Analysis of Fluid Suction Characteristics of Polyhedral Particles in Deep-Sea Hydraulic Collection Method

Abstract

:1. Introduction

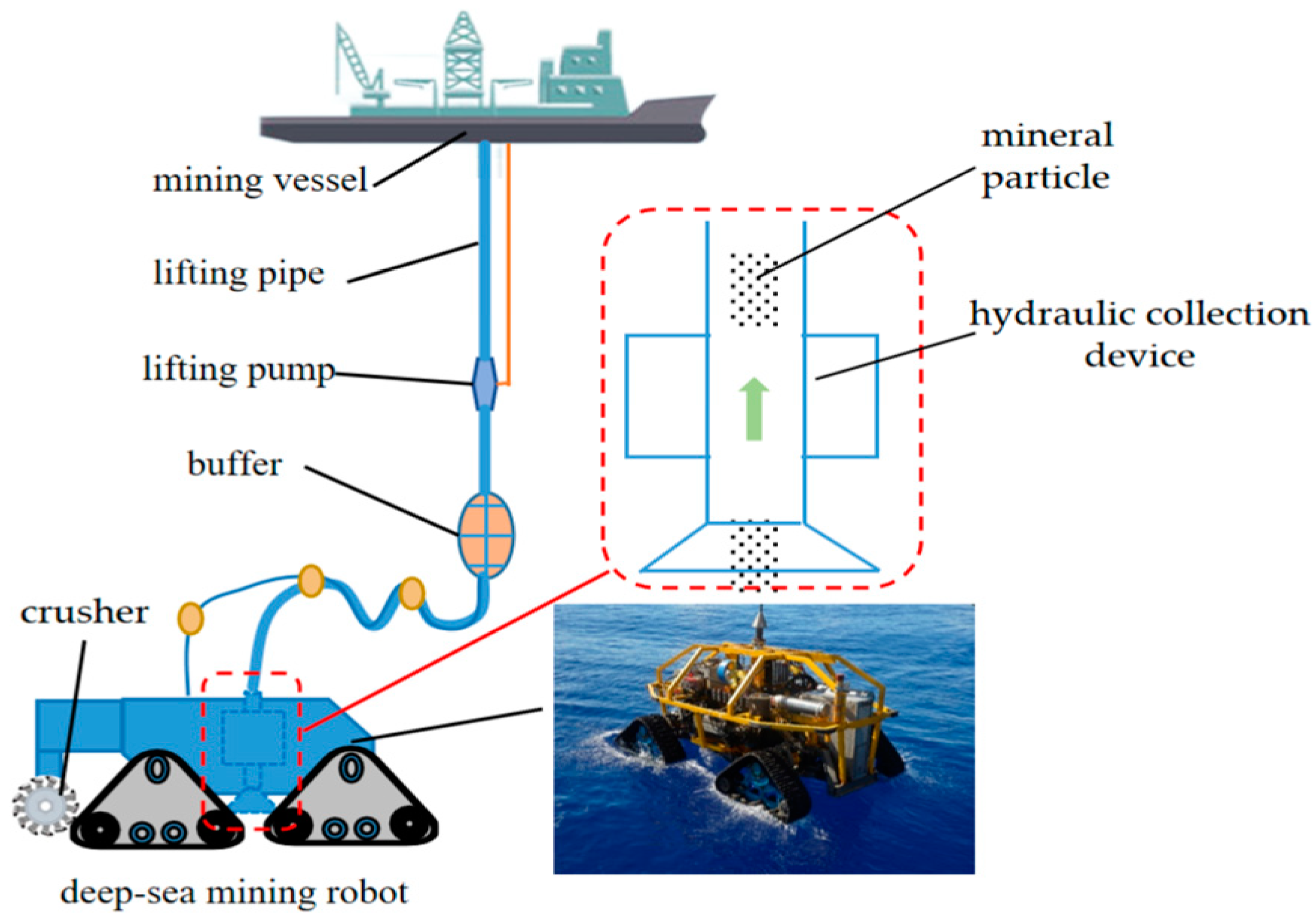

2. The Characteristics of a Suction-Based Hydraulic Collection Method

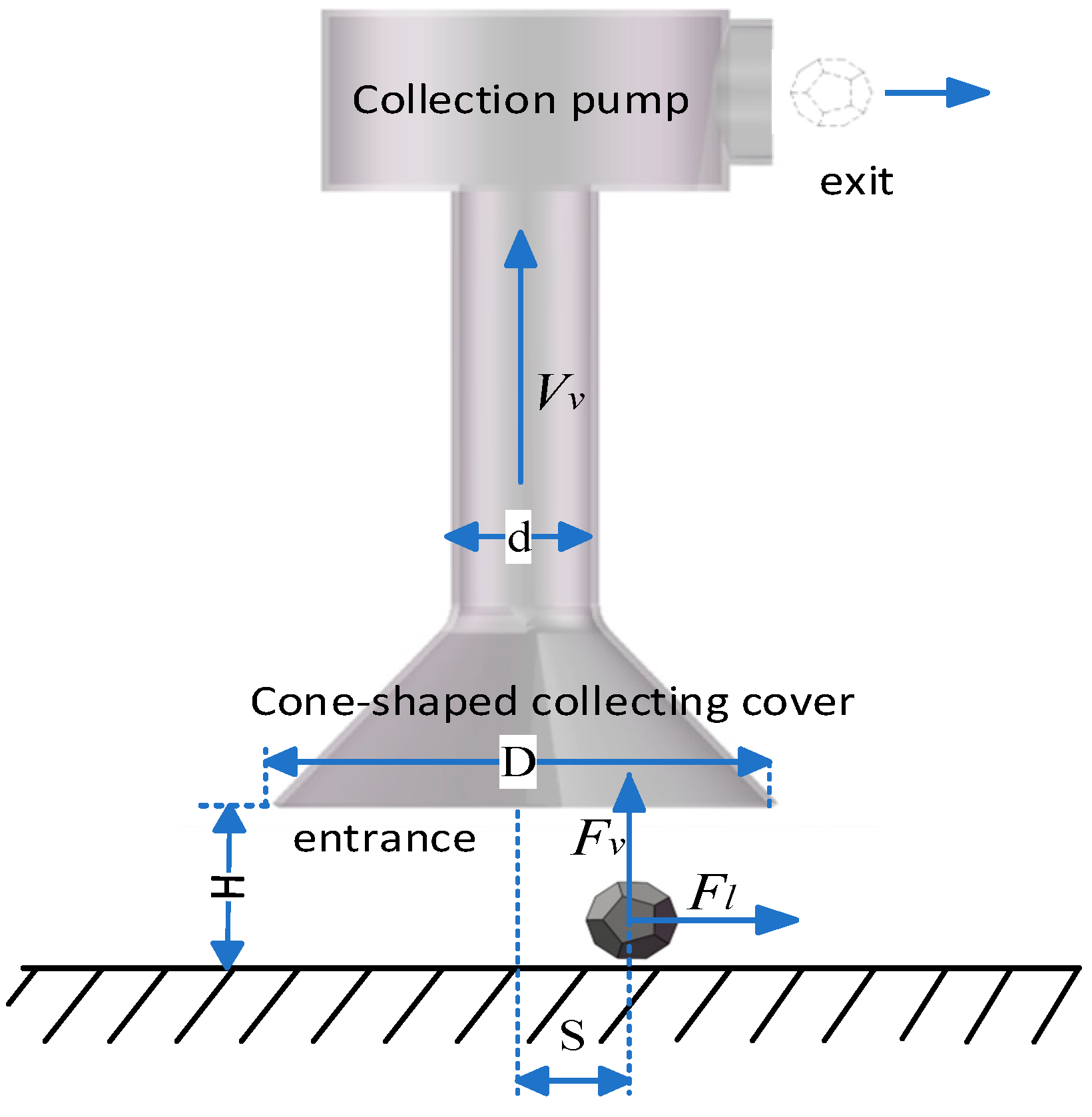

2.1. The Hydraulic Collection Model

2.2. Control Equations

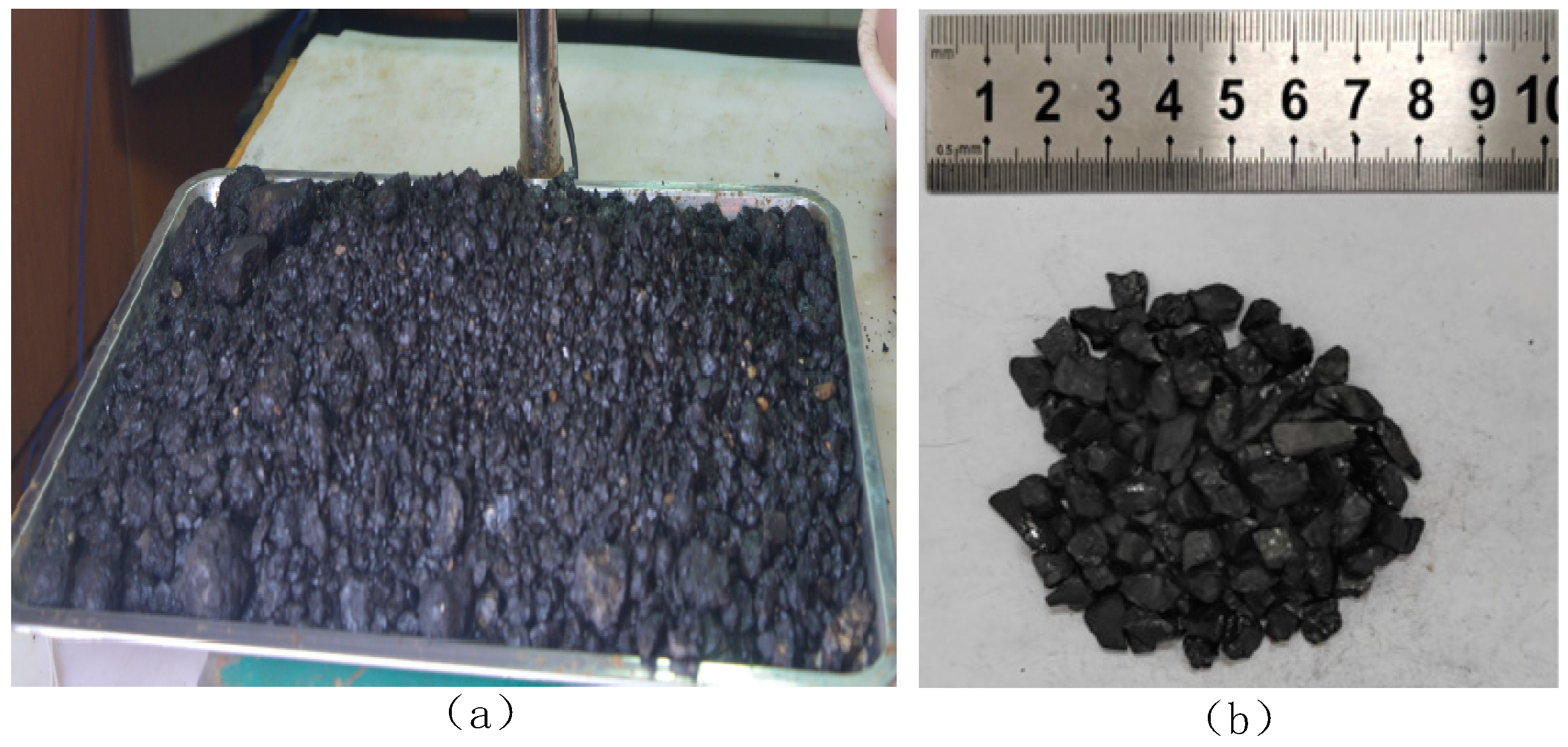

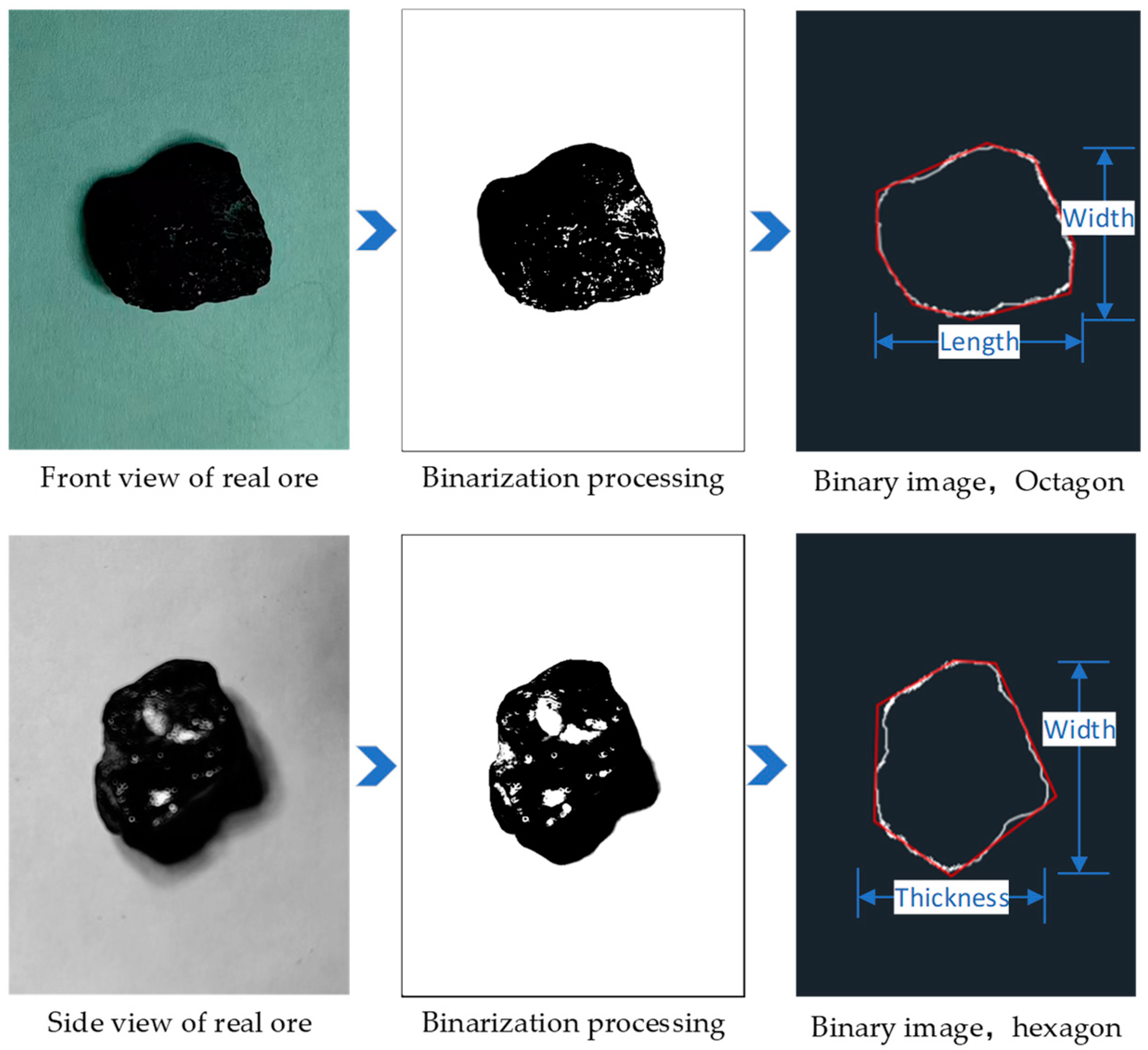

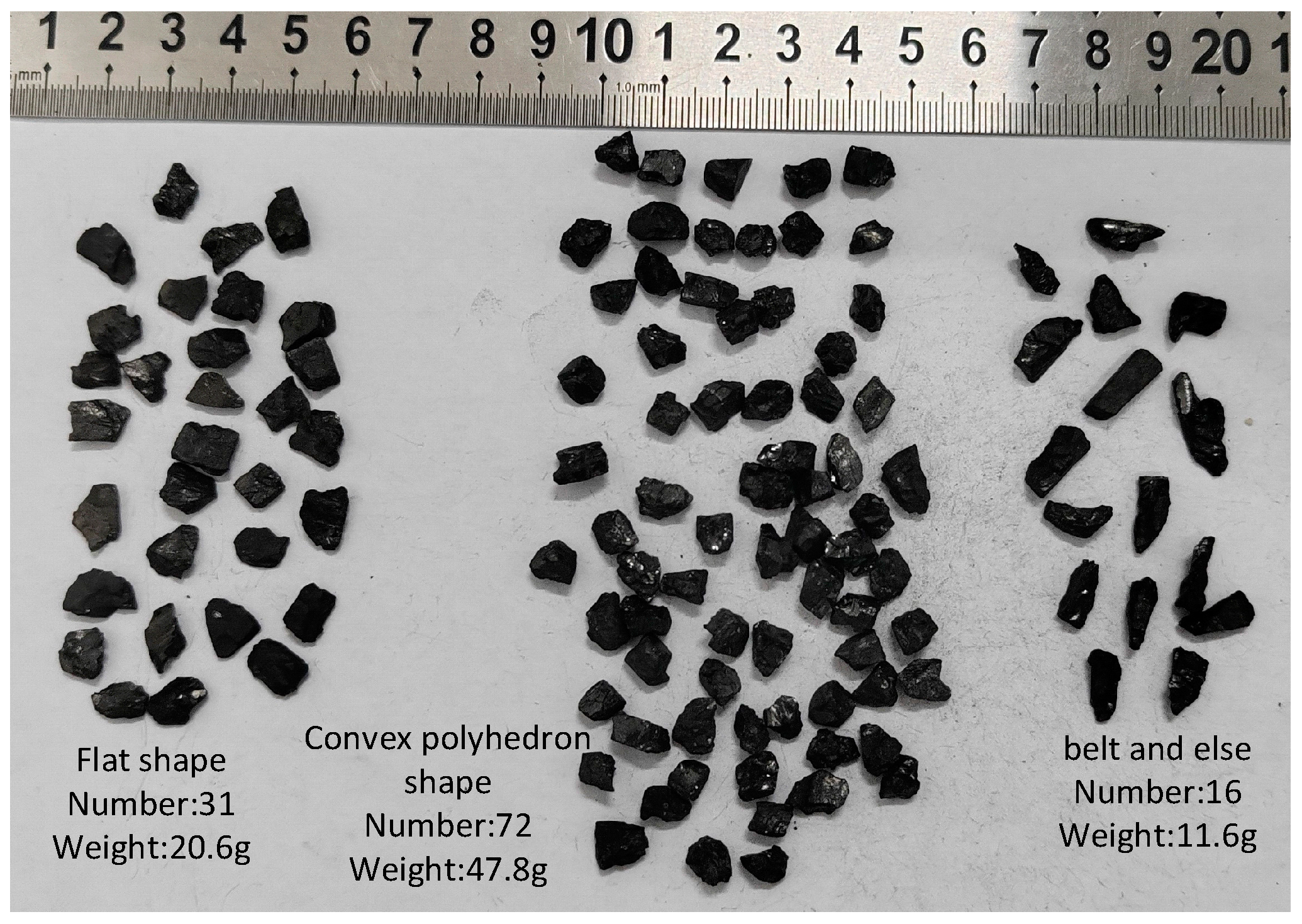

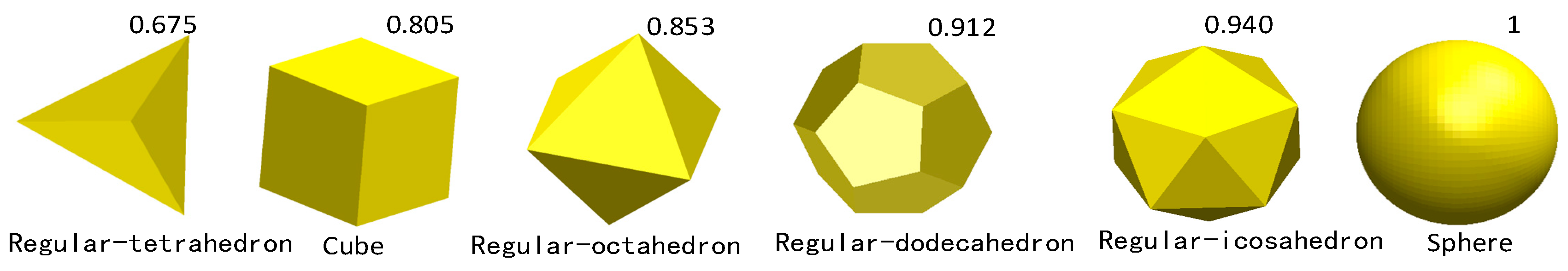

2.3. The Characters of Particles

2.4. Analysis of Dimensionless Parameters

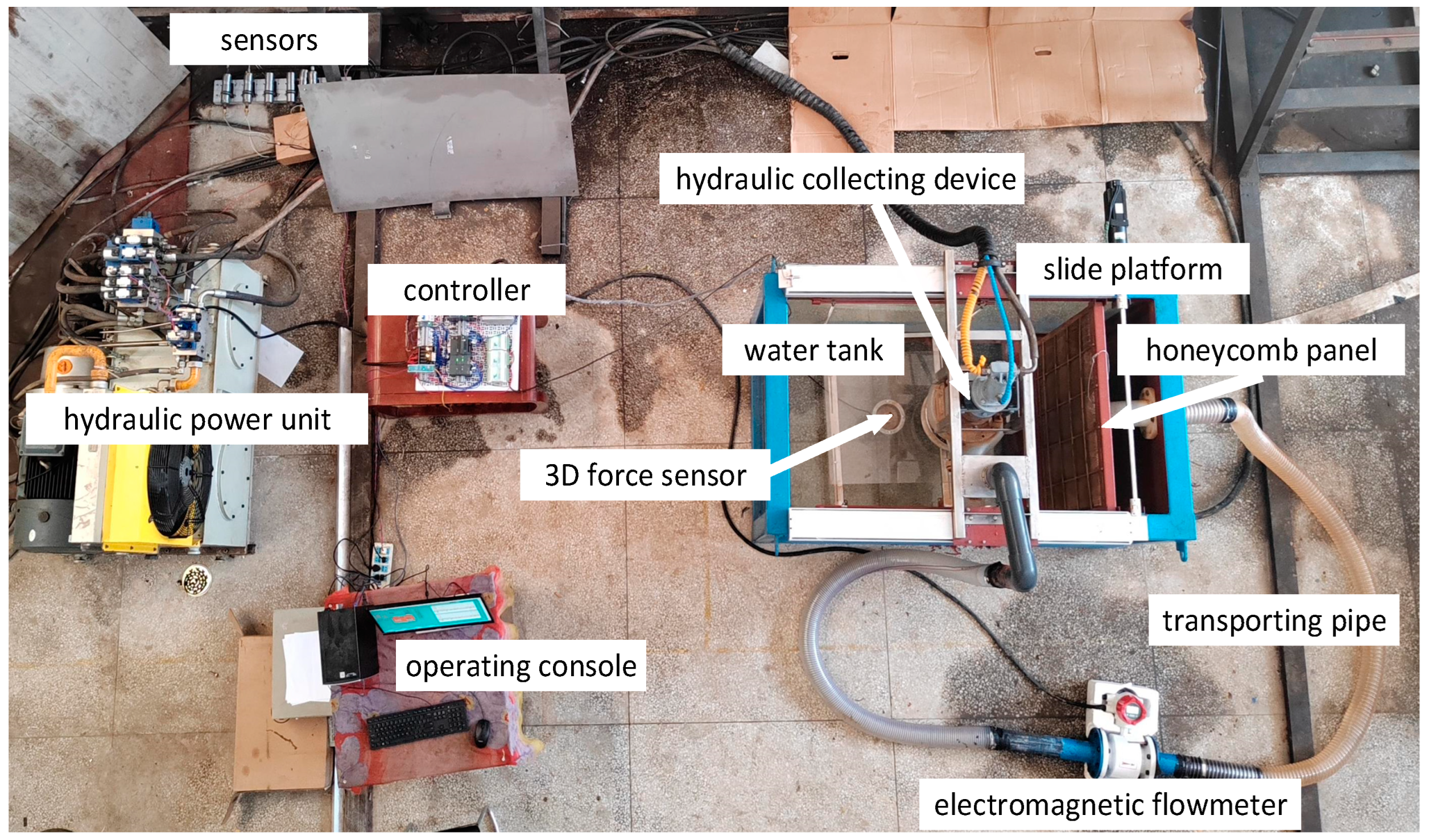

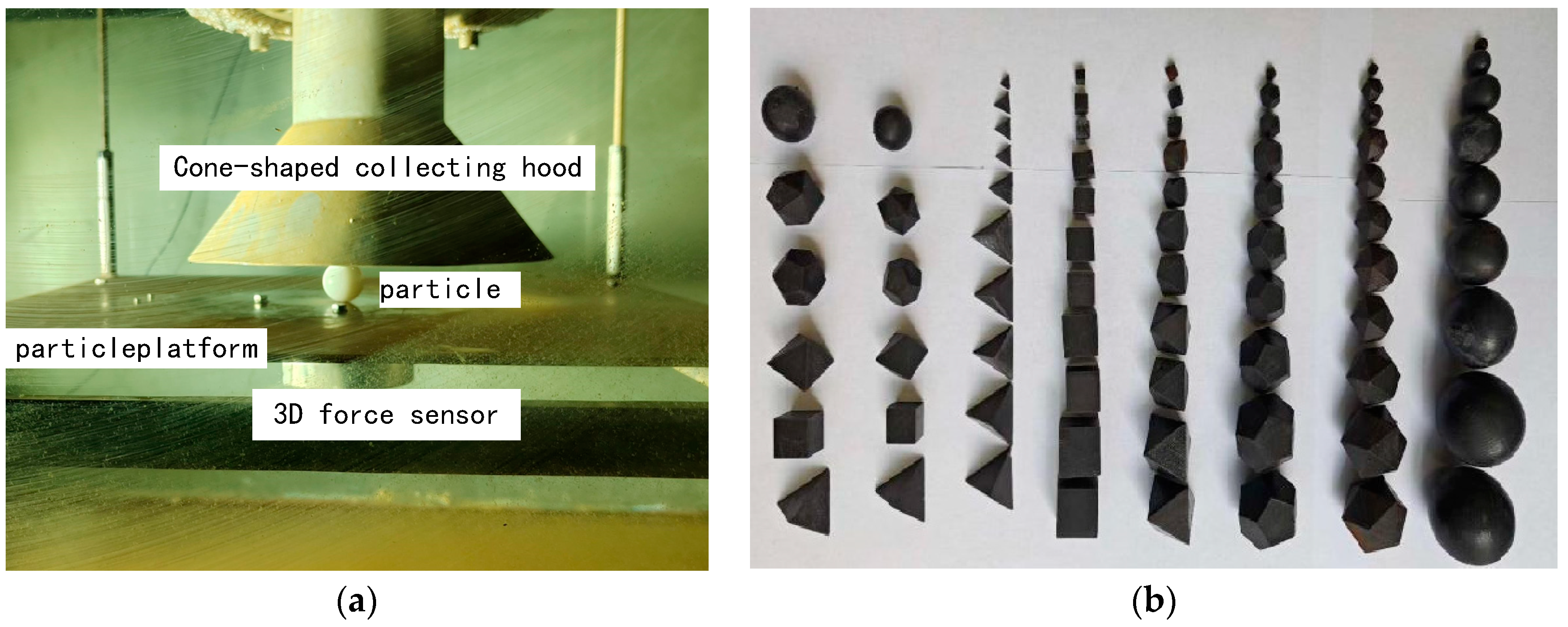

3. Description of the Hydraulic Collection Experiment

3.1. The Experimental Platform

3.2. The Experimental Conditions

4. The Flow Characteristics of the Hydraulic Collection Flow Field

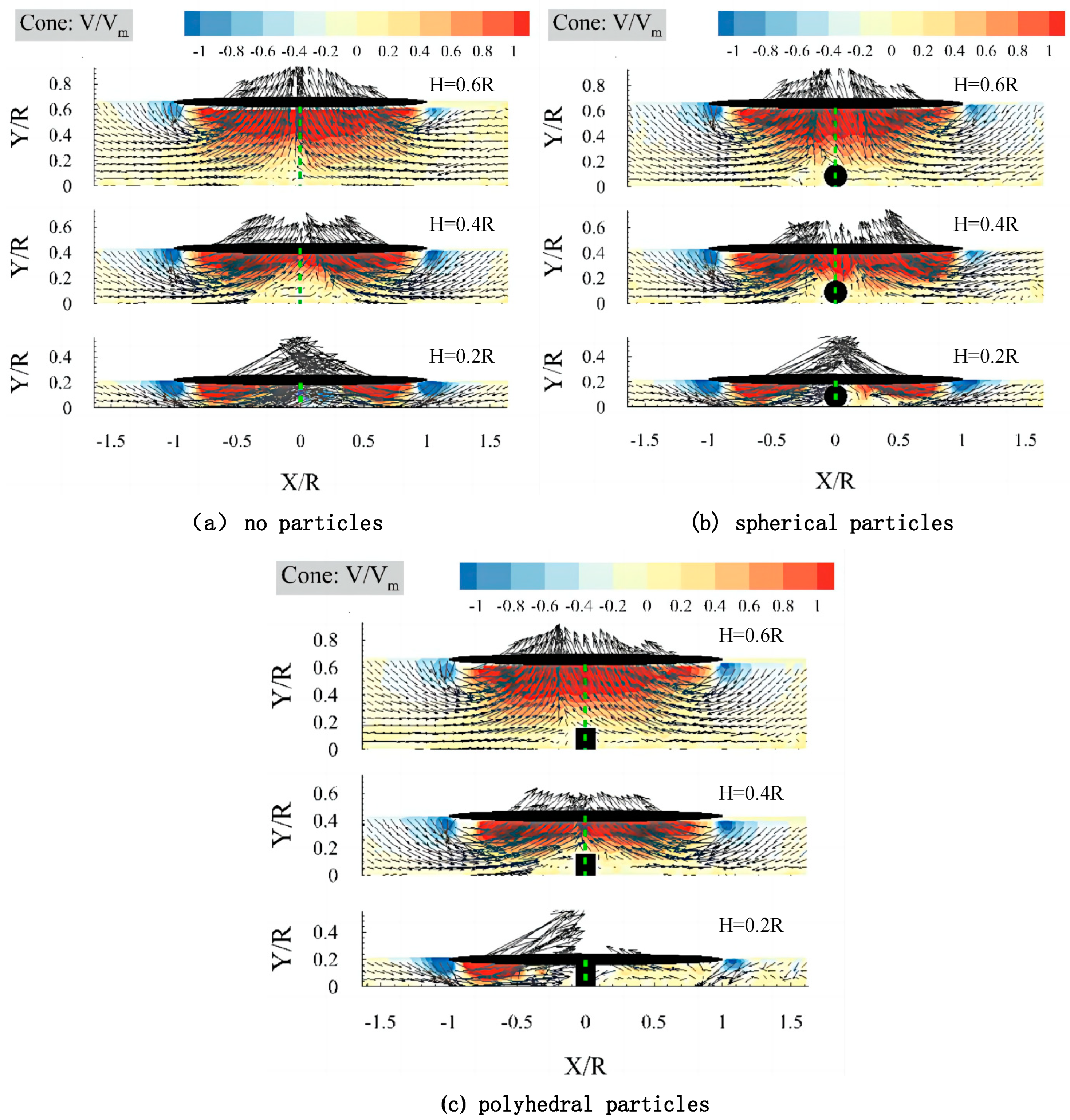

4.1. The Characteristics of the Time-Averaged Velocity of Flow Field

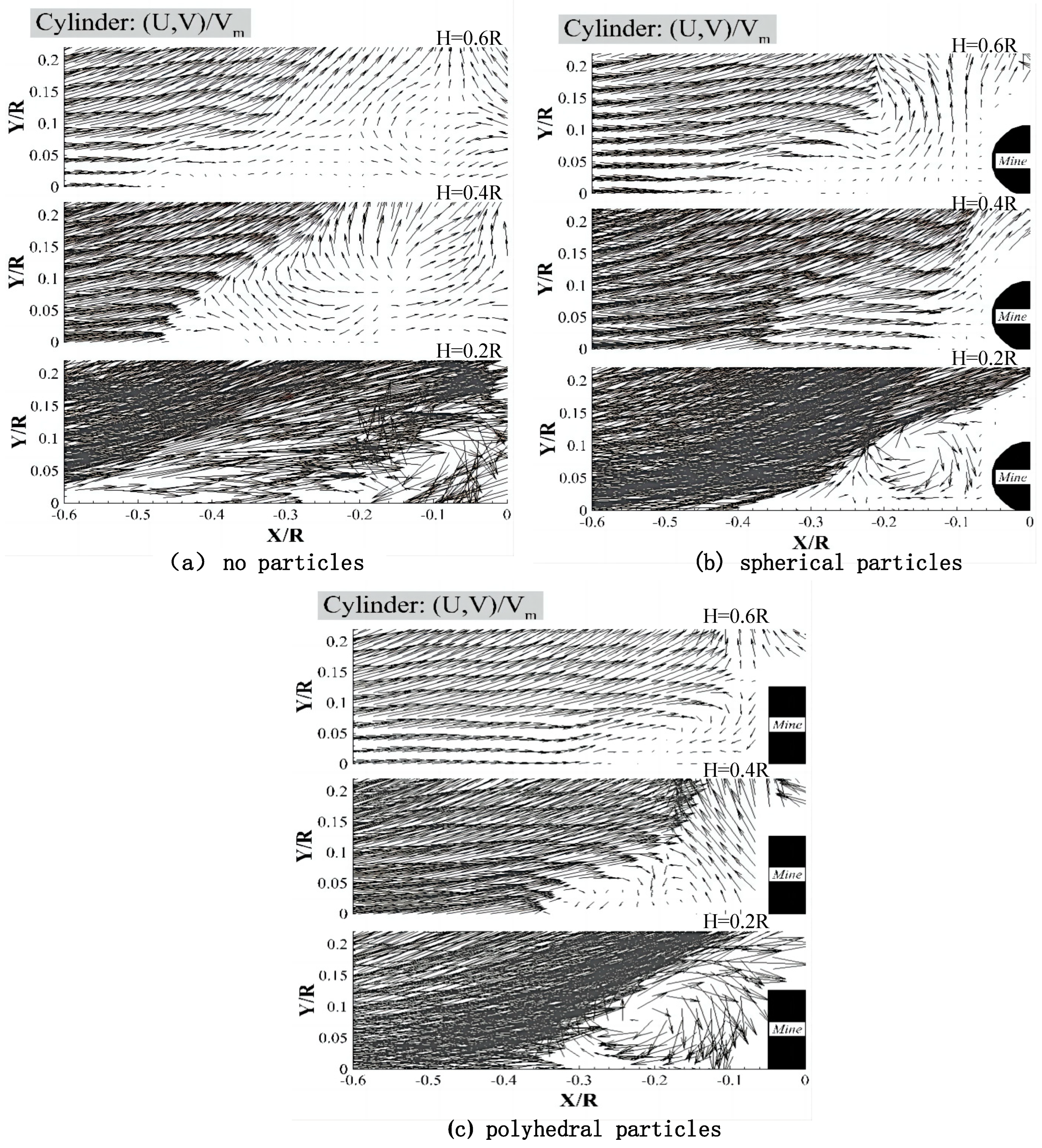

