A Comparative Study on the Cam Relationship for the Optimal Vibration and Efficiency of a Kaplan Turbine

Abstract

1. Introduction

2. Field Test Setup and Calculation Methodology

Index Text Setup and Data Processing

3. Cam Relationship Determination

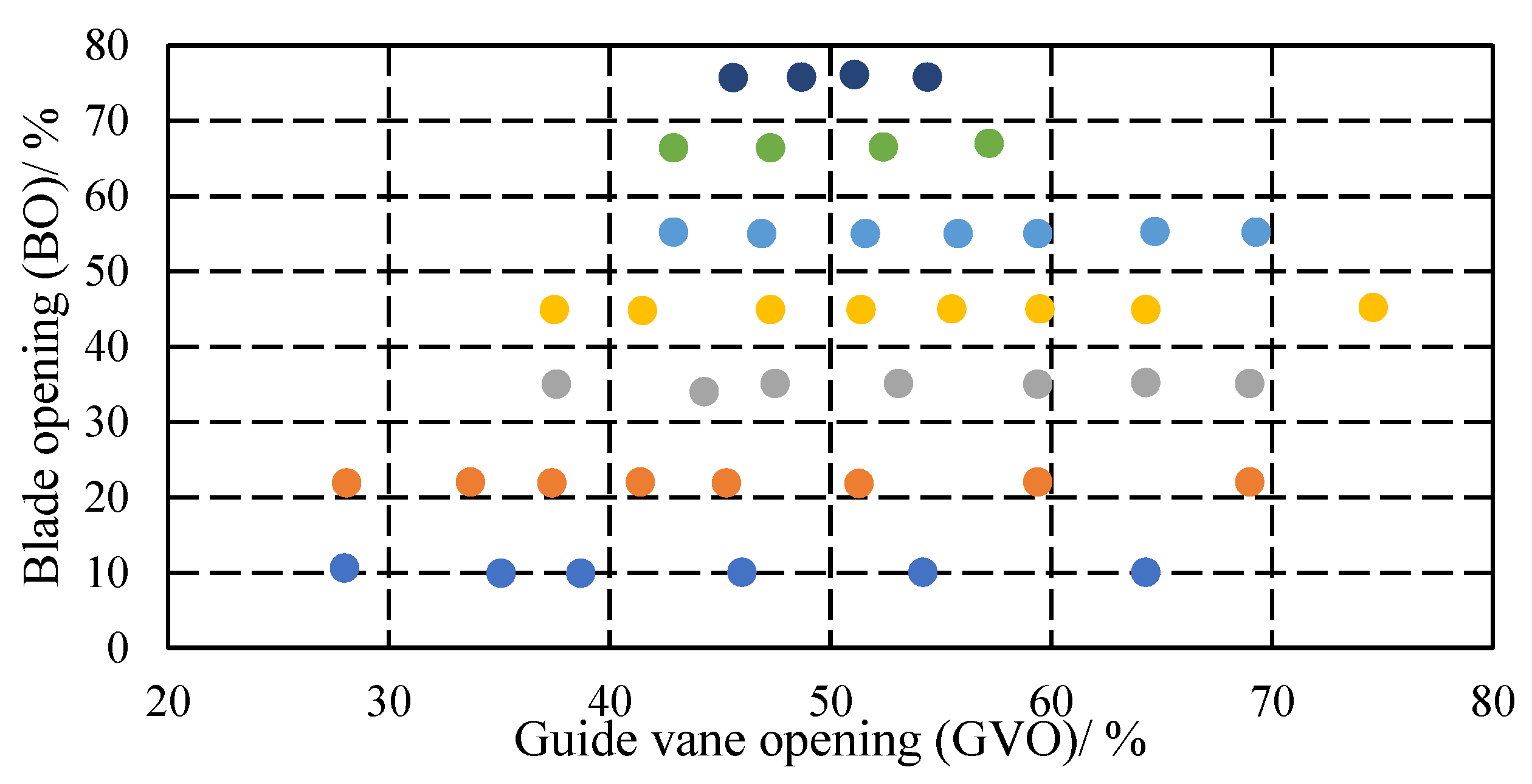

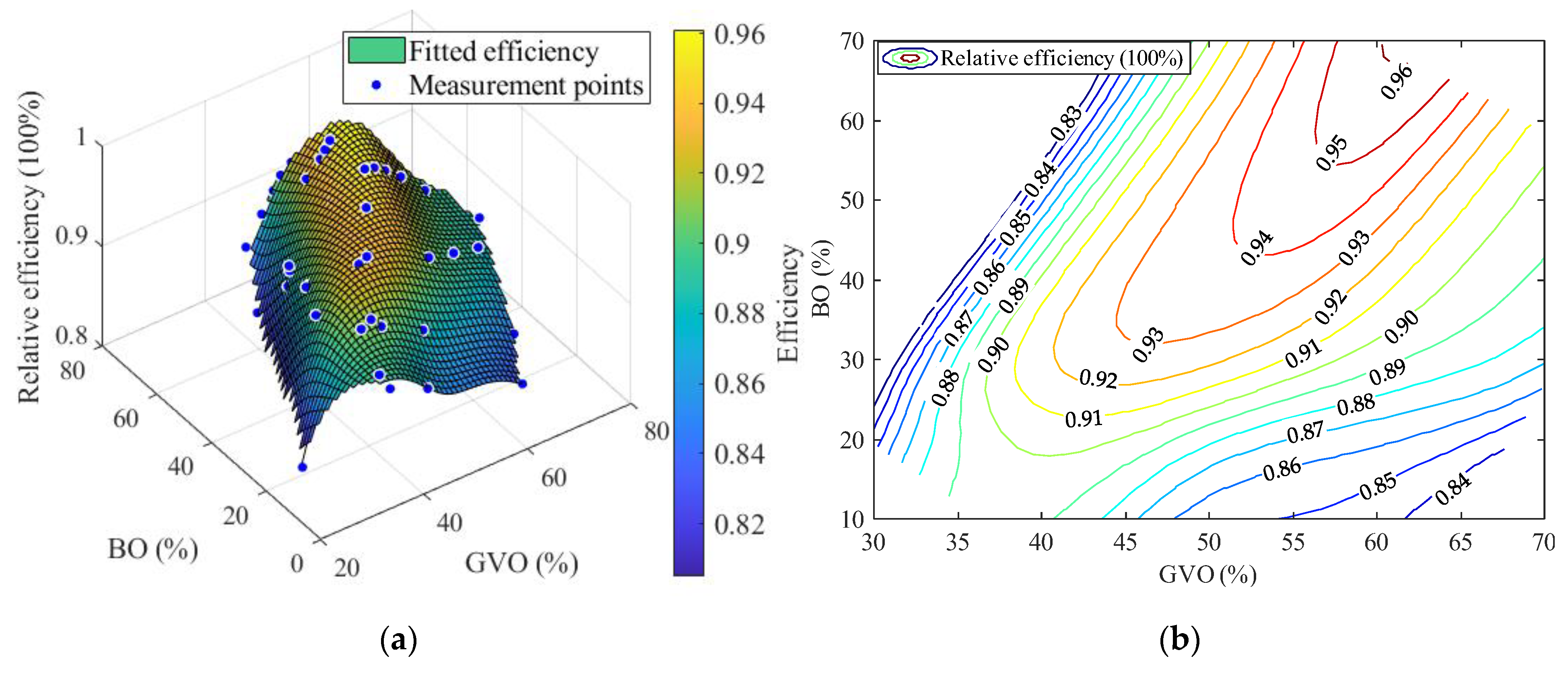

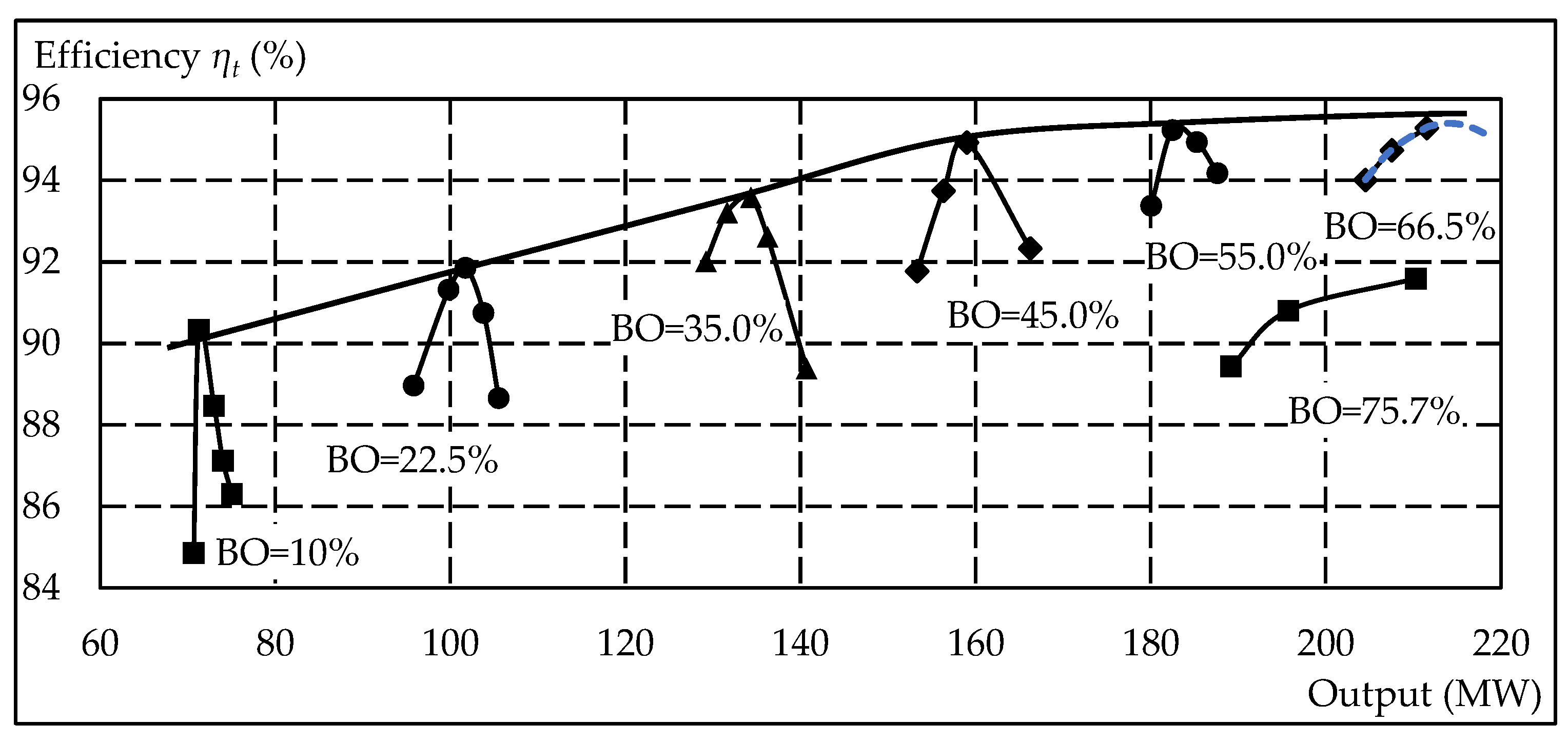

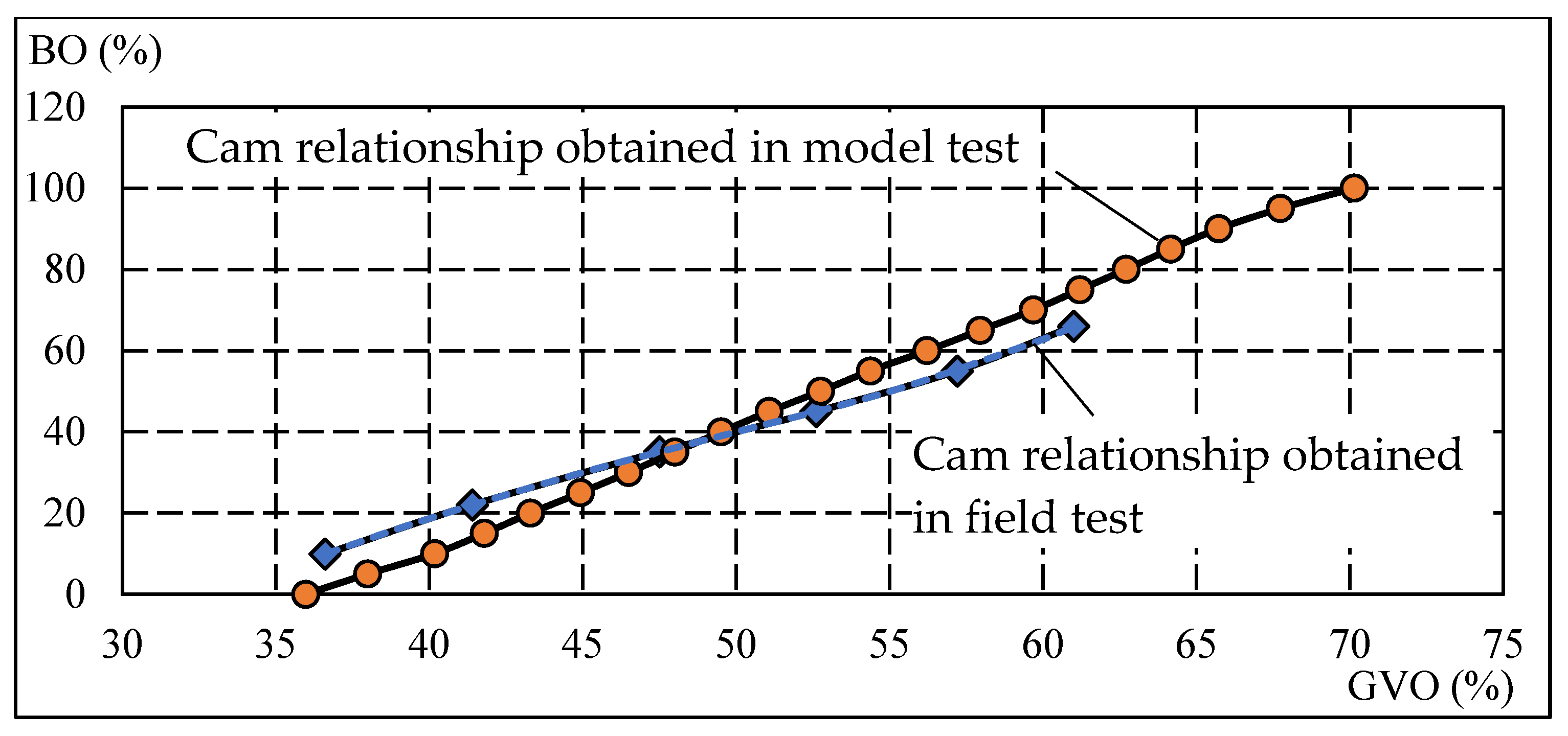

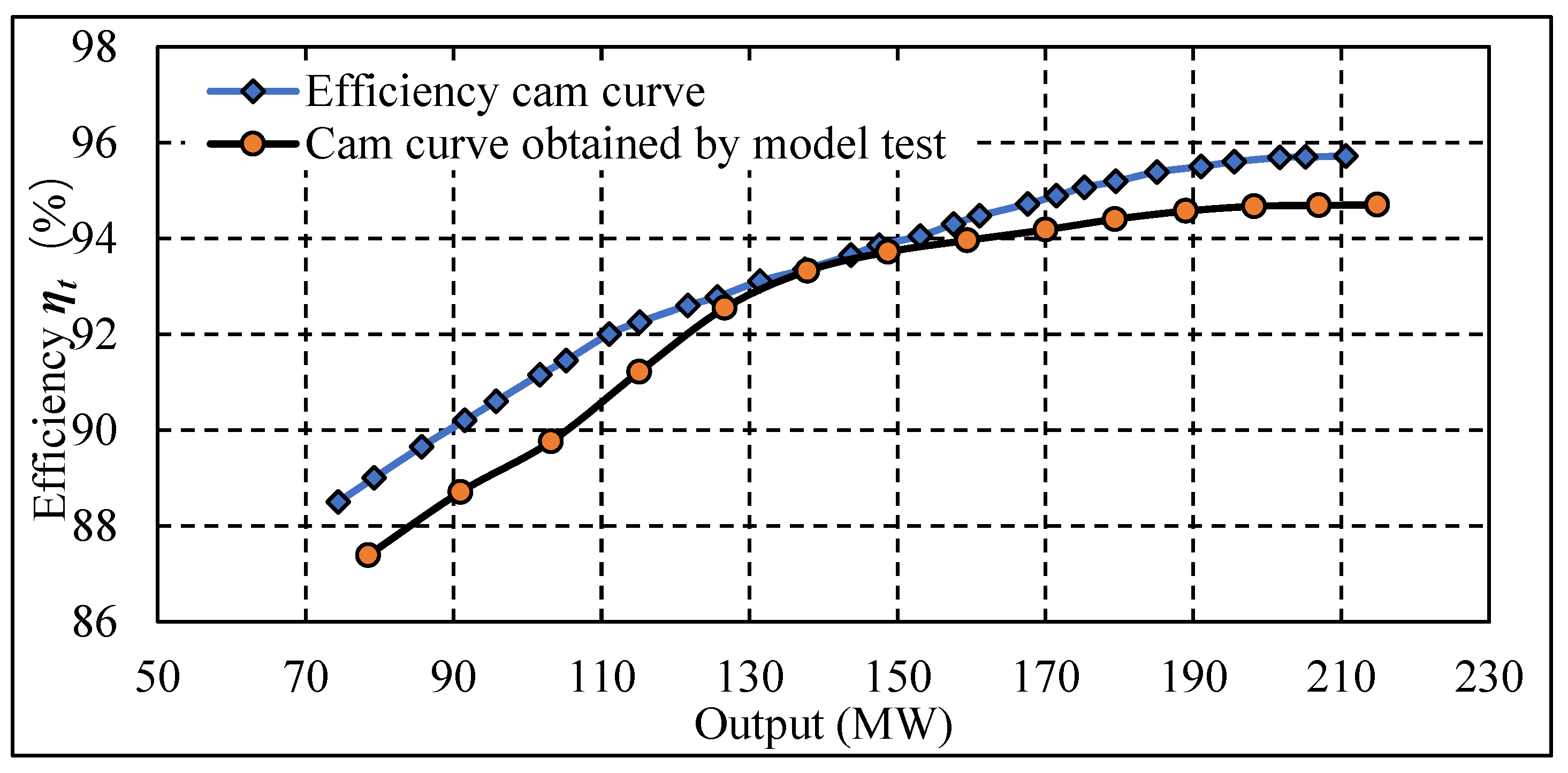

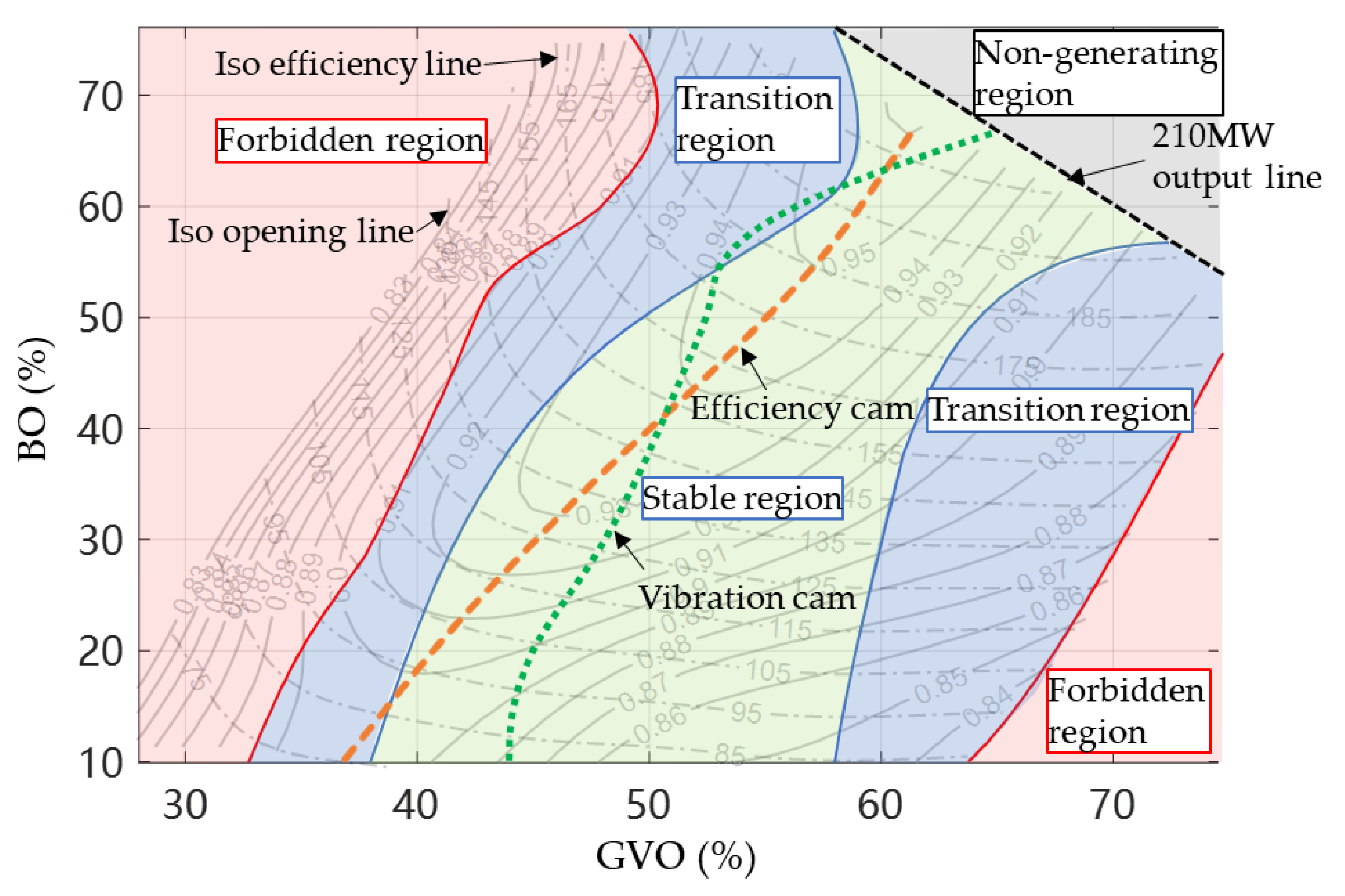

3.1. Efficiency Cam Relationship

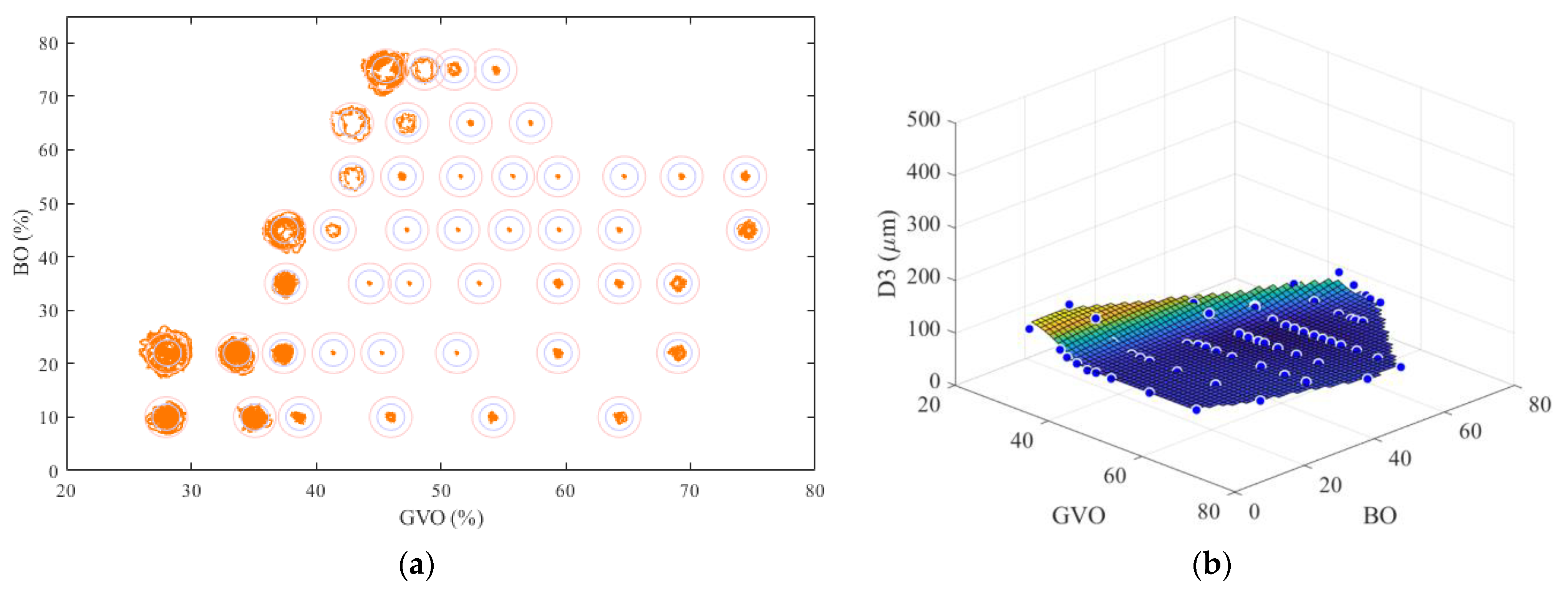

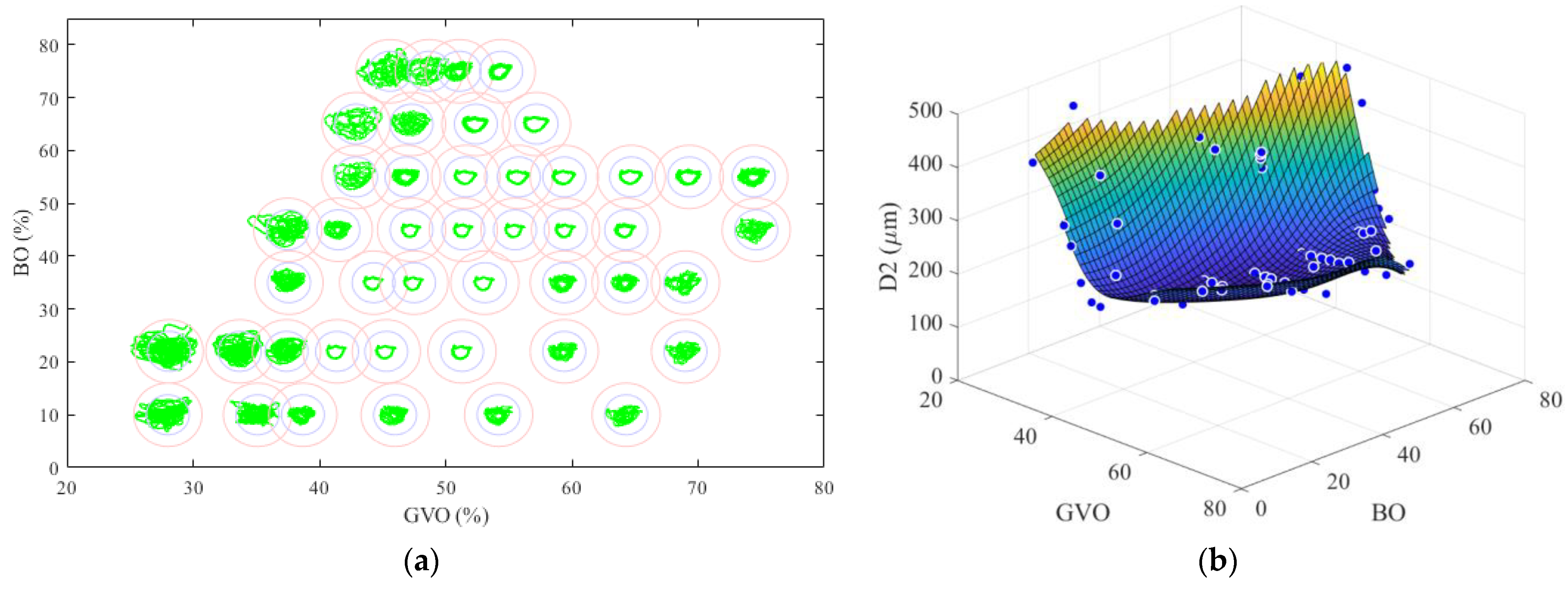

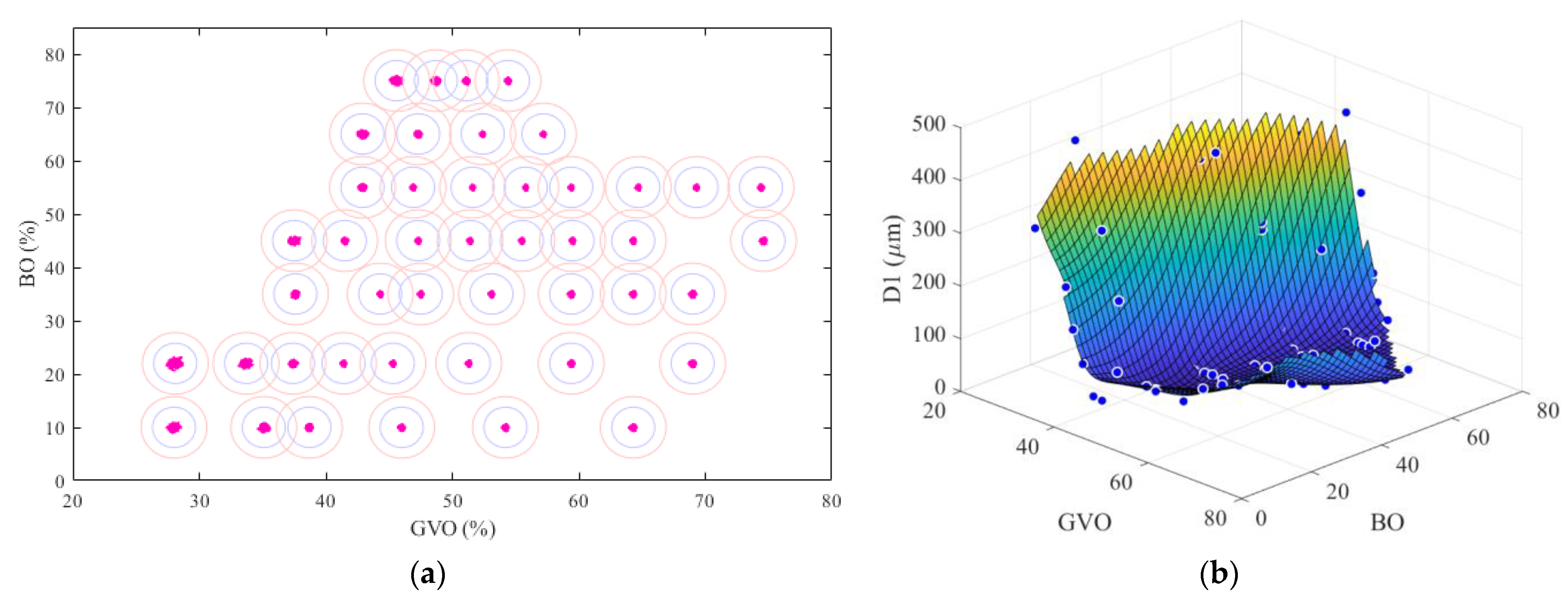

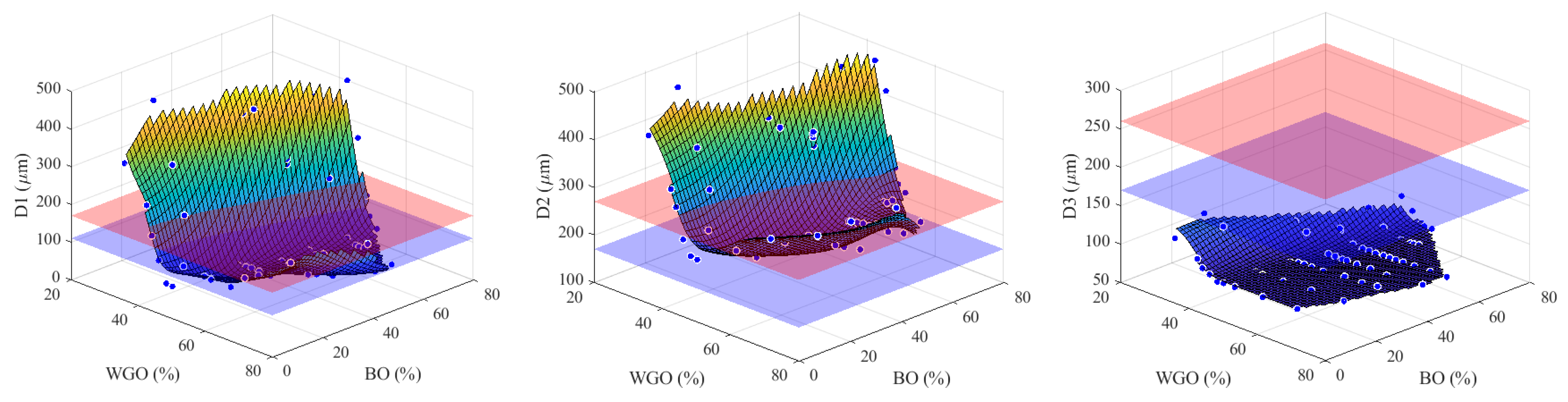

