Characterization of Abrasive Grain Signal of Oil Detection Sensor Based on LC Resonance Wireless Transmission

Abstract

:1. Introduction

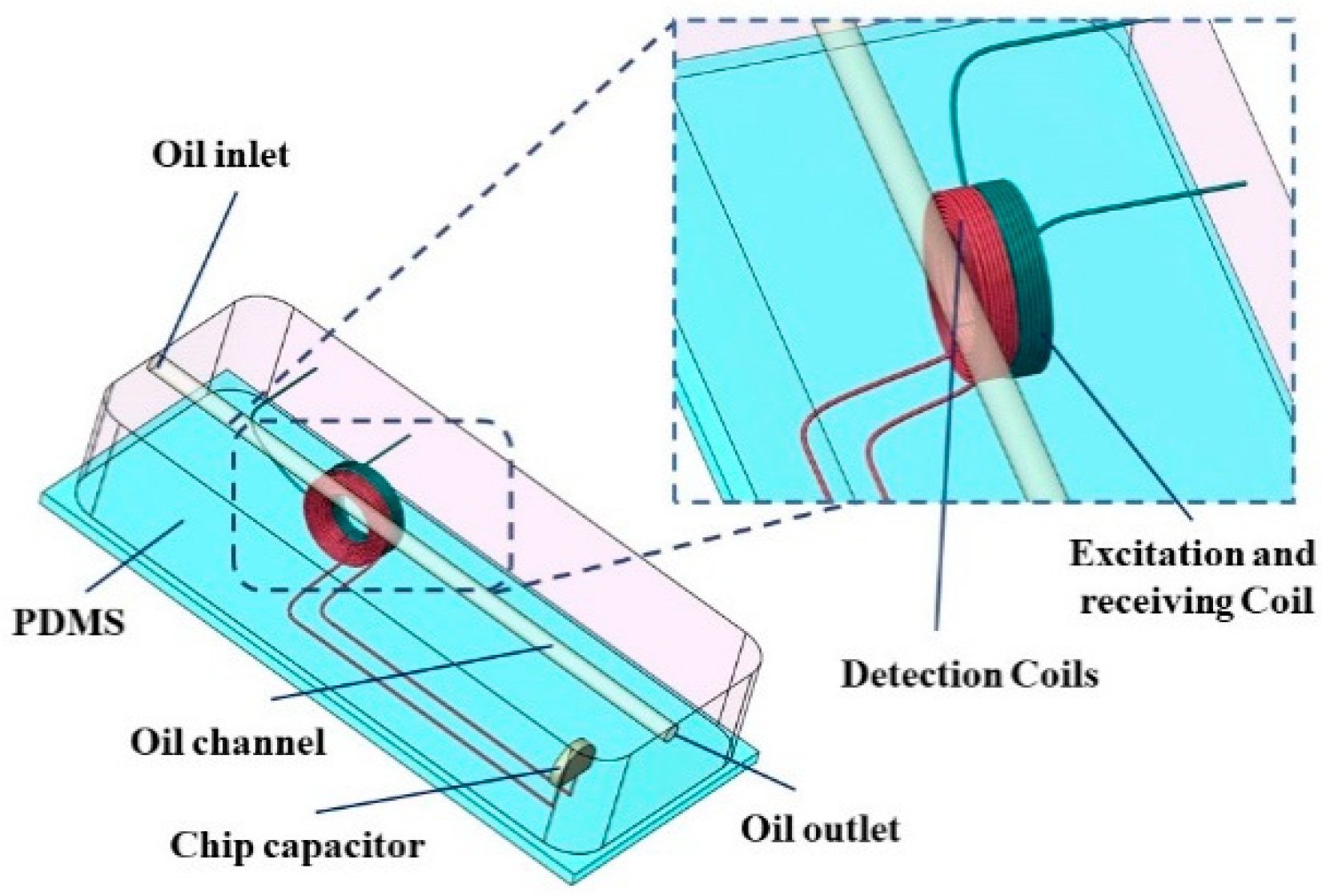

2. Sensor Design and Principle

2.1. Sensor Design

2.2. Detection Principle

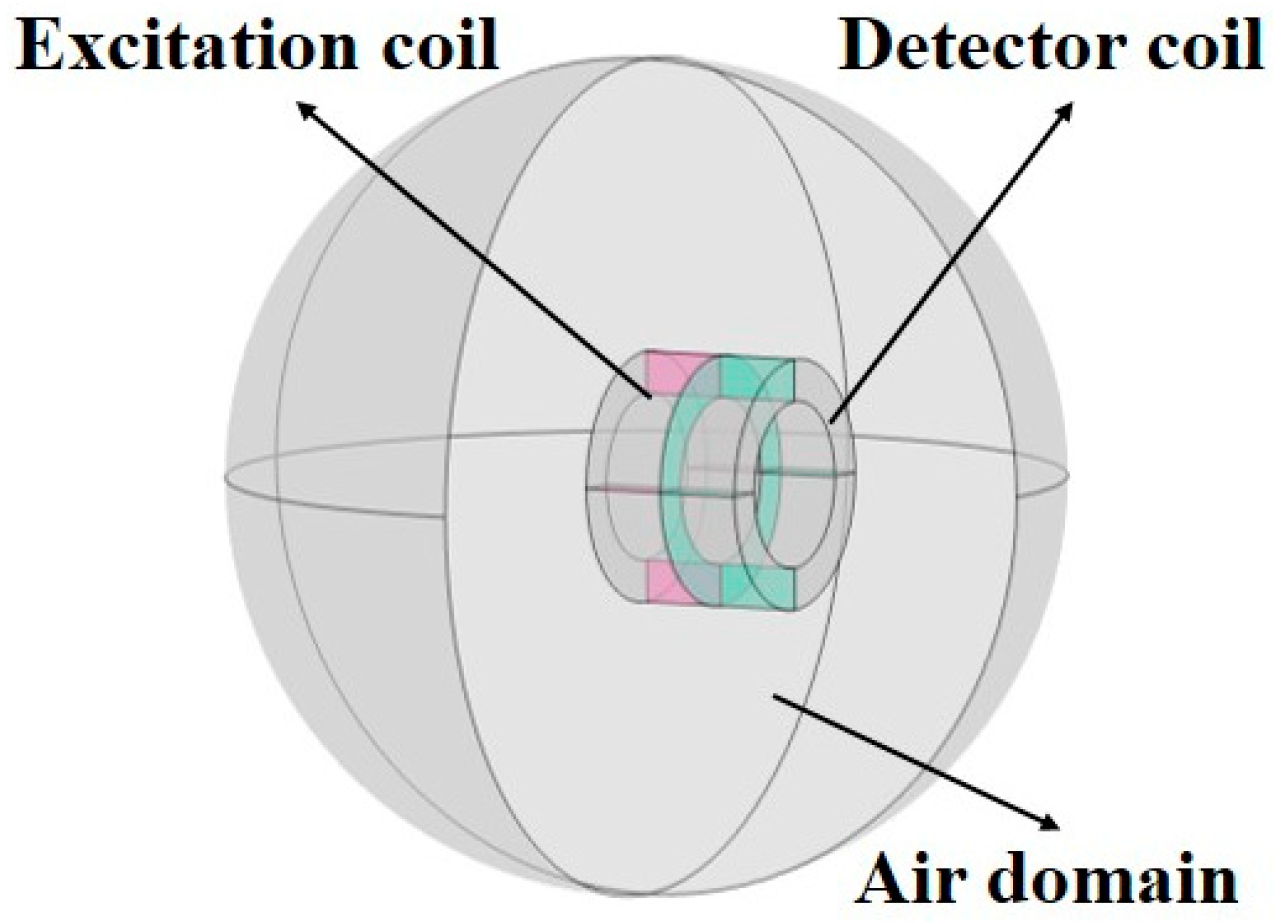

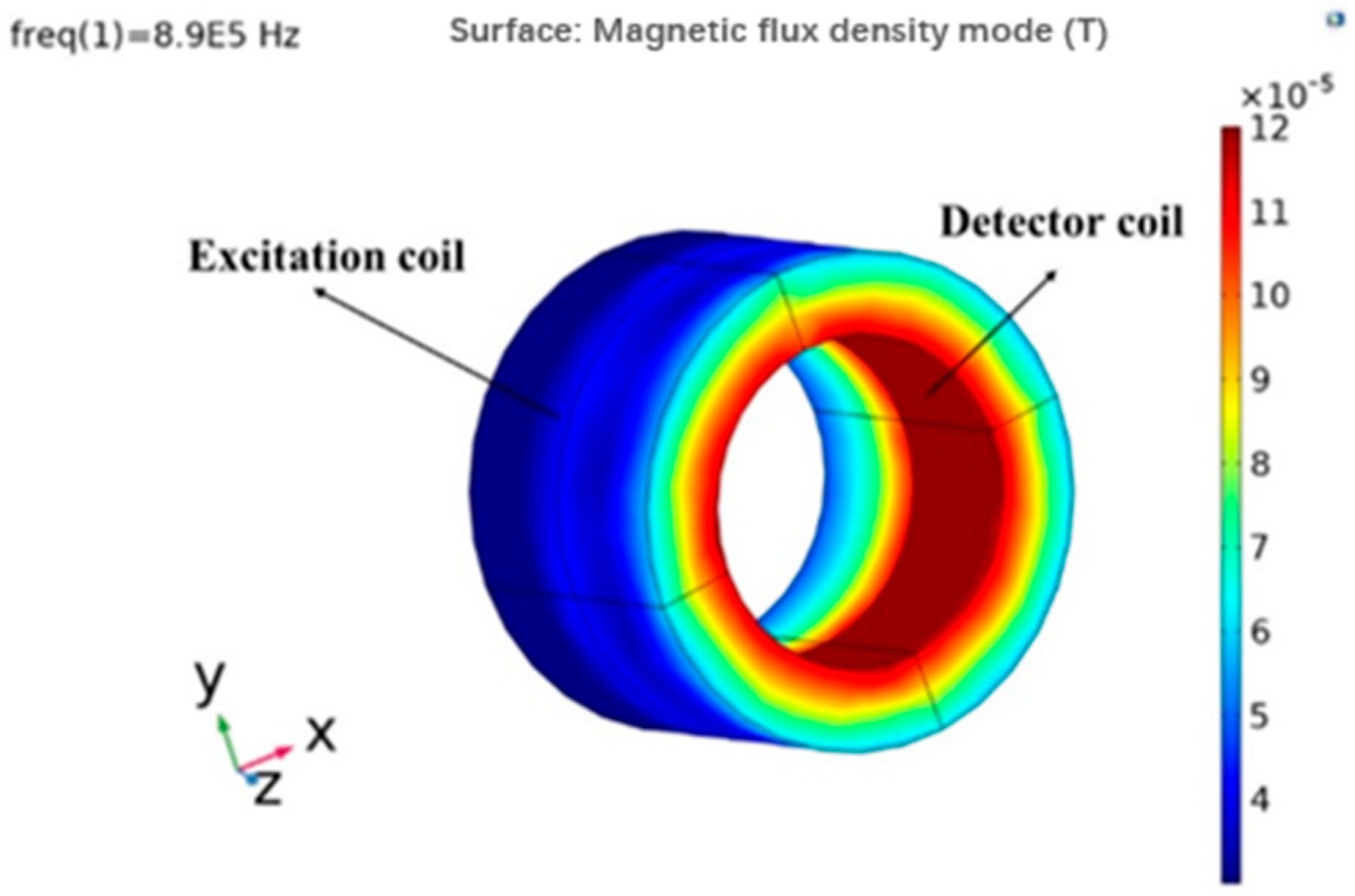

