Integration of a Geothermal Plant in a System with High Renewable Energy Penetration for Desalination Plant Self-Consumption

Abstract

:1. Introduction

2. Materials and Methods

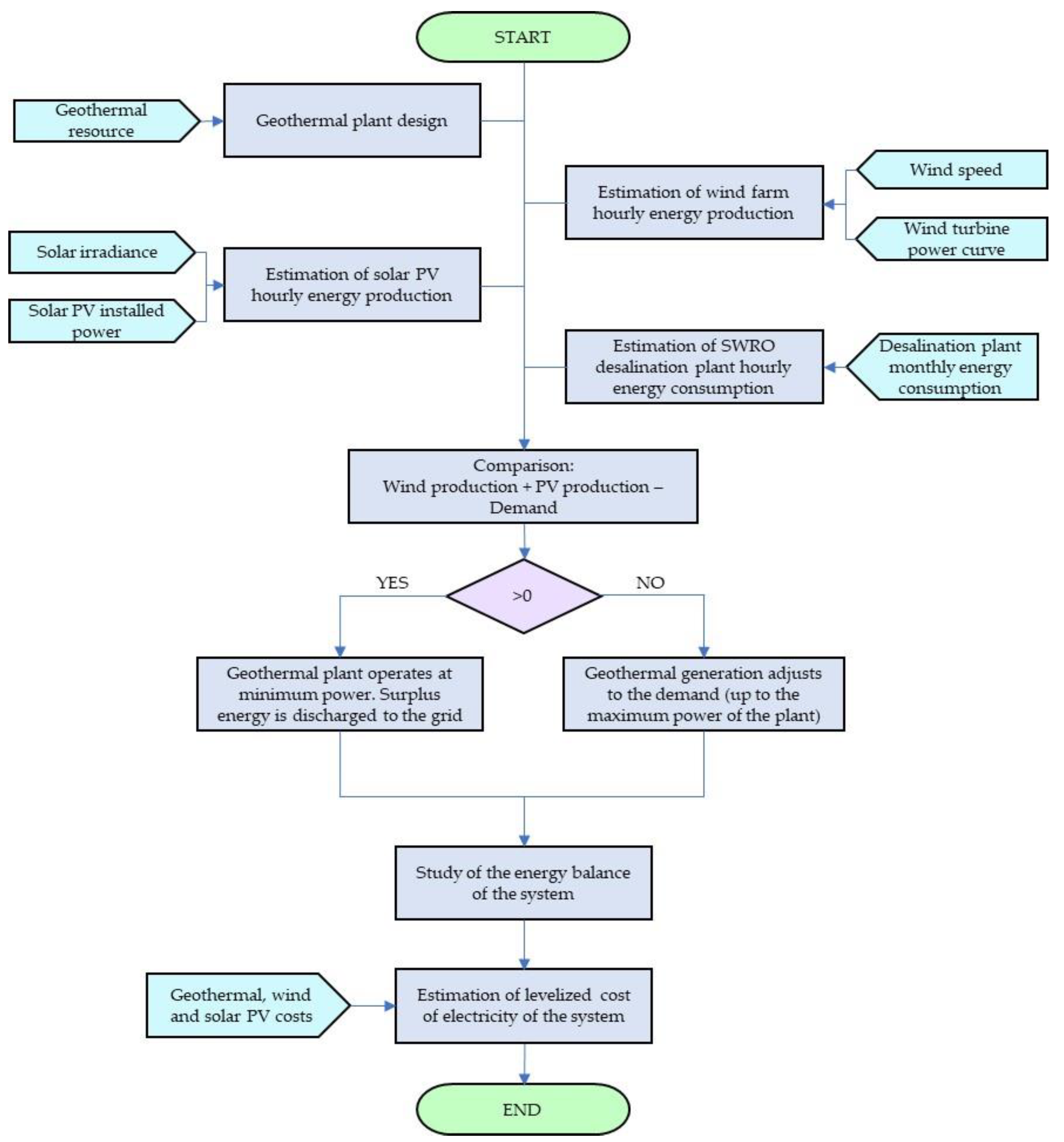

2.1. Method Developed

2.2. Description of the Diversified Renewable System

2.3. Design of the Proposed Geothermal Generation System

- Process 1-2: Expansion. The working fluid in vapour state expands in the turbine, converting kinetic energy into mechanical energy, which is subsequently transformed into electrical energy via a generator.

- Process 2-3: Condensation. The working fluid is condensed after transferring its heat energy to cold water from a cooling tower.

- Process 3-4: Compression. The pressure of the working fluid in a liquid state is increased to take it to the evaporator using a process pump.

- Processes 4-5 and 5-1: Pre-heating and evaporation. After the geothermal fluid has been extracted, its heat energy is transferred to the working fluid via a preheater and evaporator. Pre-heating corresponds to process 4-5 and evaporation corresponds to process 5-1. After absorbing all the heat, the working fluid reaches the saturated vapour state.

