Mechanical and Tribological Performance of HDPE Matrix Reinforced by Hybrid Gr/TiO2 NPs for Hip Joint Replacement

Abstract

:1. Introduction

2. Materials and Methods

3. Experiments Details

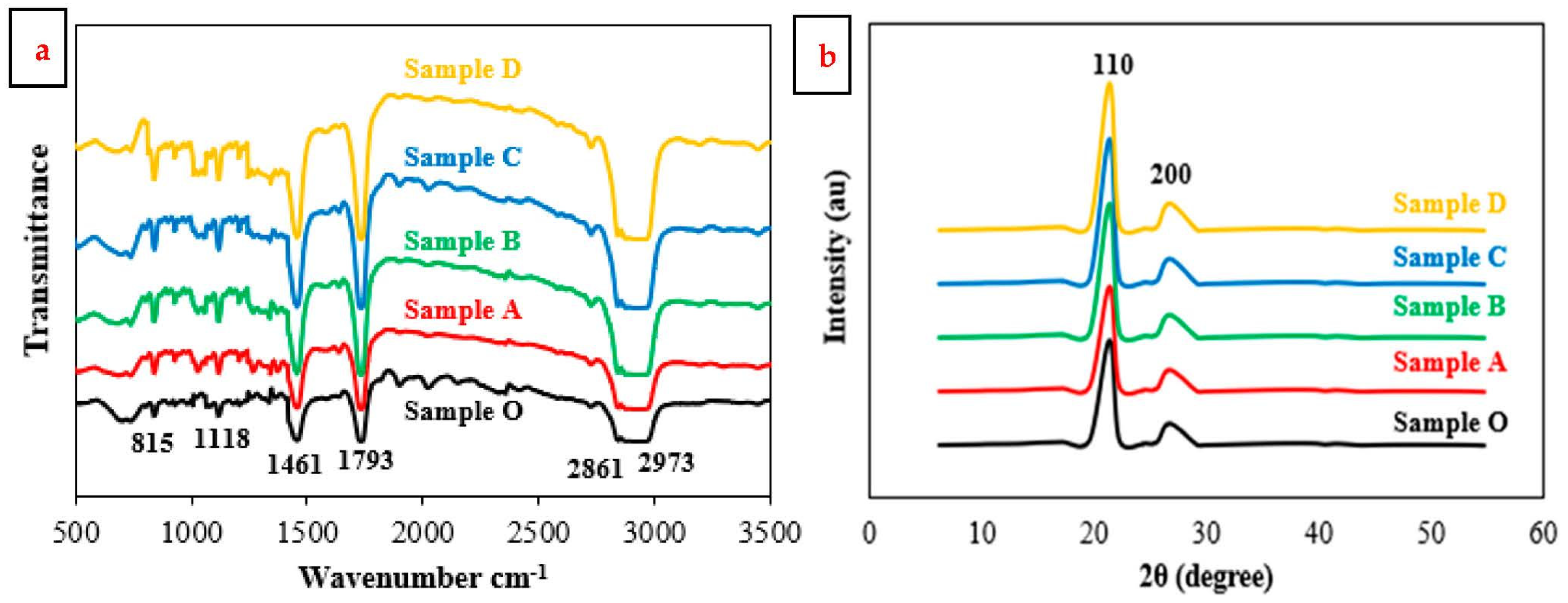

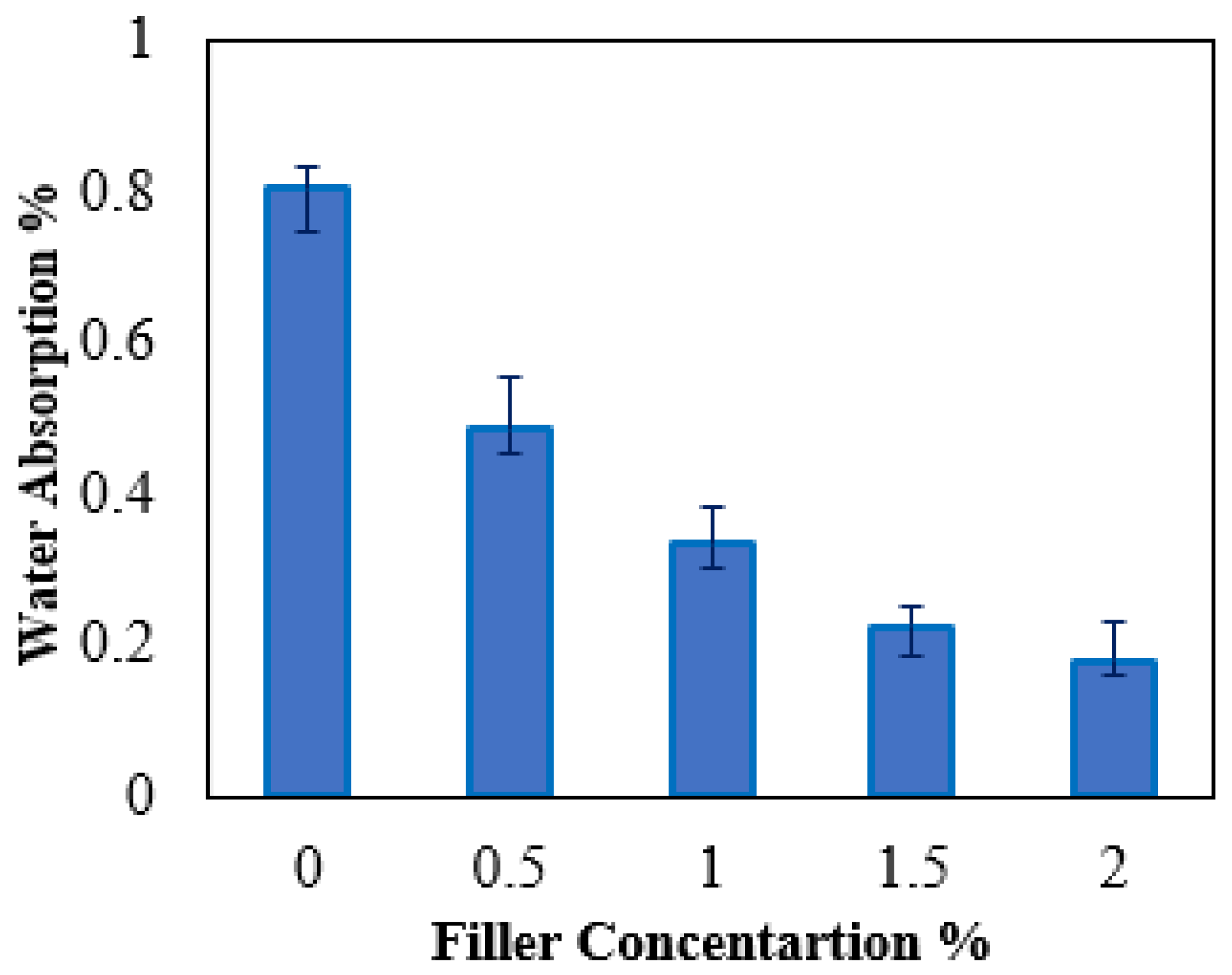

