Experimental Study on Stiffness Degradation and Liquefaction Characteristics of Marine Sand in the East Nan-Ao Area in Guangdong Province, China

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experiment Material

2.2. Experimental Apparatus and Operations

3. Results of Resonant Column Test and Prediction Model of Shear Modulus

3.1. Maximum Shear Modulus

3.2. Nonlinearity of Dynamic Shear Modulus

4. Results and Discussions of Cyclic Triaxial Test

4.1. Liquefaction Resistance of Marine Sand under Cyclic Loading

4.1.1. Effect of Relative Density on Cyclic Strength

4.1.2. Effect of Particle Size on Cyclic Strength

4.1.3. Effect of Additional Pressure on Cyclic Strength

4.2. Pore Water Pressure Development Characteristics of Marine Sand

5. Conclusions

- (1)

- With the increase of soil depth, the effective confining pressure increases and the contact between soil particles becomes closer, resulting in the larger initial shear modulus and lower nonlinearity of soil samples. From the normalized curve of shear modulus, it can be seen that with the increase of confining pressure, the G/Gmax-γ curve tends to move up to the right, indicating that the nonlinearity of the soil sample is restrained.

- (2)

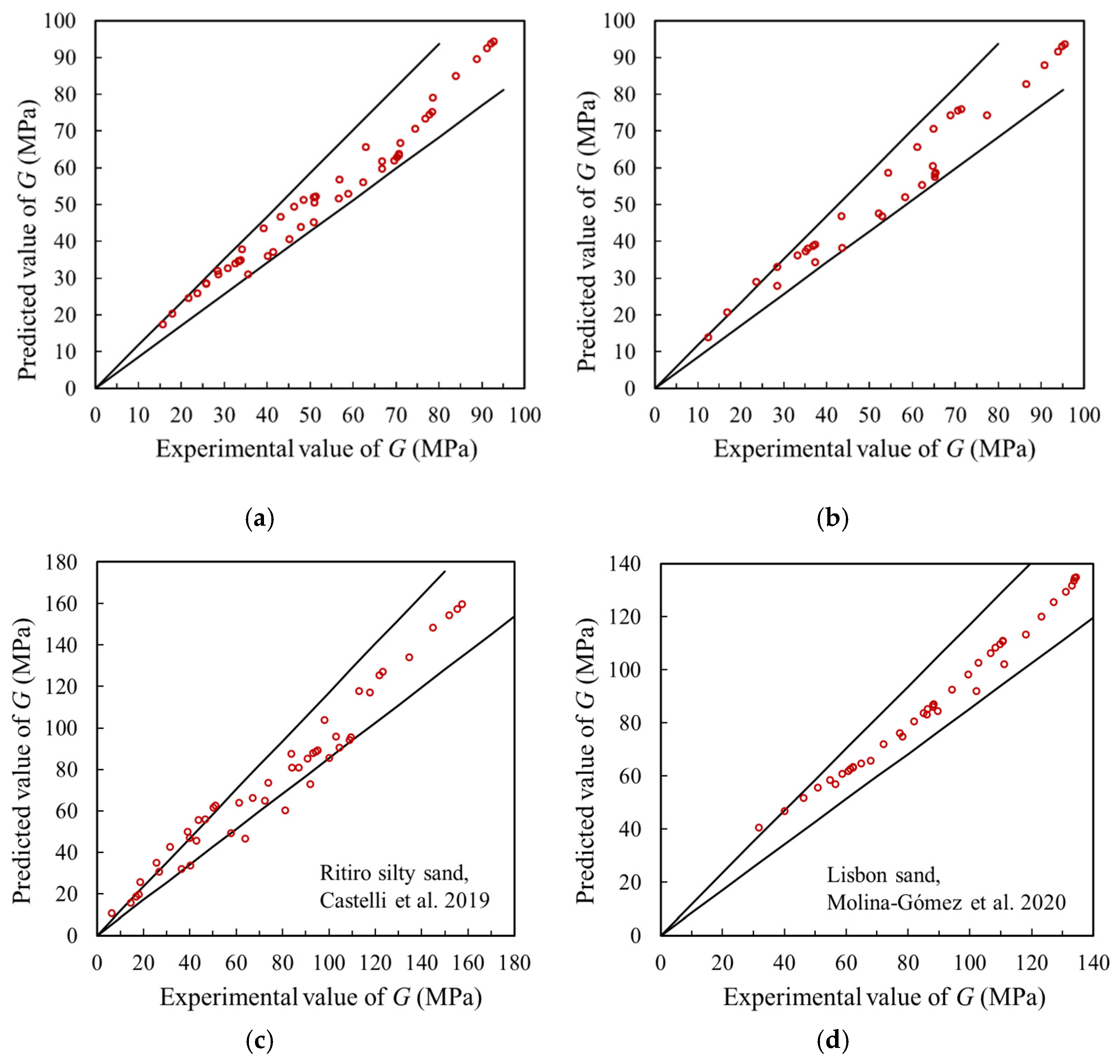

- A prediction model of the shear modulus of this site is proposed by combining the linear model and Davidenkov’s three-parameter model, and the error between the calculated value and experimental value is within ±10%. The model calculates the shear modulus of the soil layer through the effective confining pressure, which omits the complex calculation of the void ratio. In some seismic response analyses work, this model can help to obtain the dynamic parameters of soil more efficiently.

- (3)

- As the relative density of sand increases, the liquefaction resistance of sand increases significantly. Because of the good gradation of silty sand and less coarse particle content, silty samples are less liquefiable when CSR is small, while the strength is lower when CSR is large. Moreover, due to the additional stress of offshore structure, the anti-liquefaction resistance of the shallow liquefiable layer is improved, and the energy required to achieve liquefaction also increases with the increase of effective confining pressure.

- (4)