2.3.1. Energy Capacity of the Geothermal Resource

2.3.2. Initial Design Parameters

- Turbine input temperature (T1): This is established based on the temperature of the geothermal resource at the mouth of the production well (Ta), which is slightly lower than the initial temperature of the geothermal fluid at the deepest level of the aquifer due to heat losses that take place as the fluid rises (close to 2 °C per kilometre). In the case study of the present paper, the geothermal reservoir is at a temperature of 130 °C, and at the mouth of the production well, the temperature of the geothermal fluid will therefore be 126 °C. On the basis of this latter temperature, it is assumed as a hypothesis that the temperature of the working fluid before entering the turbine will be 95 °C.

- Condensation temperature (T3): This is established based on the type of heat rejection system employed and the mean ambient temperature. In this case, it is considered that the working fluid condensation process will be at 25 °C, which is slightly lower than the mean annual ambient temperature [36].

- Geothermal fluid reinjection temperature (Tc): This is established by taking into consideration that the geothermal fluid has to be reinjected at a temperature that is sufficient for preserving the temperature and pressure of the reservoir. For the particular case studied in this paper, reinjecting geothermal water at a temperature of 84 °C was decided upon.

2.3.3. Determination of Thermodynamic States

- State 1: Corresponds to the turbine’s working fluid input. The working fluid must be in saturated a vapour state at the turbine’s inlet and so its steam quality is 1 (x1 = 1 p.u.). The temperature, T1, was set as explained in the previous subsection. By introducing the values of x1 and T1 in the simulator, it is possible to determine the rest of the thermodynamic properties of the working fluid in state 1 (P1, h1, and s1).

- State 2: Corresponds to the turbine’s working fluid output or the condenser’s working fluid input, which is the same. After exiting the turbine, the working fluid is isobarically condensed, and so the pressure in 2 coincides with the pressure in 3 (P2 = P3). The procedure for obtaining the value of P3 is explained below. Expansion is an isentropic process in the ideal cycle, with specific entropy values in states 1 and 2s therefore coinciding (s1 = s2s) since subscript s corresponds to the final state after an isentropic process. Introducing the values of P2 and s2s in the simulator, it is possible to obtain the rest of the thermodynamic properties of the working fluid in the 2s state, including the specific enthalpy (h2s). However, in the real process, the irreversibility of the turbine must be taken into account. Based on specific enthalpies h1 and h2s and the isentropic efficiency of the turbine (see Equation (1)), the specific enthalpy in 2 can be calculated (h2). With the values of P2 and h2, the simulator provides the rest of the thermodynamic properties of state 2.

- State 3. The condensation temperature, T3, was established as explained in the previous subsection. As the working fluid is in a saturated liquid state, the vapour’s quality is 0 (x3 = 0 p.u.). Introducing the values of T3 and x3 in the simulator, it is possible to obtain the rest of the thermodynamic properties of state 3 (P3, h3, and s3).

- State 4. Working fluid heat absorption (Process 4-1) takes place through an isobaric process, and so the pressure in states 4 and 1 coincides (P4 = P1). In the ideal cycle, the compression process is isentropic, and so specific entropies are the same in states 3 and 4s (s3 = s4s). Introducing the values of P4 and s4s in the simulator, it is possible to obtain the rest of the thermodynamic properties of the working fluid in state 4s, including the specific enthalpy (h4s). However, in the real process, the isentropic efficiency of the process pump must be taken into account. Based on specific enthalpies h3 and h4s and the isentropic efficiency of the process pump (see Equation (2)), the specific enthalpy in state 4 can be calculated (h4). Introducing P4 and h4, the simulator can provide the rest of the thermodynamic properties in state 4.

2.3.4. Selection of the Working Fluid

2.3.5. Thermal Efficiency of the Thermodynamic Cycle

2.3.6. Law of Conservation of Energy

- : variation of the internal energy of the system (in kW);

- : amount of heat transferred to the system (in kW);

- : work carried out by the system (in kW);

- : mass flow rate (in kg/s);

- h: specific enthalpy (in kJ/kg).

- p: static pressure of the fluid (in Pa);

- ϱ: density of the fluid (in kg/m3);

- g: gravitational constant (9.81 m/s2);

- v: fluid flow velocity (in m/s);

- z: height with respect to a reference level (in m).

- : hydraulic losses (in bar);

- Q: flow rate (in l/min);

- Leq: equivalent pipe length (in m);

- C: constant that depends on the pipe material;

- d: internal diameter of the pipe (in mm).

2.3.7. Sizing of the Equipment

Production Pump P-101

- Hcolumn: manometric head of the geothermal water column (in mWC);

- Paquifer: hydrostatic pressure of the aquifer (in Pa);

- ϱgeo: density of the geothermal fluid (in kg/m3).

Reinjection Pump P-102

Preheater E-101 and Evaporator E-102

- : mass flow rate of the geothermal fluid (in kg/s);

- : specific heat of the geothermal fluid (in kJ/kg·°C);

- : mass flow rate of the working fluid (in kg/s).

Turbine ST-101

Heat Dissipation System

Process Pump P-104

2.3.8. Electrical Power Absorbed by Pumps and Fans

- : manometric head to be supplied by the pump (in mWC);

- : mass flow rate of the fluid that passes through the pump (in kg/s);

- : pump efficiency.

