Study on the Mechanical Properties of Silty Clay Sediments with Nodular Hydrate Occurrence

Abstract

:1. Introduction

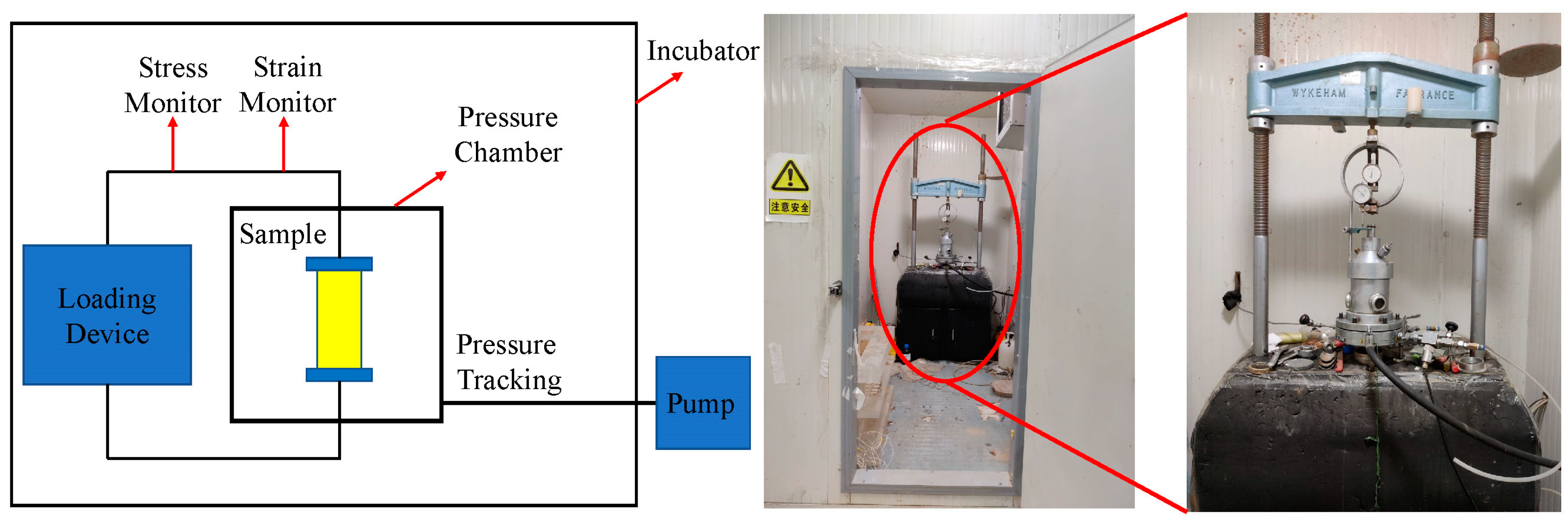

2. Materials and Methods

2.1. Soil Skeleton Materials and Experimental Set-Up

2.2. The Sample Preparation Method Containing Segregated Hydrate Masses