3.2. Vibration Cam Relationship

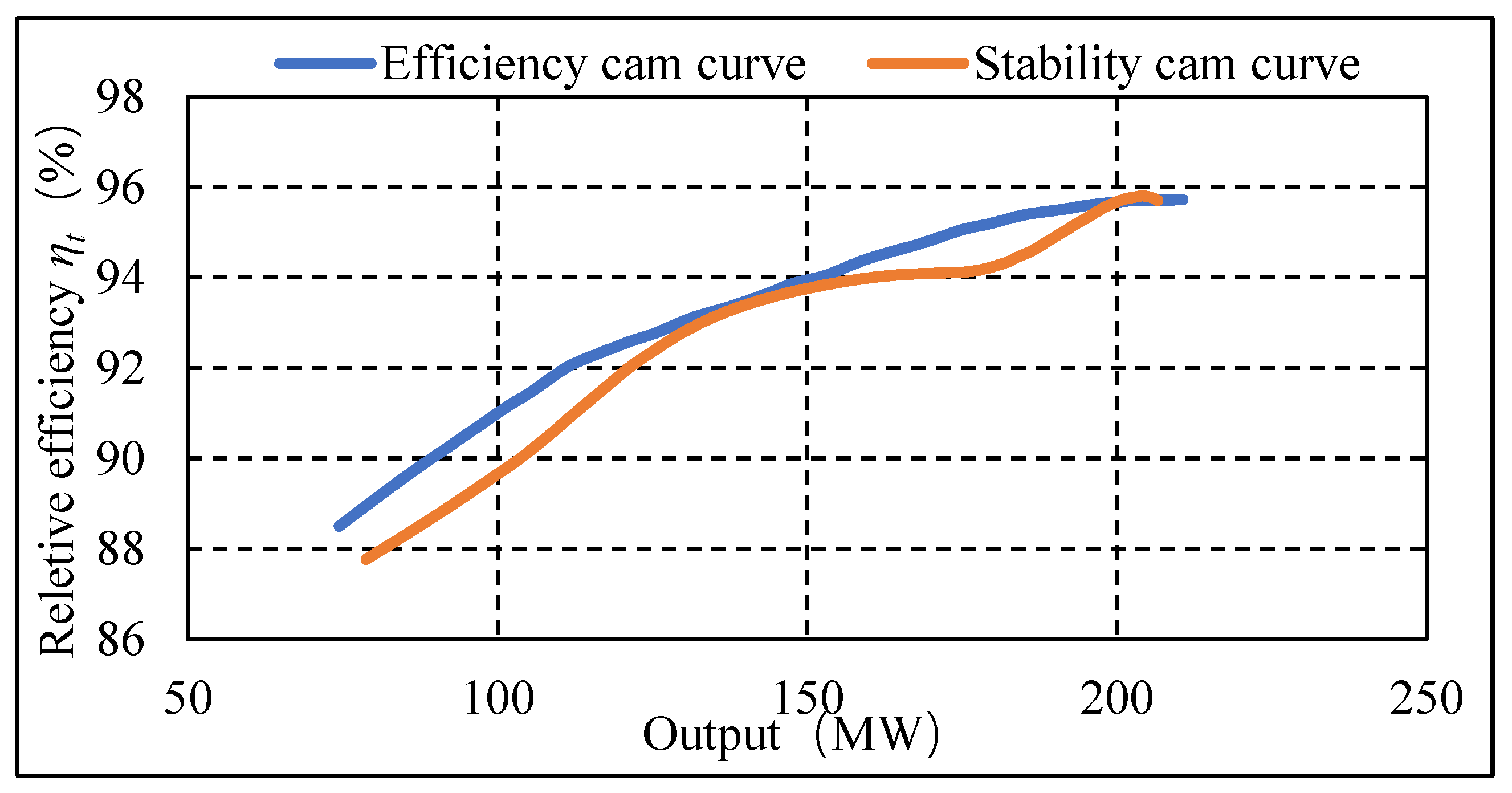

3.3. Comparative Analysis of Efficiency Coordinate Curve and Vibration Coordinate Curve

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Polák, M. A brief history of the kaplan turbine invention. Energies 2021, 14, 6211. [Google Scholar]

- Smith, B.E. The Kaplan Adjustable-Blade Turbine. Trans. Am. Soc. Mech. Eng. 1930, 52, 137–141. [Google Scholar]

- Rodriguez, C.G.; Mateos-Prieto, B.; Egusquiza, E. Monitoring of rotor-stator interaction in pump-turbine using vibrations measured with on-board sensors rotating with shaft. Shock Vib. 2014, 2014, 276796. [Google Scholar] [CrossRef]

