Abstract

This paper describes the effort of designing an unconventional exhaust manifold for a marine gas turbine engine, with an integrated passive ventilation port for cooling the engine housing. The study is part of a larger program to substitute the propulsion gas turbines for the T22R defense frigate and make the proper aerodynamic adaptations. The system in question is unique, in the sense that it uses the exhaust gas momentum to entrain outside air and ventilate the engine enclosure. In achieving this, RANS computation was used to test various concepts and dimensions for the ventilation system. Based on these analyses, the design that provided adequate air circulation with minimum pressure losses was chosen and the parts were integrated in the overall assembly. The experimental campaign performed on the entire aero-package showed good synergies of the ventilation system with the other adaptations and the engine itself. Performance was evaluated with pressure and temperature probes distributed around the aero-package and were found to be within 3.5% of the data predicted by CFD. This brings further studies closer to a technology readiness level vital for insitu testing on board the ship itself.

1. Introduction

Upgrading propulsion systems is part of the natural evolution of any heavy piece of equipment that has a high service life. Maritime ships are no exception, particularly due to their high fuel consumption rate. New environmental and energy-economic challenges urge the marine propulsion market to adapt and grow in more sustainable ways [1,2]. Of course, there are many advantages of having more modern engines such as operation costs and overall performance; however, this sometimes comes at the cost of having to re-think the way the propulsion system integrates with the existing ship.

In marine propulsion, one common choice is gas turbine engines due to their higher performance, reduced maintenance, and optimized consumption [3,4,5] when compared to their diesel counterparts. In addition, gas turbine engines are smaller, more power dense, and have lower noise and vibration levels. Additionally, their power to weight ratio allows for better maneuverability of the ship [6], being an important advantage, especially for military vessels.

Aero-derivative engines [7,8,9] have always been a good choice for marine applications and have been preferred in military ships since 1947 [10]. Along with the robust safety and rigorous maintenance systems associated with engines derived from the aviation industry [11], there is also the problem of the high initial cost, the requirement of more processed fuel, and the installation sensitivity when compared against the diesel counterpart. In terms of nitrogen oxides (NOx) [12] and carbon dioxide emissions [13], gas turbine engines are among the least polluting because of their finely tuned burning chambers and their continuous operating cycle, which maintains the temperature at a very constant level, under the threshold of NOx formation. On the other hand, catalytic converters are impossible to install due to the very high mass flow of air and the high exhaust temperature. Instead, emissions reduction, without significant investment costs, can be obtained by using fuels characterized by low carbon content and by using bio-fuels (also borrowed from the aviation industry).

The emissions are not only of ecological importance, as ship contamination from the exhaust gas is a problem that has been scrutinized in recent years both numerically and experimentally. Park et al. [14] considered the deckhouse width and exhaust pipe gas as important design variables on the contamination process from the exhaust gas. While the deckhouse width had no significant influence on the exhaust gas, the exhaust pipe height was an important variable. With the increase in the pipe height, the sulfur dioxide (SO2) concentration decreased. Good emissions can be achieved for ayp/H (height of the exhaust pipe/height of the deckhouse) higher than 2. According to Bral et al. [15], the performances of an exhaust system, from the emission point of view, can be evaluated through back-pressure and exhaust velocity. The main aim of the work in [15] was to develop a computational model for exhaust systems and further study the pressure and velocity inside the vessel for different working conditions.

The revamping program sought to replace the existing Rolls-Royce Tyne RM1C with the newer P&W Canada ST40M. This will be carried out with minimal intervention on the existing ship, in order to preserve its other functions and its overall safety during operation. With such changes, however, certain parameters such as turbine outlet back-pressure may exceed the designer’s specifications, particularly if a more powerful engine is installed in the same space. Increased back-pressure inherently leads to greater fuel consumption and engine thermal loading. This is because the engines have to assure additional mechanical work in order to compensate for the under-expansion of the exhaust gases [16]. According to [17], a lower value of back-pressure assures a more efficient operation of the engine. Sapra et al. [18] studied, using computational fluid dynamics (CFD) and experiments, the effect of back pressure on the marine diesel engine performance. Their research determined that the fuel consumption increase was small, in relation to the exhaust receiver, exhaust valve temperature, and air–excess ratio, which were the most affected parameters by the high back-pressure. The effect of the exhaust back-pressure is also described in [19], where the performances of the engine were determined using neural network modeling, exploring in this way the relation between the inputs and outputs of the engine system. However, for aero-derivative engines that depend on the expansion ratio across the turbine, these effects may be much more detrimental.

The replacement engine choice took into account the requirements such as class similarity, power, operation, efficiency, overall weight, and dimensions [20]. An engine with modular construction was chosen, which could conceivably be retrofitted with future upgrades that may be able to function with light fuels or alternate fuels (ethanol, methane etc.) and gaseous fuels (natural gas and propane-butane) [21].

The revamping process of an ST40M engine for a T22 frigate was presented by Niculescu et al. [22], where a new mechanical adaptation was developed. It shows the installation solution for the new engine, which has the gearbox located at the cold end of the engine, as opposed to the old engine, which had it at the turbine side.

This paper will focus on the development process of the exhaust structure and subsidiary systems, designed after replacing the Rolls-Royce Tyne engine with a Pratt–Whitney ST40M. Substituting an out-of-date propulsion system or updating it requires, most of the time, a new adaptation of the available space to suit the demands of the air intake, exhaust, and ventilation systems, corresponding to the engine performance.

The new engines have a different mechanical coupling system, which means that they will be installed backward when compared to the original ship engines. This makes the inlet and outlet manifolds much more complicated (length, number of bends, size packaging, safety margins as well as maintaining the capacity for an integrated ventilation system).

Hence, this paper aims to investigate the challenges brought by the maximization of the static pressure differences without compromising the main exhaust flow and also the process of using the natural draught from the exhaust flue to achieve ventilation in the engine enclosure.

2. Numerical Analysis

2.1. Geometry Definition

The performances and characteristics of aero-derivative engine ST40 were analyzed and compared with the Tyne RM1C engine, in order to ensure a proper fitting and to establish whether additional benefits such as increased propulsion efficiency and reduced weight are brought by this change [22]. Following the dismounting of the Tyne engine and the ducting connected to it, the engine compartment was studied to determine the maximum dimensions in which the new ducting could fit.

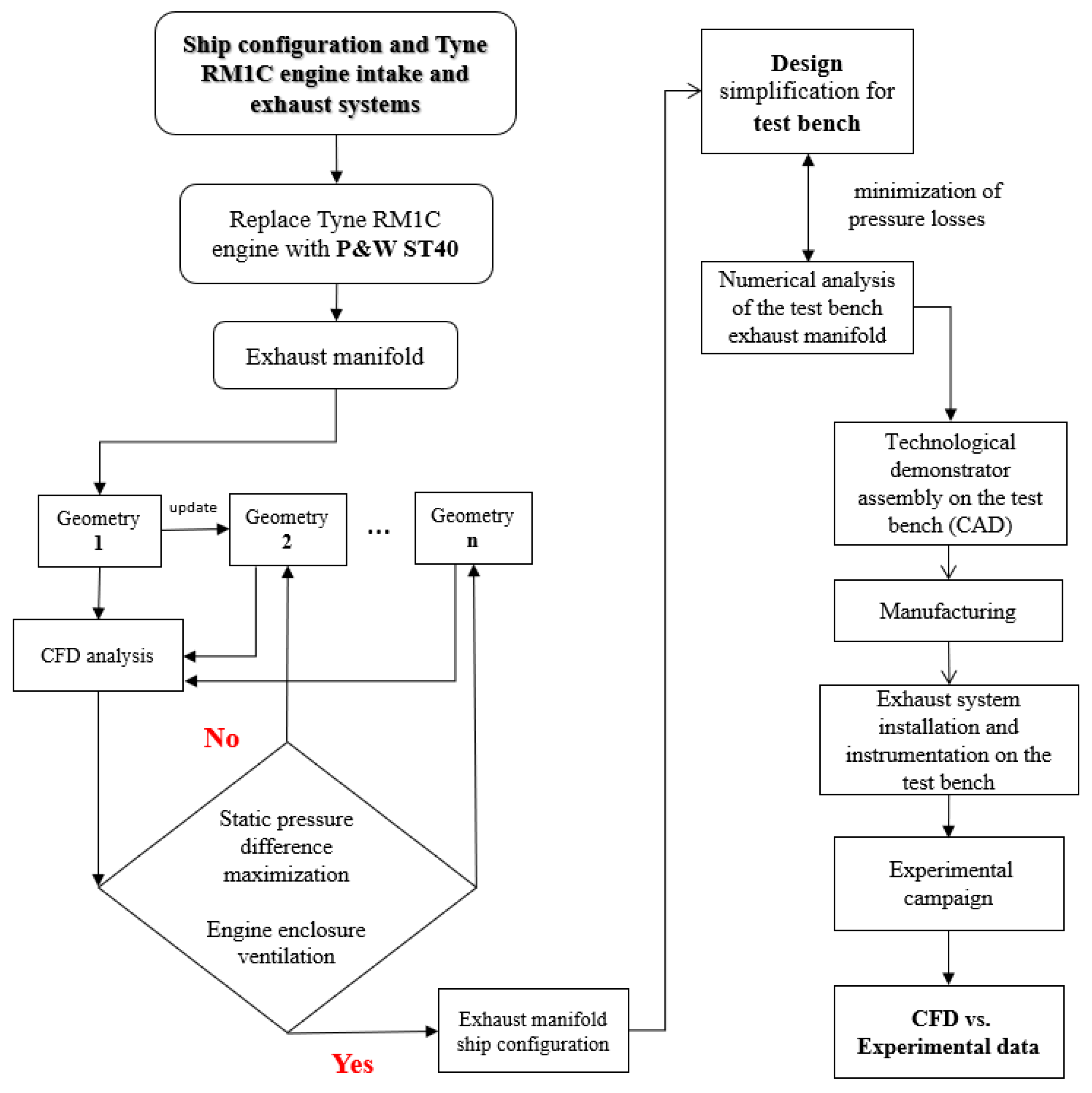

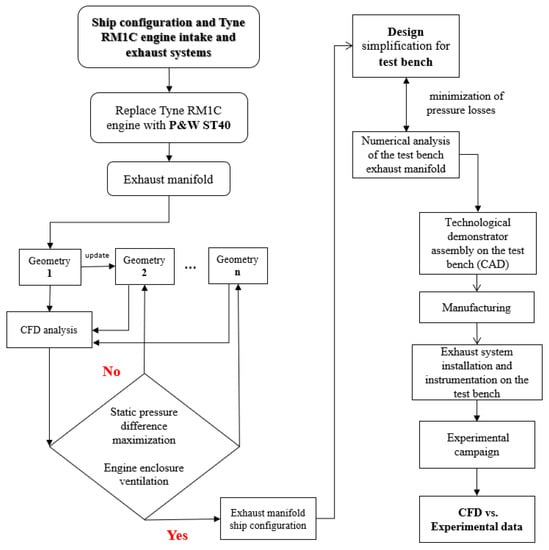

The revamping program requires many changes in the ship configuration; however, the main phases necessary for the exhaust manifold are outlined in Figure 1. The initial design starts with changes in the exhaust configuration available on the ship, so it matches the new engine orientation, but also has to integrate into the space available on the ship.

Figure 1.

Exhaust system development—design stages.

Establishing an optimal structure for the engine exhaust and properly adapting it to the ventilation system involved testing several configurations. All configurations had to meet the construction requirements imposed such as limited space on board the frigate and aerodynamic requirements as well as the safety distances from the crew walking corridors. Other key factors that were accounted for included the inlet manifold pressure distortion, total pressure losses at inlet/outlet, capacity to entrain more than 1 kg/s ventilation flow as well as all the packaging requirements (e.g., safety margins, insulation space, integration with the ship architecture). Due to the narrow space available, the entire exhaust system was divided into multiple modules, in order to guarantee a faster installation of the system as well as a fast replacement, if needed. The aerodynamic design was aided by CFD using a variety of k-epsilon models that compensate for the rotation and curvature of the streamlines. Although not as acclaimed as the shear stress transport (SST), this model combines some of the flow separation prediction capabilities while not requiring a boundary-layer type mesh, which would have been prohibitive at the early design stage.

One of the specifications of the ventilation system was that the temperature within the enclosure that houses the ST40M engine must not exceed 60°C (due to risk of ignition of possible combustible materials in the enclosure). Once an exhaust system for the ship configuration was obtained, its design was simplified for the test bench and validated through CFD and experimental data.