3. Results and Discussion

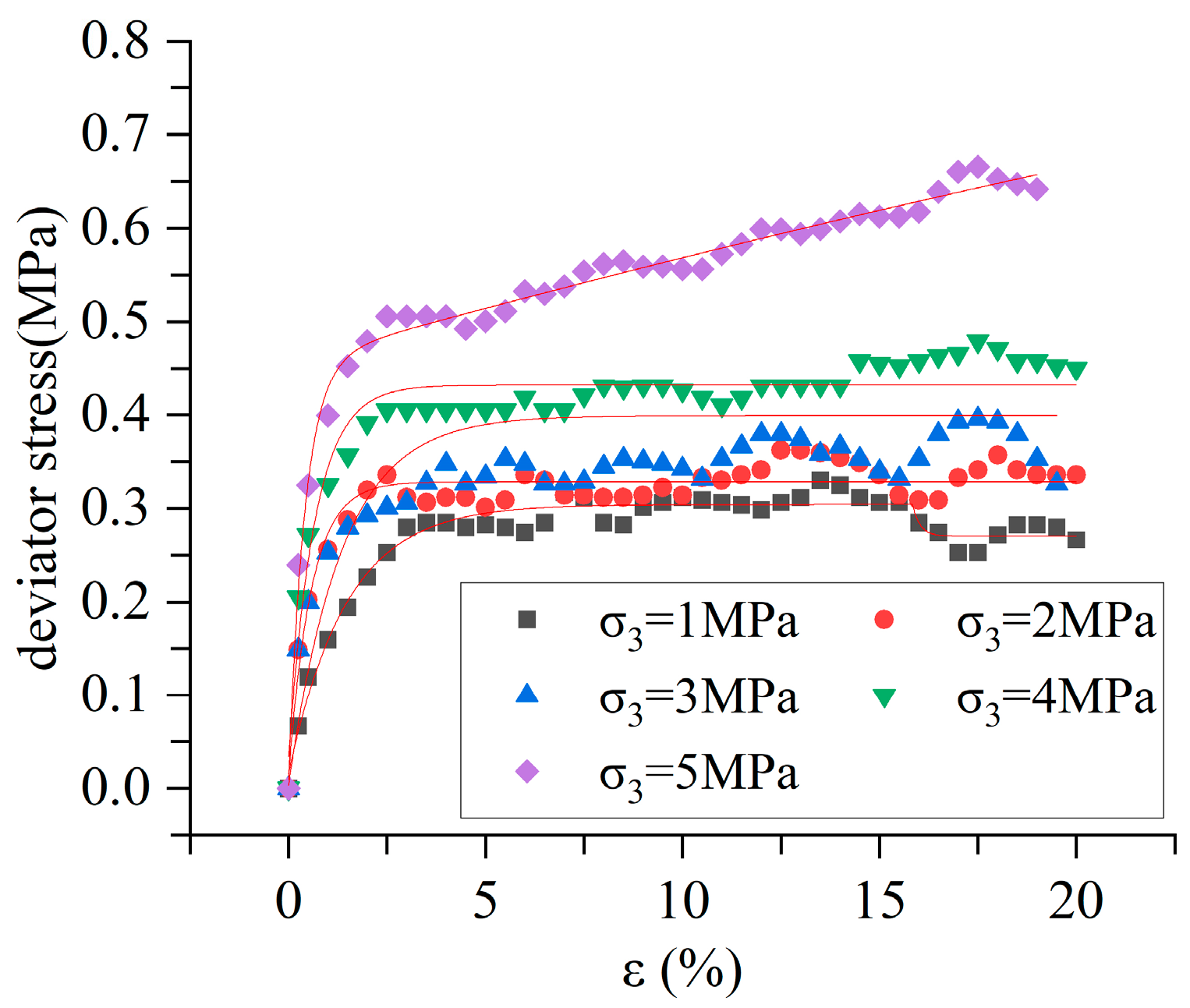

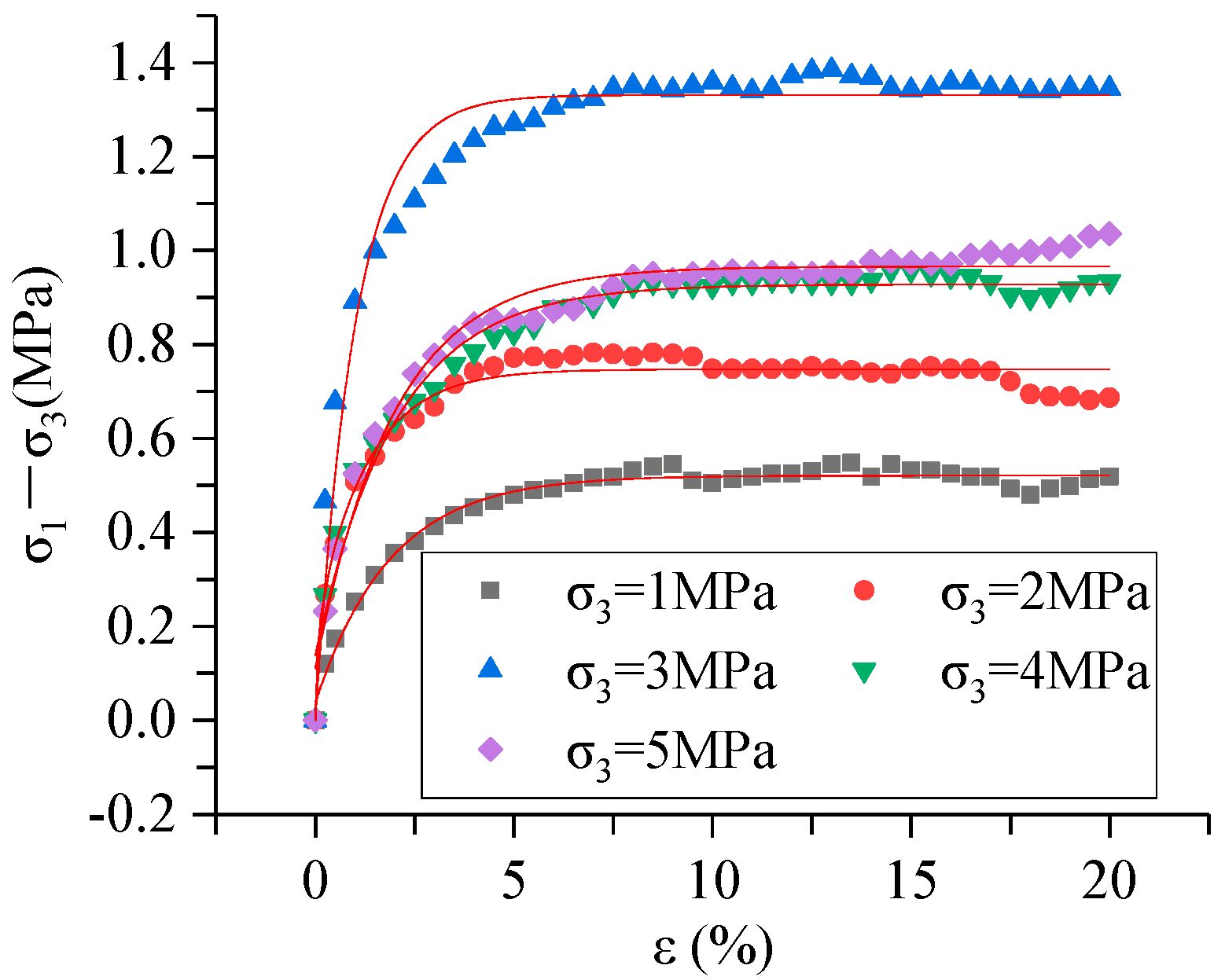

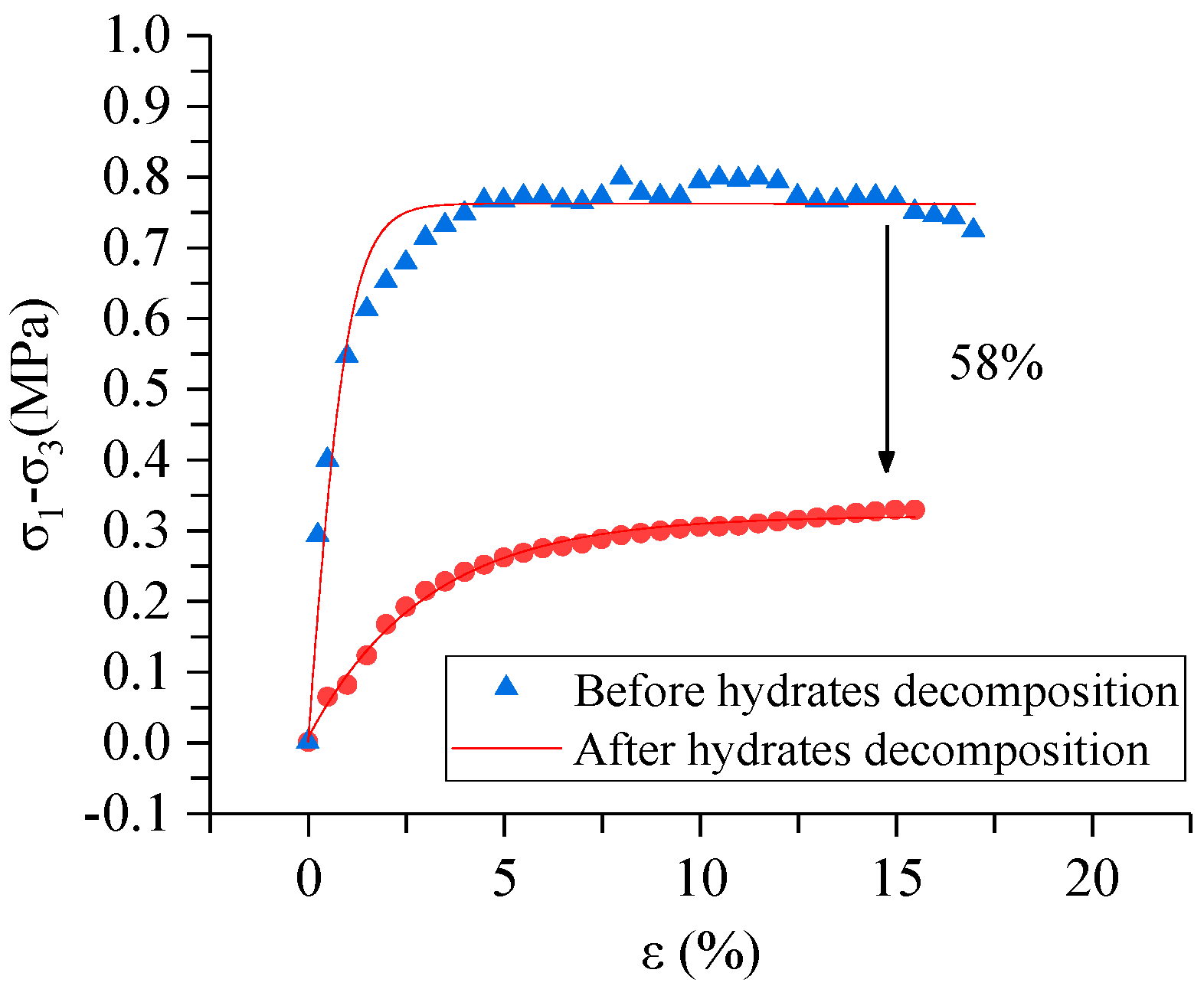

3.1. Stress–Strain Relationships

3.2. Discussion of the Modulus

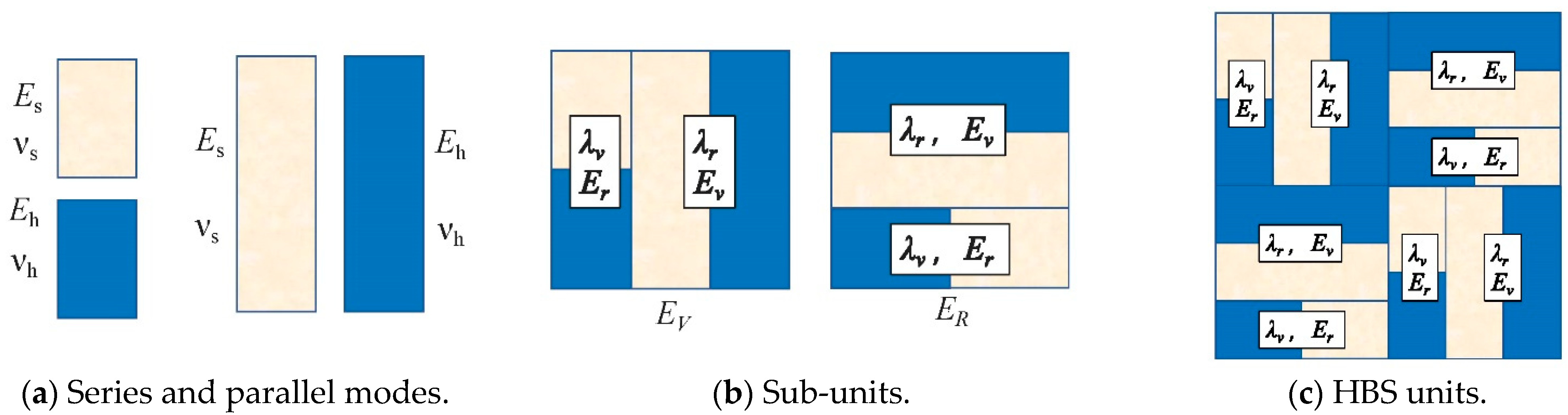

3.3. Theoretical Expressions for the Moduli of Two-Phase Composites

- (1)

- When , this elastic modulus is the upper limit:

- (2)

- When , this elastic modulus is the low limit:

4. Conclusions

- (1)

- Different from the elastic–plastic stress–strain characteristics of sandy sediments containing homogeneous pore-filled hydrates, the triaxial stress–strain curves of the test samples have obvious elastic and plastic stages. Under the same hydrate volume fraction, with the increase in confining pressure, the strengths and elastic moduli of the test samples improved, and when the confining pressure exceeded 3 MPa, the shear strength decreased due to the fracturing effect under high pressure.

