PEEK Biomaterial in Long-Term Provisional Implant Restorations: A Review

Abstract

:1. Introduction

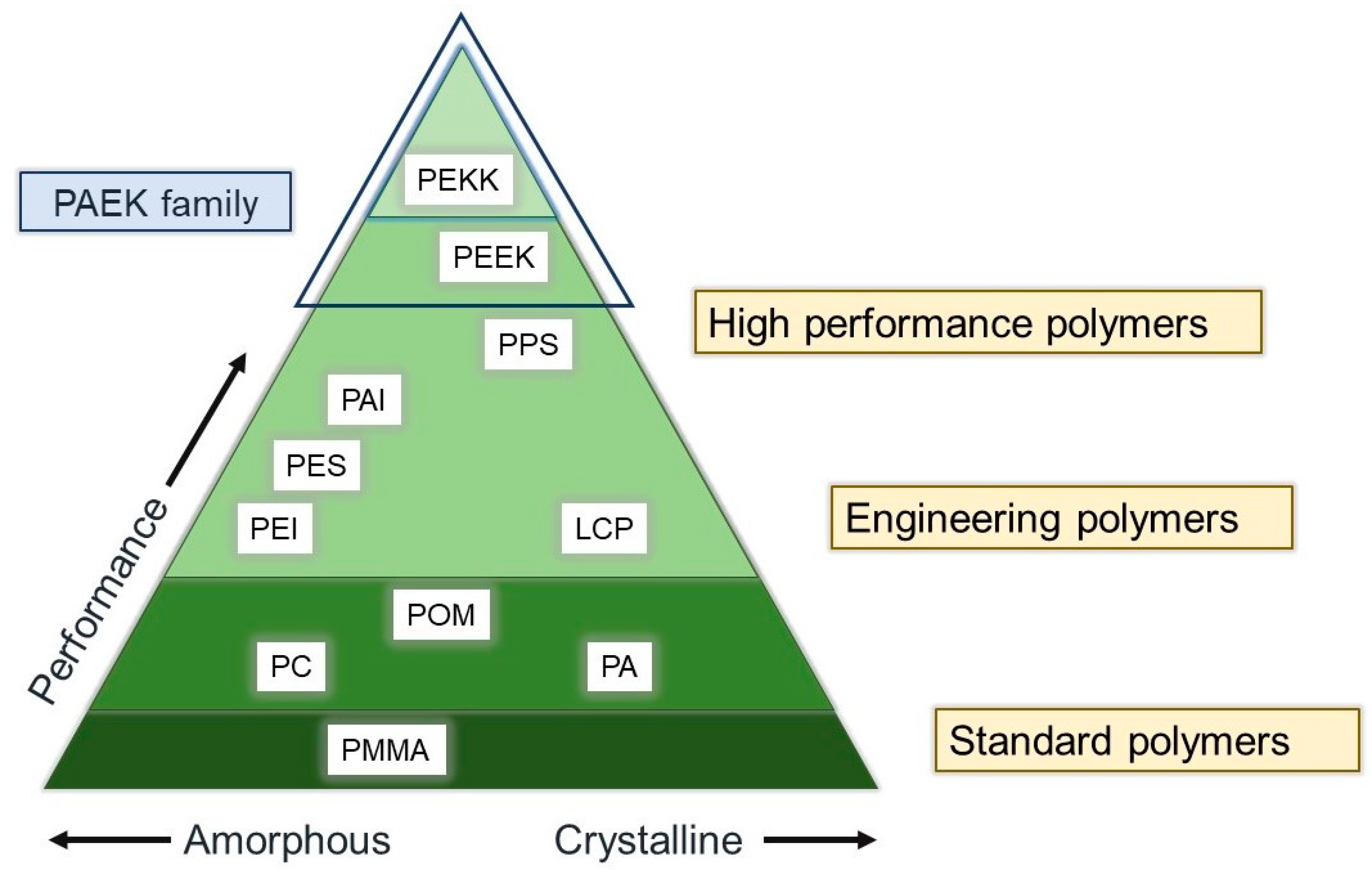

2. PEEK: Structure, Properties, and Prosthetic Applications

3. Provisional Restorations

4. A Case of PEEK Temporary Abutment Fabrication

5. PEEK Modifications

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Amornvit, P.; Rokaya, D.; Bajracharya, S.; Keawcharoen, K.; Supavanich, W. Management of obstructive sleep apnea with implant retained mandibular advancement device. World J. Dent. 2014, 5, 184–189. [Google Scholar] [CrossRef]