- : electrical power absorbed by the fan (in W);

- : mass flow of air that passes through the fan (in kg/s);

- : air density (in kg/m3);

- ΔPstatic: static pressure drop in the circuit (in Pa);

- ηfan: efficiency.

2.3.9. Net Power of the Geothermal Plant

2.3.10. Geothermal Generation

- EFLH: equivalent full load hours (in h/year);

- : electrical energy produced by the geothermal plant in a year (MWh/year);

- : net rated electrical power of the geothermal plant (in MW);

- CFgeo: capacity factor of the geothermal facility;

- t: total number of annual hours (8760 h/year).

2.4. Estimation of Wind Generation

- V: wind speed at hub height (in m/s);

- Vref: reference wind speed (in m/s);

- H: hub height (in m);

- Href: reference height (in m);

- n: roughness exponent.

2.5. Estimation of Photovoltaic Solar Generation

- EPSH: equivalent peak sun hours;

- G: hourly solar irradiance (in W/m2);

- Gmax: maximum solar irradiance (1000 W/m2).

- EPV: hourly photovoltaic productions (in kWh);

- PPV: installed photovoltaic power (in kW).

2.6. Energy Demand of the Desalination Plant

2.7. Energy Balance Study

2.8. Levelized Cost of Energy (LCOE) of the Diversified Renewable Generation System

- CAPEX: initial investment cost (in EUR);

- CRF: capital recovery factor;

- : annual operating and maintenance costs (in EUR/year);

- T: total number of hours in a year (in h).

- r: discount rate. A discount rate of 3% is considered a realistic value in stable macroeconomic situations;

- Lt: lifetime of the installation (in years). In this study, a useful life of 25 years was taken for the geothermal plant [54] and the photovoltaic plants and of 20 years for the wind farm.

- LCOEi: the mean levelized cost of renewable generation for instant “i” (in EUR/MWh);

- LCOEj: the mean levelized cost for renewable generation source “j” (geothermal, wind and photovoltaic);

- Eji: energy generated by renewable source “j” in instant “i” (in MWh).

- : the mean annual weighted cost for the diversified renewable generation system (in EUR/MWh);

- Ei: electrical energy generated in instant “i” by the diversified renewable generation system (in MWh).

3. Results and Discussion

3.1. Adapted Solution in the Design of the Geothermal Plant

3.1.1. Production Pump P-101

3.1.2. Reinjection Pump P-102

3.1.3. Preheater E-101 and Evaporator E-102

3.1.4. Turbine ST-101

3.1.5. Heat Dissipation System

- TDB: dry bulb temperature (in °C);

- RH: relative humidity (in %);

- TWB: wet bulb temperature (in °C);

- ω: humidity ratio (in kgw/kga);

- h: enthalpy at saturation (in kJ/kga);

- v: specific volume (in m3/kga).

3.1.6. Process Pump P-104

3.1.7. Net Electrical Power

3.2. Energy Balance

3.3. Economic Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| CF | Capacity factor |

| DSC | Degree of self-consumption. See Equation (29) |

| DSD | Degree of satisfied demand. See Equation (30) |

| EFLH | Equivalent full load hours. See Equation (23) |

| GWP | Global warming potential |

| LCOE | Levelized cost of energy |

| ODP | Ozone depletion potential |

| ORC | Organic Rankine cycle |

| RO | Reverse osmosis |

| SER | Surplus energy ratio. See Equation (31) |

| SWRO | Sea water reverse osmosis |

| h | Specific enthalpy (in kJ/kg) |

| H | Manometric head (in mWC) |

| Mass flow rate of the geothermal fluid (in kg/s) | |

| Mass flow rate of the working fluid (in kg/s) | |

| P | Pressure (in Pa or bar) |

| Net electrical power of the geothermal plant (in kW) | |

| RH | Relative humidity (in %) |

| s | Specific entropy (in kJ/kg·°C) |

| T | Temperature (in °C) |

| TDB | Dry bulb temperature (in °C) |

| TWB | Wet bulb temperature (in °C) |

| v | Specific volume (in m3/kga) |

| ω | Humidity ratio (in kgw/kga) |

| x | Steam quality (in p.u.) |

References

- European Parliament and of the Council. Directive (EU) 2018/2001 of the European Parliament and of the Council. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L2001 (accessed on 5 December 2022).

- Ministry for the Ecological Transition and the Demographic Challenge of the Government of Spain (MITECO). Energy and Climate National Integrated Plan (PNIEC) 2021–2030. 2020. Available online: https://www.miteco.gob.es/images/es/pnieccompleto_tcm30-508410.pdf (accessed on 5 December 2022). (In Spanish).

- Canary Government. Sustainable Energy Strategy in the Canary Islands. 2022. Available online: https://www.lamoncloa.gob.es/serviciosdeprensa/notasprensa/transicion-ecologica/Documents/2022/160222_EstrategiaSostenible_Canarias.pdf (accessed on 5 December 2022). (In Spanish).

