Intelligent Fault Diagnosis Method for Constant Pressure Variable Pump Based on Mel-MobileViT Lightweight Network

Abstract

1. Introduction

2. Based on the Basic Theory of the Mel-MoblieViT Fault Diagnosis Method

2.1. Failure Mechanism of Constant Pressure Variable Pumps

- 1.

- Loose slipper failure: This occurs when there is excessive clearance between the pump’s slipper socket and the plunger ball head, leading to periodic vibration and impact between the plunger ball head and the slipper socket during operation.

- 2.

- Slipper wear failure: Normally, an oil film of a certain thickness exists between the swashplate and the slipper in a hydraulic pump, preventing direct metal contact and reducing friction. When the oil film pressure drops due to various factors, the oil film fails, leading to accelerated wear between the slipper and the swashplate.

- 3.

- Plunger wear failure: Wear between the plunger and the cylinder block increases the gap, leading to higher leakage. When the plunger cavity connects with the high-pressure discharge port during the pump rotation, the increased leakage causes hydraulic shock, altering the vibration behavior of the pump casing.

- 4.

- Rolling bearing failure: The degradation or failure of rolling bearings can be caused by several factors, such as lubrication failure or overloading. Common failure modes include fatigue spalling, plastic deformation, wear, fractures, and overheating.

2.2. Introduction to MobileViT Model

- 1.

- The first component is the local representation module. For an input , it undergoes consecutive operations of Conv-3 × 3 and Conv-1 × 1, resulting in an output , where the 3 × 3 convolution is used for local feature modeling, and the 1 × 1 convolution is used to adjust the number of channels.

- 2.

- The next component is the global representation module, which uses the unfold operation to expand into N non-overlapping patches . Here, (where ℎ and w represent the height and width of each patch, respectively), and . Subsequently, L-stacked Transformers are used to focus on the global information of , resulting in an output . Finally, the fold operation is applied to produce , which has the same dimensions as .

- 3.

- The final component is the fusion module, which first uses a 1 × 1 convolution to adjust the number of channels back to the original size. Then, it concatenates this with the original input feature map along the channel dimension through a shortcut branch. Lastly, a 3 × 3 convolution fuses the local and global features to produce the output .

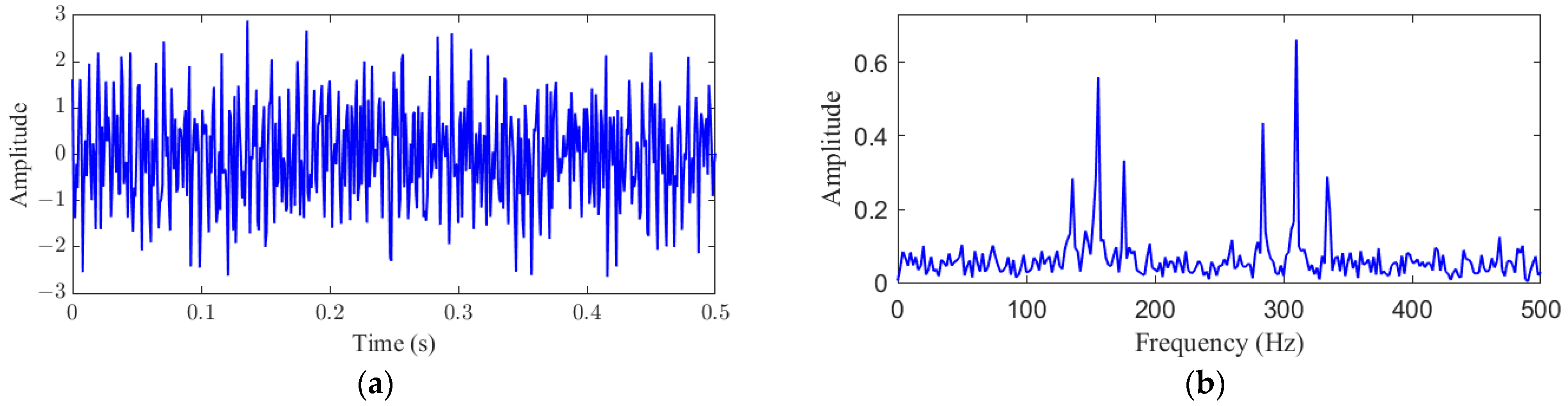

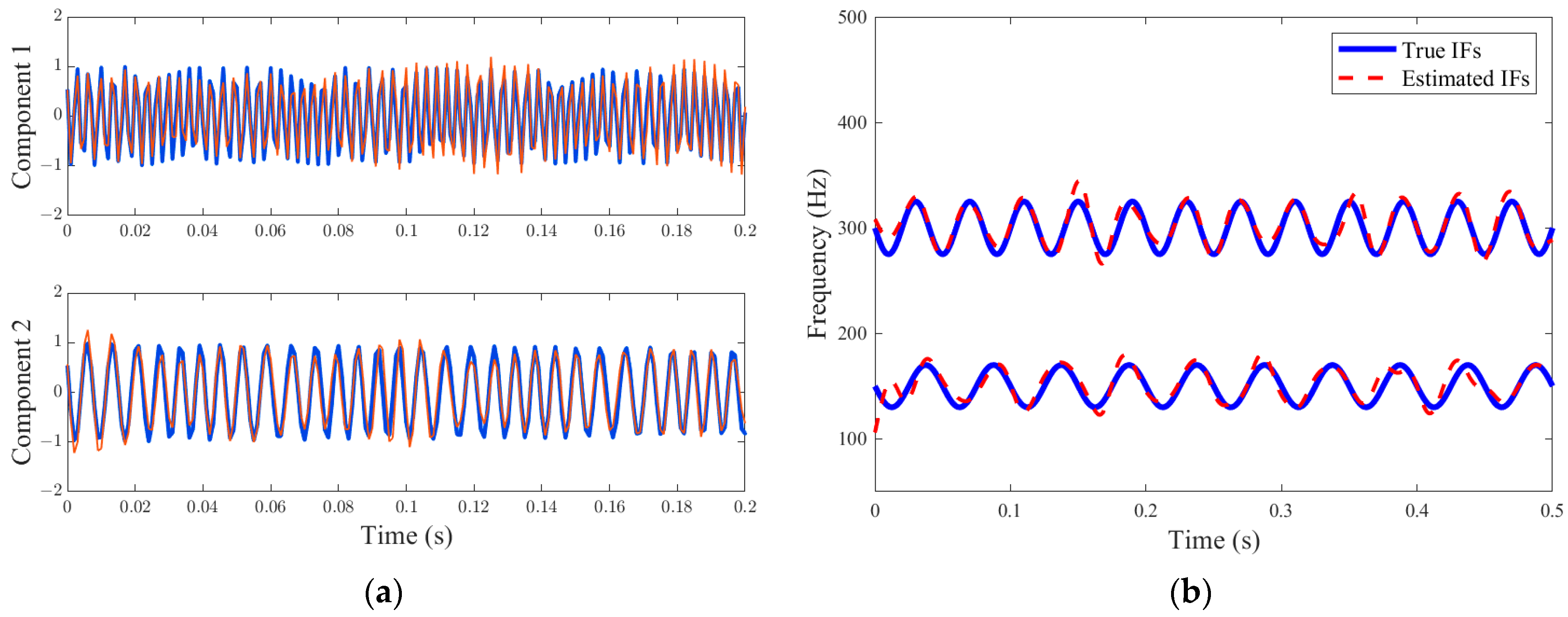

2.3. Adaptive Chirped Mode Decomposition Principle

3. Hydraulic Pump Fault Diagnosis Process

- 1.