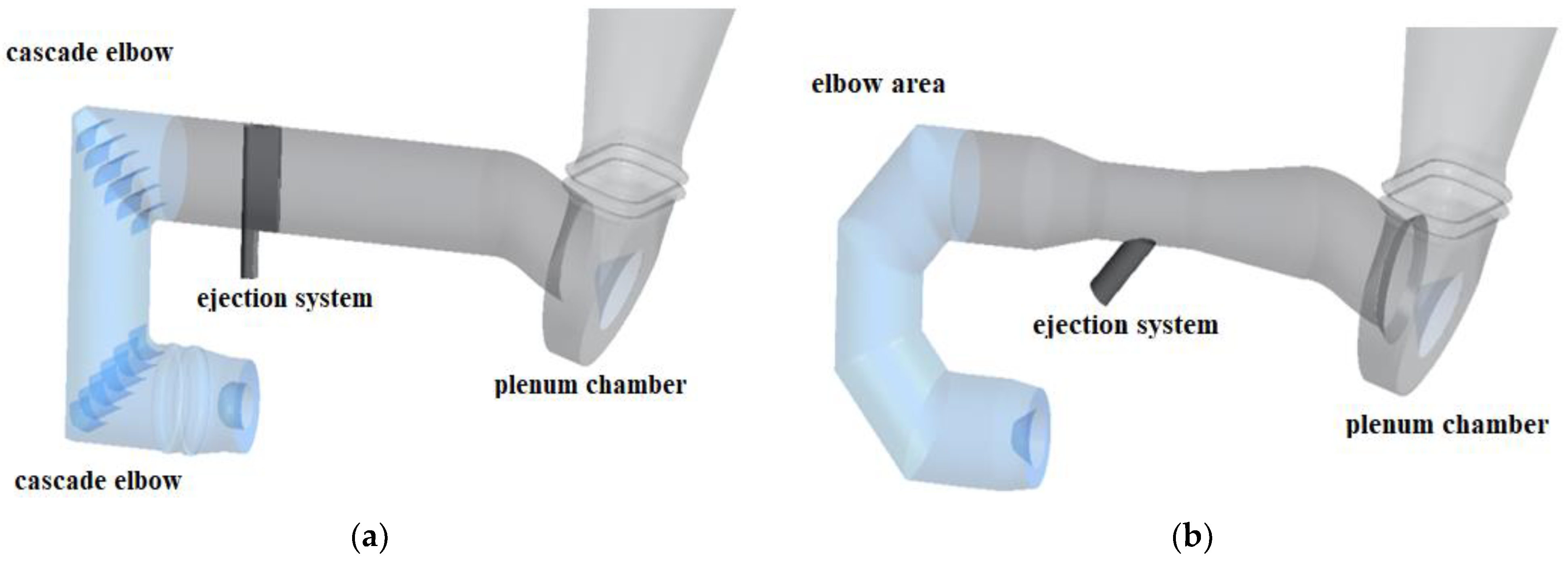

Figure 2 presents the geometries for which satisfactory results have been obtained, together with the modifications made to each exhaust manifold (the changes are highlighted in gray). The differences between the cases are given by the geometrical changes in the cascade elbow area, the connection with the exhaust pipe (which was made through a plenum chamber as well as through a guide vane) and various ejection systems to ensure engine enclosure cooling, as follows:

- (a)

- Cascade elbow with trailing edge entrainment and plenum chamber—Engine enclosure ventilation for this configuration was assured by a trailing edge entrainment. Through the numerical analysis, the mass flow obtained was insufficient to ensure enclosure cooling, being less than 0.4 kg/s.

- (b)

- Vaneless elbow with asymmetric injection and plenum chamber—Changes were made in the elbow area and the ejection system. This solution offers low mass flow for cooling and high-pressure losses. The vaneless elbow did not bring any improvements on the results.

- (c)

- Cascade elbow with annular ejection, cylindrical, and guide vane—The major changes brought by configuration (c) were for the ejection system (annular ejection) and the connection with the exhaust pipe (guide vane). An increase in the mass flow for enclosure cooling was observed, but was not considered sufficient.

- (d)

- Cascade elbow with annular ejection, high speed with guide vane—For this case the annular ejection and guide vane plenum were maintained, changing only the position of the ejection system and the pipe diameter before it. The mass flow for the engine enclosure cooling obtained was more than 1.2 kg/s.

Figure 2.

Configuration of the engine exhaust system. (a) Cascade elbow with trailing edge entrainment and plenum chamber; (b) vaneless elbow with asymmetric injection and plenum chamber; (c) cascade elbow with annular ejection, cylindrical, and guide vane; (d) cascade elbow with annular ejection, high speed with guide vane.

Figure 2.

Configuration of the engine exhaust system. (a) Cascade elbow with trailing edge entrainment and plenum chamber; (b) vaneless elbow with asymmetric injection and plenum chamber; (c) cascade elbow with annular ejection, cylindrical, and guide vane; (d) cascade elbow with annular ejection, high speed with guide vane.

Out of the configurations presented in Figure 2, the most promising results were obtained in the case where a volute (Figure 2c,d) was used to extract the hot air from the engine compartment. The main problem of this configuration was the complicated geometry of the volute, which requires a complex manufacturing process, and also the limited space available around this section. For the other configurations, the mass flow calculated was not sufficient to ensure proper cooling.

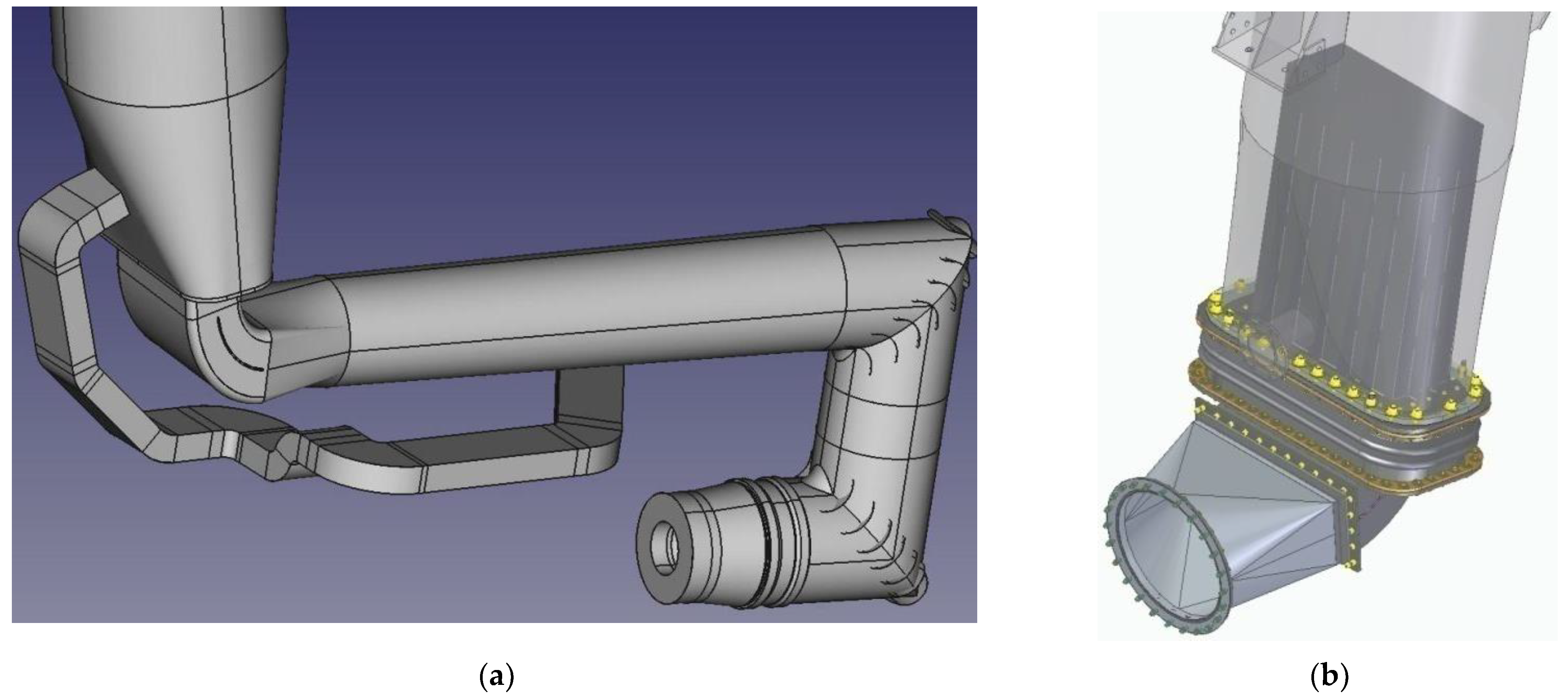

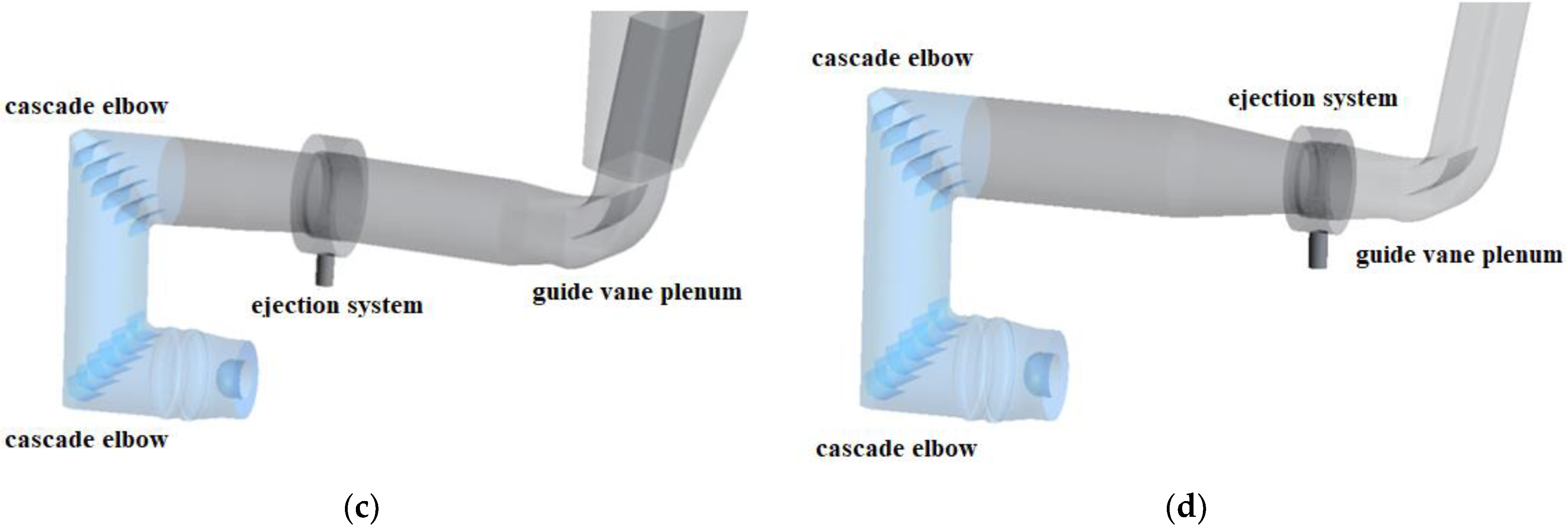

Figure 3a illustrates the exhaust manifold connection with the hot air exhaust pipe and the final section of the manifold installed inside the exhaust pipe (Figure 3b). The hot air evacuation from the engine enclosure made use of Venturi ejection, a phenomenon that occurs due to the velocity of hot gases flow passing through the exhaust pipe; the pipe to which is also connected the manifold body. Additionally, the pipe is provided with a butterfly valve of rectangular section, having the role of interrupting the air circulation through the piping, in the case of chemical attacks on the ship and in case of fire inside the enclosure.

Figure 3.

3D model of the exhaust pipe. (a) Hot air exhaust pipe connection with the exhaust flue; (b) isometric view of the guide vane plenum.

This configuration was determined and optimized based on CFD analysis and represents the ship exhaust manifold. Ensuring the real working conditions of such a system in a test bench is difficult to achieve, consequently, the performance of the ejection system was not validated on the test bench, but when the engine and related components were installed on the ship. The experimental and CFD results presented hereafter do not contain the engine cooling enclosure system.

The test bench configuration for the exhaust system was simplified in the area of the third cascade elbow to fit into the bench dimensions and to ensure the evacuation of exhaust gases into the atmosphere. In the following are presented the numerical and experimental results obtained for the test rig configuration.

2.2. CFD Model

A steady state CFD analysis was carried out using the Ansys CFX solver. The designed geometry was meshed with Ansys ICEM using unstructured meshes, with cartesian infill in order to insure model stability and accuracy. In highly curved areas as well as in the areas considered of interest, a local mesh refinement was applied to increase the accuracy of the solution. To minimize the numerical diffusion and to determine the best trade-off between the resolution and numerical stability, a grid independence study was performed following the methodology by Drăgan et al. [23]. Problems regarding the mesh quality were resolved before the Reynolds Averaged Navier–Stokes (RANS) test, obtaining an approximately 30 million elements mesh.

For the flow physical model, the standard k–ε turbulence model with streamline curvature corrections was applied and the air was considered to behave as compressible. The model is mostly used for turbulent flows conditions, being utilized in many industrial processes due to its robustness, lower computational costs, and reasonable accuracy [24]. Additionally, it proved to be reliable for free-shear flows, especially for flows with small pressure gradients.

Following mesh generation, the boundary conditions were specified as follows: Domain Inlet (mass flow: 11.55 kg/s, total temperature: 873 K), Domain Outlet (static pressure: 101,325 Pa), and the rest of the walls were considered adiabatic and without slip, since in real application they are smooth finished sheet metal surrounded by heavy insulating materials.

The operating point used corresponds to an engine regime of approximately 94% of the maximum rotational speed. These conditions respect the experimental setup and are imposed depending on the exhaust system requirements.

The numerical campaign was realized using the second-order upwind difference scheme. Solution convergence was insured by monitoring the values of interest to reach a steady solution, domain imbalances of impulse, energy, and mass to be less than 1%, and residual monitoring to reach an acceptable value (10−4 or 10−5).