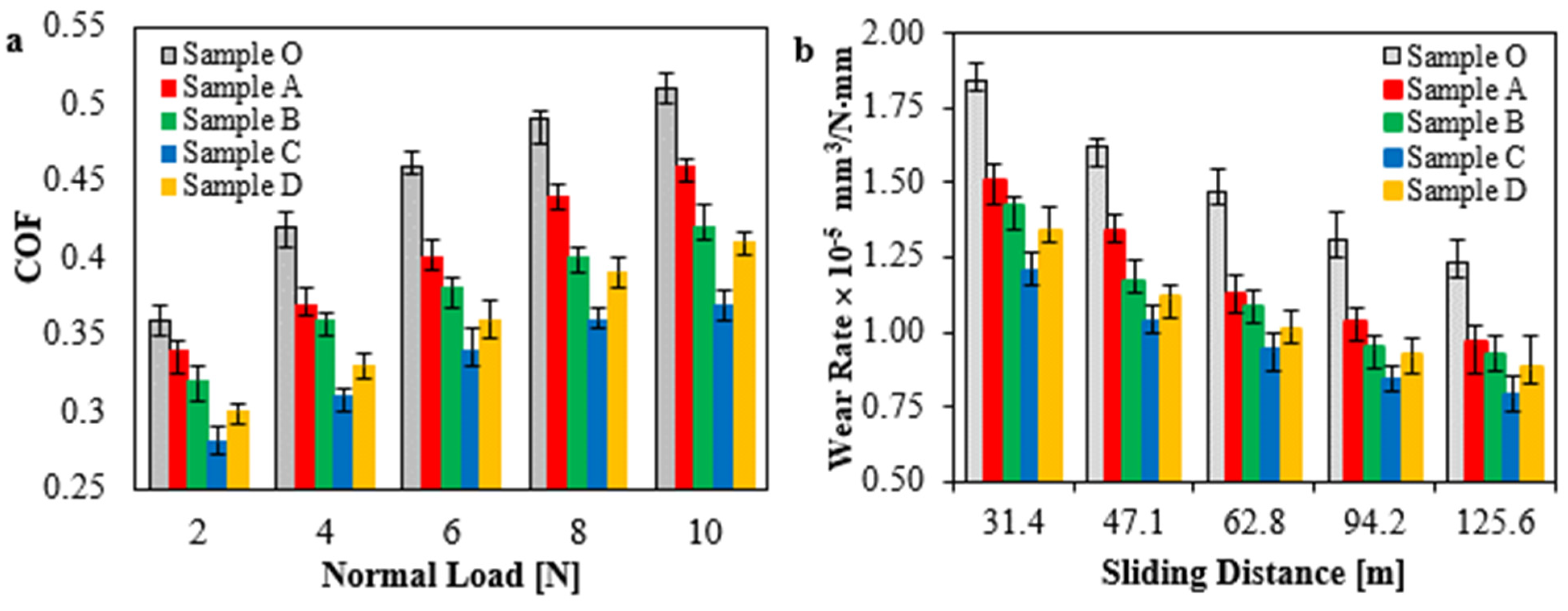

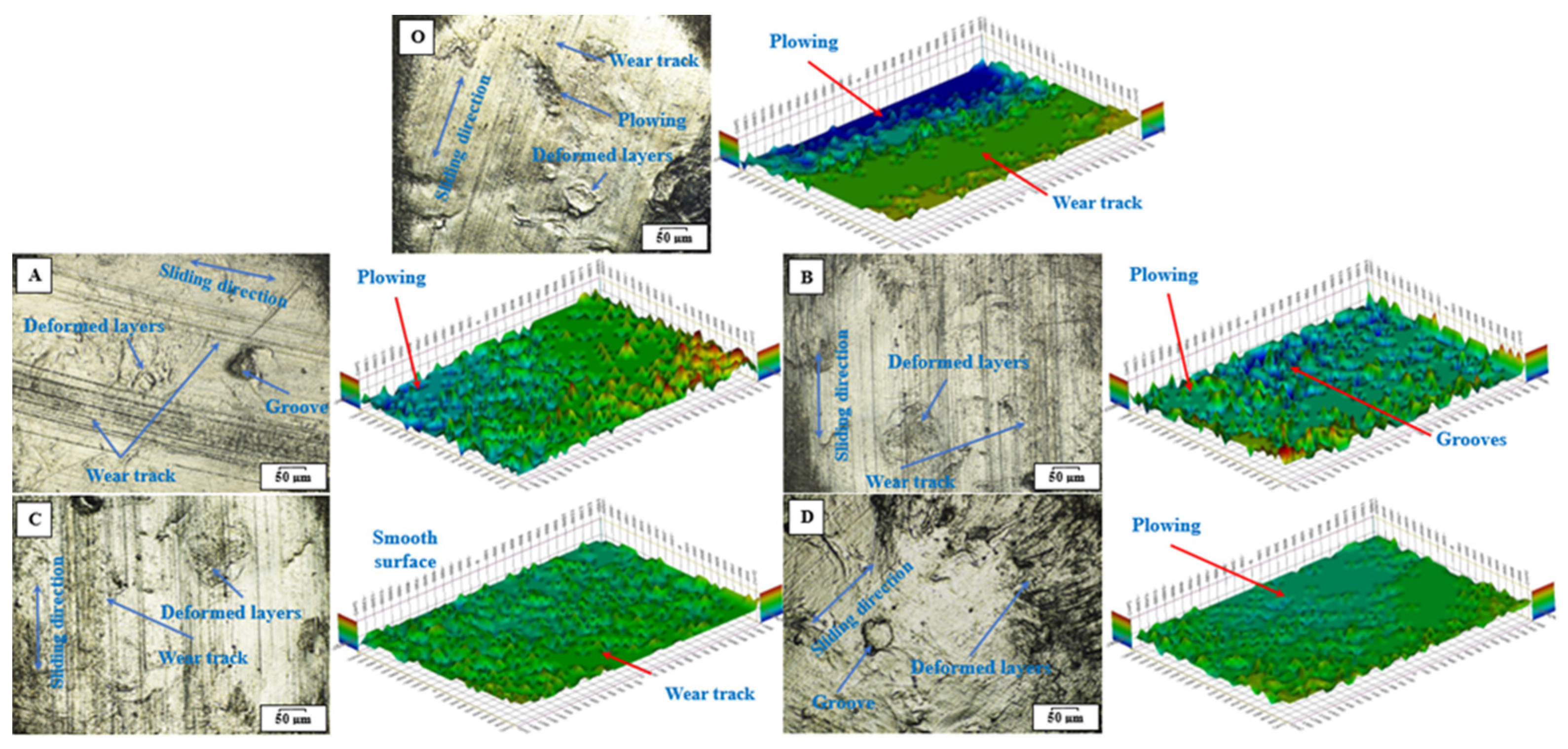

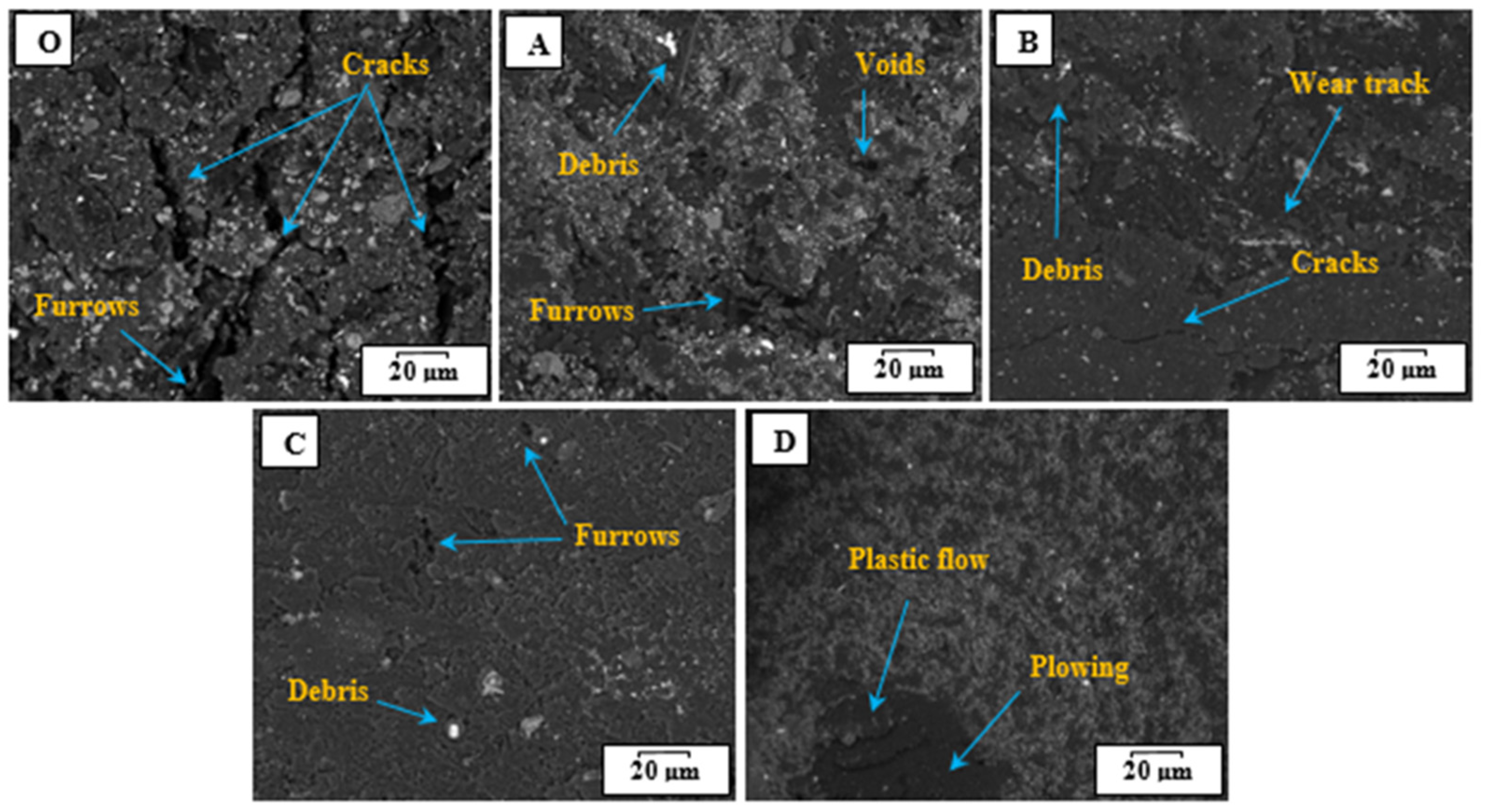

4. Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumar, S.; Bhowmik, S. Potential use of natural fiber-reinforced polymer biocomposites in knee prostheses: A review on fair inclusion in amputees. Iran. Polym. J. 2022, 31, 1297–1319. [Google Scholar] [CrossRef]

- Nabhan, A.; Taha, M.; Ghazaly, N.M. Filler loading effect of Al2O3/TiO2 nanoparticles on physical and mechanical characteristics of dental base composite (PMMA). Polym. Test. 2023, 117, 107848. [Google Scholar] [CrossRef]

- Priyadarshini, B.; Chetan, M.R.; Vijayalakshmi, U. Bioactive coating as a surface modification technique for biocompatible metallic implants: A review. J. Asian Ceram. Soc. 2019, 7, 397–406. [Google Scholar] [CrossRef] [Green Version]

- Fisher, J.; Dowson, D. Tribology of total artificial joints. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 1991, 205, 73–79. [Google Scholar] [CrossRef]

- Wilches, L.; Uribe, J.A.; Toro, A. Wear of materials used for artificial joints in total hip replacements. Wear 2008, 265, 143–149. [Google Scholar] [CrossRef]

