Numerical Evaluation of Wave Dissipation on a Breakwater Slope Covered by Precast Blocks with Different Geometrical Characteristics

Abstract

:1. Introduction

2. Numerical Methodology

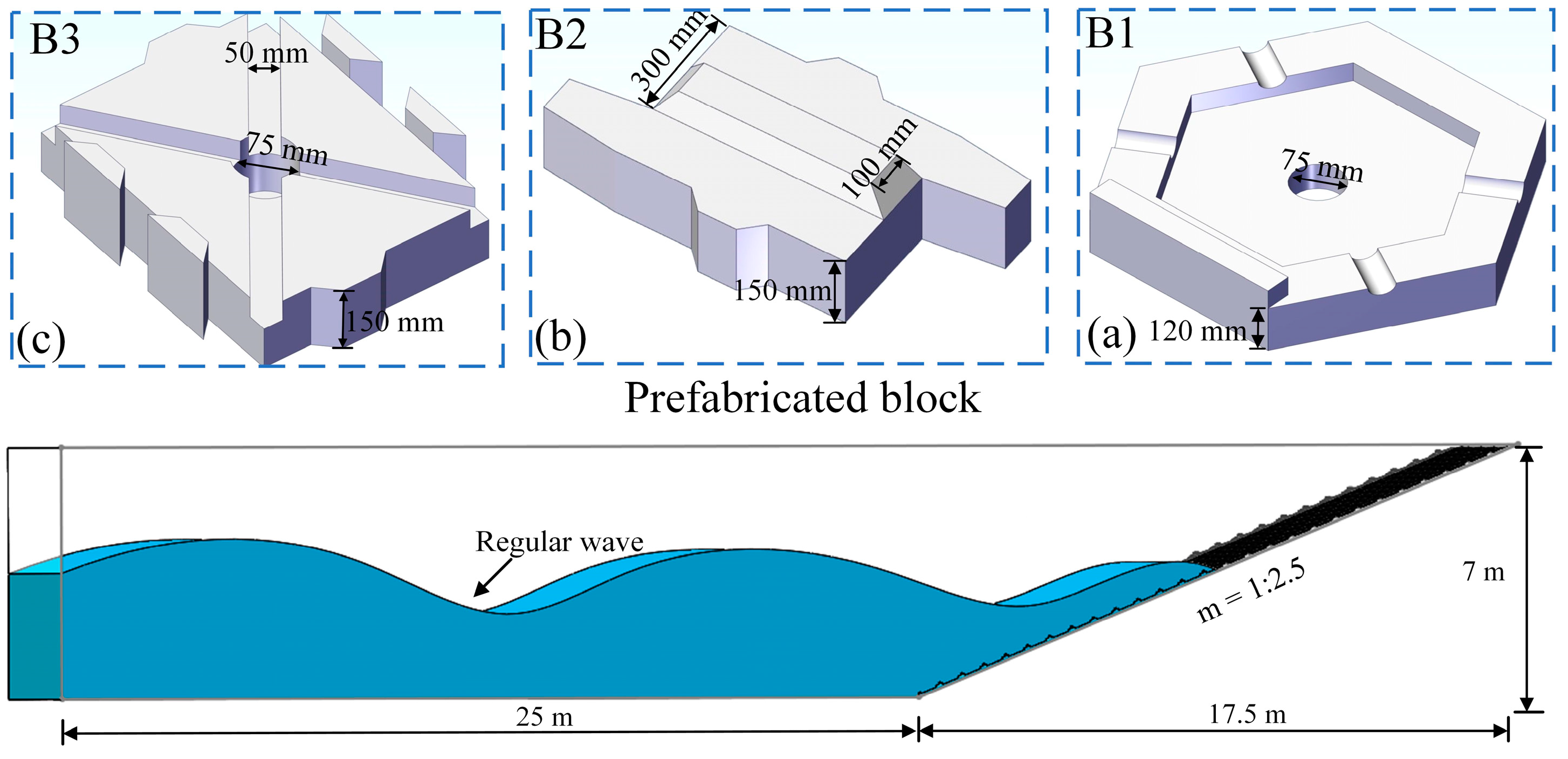

2.1. Numerical Setup

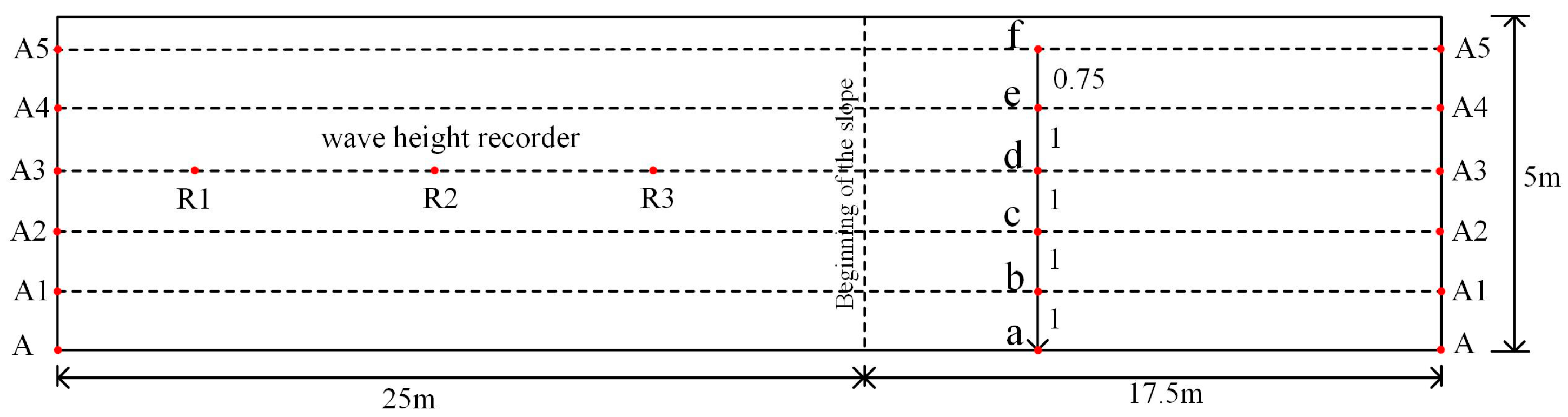

2.2. Numerical Wave Flume and Slope

2.3. Wave Generation

3. Convergence and Validation

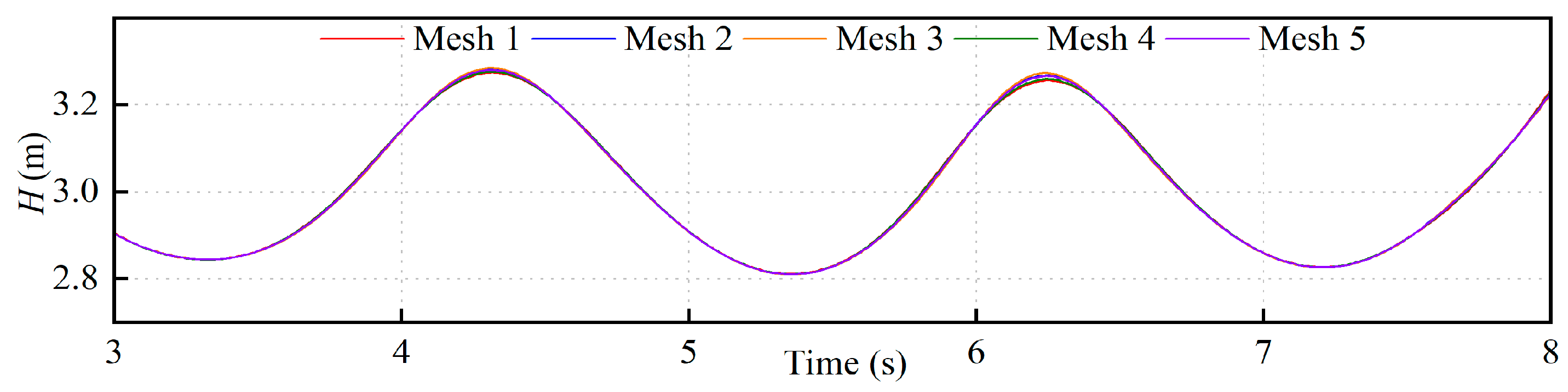

3.1. Convergence of Numerical Model

3.2. Validation