3. Experimental Methodology

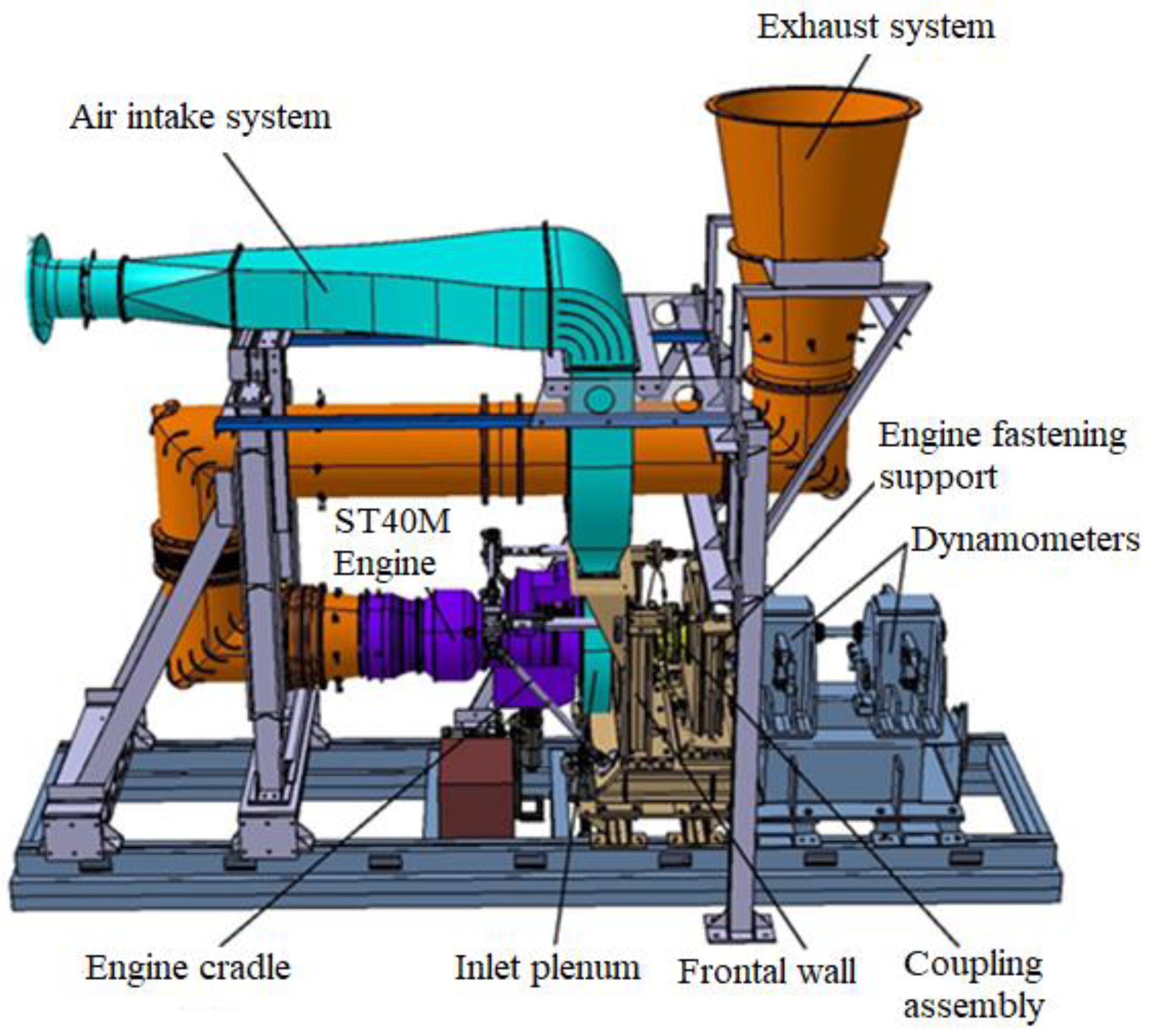

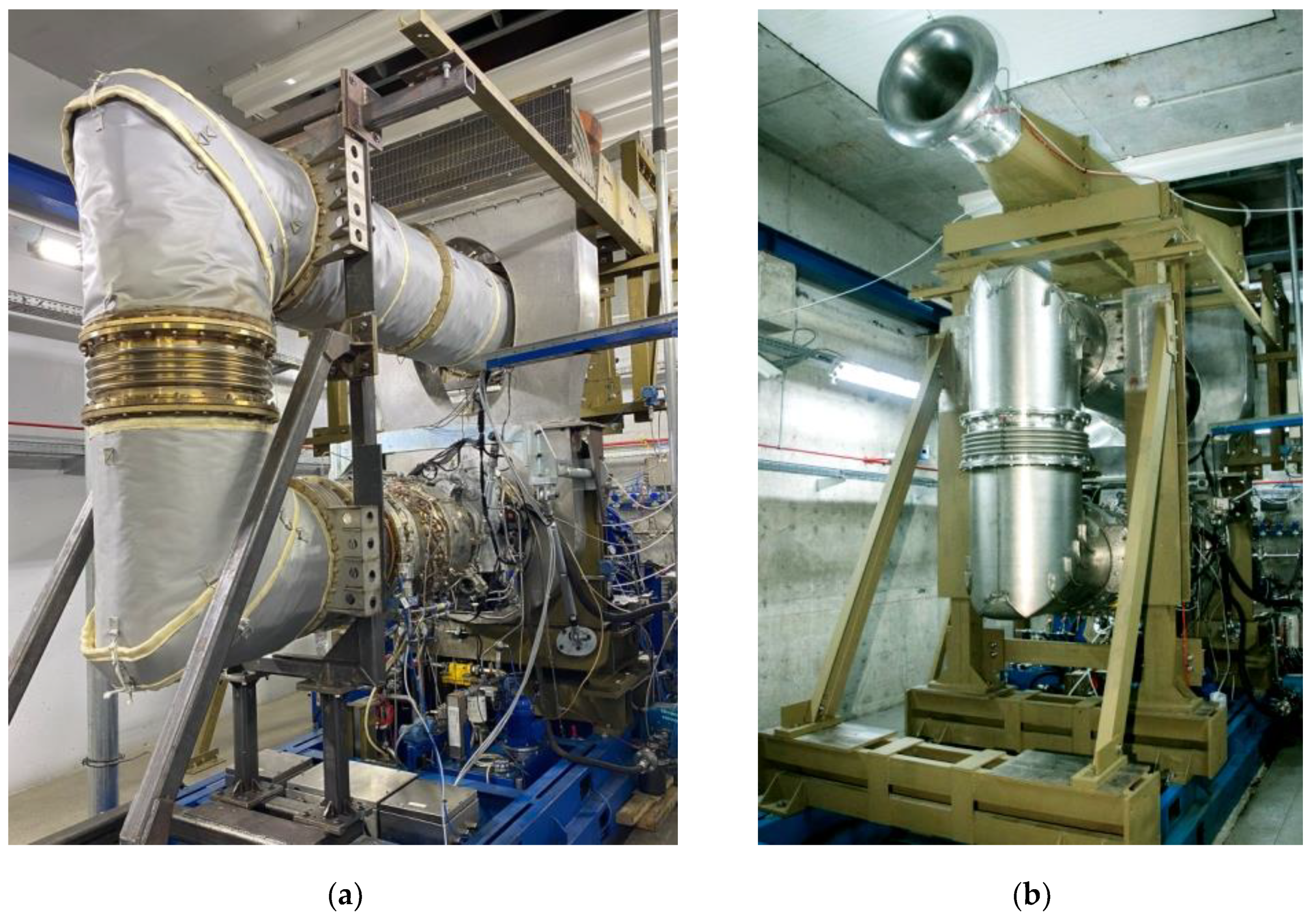

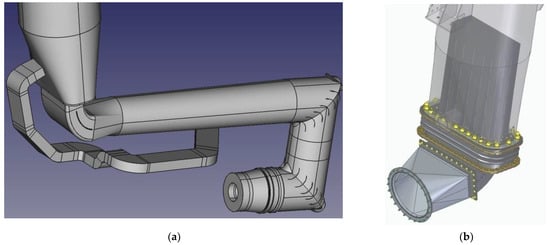

The experimental investigations were carried out on the technological demonstrator equipped with an ST40M engine, as presented in Figure 4. The functionality of the ST40M engine was tested for the entire operating domain by using the same fuel system, lubrication installations, control systems, and instrumentation designed for operation on the ship. A short description of the process can be found in [25], where the results obtained for the intake manifold are presented.

Figure 4.

Assembly of the technological demonstrator equipped with the ST40M engine on the test bench [25].

The experimental tests were conducted on the entire range of regimes with respect to the ship operations, from start up, thermal stabilization to maximum power regimes. The engine regime was controlled by the automatic control system that transformed the demand from the operator (in form of a throttle position) in a variable fuel flow in order to achieve a stabilized regime through different control loops. The engine power turbine rotational speed was controlled by the automatic system of the dynamometer. For each rotational speed, a torque value was preset in order to simulate the propeller power demand across the operational range.

Dynamic and steady state tests were performed, simulating accelerations, decelerations, and different stabilized regimes. For steady state operations, the regimes were maintained constant for approximately 5 min in order to achieve thermal stabilization and to collect relevant experimental data.

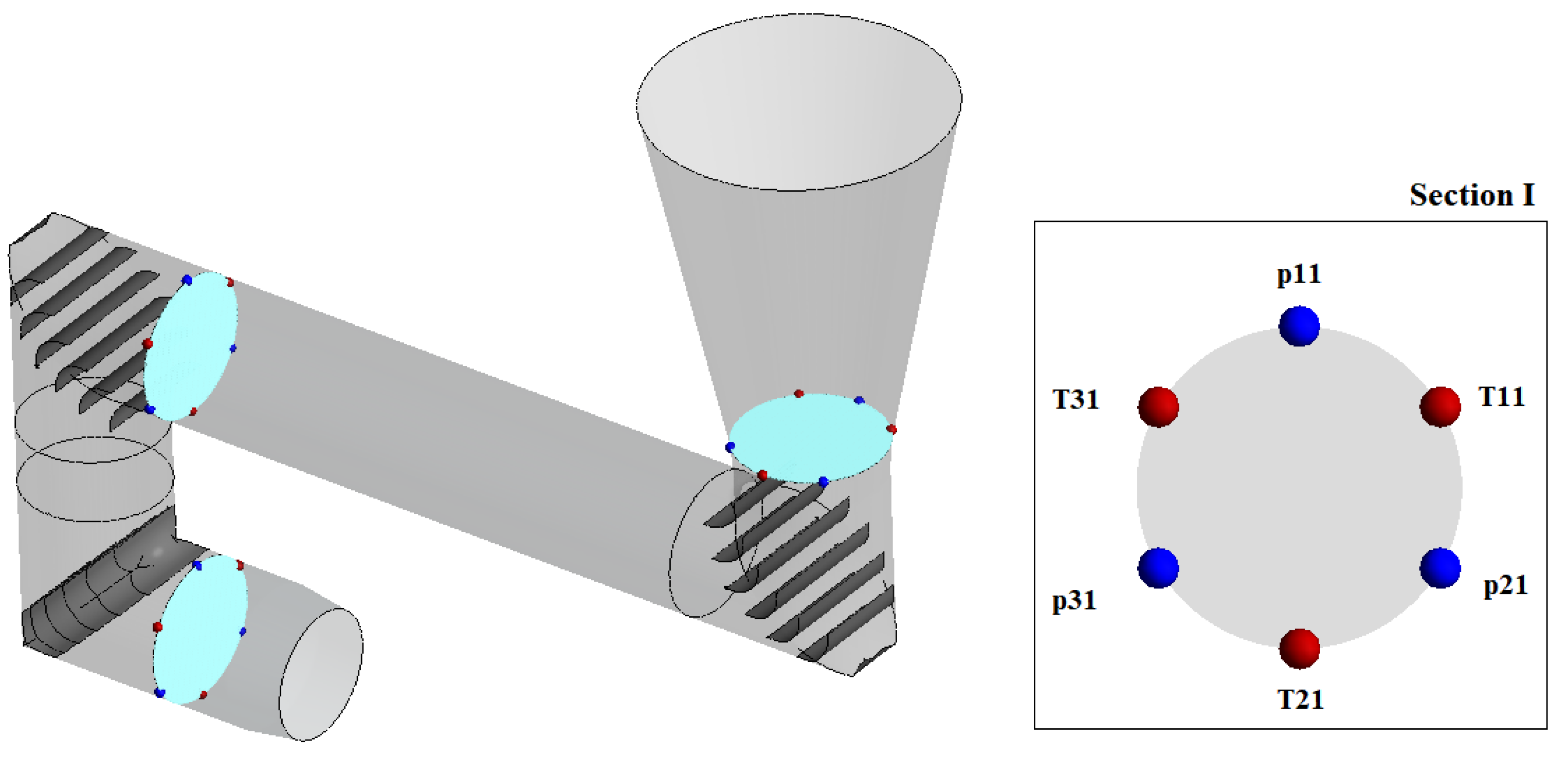

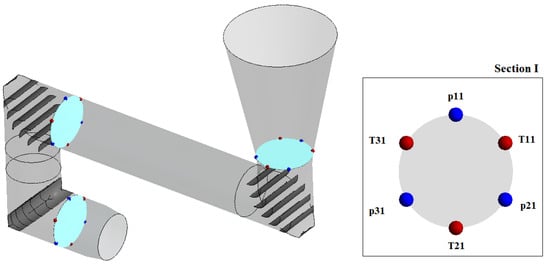

In order to validate the CFD results and to determine the performance of the demonstrator, pressure and temperature probes were positioned in three different sections of the configuration. All experimental instrumentation and tests were realized in compliance with the Advisory Group for Aerospace Research and Development (AGARD) standards [26]. Figure 5 presents the location of the three sections and the position of the measurement samples. The blue sphere represents the position of the total pressure sensors, while the red ones represent the total temperature sensors. Each parameter, pressure or temperature, was measured in three different locations spread equidistant across the duct circumference.

Figure 5.

Geometry of the computational domain showing the measurement locations.

The probes were installed taking into account the flow path instrumentation blockage. The total area occupied by the probes is less than 2 percent [27]. The probes used were as follows: temperature probes using type K thermocouple, total pressure probes, static pressure ports. The accuracy in the case of the pressure sensors was+−0.1% from the measured interval, whilst the accuracy for the temperature sensor was+−0.75% from the measured interval.

Figure 6 presents a part of the gas turbine experimentation complex where the technological demonstrator was installed. The picture from the left side illustrates the exhaust system coupled at the ST40M engine, while the other one shows the demonstrator assembly on the test bench. Figure 5a also shows that the thermal isolation used on the exhaust pipes can be observed. The thermal isolation was used to minimize the heat transfer through exhaust pipes to the surrounding atmosphere. Such losses might affect the capacity of the exhaust gases to expand and entrain the ventilation flow from the engine compartment.

Figure 6.

Test bench for the ST40 engine: (a) exhaust system connection with the ST40M engine; (b) technological demonstrator assembly.