- Kurtz, S.M. The Uhmwpe Handbook: Ultra-High Molecular Weight Polyethylene in Total Joint Replacement; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Lee, S.W.; Morillo, C.; Lira-Olivares, J.; Kim, S.H.; Sekino, T.; Niihara, K.; Hockey, B.J. Tribological and microstructural analysis of Al2O3/TiO2 nanocomposites to use in the femoral head of hip replacement. Wear 2003, 255, 1040–1044. [Google Scholar] [CrossRef]

- Okpala, C.C. Nanocomposites–an overview. Int. J. Eng. Res. Dev. 2013, 8, 17–23. [Google Scholar]

- Elshemy, E.A.; Showaib, E.A. Effect of Filler Loading on Erosive Characteristics of Epoxy/SiO2 Coatings. Solid State Technol. 2020, 63, 7824–7833. [Google Scholar]

- Thejas, R.; Naveen, C.S.; Khan, M.I.; Prasanna, G.D.; Reddy, S.; Oreijah, M.; Guedri, K.; Bafakeeh, O.T.; Jameel, M. A review on electrical and gas-sensing properties of reduced graphene oxide-metal oxide nanocomposites. Biomass Convers. Biomass Convers. Biorefinery 2022. [Google Scholar] [CrossRef]

- Fouly, A.; Nabhan, A.; Badran, A. Mechanical and Tribological Characteristics of PMMA Reinforced by Natural Materials. Egypt. J. Chem. 2021, 65, 543–553. [Google Scholar] [CrossRef]

- Katti, K.S. Biomaterials in total joint replacement. Colloids Surfaces B Biointerfaces 2004, 39, 133–142. [Google Scholar] [CrossRef]

- Mohammed, M.T. Nanocomposites in total hip joint replacements. In Applications of Nanocomposite Materials in Orthopedics; Elsevier: Amsterdam, The Netherlands, 2019; pp. 221–252. [Google Scholar]

- Taha, M.; Hassan, M.; Dewidare, M.; Kamel, M.A.; Ali, W.Y.; Dufresne, A. Evaluation of eco-friendly cellulose and lignocellulose nanofibers from rice straw using Multiple Quality Index. Egypt. J. Chem. 2021, 64, 4707–4717. [Google Scholar] [CrossRef]

- Camacho, N.; Franco-Urquiza, E.A.; Stafford, S.W. Wear performance of multiwalled carbon nanotube-reinforced ultra-high molecular weight polyethylene composite. Adv. Polym. Technol. 2018, 37, 2261–2269. [Google Scholar] [CrossRef]

- Paladugu, S.R.M.; PS, R.S. Influence of gamma radiation on wear and oxidation properties of cross-linked UHMWPE components used in total knee arthroplasty—A review. Mater. Today Proc. 2022, 56, 1097–1102. [Google Scholar] [CrossRef]

- Suñer, S.; Bladen, C.L.; Gowland, N.; Tipper, J.L.; Emami, N. Investigation of wear and wear particles from a UHMWPE/multi-walled carbon nanotube nanocomposite for total joint replacements. Wear 2014, 317, 163–169. [Google Scholar] [CrossRef]

- Fonseca, A.; Kanagaraj, S.; Oliveira, M.S.A.; Simões, J.A.O. Enhanced UHMWPE reinforced with MWCNT through mechanical ball-milling. In Defect and Diffusion Forum; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2011; Volume 312, pp. 1238–1243. [Google Scholar]

- Kumar, N.N.; Yap, S.L.; Samsudin, F.N.D.B.; Khan, M.Z.; Srinivasa, R.S.P. Effect of argon plasma treatment on tribological properties of UHMWPE/MWCNT nanocomposites. Polymers 2016, 8, 295. [Google Scholar] [CrossRef] [Green Version]

- Senatov, F.S.; Kopylov, A.N.; Anisimova, N.Y.; Kiselevsky, M.; Maksimkin, A. UHMWPE-based nanocomposite as a material for damaged cartilage replacement. Mater. Sci. Eng. C 2015, 48, 566–571. [Google Scholar] [CrossRef]