4. Wave Run-Up on the Slope

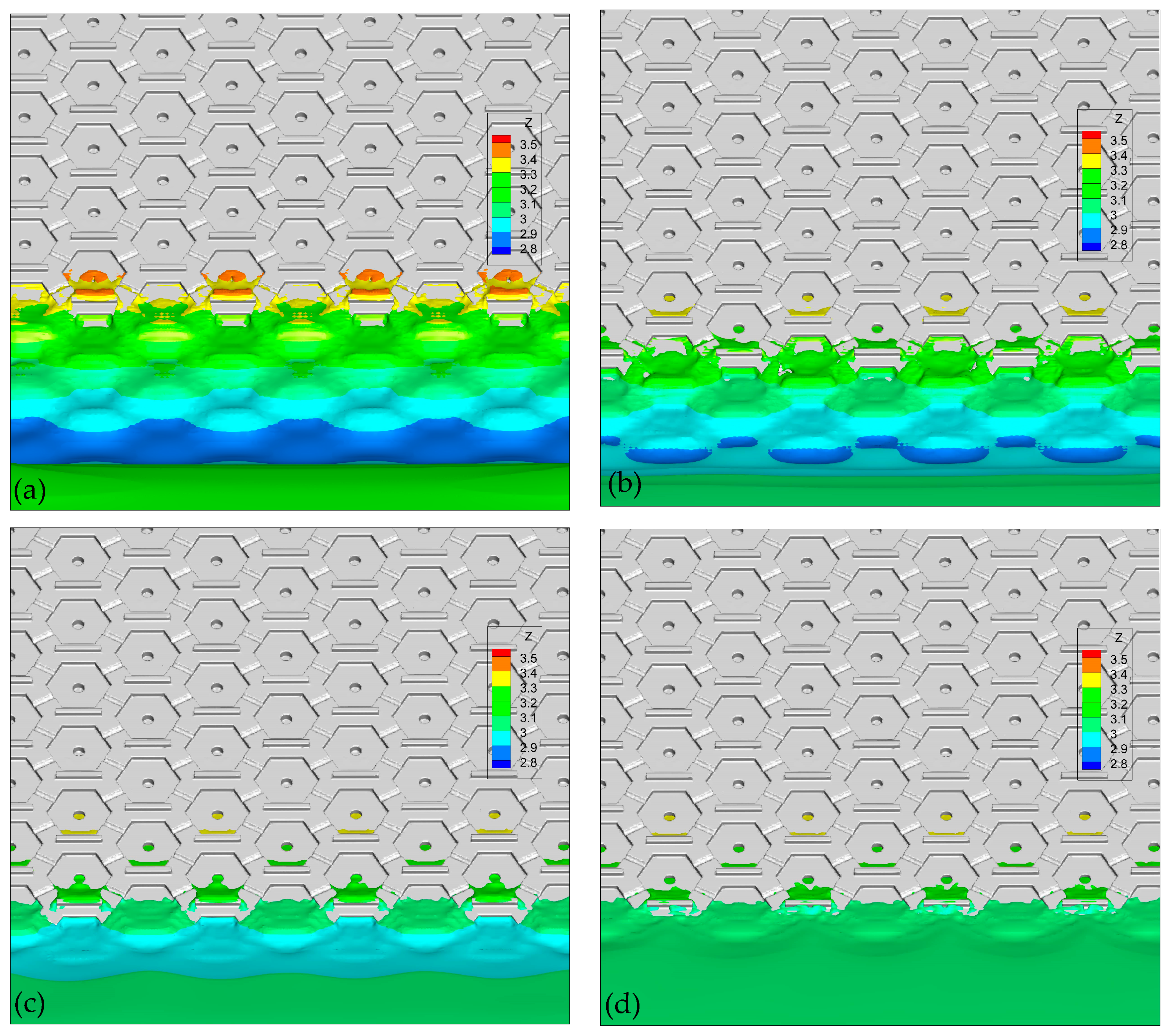

4.1. Free Surface Elevation

4.2. Distribution of the Cross-Sectional Water Surface Profile

5. Results and Discussion

5.1. Effect of Different Prefabricated Block Slopes on Wave Run-Up Height and Wave Dissipation

- Block height ratio (Hr):

5.2. Empirical Formula of the Wave-Absorbing Effect of Prefabricated Blocks

6. Conclusions

- (1)

- Prefabricated block slopes provide effective protection for inland waters in China, particularly along lakes and riverbanks. These structures are designed to dissipate wave run-up, making them ideal for environments with mild and regular wave activity. Their cost-effectiveness and aesthetic appeal make them suitable for urban and recreational slope protection, offering both economic and visual benefits. The paper used a numerical method to evaluate these blocks, demonstrating their practical value for inland water protection.

- (2)