- Valentín, D.; Presas, A.; Egusquiza, M.; Valero, C.; Egusquiza, E. Behavior of Francis turbines at part load. Field assessment in prototype: Effects on power swing. IOP Conf. Ser. Earth Environ. Sci. 2019, 240, 062012. [Google Scholar] [CrossRef]

- Valero, C.; Egusquiza, E.; Presas, A.; Valentin, D.; Egusquiza, M.; Bossio, M. Condition monitoring of a prototype turbine. Description of the system and main results. J. Phys. Conf. Ser. 2017, 813, 12041. [Google Scholar] [CrossRef]

- Zhao, W. Improved Condition Monitoring of Hydraulic Turbines Based on Artificial Intelligence Techniques. Doctoral Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2021. Available online: http://tdx.cat/handle/10803/672373 (accessed on 11 January 2024).

- Egusquiza Estévez, E. Comportament Dinàmic de Màquines Hidràuliques; Edicions UPC: Barcelona, Spain, 2003; Available online: http://hdl.handle.net/2099.3/36745 (accessed on 11 January 2024).

- Valero, C.; Egusquiza, M.; Egusquiza, E.; Presas, A.; Valentin, D.; Bossio, M. Extension of Operating Range in Pump-Turbines. Influence of Head and Load. Energies 2017, 10, 2178. [Google Scholar] [CrossRef]

- Egusquiza, E.; Valentín, D.; Presas, A.; Valero, C. Overview of the experimental tests in prototype. J. Phys. Conf. Ser. 2017, 813, 012037. [Google Scholar] [CrossRef]

