Vegetable Commodity Organ Quality Formation Simulation Model (VQSM) in Solar Greenhouses

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Data Sources

2.2.1. Crop Data

2.2.2. Meteorological Data

2.3. Validation Statistical Indicators

3. Results

3.1. Determination of Model Parameters

3.1.1. Appearance Quality Simulation

3.1.2. Physicochemical Quality Simulation

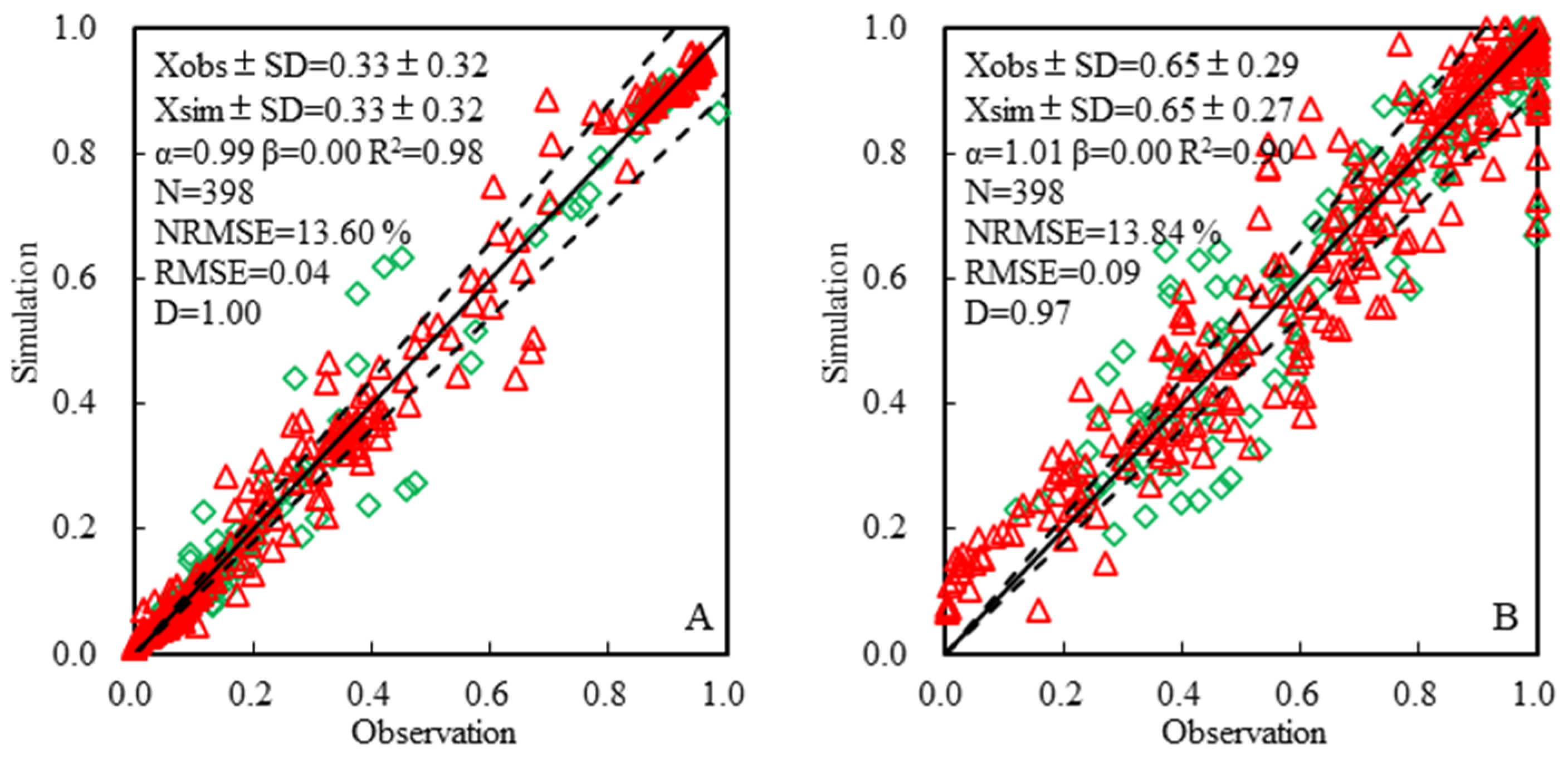

3.2. Model Validation

4. Discussion

5. Conclusions

- (1)

- There exist quantifiable relationships between different quality indicators and ATD or TEP. These relationships are mainly presented through linear functions (, , , , , , , and ), exponential functions ( and ), the logarithmic function (), and logical functions (, , , , , and ).

