Effective Chlorella vulgaris Biomass Harvesting through Sulfate and Chloride Flocculants

Abstract

1. Introduction

| Flocculant Name | Microalgae Species | Marine/ Freshwater | Flocculation Conditions | Flocculation Efficiency | References |

|---|---|---|---|---|---|

| Al2(SO4)3 | N. salina (CCAP849/3) | marine | flocculant dosage: 114.4 mg/L | 95% | [19] |

| Al2(SO4)3 | N. salina (CCAP849/3) | marine | flocculant dosage: 114.4 mg/L; feed flow rate: 56.5 mL/min | 40–50% | [19] |

| Al2(SO4)3 | N. salina (CCAP849/3) | marine | flocculant dosage: 229 mg/L; feed flow rate: 56.5 mL/min | 75% | [19] |

| Al2(SO4)3 | N. salina (CCAP849/3) | marine | flocculant dosage: 229 mg/L; feed flow rate: 20.4 mL/min | (86.1 ± 0.1)% | [19] |

| FeCl3; Al2(SO4)3 | C. minor | freshwater | initial biomass concentration: 1.0 g/L; FeCl3 250 mg/L or Al2(SO4)3 275 mg/L | >95% | [20] |

| cationic polyacrylamide polymer | Chlorella vulgaris (CS-41) | freshwater | >97% | [21] | |

| poly (c-glutamic acid) | C. vulgaris; C. protothecoides | marine; freshwater | c-PGA dosage: 22.03 mg/L; biomass concentration: 0.57 g/L; salinity: 11.56 g/L | 91%; 98% | [22] |

