Design and Experimentation on a Pneumatic Corn Seed Metering Device with Assisted Seed-Filling and Airflow-Guided Seed Release

Abstract

:1. Introduction

2. Materials and Methods

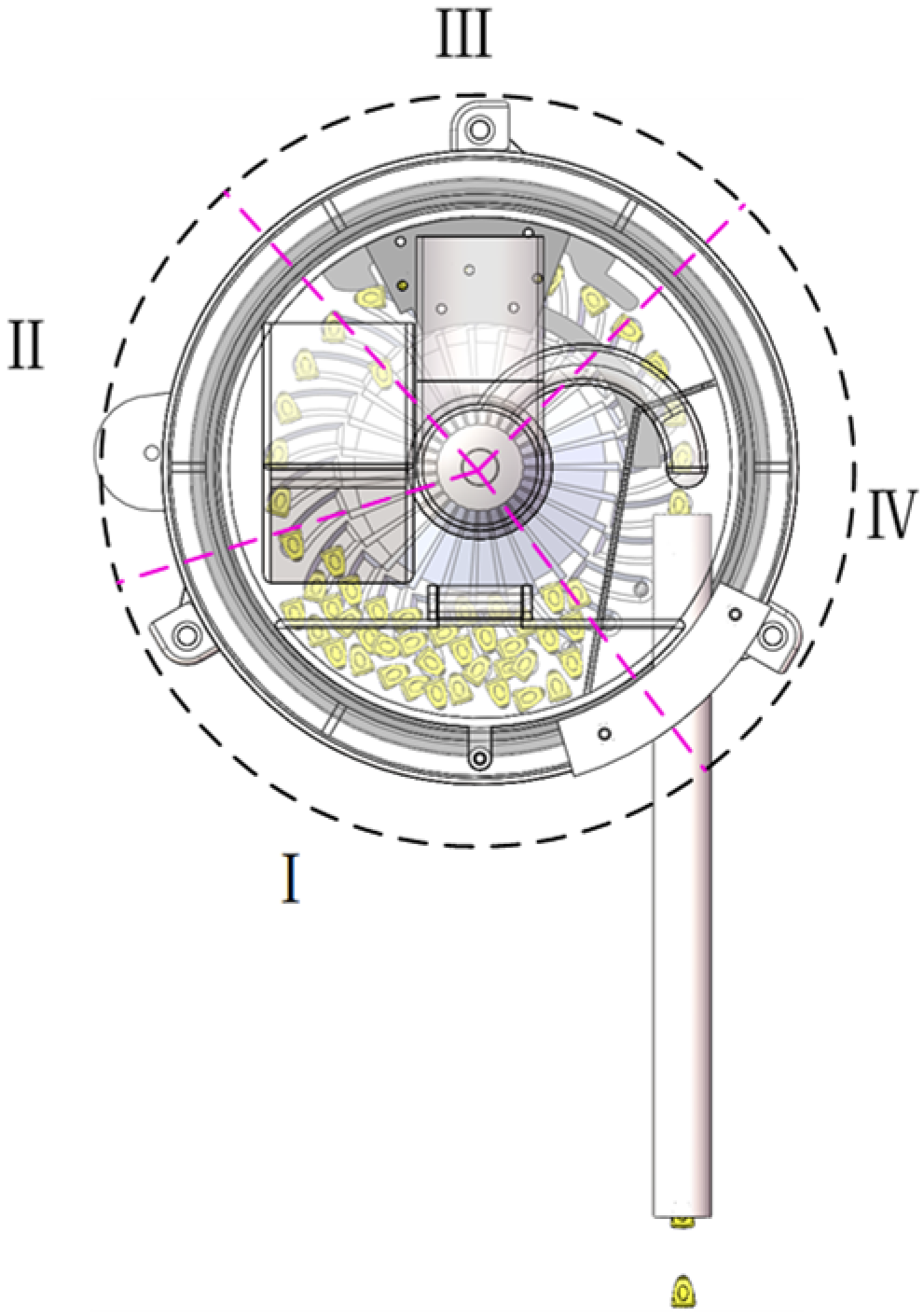

2.1. Overall Structure of the Seed Metering Device

2.2. Working Principle of the Seed Metering Device

2.3. Design and Analysis of the Seed Metering Disc

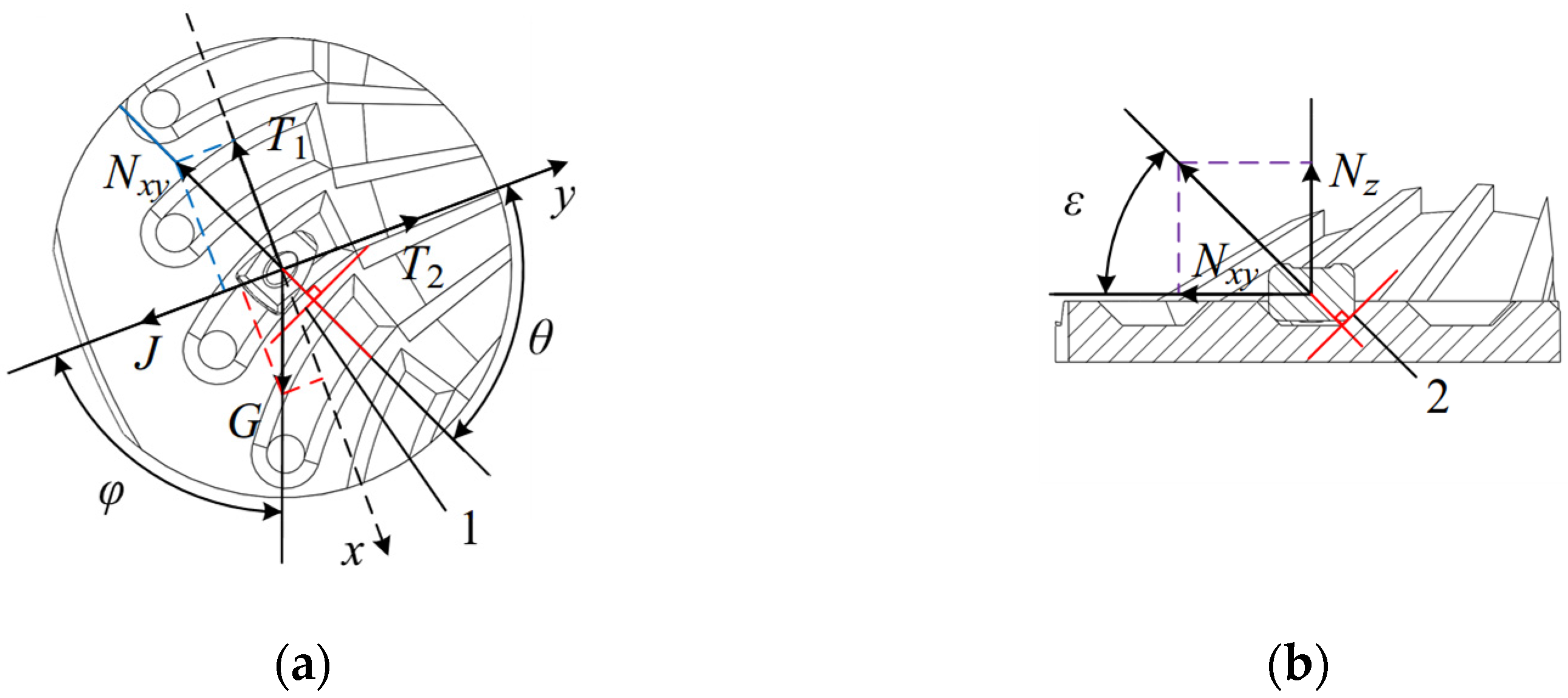

