An Experimental Study of Pulp-Lift Characteristics Using a High-Viscous Fluid Simulating Deep Muddy Seawater

Abstract

:1. Introduction

2. Materials

2.1. Working Fluid

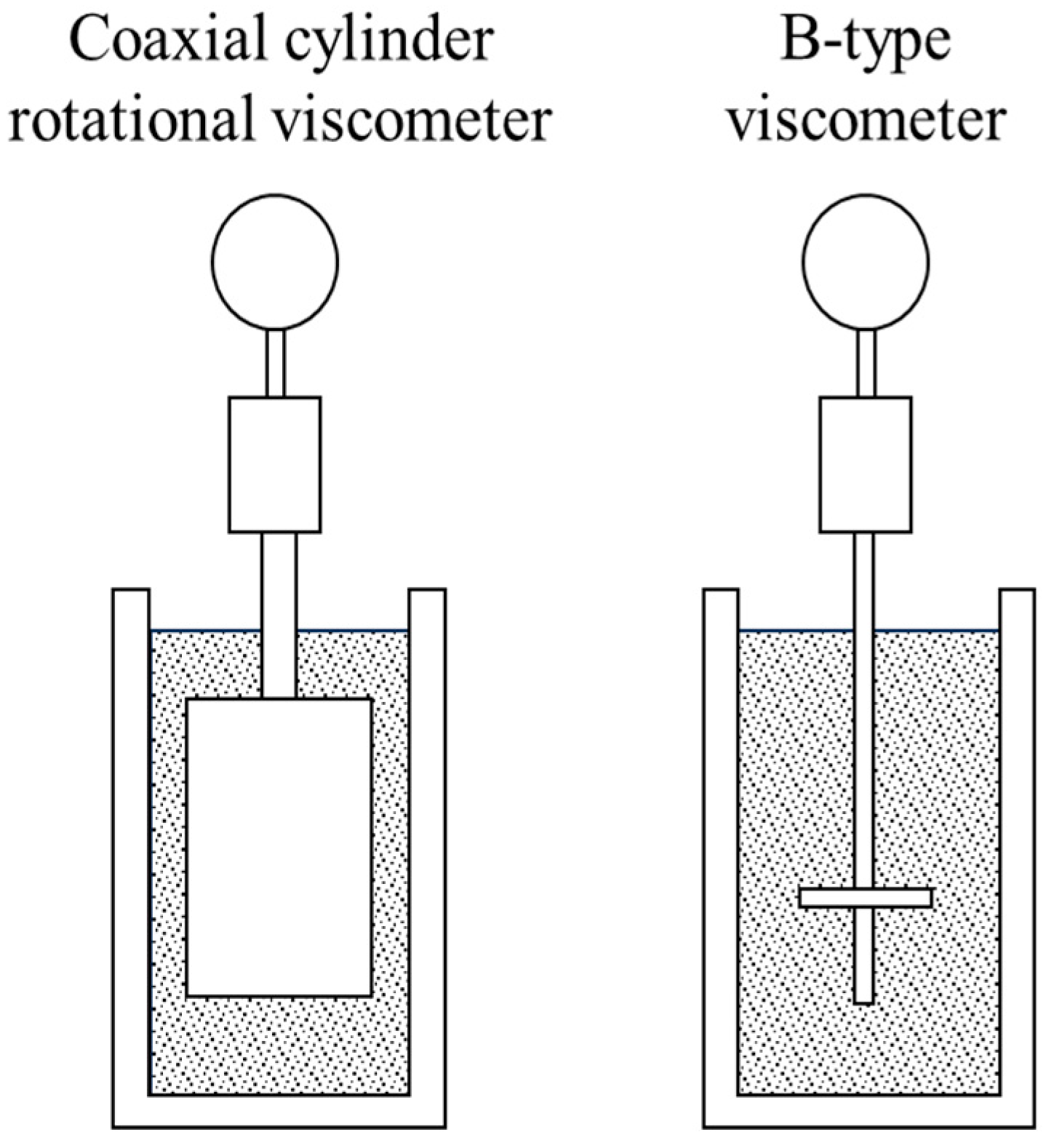

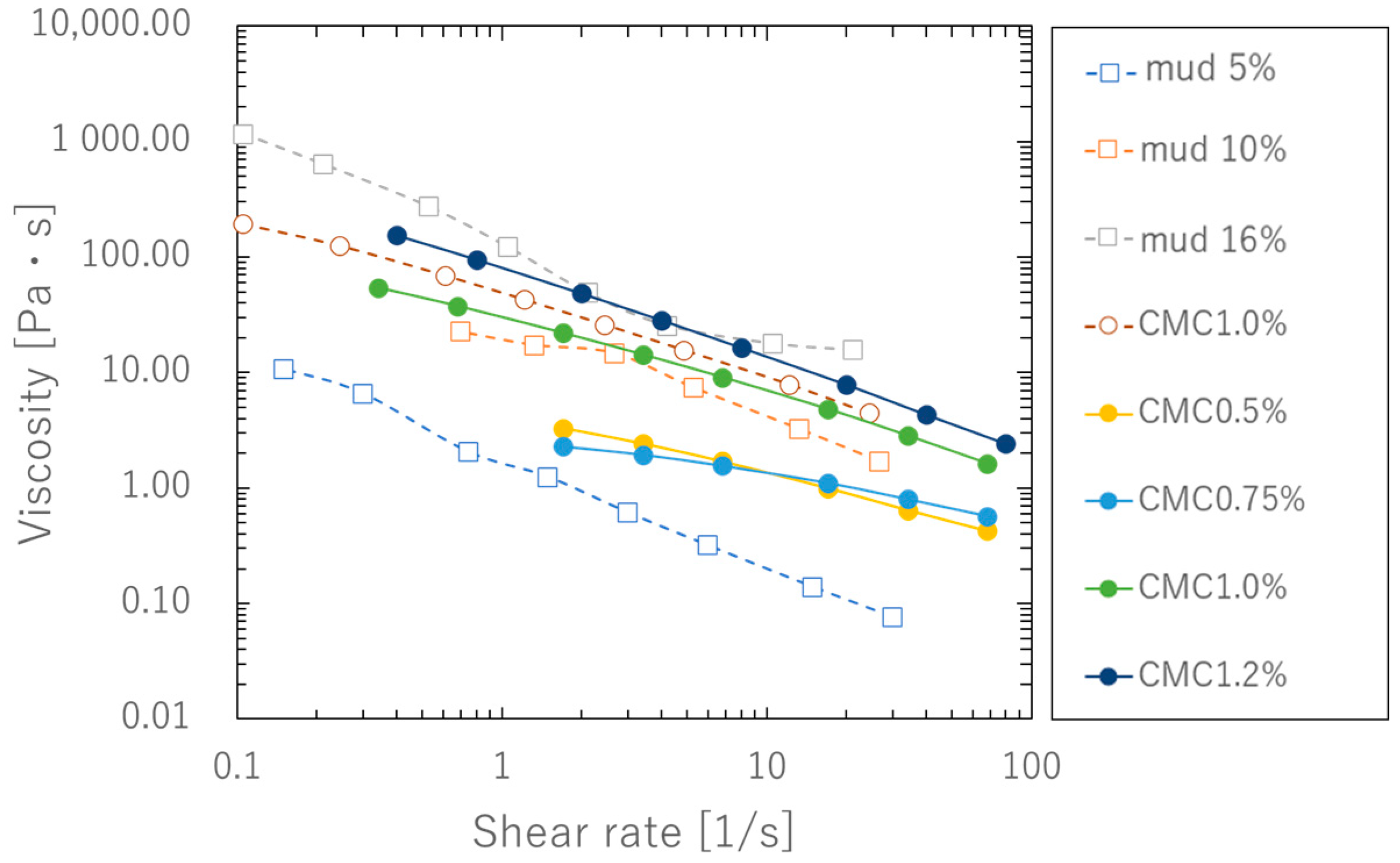

2.2. Viscosity Experiments

2.3. Results