- (2)

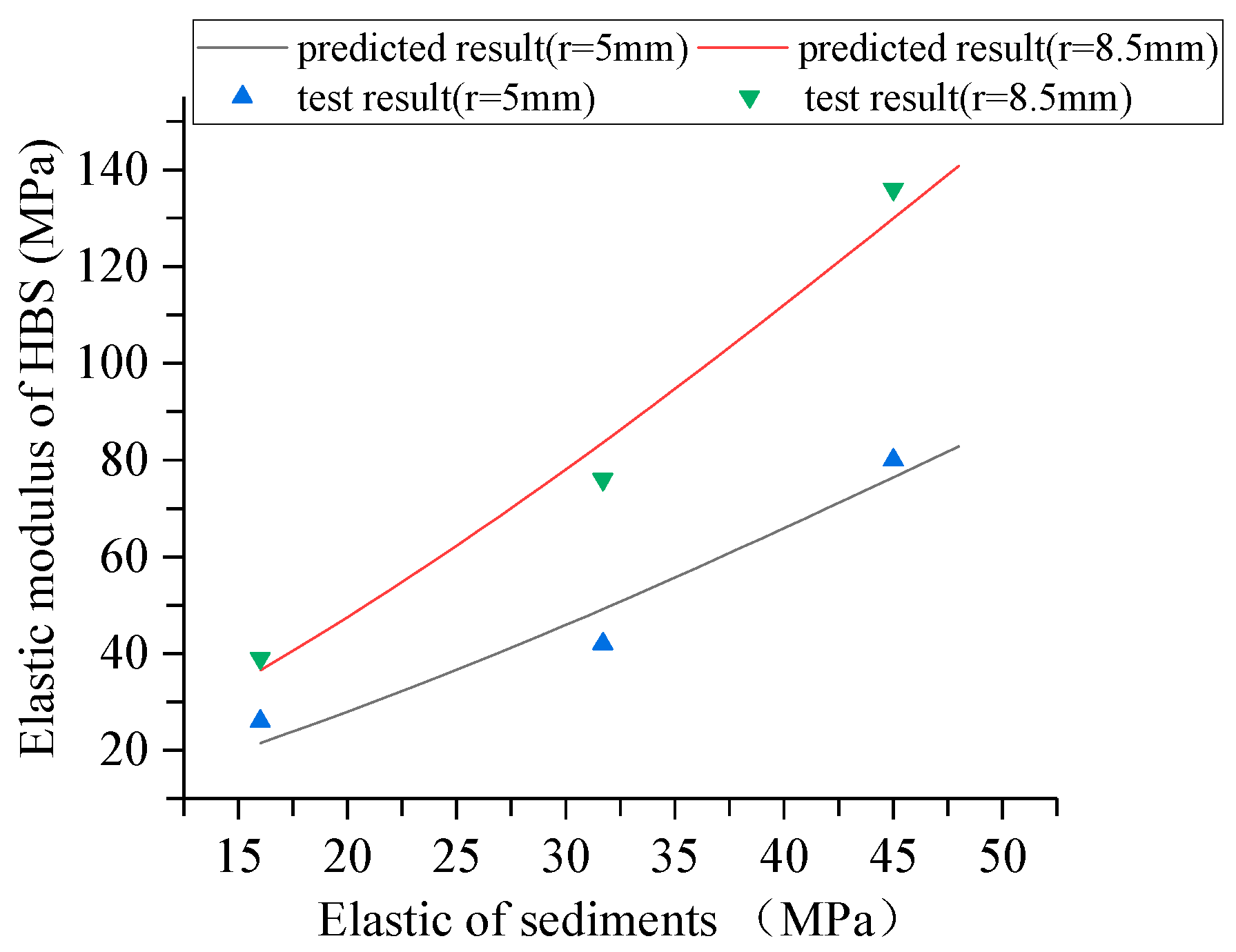

- Based on the theory of composite mechanics, the two-phase elastic modulus model proposed by Zhang et al. was improved to describe the effect of the heterogeneity of hydrates. By comparing the theoretical results with the test results, it was found that when the value was 0.5 and was −0.21, the elastic modulus predicted by the model agreed well with the test results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, H.; Luo, X.; Bi, J.; He, G.; Guo, Z. Submarine slope stability analysis during natural gas hydrate dissociation. Mar. Georesources Geotechnol. 2019, 37, 467–476. [Google Scholar] [CrossRef]

- Lijith, K.P.; Malagar, B.R.C.; Singh, D.N. A comprehensive re-view on the geomechanical properties of gas hydrate bearing sediments. Mar. Pet. Geol. 2019, 104, 270–285. [Google Scholar] [CrossRef]

- Sloan, E.D. Clathrate Hydrates of Natural Gases, 2nd ed.; Revised and Expanded; The Chemical Rubber Company Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Farahani, M.V.; Hassanpouryouzband, A.; Yang, J.; Tohidi, B. Insights Into the Climate-driven Evolution of Gas Hydrate-bearing Permafrost Sediments: Implications for Prediction of Environmental Impacts and Security of Energy in Cold Regions. RSC Adv. 2021, 11, 14334–14346. [Google Scholar] [CrossRef] [PubMed]