- Based on the Seed model, a modified model predicting pore pressure development is proposed, and the modified model can fit the excess pore pressure growth curve of soil samples in the test more accurately, especially at the initial stage of cyclic loading and near liquefaction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Wang, X.F.; Zeng, X.W.; Li, J.L.; Yang, X.; Wang, H.J. A review on recent advancements of substructures for offshore wind turbines. Energy Convers. Manag. 2018, 158, 103–119. [Google Scholar] [CrossRef]

- Beijing Declaration on Wind Energy. Available online: https://finance.sina.com.cn/china/gncj/2020-10-14/doc-iiznezxr5868564.shtml (accessed on 17 April 2021).

- Li, X.Y.; Zeng, X.W.; Yu, X.; Wang, X.F. Seismic response of a novel hybrid foundation for offshore wind turbine by geotechnical centrifuge modeling. Renew. Energy 2021, 172, 1404–1416. [Google Scholar] [CrossRef]

- Gao, F.P.; Li, J.H.; Qi, W.G.; Hu, C. On the instability of offshore foundations: Theory and mechanism. Sci. China Phys. Mech. Astron. 2015, 58, 124701. [Google Scholar] [CrossRef] [Green Version]

- Liang, F.Y.; Liang, X.; Wang, C. Seismic response from centrifuge model tests of a scoured bridge with a pile-group foundation. J. Bridge Eng. 2020, 25, 04020054. [Google Scholar] [CrossRef]

- Clayton, C.R.I. Stiffness at small strain: Research and practice. Géotechnique 2011, 61, 5–37. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.M.; Ke, H.; Chen, R.P. Correlation of shear wave velocity with liquefaction resistance based on laboratory tests. Soil Dyn. Earthq. Eng. 2005, 25, 461–469. [Google Scholar]

- Oh, K.; Nam, W.; Ryu, M.S.; Kim, J.; Epureanu, B. A review of foundations of offshore wind energy convertors: Current status and future perspectives. Renew. Sustain. Energy Rev. 2018, 88, 16–36. [Google Scholar] [CrossRef]

- Patra, S.K.; Haldar, S. Long-term drained and post-liquefaction cyclic behaviour of offshore wind turbine in silty sand using element tests. Arab. J. Sci. Eng. 2021, 46, 4791–4810. [Google Scholar] [CrossRef]

- Wang, L.Z.; Zhou, W.J.; Guo, Z.; Rui, S.J. Frequency change and accumulated inclination of offshore wind turbine jacket structure with piles in sand under cyclic loadings. Ocean Eng. 2020, 217, 108045. [Google Scholar] [CrossRef]

- Kong, D.Q.; Wen, K.; Zhu, B.; Zhu, Z.J.; Chen, Y.M. Centrifuge modeling of cyclic lateral behaviors of a tetrapod piled jacket foundation for offshore wind turbines in sand. J. Geotech. Geoenviron. Eng. 2019, 145, 4019099. [Google Scholar] [CrossRef]