- Rungsiyakull, P.; Kujarearntaworn, K.; Khongkhunthian, P.; Swain, M.; Rungsiyakull, C. Effect of the location of dental mini-implants on strain distribution under mandibular kennedy class 1 implant-retained removable partial dentures. Int. J. Dent. 2021, 2021, 6688521. [Google Scholar] [CrossRef] [PubMed]

- Rattanapanich, P.; Aunmeungtong, W.; Chaijareenont, P.; Khongkhunthian, P. Comparative study between an immediate loading protocol using the digital workflow and a conventional protocol for dental implant treatment: A randomized clinical trial. J. Clin. Med. 2019, 8, 622. [Google Scholar] [CrossRef] [PubMed]

- Paepoemsin, T.; Reichart, P.A.; Chaijareenont, P.; Strietzel, F.P.; Khongkhunthian, P. Removal torque evaluation of three different abutment screws for single implant restorations after mechanical cyclic loading. Oral Implantol. 2016, 9, 213–221. [Google Scholar]

- Sicilia, A.; Cuesta, S.; Coma, G.; Arregui, I.; Guisasola, C.; Ruiz, E.; Maestro, A. Titanium allergy in dental implant patients: A clinical study on 1500 consecutive patients. Clin. Oral Implant. Res. 2008, 19, 823–835. [Google Scholar] [CrossRef] [PubMed]

- Rokaya, D.; Srimaneepong, V.; Qin, J. Modification of titanium alloys for dental applications. In Metal, Metal Oxides and Metal Sulphides for Biomedical Applications; Rajendran, S., Naushad, M., Durgalakshmi, D., Lichtfouse, E., Eds.; Springer: Cham, Switzerland, 2021; Volume 58, pp. 51–85. [Google Scholar]

- Xu, X.; He, L.; Zhu, B.; Li, J.; Li, J. Advances in polymeric materials for dental applications. Polym. Chem. 2017, 8, 807–823. [Google Scholar] [CrossRef]

- Rokaya, D.; Srimaneepong, V.; Sapkota, J.; Qin, J.; Siraleartmukul, K.; Siriwongrungson, V. Polymeric materials and films in dentistry: An overview. J. Adv. Res. 2018, 14, 25–34. [Google Scholar] [CrossRef] [PubMed]

- Choupin, T. Mechanical Performances of Pekk Thermoplastic Composites Linked to Their Processing Parameters; Paris Institue of Technology, ENSAM: Paris, France, 2017. [Google Scholar]

- Alqurashi, H.; Khurshid, Z.; Syed, A.U.Y.; Rashid Habib, S.; Rokaya, D.; Zafar, M.S. Polyetherketoneketone (pekk): An emerging biomaterial for oral implants and dental prostheses. J. Adv. Res. 2021, 28, 87–95. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Qian, J.; Wang, G.; Cai, M. Synthesis and properties of novel copolymers of poly(ether ketone diphenyl ketone ether ketone ketone) and poly(ether amide ether amide ether ketone ketone). Polym. Eng. Sci. 2014, 54, 1757–1764. [Google Scholar] [CrossRef]

- Najeeb, S.; Zafar, M.S.; Khurshid, Z.; Siddiqui, F. Applications of polyetheretherketone (peek) in oral implantology and prosthodontics. J. Prosthodont. Res. 2016, 60, 12–19. [Google Scholar] [CrossRef]

- Abhay, S.S.; Ganapathy, D.; Veeraiyan, D.N.; Ariga, P.; Heboyan, A.; Amornvit, P.; Rokaya, D.; Srimaneepong, V. Wear resistance, color stability and displacement resistance of milled peek crowns compared to zirconia crowns under stimulated chewing and high-performance aging. Polymers 2021, 13, 3761. [Google Scholar] [CrossRef] [PubMed]