4.2. The Vortex at the Inlet of the Cone Hood

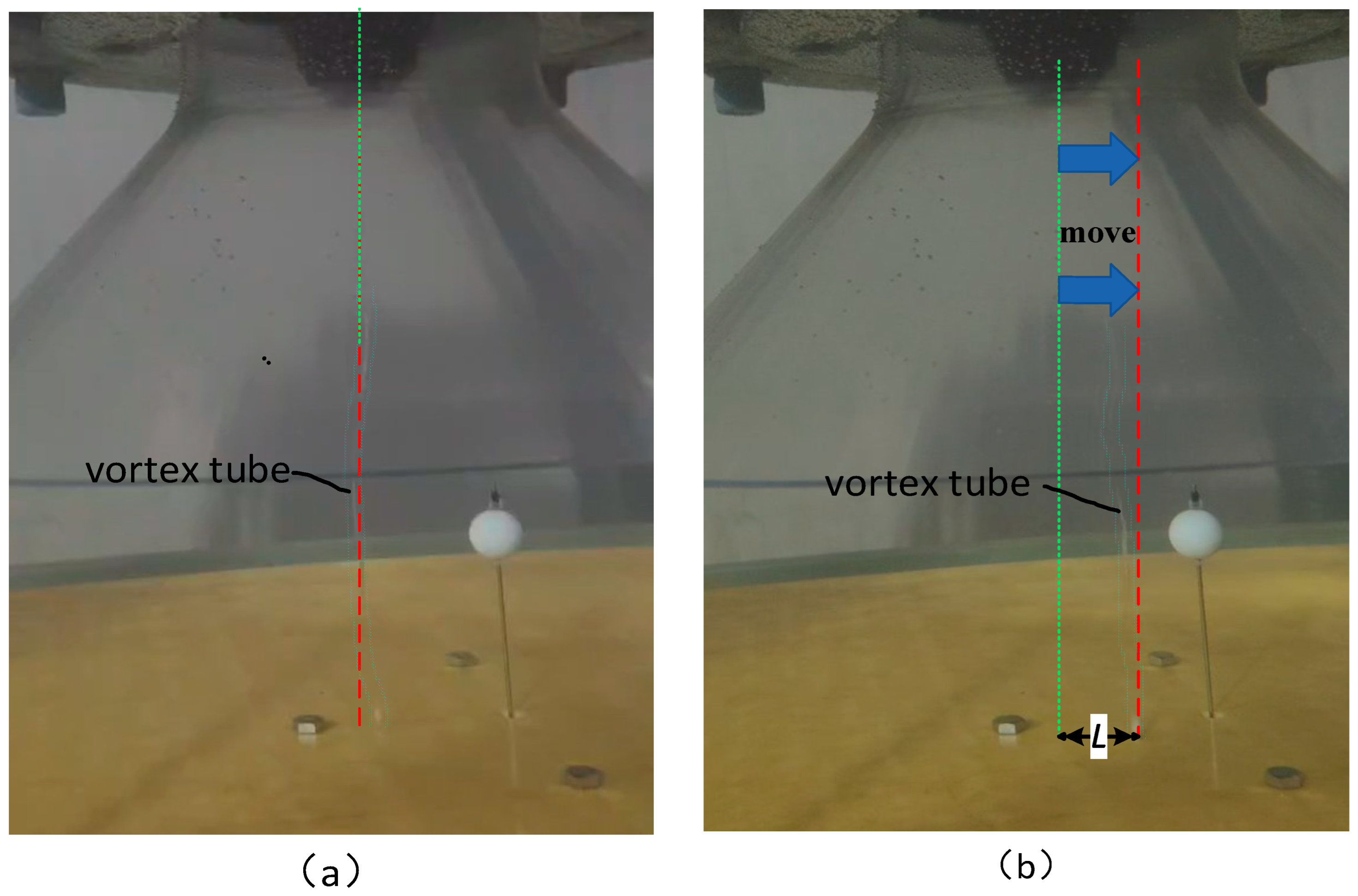

4.3. The Vertical Force of Central Particles Based on the Vortex

5. Results and Discussion

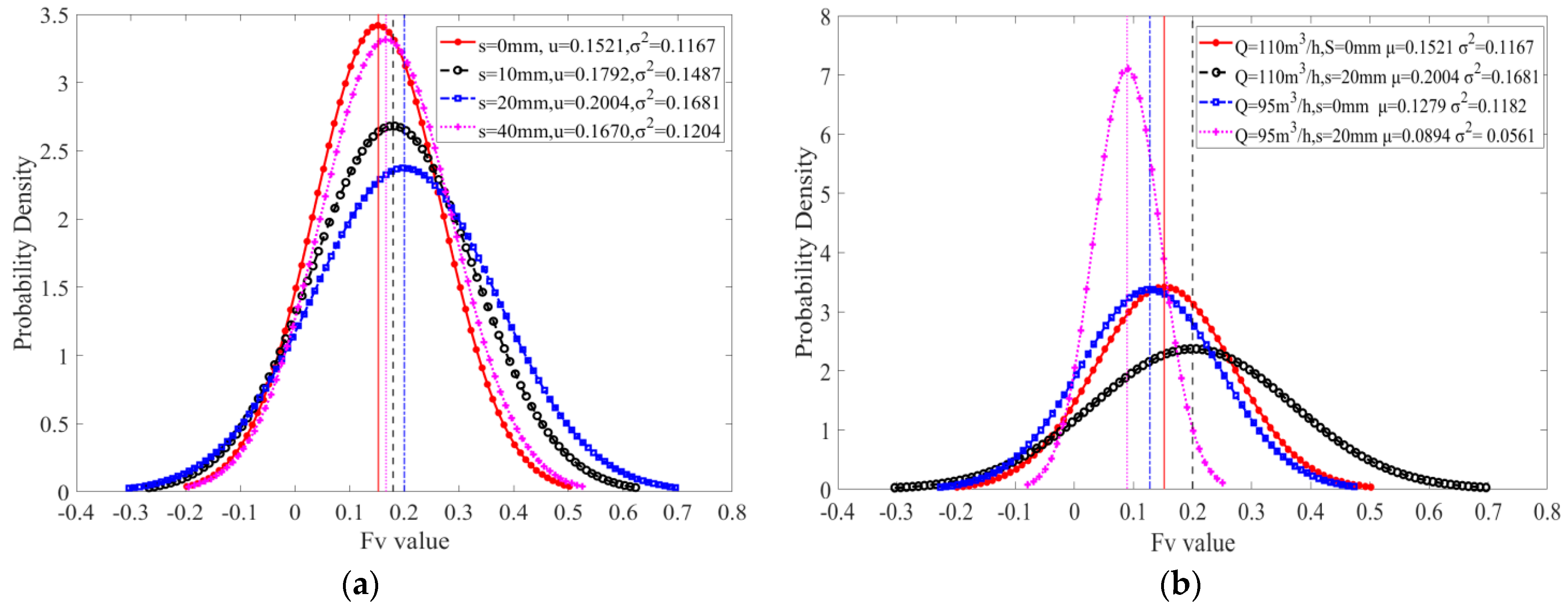

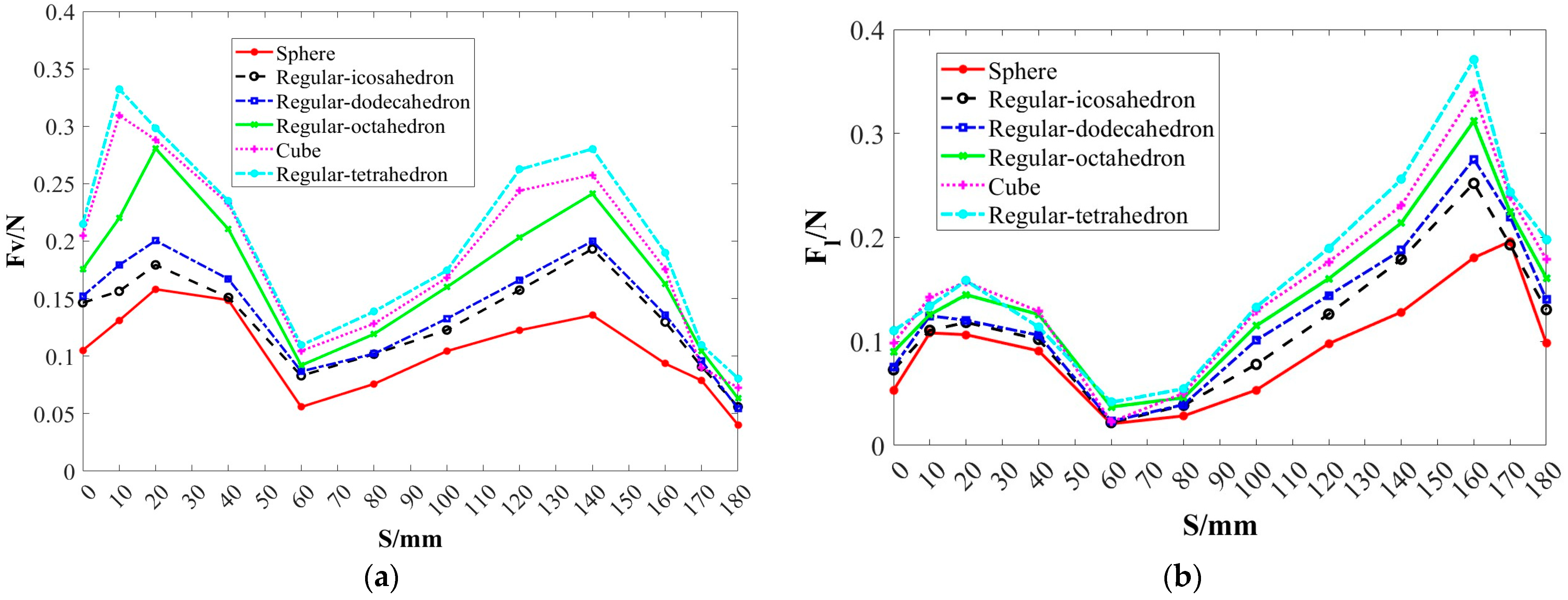

5.1. The Effect of Different Positions S and Different Particles on Suction Force Fd

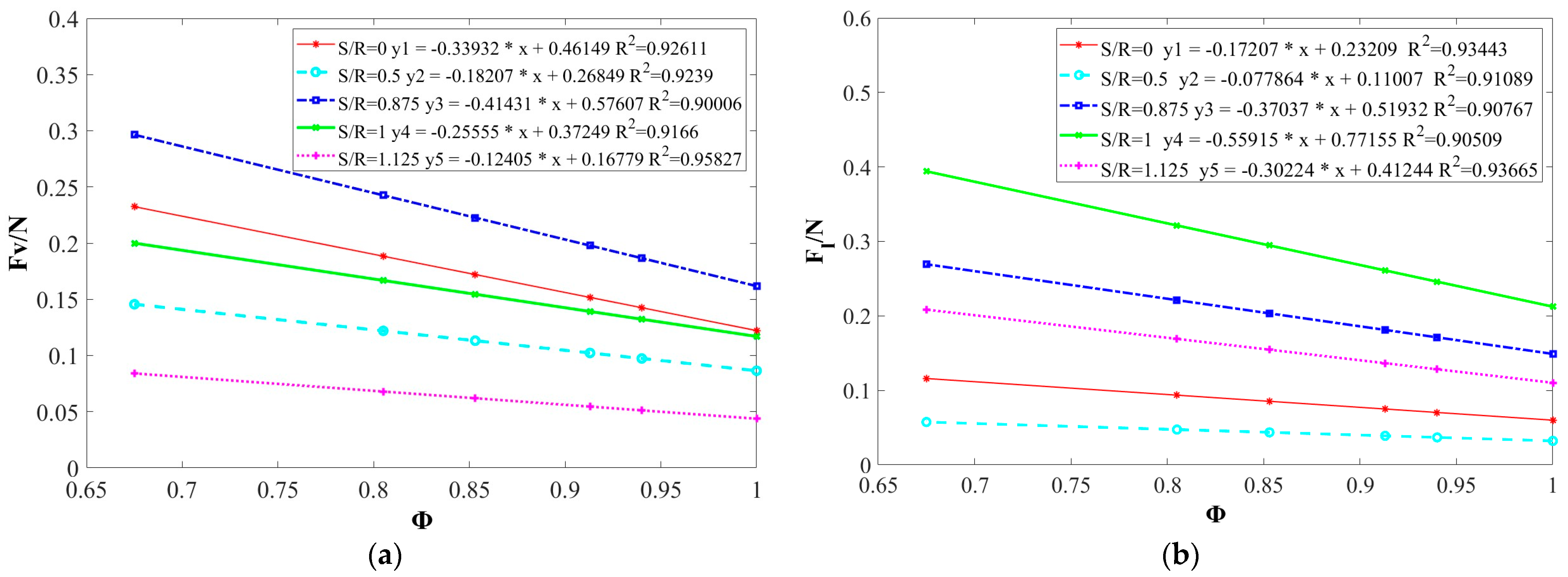

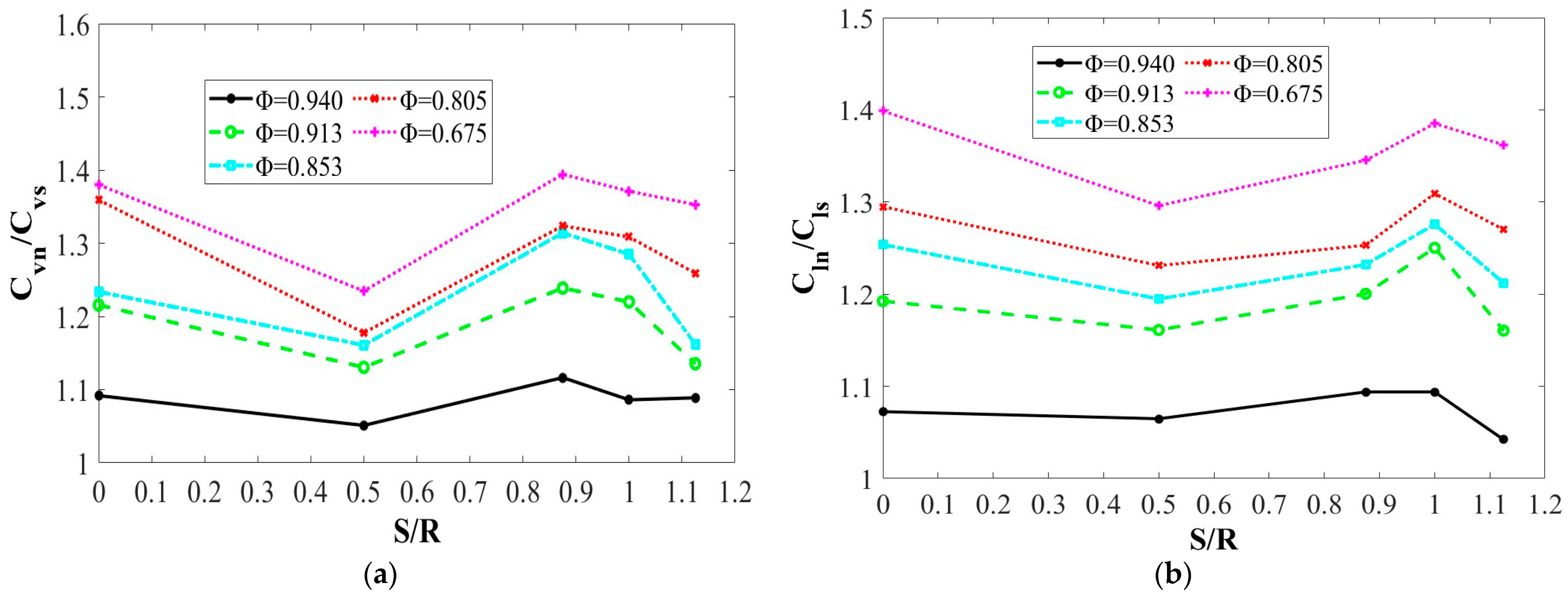

5.2. The Effect of Parameters Φ and S/R on the Suction Coefficient Ratio

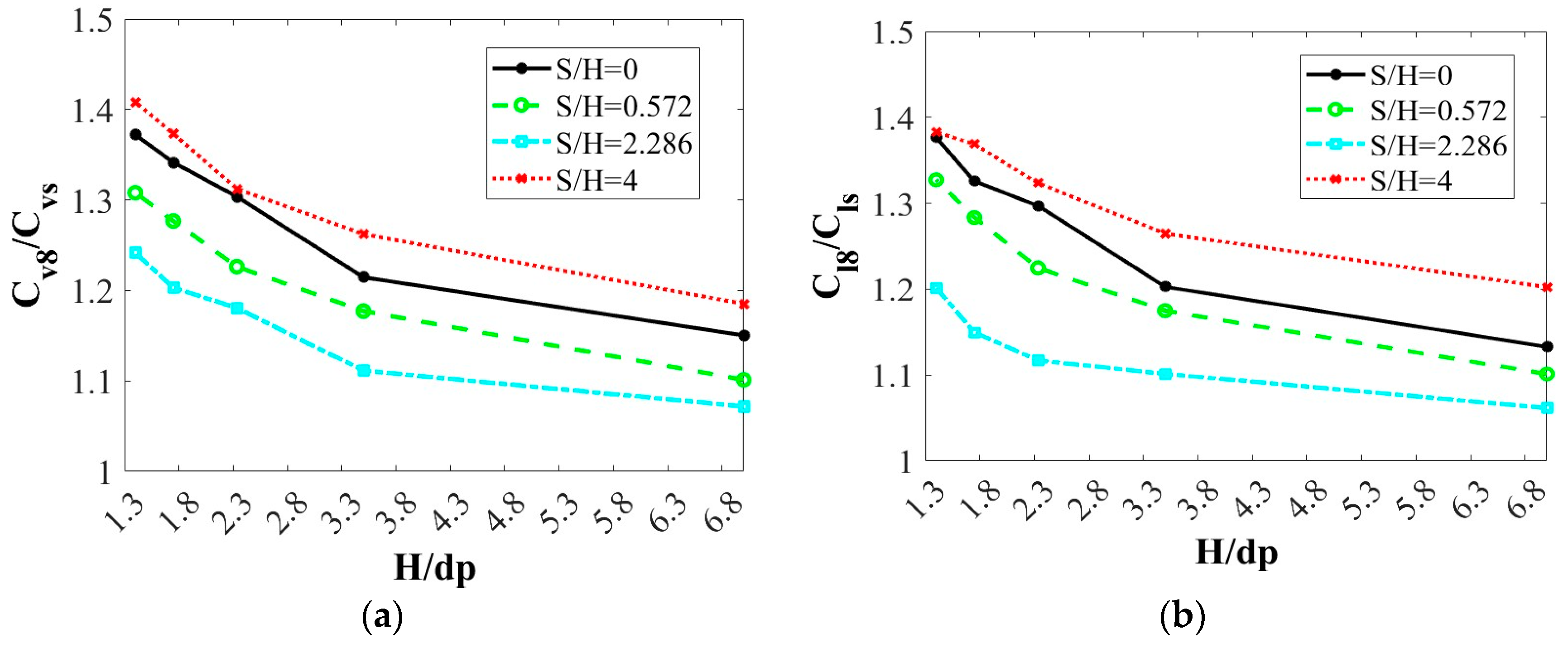

5.3. The Effect of Parameter H/dp and S/H on the Suction Coefficient Ratio

5.4. The Effect of Parameters R/H and S/R on the Suction Coefficient Ratio

6. Conclusions

- (1)

- As height H decreased, the pattern of the external flow field was observed, which showed that the fluid flow distributed along the wall of the hood and the flow velocity distribution at the center bottom were relatively low. The occurrence and movement of the suction vortex and coherent vortex were found in the central region between 