- (2)

- The normalized root mean square error (NRMSE) of the quality model for cucumber ranges from 1.13% to 29.53%, and the simulation models for , , , , , and show excellent good simulation performance. The NRMSE of the quality model for celery ranges from 1.63% to 31.47%, and the simulated models for , , , , , , , , , and show excellent simulation performance.

- (3)

- Based on the normalization methods, the average NRMSE of the VQSM model is 13.72%, demonstrating a relatively high level of accuracy in the simulation, making it suitable for practical applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Z.F.; Liu, T.; Dong, C.Y.; Xue, Q.Y.; Liu, S.M. Climate classification of solar greenhouse based on the calculation method for indoor and outdoor temperature difference at night. Trans. Chin. Soc. Agric. Eng. 2021, 37, 194–201. [Google Scholar]

- Zhu, Z.P.; Yu, J.X.; Qiao, X.H.; Yu, Z.F.; Xiong, A.S.; Sun, M. Hydrogen sulfide delays yellowing and softening, inhibits nutrient loss in postharvest celery. Sci. Hortic. 2023, 315, 111991. [Google Scholar] [CrossRef]

- Gnayem, N.; Magadley, E.; Haj-Yahya, A.; Masalha, S.; Kabha, R.; Abasi, A.; Barhom, H.; Matar, M.; Attrash, M.; Yehia, I. Examining the effect of different photovoltaic modules on cucumber crops in a greenhouse agrivoltaic system: A case study. Biosyst. Eng. 2024, 241, 83–94. [Google Scholar] [CrossRef]

- Saadi, S.; Pattey, E.; Jego, G.; Champagne, C. Prediction of rainfed corn evapotranspiration and soil moisture using the STICS crop model in eastern Canada. Field Crops Res. 2022, 287, 108664. [Google Scholar] [CrossRef]

- Dhakar, R.; Sehgal, V.K.; Chakraborty, D.; Sahoo, R.N.; Mukherjee, J.; Ines, A.V.M.; Kumar, S.N.; Shirsath, P.B.; Roy, S.B. Field scale spatial wheat yield forecasting system under limited field data availability by integrating crop simulation model with weather forecast and satellite remote sensing. Agric. Syst. 2022, 195, 103299. [Google Scholar] [CrossRef]

- Pohankova, E.; Hlavinka, P.; Kersebaum, K.C.; Rodriguez, A.; Jan, B.; Bednarik, M.; Dubrovsky, M.; Gobin, A.; Hoogenboom, G.; Moriondo, M.; et al. Expected effects of climate change on the production and water use of crop rotation management reproduced by crop model ensemble for Czech Republic sites. Eur. J. Agron. 2022, 134, 126446. [Google Scholar] [CrossRef]

- Onyekwelu, I.; Sharda, V. Root proliferation adaptation strategy improved maize productivity in the US Great Plains: Insights from crop simulation model under future climate change. Sci. Total Environ. 2024, 927, 172205. [Google Scholar] [CrossRef]

- Shen, H.; Wang, Y.; Jiang, K.; Huang, D.; Wu, J.; Wang, Y.; Ma, X. Simulation modeling for effective management of irrigation water for winter wheat. Agric. Water Manag. 2022, 269, 107720. [Google Scholar] [CrossRef]

- Wan, Y.; Zhou, M.; Le, L.; Gong, X.; Jiang, L.; Huang, J.; Cao, X.; Shi, Z.; Tan, M.; Cao, Y.; et al. Evaluation of morphology, nutrients, phytochemistry and pigments suggests the optimum harvest date for high-quality quinoa leafy vegetable. Sci. Hortic. 2022, 304, 111240. [Google Scholar] [CrossRef]

- Vanmarcke, H.; Tuytschaever, T.; Everaert, B.; Cuypere, T.D.; Sampers, I. Impact of using stored treated municipal wastewater for irrigation on the microbial quality and safety of vegetable crops. Agric. Water Manag. 2024, 297, 108842. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, J.Y.; Xu, M.S.; Shen, Y.G.; Zhou, M.; Zhu, F.N.; Luo, J.Q.; Chen, H.Z. Effect of huanglongbing on the quality of Newhall Navel Orange. Food Sci. 2019, 40, 48–53. [Google Scholar]