- Valentín, D.; Presas, A.; Egusquiza, M.; Valero, C.; Egusquiza, E. Transmission of High Frequency Vibrations in Rotating Systems. Application to Cavitation Detection in Hydraulic Turbines. Appl. Sci. 2018, 8, 451. [Google Scholar] [CrossRef]

- Wang, Z.; Qin, L.; Zeng, J.; Lin, J.; Yang, J.; Chen, W.; Luo, Y.; Yan, Z. Hydroturbine operating region partitioning based on analyses of unsteady flow field and dynamic response. Sci. China Technol. Sci. 2010, 53, 519–528. [Google Scholar] [CrossRef]

- Chen, G.; Du, J.; Liang, S. A research method of hydropower generating unit vibration area establishment based on wavelet analysis and vibration signals gray moment. Sci. Technol. Eng. 2016, 35, 215–219. [Google Scholar]

- Fan, Y.; Zhang, F.; Fu, J. Identification of vortex zone operation of hydraulic turbine based on shorttime Fourier Transform. Yangtze River 2016, 8, 85–87. [Google Scholar]

- Conrad, P.; Weber, W.; Jung, A. Deep Part Load Flow Analysis in a Francis Model turbine by means of two-phase unsteady flow simulations. J. Phys. Conf. Ser. 2017, 813, 12027. [Google Scholar] [CrossRef]

- Gajić, A.; Ignjatović, B.; Predić, Z.; Ivljanin, B. Test of cam characteristic of the Kaplan turbine by on-site measurement. FME Trans. 2005, 33, 145–149. [Google Scholar]

- Adamkowski, A.; Lewandowski, M.; Lewandowski, S. Selected experiences with optimization tests of the Kaplan-type hydraulic turbines. J. Energy Power Eng. 2014, 8, 1002–1011. [Google Scholar] [CrossRef][Green Version]

- Valentin, D.; Roehr, C.; Presas, A.; Heiss, C.; Egusquiza, E.; Bosbach, W. Experimental-Numerical Design and Evaluation of a Vibration Bioreactor using Piezoelectric Patches. Sensors 2019, 19, 436. [Google Scholar] [CrossRef]

- Iovănel, R.G.; Dehkharqani, A.S.; Bucur, D.M.; Cervantes, M.J. Numerical simulation and experimental validation of a Kaplan prototype turbine operating on a cam curve. Energies 2022, 15, 4121. [Google Scholar]

- Zhou, J.; Zhou, X.; Xia, M.; Luo, H.; Wu, Y.; Wang, Z. Research and Analysis on Model measurement and Prototype Operation of large-scale Kaplan turbine. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; p. 12045. [Google Scholar]