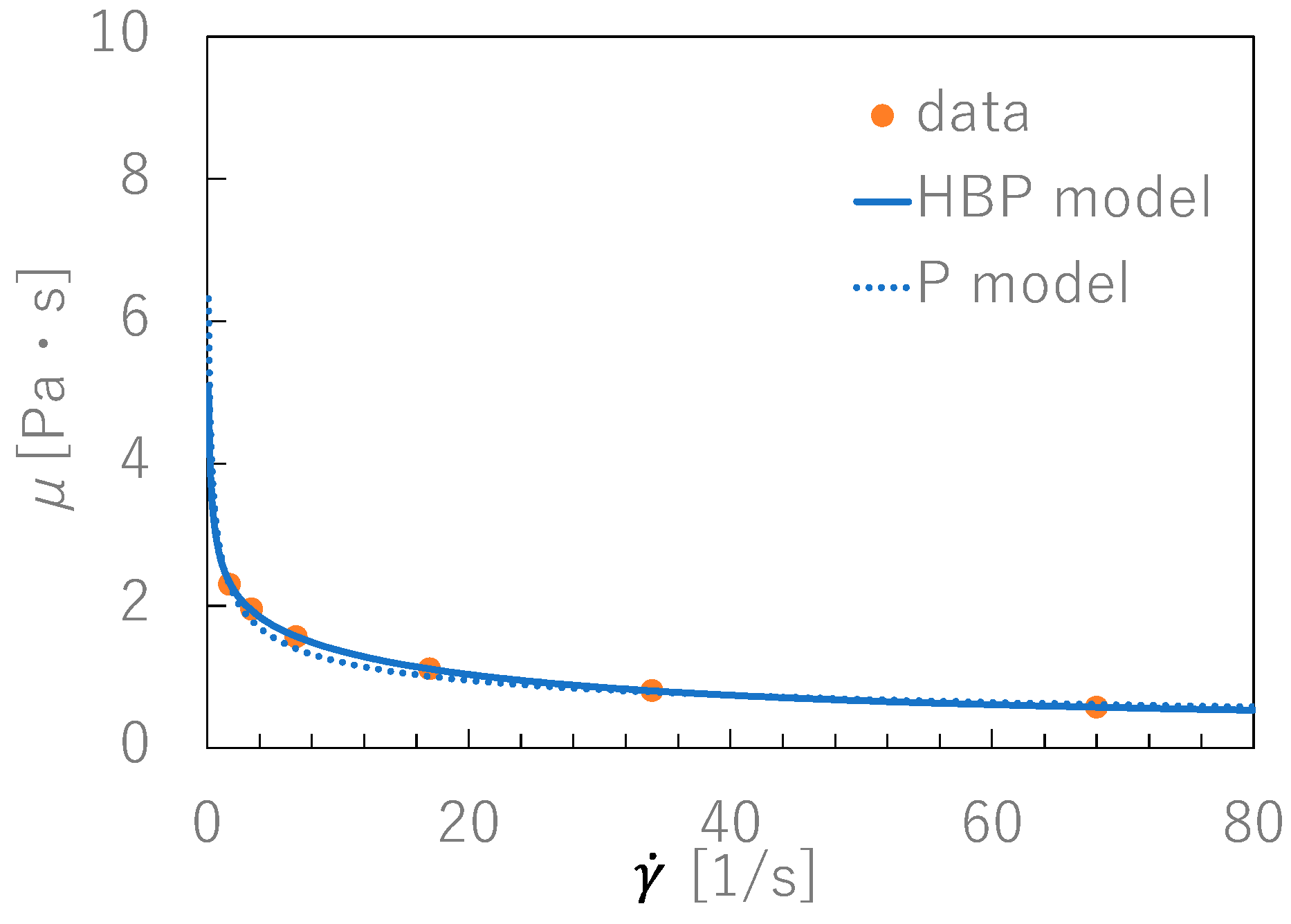

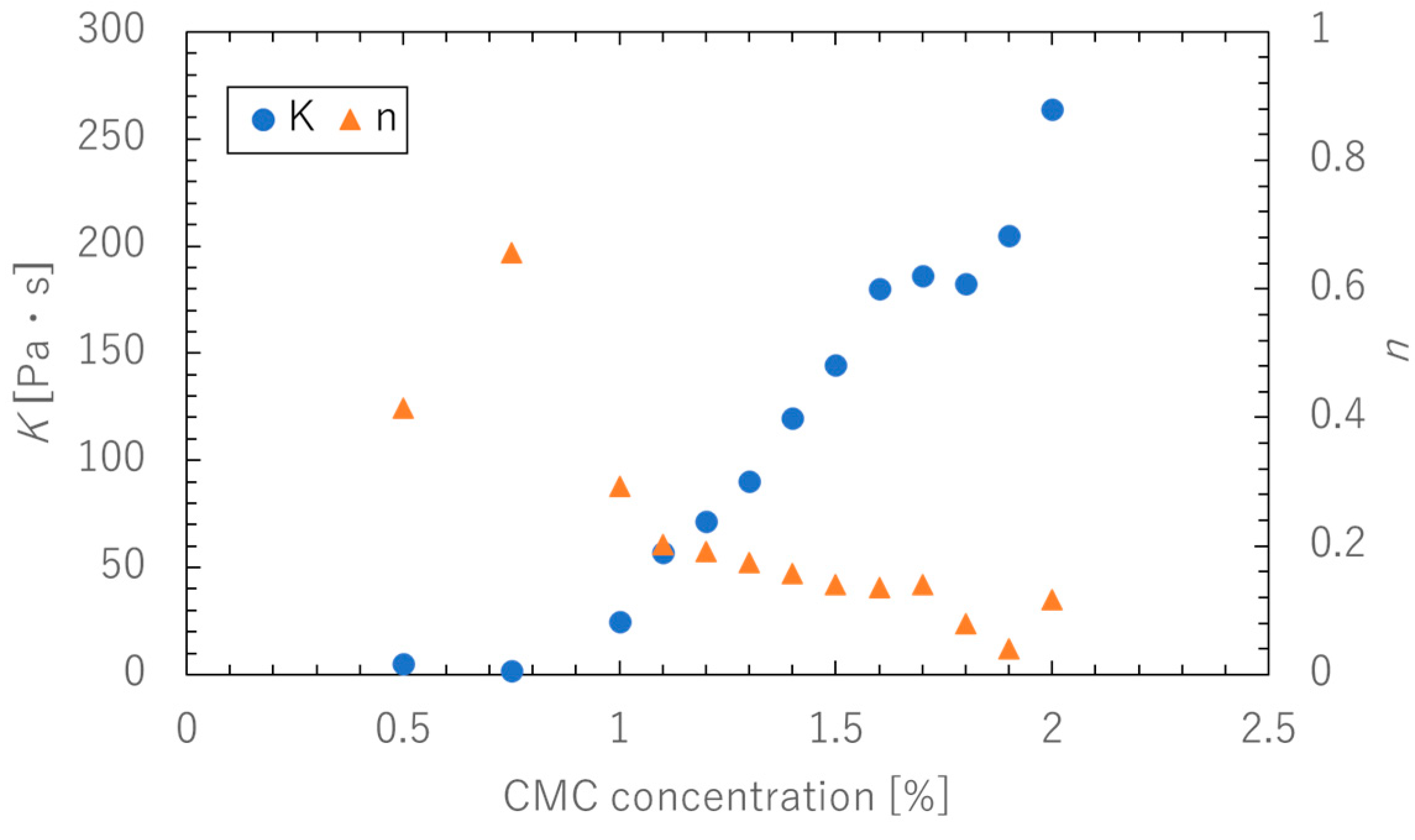

2.4. Estimation of the Viscosity Curve

3. Pulp-Lift Experiments

3.1. Experimental Conditions

3.1.1. Ore

3.1.2. Velocity Conditions

3.1.3. Observation Conditions

3.2. Results

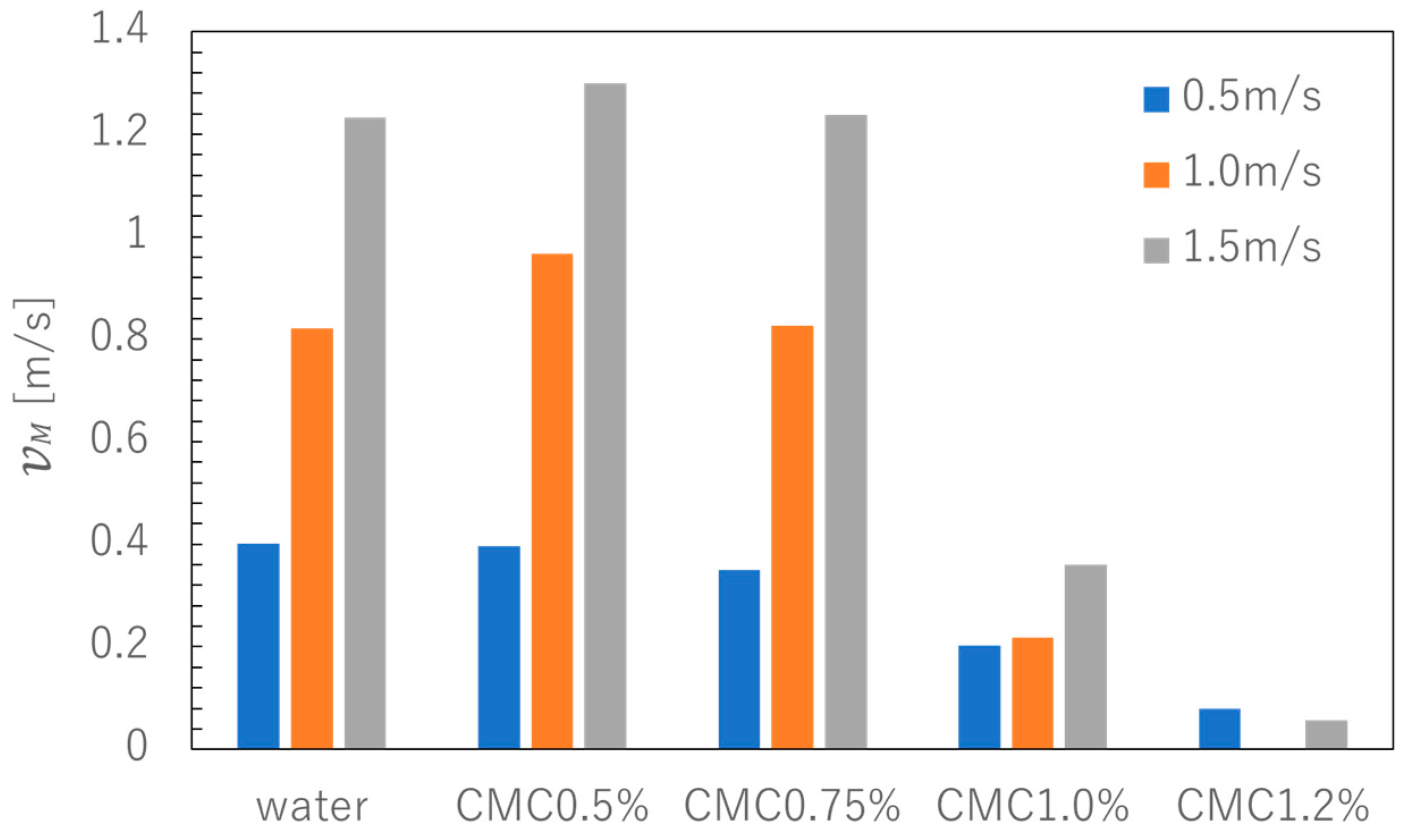

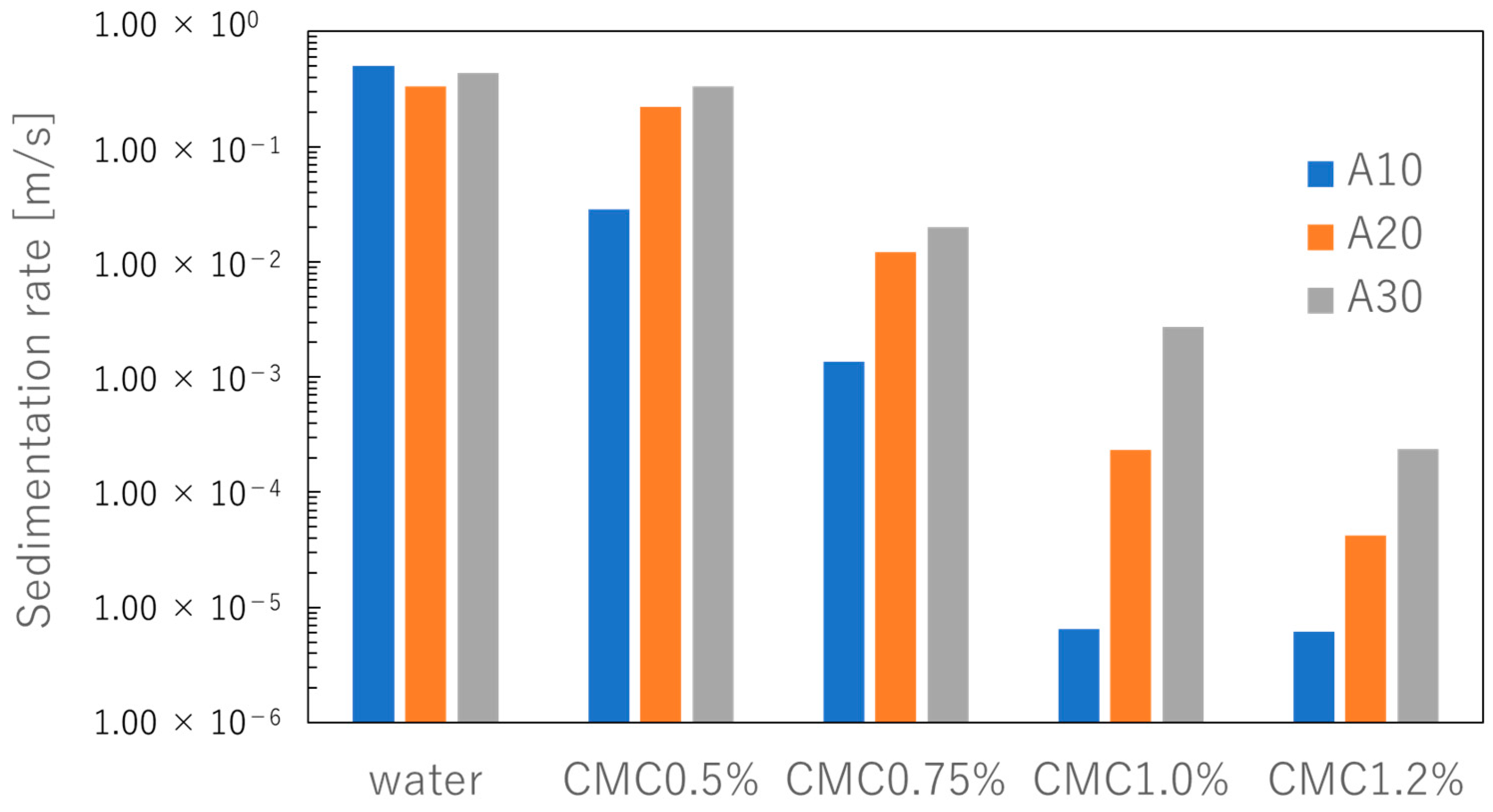