- Juventia, S.D.; Rossing, W.A.H.; Ditzler, L.; van Apeldoorn, D.F. Spatial and genetic crop diversity support ecosystem service delivery: A case of yield and biocontrol in Dutch organic cabbage production. Field Crops Res. 2021, 261, 108015. [Google Scholar] [CrossRef]

- Kawasaki, Y.; Yoneda, Y. Local temperature control in greenhouse vegetable production. Hortic. J. 2019, 88, 305–314. [Google Scholar] [CrossRef]

- Chen, Z.; Jahan, M.S.; Mao, P.P.; Wang, M.M.; Liu, X.Y.; Guo, S.R. Functional growth, photosynthesis and nutritional property analyses of lettuce grown under different temperature and light intensity. J. Hortic. Sci. Biotechnol. 2021, 96, 53–61. [Google Scholar] [CrossRef]

- Qu, Z.; Chen, Q.; Feng, H.; Hao, M.; Niu, G.L.; Liu, Y.L.; Li, C.L. Interactive effect of irrigation and blend ratio of controlled release potassium chloride and potassium chloride on greenhouse tomato production in the Yellow River Basin of China. Agric. Water Manag. 2022, 261, 107346. [Google Scholar] [CrossRef]

- Wang, R.; Shi, W.; Kronzucker, H.J.; Li, Y. Oxygenation promotes vegetable growth by enhancing P nutrient availability and facilitating a stable soil bacterial community in compacted soil. Soil Tillage Res. 2023, 230, 105686. [Google Scholar] [CrossRef]

- Vazquez-Cruz, M.A.; Guzman-Cruz, R.; Lopez-Cruz, I.L.; Cornejo-Perez, O.; Torres-Pacheco, I.; Guevara-Gonzalez, R.G. Global sensitivity analysis by means of EFAST and Sobol’ methods and calibration of reduced state-variable TOMGRO model using genetic algorithms. Comput. Electron. Agric. 2014, 100, 1–12. [Google Scholar] [CrossRef]

- Berrueta, C.; Heuvelink, E.; Giménez, G.; Dogliotti, S. Estimation of tomato yield gaps for greenhouse in Uruguay. Sci. Hortic. 2020, 265, 109250. [Google Scholar] [CrossRef]

- Cooman, A.; Schrevens, E. A monte Carlo approach for estimating the uncertainty of predictions with the tomato plant growth model, TOMGRO. Biosyst. Eng. 2006, 94, 517–524. [Google Scholar] [CrossRef]

- Ioslovich, I.; Gutman, P.O. Fitting the MBM-a model of plant growth to the data of TOMGRO: Implication for greenhouse optimal control. Acta Hortic. 2008, 801, 515–521. [Google Scholar] [CrossRef]

- Chapagain, R.; Remenyi, T.A.; Harris, R.M.B.; Mohammed, C.L.; Huth, N.; Wallach, D.; Rezaei, E.E.; Ojeda, J.J. Decomposing crop model uncertainty: A systematic review. Field Crops Res. 2022, 279, 108448. [Google Scholar] [CrossRef]

- Miao, M.; Zhang, Z.; Xu, X.; Wang, K.; Cheng, H.; Cao, B. Different mechanisms to obtain higher fruit growth rate in two cold-tolerant cucumber (Cucumis sativus L.) lines under low night temperature. Sci. Hortic. 2009, 119, 357–361. [Google Scholar] [CrossRef]

- Aparna, G.; Matthew, D.K.; Joseph, S.; Ling, P.P.; Streeter, J.G. Temperature and genotype affect anthocyanin concentrations in lettuce (Lactuca sativa). HortScience 2004, 39, 864A. [Google Scholar]

- Arya, S.S.; Parihar, D.B. Effect of moisture and temperature on storage changes in lipids and carotenoids of atta (wheat flour). Mol. Nutr. Food Res. 2010, 25, 121–126. [Google Scholar] [CrossRef]

- Piva, A.; Bertrand, A.; Gilles, B.; Yves, C.; Philippe, S. Growth and physiological response of timothy to elevated carbon dioxide and temperature under contrasted nitrogen fertilization. Crop Sci. 2013, 53, 704–715. [Google Scholar] [CrossRef]