3. Finite Element Simulation

4. Experiments and Data Analysis

4.1. Sensor System Construction

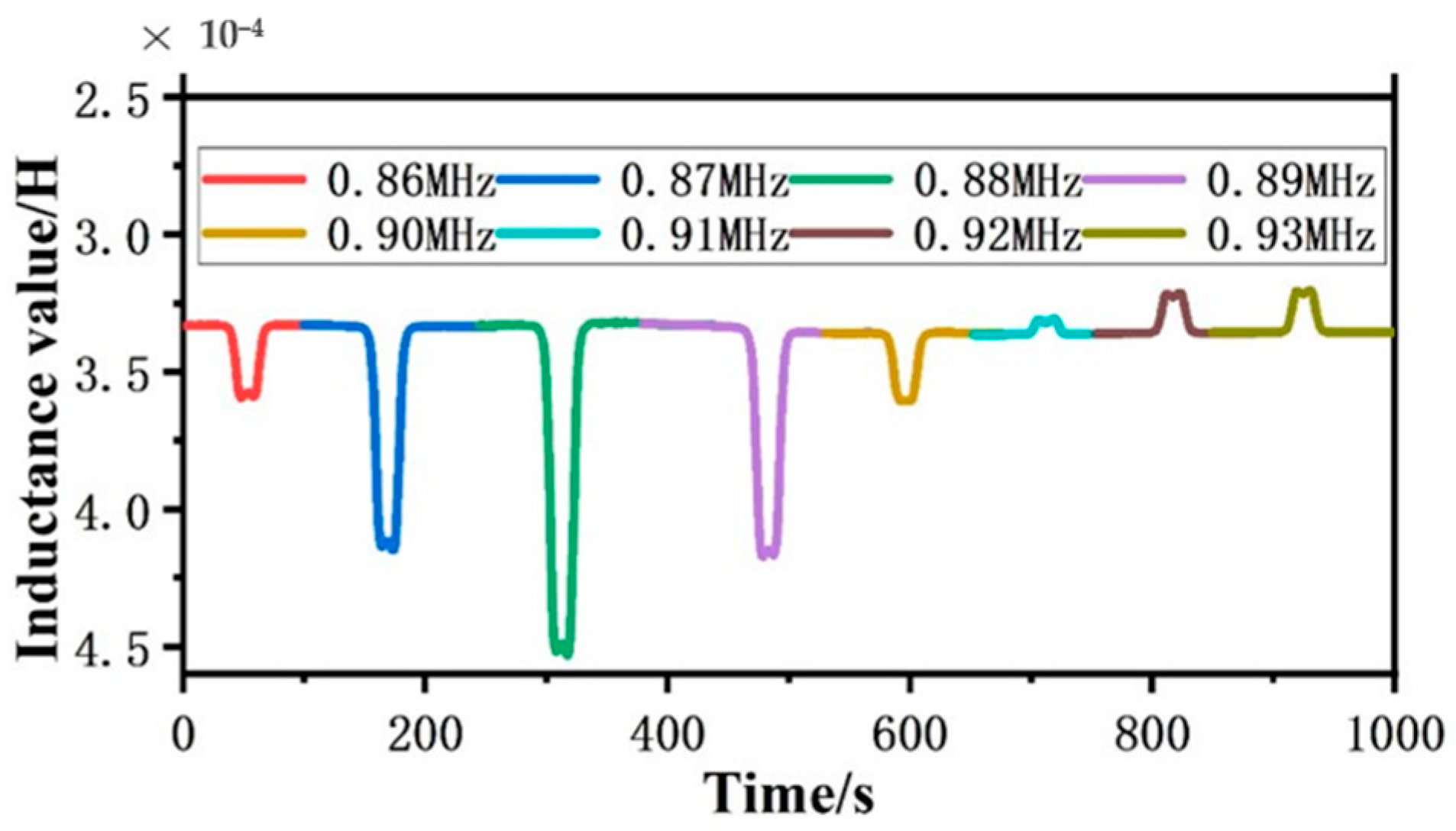

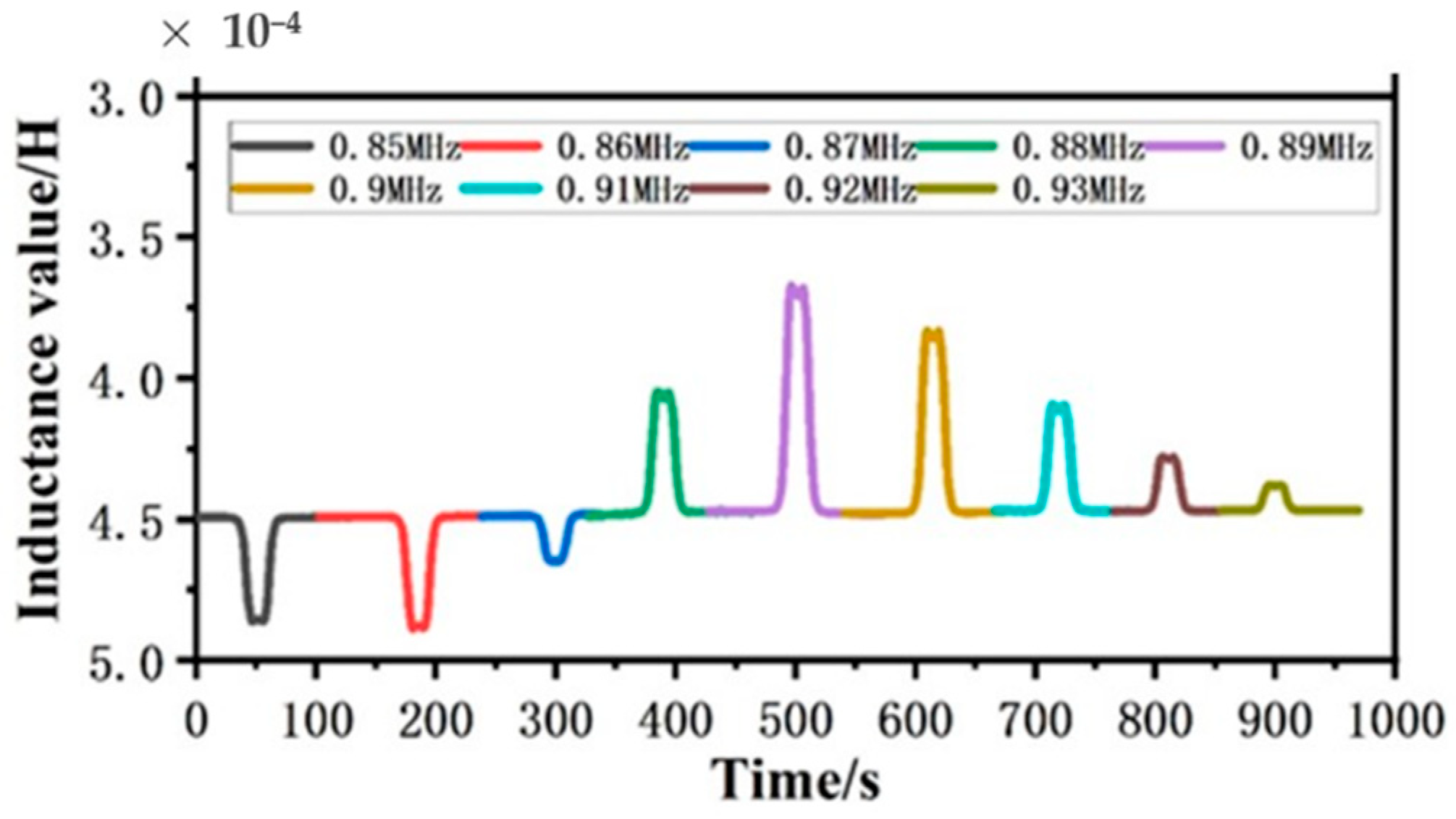

4.2. Experiment on the Selection of Optimal Excitation Frequency

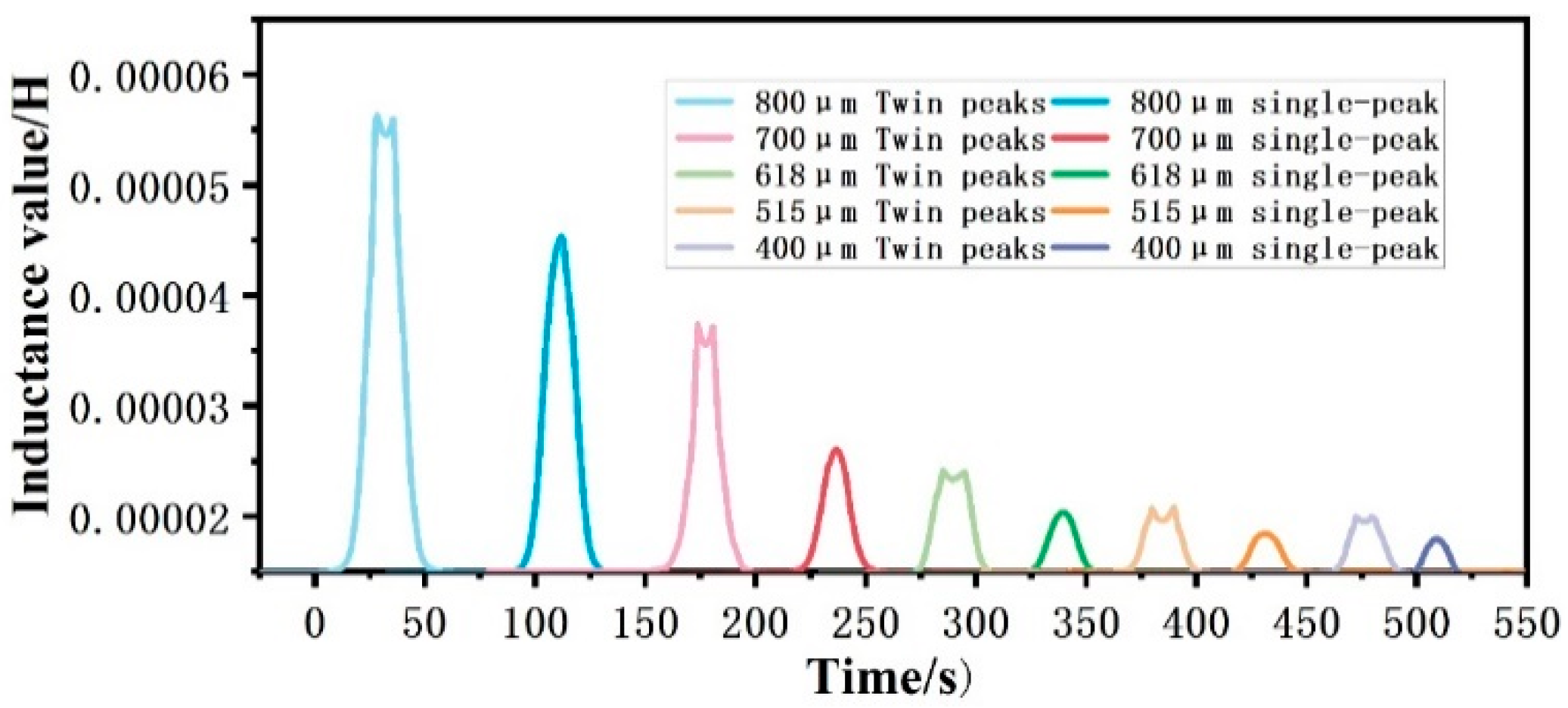

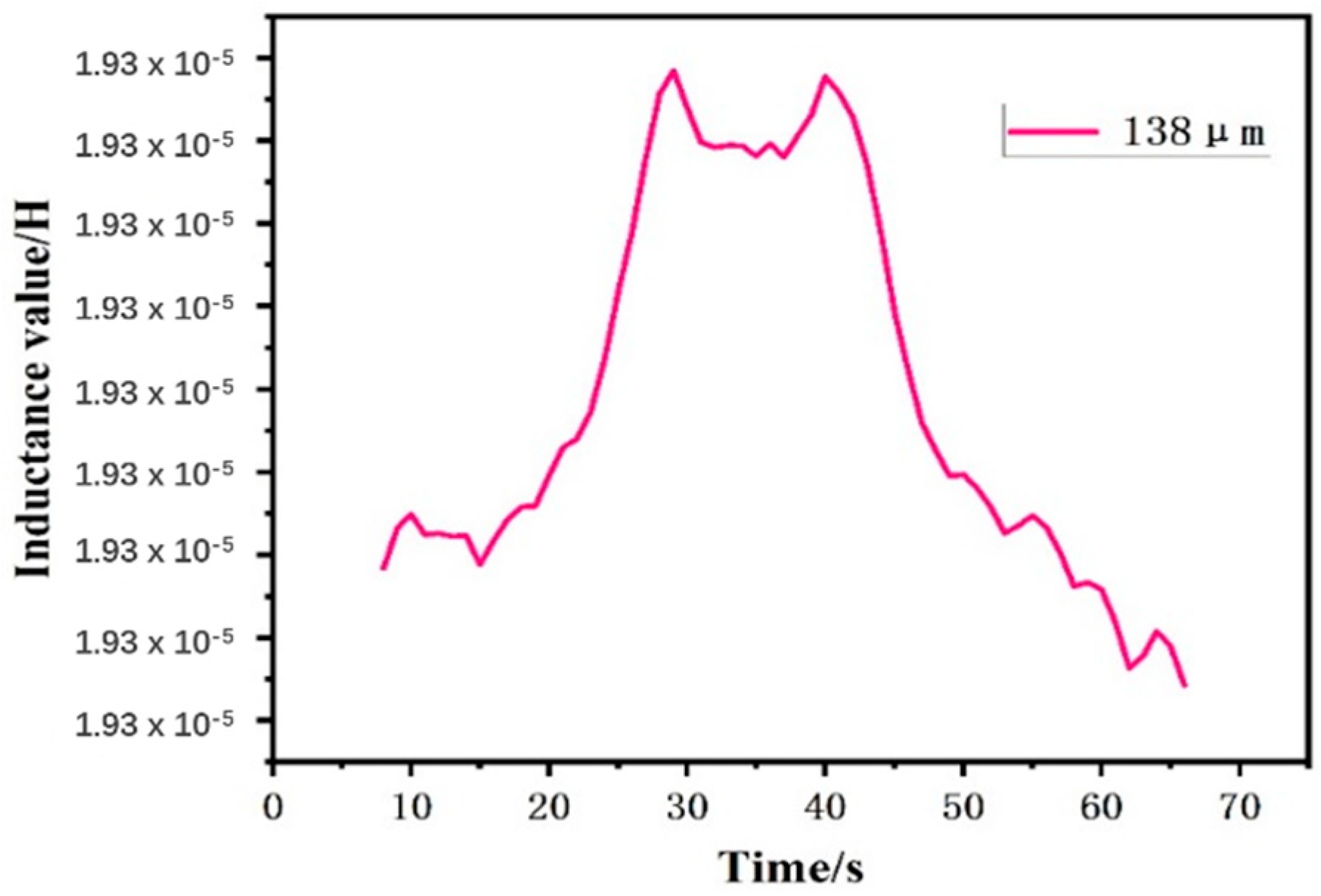