4. Results and Discussions

4.1. Technological Demonstrator Design and Its CFD Performance

The numerical analysis was conducted to predict the flow pattern inside the exhaust manifold and to determine if the aerodynamic performances obtained were in line with the instructions of the engine installation manual [28].

Terminologies of the total pressure and static pressure used to present the numerical simulation results are defined in [29].

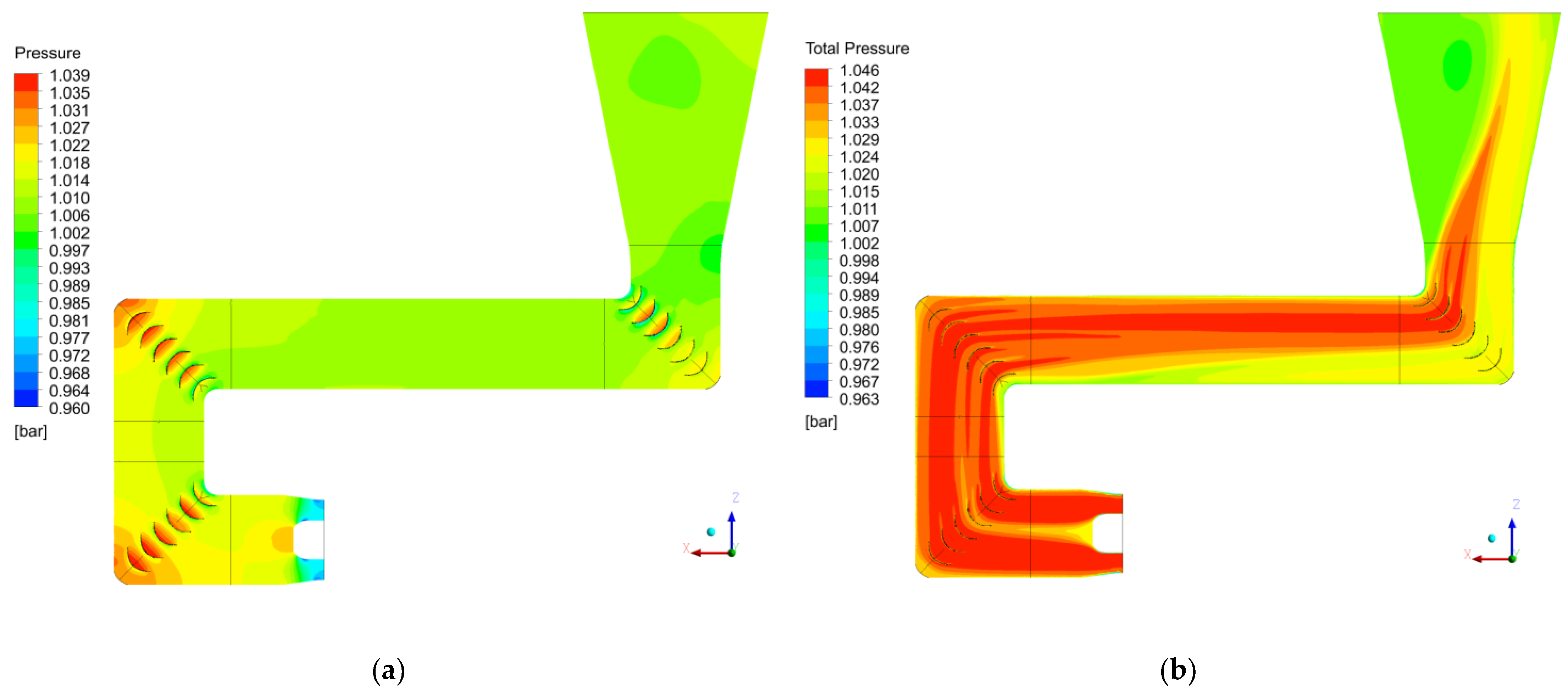

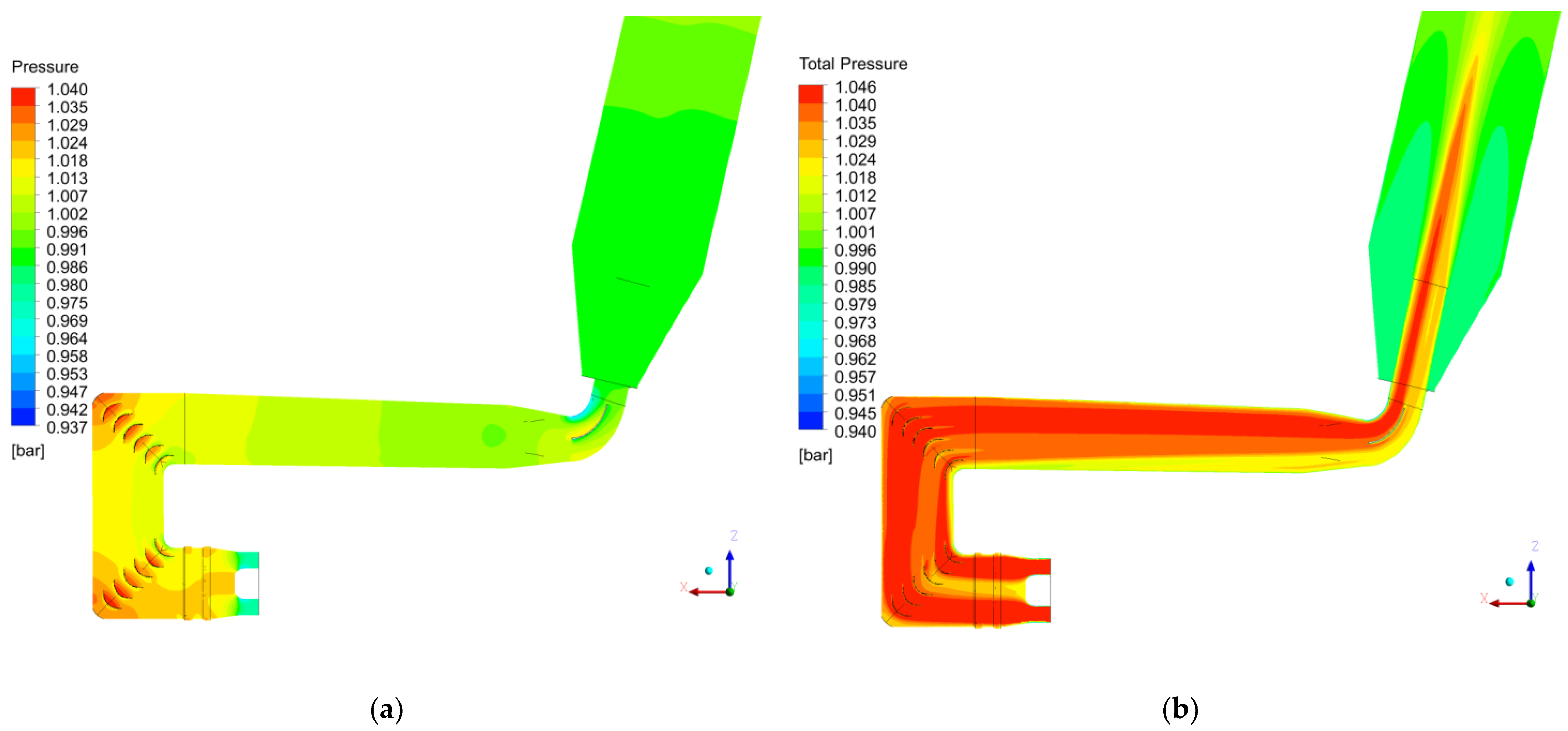

Figure 7 illustrates the static and total pressure distribution in a XZ plane positioned in the median section of the domain. Static pressure showed a small decrease along the ducting, which is natural, but otherwise there was little in the way of diffusion or acceleration. Consequently, all emphasis will be placed on the total pressure distribution and losses. Total pressure distribution in the exhaust manifold decreased as the exhaust gases from the engine headed toward the outlet domain. In the area of the cascade elbow, the total pressure was not evenly distributed, the influence of the exhaust cone in the first elbow being observed, which also propagated toward the second one. In the third cascade elbow, the fluid total pressure was much higher on the upper side of the elbow, which correlated with the fluid acceleration through the exhaust basket (Figure 8).

Figure 7.

Exhaust system. (a) Static pressure distribution; (b) total pressure distribution.

Figure 8.

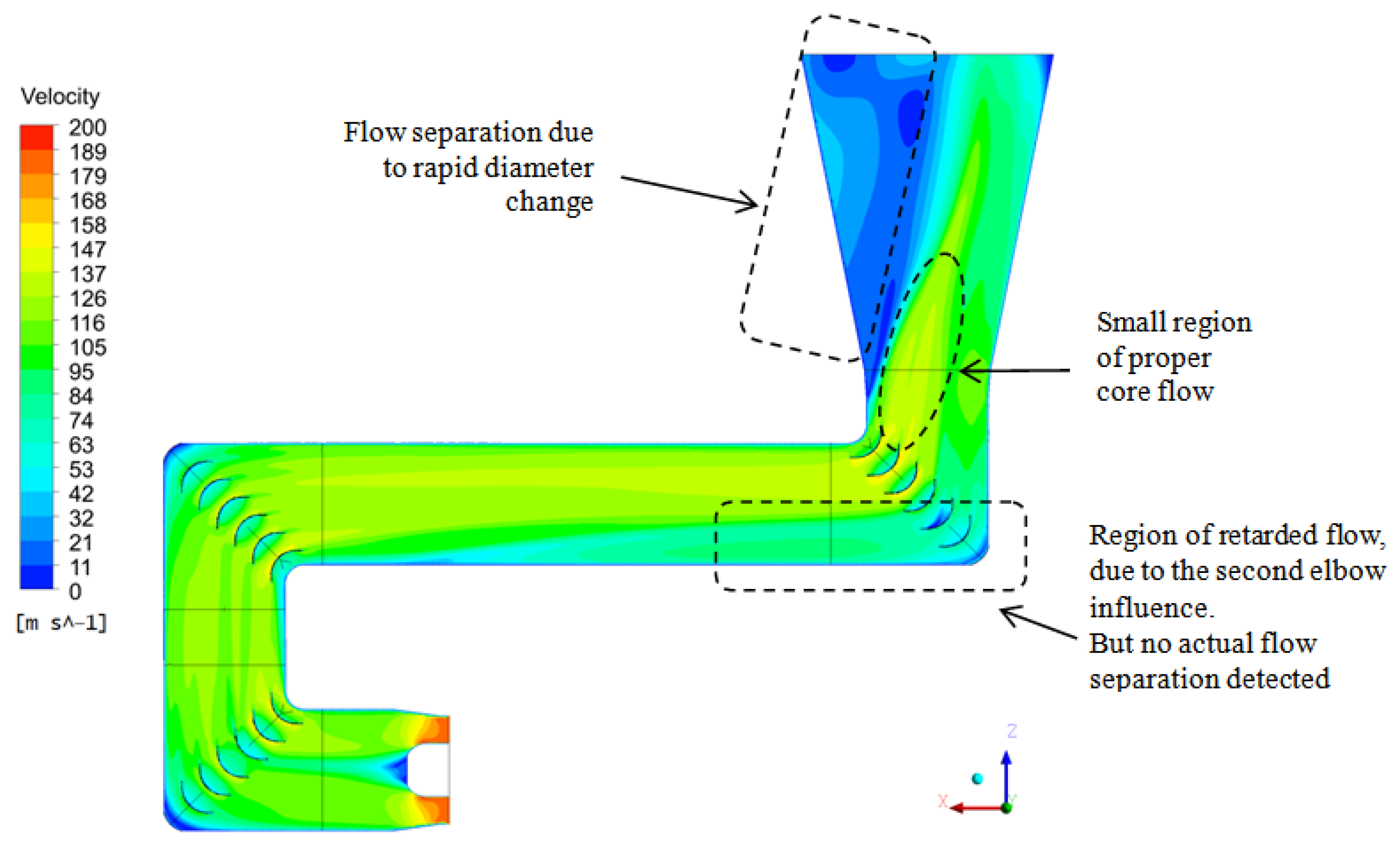

Velocity distribution in the exhaust manifold, presenting the main problems encountered due to sudden geometry changes.