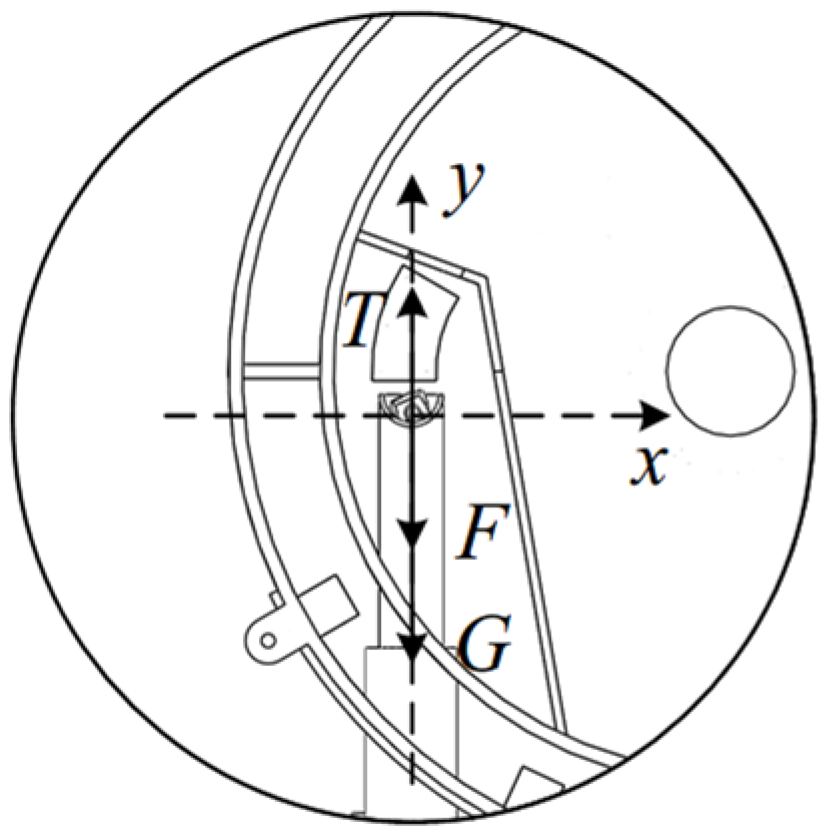

2.3.1. Force Analysis of Corn Seed Filling

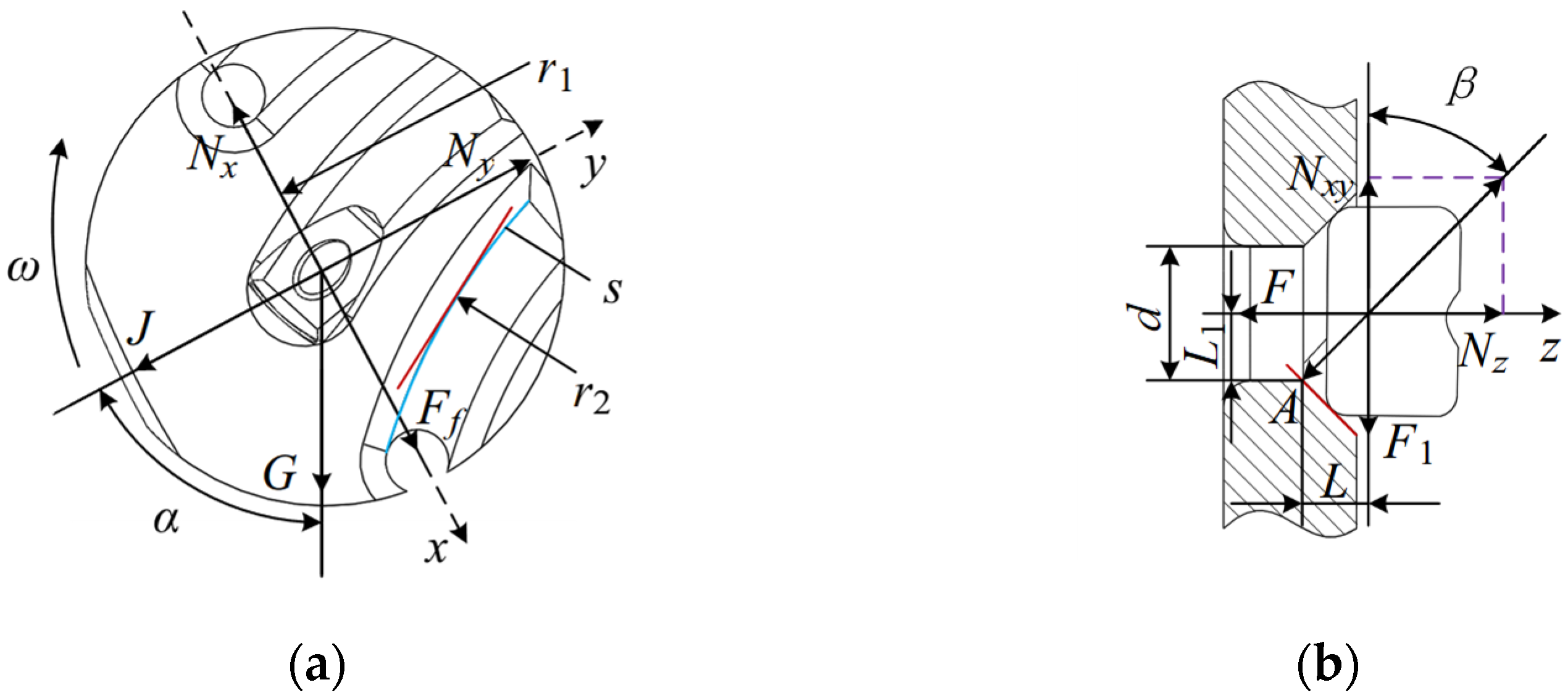

2.3.2. Metering Hole Design

2.3.3. Tapered Seed Guide Groove Design of the Seed Metering Disc

2.4. Design and Analysis of the Same-Source Airflow-Assisted Seed Release Mechanism

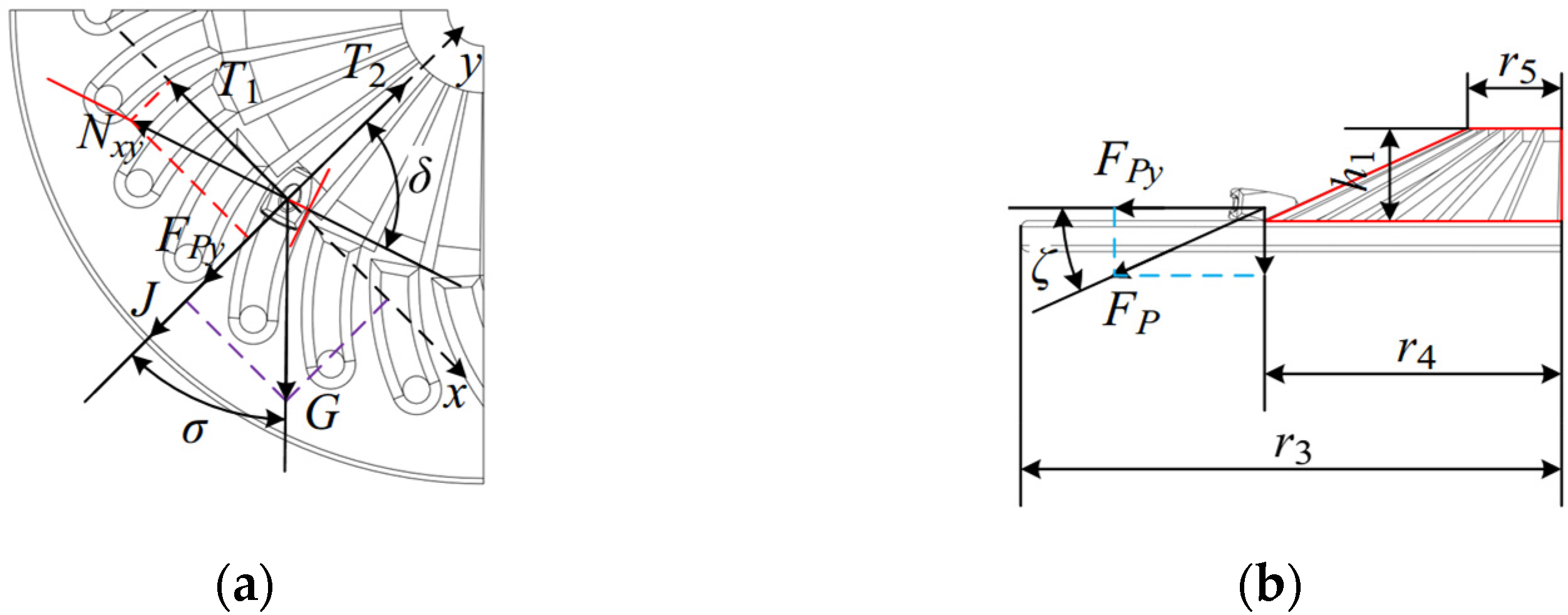

2.4.1. Force Analysis of Seeds in the Seed Release Process