4.3. Experimental Characterization of Particle Signals under Different Detection Regions of the Sensor

4.4. Pollutant Detection Experiment

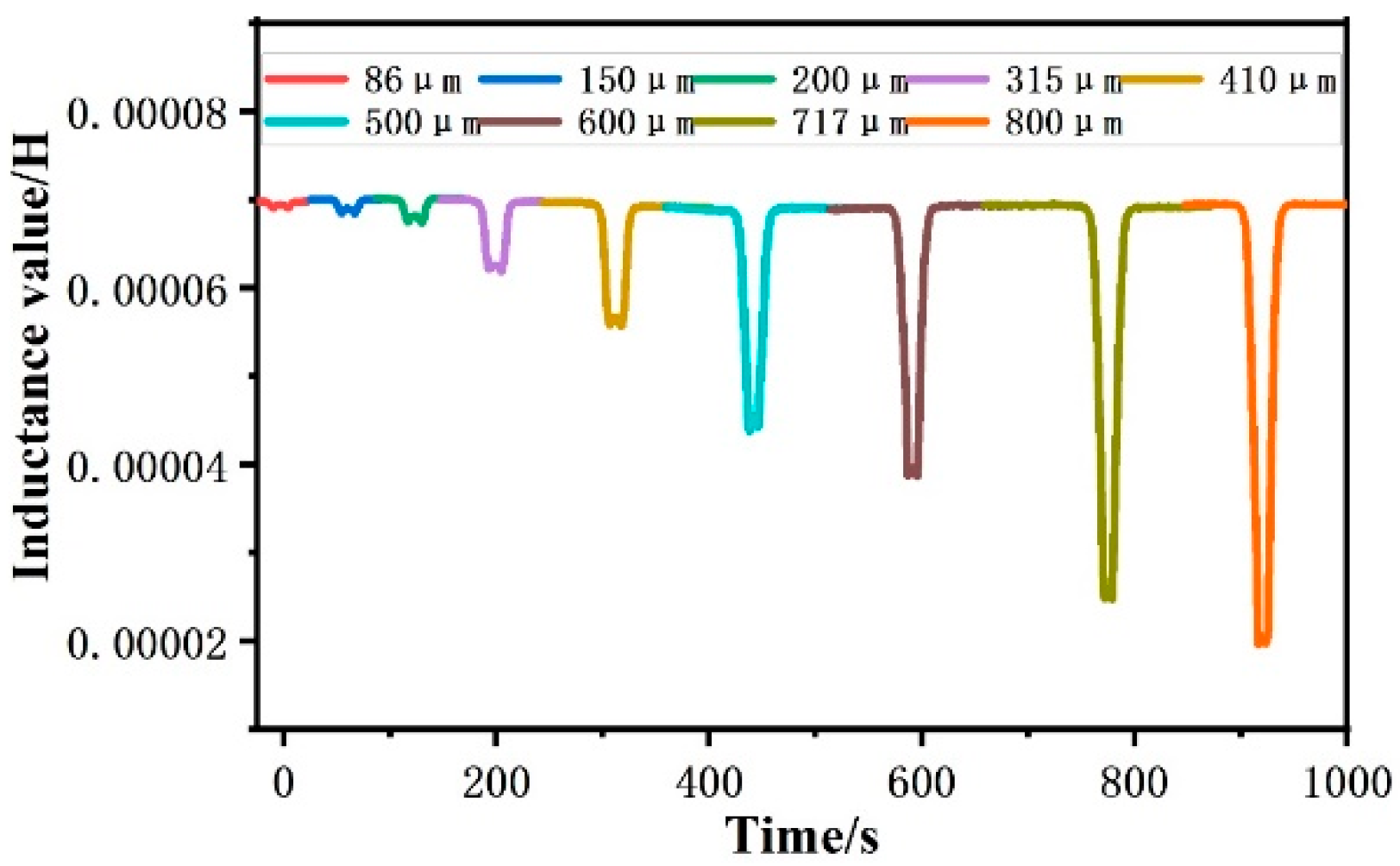

4.4.1. Ferromagnetic Metal Particle Detection Experiment

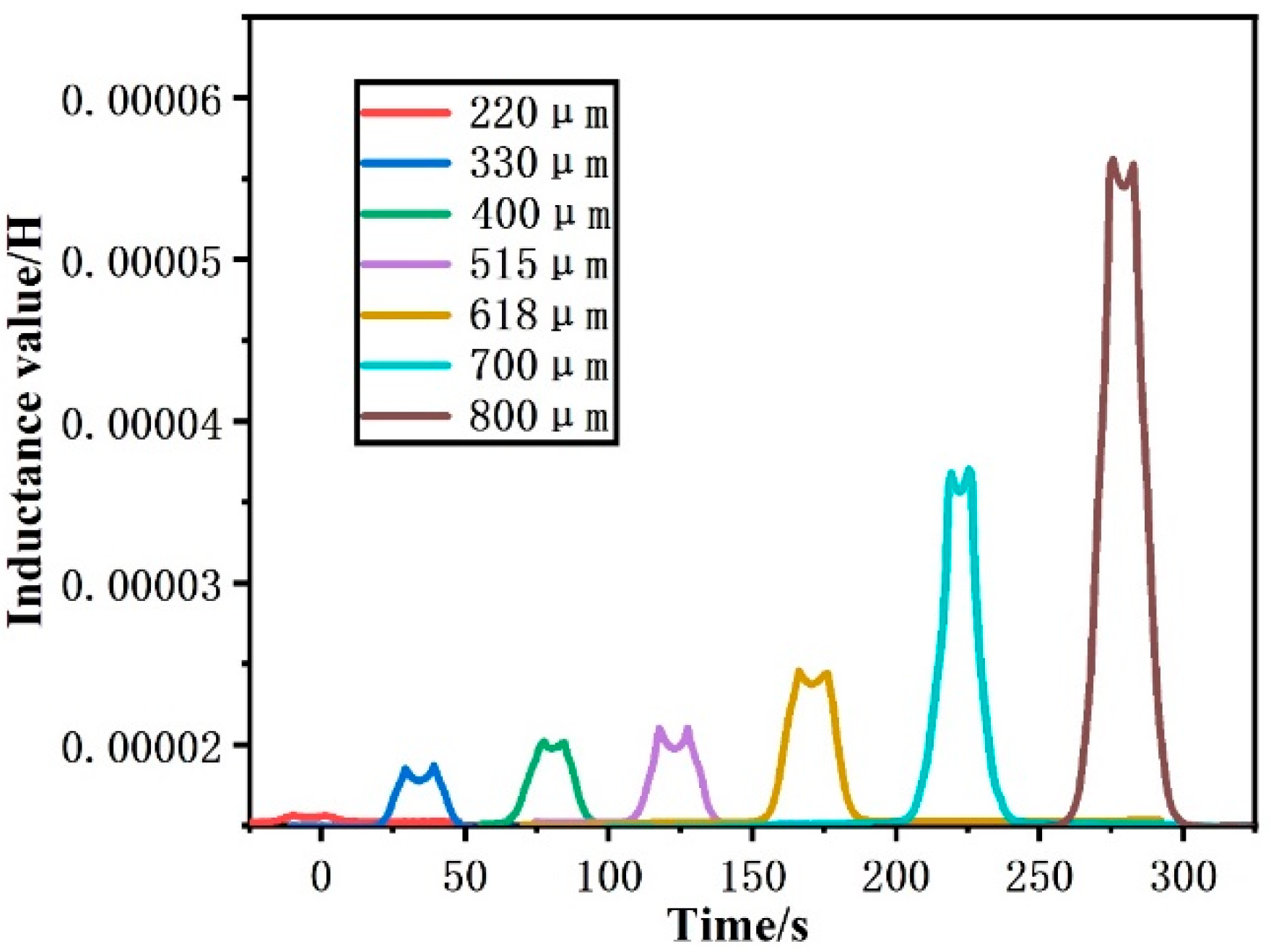

4.4.2. Non-Ferromagnetic Metal Particle Detection Experiment