- Cheng, C.; Dong, C.Y.; Li, Z.F.; Gong, Z.H.; Feng, L.P. Simulation model of external morphology and dry matter accumulation and distribution of celery in solar greenhouse. Trans. Chin. Soc. Agric. Eng. 2021, 37, 142–151. [Google Scholar]

- Shi, X.H.; Cai, H.J.; Zhao, L.L.; Yang, P.; Wang, Z.S. Greenhouse tomato dry matter production and distribution model under condition of irrigation based on product of thermal effectiveness and photosynthesis active radiation. Trans. Chin. Soc. Agric. Eng. 2016, 32, 69–77. [Google Scholar]

- Liu, F.H.; Guo, S.B.; Wang, D.; Huang, B.; Cao, Y.F. Construction and verification of an external morphology, substance accumulation, and distribution model of tomatoes in greenhouses. Trans. Chin. Soc. Agric. Eng. 2022, 38, 188–196. [Google Scholar]

- Cheng, C.; Li, C.; Li, W.M.; Ye, C.Y.; Wang, Y.S.; Zhao, C.S.; Ding, F.H.; Jin, Z.F.; Feng, L.P.; Li, Z.F. Optimal path of the simulation model in horticultural crop development and harvest period. Trans. Chin. Soc. Agric. Eng. 2023, 39, 158–167. [Google Scholar]

- Jia, K.; Lin, J.; Tan, M.; Tao, D.C. Deep multi-view learning using Neuron-Wise Correlation-Maximizing Regularizers. IEEE Trans. Image Process. 2019, 28, 5121–5134. [Google Scholar] [CrossRef]

- Kaur, R.; Chen, Z.; Motl, R.; Hernandez, M.E.; Sowers, R. Predicting multiple sclerosis from gait dynamics using an instrumented treadmill—A machine learning approach. IEEE Trans. Biomed. Eng. 2020, 68, 2666–2667. [Google Scholar] [CrossRef]

- Cheng, C.; Dong, C.Y.; Guan, X.L.; Chen, X.G.; Wu, L.; Zhu, Y.C.; Zhang, L.; Ding, F.H.; Feng, L.P.; Li, Z.F. CPSM: A dynamic simulation model for cucumber productivity in solar greenhouse based on the principle of effective accumulated temperature. Agronomy 2024, 14, 1242. [Google Scholar] [CrossRef]

- Duarte, G.N.; Maluf, W.R.; Duarte, G.R.B.; de Oliveira, A.S.; Licursi, V. Fruit color and firmness in tomato hybrids as a function of the alleles rin, nor, norA, ogc and hp. Sci. Hortic. 2023, 319, 112159. [Google Scholar] [CrossRef]

- Wu, L.; Liu, J.Y.; Liang, Y. Inheritance on fruit color character between green and red of tomato. Acta Hortic. Sin. 2016, 43, 674–682. [Google Scholar]

- Hasan, S.M.K.; Manzocco, L.; Morozova, K.; Nicoli, M.C.; Scampicchio, M. Effects of ascorbic acid and light on reactions in fresh-cut apples by microcalorimetry. Thermochim. Acta 2017, 649, 63–68. [Google Scholar] [CrossRef]

- Ezzat, A.O.; Tawfeek, A.; Mohammad, F.; Al-Lohedan, H.A. Modification of magnetite nanoparticles surface with multifunctional ionic liquids for coomassie brilliant blue R-250 dye removal from aqueous solutions. J. Mol. Liq. 2022, 358, 119195. [Google Scholar] [CrossRef]

- Li, H.S. Principles and Techniques of Plant Physiological Biochemical Experiment; Higher Education Press: Beijing, China, 2000. [Google Scholar]

- Li, X.Y.; Meng, L.; Shen, L.; Ji, H.F. Regulation of gut microbiota by vitamin C, vitamin E and β-carotene. Food Res. Int. 2023, 169, 112749. [Google Scholar] [CrossRef] [PubMed]

- Ai, P.; Ma, Y.; Hai, Y. Influence of jujube/cotton intercropping on soil temperature and crop evapotranspiration in an arid area. Agric. Water Manag. 2021, 256, 107118. [Google Scholar] [CrossRef]

- Pan, T.; Chen, Q.; Chen, J.; Pan, T.; Ge, Q.S. Plausible changes in wheat-growing periods and grain yield in China triggered by future climate change under multiple scenarios and periods. Q. J. R. Meteorol. Soc. 2021, 147, 4371–4387. [Google Scholar]