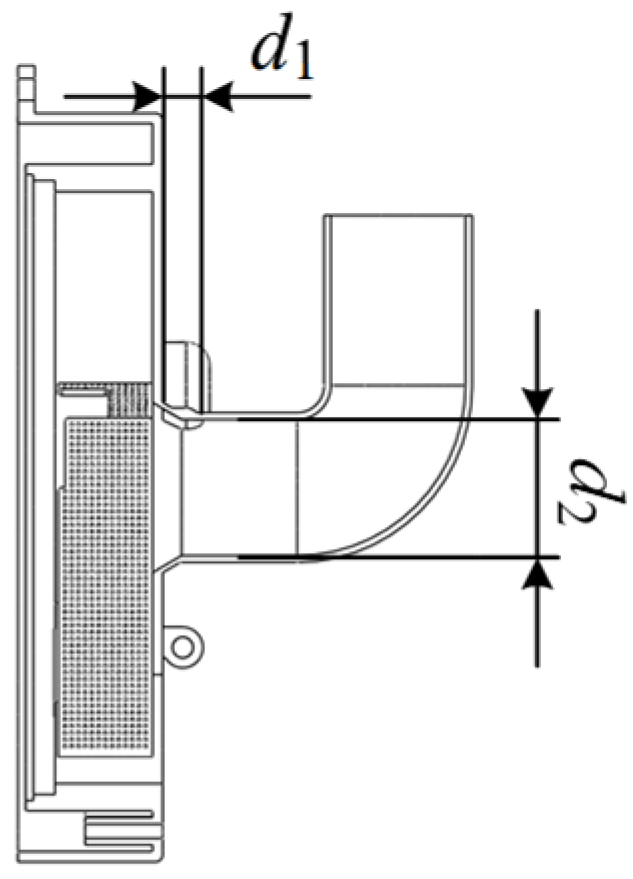

2.4.2. Design and Analysis of the Air Inlet

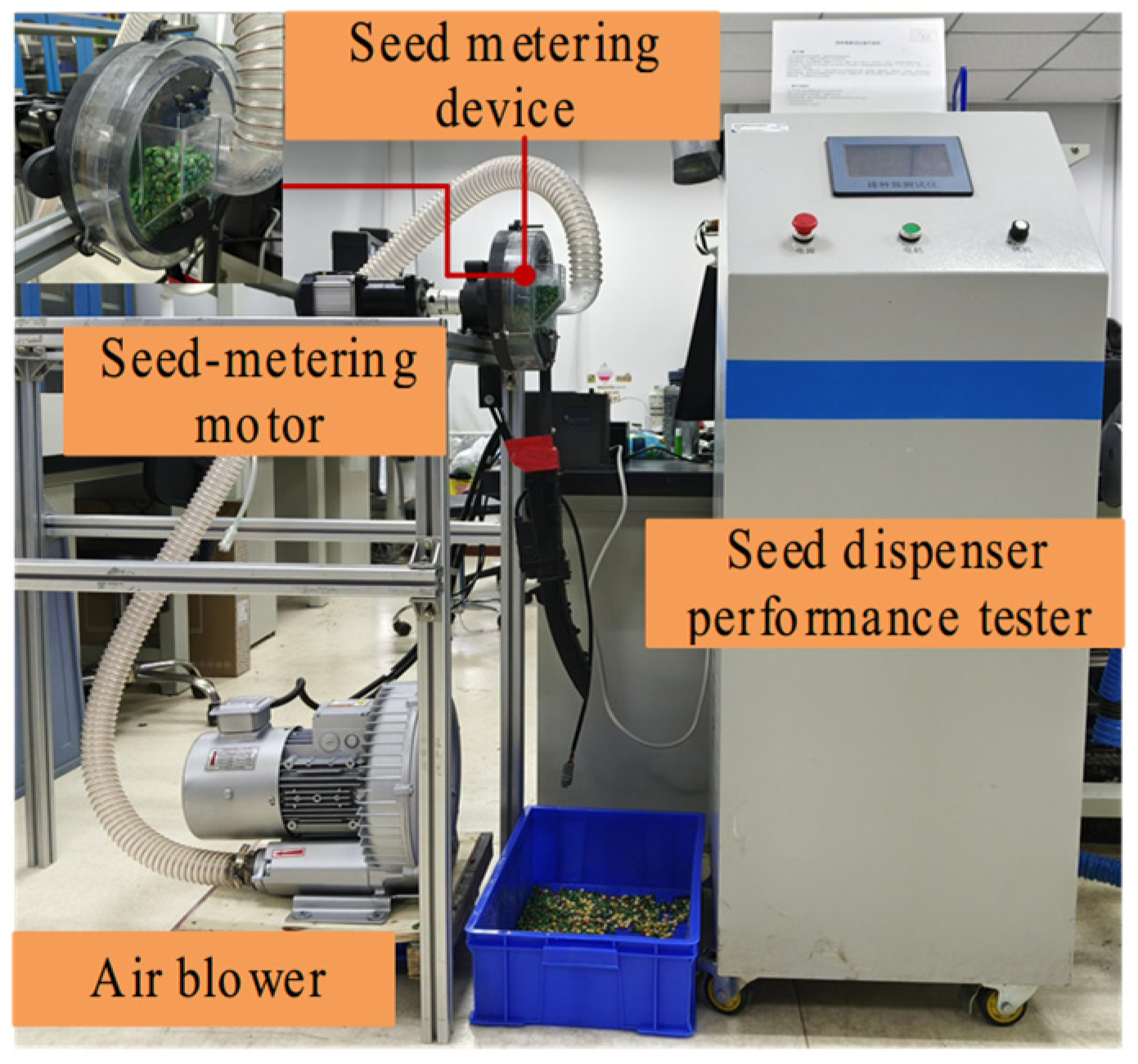

2.5. Performance Bench Experiment of the Seed Metering Device

2.5.1. Preparation of Experiment Materials

2.5.2. Experiment Method

3. Results and Discussion

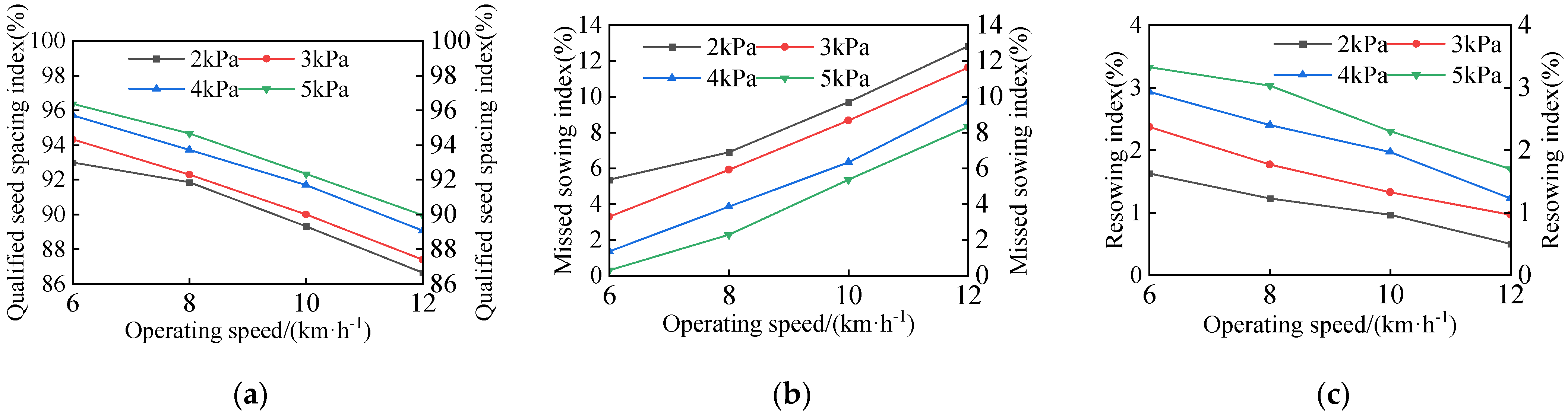

3.1. Test Bench Results and Discussion

3.1.1. Test Bench Results

3.1.2. Discussion of Test Bench Results