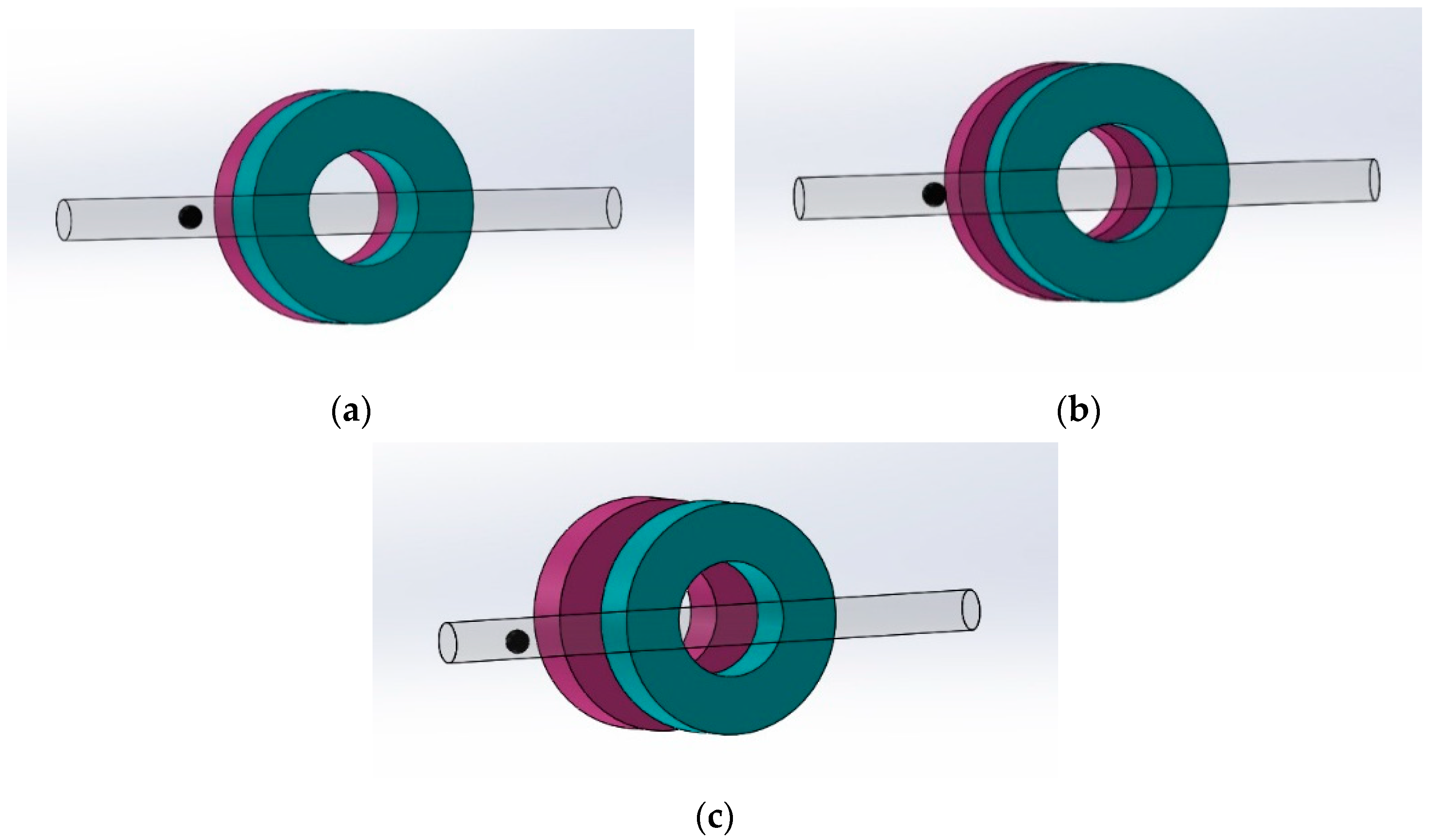

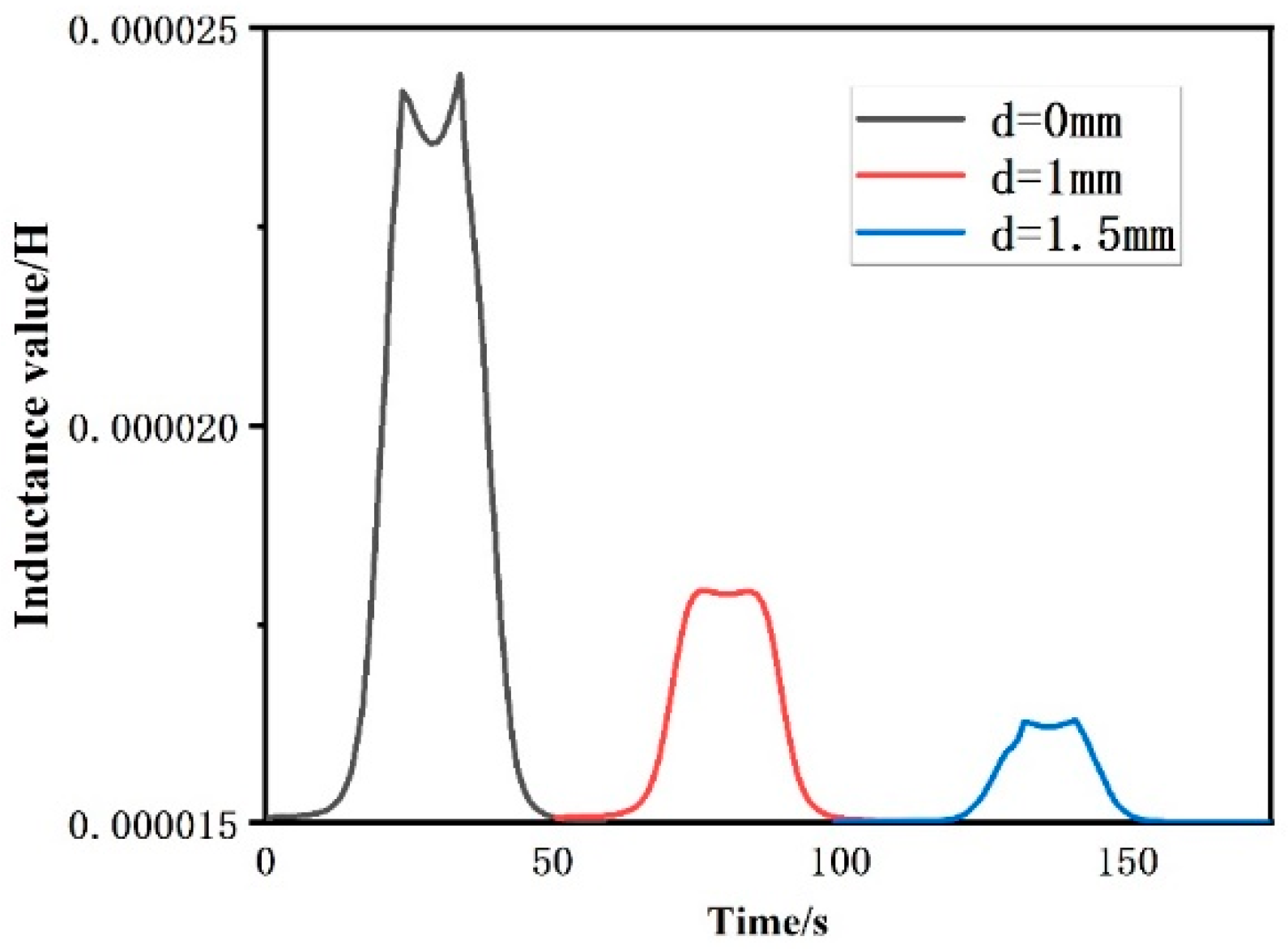

4.5. Coil Spacing Comparison Experiment

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Hu, S.; Bai, C.; Wang, C.; Li, H.; Zhang, H. Characterization of multi-abrasive mixed signals from LC resonance-based dual-coil oil detection sensors. IEEE Sens. J. 2024. [Google Scholar] [CrossRef]

- Huang, H.; He, S.; Xie, X. Research on the influence of inductive wear particle sensor coils on debris detection. AIP Adv. 2022, 12, 075204. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Y.; Zuo, H. An oil wear particles inline optical sensor based on motion characteristics for rotating machines condition monitoring. Machines 2022, 10, 727. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Y.; Zuo, H. Oil debris and viscosity monitoring using optical measurement based on Response Surface Methodology. Measurement 2022, 195, 111152. [Google Scholar] [CrossRef]

- Bastidas, S.; Allmaier, H. Application of a Wear Debris Detection System to Investigate Wear Phenomena during Running-In of a Gasoline Engine. Lubricants 2023, 11, 237. [Google Scholar] [CrossRef]

- Dang, Z.; Jiang, Y.; Su, X.; Wang, Z.; Wang, Y.; Sun, Z.; Zhao, Z.; Zhang, C.; Hong, Y.; Liu, Z. Particle Counting Methods Based on Microfluidic Devices. Micromachines 2023, 14, 1722. [Google Scholar] [CrossRef]