- Kishore, K.; Rupa, T.R.; Samant, D. Influence of shade intensity on growth, biomass allocation, yield and quality of pineapple in mango-based intercropping system. Sci. Hortic. 2021, 278, 109868. [Google Scholar] [CrossRef]

- Boros, I.F.; Szekely, G.; Balazs, L.; Csambalik, L.; Sipos, L. Effects of LED lighting environments on lettuce (Lactuca sativa L.) in PFAL systems-A review. Sci. Hortic. 2023, 321, 112351. [Google Scholar] [CrossRef]

- Lv, Z.; Liu, X.; Cao, W.; Zhu, Y. A model-based estimate of regional wheat yield gaps and water use efficiency in main winter wheat production regions of China. Sci. Rep. 2017, 7, 6081. [Google Scholar] [CrossRef] [PubMed]

- Ghasemi-Saadatabadi, F.; Zand-Parsa, S.; Gheysari, M.; Sepaskhah, A.R.; Mahbod, M.; Hoogenboom, G. Improving prediction accuracy of CSM-CERES-Wheat model for water and nitrogen response using a modified Penman-Monteith equation in a semi-arid region. Field Crops Res. 2024, 312, 109381. [Google Scholar] [CrossRef]

- Tang, S.; Zheng, N.; Ma, Q.; Zhou, J.J.; Sun, T.; Zhang, X.; Wu, L.H. Applying Nutrient Expert system for rational fertilisation to tea (Camellia sinensis) reduces environmental risks and increases economic benefits. J. Clean. Prod. 2021, 305, 127197. [Google Scholar] [CrossRef]

| Cucumber | Start Date/Y-M-D | End Date/Y-M-D | Celery | Start Date/Y-M-D | End Date/Y-M-D |

|---|---|---|---|---|---|

| AW in 2018 | 2018-09-20 | 2019-02-28 | AW in 2018 | 2018-09-10 | 2019-03-14 |

| 2018-10-17 * | 2019-02-28 | —— | —— | ||

| 2018-11-11 | 2019-02-28 | 2018-10-10 * | 2019-03-14 | ||

| SC in 2019 | 2019-03-10 | 2019-07-24 | AW in 2019 | 2019-09-10 | 2020-04-14 |

| 2019-03-26 * | 2019-07-24 | 2019-09-24 * | 2020-04-14 | ||

| 2019-04-10 | 2019-07-24 | 2019-10-09 | 2020-04-14 | ||

| AW in 2019 | 2019-09-20 | 2020-03-28 | |||

| 2019-10-10 * | 2020-04-05 | ||||

| 2019-11-01 | 2020-04-19 |

| Crop | Developmental Stage | Temperature/°C | ||

|---|---|---|---|---|

| /°C | ~/°C | /°C | ||

| Cucumber | T to ST | 13 | 25~30 | 40 |

| ST to IF | 14 | 25~30 | 40 | |

| IF to U | 16 | 25~29 | 40 | |

| Celery | T to OLG | 6 | 15~20 | 30 |

| OLG to U | 6 | 16~20 | 30 | |

| Indicators | Appearance Quality | Indicators | Physicochemical Quality | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a | b | c | d | R2 | a | b | c | d | e | R2 | |||

| Cucumber | 0.0122 | 10.016 | —— | —— | 0.8339 | —— | —— | —— | 95.36 | —— | —— | ||

| 6.8677 | 0.0015 | —— | —— | 0.6842 | 0.0069 | 2.6153 | —— | —— | —— | 0.7979 | |||

| 7.393 | 0.0015 | —— | —— | 0.7048 | 0.4233 | −0.5612 | —— | —— | —— | 0.7735 | |||

| —— | —— | —— | 9.8587 | —— | −5.165 | 30.864 | —— | —— | —— | 0.6372 | |||

| −55.008 | 15542 | —— | —— | 0.5678 | 0.1063 | 65.48 | —— | —— | —— | 0.8857 | |||

| −2.47 | 98.728 | —— | —— | 0.5787 | |||||||||

| −0.0246 | 1.8692 | 10 | —— | 0.5272 | |||||||||

| Celery | −0.0022 | 14.63 | —— | —— | 0.5852 | 0.07 | 31.014 | −0.0833 | 45.447 | 100 | 0.5154 | ||

