Influence of Conventional Shot Peening Treatment on the Service Life Improvement of Bridge Steel Piles Subjected to Sea Wave Impact

Abstract

:1. Introduction

2. Methodology

3. Experimental Work

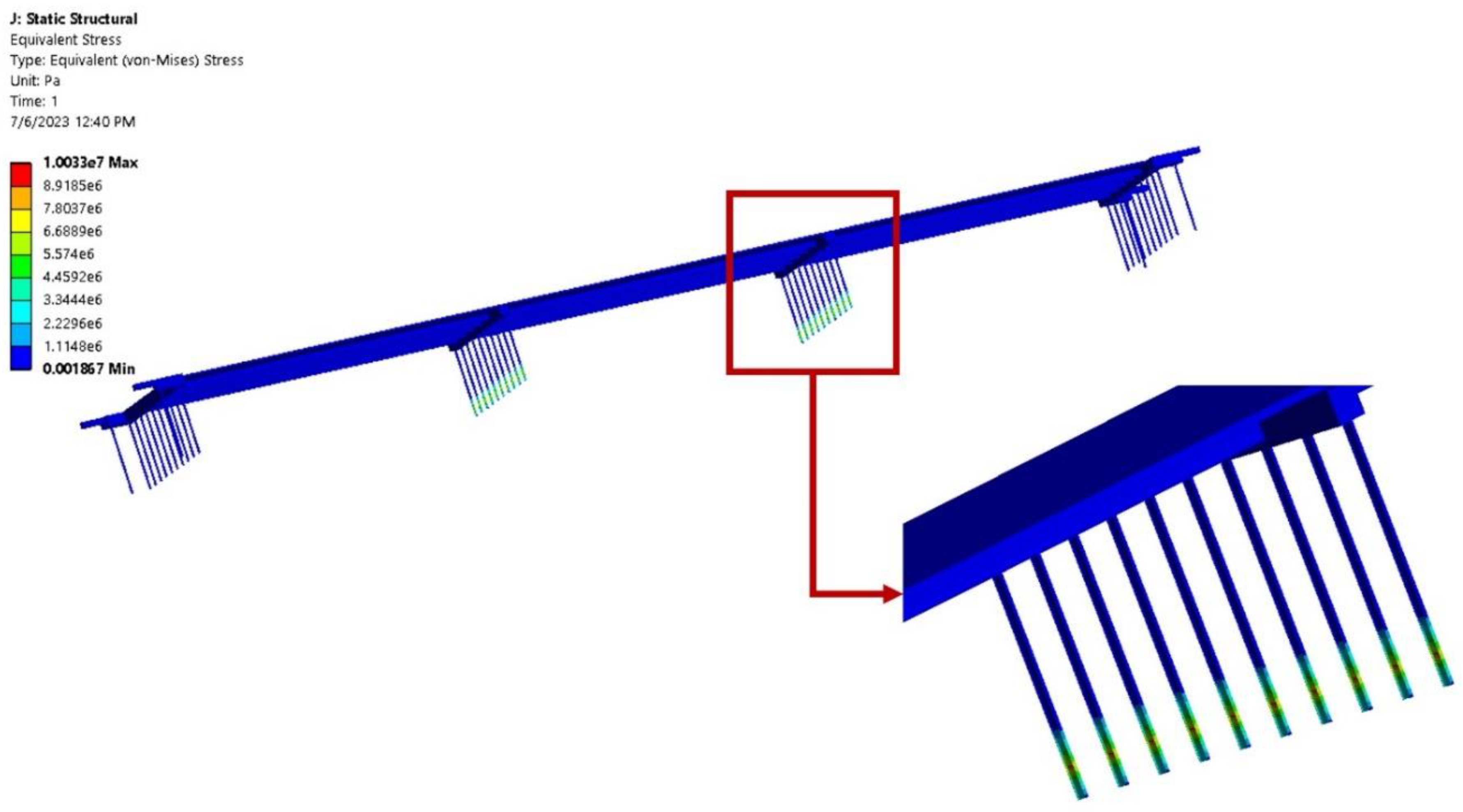

4. Finite Element Analysis

5. Results and Discussion

6. Conclusions

- Ignoring temperature variations throughout the year, the temperature difference between water and air is not large enough to cause severe temperature gradients in the system. Therefore, it does not cause any damage to the structure.

- The maximum stress applied to the steel piles of the bridge due to the pressure of motionless water is about 10 MPa, and this value is much less than can damage the bridge. This load is constant and does not affect the fatigue phenomenon on its own.