3.2.1. Pulp-Lift Results

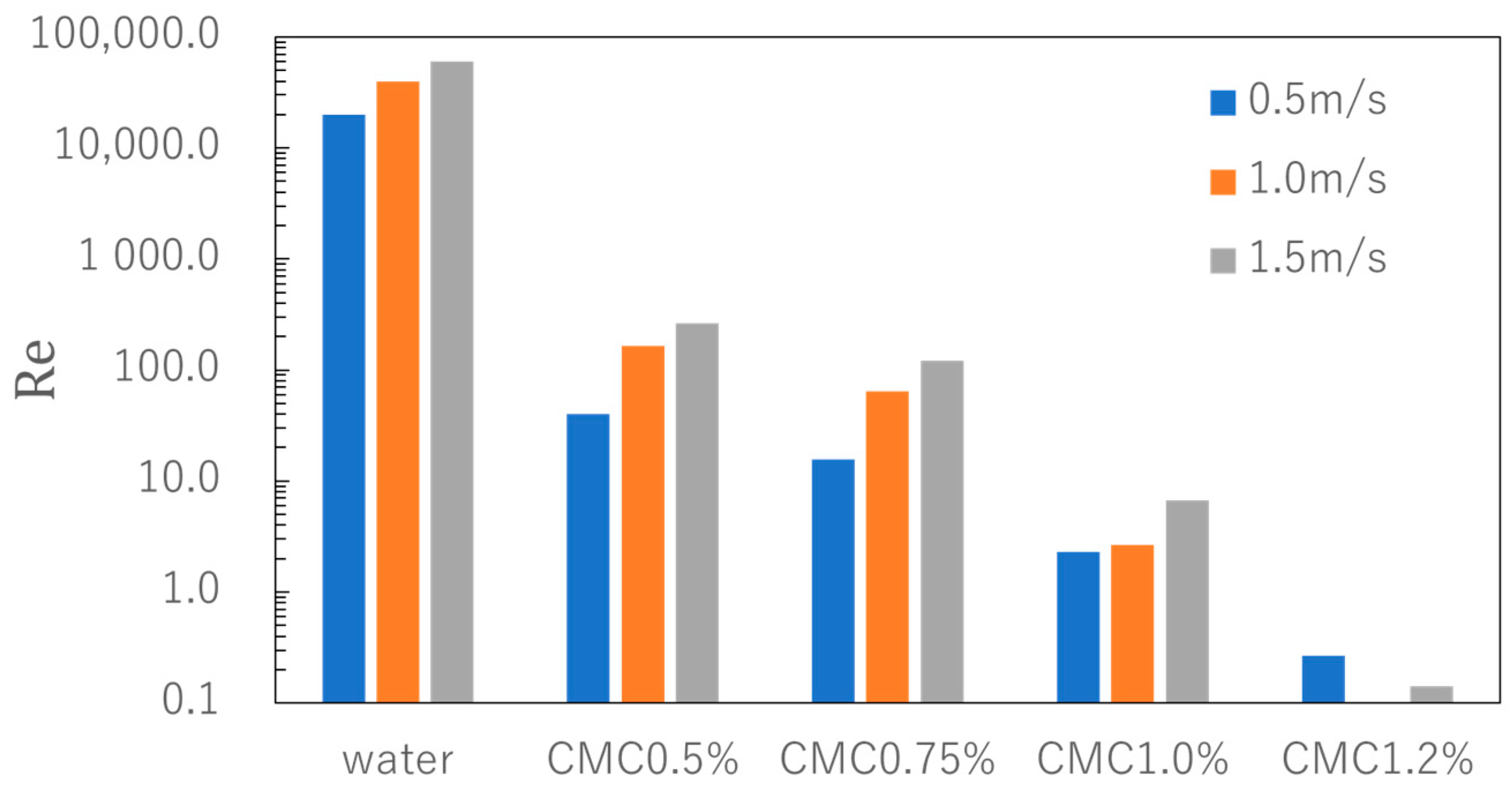

3.2.2. Reynolds Number

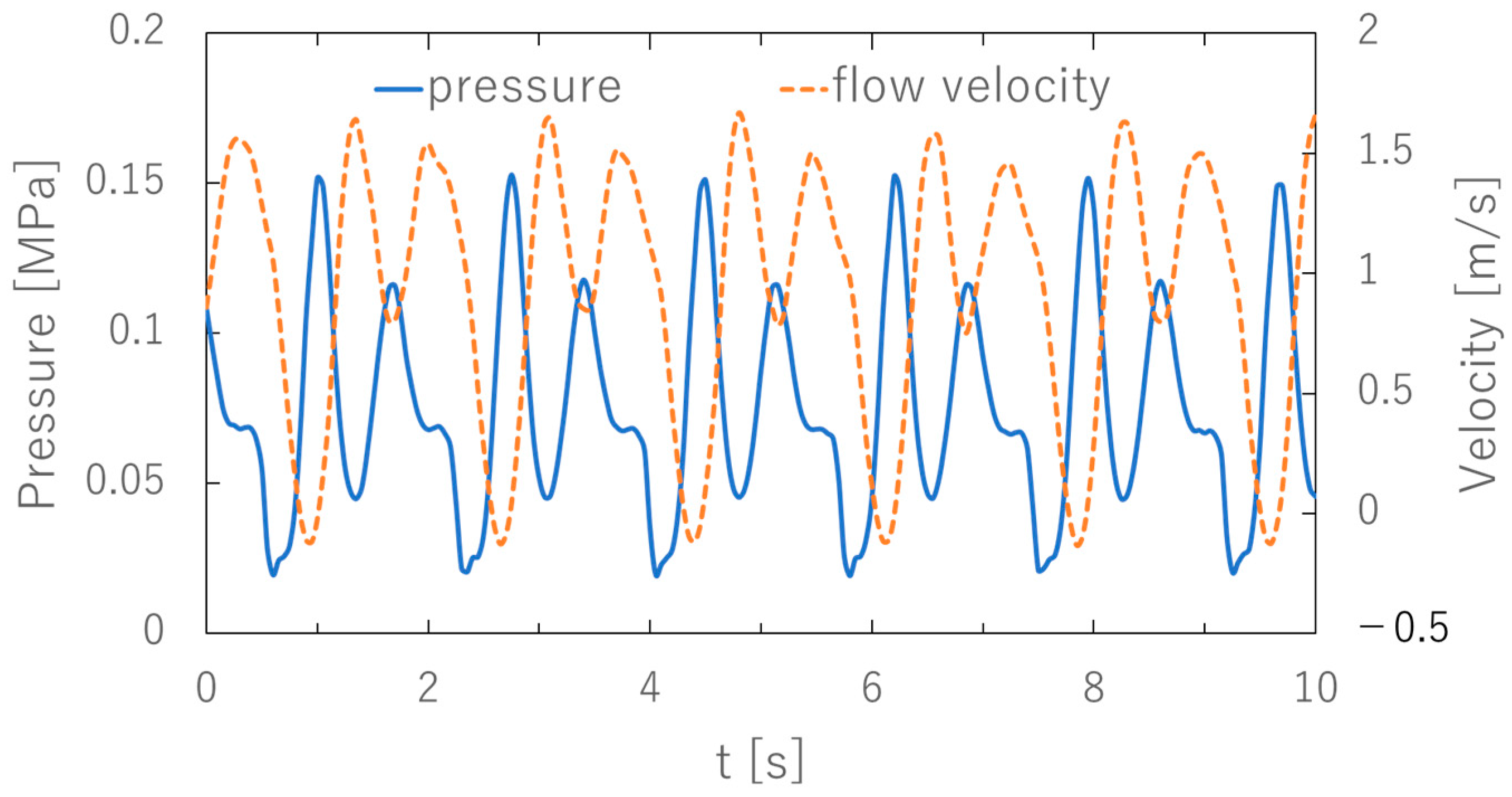

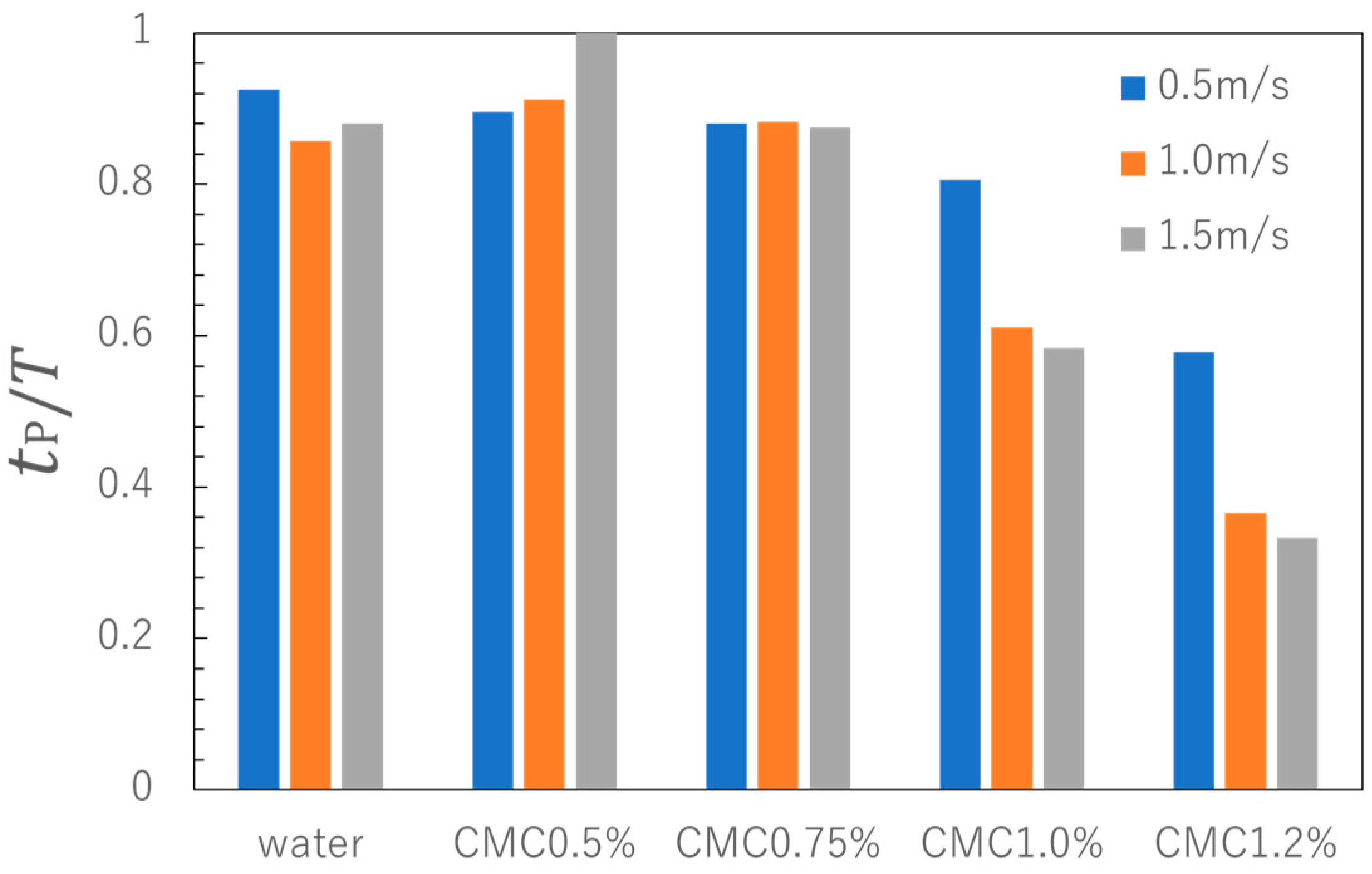

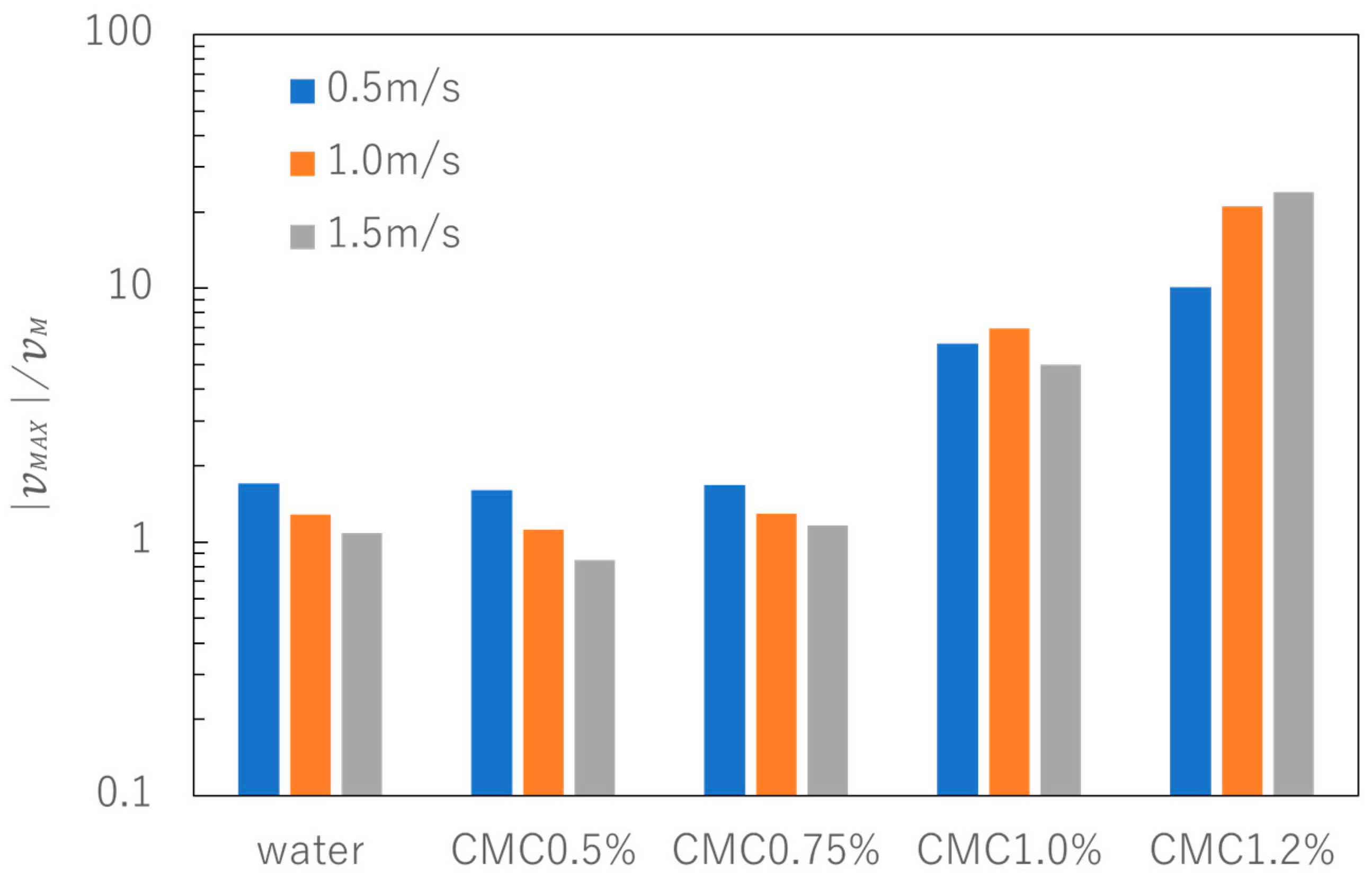

3.2.3. Pulsation

4. Discussion

4.1. Results of Lifting Ore