- Spanish Electrical System Operator (REE). REData-Generation Structure in the Canary Islands. 2021. Available online: https://www.ree.es/es/datos/generacion/potencia-instalada (accessed on 5 December 2022). (In Spanish).

- Canary Government. Canary Islands Energy Strategy 2015–2025. 2017. Available online: https://www.gobiernodecanarias.org/energia/descargas/SDE/Portal/Planificacion/Planes/EECan25_DocumentoPreliminar_junio2017.pdf (accessed on 5 December 2022). (In Spanish).

- Canary Government. Canary Islands Dispatchable Generation Strategy (v1 edition). 2022. Available online: https://www3.gobiernodecanarias.org/ceic/energia/oecan/images/Documentos/Estudios/D4_Estrategia_Generaci%C3%B3n_Gestionable.pdf (accessed on 5 December 2022). (In Spanish).

- Geological and Mining Institute of Spain (IGME). Geothermal Energy in Spain. Available online: https://www.igme.es/geotermia/presentacion2.htm (accessed on 5 December 2022). (In Spanish).

- World Nuclear Association. Carbon Dioxide Emissions from Electricity. 2022. Available online: https://www.world-nuclear.org/ (accessed on 5 December 2022).

- Canary Islands Institute of Statistics (ISTAC). Population of the Canary Islands. 2021. Available online: https://www3.gobiernodecanarias.org/istac/statistical-visualizer/visualizer/data.html?resourceType=dataset&agencyId=ISTAC&resourceId=E30245A_000002&version=1.1#visualization/table (accessed on 5 December 2022). (In Spanish).

- Canary Government. Canary Islands Yearly Energy Report. 2020. Available online: https://www3.gobiernodecanarias.org/ceic/energia/oecan/files/Anuario_Energetico_de_Canarias_2020.pdf (accessed on 5 December 2022). (In Spanish).

- Torres-Herrera, H.J.; Lozano-Medina, A. Methodological Proposal for the Assessment Potential of Pumped Hydropower Energy Storage: Case of Gran Canaria Island. Energies 2021, 14, 3553. [Google Scholar] [CrossRef]

- Ministry for the Ecological Transition and the Demographic Challenge of the Government of Spain (MITECO). Hydrological Plans and Water Resources Monitoring Report-Appendix 1.17-Gran Canaria. 2021. Available online: https://www.miteco.gob.es/es/agua/temas/planificacion-hidrologica/17-gca_2021_tcm30-481576.pdf (accessed on 5 December 2022). (In Spanish).

- Borge-Diez, D.; García-Moya, F.J.; Cabrera-Santana, P.; Rosales-Asensio, E. Feasibility analysis of wind and solar powered desalination plants: An application to islands. Sci. Total Environ. 2021, 764, 142878. [Google Scholar] [CrossRef] [PubMed]

- Institute for Energy Diversification and Saving of the Government of Spain (IDAE). Prospective Study. Energy Consumption in the Water Sector. Available online: https://www.idae.es/uploads/documentos/documentos_Estudio_de_prospectiva_Consumo_Energetico_en_el_sector_del_agua_2010_020f8db6.pdf (accessed on 5 December 2022). (In Spanish).

- Canary Islands Institute of Technology (ITC). ITC Explores New Advanced Technological Developments in Seawater Desalination. 2022. Available online: https://www3.gobiernodecanarias.org/noticias/el-itc-explora-nuevos-desarrollos-tecnologicos-avanzados-en-desalacion-de-agua-de-mar/?format=pdf (accessed on 5 December 2022). (In Spanish).

- Canary Government. Renewable Energies in Hydraulic Infrastructures of Gran Canaria. Available online: https://www3.gobiernodecanarias.org/presidencia/fdcan/project/energias-renovables-en-infraestructuras-hidraulicas/ (accessed on 5 December 2022). (In Spanish).

- Schallenberg-Rodríguez, J.; Del Rio-Gamero, B.; Melian-Martel, N.; Lis Alecio, T.; González Herrera, J. Energy supply of a large size desalination plant using wave energy. Practical case: North of Gran Canaria. Appl. Energy 2020, 278, 115681. [Google Scholar] [CrossRef]

- Calise, F.; Dentice d’Accadia, M.; Macaluso, A.; Vanoli, L.; Piacentino, A. A novel solar-geothermal trigeneration system integrating water desalination: Design, dynamic simulation and economic assessment. Energy 2016, 115, 1533–1547. [Google Scholar] [CrossRef]

- Assareh, E.; Alirahmi, S.M.; Ahmadi, P. A Sustainable model for the integration of solar and geothermal energy boosted with thermoelectric generators (TEGs) for electricity, cooling and desalination purpose. Geothermics 2021, 92, 102042. [Google Scholar] [CrossRef]

- Zhang, L.; Sobhani, B. Comprehensive economic analysis and multi-objective optimization of an integrated power and freshwater generation cycle based on flash-binary geothermal and gas turbine cycles. J. Clean. Prod. 2022, 364, 132644. [Google Scholar] [CrossRef]

