | Pilot scale | 720 | [81] |

| Grape pomace | White grape pomace (Vitis vinifera cv. Albariño) | Pilot scale | 91 | [83] |

| Grape pomace | Red grape pomace (Vitis vinifera cv. Mencía) | Pilot scale | 91 | [84] |

| Grape pomace | Red grape pomace (Vitis vinifera cv. Mencía) | Pilot scale | 112 | [85] |

| Grape pomace | White and red grape pomace (Vitis vinifera cv. Albariño and Mencía) | Pilot scale | 63 | [86] |

| Grape pomace | White and red grape pomace (Vitis vinifera cv. Albariño and Mencía) | Laboratory scale | 294 | [8] |

| Distilled pomace | White grape pomace (Vitis vinifera cv. Albariño) | Pilot scale | 42 | [87] |

| Distilled pomace | Not specified | Pilot scale | 180 | [88] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gabur, G.-D.; Teodosiu, C.; Fighir, D.; Cotea, V.V.; Gabur, I. From Waste to Value in Circular Economy: Valorizing Grape Pomace Waste through Vermicomposting. Agriculture 2024, 14, 1529. https://doi.org/10.3390/agriculture14091529

Gabur G-D, Teodosiu C, Fighir D, Cotea VV, Gabur I. From Waste to Value in Circular Economy: Valorizing Grape Pomace Waste through Vermicomposting. Agriculture. 2024; 14(9):1529. https://doi.org/10.3390/agriculture14091529

Chicago/Turabian StyleGabur, Georgiana-Diana, Carmen Teodosiu, Daniela Fighir, Valeriu V. Cotea, and Iulian Gabur. 2024. "From Waste to Value in Circular Economy: Valorizing Grape Pomace Waste through Vermicomposting" Agriculture 14, no. 9: 1529. https://doi.org/10.3390/agriculture14091529