4.2. Effects of Pulsation Caused by Increased Viscosity

5. Conclusions

- (1)

- The results of lifting ore using water and CMC as the working fluids showed that ores that could not be pumped by water could be pumped using CMC. This is because the increase in fluid viscosity suppressed turbulence in the pipe and increased the drag force. In addition, the sedimentation of the ore at the time of reversal was suppressed. Therefore, an appropriate increase in viscosity improves ore pumping efficiency.

- (2)

- On the other hand, an excessive increase in viscosity causes an increase in backward flow due to pump pulsation.

- (3)

- Therefore, there is an optimum viscosity for pulp-lift ore pumping, and a viscosity of about CMC 0.5% was optimum in this experiment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kato, Y.; Fujinaga, K.; Nakamura, K.; Takaya, Y.; Kitamura, K.; Ohta, J.; Toda, R.; Nakashima, T.; Iwamori, H. Deep-Sea Mud in the Pacific Ocean as a Potential Resource for Rare-Earth Elements. Nat. Geosci. 2011, 4, 535–539. [Google Scholar] [CrossRef]

- Bernard, J.; Bath, A.; Greger, B. Analysis and Comparison of Nodule Hydraulic Transport Systems. In Proceedings of the Offshore Technology Conference, Huston, TX, USA, 27–30 April 1987. [Google Scholar]