- The area prone to failure in the bridge is the steel piles installed in the water, in other words, the middle piles. In this case study, it was shown that row N3 is the most critical part. Within this, S28 steel pile gets the most damage. Moreover, this damage occurs in the height range between the floor and 150 cm.

- Fatigue analysis results show that the life of the S28 steel pile due to impact of sea waves is about 39 years, and this value reaches 47 years when using surface shot peening treatment.

- In the finite element simulation, the modified S-N curve obtained from the experimental tests was used as the definition of the shot peening effect. Finally, the FE results reveal that this treatment could increase the fatigue life of steel piles subjected to sea wave impact by 22%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdollahnia, H.; Alizadeh Elizei, M.H.; Reza Kashyzadeh, K. Application of Probabilistic Approach to Investigate Influence of Details in Time History of Temperature Changes on the HCF Life of Integrated Bridge Steel Piles Installed on Water. J. Mar. Sci. Eng. 2022, 10, 1802. [Google Scholar] [CrossRef]

- Karalar, M.; Dicleli, M. Effect of thermal induced flexural strain cycles on the low cycle fatigue performance of integral bridge steel H-piles. Eng. Struct. 2016, 124, 388–404. [Google Scholar] [CrossRef]

- Ng, K.W.; Garder, J.; Sritharan, S. Investigation of ultra high performance concrete piles for integral abutment bridges. Eng. Struct. 2015, 105, 220–230. [Google Scholar] [CrossRef] [Green Version]

- Abdollahnia, H.; Elizei, M.H.A.; Kashyzadeh, K.R. Low-cycle fatigue behavior of H-shaped steel piles of an integral concrete bridge subjected to temperature variations. Mater. Today Proc. 2021, 46, 1657–1662. [Google Scholar] [CrossRef]

- Amiri, N.; Shaterabadi, M.; Reza Kashyzadeh, K.; Chizari, M. A comprehensive review on design, monitoring, and failure in fixed offshore platforms. J. Mar. Sci. Eng. 2021, 9, 1349. [Google Scholar] [CrossRef]

- Fahmi, A.T.W.K.; Kashyzadeh, K.R.; Ghorbani, S. A comprehensive review on mechanical failures cause vibration in the gas turbine of combined cycle power plants. Eng. Fail. Anal. 2022, 134, 106094. [Google Scholar] [CrossRef]

- Reza Kashyzadeh, K.; Amiri, N.; Maleki, E.; Unal, O. A Critical Review on Improving the Fatigue Life and Corrosion Properties of Magnesium Alloys via the Technique of Adding Different Elements. J. Mar. Sci. Eng. 2023, 11, 527. [Google Scholar] [CrossRef]

- Razmi, J.; Ladani, L.; Aggour, M.S. Fatigue life of piles in integral-abutment bridges: Case study. J. Bridge Eng. 2013, 18, 1105–1117. [Google Scholar] [CrossRef]

- Petursson, H.; Möller, M.; Collin, P. Low-cycle fatigue strength of steel piles under bending. Struct. Eng. Int. 2013, 23, 278–284. [Google Scholar] [CrossRef]

- Karalar, M.; Dicleli, M. Effect of pile orientation on the fatigue performance of jointless bridge H-piles subjected to cyclic flexural strains. Eng. Struct. 2023, 276, 115385. [Google Scholar] [CrossRef]

- Razmi, J.; Ladani, L.; Aggour, M.S. Fatigue crack initiation and propagation in piles of integral abutment bridges. Comput.-Aided Civ. Infrastruct. Eng. 2013, 28, 389–402. [Google Scholar] [CrossRef]

- Saberi, M.R.; Rahai, A.R.; Sanayei, M.; Vogel, R.M. Bridge fatigue service-life estimation using operational strain measurements. J. Bridge Eng. 2016, 21, 04016005. [Google Scholar] [CrossRef]

- Wu, T.; Qiu, W. Fatigue life prediction of pile-supported sea-crossing bridges subject to random ice forces. J. Constr. Steel Res. 2022, 190, 107156. [Google Scholar] [CrossRef]

- Kashyzadeh, K.R. A new algorithm for fatigue life assessment of automotive safety components based on the probabilistic approach: The case of the steering knuckle. Eng. Sci. Technol. Int. J. 2020, 23, 392–404. [Google Scholar] [CrossRef]

- Reza Kashyzadeh, K.; Ostad-Ahmad Ghorabi, M.J.; Arghavan, A. Fatigue life prediction of package of suspension automotive under random vibration based on road roughness. Med. J. Model. Simul. 2015, 4, 050. [Google Scholar]