- Lopez-Querol, S.; Spyridis, M.; Moreta, P.J.M.; Arias-Trujillo, J. Simplified numerical models to simulate hollow monopile wind turbine foundations. J. Mar. Sci. Eng. 2020, 8, 837. [Google Scholar] [CrossRef]

- Hardin, B.O.; Drnevich, V.P. Shear modulus and damping in soils: Design equations and curves. J. Soil Mech. Found. Div. 1972, 98, 667–692. [Google Scholar] [CrossRef]

- Gu, X.Q.; Yang, J.; Huang, M.S.; Gao, G.Y. Bender element tests in dry and saturated sand: Signal interpretation and result comparison. Soil Found. 2015, 55, 951–962. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Gu, X.Q. Dynamic shear modulus of dry sand: Effect of test method. In Proceedings of the 14th European Conference on Earthquake Engineering, Ohrid, Macedonia, 30 August–3 September 2010. [Google Scholar]

- Yang, J.; Gu, X.Q. Shear stiffness of granular material at small strain: Does it depend on grain size? Geotechnique 2013, 63, 165–179. [Google Scholar] [CrossRef] [Green Version]

- Gu, X.Q.; Zhang, J.C.; Huang, X. DEM analysis of monotonic and cyclic behaviors of sand based on critical state soil mechanics framework. Comput. Geotech. 2020, 128, 103787. [Google Scholar] [CrossRef]

- Sun, T.; Chen, G.X.; Zhou, E.Q.; Li, X.J. Experimental study on dynamic shear modulus ratio and damping ratio of marine soils in Qiongzhou Strait with depth less than 100 m. Chin. J. Geotech. Eng. 2013, 35, 375–382. [Google Scholar]

- Rao, D.K.; Raju, G.; Sowjanya, C.; Rao, J.P. Laboratory studies on the properties of stabilized marine clay from Kakinada Sea Coast, India. Int. J. Eng. Sci. Technol. 2011, 1, 421–428. [Google Scholar]

- Rui, S.J.; Guo, Z.; Si, T.L.; Li, Y.J. Effect of particle shape on the liquefaction resistance of calcareous sand. Soil Dyn. Earthq. Eng. 2020, 137, 106302. [Google Scholar] [CrossRef]

- Li, B.; Huang, M.S. Dynamic triaxial tests on liquefaction characteristics of rubber-sand mixture. Rock Soil Mech. 2017, 38, 1344–1349. [Google Scholar]

- Li, B.; Sun, F.X. Effects of sea water corrosion on long term dynamic behavior of cemented sand. Chin. J. Undergr. Space Eng. 2015, 11, 889–895. [Google Scholar]

- Li, B.; Wang, Y.; Jin, Q.B.; Chen, H. Liquefaction characteristics of recycled concrete aggregates. Soil Dyn. Earthq. Eng. 2019, 120, 85–96. [Google Scholar] [CrossRef]

- Lentini, V.; Castelli, F.; Cavallaro, A.; Grasso, S. A laboratory study for the dynamic characterization of sandy soil. In Proceedings of the 7th lnternational Conference on Earthquake Geotechnical Engineering (VII ICEGE), Rome, Italy, 17–20 June 2019. [Google Scholar]

- Lentini, V.; Castelli, F. Liquefaction Resistance of Sandy Soils from Undrained Cyclic Triaxial Tests. Geotech. Geol. Eng. J. 2019, 37, 201–216. [Google Scholar] [CrossRef]

- Grasso, S.; Castelli, F.; Massimino, M.R.; Lentini, V. In Situ Measurements for Evaluating Liquefaction Potential under Cyclic Loading. In Proceedings of the 1st IMEKO TC-4 International Workshop on Metrology for Geotechnics, Benevento, Italy, 17–18 March 2016. [Google Scholar]

- Bhatnagar, S.; Kumari, S.; Sawant, V.A. Numerical analysis of earth embankment resting on liquefiable soil and remedial measures. Int. J. Geomech. 2016, 16, 4015021–4015029. [Google Scholar] [CrossRef]