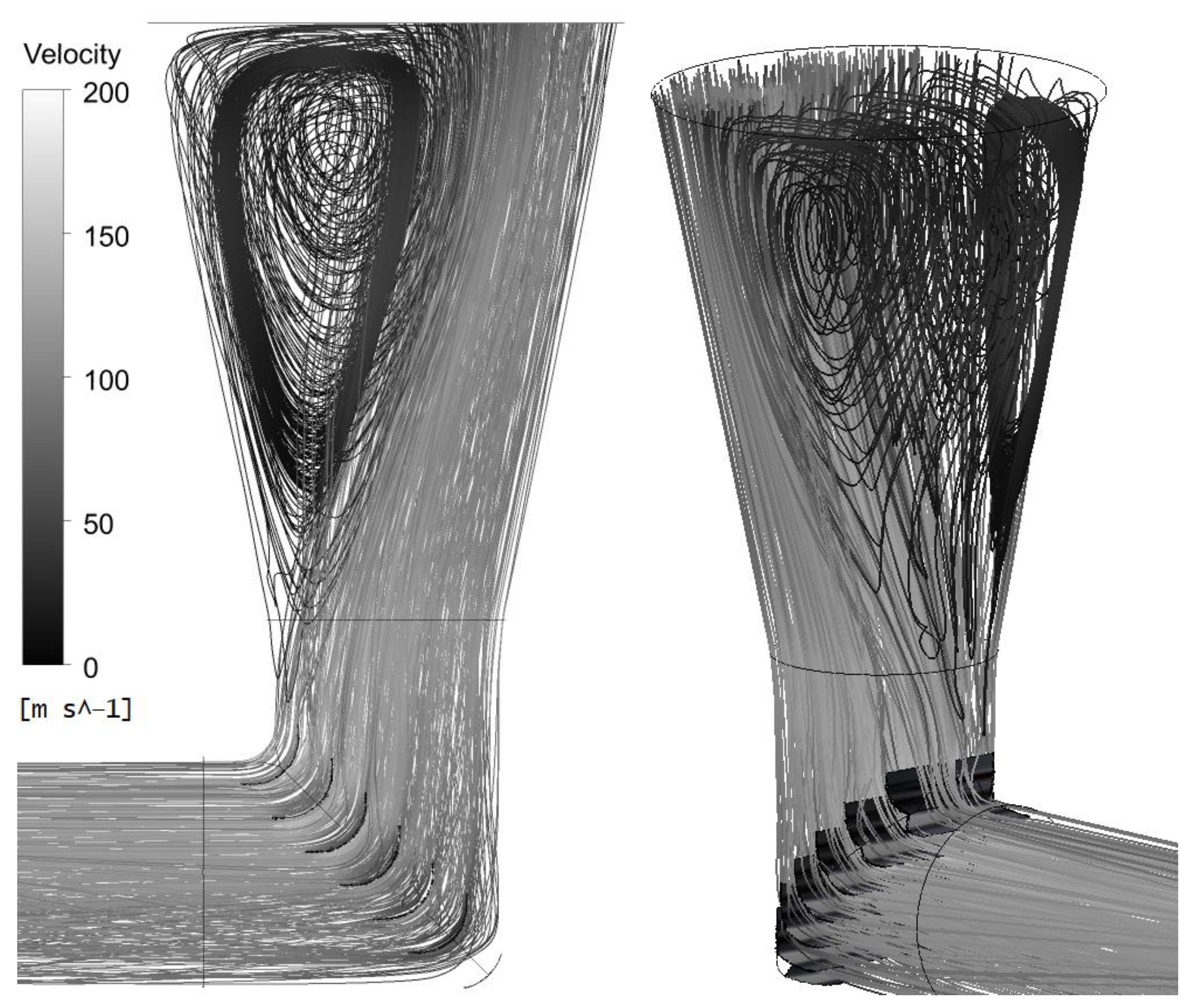

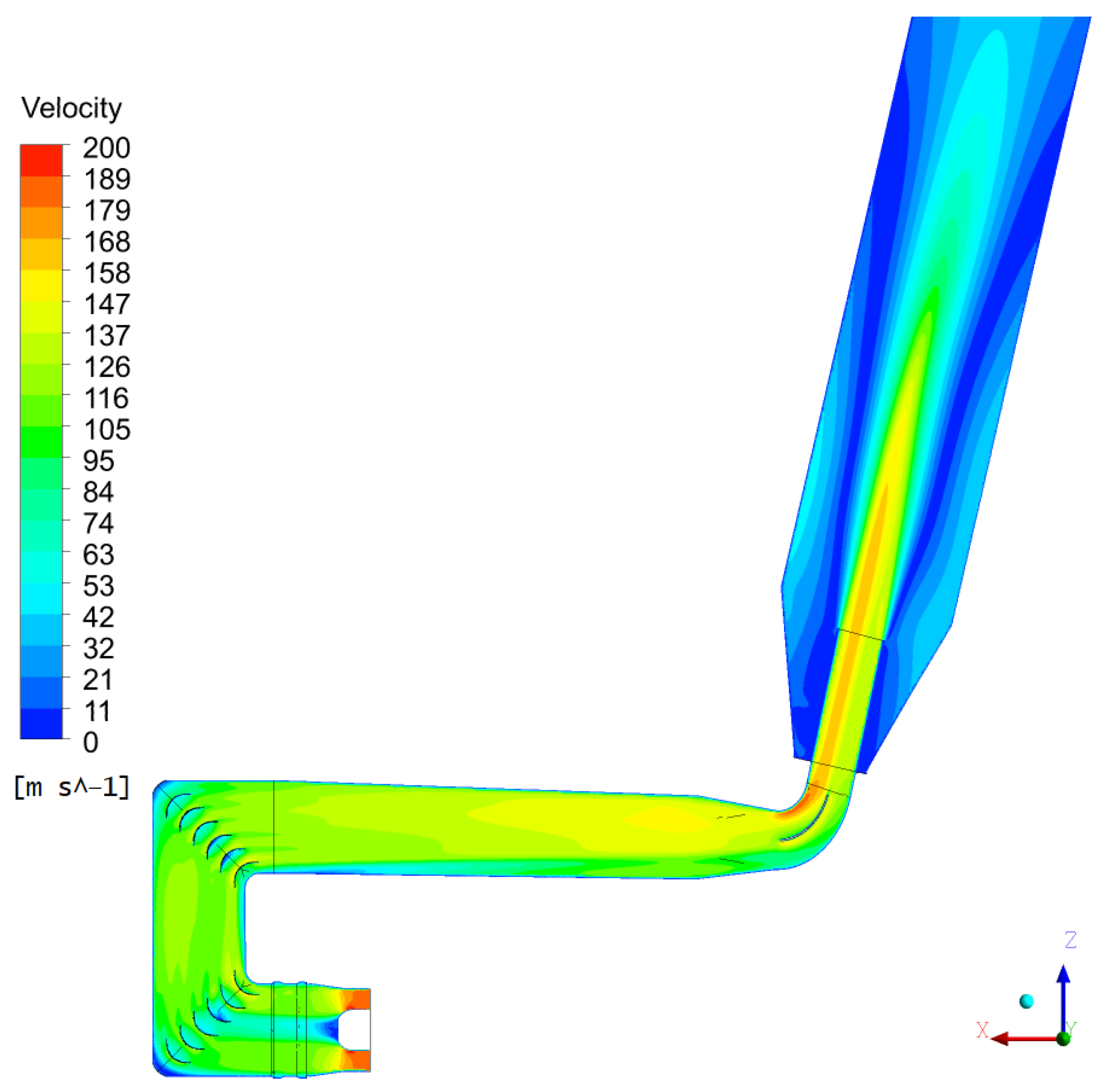

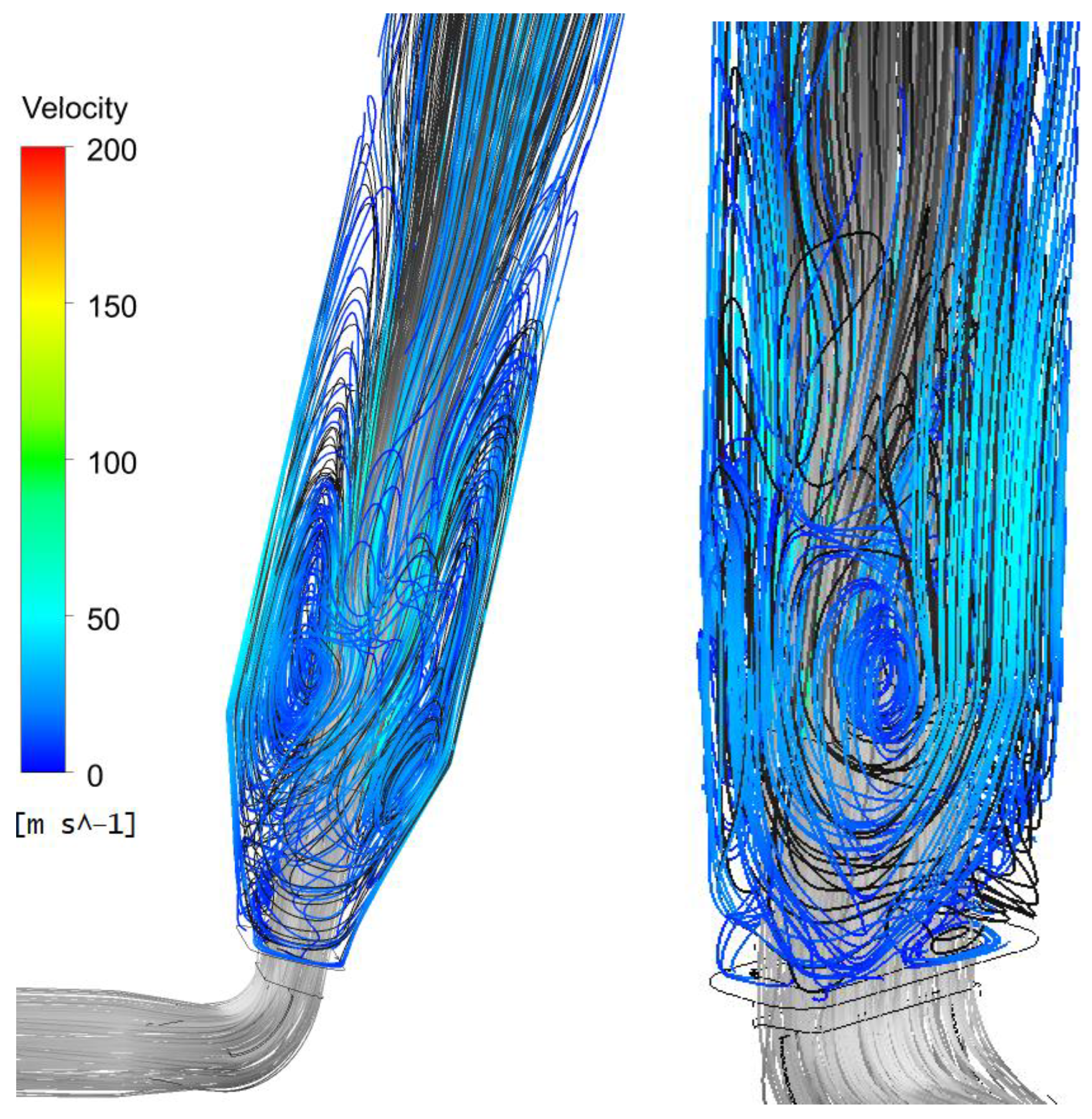

The velocity representation from Figure 9 highlights the fluid acceleration through the exhaust manifold. As the fluid approaches the exhaust basket, the fluid energy dissipates toward the exit. Massive flow separation occurs on the suction side of the basket, which leads to the proposal of a new and improved inner-tube configuration. Apart from the exhaust basket, no major flow detachment could be observed in the exhaust configuration. Any flow separation along the ducting leads to sudden changes in the pressure and temperature distribution and would have been noticed in the experimental tests.

Figure 9.

Streamline distribution in the exhaust basket.