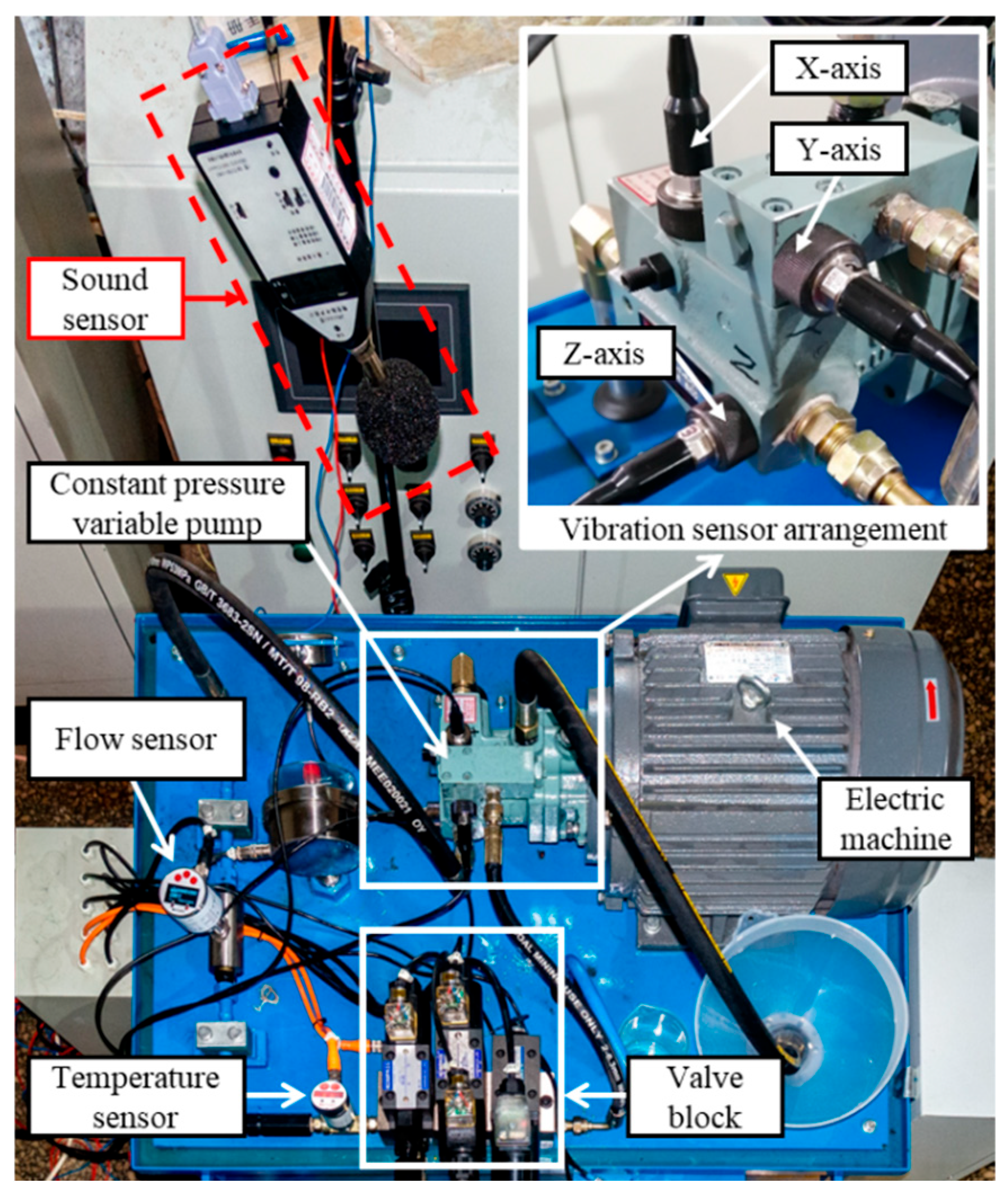

- Data acquisition: The sound sensor is used to collect the sound signals of the constant pressure variable pump in both normal and fault states.

- 2.

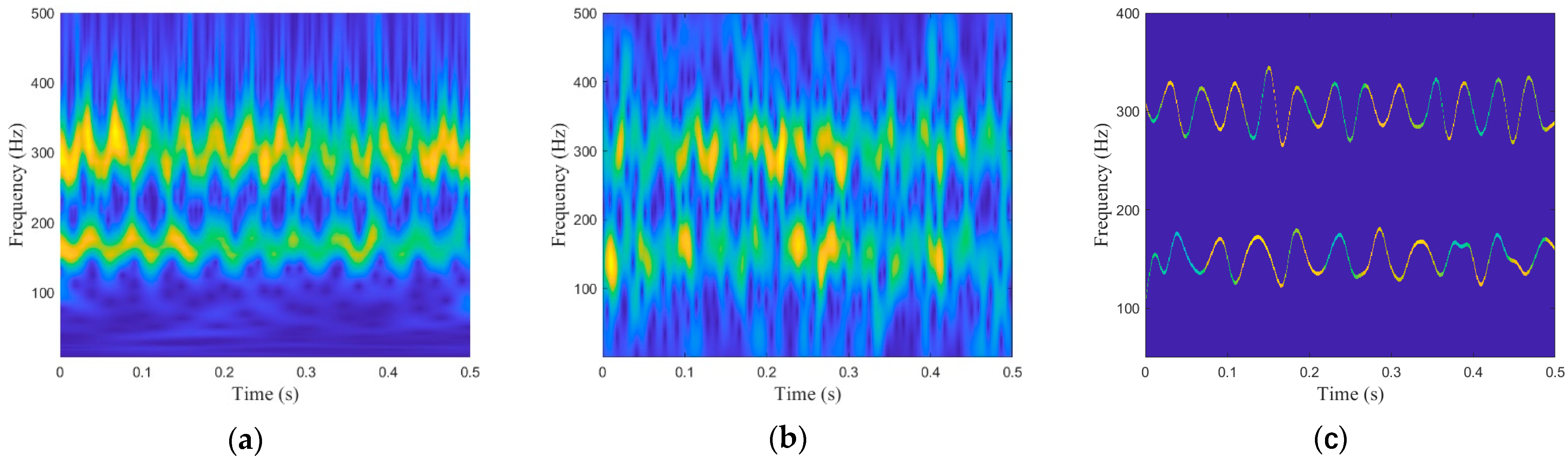

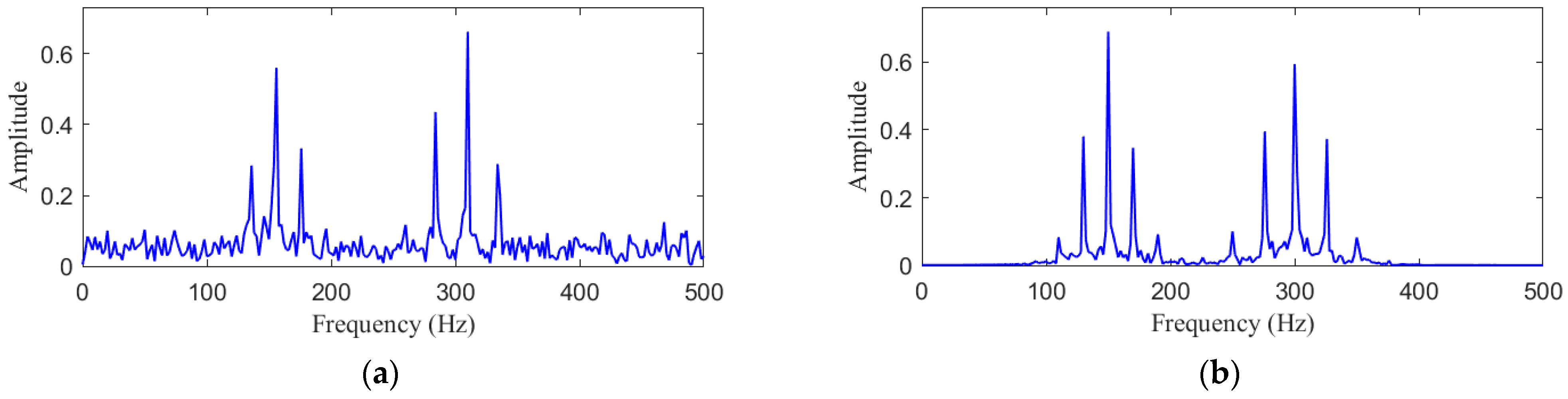

- Data pre-processing: The original sound signal is decomposed into multiple chirped mode functions (CMFs) using ACMD. The CMFs with correlation coefficients greater than 0.3 are selected for signal reconstruction to remove the noise components and enhance the fault-related features in the signal. The reconstructed signal will be used for the subsequent feature extraction and fault identification.

- 3.

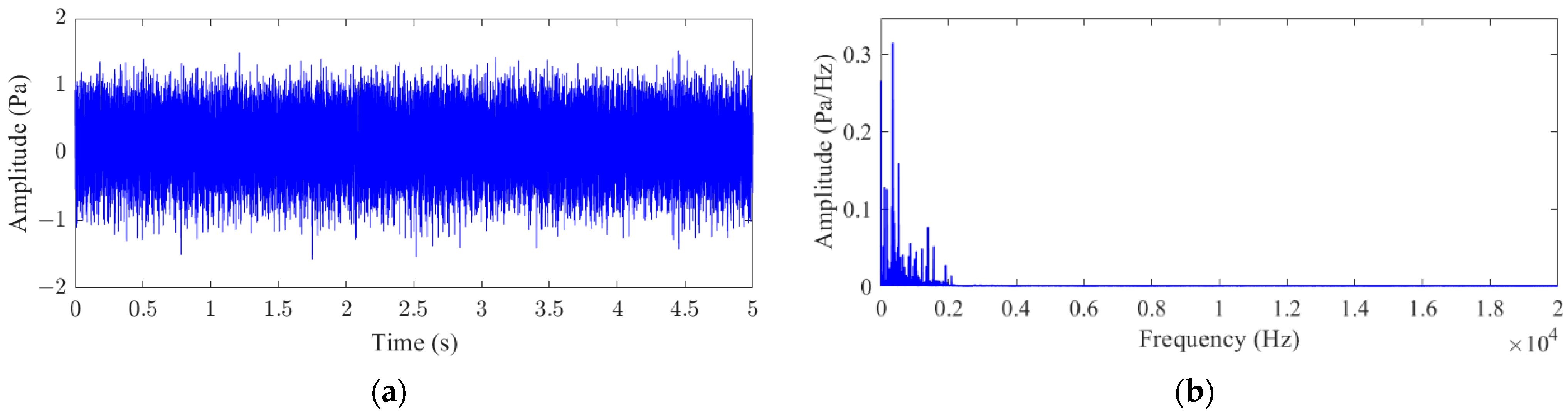

- Feature extraction: The pre-processed sound signal is converted into a Mayer spectrogram. By simulating the auditory perception mechanism of the human ear, the Mayer spectrogram can effectively capture the key characteristics of the sound signal, which is particularly important in voiceprint recognition.