- Abdollahnia, H.; Alizadeh Elizei, M.H.; Reza Kashyzadeh, K. Multiaxial fatigue life assessment of integral concrete bridge with a real-scale and complicated geometry due to the simultaneous effects of temperature variations and sea waves clash. J. Mar. Sci. Eng. 2021, 9, 1433. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Seyedi Sahebari, S.M.; Reza Kashyzadeh, K. A Novel Approach for Analyzing the Effects of Almen Intensity on the Residual Stress and Hardness of Shot-Peened (TiB + TiC)/Ti–6Al–4V Composite: Deep Learning. Materials 2023, 16, 4693. [Google Scholar] [CrossRef]

- Songsong, S.; Xiaolin, G. The HCF property research of quenched crankshaft based on the stress field intensity method and the multi-physic field Coupling Numerical simulation approach. Int. J. Fract. 2023. [Google Scholar] [CrossRef]

- Schubnell, J.; Carl, E.; Widerspan, V.; Collmann, M. Determination of Loading and Residual Stresses on Offshore Jacket Structures by X-ray Diffraction. J. Mar. Sci. Eng. 2023, 11, 1304. [Google Scholar] [CrossRef]

- Reza Kashyzadeh, K.; Farrahi, G.H.; Ahmadi, A.; Minaei, M.; Ostad Rahimi, M.; Barforoushan, S. Fatigue life analysis in the residual stress field due to resistance spot welding process considering different sheet thicknesses and dissimilar electrode geometries. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, 237, 33–51. [Google Scholar] [CrossRef]

- Mahmoudi, A.H.; Ghasemi, A.; Farrahi, G.H.; Sherafatnia, K. A comprehensive experimental and numerical study on redistribution of residual stresses by shot peening. Mater. Des. 2016, 90, 478–487. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Guagliano, M.; Bagherifard, S. The effects of shot peening, laser shock peening and ultrasonic nanocrystal surface modification on the fatigue strength of Inconel 718. Mater. Sci. Eng. A 2021, 810, 141029. [Google Scholar] [CrossRef]

- Amanov, A.; Karimbaev, R.; Maleki, E.; Unal, O.; Pyun, Y.S.; Amanov, T. Effect of combined shot peening and ultrasonic nanocrystal surface modification processes on the fatigue performance of AISI 304. Surf. Coat. Technol. 2019, 358, 695–705. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Kashyzadeh, K.R. Effects of conventional, severe, over, and re-shot peening processes on the fatigue behavior of mild carbon steel. Surf. Coat. Technol. 2018, 344, 62–74. [Google Scholar] [CrossRef]

- Qin, Z.; Li, B.; Chen, T.; Chen, C.; Chen, R.; Ma, H.; Xue, H. Comparative study of the effects of conventional shot peening and ultrasonic shot peening on very high cycle fatigue properties of GH4169 superalloy. Int. J. Fatigue 2023, 175, 107799. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Unal, O.; Jam, A.; Shao, S.; Guagliano, M.; Shamsaei, N. Superior effects of hybrid laser shock peening and ultrasonic nanocrystalline surface modification on fatigue behavior of additive manufactured AlSi10Mg. Surf. Coat. Technol. 2023, 463, 129512. [Google Scholar] [CrossRef]

- Farrahi, G.H.; Lebrijn, J.L.; Couratin, D. Effect of shot peening on residual stress and fatigue life of a spring steel. Fatigue Fract. Eng. Mater. Struct. 1995, 18, 211–220. [Google Scholar] [CrossRef]

- Bagherifard, S.; Fernandez-Pariente, I.; Ghelichi, R.; Guagliano, M. Effect of severe shot peening on microstructure and fatigue strength of cast iron. Int. J. Fatigue 2014, 65, 64–70. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Kashyzadeh, K.R. Fatigue behavior prediction and analysis of shot peened mild carbon steels. Int. J. Fatigue 2018, 116, 48–67. [Google Scholar] [CrossRef]

- Abdollahnia, H.; Alizadeh Elizei, M.H.; Reza Kashyzadeh, K. Fatigue life assessment of integral concrete bridges with H cross-section steel piles mounted in water. J. Fail. Anal. Prev. 2020, 20, 1661–1672. [Google Scholar] [CrossRef]

- ASTM E466-15; Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2015.