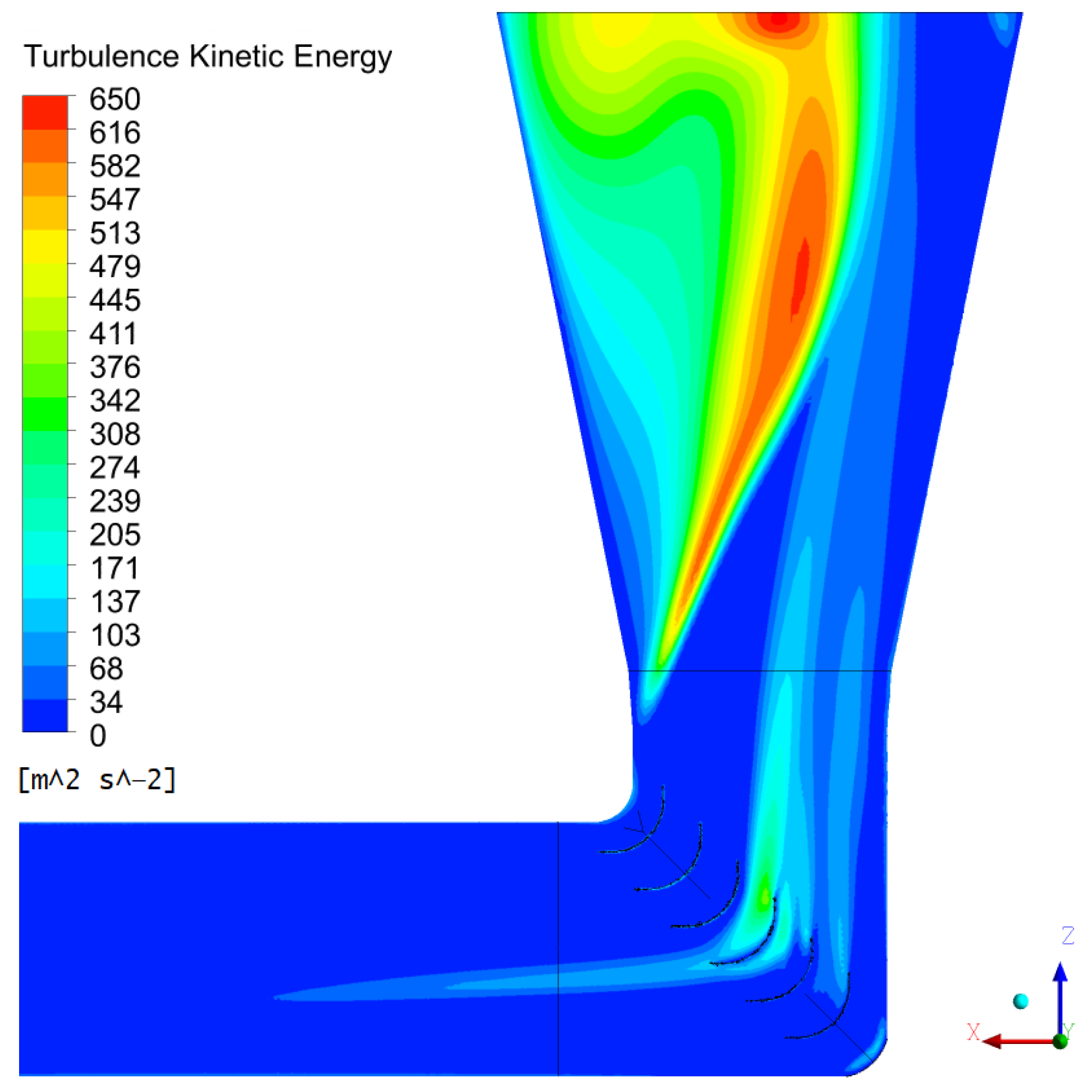

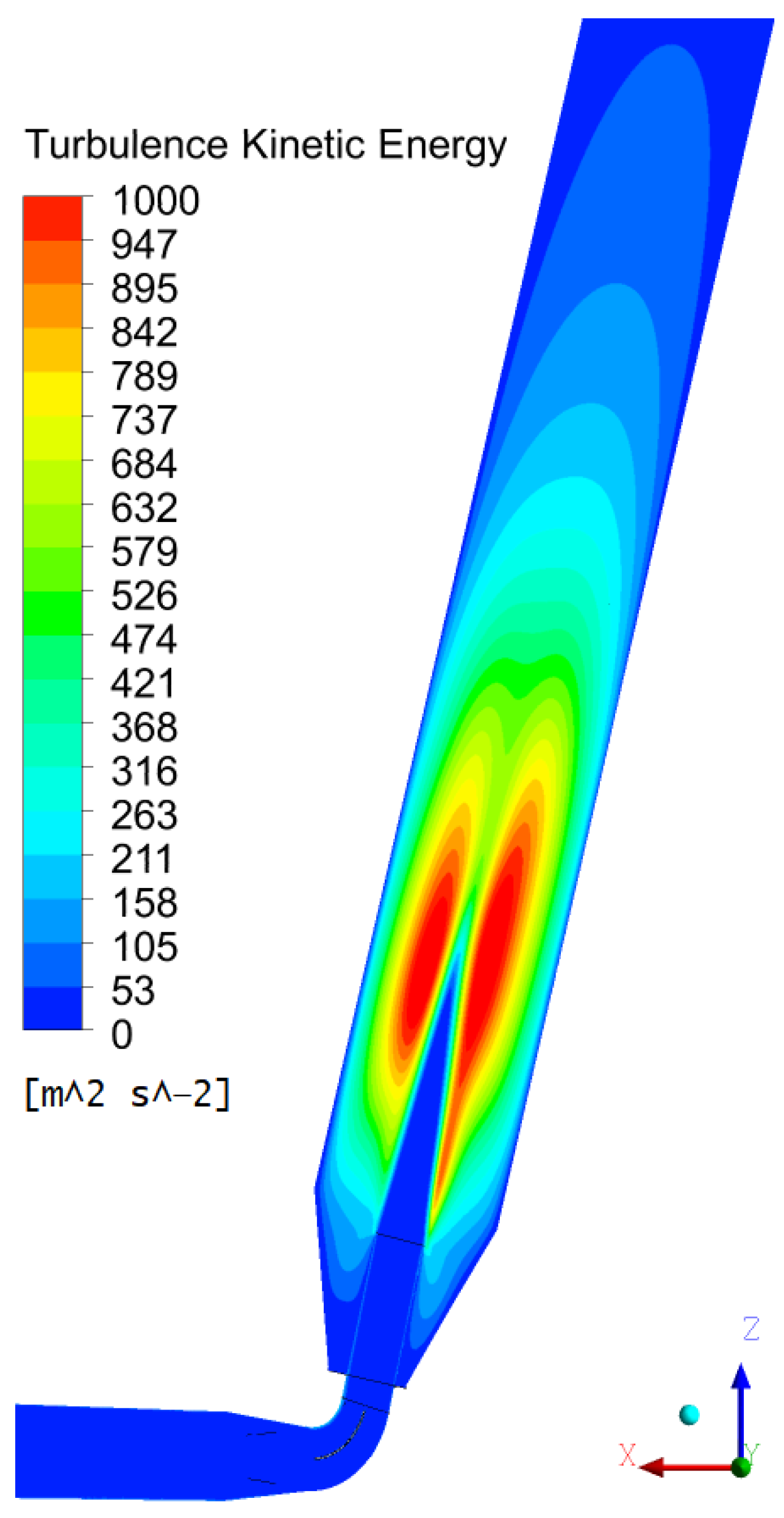

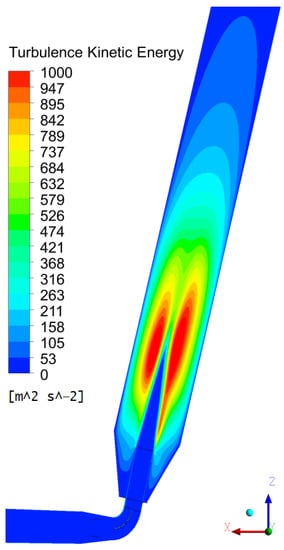

The recirculation areas developed in the exhaust basket were due to the sudden diameter change and resulted in the increased velocity from the main flow, as seen in Figure 9. The dimension of the recirculation area expands as the pipe diameter increases and the fluid approached the exit area, reaching more than half of the pipe diameter in the exit area, thus blocking a large part of the exhaust pipe. The same vortex regions could be observed through the turbulent kinetic energy plotted in Figure 10, where the extent of their blockage was nearly 60% of the exhaust outlet.

Figure 10.

Turbulent kinetic energy distribution in the exhaust basket.