- 4.

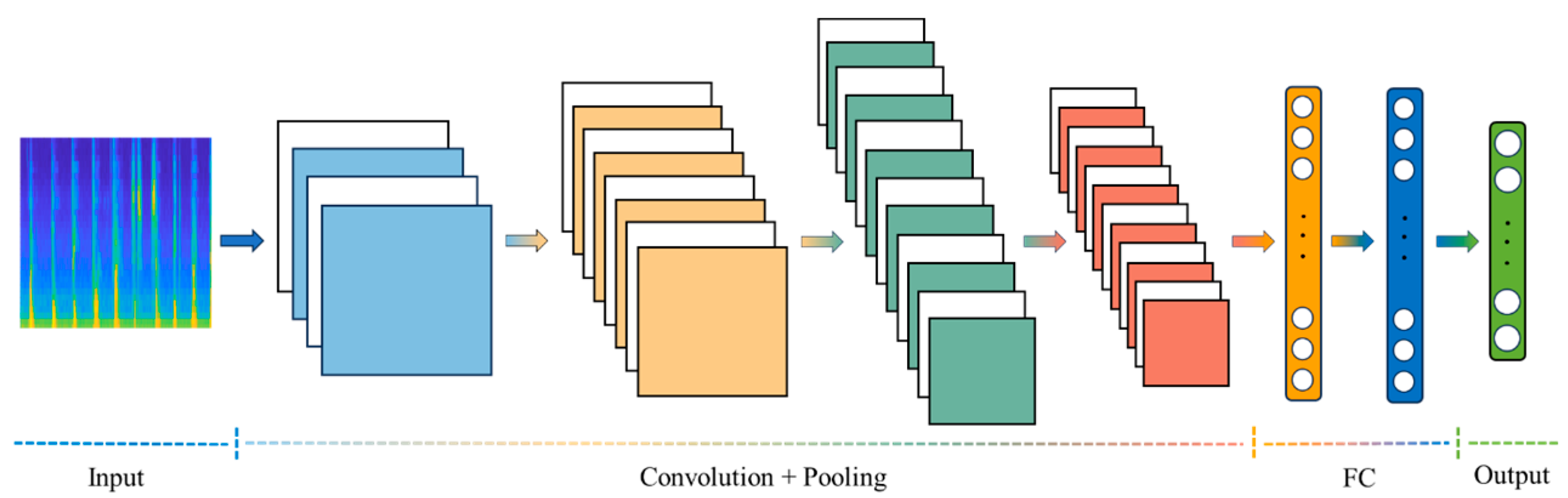

- Model training: Using the Mayer spectrogram obtained in the previous step as the input data, the MobileViT model is trained to recognize the different fault types of the pump. MobileViT is a lightweight model that combines a CNN and a Transformer for processing image data.

- 5.

- Fault identification: The trained MobileViT model is used for the fault diagnosis of the constant pressure variable pump to achieve an accurate fault type determination.