0.1R and 0.2R, which can be attributed to the height H, the flow rate , and the structural characteristics of the cone-shaped collecting hood. The suction and coherent vortex can provide favorable conditions for particles collection.

- (2)

- The suction force (Fd) generally decreased with the increase in the Φ, and the downward trend of the Fd in the flow field with the high velocity was more obvious compared to the low-velocity flow fields. Notably, there were two peaks on the curve, at S = 0.010–0.020 m and S = 0.140–0.160 m, respectively. The positions favorable for particle collection were mainly distributed within the range of 0.1–0.2R and 0.8–1R, while the weakest collection occurred between 0.4R and 0.6R, which is not conducive to ore collection.

- (3)

- The ratio generally increased with the decreasing sphericity Φ at the same hydraulic collection location, while the fluctuation of became more stable as the Φ increased. The regular icosahedral shape (Φ = 0.940) exhibited a value of approximately 1.1, which indicates its superior overall stability and similarity to a spherical shape, so the suction coefficient (Cd) of the icosahedra was close to the sphere. Moreover, it was observed that the was highly sensitive to the high-speed field, and the maximum of FV and the maximum of FL appeared at the peak points of their force values, S/R = 0.875 (S = 0.140 m) and S/R = 1(S = 0.160 m), respectively, where is significantly larger. The decreases as the parameter H/dp increases, and the decreasing trend of significantly slows down when H/dp exceeds 3.5.

- (4)

- In terms of suction force, polyhedral particles exhibit greater hydraulic collection efficiency compared to spherical particles of the same weight, which is more obvious in high-speed flow fields. However, due to their complex surface structures and larger geometric shapes, polyhedral particles may undergo more intricate motion. Therefore, our future research will focus on investigating the dynamics of polyhedral particle motion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| D | inlet diameter of cone hood |