3.2. Field Seeding Test

3.2.1. Materials and Methods for Field Test

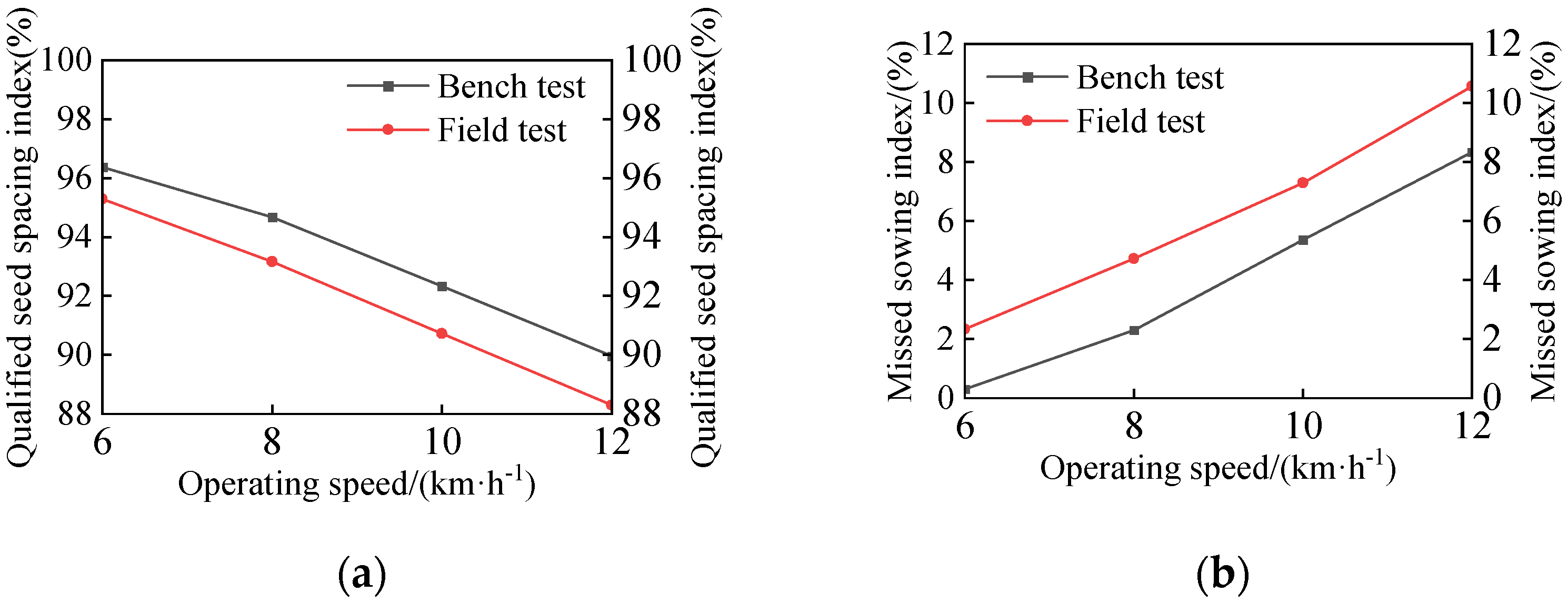

3.2.2. Field Test Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, L.; Yan, B.X.; Zhang, D.X.; Zhang, T.L.; Wang, Y.X.; Cui, T. Research progress of precision seeding technology for corn. J. Agric. Mach. 2016, 47, 38–48. [Google Scholar]

- Yuan, Y.; Bai, H.; Fang, C.; Wang, D.; Zhou, L.; Niu, K. Research progress of corn seeding and measurement and control technology. J. Agric. Mach. 2018, 49, 1–18. [Google Scholar]

- Guo, J.; Yang, Y.; Memon, M.S.; Tan, C.; Wang, L.; Tang, P. Design and simulation for seeding performance of high-speed inclined corn metering device based on discrete element method (DEM). Sci. Rep. 2022, 12, 19415. [Google Scholar]

- Tang, H.; Xu, C.; Wang, Z.; Wang, Q.; Wang, J. Optimized Design, Monitoring System Development and Experiment for a Long-Belt Finger-Clip Precision Corn Seed Metering Device. Front. Plant Sci. 2022, 13, 814747. [Google Scholar] [CrossRef]

- Hörbe, T.A.N.; Amado, T.J.C.; Reimche, G.B.; Schwalbert, R.A.; Santi, A.L.; Nienow, C. Optimization of Within-Row Plant Spacing Increases Nutritional Status and Corn Yield: A Comparative Study. Agron. J. 2016, 108, 1962–1971. [Google Scholar] [CrossRef]