- Cao, Y.; Xu, D.; Togun, H.; Dhahad, H.; Azariyan, H.A.; Azariyan, H.; Farouk, N. Feasibility analysis and capability characterization of a novel hybrid flash-binary geothermal power plant and trigeneration system through a case study. Int. J. Hydrog. Energy 2021, 46, 26241–26262. [Google Scholar] [CrossRef]

- Kaczmarczyk, M.; Tomaszewska, B.; Bujakowski, W. Innovative desalination of geothermal wastewater supported by electricity generated from low-enthalpy geothermal resources. Desalination 2022, 524, 115450. [Google Scholar] [CrossRef]

- Kolahi, M.-R.; Amidpour, M.; Yari, M. Multi-objective metaheuristic optimization of combined flash-binary geothermal and humidification dehumidification desalination systems. Desalination 2020, 490, 114456. [Google Scholar] [CrossRef]

- Pietrasanta, A.M.; Mussati, S.F.; Aguirre, P.A.; Morosuk, T.; Mussati, M.C. Water-renewable energy Nexus: Optimization of geothermal energy-powered seawater desalination systems. Renew. Energy 2022, 196, 234–246. [Google Scholar] [CrossRef]

- Insular Water Council of Gran Canaria. Hydrological Plan of the Hydrographic Demarcation of Gran Canaria. 2021. Available online: http://www.aguasgrancanaria.com/pdfs/Inundaciones/01-ES120_PH_PPP-Memoria.pdf (accessed on 5 December 2022). (In Spanish).

- Agüimes City Hall. Southeast Plans to Produce Up to 40,000 m3 of Desalinated Water Per Day from Renewable Energy Sources. 2020. Available online: https://aguimes.es/el-sureste-proyecta-producir-hasta-40-000-m3-diarios-de-agua-desalada-a-partir-de-fuentes-de-energia-renovables/ (accessed on 5 December 2022). (In Spanish).

- Institute for Energy Diversification and Saving of the Government of Spain (IDAE). Evaluation of Geothermal Energy Potential. 2011. Available online: https://www.idae.es/uploads/documentos/documentos_11227_e9_geotermia_A_db72b0ac.pdf (accessed on 5 December 2022). (In Spanish).

- Santana-Sarmiento, F.; Velázquez-Medina, S. Development of a Territorial Planning Model of Wind and Photovoltaic Energy Plants for Self-Consumption as a Low Carbon Strategy. Complexity 2021, 2021, 6617745. [Google Scholar] [CrossRef]

- Loni, R.; Mahian, O.; Najafi, G.; Sahin, A.; Rajaee, F.; Kasaeian, A.; Mehrpooya, M.; Bellos, E.; Le Roux, W. A critical review of power generation using geothermal-driven organic Rankine cycle. Therm. Sci. Eng. Prog. 2021, 25, 101028. [Google Scholar] [CrossRef]

- Haghighi, A.; Pakatchian, M.; El Haj Assad, M.; Nguyen Duy, V.; Alhuyi Nazari, M. A review on geothermal Organic Rankine cycles: Modeling and optimization. J. Therm. Anal. Calorim. 2020, 144, 1799–1814. [Google Scholar] [CrossRef]

- Yan, J.; Jia, W.; Li, K.; Yu, H.; Guo, X. Energy analysis of cyclic parameters of organic Rankine cycle system. Int. J. Low-Carbon Technol. 2021, 16, 341–350. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, Q.; Yu, Z.; Yu, G. A non-structural fuzzy decision method developed for organic Rankine cycles used in liquid-dominated geothermal fields of medium/high temperature. Energy Convers. Manag. 2021, 231, 113861. [Google Scholar] [CrossRef]

- Canary Islands Institute of Technology (ITC). Geothermal Strategy in the Canary Islands. 2020. Available online: https://www3.gobiernodecanarias.org/ceic/energia/oecan/images/Documentos/Estudios/D5_Estrategia_Geotermia_Canarias.pdf (accessed on 5 December 2022). (In Spanish).

- Tureyen, O.I.; Sarak, H.; Gulgor, A.; Erkan, B.; Satman, A. A Study on the Production and Reservoir Performance of the Germencik Geothermal Field. In Proceedings of the Thirty-Ninth Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 24 February 2014. [Google Scholar]

- Champel, B. Discrepancies in brine density databases at geothermal conditions. Geothermics 2006, 35, 600–606. [Google Scholar] [CrossRef]

- Ministry of Development of the Government of Spain. DA DB-HE/2: Verification of Limitation of Superficial and Interstitial Condensations in the Enclosures. 2013. Available online: https://www.cgate.es/hit/Hit2016-2/DA-DB-HE-2_-_Condensaciones.pdf (accessed on 5 December 2022). (In Spanish).

- University of Zaragoza. TermoGraf. Available online: http://termograf.unizar.es/ (accessed on 5 December 2022). (In Spanish).