| H | distance from the hood inlet to the seabed |

| Vl | water velocity |

| Fv | vertical force |

| Fl | horizontal force |

| actual volume of the non-spherical particle | |

| equivalent diameter | |

| du | circumcircle diameter |

| suction flow rate | |

| sphericity of particle | |

| sphericity of polyhedron particle | |

| horizontal distance between particles and the collecting center | |

| A | incoming flow area of particles |

| inlet radius of cone collecting hood | |

| Fd | suction force |

| Cd | suction force coefficient |

| fluid density | |

| fluid mean velocity | |

| Re | Reynolds number |

| viscosity coefficient of fluid | |

| vertical force coefficient ratio | |

| horizontal force coefficient ratio | |

| V | normal water velocity |

| Vm | mean suction velocity |

| U | horizontal water velocity |

| e | elongation factor of particle |

| f | flatness factor of particle |

| Subscripts: | |

| n | face number of polyhedron particle |

| l | horizontal direction |

| v | vertical direction |

References

- Pelleter, E.; Fouquet, Y.; Etoubleau, J.; Cheron, S.; Labanieh, S.; Josso, P.; Bollinger, C.; Langlade, J. Ni-Cu-Co-rich hydrothermal manganese mineralization in the Wallis and Futuna back-arc environment (SW Pacific). Ore Geol. Rev. 2017, 87, 126–146. [Google Scholar] [CrossRef]

- Volkmann, S.E.; Kuhn, T.; Lehnen, F. A comprehensive approach for a techno-economic assessment of nodule mining in the deep sea. Miner. Econ. 2018, 31, 319–336. [Google Scholar] [CrossRef]

- Sharma, R. Deep-Sea Mining: Economic, Technical, Technological, and Environmental Considerations for Sustainable Development. Mar. Technol. Soc. J. 2011, 45, 28–41. [Google Scholar] [CrossRef]

- Wijk, J.M. Vertical Hydraulic Transport for Deep Sea Mining. Ph.D. Thesis, University of Delft, Delft, The Netherlands, 2016. [Google Scholar]

- Masanobu, S.; Takano, S.; Kanada, S.; Ono, M. Pressure Loss Due to Hydraulic Transport of Large Solid Particles in Vertical Pipes Under Pulsating Flow Conditions. J. Offshore Mech. Arct. Eng. 2021, 143, 061801. [Google Scholar] [CrossRef]