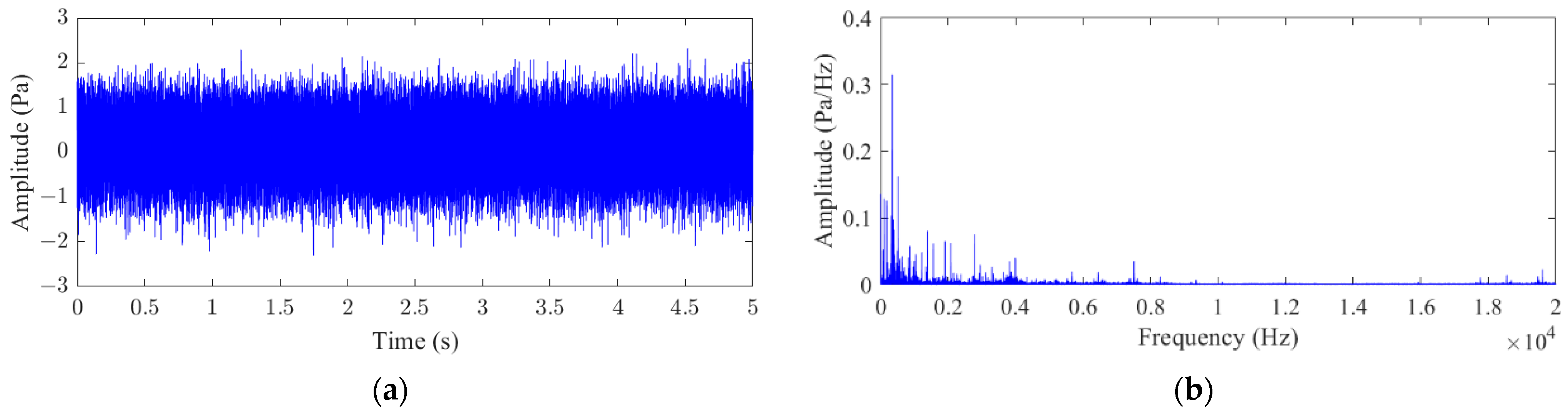

4. Data Acquisition and Feature Set Construction

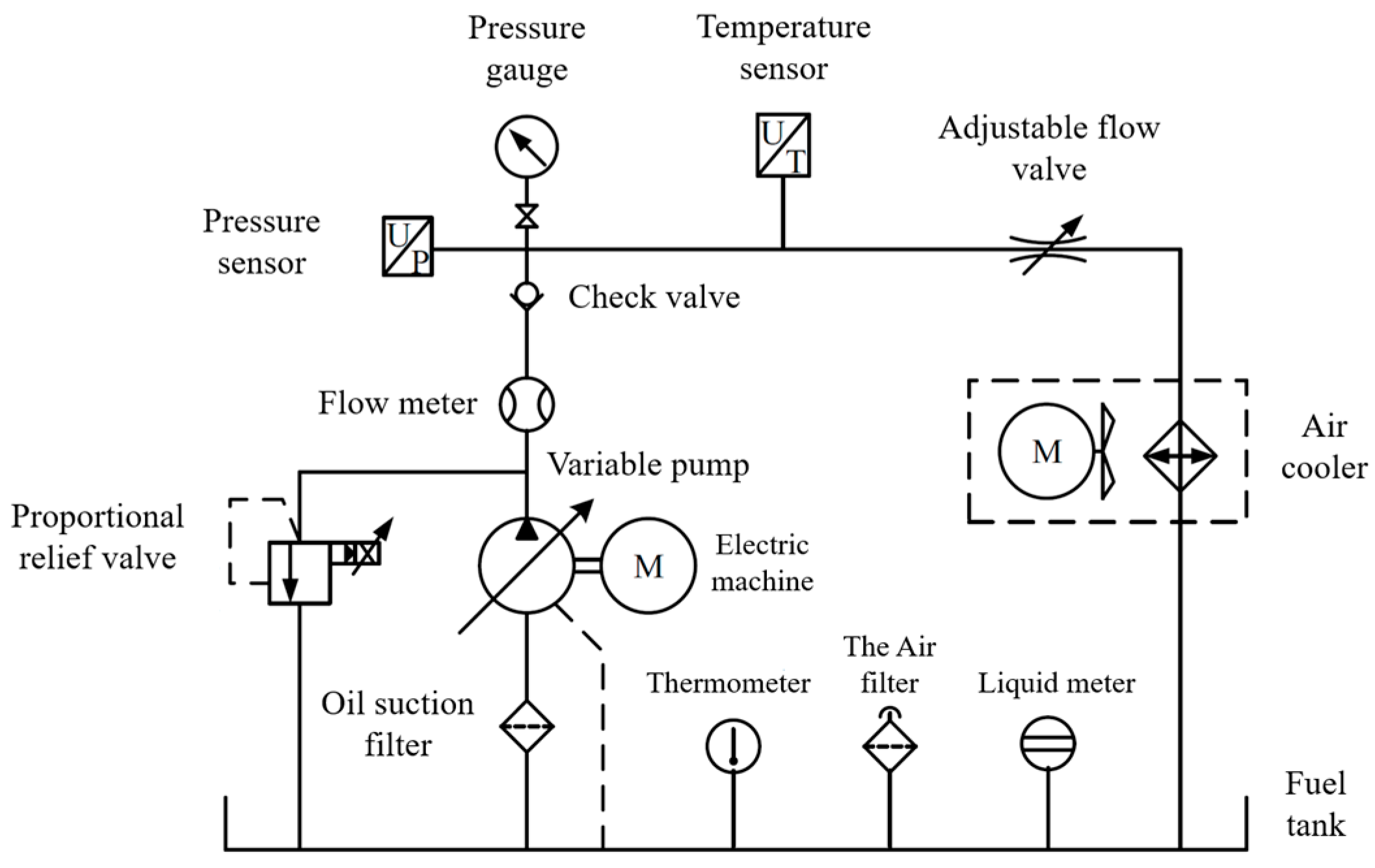

4.1. Experimental Setup

4.2. Mel Spectrum Sample Construction

5. Fault Diagnosis Model Based on Mel-MobileVIT

5.1. The Network Structure of MobileViT

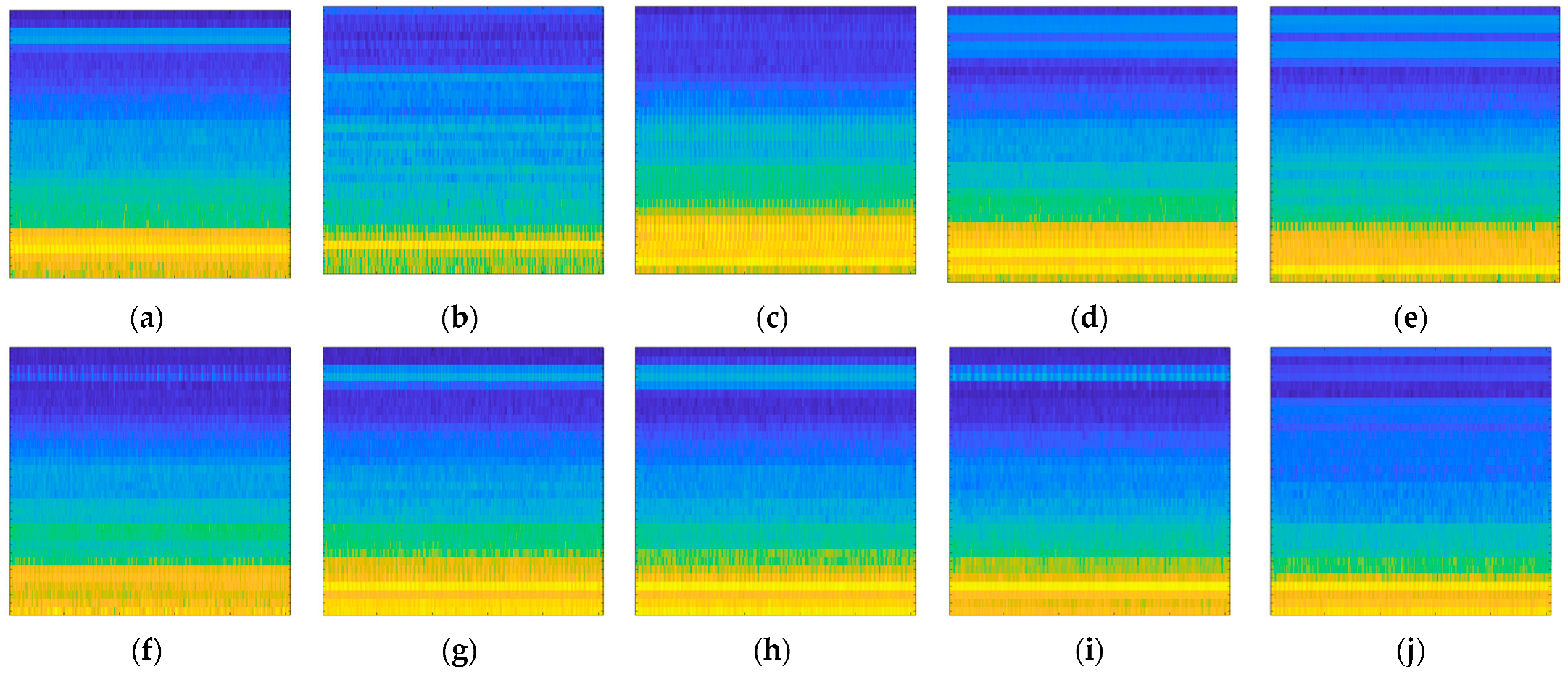

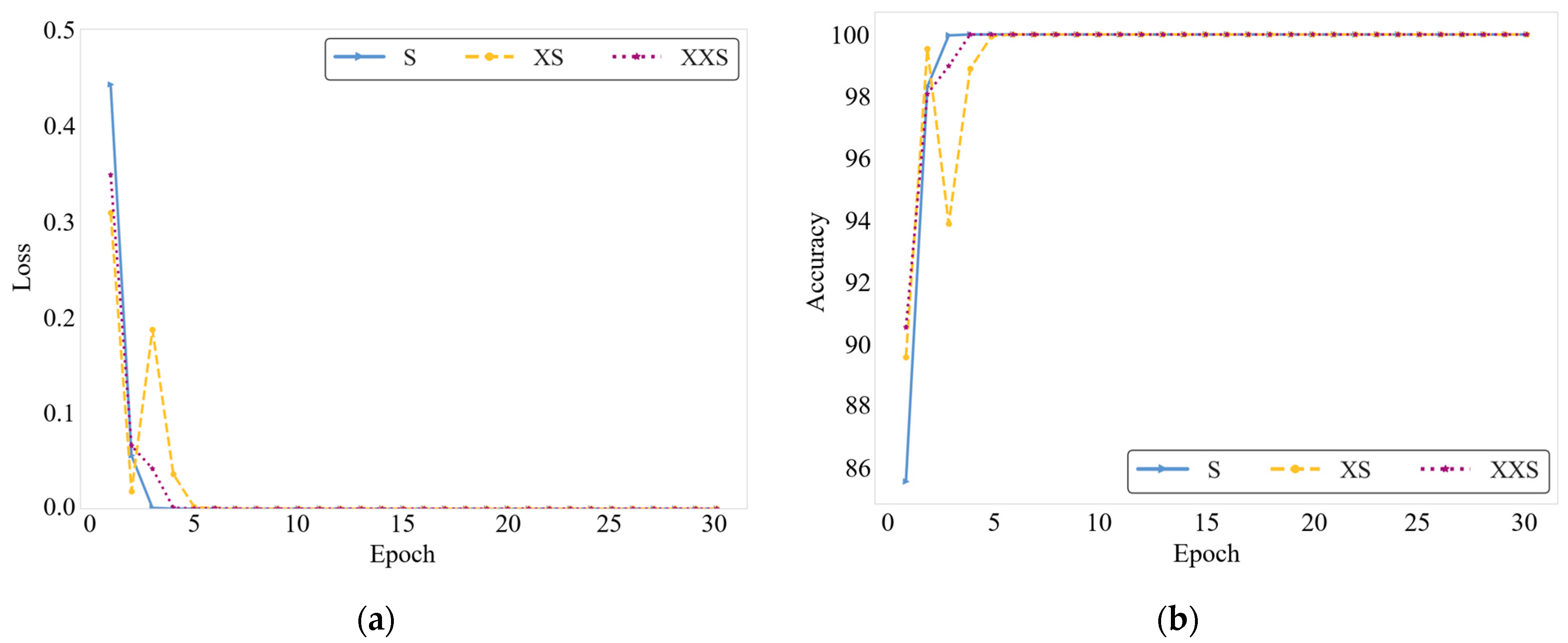

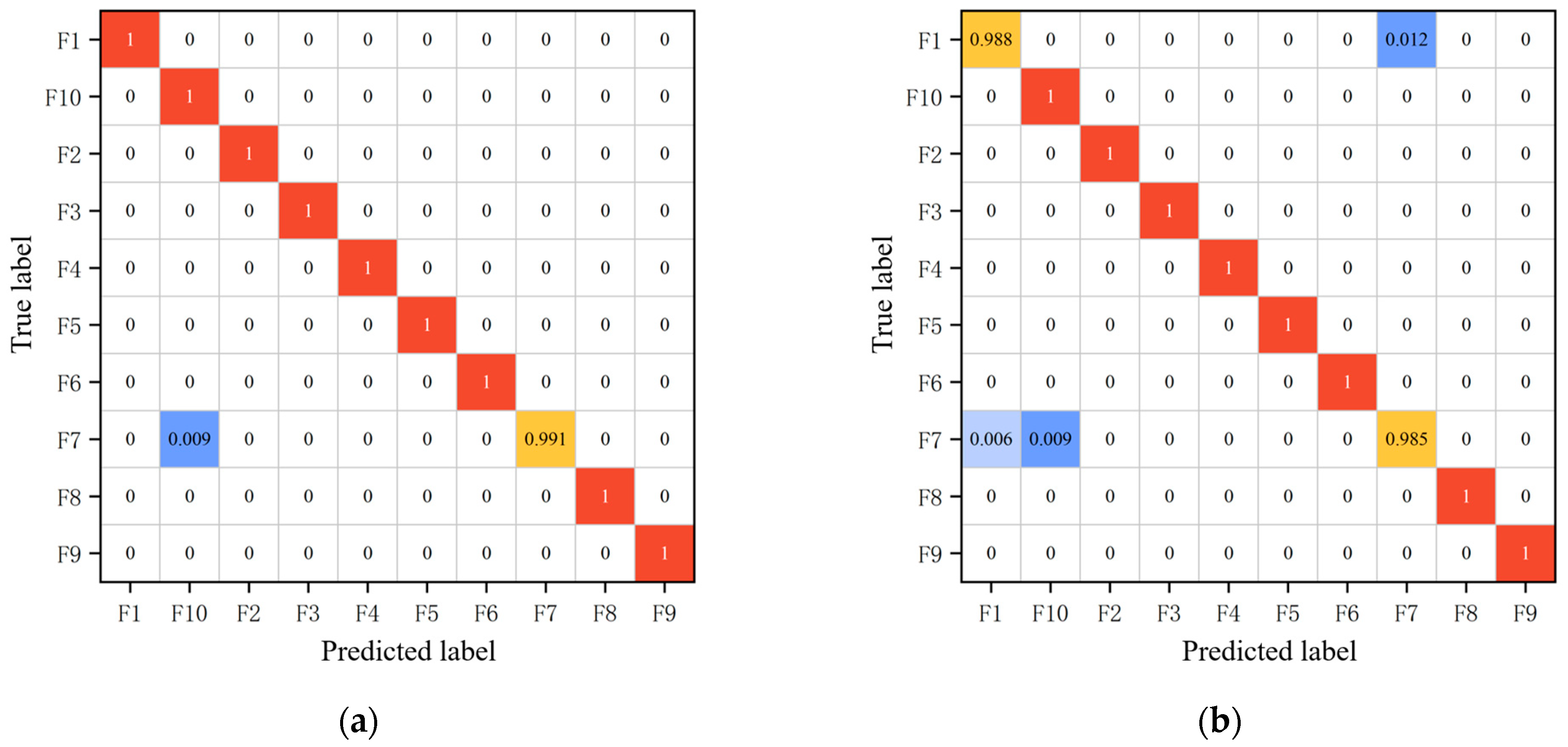

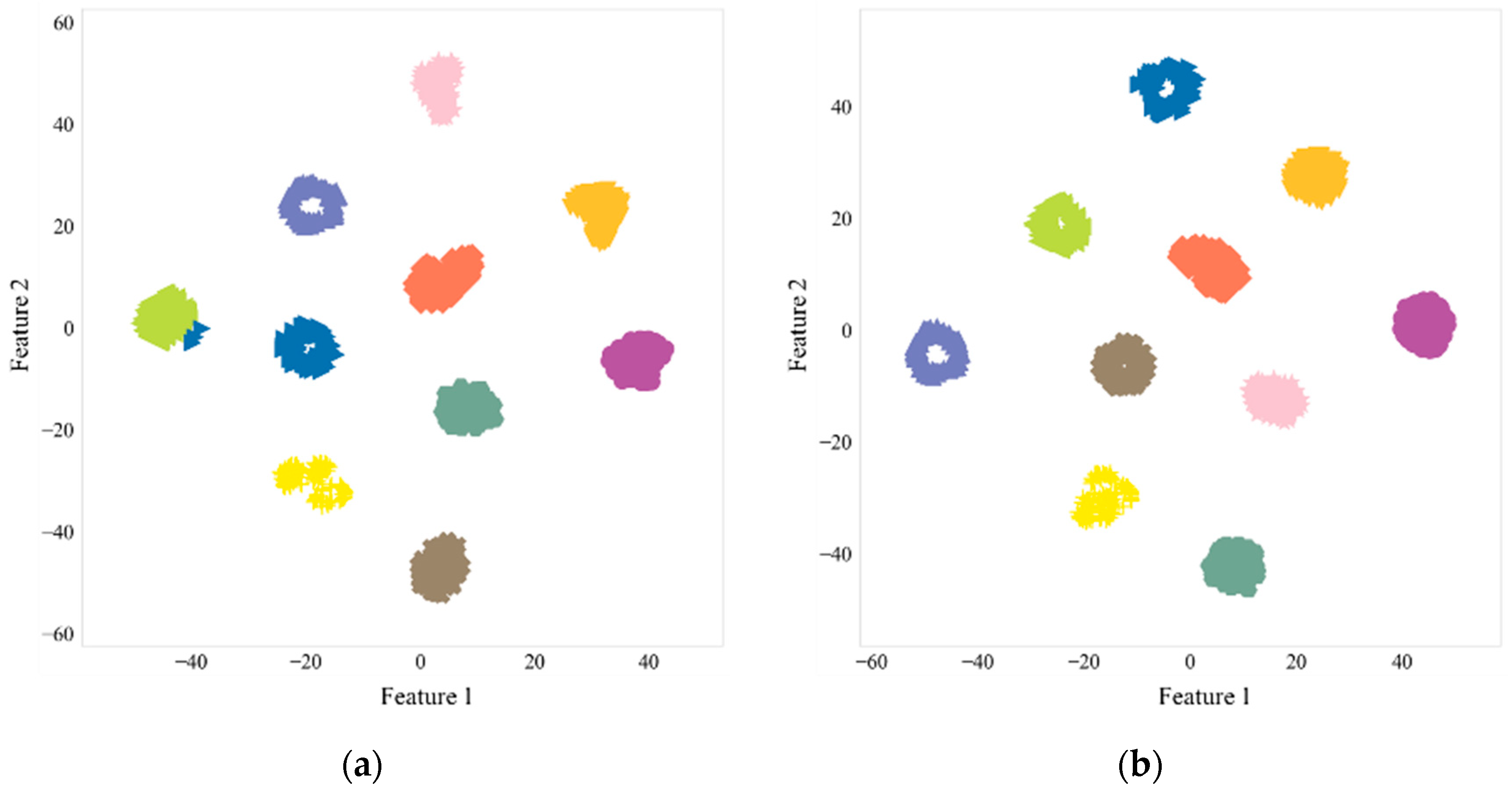

5.2. Result Analysis

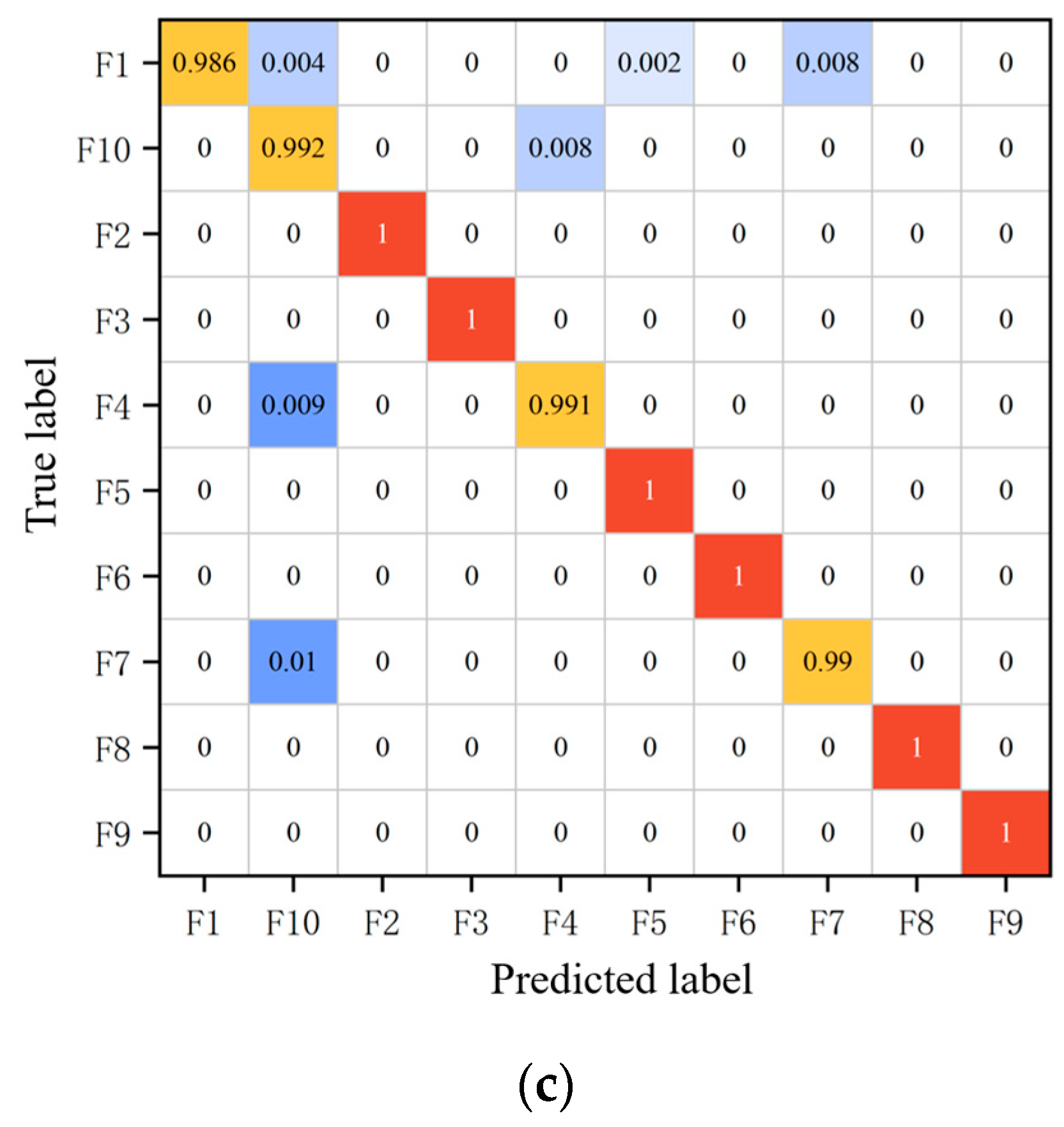

5.3. Comparative Study of Different Models

6. Conclusions

- 1.

- This paper utilizes ACMD to adaptively extract the instantaneous frequency of sound signals, separate various modal components, and reconstruct signals using highly correlated modes based on the Pearson correlation coefficient for noise reduction. It also compares well with noise reduction algorithms like EMD and VMD. The results show that ACMD is more effective in reducing noise levels when processing the sound signals from hydraulic pumps.

- 2.

- This paper applies the MobileViT network to fault diagnosis in constant pressure variable pumps and compares it with existing lightweight deep learning models. The results demonstrate that MobileViT not only maintains high recognition accuracy, but also significantly reduces the model’s computational complexity and parameter requirements, thereby enhancing the diagnostic efficiency.

- 3.

- The method proposed in this paper is non-invasive, employing sound sensors which, compared to other types of sensors, offer advantages such as easy installation, low maintenance costs, and no disruption to normal equipment operation. These benefits significantly enhance the applicability and reliability of the fault diagnosis system.

- 4.

- Although the model in this paper performs well under specific experimental conditions, the actual effect on hydraulic pumps under different working conditions may be different. In practical applications, it may be necessary to further collect more training data, covering different equipment models and working conditions, to improve the versatility and adaptability of the model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Q.; Kong, X.; Yu, B.; Ba, K.; Jin, Z.; Kang, Y. Review and Development Trend of Digital Hydraulic Technology. Appl. Sci. 2020, 10, 579. [Google Scholar] [CrossRef]