- Ye, B.; Xie, X.; Wang, X.W.; Liu, C.; Zhao, Q.H. Numerical analysis of the anti-liquefaction performance of a water reservoir dam under self-weight consolidation. Bull. Eng. Geol. Environ. 2019, 78, 5583–5597. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, Y.; Wang, L. Evolution of anti-liquefaction performance of foundation soils after dam construction. Bull. Eng. Geol. Environ. 2019, 78, 641–651. [Google Scholar] [CrossRef]

- Ding, H.Y.; Xiong, K.P.; Zhang, P.Y. Seismic response of offshore wind structure supported by bucket foundation. Trans. Tianjin Univ. 2016, 22, 294–301. [Google Scholar] [CrossRef]

- Esfeh, P.K.; Kaynia, A.M. Earthquake response of monopiles and caissons for offshore wind turbines founded in liquefiable soil. Soil Dyn. Earthq. Eng. 2020, 136, 106211–106213. [Google Scholar] [CrossRef]

- Esfeh, P.K.; Kaynia, A.M. Numerical modeling of liquefaction and its impact on anchor piles for floating offshore structures. Soil Dyn. Earthq. Eng. 2019, 127, 105831–105839. [Google Scholar] [CrossRef]

- Zhang, P.Y.; Xiong, K.P.; Ding, H.Y.; Le, C.H. Anti-liquefaction characteristics of composite bucket foundations for offshore wind turbines. J. Renew. Sustain. Energy 2014, 6, 53101–53102. [Google Scholar] [CrossRef]

- Goudarzya, M.; Rahman, M.M.; Königa, D. Influence of non-plastic fines content on maximum shear modulus of granular materials. Soils Found. 2016, 56, 973–983. [Google Scholar] [CrossRef]

- Yang, J.; Liu, X. Shear wave velocity and stiffness of sand: The role of non-plastic fines. Géotechnique 2016, 66, 500–514. [Google Scholar] [CrossRef] [Green Version]

- Ruan, B.; Miao, Y.; Chen, K. Study on the small strain shear modulus of saturated sand-fines mixtures by bender element test. Eur. J. Environ. Civ. Eng. 2021, 25, 28–38. [Google Scholar] [CrossRef]

- Yang, W.B.; Wu, Q.; Chen, G.X. Dynamic shear modulus prediction method of undisturbed soil in the estuary of the Yangtze River. Rock Soil Mech. 2019, 40, 3889–3896. [Google Scholar]

- Rong, J.S.; Li, H.G.; Li, X.J.; Lv, Y.J.; Peng, Y.J.; Xiu, L.W. Applicability of Davidenkov model for soft soils in sea areas. Chin. J. Geotech. Eng. 2013, 35, 596–600. [Google Scholar]

- Castelli, F.; Cavallaro, A.; Grasso, S.; Lentini, V. Undrained Cyclic Laboratory Behavior of Sandy Soils. Geosciences 2019, 9, 512. [Google Scholar] [CrossRef] [Green Version]

- Molina-Gómez, F.; Fonseca, A.; Ferreira, C.; Camacho-Tauta, J. Dynamic properties of two historically liquefiable sands in the Lisbon area. Soil Dyn. Earthq. Eng. 2020, 132, 106101. [Google Scholar] [CrossRef]

- Mousavi, S.; Ghayoomi, M. Liquefaction Mitigation of Sands with nonplastic fines via microbial-induced partial saturation. J. Geotech. Geoenviron. Eng. 2021, 147, 4020156. [Google Scholar] [CrossRef]

- Seed, H.B.; Tokimatsu, K.; Harder, L.F.; Chung, R.M. Influence of SPT procedures in soil liquefaction resistance evaluations. J. Geotech. Eng. 1985, 111, 1425–1445. [Google Scholar] [CrossRef]

- Yu, H.; Zeng, X.W.; Li, B.; Lian, J.J. Centrifuge modeling of offshore wind foundations under earthquake loading. Soil Dyn. Earthq. Eng. 2015, 402–415. [Google Scholar] [CrossRef]

- Wang, X.F.; Zeng, X.W.; Li, X.Y.; Li, J.L. Liquefaction characteristics of offshore wind turbine with hybrid monopile foundation via centrifuge modelling. Renew. Energy 2020, 145, 2358–2372. [Google Scholar]