- Ding, L.; Yang, L.; Zhang, D.X.; Cui, T.; Zhang, K.L.; Zhong, X.J. Analysis of the effect of adsorption attitude on seed delivery performance of air-absorbing corn seed discharger. J. Agric. Mach. 2021, 52, 40–50. [Google Scholar]

- Chen, J.; Guan, T.; Yuan, Z.; Xu, F.; Zhao, K.; Tang, H.; Zhao, J.; Wang, J. Development of high-speed precision maize metering device for dense planting pattern with standard ridges. Front. Plant Sci. 2024, 15, 1452699. [Google Scholar] [CrossRef]

- Ding, L.; Yuan, Y.; Dou, Y.; Li, C.; He, Z.; Guo, G.; Zhang, Y.; Chen, B.; Li, H. Design and Experiment of Air-Suction Maize Seed-Metering Device with Auxiliary Guide. Agriculture 2024, 14, 169. [Google Scholar] [CrossRef]

- Xiong, D.; Wu, M.; Xie, W.; Liu, R.; Luo, H. Design and Experimental Study of the General Mechanical Pneumatic Combined Seed Metering Device. Appl. Sci. 2021, 11, 7223. [Google Scholar] [CrossRef]

- Baghooee, M.; Karparvarfard, S.H.; Azimi-Nejadian, H.; Keramat-Jahromi, M.; Balanian, H.; Sardarpour, F. DEM Simulation for Seeding Performance of a Slotted Roller Seed-Metering Device for Planting Maize in Laboratory Condition. J. Biosyst. Eng. 2023, 48, 428–436. [Google Scholar] [CrossRef]

- Jiang, X.; Zhang, J.; Liu, S.; Fu, L.; Huang, D. Development and Evaluation of a Universal Seed Discharger for Precision Planting in Corn-Soybean Cropping System. Processes 2024, 12, 1595. [Google Scholar] [CrossRef]

- Liu, H.; Jia, R.; Zhou, X.; Fu, L. Virtual assembly of man-machine interactive mechanical seed-metering device based on matter-element identification. Trans. Chin. Soc. Agric. 2016, 32, 38–45. [Google Scholar]

- Tang, H.; Guan, T.; Xu, F.; Xu, C.; Wang, J. Test on adsorption posture and seeding performance of the high-speed precision dual-chamber maize metering device based on the seed characteristics. Comput. Electron. Agric. 2024, 216, 108471. [Google Scholar]

- He, X.; Wan, Y.; Zhong, P.; Lin, J.; Huang, M.; Yang, R.; Zang, Y. Design and experimental analysis of real-time detection system for The seeding accuracy of rice pneumatic seed metering device based on the improved YOLOv5n. Comput. Electron. Agric. 2024, 227, 109614. [Google Scholar]

- Li, Q.L.; Yu, J.Y.; Zhang, Q.Q.; Yu, J.Q.; Fu, H. Simulation Analysis of the Working Process of the Corn Seed Metering Device with Combination Inner-Cell. Appl. Mech. Mater. 2012, 215–216, 160–167. [Google Scholar] [CrossRef]

- Shi, S.; Zhang, D.; Yang, L.; Cui, T.; Zhang, R.; Yin, X. Design and test of pneumatic combined hole type corn precision seed discharger. J. Agric. Eng. 2014, 30, 10–18. [Google Scholar]

- Yang, S.D.; Zhang, D.X.; Gao, Z.Q.; Liu, X.Q. Simulation and test of flow field of lateral positive pressure corn seed discharger. J. Agric. Mach. 2014, 45, 35–39. [Google Scholar]

- Sun, W.S.; Yi, S.; Qi, S.J.; Qi, H.L.; Wang, S.; Li, Y.F.; Dai, Z.B. Research on double-disk staggered pneumatic pressure type high-speed precision seed discharger for zigzag dense planting of corn. J. Agric. Mach. 2024, 55, 168–179. [Google Scholar]

- Guo, P.; Zheng, X.-S.; Wang, D.-W.; Hou, J.-L.; Zhao, Z. Design and test of pneumatic-assisted seed filling type peanut precision seed discharger. J. Agric. Mach. 2024, 55, 64–74. [Google Scholar]

- Yan, B.X.; Zhang, D.X.; Cui, T.; He, X.; Ding, Y.; Yang, L. Design of pneumatic suction corn precision seed discharger with synchronized rotation of seed disks and negative pressure chambers. J. Agric. Eng. 2017, 33, 15–23. [Google Scholar]

- Ding, L.; Yang, L.; Wu, D.H.; Li, D.Y.; Zhang, D.X.; Liu, S.R. Simulation and test of corn air suction seed discharger based on DEM-CFD coupling. J. Agric. Mach. 2018, 49, 48–57. [Google Scholar]

- Ding, L.; Yang, L.; Liu, S.R.; Yan, B.X.; He, X.T.; Zhang, D.X. Design of air-aspirated high-speed precision seed discharger for corn with auxiliary seed-filling disc. J. Agric. Eng. 2018, 34, 1–11. [Google Scholar]