- Yang, Y.; Ding, L.; Xiao, J.; Fang, G.; Li, J. Current Status and Applications for Hydraulic Pump Fault Diagnosis: A Review. Sensors 2022, 22, 9714. [Google Scholar] [CrossRef] [PubMed]

- Kong, X.; Cai, B.; Liu, Y.; Zhu, H.; Liu, Y.; Shao, H.; Yang, C.; Li, H.; Mo, T. Optimal Sensor Placement Methodology of Hydraulic Control System for Fault Diagnosis. Mech. Syst. Signal Process. 2022, 174, 109069. [Google Scholar] [CrossRef]

- Ye, S.; Zhang, J.; Xu, B.; Zhu, S.; Xiang, J.; Tang, H. Theoretical Investigation of the Contributions of the Excitation Forces to the Vibration of an Axial Piston Pump. Mech. Syst. Signal Process. 2019, 129, 201–217. [Google Scholar] [CrossRef]

- Shan, Z.; Li, Z.; Zhang, X.; Huang, Y.; Li, Y.; Liu, C.; Zhang, X. Health Status Assessment of Hydraulic Pumps Based on Multi-Sensor Information Fusion and Multi-Grained Cascade Forest Model. China Mech. Eng. 2021, 32, 2374–2382. [Google Scholar] [CrossRef]

- Wang, S.; Xiang, J.; Zhong, Y.; Tang, H. A Data Indicator-Based Deep Belief Networks to Detect Multiple Faults in Axial Piston Pumps. Mech. Syst. Signal Process. 2018, 112, 154–170. [Google Scholar] [CrossRef]

- Ye, S.; Zhang, J.; Xu, B.; Hou, L.; Xiang, J.; Tang, H. A Theoretical Dynamic Model to Study the Vibration Response Characteristics of an Axial Piston Pump. Mech. Syst. Signal Process. 2021, 150, 107237. [Google Scholar] [CrossRef]

- Toutountzakis, T.; Tan, C.K.; Mba, D. Application of Acoustic Emission to Seeded Gear Fault Detection. NDT E Int. 2005, 38, 27–36. [Google Scholar] [CrossRef]

- Abdul, Z.K.; Al-Talabani, A.K. Mel Frequency Cepstral Coefficient and Its Applications: A Review. IEEE Access 2022, 10, 122136–122158. [Google Scholar] [CrossRef]