- Figueroa, J.L.; Saada, A.S.; Liang, L.Q.; Dashisaria, N.M. Evaluation of soil liquefaction by energy principles. J. Geotech. Eng. 1994, 4, 1554–1569. [Google Scholar] [CrossRef]

- Seed, H.B.; Martin, P.P.; Lysmer, J. Pore-water pressure changes during soil liquefaction. J. Geotech. Eng. 1976, 102, 323–346. [Google Scholar]

- Wang, B.; Chen, G.X. Pore water pressure increment model for saturated Nanjing fine sand subjected to cyclic loading. Chin. J. Geotech. Eng. 2011, 33, 188–194. [Google Scholar]

- Ghadr, S.; Samadzadeh, A.; Bahadori, H.; Assadi-Langroudi, A. Liquefaction resistance of fibre-reinforced silty sands under cyclic loading. Geotext. Geomembr. 2020, 48, 812–827. [Google Scholar] [CrossRef]

- Kumar, S.S.; Dey, A.; Krishna, A.M. Liquefaction Potential Assessment of Brahmaputra Sand Based on Regular and Irregular Excitations Using Stress-Controlled Cyclic Triaxial Test. KSCE J. Civ. Eng. 2020, 24, 1070–1082. [Google Scholar] [CrossRef]

| Test | Soil Classification | Borehole Number | Depth (m) | Confining Pressure σm′ (kPa) | Water Content w (%) | Density ρ (g/cm3) |

|---|---|---|---|---|---|---|

| A1 | Silty sand | ZK6 | 4.3–4.5 | 45 | 20.9 | 1.94 |

| A2 | Silty sand | ZK3 | 8.8–9.0 | 90 | 22.8 | 1.94 |

| A3 | Silty sand | ZK8 | 10.9–11.1 | 120 | 23.1 | 1.88 |

| A4 | Silty sand | ZK8 | 15.5–15.7 | 150 | 27.8 | 1.95 |

| A5 | Silty sand | ZK8 | 23.9–24.1 | 200 | 30.5 | 1.90 |

| B1 | Medium sand | ZK10 | 4.3–4.5 | 45 | 21.2 | 1.96 |

| B2 | Medium sand | ZK3 | 9.9–10.0 | 100 | 22.5 | 1.93 |

| B3 | Medium sand | ZK7 | 16.7–16.9 | 150 | 32.3 | 1.99 |

| B4 | Medium sand | ZK8 | 24.5–24.7 | 200 | 30.4 | 1.96 |

| Sample | d10 (mm) | d50 (mm) | d60 (mm) | Cu | Cc | Minimum Dry Density ρdmin (g/cm3) | Maximum Dry Density ρdmax (g/cm3) | Relative Density Dr (%) |

|---|---|---|---|---|---|---|---|---|

| Silty sand | 0.03 | 0.20 | 0.28 | 11.20 | 2.06 | 1.40 | 2.02 | 45 |

| Medium sand | 0.08 | 0.58 | 0.80 | 10.67 | 1.04 | 1.45 | 2.11 | 45 |

| Test | Sample | Relative Density Dr (%) | Confining Pressure σm′ (kPa) | Cyclic shear Stress Ratio σd /2σm′ | ||

|---|---|---|---|---|---|---|

| C1–C3 | Silty sand | 45 | 50 | 0.171 | 0.199 | 0.220 |

| C4–C6 | Silty sand | 45 | 100 | 0.148 | 0.185 | 0.231 |

| C7–C9 | Silty sand | 45 | 180 | 0.112 | 0.131 | 0.178 |

| C10–C12 | Silty sand | 70 | 100 | 0.153 | 0.196 | 0.256 |

| C13–C15 | Silty sand | 70 | 180 | 0.139 | 0.202 | 0.240 |

| C16–C18 | Medium sand | 45 | 50 | 0.130 | 0.174 | 0.196 |

| Sample | A | n | R2 |

|---|---|---|---|

| Silty sand | 17.682 | 3.802 | 0.9965 |

| Medium sand | 23.963 | 3.516 | 0.9554 |

| Sample | γ0 | β | α | R2 |

|---|---|---|---|---|

| Silty sand | 7.56 × 10−4 | 0.4297 | 0.98 | 0.9738 |

| Medium sand | 2.03 × 10−4 | 0.3877 | 1.55 | 0.9798 |

| Sample | A | n | γ0 | β | α |

|---|---|---|---|---|---|

| Ritiro silty sand | 30.690 | 3.257 | 3.62 × 10−4 | 0.4276 | 1.21 |

| Lisbon sand | 39.400 | 4.770 | 0.79 × 10−4 | 0.2949 | 3.30 |

| Relative Density Dr (%) | Confining Pressure σm′ (kPa) | Shear Stress τd (kPa) | Unit Energy W (J/m3) |