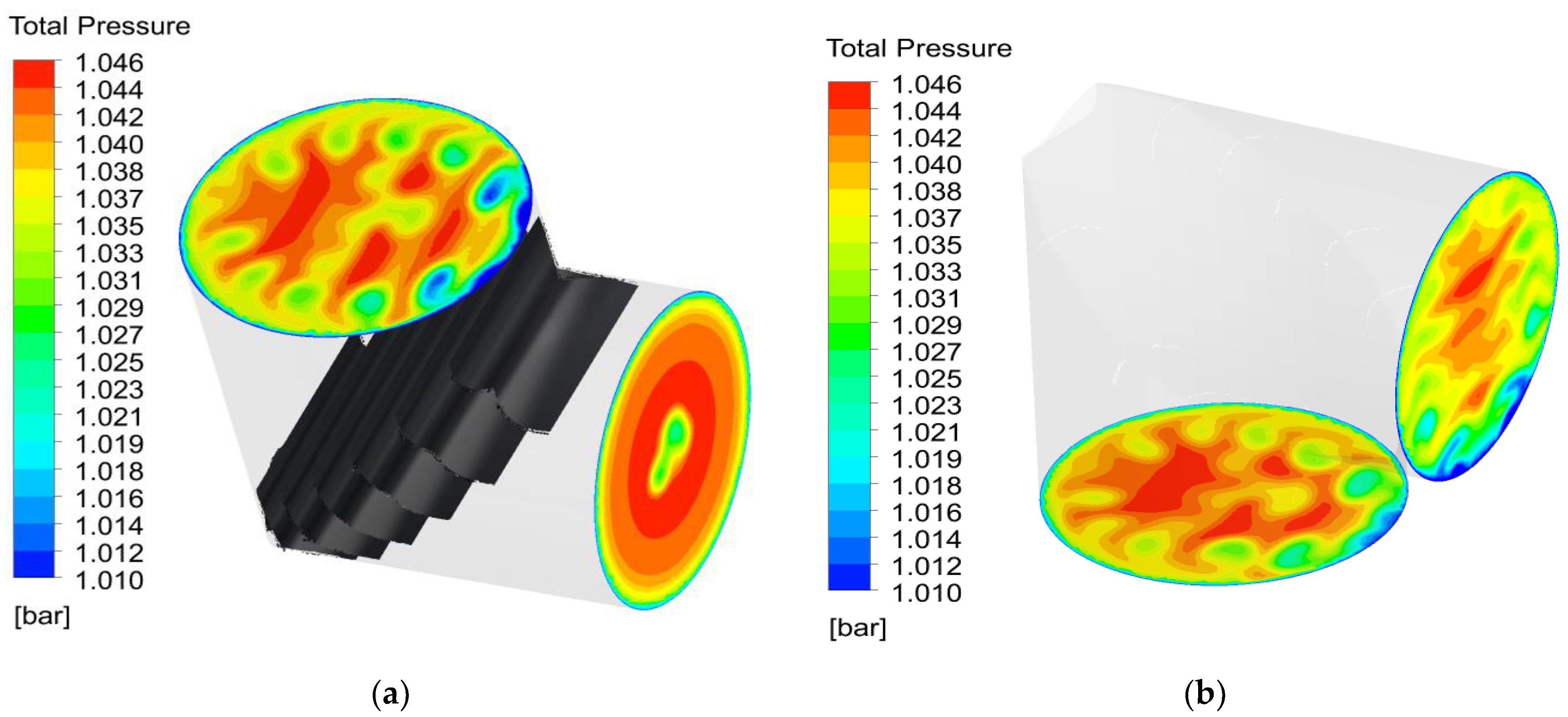

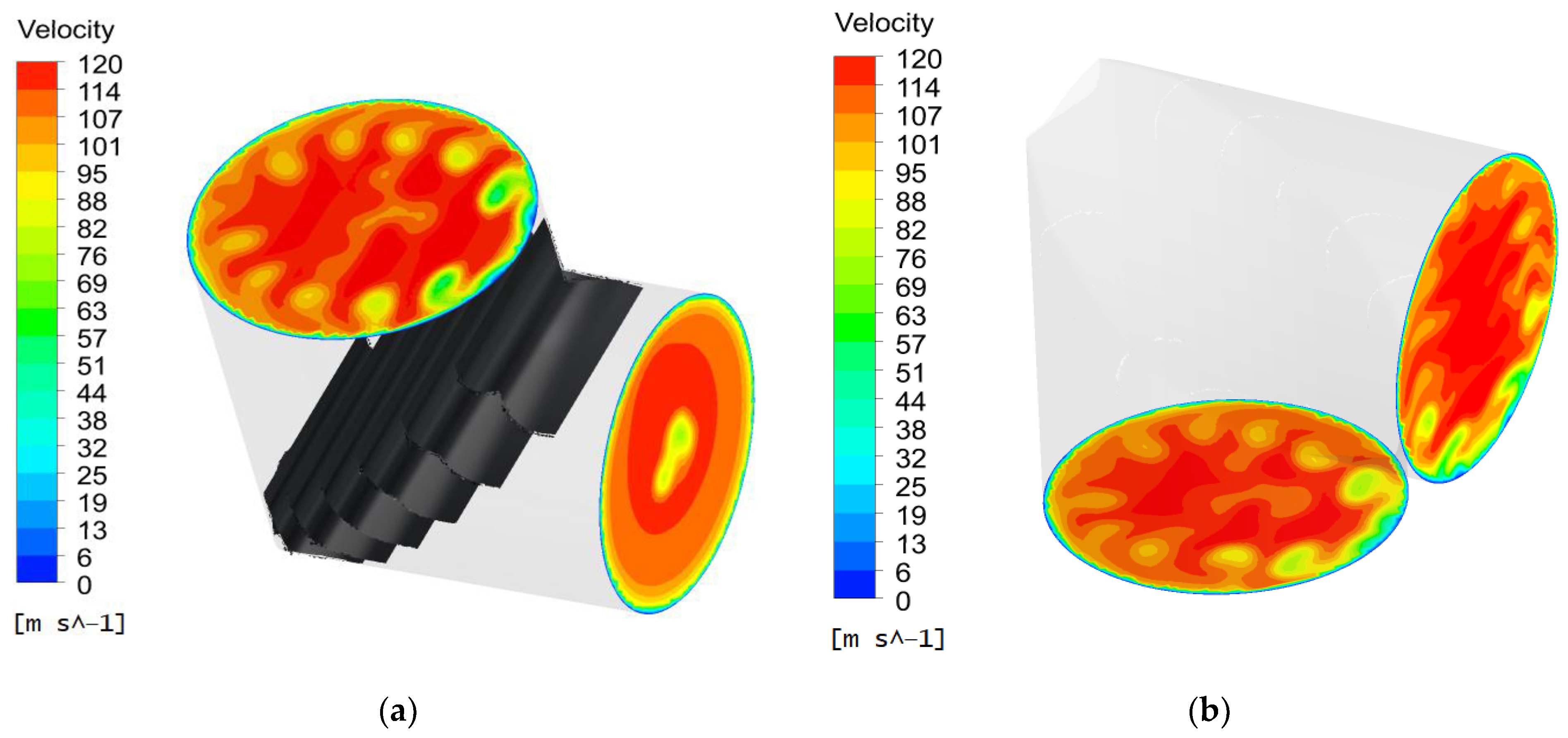

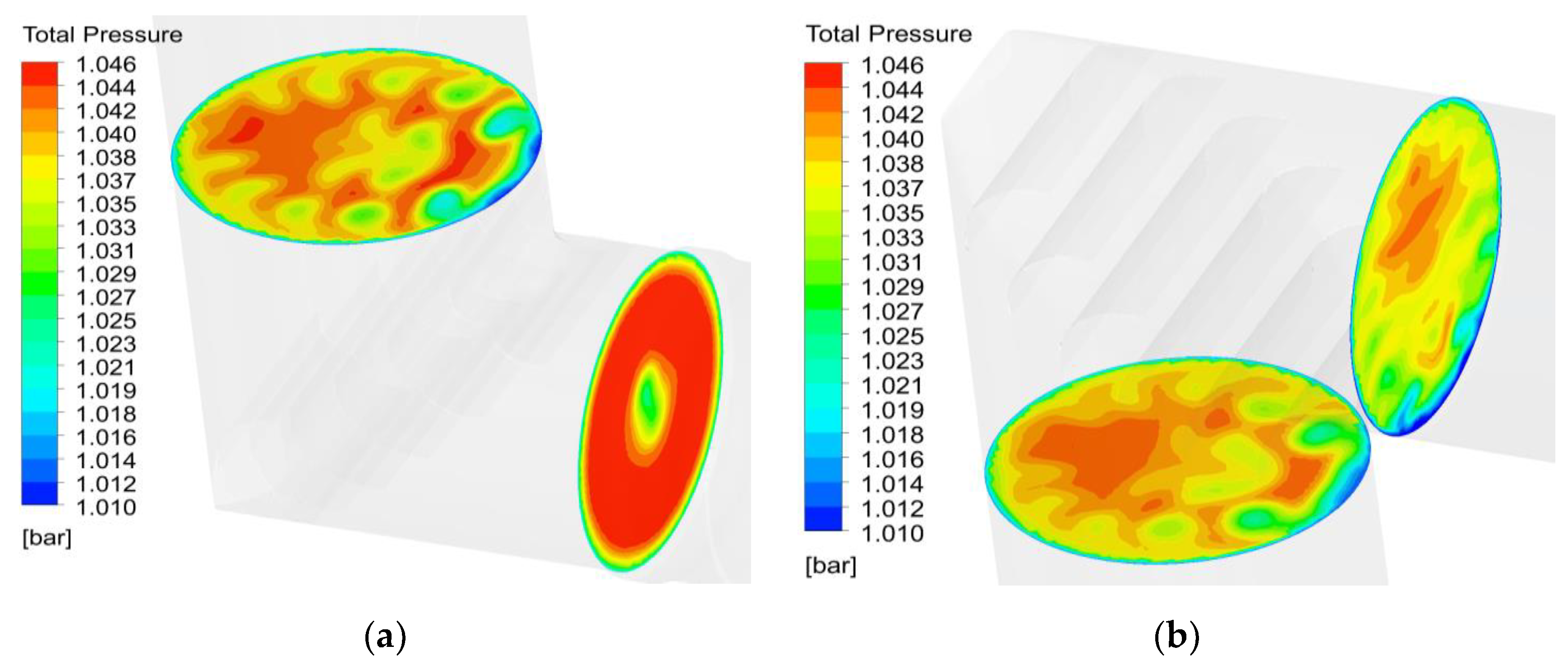

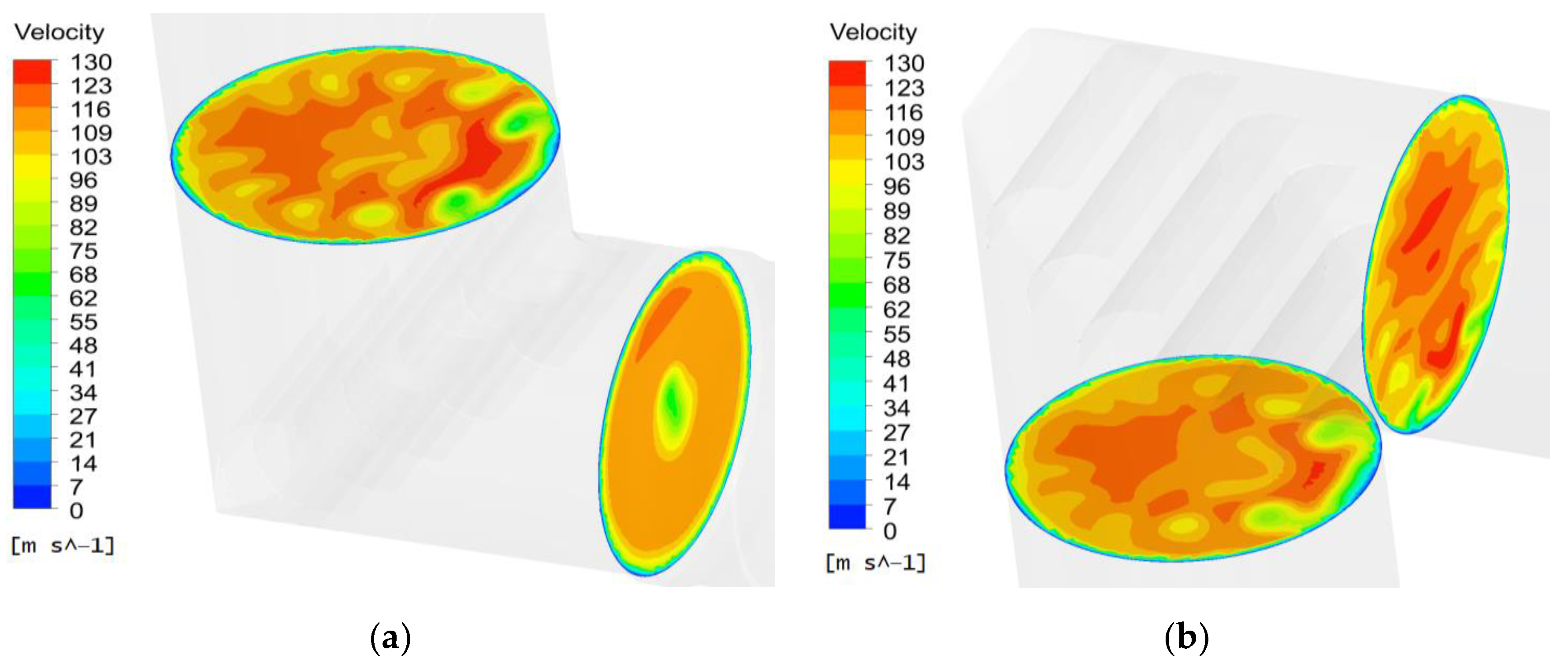

Figure 11 and Figure 12 present the total pressure and velocity, on four planes, all positioned on the cascade elbow area, representing the input and output from the first elbow, input and output from the second elbow. The pressure losses (of around 428 Pa), obtained for the first cascade elbow displayed in Figure 11a and Figure 12a, were caused by the engine cone influence and elbow geometry. The entry in the second elbow (Figure 11b and Figure 12b) was influenced by the upstream flow propagating these disturbances in the guide vanes. In this section, the total pressure loss was found to be around 304 Pa. The overall pressure loss percentage obtained for the entire exhaust assembly represented approximately 3.7%, highlighting the importance of the flow pattern through the system. In terms of velocity distribution, the influence of guide vanes and engine cones remained detectable in all sections.

Figure 11.

Total pressure distribution. (a) Cascade elbow I; (b) cascade elbow II.

Figure 12.

Velocity distribution. (a) Cascade elbow I; (b) cascade elbow II.

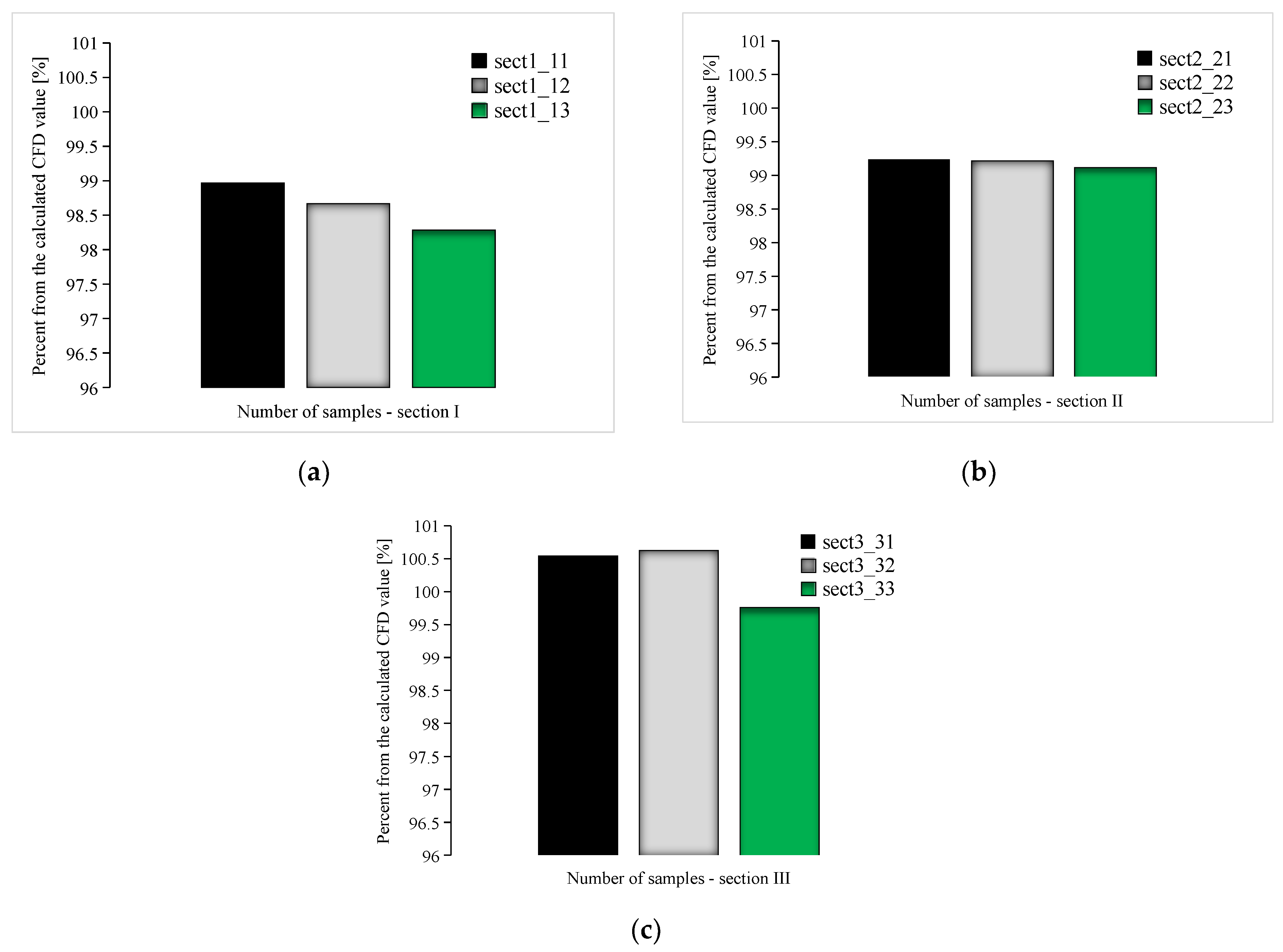

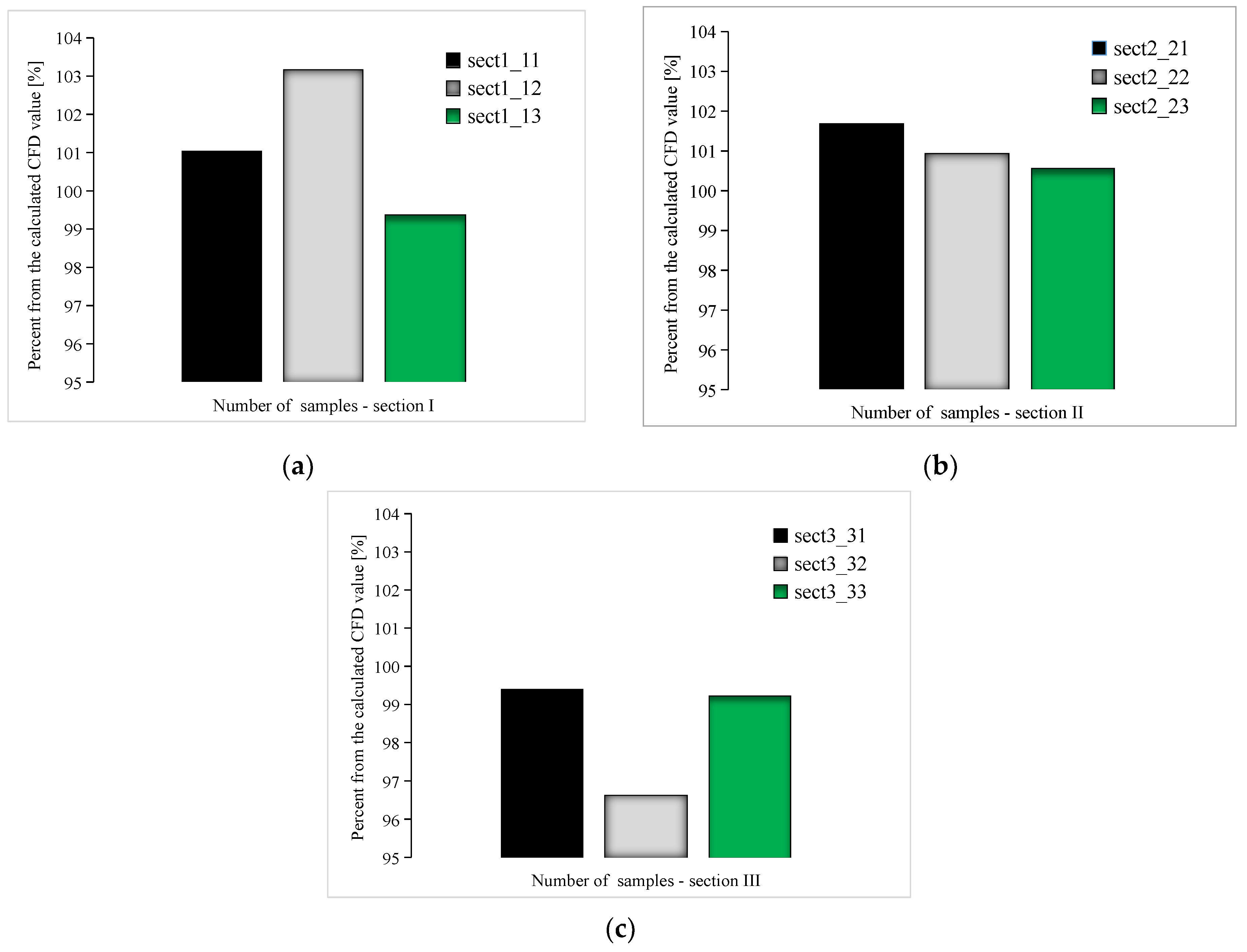

The comparison between the numerical studies and experimental data indicates a good agreement among cases, validating the CFD methods applied. Figure 13 illustrates the experimental test results for the three sections and the difference between CFD and the experiment. Overall, the CFD analysis overestimated the total pressure values, obtaining a maximum discrepancy of 1.17% in section I.

Figure 13.

Total pressure losses mass averaged for the three sections illustrated in Figure 4. (a) Section I; (b) section II; (c) section III.