- Hyodo, M.; Wu, Y.; Nakashima, K.; Kajiyama, S.; Nakata, Y. Influence of Fines Content on the Mechanical Behavior of Methane Hydrate-bearing Sediments. J. Geophys. Res. Solid Earth 2017, 122, 7511–7524. [Google Scholar] [CrossRef]

- Winters, W.J.; Pecher, I.A.; Waite, W.; Mason, D.H. Physical Properties and Rock Physics Models of Sediment Containing Natural and Laboratory-formed Methane Gas Hydrate. Am. Mineral. 2004, 89, 1221–1227. [Google Scholar] [CrossRef]

- Winters, W.; Waite, W.; Mason, D.; Gilbert, L.; Pecher, I. Methane Gas Hydrate Effect on Sediment Acoustic and Strength Properties. J. Pet. Sci. Eng. 2007, 56, 127–135. [Google Scholar] [CrossRef] [Green Version]

- Winters, W.J.; Dallimore, S.R.; Collett, T.S.; Jenner, K.A.; Katsube, J.T.; Cranston, R.E.; Uchida, T. Relation between Gas Hydrate and Physical Properties at the Mallik 2l–38 Research Well in the Mackenzie Delta. Ann. N. Y. Acad. Sci. 2010, 912, 94–100. [Google Scholar] [CrossRef]

- Clayton, C.; Priest, J.A.; Best, A.I. The Effects of Disseminated Methane Hydrate on the Dynamic Stiffness and Damping of a Sand. Géotechnique 2005, 55, 423–434. [Google Scholar] [CrossRef]

- Kajiyama, S.; Hyodo, M.; Nakata, Y.; Yoshimoto, N.; Wu, Y.; Kato, A. Shear Behaviour of Methane Hydrate-bearing Sand with various particle characteristics and fines. Soils Found. 2007, 57, 176–193. [Google Scholar] [CrossRef]

- Masui, A.; Haneda, H.; Ogata, Y.; Aoki, K. Compaction behavior of Toyoura sand during methane hydrate dissociation. In Proceedings of the Seventh (2007) Isope Ocean Mining (& Gas Hydrates) Symposium, Lisbon, Portugal, 1–6 July 2007; pp. 53–56. [Google Scholar]

- Yun, T.S.; Santamarina, J.C.; Ruppel, C. Mechanical Properties of Sand, Silt, and Clay Containing Tetrahydrofuran Hydrate. J. Geophys. Res. -Solid Earth 2007, 112. [Google Scholar] [CrossRef]

- Nagashima, K.; Suzuki, T.; Nagamoto, M.; Shimizu, T. Formation of periodic layered pattern of tetrahydrofuran clathrate hydrates in porous media. J. Phys. Chem. B 2008, 112, 9876–9882. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.H.; Wang, S.Y. Advances in Study of Mechanical Properties of Gas Hydrate-Bearing Sediments. Open Ocean. Eng. J. 2013, 6, 26–40. [Google Scholar]

- Vlasic, T.M.; Servio, P.D.; Rey, A.D. THF Hydrates as Model Systems for Natural Gas Hydrates: Comparing Their Mechanical and Vibrational Properties. Ind. Eng. Chem. Res. 2019, 58, 16588–16596. [Google Scholar] [CrossRef]

- Lee, J.Y.; Santamarina, J.C.; Ruppel, C. Mechanical and Electromagnetic Properties of Northern Gulf of Mexico Sediments with and without Thf Hydrates. Mar. Pet. Geol. 2008, 25, 884–895. [Google Scholar] [CrossRef]

- Zhang, X.-H.; Lu, X.-B.; Zhang, L.-M.; Wang, S.-Y.; Li, Q.-P. Experimental Study on Mechanical Properties of Methane-hydrate-bearing Sediments. Acta Mech. Sin. 2012, 28, 1356–1366. [Google Scholar] [CrossRef] [Green Version]

- Luo, T.; Song, Y.; Zhu, Y.; Liu, W.; Liu, Y.; Li, Y.; Wu, Z. Triaxial Experiments on the Mechanical Properties of Hydrate-bearing Marine Sediments of South China Sea. Mar. Pet. Geol. 2016, 77, 507–514. [Google Scholar] [CrossRef]