2. Materials and Methods

2.1. Microalgae Strain and Culture Conditions

2.2. Flocculation Experiment

2.3. Evaluation of Flocculation Efficiency

2.4. Reculture of Microalgal Cells in Flocs and Recycling of Spent Medium

2.5. Microscopic Images

2.6. Analysis Methods and Statistical Analysis

3. Results and Discussion

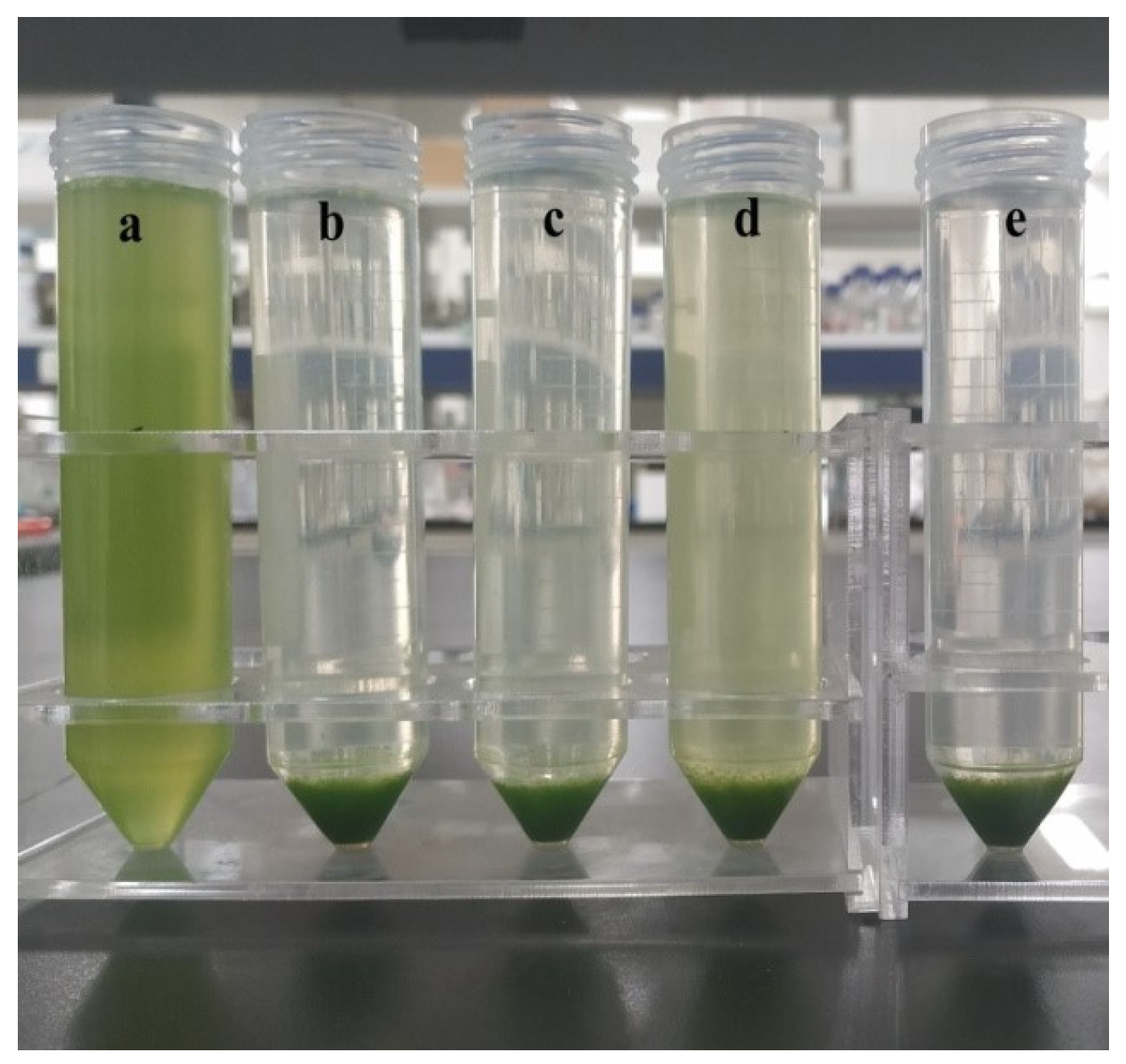

3.1. Flocculants Dose

3.2. Flocculation Time

3.3. Stirring Speed

3.4. Stirring Time

3.5. Flocculation pH

3.6. Flocs Morphology

3.7. Biomass Composition

3.8. Regrowth of Settled Flocs

3.9. Reuse of Spent Medium

4. Practical Applications and Prospects

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Safi, C.; Zebib, B.; Merah, O.; Pontalier, P.-Y.; Vaca-Garcia, C. Morphology, composition, production, processing and applications of Chlorella vulgaris: A review. Renew. Sustain. Energy Rev. 2014, 35, 265–278. [Google Scholar] [CrossRef]

- Muhammad, G.; Alam, M.A.; Mofijur, M.; Jahirul, M.I.; Lv, Y.; Xiong, W.; Ong, H.C.; Xu, J. Modern developmental aspects in the field of economical harvesting and biodiesel production from microalgae biomass. Renew. Sustain. Energy Rev. 2020, 135, 110209. [Google Scholar] [CrossRef]

- Abu Tayeh, H.N.; Álvarez-Cao, M.E.; Azaizeh, H.; Balagurunathan, R.; Balakrishnan, R.; Becerra, M.; Bela, R.B.; Diwan, B.; Doble, M.; Ganesan, S.; et al. Contributors. In Biovalorisation of Wastes to Renewable Chemicals and Biofuels; Krishnaraj Rathinam, N., Sani, R.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. ix–xi. [Google Scholar]

- Singh, G.; Patidar, S.K. Microalgae harvesting techniques: A review. J. Environ. Manag. 2018, 217, 499–508. [Google Scholar] [CrossRef] [PubMed]

- Barros, A.I.; Gonçalves, A.L.; Simões, M.; Pires, J.C.M. Harvesting techniques applied to microalgae: A review. Renew. Sustain. Energy Rev. 2015, 41, 1489–1500. [Google Scholar] [CrossRef]

- Butler, T.O.; Acurio, K.; Mukherjee, J.; Dangasuk, M.M.; Corona, O.; Vaidyanathan, S. The transition away from chemical flocculants: Commercially viable harvesting of Phaeodactylum tricornutum. Sep. Purif. Technol. 2021, 255, 117733. [Google Scholar] [CrossRef]