- Kwan, J.C.; Kwan, N. Clinical application of peek as a provisional fixed dental prosthesis retained by reciprocated guide surfaces of healing abutments during dental implant treatment. Int. J. Oral Maxillofac. Implant. 2021, 36, 581–586. [Google Scholar] [CrossRef] [PubMed]

- Papathanasiou, I.; Kamposiora, P.; Papavasiliou, G.; Ferrari, M. The use of peek in digital prosthodontics: A narrative review. BMC Oral Health 2020, 20, 217. [Google Scholar] [CrossRef] [PubMed]

- Zoidis, P.; Bakiri, E.; Polyzois, G. Using modified polyetheretherketone (peek) as an alternative material for endocrown restorations: A short-term clinical report. J. Prosthet. Dent. 2017, 117, 335–339. [Google Scholar] [CrossRef] [PubMed]

- Zoidis, P.; Papathanasiou, I.; Polyzois, G. The use of a modified poly-ether-ether-ketone (peek) as an alternative framework material for removable dental prostheses. A clinical report. J. Prosthodont. 2016, 25, 580–584. [Google Scholar] [CrossRef] [PubMed]

- Kurtz, S.M.; Devine, J.N. Peek biomaterials in trauma, orthopedic, and spinal implants. Biomaterials 2007, 28, 4845–4869. [Google Scholar] [CrossRef]

- Kang, J.; Zhang, J.; Zheng, J.; Wang, L.; Li, D.; Liu, S. 3d-printed peek implant for mandibular defects repair—A new method. J. Mech. Behav. Biomed. Mater. 2021, 116, 104335. [Google Scholar] [CrossRef]

- Sorte, N.; Bhat, V.; Hegde, C. Poly-ether-ether-ketone (peek): A review. Int. J. Recent. Sci. Res. 2017, 8, 19208–19211. [Google Scholar]

- Stawarczyk, B.; Eichberger, M.; Uhrenbacher, J.; Wimmer, T.; Edelhoff, D.; Schmidlin, P.R. Three-unit reinforced polyetheretherketone composite fdps: Influence of fabrication method on load-bearing capacity and failure types. Dent. Mater. J. 2015, 34, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Bathala, L.; Majeti, V.; Rachuri, N.; Singh, N.; Gedela, S. The role of polyether ether ketone (peek) in dentistry—A review. J. Med. Life. 2019, 12, 5–9. [Google Scholar] [CrossRef]

- Najeeb, S.; Khurshid, Z.; Matinlinna, J.P.; Siddiqui, F.; Nassani, M.Z.; Baroudi, K. Nanomodified peek dental implants: Bioactive composites and surface modification—A review. Int. J. Dent. 2015, 2015, 381759. [Google Scholar] [CrossRef] [PubMed]

- Santing, H.J.; Meijer, H.J.; Raghoebar, G.M.; Özcan, M. Fracture strength and failure mode of maxillary implant-supported provisional single crowns: A comparison of composite resin crowns fabricated directly over peek abutments and solid titanium abutments. Clin. Implant Dent. Relat. Res. 2012, 14, 882–889. [Google Scholar] [CrossRef]

- Zoidis, P.; Bakiri, E.; Papathanasiou, I.; Zappi, A. Modified peek as an alternative crown framework material for weak abutment teeth: A case report. Gen. Dent. 2017, 65, 37–40. [Google Scholar] [PubMed]

- Amornvit, P.; Rokaya, D.; Sanohkan, S. Applications of peek in implant retained finger prosthesis. J. Int. Dent. Med. Res. 2019, 12, 1606–1609. [Google Scholar]

- Tekin, S.; Değer, Y.; Demirci, F. Evaluation of the use of peek material in implant-supported fixed restorations by finite element analysis. Niger. J. Clin. Pract. 2019, 22, 1252–1258. [Google Scholar] [PubMed]

- Zoidis, P.; Papathanasiou, I. Modified peek resin-bonded fixed dental prosthesis as an interim restoration after implant placement. J. Prosthet. Dent. 2016, 116, 637–641. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.T.; Koak, J.Y.; Lim, Y.J.; Kim, S.K.; Kwon, H.B.; Kim, M.J. Stress shielding and fatigue limits of poly-ether-ether-ketone dental implants. J. Biomed. Mater. Res. B Appl. Biomater. 2012, 100, 1044–1052. [Google Scholar] [CrossRef]