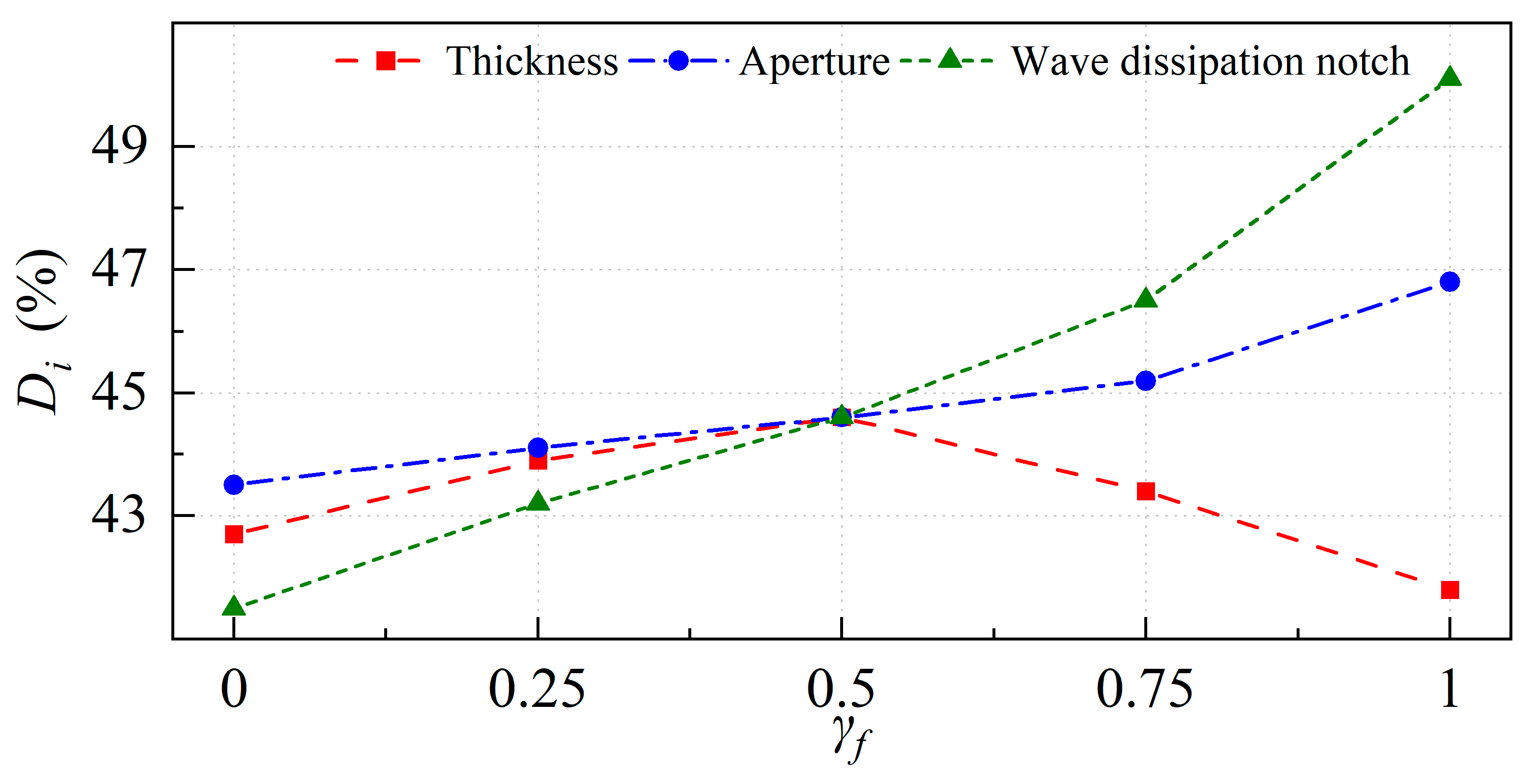

- Among the three prefabricated block types tested, block B1 exhibited superior performance, with a wave run-up reduction efficiency of 44.6% at T = 2.0 s and 50.7% at T = 3.0 s. The optimized aperture, thickness, and wave dissipation notch of B1 were key to its higher performance. The wave dissipation notch was crucial in disrupting wave energy, making B1 more effective. This study highlights the innovative role of this notch in reducing wave run-up, offering design insights for artificial blocks. Adjusting its size impacts the run-up height, providing a novel approach to optimizing wave attenuation structures.

- (3)

- Empirical formulas were used to predict the wave run-up height when using B1 in specific engineering scenarios. These formulas were based on a limited dataset and primarily validated through numerical simulations, demonstrating an error margin of no more than 10% within the scope of the study. It is important to note that these formulas are intended for preliminary analysis and should not be used to draw definitive conclusions about real-world dike performance or actual wave conditions. Further validation through broader experimental data and physical testing is necessary if we are to improve the accuracy and applicability of these formulas. As such, this study serves as an initial step in