- Liu, L.; Li, X.; Tian, X.-L.; Zhang, X.-T.; Xu, L.-X.; Zhang, X.-Z. Numerical Investigation on Inclined Hydraulic Transport of Large Particles for Deepsea Mining. China Ocean Eng. 2023, 37, 420–432. [Google Scholar] [CrossRef]

- Cao, Y.; Gu, H.; Guo, H.; Li, X. Modeling and dynamic analysis of integral vertical transport system for deep-sea mining in three-dimensional space. Ocean Eng. 2023, 271, 113749. [Google Scholar] [CrossRef]

- Guo, X.; Fan, N.; Liu, Y.; Liu, X.; Wang, Z.; Xie, X.; Jia, Y. Deep seabed mining: Frontiers in engineering geology and environment. Int. J. Coal Sci. Technol. 2023, 10, 23. [Google Scholar] [CrossRef]

- Fairley, P. Robot miners of the briny deep. IEEE Spectr. 2015, 53, 44–47. [Google Scholar] [CrossRef]

- Li, B.; Chen, Z.; Chai, X.; Hou, B.; Liu, Y.; Chen, L.; Wei, D. Overall Development of the Internet Plus Initiative Against the Backdrop of Intelligence Plus. Strateg. Study Chin. Acad. Eng. 2020, 22, 1–9. [Google Scholar] [CrossRef]