- Vu, H.P.; Nguyen, L.N.; Lesage, G.; Nghiem, L.D. Synergistic effect of dual flocculation between inorganic salts and chitosan on harvesting microalgae Chlorella vulgaris. Environ. Technol. Innovat. 2020, 17, 100622. [Google Scholar] [CrossRef]

- Wu, J.; Liu, J.; Lin, L.; Zhang, C.; Li, A.; Zhu, Y.; Zhang, Y. Evaluation of several flocculants for flocculating microalgae. Bioresour. Technol. 2015, 197, 495–501. [Google Scholar] [CrossRef]

- Ummalyma, S.B.; Mathew, A.K.; Pandey, A.; Sukumaran, R.K. Harvesting of microalgal biomass: Efficient method for flocculation through pH modulation. Bioresour. Technol. 2016, 213, 216–221. [Google Scholar] [CrossRef]

- Scherer, M.D.; Magalhaes Filho, F.J.C.; Oliveira, A.C.; Selesu, N.F.H.; Ugaya, C.M.L.; Mariano, A.B.; Vargas, J.V.C. Environmental evaluation of flocculation efficiency in the separation of the microalgal biomass of Scenedesmus sp. cultivated in full-scale photobioreactors. J. Environ. Sci. Health Part A 2018, 53, 938–945. [Google Scholar] [CrossRef]

- Reyes, J.F.; Labra, C. Biomass harvesting and concentration of microalgae scenedesmus sp cultivated in a pilot phobioreactor. Biomass. Bioenerg. 2016, 87, 78–83. [Google Scholar] [CrossRef]

- del Carmen Cuéllar Martínez, T.; Rodríguez, R.A.; Voltolina, D.; Morquecho, L. Effectiveness of coagulants-flocculants for removing cells and toxins of Gymnodinium catenatum. Aquaculture 2016, 452, 188–193. [Google Scholar] [CrossRef]

- Wu, S.C.; Xie, X.J.; Huan, L.; Zheng, Z.B.; Zhao, P.P.; Kuang, J.X.; Liu, X.P.; Wang, G.C. Selection of optimal flocculant for effective harvesting of the fucoxanthin-rich marine microalga Isochrysis galbana. J. Appl. Phycol. 2016, 28, 1579–1588. [Google Scholar] [CrossRef]

- de Carvalho, J.C.; Sydney, E.B.; Assú Tessari, L.F.; Soccol, C.R. Chapter 2—Culture media for mass production of microalgae. In Biofuels from Algae, 2nd ed.; Pandey, A., Chang, J.S., Soccol, C.R., Lee, D.J., Chisti, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 33–50. [Google Scholar]

- Fret, J.; Roef, L.; Blust, R.; Diels, L.; Tavernier, S.; Vyverman, W.; Michiels, M. Reuse of rejuvenated media during laboratory and pilot scale cultivation of Nannochloropsis sp. Algal. Res. 2017, 27, 265–273. [Google Scholar] [CrossRef]

- Granados, M.R.; Acién, F.G.; Gómez, C.; Fernández-Sevilla, J.M.; Molina Grima, E. Evaluation of flocculants for the recovery of freshwater microalgae. Bioresour. Technol. 2012, 118, 102–110. [Google Scholar] [CrossRef]

- Pandey, A.; Shah, R.; Yadav, P.; Verma, R.; Srivastava, S. Harvesting of freshwater microalgae Scenedesmus sp. by electro–coagulation–flocculation for biofuel production: Effects on spent medium recycling and lipid extraction. Environ. Sci. Pollut. Res. 2020, 27, 3497–3507. [Google Scholar] [CrossRef]

- Farooq, W.; Moon, M.; Ryu, B.-G.; Suh, W.I.; Shrivastav, A.; Park, M.S.; Mishra, S.K.; Yang, J.W. Effect of harvesting methods on the reusability of water for cultivation of Chlorella vulgaris, its lipid productivity and biodiesel quality. Algal. Res. 2015, 8, 1–7. [Google Scholar] [CrossRef]