- DiPippo, R. Geothermal Power Plants: Principles, Applications, Case Studies and Environmental Impact, 3rd ed.; Butterworth-Heinemann (Elsevier): Oxford, UK, 2012. [Google Scholar]

- Wang, X.; Levy, E.K.; Pan, C.; Romero, C.E.; Banerjee, A.; Rubio-Maya, C.; Pan, L. Working fluid selection for organic Rankine cycle power generation using hot produced supercritical CO2 from a geothermal reservoir. Appl. Therm. Eng. 2019, 149, 1287–1304. [Google Scholar] [CrossRef]

- Perry, R.H.; Green, D.W.; Maloney, J.O. Perry’s Chemical Engineers’ Handbook, 7th ed.; McGraw-Hill: New York, NY, USA, 1997. [Google Scholar]

- Process Engineer’s Tools. Shell-Tube Heat Exchanger: Pressure Drop in the Tubes. Available online: https://powderprocess.net/Tools_html/Thermodynamics/Shell_Tube_Pressure_Drop_Tube_Side.html (accessed on 5 December 2022).

- Serth, R.W. Process Heat Transfer. In Principles and Applications, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Pinedo-Mines, C.; Ramírez-Pintado, E. Analysis and Evaluation of the Geothermal Potential for Its Use through a Binary Cycle Plant for the Generation of Electrical Power in the Corongo-Ancash Region, Peru. 2015. Available online: http://repositorio.uns.edu.pe/handle/UNS/2001 (accessed on 5 December 2022). (In Spanish).

- Khaireh, A. Cooling System Design for a Binary Power Plant in North-Goubhet Field, Djibouti. Geothermal Training Programme. Reykjavik. 2012. Available online: https://orkustofnun.is/gogn/unu-gtp-report/UNU-GTP-2012-18.pdf (accessed on 5 December 2022).

- Song, J.; Chen, J.; Wu, Y.; Li, L. Topology Optimization-Driven Design for Offshore Composite Wind Turbine Blades. J. Mar. Sci. Eng. 2022, 10, 1487. [Google Scholar] [CrossRef]

- Sánchez-Ramírez, J. Self-Consumption Wind Farm Associated with the Water Cycle of the Southeast Consortium of Municipalities of Gran Canaria. 2021. Available online: https://www.surestegc.org/ (accessed on 5 December 2022). (In Spanish).

- Enercon. Technical Data of Enercon Wind Turbines. Available online: https://www.enercon.de/en/products/ (accessed on 5 December 2022).

- Canary Islands Institute of Technology (ITC). Available online: https://www.itccanarias.org/web/es/ (accessed on 5 December 2022). (In Spanish).

- Saint-Drenan, Y.-M.; Besseau, R.; Jansen, M.; Staffell, I.; Troccoli, A.; Dubus, L.; Schmidt, J.; Gruber, K.; Simões, S.G.; Heier, S. A parametric model for wind turbine power curves incorporating environmental conditions. Renew. Energy 2020, 157, 754–768. [Google Scholar] [CrossRef]

- Danish Wind Industry Asociation. Roughness Classes and Roughness Lengths. Available online: www.windpower.org (accessed on 5 December 2022).

- Sánchez-Ramírez, J. Implementation of Renewable Energies for the Water Cycle of the Southeast Consortium of Municipalities of Gran Canaria. Installation of a Photovoltaic Plant at IDAM Phase III and IV. 2021. Available online: https://www.surestegc.org/ (accessed on 5 December 2022). (In Spanish).

- Photovoltaic Geographical Information System (PVGIS). 2022. Available online: https://joint-research-centre.ec.europa.eu/pvgis-photovoltaic-geographical-information-system_en (accessed on 5 December 2022).

- Roams Energy. 6.1 TD Tariff. 2022. Available online: https://energia.roams.es/luz/tarifa/6-1/ (accessed on 5 December 2022). (In Spanish).

- International Renewable Energy Agency (IRENA). Geothermal Power: Technology Brief. 2017. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2017/Aug/IRENA_Geothermal_Power_2017.pdf (accessed on 5 December 2022).

- Polytechnic University of Catalonia. Pipe Calculation Bases. Available online: https://upcommons.upc.edu/bitstream/handle/2099.1/17145/ANEXO?sequence=7 (accessed on 5 December 2022). (In Spanish).

- Sulzer. SJT Vertical Turbine Pump. 2015. Available online: https://www.sulzer.com/spain/-/media/files/products/pumps/vertical-pumps/brochures/sjt_vertical_turbine_pump_e10004.pdf?la=en (accessed on 5 December 2022).

- Sulzer. OHH and OHHL ISO 13709 (API 610) Type OH2 Single Stage end Suction Process Pumps. 2015. Available online: https://www.sulzer.com/-/media/files/products/pumps/single-stage-pumps/brochures/ohh_ohhl_singlestageendsuctionprocesspumps_e00697.pdf?la=en (accessed on 5 December 2022).

- Siemens Energy. Dresser-Rand Steam Turbines. 2022. Available online: https://www.siemens-energy.com/global/en/offerings/power-generation/steam-turbines/d-r-steam-turbines.html (accessed on 5 December 2022).

- Torraval. MCC-MCE-HBR: Evaporative Coolers and Condensers. Available online: www.torraval.com (accessed on 5 December 2022). (In Spanish).