- Bai, C.; Zhang, H.; Zeng, L. High-Throughput Sensor to Detect Hydraulic Oil Contamination Based on Microfluidics. IEEE Sens. J. 2019, 19, 8590–8596. [Google Scholar] [CrossRef]

- Weser, R.; Wöckel, S.; Hempel, U. Particle characterization in highly concentrated suspensions by ultrasound scattering method. Sens. Actuators A Phys. 2013, 202, 30–36. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J. An integrated ultrasonic–inductive pulse sensor for wear debris detection. Smart Mater. Struct. 2012, 22, 025003. [Google Scholar] [CrossRef]

- Iwai, Y.; Honda, T.; Miyajima, T. Quantitative estimation of wear amounts by real time measurement of wear debris in lubricating oil. Tribol. Int. 2010, 43, 388–394. [Google Scholar] [CrossRef]

- Zeng, X. A high sensitive multi-parameter micro sensor for the detection of multi-contamination in hydraulic oil. Sens. Actuators A. Phys. 2018, 282, 197–205. [Google Scholar] [CrossRef]

- Han, Z.; Wang, Y.; Qing, X. Characteristics study of in-situ capacitive sensor for monitoring lubrication oil debris. Sensors 2017, 17, 2851. [Google Scholar] [CrossRef] [PubMed]

- Raadnui, S.; Kleesuwan, S. Low-cost condition monitoring sensor for used oil analysis. Wear 2005, 259, 1502–1506. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J. Parallel sensing of metallic wear debris in lubricants using under sampling data processing. Tribol. Int. 2012, 53, 28–34. [Google Scholar] [CrossRef]

- Xiao, H.; Wang, X.; Li, H. An inductive debris sensor for a large-diameter lubricating oil circuit based on a high-gradient magnetic field. Appl. Sci. 2019, 9, 1546. [Google Scholar] [CrossRef]

- Sun, J.; Wang, L.; Li, J. Online oil debris monitoring of rotating machinery: A detailed review of more than three decades. Mech. Syst. Signal Process. 2021, 149, 107341. [Google Scholar] [CrossRef]

- Zhang, Y.; Hong, J.; Shi, H. Magnetic plug sensor with bridge nonlinear correction circuit for oil condition monitoring of marine machinery. J. Mar. Sci. Eng. 2022, 10, 1883. [Google Scholar] [CrossRef]

- Yu, B.; Cao, N.; Zhang, T. A novel signature extracting approach for inductive oil debris sensors based on simplistic geometry mode decomposition. Measurement 2021, 185, 110056. [Google Scholar] [CrossRef]

- Shen, X.; Han, Q.; Wang, Y. Research on Detection Performance of Four-Coil Inductive Debris Sensor. IEEE Sens. J. 2023, 23, 6717–6727. [Google Scholar] [CrossRef]

- Qian, M.; Ren, Y.; Feng, Z. Wear Debris Sensor Using Intermittent Excitation for High Sensitivity, Wide Detectable Size Range, and Low Heat Generation. IEEE Trans. Ind. Electron. 2022, 70, 6386–6394. [Google Scholar] [CrossRef]

- Zhu, X.; Du, L.; Zhe, J. A 3 × 3 wear debris sensor array for real time lubricant oil conditioning monitoring using synchronized sampling. Mech. Syst. Signal Process. 2017, 83, 296–304. [Google Scholar] [CrossRef]

- Xie, Y.C.; Shi, H.T.; Zhang, H.P. A bridge-type inductance sensor with a two-stage filter circuit for high-precision detection of metal debris in the oil. IEEE Sens. J. 2021, 21, 17738–17748. [Google Scholar] [CrossRef]

- Feng, S.; Tan, J.; Wen, Y. Sensing model for detecting ferromagnetic debris based on a high-gradient magnetostatic field. IEEE/ASME Trans. Mechatron. 2021, 27, 2440–2449. [Google Scholar] [CrossRef]

- Zhao, K.; Wei, Y.; Zhao, P. Tunable magnetophoretic method for distinguishing and separating wear debris particles in a Fe-PDMS based microfluidic chip. Electrophoresis 2023, 44, 1210–1219. [Google Scholar] [CrossRef]

- Available online: https://baike.baidu.com/item/SINR (accessed on 15 January 2024).

- Zhang, H.P.; Zhang, Z.; Zhao, X.P.; Li, H.; Li, W.; Wang, C.Y.; Bai, C.Z.; Hu, S.K. An LC resonance-based sensor for multi-contaminant detection in oil fluids. IEEE Sens. J. 2024, 24, 9772–9782. [Google Scholar] [CrossRef]

| Principle | Advantage | Disadvantage |

|---|---|---|

| optical methods [2,3,4] | Can detect attributes such as geometry, size, and coloration of wear particles | Require a high level of fluid cleanliness |

| acoustic method [7] | Fluid cleanliness does not affect the operation of acoustic sensors | Less resistant to external sound and vibration interference |

| capacitance method [11,12,13] | The purity and moisture content of the oil can be monitored in real-time | Unable to distinguish between ferromagnetic and non-ferromagnetic particles |

| inductive method [14] | Can distinguishbetween ferromagnetic and non-ferromagnetic metal particles | Can easily lead to clogging of wear particles/needs to address the problem of the large size of individual microfluidic channels |

| this work | Can increase the detection flux without decreasing the detection sensitivity | Cannot distinguish between water and air bubbles |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Zhang, Z.; Bai, C.; Hu, S.; Wang, J.; Wang, C.; Zhang, H. Characterization of Abrasive Grain Signal of Oil Detection Sensor Based on LC Resonance Wireless Transmission. J. Mar. Sci. Eng. 2024, 12, 1704. https://doi.org/10.3390/jmse12101704

Zhang S, Zhang Z, Bai C, Hu S, Wang J, Wang C, Zhang H. Characterization of Abrasive Grain Signal of Oil Detection Sensor Based on LC Resonance Wireless Transmission. Journal of Marine Science and Engineering. 2024; 12(10):1704. https://doi.org/10.3390/jmse12101704

Chicago/Turabian StyleZhang, Shaoxuan, Zuo Zhang, Chenzhao Bai, Shukui Hu, Jizhe Wang, Chenyong Wang, and Hongpeng Zhang. 2024. "Characterization of Abrasive Grain Signal of Oil Detection Sensor Based on LC Resonance Wireless Transmission" Journal of Marine Science and Engineering 12, no. 10: 1704. https://doi.org/10.3390/jmse12101704