- Glowacz, A.; Glowacz, W.; Glowacz, Z.; Kozik, J. Early Fault Diagnosis of Bearing and Stator Faults of the Single-Phase Induction Motor Using Acoustic Signals. Measurement 2018, 113, 1–9. [Google Scholar] [CrossRef]

- Tang, L.; Wu, X.; Wang, D.; Liu, X. A Comparative Experimental Study of Vibration and Acoustic Emission on Fault Diagnosis of Low-Speed Bearing. IEEE Trans. Instrum. Meas. 2023, 72, 1–11. [Google Scholar] [CrossRef]

- Hou, D.; Qi, H.; Wang, C.; Han, D. High-Speed Train Wheel Set Bearing Fault Diagnosis and Prognostics: Fingerprint Feature Recognition Method Based on Acoustic Emission. Mech. Syst. Signal Process. 2022, 171, 108947. [Google Scholar] [CrossRef]

- Elasha, F.; Greaves, M.; Mba, D. Planetary Bearing Defect Detection in a Commercial Helicopter Main Gearbox with Vibration and Acoustic Emission. Struct. Health Monit. 2018, 17, 1192–1212. [Google Scholar] [CrossRef]

- Pham, M.T.; Kim, J.-M.; Kim, C.H. Rolling Bearing Fault Diagnosis Based on Improved GAN and 2-D Representation of Acoustic Emission Signals. IEEE Access 2022, 10, 78056–78069. [Google Scholar] [CrossRef]

- Tang, S.; Zhu, Y.; Yuan, S. Intelligent Fault Diagnosis of Hydraulic Piston Pump Based on Deep Learning and Bayesian Optimization. ISA Trans. 2022, 129, 555–563. [Google Scholar] [CrossRef]

- Shan, S.; Liu, J.; Wu, S.; Shao, Y.; Li, H. A Motor Bearing Fault Voiceprint Recognition Method Based on Mel-CNN Model. Measurement 2023, 207, 112408. [Google Scholar] [CrossRef]

- Tran, T.; Lundgren, J. Drill Fault Diagnosis Based on the Scalogram and Mel Spectrogram of Sound Signals Using Artificial Intelligence. IEEE Access 2020, 8, 203655–203666. [Google Scholar] [CrossRef]

- Islam, M.M.M.; Kim, J.-M. Automated Bearing Fault Diagnosis Scheme Using 2D Representation of Wavelet Packet Transform and Deep Convolutional Neural Network. Comput. Ind. 2019, 106, 142–153. [Google Scholar] [CrossRef]

- Kumar, A.; Gandhi, C.P.; Zhou, Y.; Kumar, R.; Xiang, J. Improved Deep Convolution Neural Network (CNN) for the Identification of Defects in the Centrifugal Pump Using Acoustic Images. Appl. Acoust. 2020, 167, 107399. [Google Scholar] [CrossRef]