|---|---|---|---|

| 45 | 50 | 9.9 | 104.2 |

| 11.0 | 102.8 | ||

| 45 | 100 | 14.8 | 310.2 |

| 18.5 | 262.1 | ||

| 45 | 180 | 20.2 | 804.8 |

| 23.6 | 762.9 |

| Sample | Confining Pressure σ3 (kPa) | CSR | Seed Model | Modified Model | |||

|---|---|---|---|---|---|---|---|

| θ | R2 | θ′ | a | R2 | |||

| Silty sand | 50 | 0.20 | 2.3386 | 0.7938 | 1.3473 | 0.2678 | 0.9926 |

| Silty sand | 50 | 0.22 | 1.8758 | 0.9707 | 1.6472 | 0.0615 | 0.9911 |

| Silty sand | 100 | 0.15 | 1.4941 | 0.9897 | 1.5076 | −0.0045 | 0.9898 |

| Silty sand | 100 | 0.18 | 1.0233 | 0.9940 | 0.9950 | 0.0142 | 0.9948 |

| Silty sand | 180 | 0.11 | 0.8137 | 0.8926 | 1.0614 | −0.1259 | 0.9714 |

| Silty sand | 180 | 0.13 | 0.7570 | 0.9372 | 0.8780 | −0.0694 | 0.9549 |

| Medium sand | 50 | 0.17 | 1.5022 | 0.9195 | 1.1051 | 0.1546 | 0.9897 |

| Medium sand | 50 | 0.20 | 1.2847 | 0.9413 | 0.9931 | 0.1277 | 0.9892 |

| Sample | Confining Pressure σ3 (kPa) | CSR | Seed Model | Modified Model | |||

|---|---|---|---|---|---|---|---|

| θ | R2 | θ′ | a | R2 | |||

| Nanjing fine sand | 100 | 0.18 | 1.3988 | 0.9633 | 1.1799 | 0.0846 | 0.9887 |

| Nanjing fine sand | 100 | 0.20 | 2.2104 | 0.8979 | 1.5545 | 0.1601 | 0.9960 |

| Firoozkuh sand | 200 | 0.15 | 1.4689 | 0.9378 | 1.1711 | 0.1165 | 0.9833 |

| Brahmaptutra sand | 100 | 0.18 | 1.1373 | 0.9680 | 1.2965 | −0.0654 | 0.9904 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, F.; Zhang, Z.; Wang, C.; Gu, X.; Lin, Y.; Yang, W. Experimental Study on Stiffness Degradation and Liquefaction Characteristics of Marine Sand in the East Nan-Ao Area in Guangdong Province, China. J. Mar. Sci. Eng. 2021, 9, 638. https://doi.org/10.3390/jmse9060638

Liang F, Zhang Z, Wang C, Gu X, Lin Y, Yang W. Experimental Study on Stiffness Degradation and Liquefaction Characteristics of Marine Sand in the East Nan-Ao Area in Guangdong Province, China. Journal of Marine Science and Engineering. 2021; 9(6):638. https://doi.org/10.3390/jmse9060638

Chicago/Turabian StyleLiang, Fayun, Zewang Zhang, Chen Wang, Xiaoqiang Gu, Yifeng Lin, and Wei Yang. 2021. "Experimental Study on Stiffness Degradation and Liquefaction Characteristics of Marine Sand in the East Nan-Ao Area in Guangdong Province, China" Journal of Marine Science and Engineering 9, no. 6: 638. https://doi.org/10.3390/jmse9060638

APA StyleLiang, F., Zhang, Z., Wang, C., Gu, X., Lin, Y., & Yang, W. (2021). Experimental Study on Stiffness Degradation and Liquefaction Characteristics of Marine Sand in the East Nan-Ao Area in Guangdong Province, China. Journal of Marine Science and Engineering, 9(6), 638. https://doi.org/10.3390/jmse9060638