- Chatsungnoen, T.; Chisti, Y. Continuous flocculation-sedimentation for harvesting Nannochloropsis salina biomass. J. Biotechnol. 2016, 222, 94–103. [Google Scholar] [CrossRef]

- Chatsungnoen, T.; Chisti, Y. Harvesting microalgae by flocculation–sedimentation. Algal. Res. 2016, 13, 271–283. [Google Scholar] [CrossRef]

- Vu, H.P.; Nguyen, L.N.; Emmerton, B.; Wang, Q.; Ralph, P.J.; Nghiem, L.D. Factors governing microalgae harvesting efficiency by flocculation using cationic polymers. Bioresour. Technol. 2021, 340, 125669. [Google Scholar] [CrossRef]

- Zheng, H.; Gao, Z.; Yin, J.; Tang, X.; Ji, X.; Huang, H. Harvesting of microalgae by flocculation with poly (γ-glutamic acid). Bioresour. Technol. 2012, 112, 212–220. [Google Scholar] [CrossRef]

- Taghavijeloudar, M.; Kebria, D.Y.; Yaqoubnejad, P. Simultaneous harvesting and extracellular polymeric substances extrusion of microalgae using surfactant: Promoting surfactant-assisted flocculation through pH adjustment. Bioresour. Technol. 2021, 319, 124224. [Google Scholar] [CrossRef] [PubMed]

- Haldar, D.; Sen, D.; Gayen, K. Development of spectrophotometric method for the analysis of multi-component carbohydrate mixture of different moieties. Appl. Biochem. Biotech. 2017, 181, 1416–1434. [Google Scholar] [CrossRef] [PubMed]

- Sedmak, J.J.; Grossberg, S.E. A rapid, sensitive, and versatile assay for protein using Coomassie brilliant blue G250. Anal. Biochem. 1977, 79, 544–552. [Google Scholar] [CrossRef] [PubMed]

- Bligh, E.G.; Dyer, W.J. A rapid method of total lipid extraction and purification. Can. J. Biochem. Physiol. 1959, 37, 911–917. [Google Scholar] [CrossRef]

- Wellburn, A.R. The spectral determination of Chlorophylls a and b, as well as total carotenoids, using various solvents with spectrophotometers of different resolution. J. Plant. Physiol. 1994, 144, 307–313. [Google Scholar] [CrossRef]

- Mu, R.M.; Zhao, Y.L.; Bu, Q.W.; Wang, M.X.; Liu, D. The effects of three different flocculants on the harvest of microalgae Chlorella vulgaris. IOP Conf. Ser. Earth Environ. Sci. 2018, 191, 012042. [Google Scholar] [CrossRef]

- Zeng, D.F.; Hu, D.; Cheng, J. Experimental study on chitosan composite flocculant for treating papermaking wastewater. J. Water Chem. Technol. 2012, 34, 35–41. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, A.; Pan, S.-Y.; Sun, W.; Zhu, C.; Shah, K.J.; Zheng, H. Novel chitosan-based flocculants for chromium and nickle removal in wastewater via integrated chelation and flocculation. J. Environ. Manag. 2019, 248, 109241. [Google Scholar] [CrossRef]

- Wang, W.; Sha, J.; Lu, Z.; Shao, S.; Sun, P.; Hu, Q.; Zhang, X. Implementation of UV-based advanced oxidation processes in algal medium recycling. Sci. Total Environ. 2018, 634, 243–250. [Google Scholar] [CrossRef]

- Singh, G.; Patidar, S.K. Water quality restoration by harvesting mixed culture microalgae using Moringa oleifera. Water Environ. Res. 2020, 92, 1268–1282. [Google Scholar] [CrossRef]