- Zhang, Y.L.; Wu, Y.B.; Wei, J.W.; Wang, Z.W.; Zhou, L.J. Clearance flow field characteristics of Kaplan turbine under different flange clearance. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; p. 12023. [Google Scholar]

- Jovanović, R.Ž.; Božić, I.O. Feedforward neural network and ANFIS-based approaches to forecasting the off-cam energy characteristics of Kaplan turbine. Neural Comput. Appl. 2018, 30, 2569–2579. [Google Scholar]

- Dunca, G.; Bucur, D.M.; Călinoiu, C.; Isbăşoiu, E.C. Experimental analysis of the optimal cam characteristic for a kaplan turbine. In Proceedings of the IGHEM 2012, Trondheim, Norway, 27–30 June 2012. [Google Scholar]

- Amiri, K.; Mulu, B.; Cervantes, M.J.; Raisee, M. Effects of load variation on a Kaplan turbine runner. Int. J. Fluid Mach. Syst. 2016, 9, 182–193. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, S.; Dou, H.-S.; Wu, S.; Chen, T. Numerical prediction and similarity study of pressure fluctuation in a prototype Kaplan turbine and the model turbine. Comput. Fluids 2012, 56, 128–142. [Google Scholar] [CrossRef]

- Luna-Ramírez, A.; Campos-Amezcua, A.; Dorantes-Gómez, O.; Mazur-Czerwiec, Z.; Muñoz-Quezada, R. Failure analysis of runner blades in a Francis hydraulic turbine—Case study. Eng. Fail. Anal. 2016, 59, 314–325. [Google Scholar]

- Peltier, R.; Boyko, A.; Popov, S.; Krajisnik, N. Investigating the Sayano-Shushenskaya hydro power plant disaster. Power 2010, 154, 48. [Google Scholar]

- Zhao, Q.; Chai, J.; Ma, C.; Ding, J.; Li, B. Causes of Header Bolt Fracture of a Pumped Storage Power Station. J. Yangtze River Sci. Res. Inst. 2019, 36, 134–138. [Google Scholar] [CrossRef]

- Li, Z. The Research of Combination Relationship and Performance of Bulb Tubular Turbine. Ph.D. Thesis, Lanzhou University of Technology, Lanzhou, China, 2006. [Google Scholar]

- Isaksson, H. Uncertainties in Kaplan Cam Curve. Luleå University of Technology, Norrbotten County, Sweden. 2016. Available online: https://ltu.diva-portal.org/smash/record.jsf?pid=diva2%3A1026401&dswid=640 (accessed on 11 January 2024).

- Gajic, A.; Ignjatovic, B.; Komarov, D.; Daskalovic, L.; Stojkovic, D.; Predic, Z. Cam characteristics of the Kaplan turbine determined by efficiency and bearing vibrations. In Proceedings of the 6th International Conference on Hydraulic Machinery and Hydrodynamics, Timisoara, Romania, 21–22 October 2004. [Google Scholar]

- Kaniecki, M.; Krzemianowski, Z.; Banaszek, M. Computational fluid dynamics simulations of small capacity Kaplan turbines. Trans. Inst. Fluid-Flow Mach. 2011, 123, 71–84. [Google Scholar]

- Sheldon, L.H. Field testing and optimising efficiency of hydro turbines. Int. Water Power Dam Constr. 1982, 34, 22–28. [Google Scholar]

- ISO 20816-5:2018; Mechanical Vibration—Measurement and Evaluation of Machine Vibration—Part 5: Machine Sets in Hydraulic Power Generating and Pump-Storage Plants. ISO: Geneva, Switzerland, 2018; p. 60.

| Parameter | Value | Unit |

|---|---|---|

| Highest head | 37.79 | m |

| Rated head | 25.0 | m |

| Lowest head | 12.91 | m |

| Rated discharge | 890.34 | m3/s |

| Runner diameter | 10.4 | m |

| Rated output | 200 | MW |

| Run-away speed | 195.1 | rpm |

| Installation level | 14.71 | m |

| Best efficiency | 95.67 | M/P (%) |

| Rated efficiency | 95.67 | M/P (%) |

| Sensor Type | Measurement Position | Specification |

|---|---|---|

| Displacement sensor | Headcover (X-direction: A11; Y-direction: A14), lower bracket (X-direction: A21; Y-direction: A24), upper bracket (X-direction: A31; Y-direction: A34) | Sensitivity: 8 mV/µm |

| Proximity probe | Turbine bearing (X-direction: D11; Y-direction: D14), lower generator bearing (X-direction: D21; Y-direction: D24), upper generator bearing (X-direction: D31; Y-direction: D34) | Sensitivity: 4 V/mm |

| Pressure sensor | Spiral casing inlet (50 kPa), draft tube outlet (20 kPa) | Output range: 4~20 mA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, S.; Zhao, W.; Huang, T.; Xia, M.; Wang, Z. A Comparative Study on the Cam Relationship for the Optimal Vibration and Efficiency of a Kaplan Turbine. J. Mar. Sci. Eng. 2024, 12, 241. https://doi.org/10.3390/jmse12020241

Deng S, Zhao W, Huang T, Xia M, Wang Z. A Comparative Study on the Cam Relationship for the Optimal Vibration and Efficiency of a Kaplan Turbine. Journal of Marine Science and Engineering. 2024; 12(2):241. https://doi.org/10.3390/jmse12020241

Chicago/Turabian StyleDeng, Sen, Weiqiang Zhao, Tianbao Huang, Ming Xia, and Zhengwei Wang. 2024. "A Comparative Study on the Cam Relationship for the Optimal Vibration and Efficiency of a Kaplan Turbine" Journal of Marine Science and Engineering 12, no. 2: 241. https://doi.org/10.3390/jmse12020241

APA StyleDeng, S., Zhao, W., Huang, T., Xia, M., & Wang, Z. (2024). A Comparative Study on the Cam Relationship for the Optimal Vibration and Efficiency of a Kaplan Turbine. Journal of Marine Science and Engineering, 12(2), 241. https://doi.org/10.3390/jmse12020241