- Wang, H.; Xu, M.; Zhang, W.; Kwok, D.T.; Jiang, J.; Wu, Z.; Chu, P.K. Mechanical and biological characteristics of diamond-like carbon coated poly aryl-ether-ether-ketone. Biomaterials 2010, 31, 8181–8187. [Google Scholar] [CrossRef]

- Mishra, S.; Chowdhary, R. Peek materials as an alternative to titanium in dental implants: A systematic review. Clin. Implant Dent. Relat. Res. 2019, 21, 208–222. [Google Scholar] [CrossRef]

- Brum, R.S.; Labes, L.G.; Volpato CÂ, M.; Benfatti, C.A.M.; Pimenta, A.L. Strategies to reduce biofilm formation in peek materials applied to implant dentistry-a comprehensive review. Antibiotics 2020, 9, 609. [Google Scholar] [CrossRef]

- Huang, R.; Liu, Y.; Huang, B.; Zhou, F.; Chen, Z.; Li, Z. Improved accuracy of digital implant impressions with newly designed scan bodies: An in vivo evaluation in beagle dogs. BMC Oral Health 2021, 21, 623. [Google Scholar] [CrossRef] [PubMed]

- Brandt, J.; Lauer, H.C.; Peter, T.; Brandt, S. Digital process for an implant-supported fixed dental prosthesis: A clinical report. J. Prosthet. Dent. 2015, 114, 469–473. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Son, K.; Lee, K.B. Displacement of scan body during screw tightening: A comparative in vitro study. J. Adv. Prosthodont. 2020, 12, 307–315. [Google Scholar] [CrossRef] [PubMed]

- Albdour, E.A.; Shaheen, E.; Vranckx, M.; Mangano, F.G.; Politis, C.; Jacobs, R. A novel in vivo method to evaluate trueness of digital impressions. BMC Oral Health 2018, 18, 117. [Google Scholar] [CrossRef] [PubMed]

- Mizumoto, R.M.; Yilmaz, B. Intraoral scan bodies in implant dentistry: A systematic review. J. Prosthet. Dent. 2018, 120, 343–352. [Google Scholar] [CrossRef] [PubMed]

- Amornvit, P.; Rokaya, D.; Sanohkan, S. Comparison of accuracy of current ten intraoral scanners. Biomed. Res. Int. 2021, 2021, 2673040. [Google Scholar] [CrossRef] [PubMed]

- Rutkunas, V.; Larsson, C.; Vult von Steyern, P.; Mangano, F.; Gedrimiene, A. Clinical and laboratory passive fit assessment of implant-supported zirconia restorations fabricated using conventional and digital workflow. Clin. Implant Dent. Relat. Res. 2020, 22, 237–245. [Google Scholar] [CrossRef] [PubMed]

- Moreira, A.H.; Rodrigues, N.F.; Pinho, A.C.; Fonseca, J.C.; Vilaça, J.L. Accuracy comparison of implant impression techniques: A systematic review. Clin. Implant Dent. Relat. Res. 2015, 17 (Suppl. S2), e751–e764. [Google Scholar] [CrossRef] [PubMed]

- Humagain, M.; Rokaya, D. Integrating digital technologies in dentistry to enhance the clinical success. Kathmandu Univ. Med. J. (KUMJ) 2019, 17, 256–257. [Google Scholar]

- Huang, R.; Liu, Y.; Huang, B.; Zhang, C.; Chen, Z.; Li, Z. Improved scanning accuracy with newly designed scan bodies: An in vitro study comparing digital versus conventional impression techniques for complete-arch implant rehabilitation. Clin. Oral Implant. Res. 2020, 31, 625–633. [Google Scholar] [CrossRef] [PubMed]

- Yuzbasioglu, E.; Kurt, H.; Turunc, R.; Bilir, H. Comparison of digital and conventional impression techniques: Evaluation of patients’ perception, treatment comfort, effectiveness and clinical outcomes. BMC Oral Health 2014, 14, 10. [Google Scholar] [CrossRef] [PubMed]

- Alikhasi, M.; Siadat, H.; Nasirpour, A.; Hasanzade, M. Three-dimensional accuracy of digital impression versus conventional method: Effect of implant angulation and connection type. Int. J. Dent. 2018, 2018, 3761750. [Google Scholar] [CrossRef] [PubMed]