- Liao, S. A buoyancy vertical transport system of deep-sea mining. J. Ocean Eng. Sci. 2020, 5, 294–295. [Google Scholar] [CrossRef]

- Zhao, G.; Xiao, L.; Yue, Z.; Liu, M.; Peng, T.; Zhao, W. Performance characteristics of nodule pick-up device based on spiral flow principle for deep-sea hydraulic collection. Ocean Eng. 2021, 226, 108818. [Google Scholar] [CrossRef]

- Oebius, H.U.; Becker, H.J.; Rolinski, S.; Jankowski, J.A. Parametrization and evaluation of marine environmental impacts produced by deep-sea manganese nodule mining. Deep Sea Res. Part II Top. Stud. Oceanogr. 2001, 48, 3453–3467. [Google Scholar] [CrossRef]

- Leng, D.; Shao, S.; Xie, Y.; Wang, H.; Liu, G. A brief review of recent progress on deep sea mining vehicle. Ocean Eng. 2021, 228, 108565. [Google Scholar] [CrossRef]

- Zou, L.; Dong, Y.; Jin, G.; Yu, Z.; Sun, T. Analysis of non-dimensional parameters for double-row jet hydraulic collection method on flow field characteristics. Ocean Eng. 2024, 303, 117600. [Google Scholar] [CrossRef]

- Kim, S.; Cho, S.G.; Lee, M.; Kim, J.; Lee, T.H.; Park, S.; Hong, S.; Kim, H.-W.; Min, C.-H.; Chi, S.B.; et al. Reliability-based design optimization of a pick-up device of a manganese nodule pilot mining robot using the Coandă effect. J. Mech. Sci. Technol. 2019, 33, 3665–3672. [Google Scholar] [CrossRef]

- Alhaddad, S.; Mehta, D.; Helmons, R. Mining of deep-seabed nodules using a Coandă-effect-based collector. Results Eng. 2023, 17, 100852. [Google Scholar] [CrossRef]

- Chen, Y.X.; Xiong, H.; Cheng, H.; Chen, Y. Experimental study on the incipient motion of a single spherical particle in hydraulic collecting. J. Cent. South Univ. 2019, 50, 2831–2838. [Google Scholar]

- El-Sapa, S.; Saad, E.; Faltas, M. Axisymmetric motion of two spherical particles in a Brinkman medium with slip surfaces. Eur. J. Mech. B/Fluids 2018, 67, 306–313. [Google Scholar] [CrossRef]

- Sherief, H.; Faltas, M.; El-Sapa, S. Interaction between two rigid spheres moving in a micropolar fluid with slip surfaces. J. Mol. Liq. 2019, 290, 111165. [Google Scholar] [CrossRef]

- Zhao, G.; Lu, H.; Xiao, L.; Hu, J. Shape Effect of Polymetallic Nodules on Suction Forces and Flow Field During Seabed Hydraulic Collection. J. Offshore Mech. Arct. Eng. 2021, 144, 011204. [Google Scholar] [CrossRef]

- Xiong, H.; Chen, Y.; Yang, N.; Xiao, J.; Li, L. Numerical Study on Settling and Floating Movements of a Sphere Particle Flowing in a Vertical Pipe. In Proceedings of the 28th International Ocean and Polar Engineering Conference, Sapporo, Japan, 10–15 June 2018. [Google Scholar]

- Loth, E. Drag of non-spherical solid particles of regular and irregular shape. Powder Technol. 2007, 182, 342–353. [Google Scholar] [CrossRef]

- Zhao, G.; Xiao, L.; Peng, T.; Zhang, M. Experimental Research on Hydraulic Collecting Spherical Particles in Deep Sea Mining. Energies 2018, 11, 1938. [Google Scholar] [CrossRef]

- Galdi, G.P. Navier–Stokes EquationsNavier–Stokes equations: A Mathematical Analysis. In Encyclopedia of Complexity and Systems Science; Meyers, R.A., Ed.; Springer: New York, NY, USA, 2009; pp. 5925–5959. [Google Scholar]

- Zhu, H.P.; Zhou, Z.Y.; Yang, R.Y.; Yu, A.B. Discrete particle simulation of particulate systems: Theoretical developments. Chem. Eng. Sci. 2007, 62, 3378–3396. [Google Scholar] [CrossRef]

- Lin, C.; Miller, J. 3D characterization and analysis of particle shape using X-ray microtomography (XMT). Powder Technol. 2005, 154, 61–69. [Google Scholar] [CrossRef]

- Arocena, V.M.; Abuan, B.E.; Reyes, J.G.T.; Rodgers, P.L.; Danao, L.A.M. Reduction of Entrained Vortices in Submersible Pump Suction Lines Using Numerical Simulations. Energies 2020, 13, 6136. [Google Scholar] [CrossRef]

| e | f | ||

|---|---|---|---|

| Value Range | Quantity | Value Range | Quantity |

| 0.9–1 | 18 | 0.9–1 | 7 |

| 0.7–0.9 | 55 | 0.7–0.9 | 19 |

| 0.5–0.7 | 34 | 0.5–0.7 | 42 |

| 0.3–0.5 | 11 | 0.3–0.5 | 31 |

| <0.3 | 1 | <0.3 | 20 |

| total | 119 | 119 | |

| Approximate Shape | Geometric Figure | Range of Form Factors | Quantity | Weight/g |

|---|---|---|---|---|

| convex polyhedron shape |  | e > 0.4 and f ≥ 0.4 | 72 | 47.8 |

| flat shape |  | e > 0.4 and f < 0.4 | 31 | 20.6 |

| belt shape |  | e ≤ 0.4 and f ≤ 0.4 | 12 | 8.9 |

| other | irregular shape | 4 | 2.7 | |

| total | 119 | 80 |

| Polyhedron | Regular Tetrahedron | Regular Hexahedron | Regular Octahedron | Regular Dodecahedron | Regular Icosahedron | Sphere |

|---|---|---|---|---|---|---|

| equivalent grain/dp | 0.61L4 | 1.24L6 | 0.97L8 | 2.45L12 | 1.61L20 | dpb |

| sphericity/ | 0.675 | 0.805 | 0.853 | 0.913 | 0.940 | 1.000 |

| circumcircle/du | 2.012dp4 | 1.397dp6 | 1.464dp8 | 1.146dp12 | 1.182dp20 | dps |

| Order Number | Horizontal Position/S (m) | Height of Hood to Bottom/H (m) | Equivalent Diameter/dp (m) | (m3/h) | Cone-Shaped Hood/R (m) | Remarks | |

|---|---|---|---|---|---|---|---|

| 1 | 0.805, 1 | 0 | 0.02, 0.04, 0.06 | 0.008 | 35 | 0.05 | Section 4.1 |

| 2 | 1 | 0 | 0.035 | 0.015 | 105, 115 | 0.16 | Section 4.3 |

| 3 | 0.940 | 0, 0.01, 0.02, 0.04 | 0.035 | 0.015 | 95, 110 | 0.16 | Section 4.3 Figure 13 |

| 4 | 1 | 0 | 0.045 | 0.025 | 95, 105, 115 | 0.16 | Section 4.3 Figure 14 |

| 5 | 0.675, 0.805, 0.853, 0.913, 0.940, 1 | 0, 0.01, 0.02, 0.04, 0.06, 0.08, 0.10, 0.12, 0.14, 0.16, 0.17, 0.18 | 0.035 | 0.015 | 110 | 0.16 | Section 5.1 |

| 6 | 0.675, 0.805, 0.853, 0.913, 0.940, 1 | 0, 0.02, 0.08, 0.14, 0.16 | 0.035 | Section 5.2 | |||

| 7 | 0.853, 1 | 0, 0.02, 0.08, 0.14, 0.16 | 0.035 | Section 5.3 | |||

| 8 | 0.853, 1 | 0, 0.02, 0.08, 0.14, 0.16 | 0.035, 0.045, 0.055, 0.065 | 0.16 | Section 5.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, M.; Chen, B.; Li, K. Analysis of Fluid Suction Characteristics of Polyhedral Particles in Deep-Sea Hydraulic Collection Method. J. Mar. Sci. Eng. 2024, 12, 1543. https://doi.org/10.3390/jmse12091543

Jiang M, Chen B, Li K. Analysis of Fluid Suction Characteristics of Polyhedral Particles in Deep-Sea Hydraulic Collection Method. Journal of Marine Science and Engineering. 2024; 12(9):1543. https://doi.org/10.3390/jmse12091543

Chicago/Turabian StyleJiang, Min, Bingzheng Chen, and Kaihui Li. 2024. "Analysis of Fluid Suction Characteristics of Polyhedral Particles in Deep-Sea Hydraulic Collection Method" Journal of Marine Science and Engineering 12, no. 9: 1543. https://doi.org/10.3390/jmse12091543