- Parra-Sanchez, R. Technical-Economic Study of the Industrial Implementation of a Cooling Tower. 2018. Available online: https://oa.upm.es/52155/1/PFC_RAQUEL_PARRA_SANCHEZ.pdf (accessed on 5 December 2022). (In Spanish).

- KSB. Characteristic Curves Booklet. 2018. Available online: https://www.ksb.com/en-global (accessed on 5 December 2022).

- Spirax-Sarco Engineering. Technical Reference Guide-Steam Distribution. Available online: https://www.fnmt.es/documents/10179/10666378/Distribucion+del+vapor.pdf/fca09a6d-70ab-da86-5d9d-f19321638315#:~:text=La%20velocidad%20del%20vapor%20m%C3%A1xima%20aceptable%20es%20de%2025%20m%2Fs (accessed on 5 December 2022). (In Spanish).

- Institute for Energy Diversification and Saving of the Government of Spain (IDAE). Renewable Energies Plan 2011–2020. 2011. Available online: https://www.idae.es/uploads/documentos/documentos_11227_PER_2011-2020_def_93c624ab.pdf (accessed on 5 December 2022). (In Spanish).

- Stamford, A.v.K. DIG156 Alternator. Available online: https://www.stamford-avk.com/es/alternators/avk/dig156 (accessed on 5 December 2022). (In Spanish).

- International Renewable Energy Agency (IRENA). Renewable Power Generation Costs in 2021. 2022. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2022/Jul/IRENA_Power_Generation_Costs_2021.pdf?rev=34c22a4b244d434da0accde7de7c73d8 (accessed on 5 December 2022).

| Equipment | Energy Balance Equation | Equation |

|---|---|---|

| E-101 | (8) | |

| E-102 | (9) | |

| ST-101 | (10) | |

| E-103 | (11) | |

| P-104 | (12) |

| Mass or Energy Balance Equation | Equation |

|---|---|

| (15) | |

| (16) | |

| (17) |

| Height (m agl) | 20 | 60 | 80 |

|---|---|---|---|

| January | 4.48 | 5.03 | 5.19 |

| February | 5.44 | 5.98 | 6.13 |

| March | 4.87 | 5.39 | 5.53 |

| April | 8.41 | 8.87 | 8.99 |

| May | 8.70 | 9.13 | 9.25 |

| June | 8.93 | 9.34 | 9.46 |

| July | 10.94 | 11.25 | 11.33 |

| August | 10.00 | 10.40 | 10.51 |

| September | 8.65 | 9.12 | 9.25 |

| October | 4.92 | 5.44 | 5.58 |

| November | 6.35 | 6.84 | 6.97 |

| December | 4.54 | 5.09 | 5.24 |

| Photovoltaic Plant | UTMX | UTMY |

|---|---|---|

| PV-1 | 458,042.7 | 3,076,671.3 |

| PV-2 | 460,035.6 | 3,080,652.4 |

| Month | 7 h | 8 h | 9 h | 10 h | 11 h | 12 h | 13 h | 14 h | 15 h | 16 h | 17 h | 18 h | 19 h |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| January | 0 | 23 | 255 | 458 | 624 | 749 | 779 | 761 | 654 | 496 | 285 | 44 | 0 |

| February | 0 | 75 | 297 | 505 | 690 | 813 | 859 | 840 | 745 | 573 | 361 | 133 | 0 |

| March | 0 | 159 | 389 | 615 | 809 | 901 | 952 | 922 | 799 | 619 | 406 | 178 | 1 |

| April | 42 | 241 | 470 | 682 | 852 | 948 | 964 | 903 | 800 | 628 | 420 | 193 | 14 |

| May | 83 | 278 | 501 | 703 | 871 | 952 | 961 | 914 | 802 | 632 | 426 | 210 | 34 |

| June | 88 | 280 | 487 | 694 | 853 | 950 | 961 | 919 | 817 | 650 | 446 | 235 | 53 |

| July | 70 | 259 | 474 | 686 | 851 | 965 | 1000 | 961 | 860 | 689 | 473 | 250 | 64 |

| August | 46 | 237 | 461 | 681 | 850 | 964 | 1000 | 959 | 844 | 671 | 453 | 222 | 35 |

| September | 25 | 225 | 455 | 672 | 833 | 943 | 952 | 875 | 767 | 577 | 363 | 140 | 1 |

| October | 1 | 205 | 421 | 633 | 787 | 870 | 871 | 794 | 659 | 478 | 265 | 47 | 0 |

| November | 0 | 132 | 339 | 543 | 693 | 791 | 818 | 740 | 602 | 428 | 209 | 0 | 0 |

| December | 0 | 58 | 278 | 480 | 631 | 737 | 765 | 727 | 617 | 436 | 222 | 0 | 0 |

| Month | 7 h | 8 h | 9 h | 10 h | 11 h | 12 h | 13 h | 14 h | 15 h | 16 h | 17 h | 18 h | 19 h |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| January | 0 | 21 | 254 | 459 | 621 | 739 | 761 | 749 | 640 | 490 | 283 | 41 | 0 |