- Wu, N.; Li, Y.; Wan, Y.; Sun, J.; Huang, L.; Mao, P. Prospect of marine natural gas hydrate stimulation theory and technology system. Nat. Gas Ind. 2020, 40, 100–115. [Google Scholar] [CrossRef]

- Lei, L.; Santamarina, J.C. Laboratory Strategies for Hydrate Formation in Fine-grained Sediments. J. Geophys. Res. Solid Earth 2018, 123, 2583–2596. [Google Scholar] [CrossRef]

- Lv, J.; Zhao, J.; Jiang, L.; Liu, Y.; Mu, H. A Review of Micro Computed Tomography Studies on the Gas Hydrate Pore Habits and Seepage Properties in Hydrate Bearing Sediments. J. Nat. Gas Sci. Eng. 2020, 83, 103555. [Google Scholar] [CrossRef]

- Lei, L.; Santamarina, J.C. Physical properties of fine-grained sediments with segregated hydrate lenses. Mar. Pet. Geol. 2019, 109, 899–911. [Google Scholar] [CrossRef]

- Liang, J.; Zhang, W.; Lu, J.A.; Wei, J.; Kuang, Z.; He, Y. Geological Occurrence and Accumulation Mechanism of Natural Gas Hydrates in the Eastern Qiongdongnan Basin of the South China Sea Insights From Site Gmgs5-w9-2018. Mar. Geol. 2019, 418, 106042. [Google Scholar] [CrossRef]

- Ye, J.; Wei, J.; Liang, J.; Lu, J.; Lu, H.; Zhang, W. Complex Gas Hydrate System in a Gas Chimney, South China Sea. Mar. Pet. Geol. 2019, 104, 29–39. [Google Scholar] [CrossRef]

- Ning, F.L.; Liang, J.Q.; Wu, N.Y.; Zhu, Y.H.; Wu, S.G.; Liu, C.L.; Ou, W.J. Reservoir characteristics of natural gas hydrates in China. Nat. Gas Ind. 2020, 40, 1–24, (In Chinese with English Abstract). [Google Scholar]

- Ghosh, R.; Sain, K.; Ojha, M. Effective medium modeling of gas hydrate-filled fractures using the sonic log in the Krishna-Godavari basin, offshore eastern India. Geophys. Res. Solid Earth 2010, 115, B06101. [Google Scholar] [CrossRef]

- Yun, T.S.; Lee, C.; Lee, J.S.; Bahk, J.J.; Santamarina, J.C. A pressure core based characterization of hydrate-bearing sediments in the Ulleung Basin, Sea of Japan (East Sea). Geophys. Res. Solid Earth 2011, 116, B02204. [Google Scholar] [CrossRef]

- Li, Y.L.; Liu, C.L.; Liao, H.L.; Dong, L.; Bu, Q.; Liu, Z. Mechanical properties of the mixed system of clayey-silt sediments and natural gas hydrates. Nat. Gas Ind. 2020, 40, 159–168, (In Chinese with English Abstract). [Google Scholar]

- Farahani, M.V.; Hassanpouryouzband, A.; Yang, J.; Tohidi, B. Development of a Coupled Geophysical-geothermal Scheme for Quantification of Hydrates in Gas Hydrate-bearing Permafrost Sediments. Phys. Chem. Chem. Phys. 2021, 23, 24249–24264. [Google Scholar] [CrossRef] [PubMed]

- Hassanpouryouzband, A.; Joonaki, E.; Farahani, M.V.; Takeya, S.; Ruppel, C.; Yang, J.; Tohidi, B. Gas Hydrates in Sustainable Chemistry. Chem. Soc. Rev. 2020, 49, 5225–5309. [Google Scholar]

- Yu, F.; Song, Y.; Li, Y.; Liu, W.; Lam, W. Analysis of Stress-strain Behavior and Constitutive Relation of Methane Hydrate-bearing Sediments with Various Porosity. Int. J. Offshore Polar Eng. 2011, 21, 316–322. [Google Scholar]

- Yu, F.; Song, Y.; Liu, W.; Li, Y.; Lam, W. Analyses of Stress Strain Behavior and Constitutive Model of Artificial Methane Hydrate-Sciencedirect. J. Pet. Sci. Eng. 2011, 77, 183–188. [Google Scholar] [CrossRef]

- Miyazaki, K.; Tenma, N.; Aoki, K.; Yamaguchi, T. A Nonlinear Elastic Model for Triaxial Compressive Properties of Artificial Methane-hydrate-bearing Sediment Samples. Energies 2012, 5, 4057–4075. [Google Scholar] [CrossRef] [Green Version]