exploring the behavior of prefabricated blocks in controlled-wave conditions rather than offering conclusive predictions for use within large-scale coastal infrastructure. With additional refinement and testing, these formulas could enhance the reliability of wave run-up forecasts, contributing to more effective design and implementation of coastal protection in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Samaras, A.G.; Karambas, T.V. Modelling the impact of climate change on coastal flooding: Implications for coastal structures design. J. Mar. Sci. Eng. 2021, 9, 1008. [Google Scholar] [CrossRef]

- Galiatsatou, P.; Makris, C.; Prinos, P. Optimized Reliability Based Upgrading of Rubble Mound Breakwaters in a Changing Climate. J. Mar. Sci. 2018, 6, 92. [Google Scholar] [CrossRef]

- De-León, D.; Loza, L. Reliability-based analysis of Lázaro Cárdenas breakwater including the economical impact of the port activity. Int. J. Disaster Risk Reduct. 2019, 40, 101276. [Google Scholar] [CrossRef]

- Koutrouveli, T.I.; Dimas, A.A. Wave and hydrodynamic processes in the vicinity of a rubble-mound, permeable, zero-freeboard breakwater. J. Mar. Sci. Eng. 2020, 8, 206. [Google Scholar] [CrossRef]

- Magdalena, I.; Erwina, N. An efficient two-layer non-hydrostatic model for investigating wave run-up phenomena. Computation 2019, 8, 1. [Google Scholar] [CrossRef]