- Ji, S.; Han, B.; Zhang, Z.; Wang, J.; Lu, B.; Yang, J.; Jiang, X. Parallel Sparse Filtering for Intelligent Fault Diagnosis Using Acoustic Signal Processing. Neurocomputing 2021, 462, 466–477. [Google Scholar] [CrossRef]

- Shao, Y.; Chao, Q.; Xia, P.; Liu, C. Fault Severity Recognition in Axial Piston Pumps Using Attention-Based Adversarial Discriminative Domain Adaptation Neural Network. Phys. Scr. 2024, 99, 056009. [Google Scholar] [CrossRef]

- Huang, W.; Shen, Z.; Huang, N.E.; Fung, Y.C. Engineering Analysis of Biological Variables: An Example of Blood Pressure over 1 Day. Proc. Natl. Acad. Sci. USA 1998, 95, 4816–4821. [Google Scholar] [CrossRef] [PubMed]

- Huang, N.E. Review of Empirical Mode Decomposition. In Wavelet Applications VIII; Szu, H.H., Donoho, D.L., Lohmann, A.W., Campbell, W.J., Buss, J.R., Eds.; Spie-Int Soc Optical Engineering: Bellingham, WA, USA, 2001; Volume 4391, pp. 71–80. [Google Scholar]

- Dragomiretskiy, K.; Zosso, D. Variational Mode Decomposition. IEEE Trans. Signal Process. 2014, 62, 531–544. [Google Scholar] [CrossRef]

- Chen, S.; Yang, Y.; Peng, Z.; Wang, S.; Zhang, W.; Chen, X. Detection of Rub-Impact Fault for Rotor-Stator Systems: A Novel Method Based on Adaptive Chirp Mode Decomposition. J. Sound Vibr. 2019, 440, 83–99. [Google Scholar] [CrossRef]

- Chen, S.; Yang, Y.; Peng, Z.; Dong, X.; Zhang, W.; Meng, G. Adaptive Chirp Mode Pursuit: Algorithm and Applications. Mech. Syst. Signal Proc. 2019, 116, 566–584. [Google Scholar] [CrossRef]

- Bhatt, D.; Patel, C.; Talsania, H.; Patel, J.; Vaghela, R.; Pandya, S.; Modi, K.; Ghayvat, H. CNN Variants for Computer Vision: History, Architecture, Application, Challenges and Future Scope. Electronics 2021, 10, 2470. [Google Scholar] [CrossRef]

- Liu, Y.; Pu, H.; Sun, D.-W. Efficient Extraction of Deep Image Features Using Convolutional Neural Network (CNN) for Applications in Detecting and Analysing Complex Food Matrices. Trends Food Sci. Technol. 2021, 113, 193–204. [Google Scholar] [CrossRef]

- Yao, Q.; Wang, R.; Fan, X.; Liu, J.; Li, Y. Multi-Class Arrhythmia Detection from 12-Lead Varied-Length ECG Using Attention-Based Time-Incremental Convolutional Neural Network. Inf. Fusion 2020, 53, 174–182. [Google Scholar] [CrossRef]

- Tang, S.; Zhu, Y.; Yuan, S. An Improved Convolutional Neural Network with an Ad Learning Rate towards Multi-Signal Fault Diagnosis of Hydraulic Piston Pump. Adv. Eng. Inform. 2021, 50, 101406. [Google Scholar] [CrossRef]

- Khan, A.; Sohail, A.; Zahoora, U.; Qureshi, A.S. A Survey of the Recent Architectures of Deep Convolutional Neural Networks. Artif. Intell. Rev. 2020, 53, 5455–5516. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, Y.; Yin, C.; Ding, W. Ultra-Lightweight CNN Design Based on Neural Architecture Search and Knowledge Distillation: A Novel Method to Build the Automatic Recognition Model of Space Target ISAR Images. Def. Technol. 2022, 18, 1073–1095. [Google Scholar] [CrossRef]

- Zhong, H.; Lv, Y.; Yuan, R.; Yang, D. Bearing Fault Diagnosis Using Transfer Learning and Self-Attention Ensemble Lightweight Convolutional Neural Network. Neurocomputing 2022, 501, 765–777. [Google Scholar] [CrossRef]

- Ruan, D.; Han, J.; Yan, J.; Gühmann, C. Light Convolutional Neural Network by Neural Architecture Search and Model Pruning for Bearing Fault Diagnosis and Remaining Useful Life Prediction. Sci. Rep. 2023, 13, 5484. [Google Scholar] [CrossRef] [PubMed]

- Mehta, S.; Rastegari, M. MobileViT: Light-Weight, General-Purpose, and Mobile-Friendly Vision Transformer. arXiv 2021. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, A.; Bharti, V.; Singh, A.K.; Singh, S.K.; Saxena, S. MobiHisNet: A Lightweight CNN in Mobile Edge Computing for Histopathological Image Classification. IEEE Internet Things J. 2021, 8, 17778–17789. [Google Scholar] [CrossRef]

| Components | Model Number | Argument |

|---|---|---|

| Constant pressure variable pump | P08-B3-F-R-01 | No-load displacement: 8 cm3/r |

| Pressure regulation range: 3~21 MPa | ||

| Speed range: 500~2000 r/min | ||

| Drive motor | C07-43BO | Rated power: 5.5 kW |

| Rated speed: 1440 r/min | ||

| Sound level meter | AWA5661 | Measuring range: 25~140 dB |

| Sensitivity: 40 mV/Pa | ||

| Frequency range: 10 Hz–16 kHz |

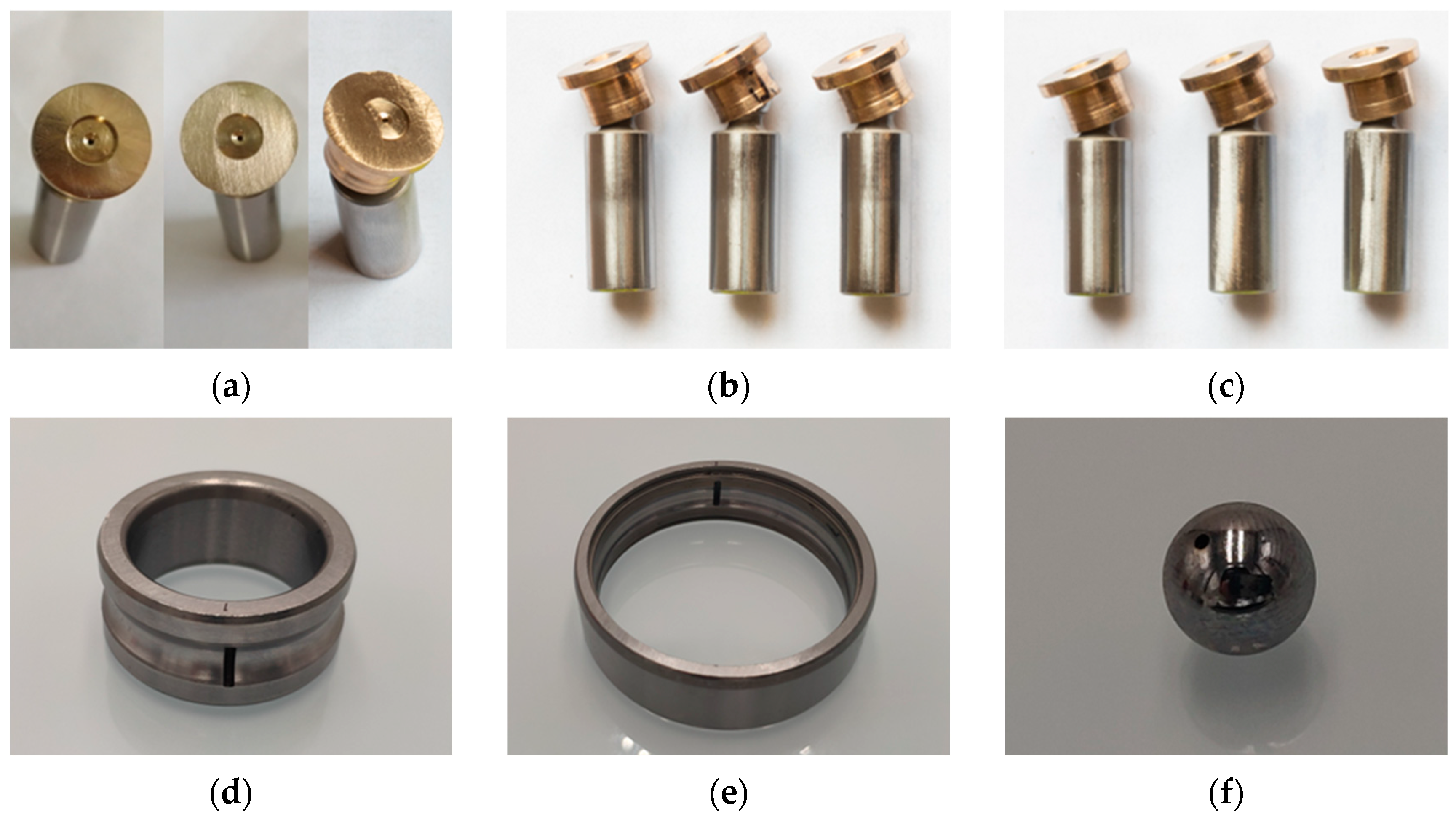

| Serial Number | Failure Form | Injection Mode | Tag |

|---|---|---|---|

| 1 | Normal | — | F1 |

| 2 | Slipper wear (light) | Using 80-grit sandpaper, the slipper pad was sanded until its mass decreased by 0.2 g, and it was appropriately biased during sanding. | F2 |