- Stawarczyk, B.; Thrun, H.; Eichberger, M.; Roos, M.; Edelhoff, D.; Schweiger, J.; Schmidlin, P.R. Effect of different surface pretreatments and adhesives on the load-bearing capacity of veneered 3-unit peek fdps. J. Prosthet. Dent. 2015, 114, 666–673. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, V.; Tobar, C.; López-Suárez, C.; Peláez, J.; Suárez, M.J. Fracture load of metal, zirconia and polyetheretherketone posterior cad-cam milled fixed partial denture frameworks. Materials 2021, 14, 959. [Google Scholar] [CrossRef] [PubMed]

- Schwitalla, A.D.; Abou-Emara, M.; Zimmermann, T.; Spintig, T.; Beuer, F.; Lackmann, J.; Müller, W.D. The applicability of peek-based abutment screws. J. Mech. Behav. Biomed. Mater. 2016, 63, 244–251. [Google Scholar] [CrossRef] [PubMed]

- Souza, J.C.M.; Pinho, S.S.; Braz, M.P.; Silva, F.S.; Henriques, B. Carbon fiber-reinforced peek in implant dentistry: A scoping review on the finite element method. Comput. Methods Biomech. Biomed. Eng. 2021, 24, 1355–1367. [Google Scholar] [CrossRef] [PubMed]

- Neumann, E.A.; Villar, C.C.; França, F.M. Fracture resistance of abutment screws made of titanium, polyetheretherketone, and carbon fiber-reinforced polyetheretherketone. Braz. Oral Res. 2014, 28, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Schwitalla, A.D.; Zimmermann, T.; Spintig, T.; Abou-Emara, M.; Lackmann, J.; Müller, W.D.; Houshmand, A. Maximum insertion torque of a novel implant-abutment-interface design for peek dental implants. J. Mech. Behav. Biomed. Mater. 2018, 77, 85–89. [Google Scholar] [CrossRef] [PubMed]

- Guo, C.; Liu, X.; Liu, G. Surface finishing of fdm-fabricated amorphous polyetheretherketone and its carbon-fiber-reinforced composite by dry milling. Polymers 2021, 13, 2175. [Google Scholar] [CrossRef]

- Blanch-Martínez, N.; Arias-Herrera, S.; Martínez-González, A. Behavior of polyether-ether-ketone (peek) in prostheses on dental implants. A review. J. Clin. Exp. Dent. 2021, 13, e520–e526. [Google Scholar] [CrossRef] [PubMed]

- Paratelli, A.; Perrone, G.; Ortega, R.; Gómez-Polo, M. Polyetheretherketone in implant prosthodontics: A scoping review. Int. J. Prosthodont. 2020, 33, 671–679. [Google Scholar] [CrossRef] [PubMed]

- Wachtel, A.; Zimmermann, T.; Sütel, M.; Adali, U.; Abou-Emara, M.; Müller, W.D.; Mühlemann, S.; Schwitalla, A.D. Bacterial leakage and bending moments of screw-retained, composite-veneered peek implant crowns. J. Mech. Behav. Biomed. Mater. 2019, 91, 32–37. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suphangul, S.; Rokaya, D.; Kanchanasobhana, C.; Rungsiyakull, P.; Chaijareenont, P. PEEK Biomaterial in Long-Term Provisional Implant Restorations: A Review. J. Funct. Biomater. 2022, 13, 33. https://doi.org/10.3390/jfb13020033

Suphangul S, Rokaya D, Kanchanasobhana C, Rungsiyakull P, Chaijareenont P. PEEK Biomaterial in Long-Term Provisional Implant Restorations: A Review. Journal of Functional Biomaterials. 2022; 13(2):33. https://doi.org/10.3390/jfb13020033

Chicago/Turabian StyleSuphangul, Suphachai, Dinesh Rokaya, Chatruethai Kanchanasobhana, Pimduen Rungsiyakull, and Pisaisit Chaijareenont. 2022. "PEEK Biomaterial in Long-Term Provisional Implant Restorations: A Review" Journal of Functional Biomaterials 13, no. 2: 33. https://doi.org/10.3390/jfb13020033