- Bozbaş, S.K.; Boz, Y. Low-cost biosorbent: Anadara inaequivalvis shells for removal of Pb(II) and Cu(II) from aqueous solution. Process. Saf. Environ. Prot. 2016, 103, 144–152. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, Y.; Tao, Y.; Zhang, Y.; Li, A.; Li, T.; Sang, M.; Zhang, C. Freshwater microalgae harvested via flocculation induced by pH decrease. Biotechnol. Biofuels 2013, 6, 98. [Google Scholar] [CrossRef] [PubMed]

- Das, P.; Thaher, M.I.; Hakim, M.A.Q.M.A.; Al-Jabri, H.M.S.J.; Alghasal, G.S.H.S. Microalgae harvesting by pH adjusted coagulation-flocculation, recycling of the coagulant and the growth media. Bioresour. Technol. 2016, 216, 824–829. [Google Scholar] [CrossRef]

- Yang, F.; Xiang, W.; Fan, J.; Wu, H.; Li, T.; Long, L. High pH-induced flocculation of marine Chlorella sp. for biofuel production. J. Appl. Phycol. 2016, 28, 747–756. [Google Scholar] [CrossRef]

- Vandamme, D.; Pohl, P.I.; Beuckels, A.; Foubert, I.; Brady, P.V.; Hewson, J.C.; Muylaert, K. Alkaline flocculation of Phaeodactylum tricornutum induced by brucite and calcite. Bioresour. Technol. 2015, 196, 656–661. [Google Scholar] [CrossRef] [PubMed]

- Seo, Y.H.; Sung, M.; Kim, B.; Oh, Y.-K.; Kim, D.Y.; Han, J.-I. Ferric chloride based downstream process for microalgae based biodiesel production. Bioresour. Technol. 2015, 181, 143–147. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.H.; Hong, I.T.; Oh, J.M. Size- and surface charge-controlled layered double hydroxides for efficient algal flocculation. Environ. Sci.-Nano. 2018, 5, 183–190. [Google Scholar] [CrossRef]

- Choy, S.Y.; Prasad, K.M.N.; Wu, T.Y.; Raghunandan, M.E.; Phang, S.-M.; Juan, J.C.; Ramanan, R.N. Separation of Chlorella biomass from culture medium by flocculation with rice starch. Algal. Res. 2018, 30, 162–172. [Google Scholar] [CrossRef]

- Augustine, A.; Kumaran, J.; Puthumana, J.; Sabu, S.; Bright Singh, I.S.; Joseph, V. Multifactorial interactions and optimization in biomass harvesting of marine picoalga Picochlorum maculatum MACC3 with different flocculants. Aquaculture 2017, 474, 18–25. [Google Scholar] [CrossRef]

- Wu, M.; Li, J.; Qin, H.; Lei, A.; Zhu, H.; Hu, Z.; Wang, J. Pre-concentration of microalga Euglena gracilis by alkalescent pH treatment and flocculation mechanism of Ca3(PO4)2, Mg3(PO4)2, and derivatives. Biotech. Biofuels 2020, 13, 98. [Google Scholar] [CrossRef]

- Guldhe, A.; Misra, R.; Singh, P.; Rawat, I.; Bux, F. An innovative electrochemical process to alleviate the challenges for harvesting of small size microalgae by using non-sacrificial carbon electrodes. Algal. Res. 2016, 19, 292–298. [Google Scholar] [CrossRef]

- Morocho-Jácome, A.L.; Mascioli, G.F.; Sato, S.; de Carvalho, J.C.M. Evaluation of physicochemical treatment conditions for the reuse of a spent growth medium in Arthrospira platensis cultivation. Algal. Res. 2016, 13, 159–166. [Google Scholar] [CrossRef]

- Zhu, L.; Hu, T.; Li, S.; Nugroho, Y.K.; Li, B.; Cao, J.; Show, P.L.; Hiltunen, E. Effects of operating parameters on algae Chlorella vulgaris biomass harvesting and lipid extraction using metal sulfates as flocculants. Biomass. Bioenerg. 2020, 132, 105433. [Google Scholar] [CrossRef]