- Baker, R.J.W. Precast Concrete Blocks for High-Velocity Flow Applications. Water Environ. J. 1990, 4, 552–558. [Google Scholar] [CrossRef]

- Safari, I.; Mouazé, D.; Aliasgary, S.; Carpentier, G.; Ropert, F. Hydraulic Response and Overtopping Performance of Single-Layer Double Cube Unit Armored Mound Breakwater. J. Mar. Sci. Eng. 2023, 11, 1382. [Google Scholar] [CrossRef]

- Zhao, H.; Ding, F.; Ye, J.; Jiang, H.; Chen, W.; Gu, W.; Yu, G.; Li, Q. Physical Experimental Study on the Wave Reflection and Run-Up of a New Ecological Hollow Cube. J. Mar. Sci. Eng. 2024, 12, 664. [Google Scholar] [CrossRef]

- Breteler, M.K.; Pilarczyk, K. Stability of artificial roughness elements and run-up reduction. In Coastal Engineering 1996; ASCE Library: Reston, VA, USA, 1996; pp. 1556–1568. [Google Scholar] [CrossRef]

- Stagnitti, M.; Lara, J.L.; Musumeci, R.E.; Foti, E. Assessment of the variation of failure probability of upgraded rubble-mound breakwaters due to climate change. Front. Mar. Sci. 2022, 9, 986993. [Google Scholar] [CrossRef]

- Kreyenschulte, M.; Schürenkamp, D.; Bratz, B.; Schüttrumpf, H.; Goseberg, N. Wave Run-Up on Mortar-Grouted Riprap Revetments. Water 2020, 12, 3396. [Google Scholar] [CrossRef]

- Zhao, E.; Mu, L.; Hu, Z.; Wang, X.; Sun, J.; Zhang, Z. Physical and Numerical Investigations on Wave Run-Up and Dissipation under Breakwater with Fence Revetment. J. Mar. Sci. Eng. 2021, 9, 1355. [Google Scholar] [CrossRef]

- De Waal, J.; Van der Meer, J. Wave runup and overtopping on coastal structures. In Coastal Engineering 1992; ASCE Library: Reston, VA, USA, 1993; pp. 1758–1771. [Google Scholar] [CrossRef]

- Tang, W.; Mohseni, E.; Wang, Z. Development of vegetation concrete technology for slope protection and greening. Constr. Build. Mater. 2018, 179, 605–613. [Google Scholar] [CrossRef]

- Cao, W.; Omran, B.A.; Lei, Y.; Zhao, X.; Yang, X.; Chen, Q.; Tian, G. Studying early stage slope protection effects of vegetation communities for Xinnan Highway in China. Ecol. Eng. 2018, 110, 87–98. [Google Scholar] [CrossRef]

- Dang, B.-L.; Nguyen-Ngoc, H.; Hoang, T.D.; Nguyen-Xuan, H.; Abdel Wahab, M. Numerical investigation of novel prefabricated hollow concrete blocks for stepped-type seawall structures. Eng. Struct. 2019, 198, 109558. [Google Scholar] [CrossRef]

- Hashim, A.M.; Noor, N. Performance evaluation of innovative concrete armor unit for coastal protection structure. In Proceedings of the 2013 IEEE Business Engineering and Industrial Applications Colloquium (BEIAC), Langkawi, Malaysia, 7–9 April 2013; pp. 673–678. [Google Scholar]

- Asamoah, R.O.; Ankrah, J.S.; Offei-Nyako, K.; Tutu, E.O. Cost analysis of precast and cast-in-place concrete construction for selected public buildings in Ghana. J. Constr. Eng. 2016, 2016, 8785129. [Google Scholar] [CrossRef]

- Denagama, T.; Jayasooriya, J. Comparative analysis of precast construction and conventional construction of small-scale concrete building in terms of cost. Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 573–578. [Google Scholar] [CrossRef]