| −0.0017 | 0.5942 | 14 | —— | 0.8035 | —— | —— | —— | 83.50 | —— | —— | |||

| −31,720 | 174,545 | —— | —— | 0.6618 | 2.0953 | 85.08 | —— | —— | —— | 0.5403 | |||

| —— | —— | —— | 84.99 | —— | 2.1609 | 79.615 | —— | —— | —— | 0.3740 | |||

| 0.0244 | −0.6255 | —— | —— | 0.7155 | 0.0485 | 0.5289 | −6.429 | 37.347 | 130 | 0.9426 | |||

| −0.0209 | 1.0696 | 102 | —— | 0.7014 | −0.0208 | 0.6682 | 2.9 | —— | —— | 0.9048 | |||

| −0.0028 | 1.6314 | 92 | —— | 0.8552 | 0.0289 | 0.9395 | −2.821 | 18.019 | 130 | 0.9248 | |||

| −0.0024 | 2.3657 | 5400 | —— | 0.6639 | |||||||||

| −8875 | 57,056 | —— | —— | 0.8627 | |||||||||

| —— | —— | —— | 87.33 | —— | |||||||||

| 0.0324 | −0.0332 | —— | —— | 0.7540 | |||||||||

| 0.5478 | −21.519 | —— | —— | 0.8458 | |||||||||

| 0.0576 | 8.3443 | —— | —— | 0.8135 | |||||||||

| 0.6054 | −13.175 | —— | —— | 0.8489 | |||||||||

| Indicators | Unit | ± SD | ± SD | α | β | R2 | RMSE | NRMSE (%) | D | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Appearance | Cucumber | N | 15.05 ± 3.53 | 14.82 ± 2.99 | 1.12 | −1.56 | 0.90 | 1.16 | 7.69 * | 0.97 | |

| cm | 13.20 ± 5.83 | 12.4 ± 4.68 | 1.00 | 0.76 | 0.65 | 3.46 | 26.23 $ | 0.88 | |||

| cm | 1.40 ± 0.51 | 1.33 ± 0.50 | 0.85 | 0.26 | 0.71 | 0.28 | 20.15 $ | 0.91 | |||

| —— | 9.88 ± 0.76 | 9.86 | —— | —— | —— | 0.74 | 7.47 * | —— | |||

| —— | 11,828 ± 2685 | 12,035 ± 2101 | 1.13 | −1799 | 0.78 | 1257 | 10.63 # | 0.92 | |||

| —— | 88.52 ± 1.93 | 88.81 ± 1.56 | 0.90 | 8.24 | 0.54 | 1.32 | 1.49 * | 0.83 | |||

| —— | 4.46 ± 2.13 | 4.51 ± 2.04 | 0.83 | 0.73 | 0.63 | 1.30 | 29.21 $ | 0.89 | |||

| Celery | N | 12.74 ± 0.77 | 12.97 ± 0.54 | 1.11 | −1.63 | 0.60 | 0.50 | 3.96 * | 0.82 | ||

| —— | 8.8 ± 1.83 | 9.05 ± 1.93 | 0.86 | 0.98 | 0.83 | 0.79 | 9.00 * | 0.95 | |||

| —— | 35,609± 18,311 | 30,566 ± 12,290 | 1.29 | −3971 | 0.76 | 10234 | 28.74 $ | 0.86 | |||

| —— | 87.35 ± 4.76 | 84.99 | —— | —— | —— | 4.94 | 5.66 * | —— | |||

| —— | 2.19 ± 1.31 | 1.96 ± 1.12 | 1.11 | 0.01 | 0.90 | 0.46 | 21.04 $ | 0.96 | |||

| cm | 68.37 ± 25.09 | 64.61 ± 20.79 | 1.14 | −5.16 | 0.89 | 9.43 | 13.79 # | 0.96 | |||

| —— | 57.92 ± 21.45 | 59.28 ± 22.56 | 0.89 | 4.87 | 0.89 | 7.59 | 13.11 # | 0.97 | |||

| cm2 | 2317 ± 1355 | 2455 ± 1403 | 0.87 | 175 | 0.82 | 612 | 26.41 $ | 0.95 | |||

| —— | 18,968 ± 9831 | 18,489 ± 7785 | 1.25 | −4073 | 0.97 | 2324 | 12.25 # | 0.98 | |||