- Maleki, E.; Farrahi, G.H.; Reza Kashyzadeh, K.; Unal, O.; Gugaliano, M.; Bagherifard, S. Effects of conventional and severe shot peening on residual stress and fatigue strength of steel AISI 1060 and residual stress relaxation due to fatigue loading: Experimental and numerical simulation. Met. Mater. Int. 2021, 27, 2575–2591. [Google Scholar] [CrossRef]

- Kashyzadeh, K.R.; Arghavan, A. Study of the effect of different industrial coating with microscale thickness on the CK45 steel by experimental and finite element methods. Strength Mater. 2013, 45, 748–757. [Google Scholar] [CrossRef]

- Arghavan, A.; Reza Kashyzadeh, K.; Asfarjani, A.A. Investigating effect of industrial coatings on fatigue damage. Appl. Mech. Mater. 2011, 87, 230–237. [Google Scholar] [CrossRef]

- Farrahi, G.H.; Kashyzadeh, K.R.; Minaei, M.; Sharifpour, A.; Riazi, S. Analysis of resistance spot welding process parameters effect on the weld quality of three-steel sheets used in automotive industry: Experimental and finite element simulation. Int. J. Eng. 2020, 33, 148–157. [Google Scholar] [CrossRef]

| |||||||||||||||

| Symbol | h | B | S | t | r | c | h-2c | A | G | ||||||

| Unit | mm | mm | mm | mm | mm | mm | mm | cm2 | kg/m | cm4 | cm3 | cm | cm4 | cm3 | cm |

| Value | 220 | 110 | 5.9 | 9.2 | 12 | 21.2 | 177 | 33.4 | 26.2 | 2770 | 252 | 9.11 | 205 | 37.3 | 2.48 |

| Parameter | Unit | Value | |

|---|---|---|---|

| St52 | Ordinary Concrete | ||

| Density | 7850 | 2300 | |

| Young Modulus | GPa | 200 | 30 |

| Poisson’s Ratio | --- | 0.3 | 0.18 |

| Bulk Modulus | GPa | 166 | --- |

| Shear Modulus | GPa | 76.92 | --- |

| Tensile Yield Stress | MPa | 250 | --- |

| Compressive Yield Stress | MPa | 250 | --- |

| Tensile Ultimate Strength | MPa | 460 | 5 |

| Compression Ultimate Strength | MPa | --- | 41 |

| Analysis No. | Element Size (m) | Number of Elements | Maximum Deformation (mm) | Difference Compared to the First State | ||||

|---|---|---|---|---|---|---|---|---|

| Deck | Wall | Rib | IPE-600 | IPE-220 | ||||

| 1 | 0.5 | 0.1 | 0.1 | 0.1 | 0.1 | 327,612 | 0.0016380 | --------- |

| 2 | 0.5 | 0.2 | 0.2 | 0.2 | 0.2 | 207,104 | 0.0016456 | 0.46 |

| 3 | 1 | 0.5 | 0.2 | 0.2 | 0.2 | 121,655 | 0.0016348 | 0.19 |

| 4 | 1 | 0.5 | 0.5 | 0.5 | 0.5 | 18,643 | 0.0016262 | 0.72 |

| 5 | 2 | 0.5 | 0.5 | 0.5 | 0.5 | 17,873 | 0.0016566 | 1.13 |

| 6 | 2 | 0.5 | 0.5 | 0.8 | 0.8 | 10,623 | 0.0016573 | 1.18 |

| 7 | 2 | 0.5 | 0.5 | 1 | 1 | 8868 | 0.0016515 | 0.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reza Kashyzadeh, K.; Chizari, M. Influence of Conventional Shot Peening Treatment on the Service Life Improvement of Bridge Steel Piles Subjected to Sea Wave Impact. J. Mar. Sci. Eng. 2023, 11, 1570. https://doi.org/10.3390/jmse11081570

Reza Kashyzadeh K, Chizari M. Influence of Conventional Shot Peening Treatment on the Service Life Improvement of Bridge Steel Piles Subjected to Sea Wave Impact. Journal of Marine Science and Engineering. 2023; 11(8):1570. https://doi.org/10.3390/jmse11081570

Chicago/Turabian StyleReza Kashyzadeh, Kazem, and Mahmoud Chizari. 2023. "Influence of Conventional Shot Peening Treatment on the Service Life Improvement of Bridge Steel Piles Subjected to Sea Wave Impact" Journal of Marine Science and Engineering 11, no. 8: 1570. https://doi.org/10.3390/jmse11081570

APA StyleReza Kashyzadeh, K., & Chizari, M. (2023). Influence of Conventional Shot Peening Treatment on the Service Life Improvement of Bridge Steel Piles Subjected to Sea Wave Impact. Journal of Marine Science and Engineering, 11(8), 1570. https://doi.org/10.3390/jmse11081570