- Chan, T.K. Comparison of precast construction costs–case studies in Australia and Malaysia. In Proceedings of the 27th Annual ARCOM Conference, Bristol, UK, 5–7 September 2011; pp. 5–7. [Google Scholar]

- Attri, G.K.; Gupta, R.C.; Shrivastava, S. Sustainable precast concrete blocks incorporating recycled concrete aggregate, stone crusher, and silica dust. J. Clean. Prod. 2022, 362, 132354. [Google Scholar] [CrossRef]

- Zhao, Z.; Courard, L.; Groslambert, S.; Jehin, T.; LÉOnard, A.; Xiao, J. Use of recycled concrete aggregates from precast block for the production of new building blocks: An industrial scale study. Resour. Conserv. Recycl. 2020, 157, 104786. [Google Scholar] [CrossRef]

- Lima, P.R.; Barros, J.A.; Roque, A.B.; Fontes, C.M.; Lima, J.M. Short sisal fiber reinforced recycled concrete block for one-way precast concrete slabs. Constr. Build. Mater. 2018, 187, 620–634. [Google Scholar] [CrossRef]

- Stagnitti, M.; Lara, J.; Musumeci, R.; Foti, E. Numerical modeling of wave overtopping of damaged and upgraded rubble-mound breakwaters. Ocean Eng. 2023, 280, 114798. [Google Scholar] [CrossRef]

- Shounda, J.; Barman, K.; Debnath, K. Effect of wave-current flow on double-averaged turbulence properties over rough bed of hemispherical obstacles. Coast. Eng. J. 2023, 65, 572–596. [Google Scholar] [CrossRef]

- Magdalena, I.; La’lang, R.; Mendoza, R. Quantification of wave attenuation in mangroves in manila bay using nonlinear shallow water equations. J. Results Appl. Math. 2021, 12, 100191. [Google Scholar] [CrossRef]

- Andersen, T.L.; Burcharth, H.F.; Gironella, X. Comparison of new large and small scale overtopping tests for rubble mound breakwaters. Coast. Eng. 2011, 58, 351–373. [Google Scholar] [CrossRef]

- Wroniszewski, P.A.; Verschaeve, J.C.; Pedersen, G.K. Benchmarking of Navier–Stokes codes for free surface simulations by means of a solitary wave. Coast. Eng. 2014, 91, 1–17. [Google Scholar] [CrossRef]

- Chen, W.; Warmink, J.; Van Gent, M.; Hulscher, S. Numerical modelling of wave overtopping at dikes using OpenFOAM®. Coast. Eng. 2021, 166, 103890. [Google Scholar] [CrossRef]

- Jacobsen, N.G.; Fuhrman, D.R.; Fredsøe, J. A wave generation toolbox for the open-source CFD library: OpenFoam®. J. Numer. Methods Fluids 2012, 70, 1073–1088. [Google Scholar] [CrossRef]

- Ferziger, J.H.; Perić, M. Computational Methods for Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Gao, Y.; Zhu, J.; Qu, X.; Wang, L.; Wang, B. Numerical simulation of wave run-up on three cylinders in an equilateral-triangular arrangement. Ocean Eng. 2021, 233, 109176. [Google Scholar] [CrossRef]

- Molin, B.; Kimmoun, O.; Liu, Y.; Remy, F.; Bingham, H.B. Experimental and numerical study of the wave run-up along a vertical plate. J. Fluid Mech. 2010, 654, 363–386. [Google Scholar] [CrossRef]

- Craik, A.D. Wave Interactions and Fluid Flows; Cambridge University Press: Cambridge, UK, 1988. [Google Scholar]

- Clavero, M.; Díaz-Carrasco, P.; Losada, M.Á. Bulk wave dissipation in the armor layer of slope rock and cube armored breakwaters. J. Mar. Sci. Eng. 2020, 8, 152. [Google Scholar] [CrossRef]