- Freij-Ayoub, R.; Tan, C.; Clennell, B.; Tohidi, B.; Yang, J. A Wellbore Stability Model for Hydrate Bearing Sediments. J. Pet. Sci. Eng. 2007, 57, 209–220. [Google Scholar] [CrossRef]

- Klar, A.; Soga, K.; Ng, M. Coupled Deformation-flow Analysis for Methane Hydrate Extraction. Géotechnique 2010, 60, 765–776. [Google Scholar] [CrossRef]

- Pinkert, S.; Grozic, J. An Analytical-experimental Investigation of Gas Hydrate-bearing Sediment Properties. In Proceedings of the Canadian Geotechnical Conference and the 11th Joint Cgs/iahcnc Ground Water Conference, Montreal, CA, USA, 29 September–3 October 2013. [Google Scholar]

- Pinkert, S.; Grozic, J. Prediction of the Mechanical Response of Hydrate-bearing Sands. J. Geophys. Res. Solid Earth 2014, 119, 4695–4707. [Google Scholar] [CrossRef]

- Uchida, S.; Soga, K.; Yamamoto, K. Critical State Soil Constitutive Model for Methane Hydrate Soil. J. Geophys. Res. -Solid Earth 2012, 117. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Sun, B.; Sun, X.; Liao, Y. A constitutive model of hydrate bearing sediments in water-rich phase environments. Chin. J. Undergr. Space Eng. 2019, 15 (Suppl. 2), 563–568. [Google Scholar]

- Zhang, X.; Liu, L.-L.; Zhou, J.; Lu, X.; Wang, S.; Liu, C.; Ye, Y. Model for the Elastic Modulus of Hydrate-bearing Sediments. Int. J. Offshore Polar Eng. 2015, 25, 314–319. [Google Scholar] [CrossRef] [Green Version]

- Liang, W.; Zhou, J.; Chen, P.; Wei, C. An elastoplastic constitutive model of gas hydrate bearing sediments based on homogenization theory. Rock Soil Mech. 2021, 42, 481–490, (In Chinese with English Abstract). [Google Scholar]

- Wang, S.; Luo, D.; Zhang, X.; Lu, X.; Shi, Y. Experimental study of mechanical properties of hydrate clay. J. Exp. Mech. 2018, 33, 245–252. Available online: https://mall.cnki.net/magazine/Article/SYLX201802010.htm (accessed on 29 July 2022). (In Chinese with English Abstract).

- Bathe, M.; Vagle, S.; Saunders, G.A.; Lambson, E.F. Ultrasonic Wave Velocities in the Structure Ii Clathrate Hydrate Thf·17h2o. J. Mater. Sci. Lett. 1984, 3, 904–906. [Google Scholar] [CrossRef]

| Confining pressure (MPa) | 1 | 2 | 3 |

| Secant modulus (MPa) | 16 | 32 | 45 |

| Confining pressure (MPa) | 1 | 2 | 3 |

| Secant modulus (MPa) | 26 | 42 | 80 |

| Confining pressure (MPa) | 1 | 2 | 3 |

| Secant modulus (MPa) | 39 | 76 | 136 |

| 16 | 9000 | 89 | 11 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, C.; Xie, P.; Li, H.; Zhang, X.; Lu, X.; Zhang, B.; Zhang, Z.; Qin, X.; Zhang, S.; Bian, H. Study on the Mechanical Properties of Silty Clay Sediments with Nodular Hydrate Occurrence. J. Mar. Sci. Eng. 2022, 10, 1059. https://doi.org/10.3390/jmse10081059

Lu C, Xie P, Li H, Zhang X, Lu X, Zhang B, Zhang Z, Qin X, Zhang S, Bian H. Study on the Mechanical Properties of Silty Clay Sediments with Nodular Hydrate Occurrence. Journal of Marine Science and Engineering. 2022; 10(8):1059. https://doi.org/10.3390/jmse10081059

Chicago/Turabian StyleLu, Cheng, Pengfei Xie, Hui Li, Xuhui Zhang, Xiaobing Lu, Bin Zhang, Ziqin Zhang, Xuwen Qin, Shuai Zhang, and Hang Bian. 2022. "Study on the Mechanical Properties of Silty Clay Sediments with Nodular Hydrate Occurrence" Journal of Marine Science and Engineering 10, no. 8: 1059. https://doi.org/10.3390/jmse10081059