- Lai, H. Design and Testing of a Pneumatic Cone Disc Precision Spaced Planter for Wide Wheat Seedlings. Master’s Thesis, Huazhong Agricultural University, Wuhan, China, 2023. [Google Scholar]

- Chinese Academy of Agricultural Mechanization Sciences. Handbook of Agricultural Machinery; China Agricultural Science and Technology Press: Beijing, China, 2007. [Google Scholar]

- Zheng, J.; Lai, H.; Li, S.; Li, Y.-T.; Liao, Q.; Liao, Y. Design and test of wheat wide seedling belt pneumatic suction precision seed discharger. J. Agric. Mach. 2024, 55, 165–176+335. [Google Scholar]

| Instrument | Model | Parameters |

|---|---|---|

| Seed dispenser performance tester | Huai yu N288 | Row spacing range: 10~35 cm |

| Metering hole count range: 6~40 | ||

| Target number of seeds: 0~9999 | ||

| Air blower | RB-51D-4 | Power: 2.2 kW |

| Air pressure: 27~29 kPa | ||

| Airflow rate: 210~255 m3/h | ||

| Anemometer | testo440 | Range: 0~30 m/s |

| Resolution: 0.01 m/s | ||

| Seed-metering motor | QW80BL00730-450J30 | Power: 450 W |

| Speed range: 1~100 r/min |

| Levels | Factor A | Factor B |

|---|---|---|

| Operating Speed | Working Pressure | |

| 1 | 6 | 2 |

| 2 | 8 | 3 |

| 3 | 10 | 4 |

| 4 | 12 | 5 |

| Operating Speed/(km/h) | Working Pressure/(kPa) | Qualified Seed Spacing Index/(%) | Missed Sowing Index/(%) | Resowing Index/(%) | Coefficient of Variation in Qualified Seed Spacing/(%) |

|---|---|---|---|---|---|

| 6 | 2 | 93.00 | 5.37 | 1.63 | 20.07 |

| 3 | 94.33 | 3.30 | 2.37 | 19.13 | |

| 4 | 95.70 | 1.37 | 2.93 | 18.53 | |

| 5 | 96.37 | 0.30 | 3.33 | 17.37 | |

| 8 | 2 | 91.87 | 6.90 | 1.23 | 21.33 |

| 3 | 92.30 | 5.93 | 1.77 | 20.67 | |

| 4 | 93.73 | 3.87 | 2.40 | 19.97 | |

| 5 | 94.67 | 2.30 | 3.03 | 19.17 | |

| 10 | 2 | 89.33 | 9.70 | 0.97 | 22.33 |

| 3 | 90.00 | 8.67 | 1.33 | 21.83 | |

| 4 | 91.70 | 6.33 | 1.97 | 21.03 | |

| 5 | 92.33 | 5.37 | 2.30 | 20.57 | |

| 12 | 2 | 86.67 | 12.83 | 0.50 | 24.47 |

| 3 | 87.40 | 11.63 | 0.97 | 23.17 | |

| 4 | 89.07 | 9.70 | 1.23 | 22.93 | |

| 5 | 89.97 | 8.33 | 1.70 | 21.53 |

| Operating Speed/(km/h) | Performance Indicators | ||

|---|---|---|---|

| Qualified Seed Spacing Index/(%) | Missed Sowing Index/(%) | Resowing Index/(%) | |

| 6 | 95.30 | 2.33 | 2.37 |

| 8 | 93.17 | 4.73 | 2.10 |

| 10 | 90.73 | 7.30 | 1.97 |

| 12 | 88.30 | 10.57 | 1.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, J.; Wu, G.; Liu, R.; Li, L.; Xiao, Y.; Guo, J.; Yan, B. Design and Experimentation on a Pneumatic Corn Seed Metering Device with Assisted Seed-Filling and Airflow-Guided Seed Release. Agriculture 2025, 15, 745. https://doi.org/10.3390/agriculture15070745

Yan J, Wu G, Liu R, Li L, Xiao Y, Guo J, Yan B. Design and Experimentation on a Pneumatic Corn Seed Metering Device with Assisted Seed-Filling and Airflow-Guided Seed Release. Agriculture. 2025; 15(7):745. https://doi.org/10.3390/agriculture15070745

Chicago/Turabian StyleYan, Jiahua, Guangwei Wu, Rui Liu, Liwei Li, Yuejin Xiao, Junxian Guo, and Bingxin Yan. 2025. "Design and Experimentation on a Pneumatic Corn Seed Metering Device with Assisted Seed-Filling and Airflow-Guided Seed Release" Agriculture 15, no. 7: 745. https://doi.org/10.3390/agriculture15070745

APA StyleYan, J., Wu, G., Liu, R., Li, L., Xiao, Y., Guo, J., & Yan, B. (2025). Design and Experimentation on a Pneumatic Corn Seed Metering Device with Assisted Seed-Filling and Airflow-Guided Seed Release. Agriculture, 15(7), 745. https://doi.org/10.3390/agriculture15070745