| —— | 85.14 ± 8.09 | 87.33 | —— | —— | —— | 7.70 | 9.05 * | —— | |||

| —— | 3.36 ± 2.16 | 3.26 ± 1.75 | 1.05 | −0.04 | 0.72 | 1.06 | 31.47 ! | 0.91 | |||

| g | 443.44 ± 353.06 | 479.70 ± 299.94 | 1.12 | −92.50 | 0.90 | 119.76 | 27.01 $ | 0.96 | |||

| g | 59.77 ± 35.47 | 61.05 ± 31.54 | 1.02 | −2.51 | 0.82 | 14.68 | 24.57 $ | 0.95 | |||

| g | 503.22 ± 386.86 | 540.74 ± 331.48 | 1.11 | −95.94 | 0.90 | 129.56 | 25.75 $ | 0.97 | |||

| Physicochemical | Cucumber | % | 95.31 ± 1.11 | 95.36 | —— | —— | —— | 1.08 | 1.13 * | —— | |

| % | 3.06 ± 0.29 | 3 ± 0.24 | 1.13 | −0.34 | 0.86 | 0.12 | 3.93 * | 0.94 | |||

| mg/g | 1.28 ± 0.51 | 1.26 ± 0.4 | 1.17 | −0.20 | 0.87 | 0.18 | 13.96 # | 0.95 | |||

| mg/g | 8.68 ± 5.11 | 7.97 ± 4.48 | 0.97 | 0.96 | 0.72 | 2.56 | 29.53 $ | 0.91 | |||

| mg/kg | 77.4 ± 6.65 | 76.67 ± 7.98 | 0.81 | 15.25 | 0.95 | 2.09 | 2.70 * | 0.98 | |||

| Celery | SPAD | 35.75 ± 2.79 | 35.1 ± 1.77 | 0.81 | 7.33 | 0.26 | 2.44 | 6.83 * | 0.67 | ||

| % | 94.23 ± 2.19 | 93.9 ± 1.6 | 0.98 | 2.54 | 0.51 | 1.54 | 1.63 * | 0.81 | |||

| % | 81.81 ± 6.29 | 83.5 | —— | —— | —— | 6.39 | 7.81 * | —— | |||

| % | 88.02 ± 3.88 | 88.71 ± 1.65 | 2.06 | −94.78 | 0.77 | 2.60 | 2.96 * | 0.77 | |||

| % | 2.28 ± 0.44 | 2.34 ± 0.41 | 1.03 | −0.13 | 0.94 | 0.11 | 4.94 * | 0.98 | |||

| % | 4.43 ± 1.14 | 4.47 ± 1.13 | 0.96 | 0.15 | 0.89 | 0.36 | 8.04 * | 0.97 | |||

| % | 3.35 ± 0.69 | 3.4 ± 0.66 | 0.98 | 0.01 | 0.88 | 0.23 | 6.74 * | 0.97 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, C.; Feng, L.; Dong, C.; Chen, X.; Yang, F.; Wu, L.; Yang, J.; Zhao, C.; Yuan, G.; Li, Z. Vegetable Commodity Organ Quality Formation Simulation Model (VQSM) in Solar Greenhouses. Agriculture 2024, 14, 1531. https://doi.org/10.3390/agriculture14091531

Cheng C, Feng L, Dong C, Chen X, Yang F, Wu L, Yang J, Zhao C, Yuan G, Li Z. Vegetable Commodity Organ Quality Formation Simulation Model (VQSM) in Solar Greenhouses. Agriculture. 2024; 14(9):1531. https://doi.org/10.3390/agriculture14091531

Chicago/Turabian StyleCheng, Chen, Liping Feng, Chaoyang Dong, Xianguan Chen, Feiyun Yang, Lu Wu, Jing Yang, Chengsen Zhao, Guoyin Yuan, and Zhenfa Li. 2024. "Vegetable Commodity Organ Quality Formation Simulation Model (VQSM) in Solar Greenhouses" Agriculture 14, no. 9: 1531. https://doi.org/10.3390/agriculture14091531

APA StyleCheng, C., Feng, L., Dong, C., Chen, X., Yang, F., Wu, L., Yang, J., Zhao, C., Yuan, G., & Li, Z. (2024). Vegetable Commodity Organ Quality Formation Simulation Model (VQSM) in Solar Greenhouses. Agriculture, 14(9), 1531. https://doi.org/10.3390/agriculture14091531