Regarding the total temperature variation (Figure 14), the CFD analysis underestimated the temperature values, obtaining a maximum difference of 3.48% in section III. Even with this increase, there was at least one measurement point with a difference lower than 1% for every section.

Figure 14.

Total temperature losses mass averaged for the three sections illustrated in Figure 4. (a) Section I; (b) section II; (c) section III.

For both the total pressure and temperature, the differences between the CFD and experiments were relatively low, without major discrepancies for any of the three sections, concluding that the CFD model properly estimated the performances of the exhaust system and can be further used for future design optimization campaigns.

4.2. The Improved Design and Its CFD Performance

The CFD data of the improved design are presented in the following. This configuration represents the ship manifold exhaust, without the ventilation system.

Figure 15 displays the static and total pressure distribution in a XZ plane positioned in the median section of the domain. Static pressure in the exhaust manifold decreases as the exhaust gases from the engine head toward the outlet. In the region of the cascade elbow, the total pressure is not evenly distributed because of the influence of the exhaust cone, especially in the first elbow. In the outlet guide vane region, the fluid total pressure is much higher on the pressure side, correlating with a fluid acceleration through the exhaust basket (Figure 15a and Figure 16). This is a result of the interaction between the wake of the second elbow and the constriction before the third.

Figure 15.

Exhaust system. (a) Static pressure distribution; (b) total pressure distribution.

Figure 16.

Velocity distribution in the exhaust system.

The velocity depiction from Figure 16 presents the fluid acceleration through the exhaust manifold. As the fluid approaches the exhaust basket, the fluid energy dissipates toward the exit, but allows for a lateral wake region that serves as an insertion point for the outlet of the ventilation ducting. Along the pipeline, until the fluid entered the exhaust basket, no recirculation regions were observed. This was, however, not the case in the region immediately adjacent to the interior tube, whereby design, the purpose was to promote a recirculation bubble that would help draw air from the ventilation ducting.

The recirculation areas in the exhaust basket were located mostly in the first half of the pipe due to the sudden diameter change and increased velocity from the main flow, as shown in Figure 17. The dimension of the recirculation areas and position did not block the exhaust pipe, but instead caused pressure losses. The same vortex regions could be observed through turbulent kinetic energy, as shown in Figure 18, where their expansion was only local, dissipating downstream.

Figure 17.

Streamline distribution for the ventilation duct and exhaust basket.

Figure 18.

Turbulent kinetic energy distribution in the exhaust pipe.

Figure 19 and Figure 20 present the total pressure and velocity, on four planes, all positioned on cascade elbow area, as shown in Figure 11. In the first cascade elbow, the pressure loss, namely 350 Pa, was caused by the engine cone influence and elbow geometry, as shown in Figure 19a and Figure 20a. The pressure loss in the second elbow (Figure 19b and Figure 20b) was influenced by the upstream flow, propagating these disturbances in the guide vanes. For this section, the total pressure loss was found to be around 290 Pa. The overall pressure loss for the entire configuration was around 4%, which was a little higher than the test bench configuration, but the pressure loss in the exhaust basket represented a major part of this value.

Figure 19.

Total pressure distribution. (a) Cascade elbow I; (b) cascade elbow II.

Figure 20.

Velocity distribution. (a) Cascade elbow I; (b) cascade elbow II.

5. Conclusions

Substituting an out-of-date propulsion system or updating it requires, most of the time, a new adaptation of the available space to suit the demands of the air intake, exhaust, and ventilation systems, corresponding to the engine performance. However, Rolls Royce has announced the termination of production for the gas turbine Tyne RM1C and are no longer providing maintenance services, forcing the replacement of the old engine generation with newer ones.

Marine propulsion is responsible for a large part of carbon dioxide emissions. The energy efficiency of the propulsion system represents a sustainable approach for the environment, and revamping could be one of the solutions for older ships. Changes made by replacing the engines assure higher performance and improved fuel consumption, and therefore lower operational costs, lower emissions, and reduced maintenance costs. Proper engine operability and maintenance could lead to a more environmentally friendly propulsion system, and contribute to a reduction in the overall costs.

The paper presents the development and validation, by both numerical analysis and experimental testing, performed for an exhaust manifold of a T22 defense frigate, whose engine was upgraded to a Pratt–Whitney ST40M model. Numerical simulations of the exhaust manifold were carried out using commercial software Ansys CFX and were further validated against the experimental data. The experimental campaign was conducted in COMOTI’s gas turbine experimentation complex, where a part of the conditions and systems available on the ship were reproduced in order to ensure relevant operational environment.

Numerous configurations were designed and numerically conducive to a proper fitting of the geometry on the frigate, but at the same time, to ensure engine enclosure cooling. The results of the exhaust manifold for the ship configuration were presented only for the CFD analysis, which showed an improvement in pressure losses and in the overall stability of the flow.

For the test bench experimental campaign, the exhaust geometry was simplified and redesigned through numerical analysis. The results from testing campaigns, CFD and the experiments were compared in terms of the total pressure and total temperature in three different sections of the configuration. To determine the variation in these parameters on the pipe circumference, three monitoring probes were installed for each parameter. The comparison between the two validation methods showed good agreement, obtaining a difference of approximately 3.5% for the total temperature probes and 1.17% for pressure.

Certain findings from this research may extend to other applications that require natural draught from the exhaust gas; however, the main applicability of the study is to marine applications. The design process applied can be beneficial for exhaust manifold designers that encounter problems in the definition of the ejection cooling system. However, the test bench configuration and validation though the CFD analysis brings further studies closer to a technology readiness level crucial for the experimental tests carried out on board the ship.

Author Contributions

Conceptualization, V.D., O.D., B.G., D.O. and N.M.; Methodology, V.D. and O.D.; Software, O.D. and V.D.; Validation, V.D., O.D., B.G., N.M., D.O. and R.N.; Investigation, N.M., O.D., V.D., B.G., D.O.; Resources, N.M. and B.G.; Data curation, O.D. and R.N.; Writing—original draft preparation, O.D. and V.D.; Writing—review and editing, O.D., V.D. and R.N.; Supervision, B.G. and N.M.; Project administration, N.M. and D.O. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a grant of the Ministry of Research, Innovation and Digitization, CNCS/CCCDI-UEFISCDI, project number PN-III-P2-2.1-SOL-2021-2-0169, within PNCDI III.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This work was carried out within the PNCDI III, Project “Development and implementation of a modern solution to replace Romanian Naval Forces Fast Patrol Boats (Missile) propulsion systems”, acronym NAVYPROM, Grant no. 34SOL/01.10.2021, project supported by a grant of the Ministry of Research, Innovation and Digitization, CNCS/CCCDI-UEFISCDI.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- WLPGA. LPG for Marine Engines, the Marine Alternative Fuel, Commercial, Passenger, Offshore Boats/Ships, Recreational Crafts and Other Boats. 2018. Available online: https://www.wlpga.org/wp-content/uploads/2018/02/LPG-for-Marine-Engines-2017-.pdf (accessed on 15 December 2022).

- UNCTAD—United Nations Conference on Trade and Development. Review of Maritime Transport 2021; United Nations Publications: New York, NY, USA, 2021; ISBN 978-92-1-113026-3. [Google Scholar]

- Bhargava, R.K.; Blanchi, M.; Campanari, S.; Pascale, A.; Montenegro, G.N.; Peretto, A. A Parametric Thermodynamic Evaluation of High Performance Gas Turbine Based Power Cycles. J. Eng. Gas Turbines Power 2010, 132, 2. [Google Scholar] [CrossRef]

- Najjar, Y.S.H. Gas Turbines Cogeneration Systems: A Review of Some Novel Cycles. Appl. Therm. Eng. 2000, 20, 179–197. [Google Scholar] [CrossRef]

- Yang, W. Reduction of Specific Fuel Consumption in Gas Turbine Power Plants. Energy Convers. Manag. 1997, 38, 1219–1224. [Google Scholar] [CrossRef]

- Domachowski, Z.; Dzida, M. An analysis of characteristics of ship gas turbine propulsion system (in the light of the requirements for ship operation in the Baltic Sea). Pol. Marit. Res. 2004, 1, 73–78. [Google Scholar]

- Nkoi, B.; Lebele-Alawa, B.T. Comparative Assessment of Combined-Heat-and-Power Performance of Small-Scale Aero-Derivative Gas Turbine Cycles. J. Power Energy Eng. 2015, 3, 20–32. [Google Scholar] [CrossRef]

- Roy, G.K. Selecting Heavy-Duty or Aero—Derivative Gas Turbines. Hydrocarb. Process. 2012, 75, 57. [Google Scholar]

- Doom, T.R. Aero-Derivative Gas Turbines. In Case Studies on the Government’s Role in Energy Technology Innovation; American Energy Innovation Council: Washington, DC, USA, 2013. [Google Scholar]

- Packalén, S.; Karlsson, N. Combined Gas- and Steam Turbine as Prime Mover in Marine Applications; Department of Shipping and Marine Technology, Chalmers University of Technology: Gothenburg, Sweden, 2017; Available online: http://americanenergyinnovation.org/wp-content/uploads/2013/08/Case-Gas-Turbines.pdf (accessed on 15 December 2022).

- Sayma, A.I. Gas Turbines for Marine Applications. In Encyclopedia of Maritime and Offshore Engineering; Carlton, J., Jukes, P., Sang, C.-Y., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2017; pp. 1–10. ISBN 9781118476406. [Google Scholar]

- Keller, S.C.; Studniarz, J.J. Aero-Derivative Gas Turbines Can Meet Stringent NOx Control Requirements. In Proceedings of the 9th Annual Industrial Energy Technology Conference, Houston, TX, USA, 6–18 September 1987; pp. 253–260. [Google Scholar]

- IMO. Interim Guidelines on the Method of Calculation of the Energy Efficiency Design Index (EEDI) for New Ships. MEPC 1/Circ: 681; IMO: London, UK, 2009. [Google Scholar]

- Park, S.; Yang, J.; Rhee, S.H. Parametric study on ship’s exhaust-gas behavior using computational fluid dynamics. Eng. Appl. Comput. Fluid Mech. 2017, 11, 159–171. [Google Scholar] [CrossRef]

- Bral, P.; Prakash, J.P.; Saurabh, D.; Mahato, A.C. CFD analysis of an exhaust manifold for emission reduction. Mater. Today Proc. 2022, 63, 354–361. [Google Scholar] [CrossRef]

- Bajpai, K.; Chandrakar, A.; Agrawal, A.; Shekhar, S. CFD Analysis of Exhaust Manifold of SI Engine and Comparison of Back Pressure using Alternative Fuels. IOSR J. Mech. Civ. Eng. 2017, 14, 23–29. [Google Scholar] [CrossRef]

- Nursal, R.S.; Hashim, A.H.; Nordin, N.I.; Danuri, M.R. CFD Analysis on the Effects of Exhaust Backpressure Generated by Four-Stroke Marine Diesel Generator after Modification of Silencer and Exhaust Flow Design. J. Eng. Appl. Sci. 2017, 12, 1271–1280. [Google Scholar]

- Sapraa, H.; Godjevaca, M.; Vissera, K.; Stapersmaa, D.; Dijkstra, C. Experimental and simulation—Based investigations of marine diesel engine performance against static back pressure. Appl. Energy 2017, 204, 78–92. [Google Scholar] [CrossRef]

- Gulmez, Y.; Ozmen, G. Effect of Exhaust Backpressure on Performance of a Diesel Engine: Neural Network based Sensitivity Analysis. Int. J. Automot. Technol. 2022, 23, 215–223. [Google Scholar] [CrossRef]

- Molland, A.F. (Ed.) The Maritime Engineering Reference Book; Butterworth-Heinemann: Oxford, UK, 2008; pp. 344–482. ISBN 978-0-7506-8987-8. [Google Scholar]

- Wirkowski, P. Assessment of turbine engines exhaust emissions from vessels propulsion systems. Diagnostyka 2019, 20, 97–103. [Google Scholar] [CrossRef]

- Niculescu, F.; Borzea, C.; Vasile, M.L. Marine Gas Turbine for Efficient Ship Propulsion. EMERG 2020, 6, 85–93. [Google Scholar] [CrossRef]

- Dragan, V.; Dumitrescu, O.; Malael, I.; Porumbel, I.; Gherman, B.; Puscasu, C. Turbulence model sensitivity on steady state mapping of a very high pressure ratio compressor stage. AIP Conf. Proc. 2018, 2046, 020024. [Google Scholar] [CrossRef]

- Cable, M. An Evaluation of Turbulence Models for the Numerical Study of Forced and Natural Convective Flow in Atria. Master’s Thesis, Queen’s University, Kingston, ON, Canada, 2009. [Google Scholar]

- Honaryar, A.; Ghiasi, M.; Liu, P.; Honaryar, A. A new phenomenon in interference effect on catamaran dynamic response. Int. J. Mech. Sci. 2021, 190, 106041. [Google Scholar] [CrossRef]

- Gherman, B.; Drăgan, V.; Dumitrescu, O.; Olaru, D.; Macrișoiu, N. Numerical and Experimental Research for an Unconventional Turboshaft Intake Manifold. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Virtual, 24–28 August 2020. [Google Scholar]

- Krain, H. Experimental and Theoretical Investigations on the Internal Flow in a Centrifugal Compressor Diffuser, In: Centrifugal Compressors, Flow Phenomena and Performance AGARD Conference Proceedings; AGARD: Verneuil-sur-Seine, France, 1980; Volume AGARD-CP-282. [Google Scholar]

- Saravanamutto, H.I.H. Advisory Report No. 245—Recommended Practices for Measurement of Gas Path Pressures and Temperatures for Performance Assessment of Aircraft Turbine Engines and Components; Specialised Printing Services Limited: Loughton, UK, 1990; pp. 1–17. ISBN 92-835-0499-2. [Google Scholar]

- McKeever, K. Installation Manual ST40M Marine Gas Turbine, Revision D, Engineering Report No. 5847; Pratt & Whitney Canada Corp.: Longueuil, QC, Canada, 2005. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).