- EurOtop Manual. Manual on Wave Overtopping of Sea Defences and Related Structures: An Overtopping Manual Largely Based on European Research, Home—Overtopping Manual. 2018. Available online: http://www.overtopping-manual.com (accessed on 5 March 2024).

| Case | Mesh | Total Cell Count | L (Wavelength)/Δx | H (Wave Height)/Δz |

|---|---|---|---|---|

| B1 | Mesh 1 | 1.06 × 106 | 20 | 10 |

| Mesh 2 | 2.65 × 106 | 40 | 10 | |

| Mesh 3 | 4.96 × 106 | 60 | 10 | |

| Mesh 4 | 2.79 × 106 | 40 | 15 | |

| Mesh 5 | 2.79 × 106 | 40 | 20 |

| Time/Horizontal Distance | B1 (cm) | B2 (cm) | B3 (cm) | Pearson Correlation | NRMSE (%) | NError (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| Exp | Num | Exp | Num | Exp | Num | ||||

| 1.875 s/23.6 cm | 5.07 | 5.23 | 5.55 | 5.55 | 6.50 | 6.81 | 0.95 | 2.97 | 3.15 |

| 1.875 s/30.6 cm | 14.72 | 15.26 | 14.76 | 15.32 | 14.99 | 15.71 | 0.96 | 3.44 | 3.67 |

| 2.5 s/30.6 cm | 7.17 | 7.34 | 7.29 | 7.64 | 7.43 | 7.79 | 0.92 | 2.85 | 2.37 |

| Period (s) | B0 (m) | B1 (m) | B2 (m) | B3 (m) |

|---|---|---|---|---|

| 1.5 | 0.660 | 0.362 | 0.397 | 0.432 |

| 2.0 | 0.672 | 0.432 | 0.443 | 0.453 |

| 2.5 | 0.725 | 0.478 | 0.530 | 0.546 |

| 3.0 | 1.044 | 0.524 | 0.644 | 0.649 |

| Period (s) | B1 (%) | B2 (%) | B3 (%) |

|---|---|---|---|

| 1.5 | 45.2 | 39.8 | 34.5 |

| 2.0 | 44.6 | 41.0 | 37.6 |

| 2.5 | 34.1 | 26.9 | 24.7 |

| 3.0 | 50.7 | 38.3 | 37.8 |

| Wave Condition | Fr | Re | Hr | Ar | Nr |

|---|---|---|---|---|---|

| H= 0.5 m, L = 10 m, v = 0.5 m/s | 0.50 | 5 × 105 | 0.24 | 0.01 | 0.10 |

| H = 1 m, L = 15 m, v = 0.5 m/s | 0.41 | 7.5 × 105 | 0.12 | 0.007 | 0.05 |

| H = 1.5 m, L = 20 m, v = 0.5 m/s | 0.35 | 1 × 106 | 0.08 | 0.005 | 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, B.; Zhao, Q.; Chen, F.; Liu, C.; Fang, Q. Numerical Evaluation of Wave Dissipation on a Breakwater Slope Covered by Precast Blocks with Different Geometrical Characteristics. J. Mar. Sci. Eng. 2024, 12, 1735. https://doi.org/10.3390/jmse12101735

Jiao B, Zhao Q, Chen F, Liu C, Fang Q. Numerical Evaluation of Wave Dissipation on a Breakwater Slope Covered by Precast Blocks with Different Geometrical Characteristics. Journal of Marine Science and Engineering. 2024; 12(10):1735. https://doi.org/10.3390/jmse12101735

Chicago/Turabian StyleJiao, Bowen, Qingli Zhao, Fang Chen, Chunhui Liu, and Qinghe Fang. 2024. "Numerical Evaluation of Wave Dissipation on a Breakwater Slope Covered by Precast Blocks with Different Geometrical Characteristics" Journal of Marine Science and Engineering 12, no. 10: 1735. https://doi.org/10.3390/jmse12101735