| February | 0 | 73 | 298 | 503 | 682 | 798 | 838 | 817 | 721 | 562 | 354 | 131 | 0 |

| March | 0 | 159 | 388 | 610 | 796 | 874 | 924 | 881 | 774 | 607 | 401 | 175 | 1 |

| April | 42 | 242 | 467 | 675 | 836 | 919 | 933 | 882 | 777 | 613 | 411 | 193 | 14 |

| May | 84 | 280 | 502 | 693 | 846 | 929 | 941 | 889 | 789 | 625 | 423 | 208 | 34 |

| June | 88 | 280 | 490 | 691 | 848 | 942 | 960 | 918 | 810 | 652 | 448 | 235 | 53 |

| July | 70 | 260 | 478 | 685 | 854 | 964 | 1000 | 964 | 862 | 691 | 478 | 252 | 64 |

| August | 46 | 239 | 466 | 681 | 848 | 966 | 1000 | 959 | 850 | 673 | 455 | 223 | 35 |

| September | 26 | 225 | 451 | 669 | 821 | 920 | 933 | 861 | 759 | 574 | 361 | 141 | 1 |

| October | 1 | 206 | 422 | 624 | 778 | 847 | 848 | 762 | 641 | 469 | 261 | 46 | 0 |

| November | 0 | 130 | 341 | 530 | 684 | 768 | 800 | 723 | 591 | 423 | 207 | 0 | 0 |

| December | 0 | 56 | 280 | 478 | 630 | 732 | 764 | 712 | 598 | 428 | 220 | 0 | 0 |

| Period | 0 h | 1 h | 2 h | 3 h | 4 h | 5 h | 6 h | 7 h | 8 h | 9 h | 10 h | 11 h |

| Winter | 9028.3 | 9028.3 | 9028.3 | 9028.3 | 9028.3 | 9028.3 | 9028.3 | 9028.3 | 5097.0 | 5097.0 | 2130.0 | 2130.0 |

| Summer | 9299.3 | 9299.3 | 9299.3 | 9299.3 | 9299.3 | 9299.3 | 9299.3 | 9299.3 | 6140.0 | 6140.0 | 2286.4 | 2286.4 |

| Period | 12 h | 13 h | 14 h | 15 h | 16 h | 17 h | 18 h | 19 h | 20 h | 21 h | 22 h | 23 h |

| Winter | 2130.0 | 2130.0 | 2130.0 | 5097.0 | 5097.0 | 5097.0 | 2130.0 | 2130.0 | 2130.0 | 2130.0 | 5097.0 | 5097.0 |

| Summer | 2286.4 | 2286.4 | 2286.4 | 6140.0 | 6140.0 | 6140.0 | 2286.4 | 2286.4 | 2286.4 | 2286.4 | 6140.0 | 6140.0 |

| State | T (°C) | P (bar) | h (kJ/kg) | s (kJ/kg·°C) |

|---|---|---|---|---|

| 1 | 95.00 | 5.27 | 590.19 | 1.76 |

| 2 | 52.23 | 0.69 | 526.55 | 1.79 |

| 3 | 25.00 | 0.69 | 114.41 | 0.42 |

| 4 | 25.20 | 5.27 | 115.34 | 0.42 |

| 5 | 95.00 | 5.27 | 287.90 | 0.94 |

| Parameter | State 9 | State 10 |

|---|---|---|

| TDB | 20.48 | 34.00 |

| RH | 67.33 | 95.00 |

| TWB | 16.49 | 33.24 |

| 0.0101 | 0.033 | |

| h | 46.30 | 117.92 |

| 0.84 | 0.92 |

| Energy Indicator | Without Geothermal Energy | With Geothermal Energy |

|---|---|---|

| Self-consumed energy (MWh/year) | 20,771.43 | 39,029.69 |

| Energy surplus (MWh/year) | 10,066.88 | 13,451.81 |

| Energy deficit (MWh/year) | 28,663.71 | 10,405.45 |

| DSC | 67.4% | 74.4% |

| DSD | 42% | 79% |

| SER | 32.6% | 25.6% |

| Geothermal Plant | Wind Farm | Photovoltaic Plants |

|---|---|---|

| 85.17 | 38.19 | 32.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montesdeoca-Martínez, F.; Velázquez-Medina, S. Integration of a Geothermal Plant in a System with High Renewable Energy Penetration for Desalination Plant Self-Consumption. J. Mar. Sci. Eng. 2023, 11, 353. https://doi.org/10.3390/jmse11020353

Montesdeoca-Martínez F, Velázquez-Medina S. Integration of a Geothermal Plant in a System with High Renewable Energy Penetration for Desalination Plant Self-Consumption. Journal of Marine Science and Engineering. 2023; 11(2):353. https://doi.org/10.3390/jmse11020353

Chicago/Turabian StyleMontesdeoca-Martínez, Fernando, and Sergio Velázquez-Medina. 2023. "Integration of a Geothermal Plant in a System with High Renewable Energy Penetration for Desalination Plant Self-Consumption" Journal of Marine Science and Engineering 11, no. 2: 353. https://doi.org/10.3390/jmse11020353