| 3 | Slipper wear (heavy) | Using 40-grit sandpaper, the slipper pad was sanded until its mass decreased by 0.6 g, and it was appropriately biased during sanding. | F3 |

| 4 | Loose boots (light) | Select a plunger with a certain degree of loose slipper pad, with a clearance of 0.24 mm. | F4 |

| 5 | Loose boots (heavy) | Select a plunger with a certain degree of loose slipper pad, with a clearance of 0.48 mm. | F5 |

| 6 | Plunger wear (light) | Using 180-grit sandpaper, the plunger was sanded until its mass was reduced by 0.15 g. | F6 |

| 7 | Plunger wear (heavy) | Using 100-grit sandpaper, the plunger was sanded until its mass was reduced by 0.45 g. | F7 |

| 8 | Inner race bearing fault | Using electrical discharge machining (EDM), a groove 1 mm wide and 1 mm deep was machined across the raceway of the inner ring of a rolling bearing, oriented perpendicular to the raceway direction. | F8 |

| 9 | Outer race bearing fault | Using EDM, a groove 1 mm wide and 1 mm deep was machined across the raceway of the outer ring of a rolling bearing, oriented perpendicular to the raceway direction. | F9 |

| 10 | Rolling element bearing fault | A pit with a diameter of 1 mm and a depth of 1 mm was machined on one of the rolling elements of a rolling bearing using EDM. | F10 |

| Fault Type | Sample Size | Training Set | Test Set | Validation Set | Tag |

|---|---|---|---|---|---|

| Normal state | 570 | 342 | 114 | 114 | F1 |

| Slipper wear (light) | 570 | 342 | 114 | 114 | F2 |

| Slipper wear (heavy) | 570 | 342 | 114 | 114 | F3 |

| Loose boots (light) | 570 | 342 | 114 | 114 | F4 |

| Loose boots (heavy) | 570 | 342 | 114 | 114 | F5 |

| Plunger wear (light) | 570 | 342 | 114 | 114 | F6 |

| Plunger wear (heavy) | 570 | 342 | 114 | 114 | F7 |

| Inner race bearing fault | 570 | 342 | 114 | 114 | F8 |

| Outer race bearing fault | 570 | 342 | 114 | 114 | F9 |

| Rolling element bearing fault | 570 | 342 | 114 | 114 | F10 |

| Layer | Output size | Repeat | Output Channels | |||

|---|---|---|---|---|---|---|

| XXS | XS | S | ||||

| Image | 256 × 256 | |||||

| Layer 1 | Conv-3 × 3, ↓ 2 MV2 | 128 × 128 | 1 1 | 16 16 | 16 32 | 16 32 |

| Layer 2 | MV2, ↓ 2 MV2 | 64 × 64 | 1 2 | 24 24 | 48 48 | 64 64 |

| Layer 3 | MV2, ↓ 2 MobileViT block (L = 2) | 32 × 32 | 1 1 | 48 48 (d = 64) | 64 64 (d = 96) | 96 96 (d = 144) |

| Layer 4 | MV2, ↓ 2 MobileViT block (L = 4) | 16 × 16 | 1 1 | 64 64 (d = 80) | 80 80 (d = 120) | 128 128 (d = 192) |

| Layer 5 | MV2, ↓ 2 MobileViT block (L = 3) Conv-1 × 1 | 8 × 8 | 1 1 1 | 80 80 (d = 96) 320 | 96 96 (d = 144) 384 | 160 160 (d = 240) 640 |

| Layer 6 | Global pool Linear | 1 × 1 | 1 | 10 | 10 | 10 |

| Model | Acc. (%) | MFLOPs | Params/106 | MemR+W (MB) | Images/s |

|---|---|---|---|---|---|

| MobileViT-S | 99.91 | 1776.54 | 5 | 426.03 | 5.35 |

| MobileViT-XS | 99.73 | 922.82 | 2 | 335.89 | 31.26 |

| MobileViT-XXS | 99.59 | 341.54 | 1.01 | 136.90 | 75.95 |

| Class | MobileViT-S | MobileViT-XS | MobileViT-XXS | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Precision | Recall | F1 Score | Precision | Recall | F1 Score | Precision | Recall | F1 Score | |

| F1 | 1 | 1 | 1 | 0.994 | 0.988 | 0.991 | 1 | 0.986 | 0.993 |

| F10 | 0.991 | 1 | 0.996 | 0.991 | 1 | 0.996 | 0.977 | 0.992 | 0.985 |

| F2 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| F3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| F4 | 1 | 1 | 1 | 1 | 1 | 1 | 0.992 | 0.991 | 0.991 |

| F5 | 1 | 1 | 1 | 1 | 1 | 1 | 0.998 | 1 | 0.999 |

| F6 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| F7 | 1 | 0.991 | 0.995 | 0.988 | 0.985 | 0.986 | 0.991 | 0.99 | 0.991 |

| F8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| F9 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Model | Acc. (%) | MFLOPs | Params/106 | MemR+W (MB) | Images/s |

|---|---|---|---|---|---|

| MobileViT-XXS | 99.59 | 341.54 | 1.01 | 136.90 | 75.95 |

| MobileNetV2 | 99.72 | 426.07 | 2.23 | 163.76 | 100.76 |

| MobileNetV1 | 98.10 | 767.86 | 3.21 | 208.91 | 118.21 |

| Class | MobileViT-XXS | MobileNetV1 | MobileNetV2 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Precision | Recall | F1 Score | Precision | Recall | F1 Score | Precision | Recall | F1 Score | |

| F1 | 1 | 0.986 | 0.993 | 1 | 0.885 | 0.939 | 0.994 | 1 | 0.997 |

| F10 | 0.977 | 0.992 | 0.985 | 0.991 | 1 | 0.996 | 0.988 | 0.99 | 0.989 |

| F2 | 1 | 1 | 1 | 0.862 | 1 | 0.926 | 1 | 1 | 1 |

| F3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| F4 | 0.992 | 0.991 | 0.991 | 1 | 0.991 | 0.995 | 1 | 1 | 1 |

| F5 | 0.998 | 1 | 0.999 | 1 | 0.991 | 0.995 | 1 | 1 | 1 |

| F6 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| F7 | 0.991 | 0.99 | 0.991 | 1 | 0.947 | 0.973 | 0.99 | 0.982 | 0.986 |

| F8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| F9 | 1 | 1 | 1 | 0.983 | 1 | 0.991 | 1 | 1 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Jiang, A.; Jiang, W.; Yang, X.; Xia, X.; Gu, X. Intelligent Fault Diagnosis Method for Constant Pressure Variable Pump Based on Mel-MobileViT Lightweight Network. J. Mar. Sci. Eng. 2024, 12, 1677. https://doi.org/10.3390/jmse12091677

Zhao Y, Jiang A, Jiang W, Yang X, Xia X, Gu X. Intelligent Fault Diagnosis Method for Constant Pressure Variable Pump Based on Mel-MobileViT Lightweight Network. Journal of Marine Science and Engineering. 2024; 12(9):1677. https://doi.org/10.3390/jmse12091677

Chicago/Turabian StyleZhao, Yonghui, Anqi Jiang, Wanlu Jiang, Xukang Yang, Xudong Xia, and Xiaoyang Gu. 2024. "Intelligent Fault Diagnosis Method for Constant Pressure Variable Pump Based on Mel-MobileViT Lightweight Network" Journal of Marine Science and Engineering 12, no. 9: 1677. https://doi.org/10.3390/jmse12091677

APA StyleZhao, Y., Jiang, A., Jiang, W., Yang, X., Xia, X., & Gu, X. (2024). Intelligent Fault Diagnosis Method for Constant Pressure Variable Pump Based on Mel-MobileViT Lightweight Network. Journal of Marine Science and Engineering, 12(9), 1677. https://doi.org/10.3390/jmse12091677