- Kim, D.G.; La, H.J.; Ahn, C.Y.; Park, Y.H.; Oh, H.M. Harvest of Scenedesmus sp. with bioflocculant and reuse of culture medium for subsequent high-density cultures. Bioresour. Technol. 2011, 102, 3163–3168. [Google Scholar] [CrossRef]

- Roy, M.; Mohanty, K. Valorization of waste eggshell-derived bioflocculant for harvesting T. obliquus: Process optimization, kinetic studies and recyclability of the spent medium for circular bioeconomy. Bioresour. Technol. 2020, 307, 123205. [Google Scholar] [CrossRef]

- Hesse, M.C.S.; Santos, B.; Selesu, N.F.H.; Corrêa, D.O.; Mariano, A.B.; Vargas, J.V.C.; Vieira, R.B. Optimization of flocculation with tannin-based flocculant in the water reuse and lipidic production for the cultivation of Acutodesmus obliquus. Sep. Sci. Technol. 2017, 52, 936–942. [Google Scholar] [CrossRef]

- Zhu, L.; Li, Z.; Hiltunen, E. Microalgae Chlorella vulgaris biomass harvesting by natural flocculant: Effects on biomass sedimentation, spent medium recycling and lipid extraction. Biotechnol. Biofuels 2018, 11, 183. [Google Scholar] [CrossRef]

- Pirwitz, K.; Rihko-Struckmann, L.; Sundmacher, K. Comparison of flocculation methods for harvesting Dunaliella. Bioresour. Technol. 2015, 196, 145–152. [Google Scholar] [CrossRef]

- Vasistha, S.; Khanra, A.; Clifford, M.; Rai, M.P. Current advances in microalgae harvesting and lipid extraction processes for improved biodiesel production: A review. Renew. Sustain. Energy Rev. 2021, 137, 110498. [Google Scholar] [CrossRef]

| Total Carbohydrate | Total Protein | Total Lipid | Carotenoid | |

|---|---|---|---|---|

| Control | 21.60 ± 0.36 a | 40.83 ± 0.70 a | 15.50 ± 0.30 a | 4.13 ± 0.15 a |

| Al2(SO4)3 | 20.70 ± 0.40 ab | 40.37 ± 0.21 a | 14.93 ± 0.25 b | 3.93 ± 0.06 a |

| AlCl3 | 20.77 ± 0.57 ab | 40.23 ± 0.60 a | 14.87 ± 0.21 b | 3.97 ± 0.21 a |

| Fe2(SO4)3 | 20.37 ± 0.31 b | 40.63 ± 0.42 a | 15.00 ± 0.36 ab | 3.87 ± 0.21 a |

| FeCl3 | 21.03 ± 0.90 ab | 40.37 ± 0.67 a | 15.10 ± 0.20 ab | 4.00 ± 0.10 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, W.; Feng, C.; Guan, F.; Ma, D.; Cai, J. Effective Chlorella vulgaris Biomass Harvesting through Sulfate and Chloride Flocculants. J. Mar. Sci. Eng. 2023, 11, 47. https://doi.org/10.3390/jmse11010047

Ma W, Feng C, Guan F, Ma D, Cai J. Effective Chlorella vulgaris Biomass Harvesting through Sulfate and Chloride Flocculants. Journal of Marine Science and Engineering. 2023; 11(1):47. https://doi.org/10.3390/jmse11010047

Chicago/Turabian StyleMa, Wei, Chenchen Feng, Fachun Guan, Dianrong Ma, and Jinling Cai. 2023. "Effective Chlorella vulgaris Biomass Harvesting through Sulfate and Chloride Flocculants" Journal of Marine Science and Engineering 11, no. 1: 47. https://doi.org/10.3390/jmse11010047

APA StyleMa, W., Feng, C., Guan, F., Ma, D., & Cai, J. (2023). Effective Chlorella vulgaris Biomass Harvesting through Sulfate and Chloride Flocculants. Journal of Marine Science and Engineering, 11(1), 47. https://doi.org/10.3390/jmse11010047