- Yamazaki, T.; Nakatani, N.; Arai, R.; Sekimoto, T.; Katayama, H. Combined Mining and Pulp-Lifting of Ferromanganese Nodules and Rare-Earth Element-Rich Mud around Minamitorishima Island in the Western North Pacific: A Prefeasibility Study. Minerals 2021, 11, 310. [Google Scholar] [CrossRef]

- Sugahara, H.; Shimomura, K.; Nakatani, N.; Yamazaki, T.; Katayama, H.; Kumagai, T. Fundamental Study of Pulp Lift Method for Mixed Lifting of Submarine Mineral Resources. Jpn. J. JSCE 2023, 79, 23–18091. [Google Scholar] [CrossRef]

- Orita, K.; Tani, K.; Suzuki, A.; Kosho, T. Study of Ore Lifting Efficiency Using Mixture of Bentonite Suspension and Sand for Deep Sea Mining. J. JSCE Ser. B3 2021, 77, I_523–I_528. [Google Scholar] [CrossRef] [PubMed]

- Nunoya, N.; Tsuchida, T.; Abe, T. Flow Characteristics of Marine Clays of High Water Content Condition. J. Jpn. Soc. Civ. Eng. Ser. B2 (Coast. Eng.) 2012, 68, I_551–I_555. [Google Scholar] [CrossRef]

- Japanese Standards Association (1991). JIS Z 8803: Methods for Viscosity Measurement of Liquid. 2011. Available online: https://kikakurui.com/z8/Z8803-2011-01.html (accessed on 19 July 2024).

- Shimizu, Y.; Hatakeyama, N.; Hanamura, E.; Watanabe, K.; Yokoyama, Y.; Masuyama, T. Flow Characteristics of Slurry with Rare-Earth Rich Mud under Deep Seabed around Minamitorishima. J. Min. Mater. Process. Inst. Jpn. 2019, 135, 52–62. [Google Scholar] [CrossRef]

- Asai, K.; Ichiyanagi, M.; Satone, H.; Mori, T.; Tsubaki, J.; Itoh, Y. The Influence of Non-Newtonian Property on the Apparent Viscosity Measured by Single Cylinder Rotational Viscometer (Type-B Viscometer). J. Soc. Powder Technol. Jpn. 2009, 46, 873–880. [Google Scholar] [CrossRef]

- Hatakeyama, N.; Shimizu, Y.; Masuyama, T. Spreadsheet Solutions for Rheological Properties and Viscoplastic Fluid Flow in Circular Pipes and in Parallel-Plates. J. Min. Mater. Process. Inst. Jpn. 2019, 135, 15–24. [Google Scholar] [CrossRef]

- Orita, K.; Tani, K.; Kosho, T.; Suzuki, A.; Tanaka, K. Study of Drag Force to Falling Spheres in Carrier Materials (Mixture of Viscous Fluid and Fine Particles) for Ore Lifting Technology and Interpretation of Rheological Constants. J. JSCE Ser. B3 2020, 76, I_881–I_886. [Google Scholar] [CrossRef] [PubMed]

| Working Fluid | Density [kg/m3] |

|---|---|

| Water | 999.9 |

| CMC 0.5% | 1031 |

| CMC 0.75% | 1007 |

| CMC 1.0% | 1015 |

| CMC 1.2% | 1090 |

| Ore | Diameter [mm] | Mass [g] | Density [kg/m3] |

|---|---|---|---|

| Aluminum small (A10) | 10 | 1.47 | 2800 |

| Aluminum medium (A20) | 20 | 11.7 | 2800 |

| Aluminum large (A30) | 30 | 39.7 | 2810 |

| Manganese Nodules | 30 | 7.07 | 2000 |

| Title | Contents |

|---|---|

| Working fluid | Water, CMC 0.5%, CMC 0.75%, CMC 1.0%, CMC 1.2% |

| Velocity [m/s] | 0.5, 1.0, 1.5 |

| Ore | A10, A20, A30 |

| Height [m] | 5.0 |

| No. | V [m/s] | Ore | Working Fluid | |||

|---|---|---|---|---|---|---|

| Water | CMC 0.5% | CMC 1.0% | CMC 1.2% | |||

| 1 | 0.5 | A10 | - | 〇 | 〇 | 〇 |

| 2 | A20 | - | 〇 | 〇 | 〇 | |

| 3 | A30 | - | 〇 | 〇 | 〇 | |

| 4 | 1.0 | A10 | 〇 | 〇 | 〇 | 〇 |

| 5 | A20 | - | 〇 | 〇 | 〇 | |

| 6 | A30 | - | 〇 | 〇 | 〇 | |

| 7 | 1.5 | A10 | 〇 | 〇 | 〇 | 〇 |

| 8 | A20 | 〇 | 〇 | 〇 | - | |

| 9 | A30 | 〇 | 〇 | 〇 | - | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onishi, S.; Itagaki, Y.; Nakatani, N.; Ohara, K.; Katayama, H.; Yamazaki, T. An Experimental Study of Pulp-Lift Characteristics Using a High-Viscous Fluid Simulating Deep Muddy Seawater. J. Mar. Sci. Eng. 2024, 12, 1448. https://doi.org/10.3390/jmse12081448

Onishi S, Itagaki Y, Nakatani N, Ohara K, Katayama H, Yamazaki T. An Experimental Study of Pulp-Lift Characteristics Using a High-Viscous Fluid Simulating Deep Muddy Seawater. Journal of Marine Science and Engineering. 2024; 12(8):1448. https://doi.org/10.3390/jmse12081448

Chicago/Turabian StyleOnishi, Sakai, Yurie Itagaki, Naoki Nakatani, Kyara Ohara, Hiroyuki Katayama, and Tetsuo Yamazaki. 2024. "An Experimental Study of Pulp-Lift Characteristics Using a High-Viscous Fluid Simulating Deep Muddy Seawater" Journal of Marine Science and Engineering 12, no. 8: 1448. https://doi.org/10.3390/jmse12081448