- Gallab, M.; Taha, M.; Rashed, A.; Nabhan, A. Effect of Low Content of Al2O3 Nanoparticles on the Mechanical and Tribological Properties of Polymethyl Methacrylate as a Denture Base Material. Egypt. J. Chem. 2022, 65, 1–9. [Google Scholar] [CrossRef]

- Rashed, A.; Nabhan, A. Influence of adding nano graphene and hybrid SiO2-TiO2 nano particles on tribological characteristics of polymethyl methacrylate (PMMA). KGK Kautsch. Gummi Kunstst. 2018, 71, 32–37. [Google Scholar]

- Saba, N.; Tahir, P.M.; Jawaid, M. A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers 2014, 6, 2247–2273. [Google Scholar] [CrossRef]

- Salari, M.; Taromsari, S.M.; Bagheri, R.; Sani, M.A.F. Improved wear, mechanical, and biological behavior of UHMWPE-HAp-zirconia hybrid nanocomposites with a prospective application in total hip joint replacement. J. Mater. Sci. 2018, 54, 4259–4276. [Google Scholar] [CrossRef]

- Salama, A.; Kamel, B.M.; Osman, T.A.; Rashad, R.M. Investigation of mechanical properties of UHMWPE composites reinforced with HAP+TiO2 fabricated by solvent dispersing technique. J. Mater. Res. Technol. 2022, 21, 4330–4343. [Google Scholar] [CrossRef]

- Yousef, S.; Visco, A.; Galtieri, G.; Nocita, D.; Espro, C. Wear behaviour of UHMWPE reinforced by carbon nanofiller and paraffin oil for joint replacement. Mater. Sci. Eng. C 2017, 73, 234–244. [Google Scholar] [CrossRef] [PubMed]

- Visco, A.; Yousef, S.; Scolaro, C.; Espro, C.; Cristani, M. Tribological behavior of nanocomposites based on UHMWPE aged in simulated synovial fluid. Polymers 2018, 10, 1291. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Visco, A.; Yousef, S.; Galtieri, G.; Nocita, D.; Pistone, A.; Njuguna, J. Thermal, mechanical and rheological behaviors of nanocomposites based on UHMWPE/paraffin oil/carbon nanofiller obtained by using different dispersion techniques. Jom 2016, 68, 1078–1089. [Google Scholar] [CrossRef] [Green Version]

- Wood, W.J.; Maguire, R.G.; Zhong, W.H. Improved wear and mechanical properties of UHMWPE–carbon nanofiber composites through an optimized paraffin-assisted melt-mixing process. Compos. Part B Eng. 2011, 42, 584–591. [Google Scholar] [CrossRef]

- Puértolas, J.A.; Kurtz, S.M. Evaluation of carbon nanotubes and graphene as reinforcements for UHMWPE-based composites in arthroplastic applications: A review. J. Mech. Behav. Biomed. Mater. 2014, 39, 129–145. [Google Scholar] [CrossRef]

- Tai, Z.; Chen, Y.; An, Y.; Yan, X.; Xue, Q. Tribological behavior of UHMWPE reinforced with graphene oxide nanosheets. Tribol. Lett. 2012, 46, 55–63. [Google Scholar] [CrossRef]

- Aguiar, V.O.; Maru, M.M.; Soares, I.T.; Kapps, V.; Almeida, C.M.; Perez, G.; Archanjo, B.S.; Pita, V.J.; Marques, M.D.F.V. Effect of incorporating multi-walled carbon nanotube and graphene in UHMWPE matrix on the enhancement of thermal and mechanical properties. J. Mater. Sci. 2022, 57, 21104–21116. [Google Scholar] [CrossRef]

- Chih, A.; Ansón-Casaos, A.; Puértolas, J.A. Frictional and mechanical behaviour of graphene/UHMWPE composite coatings. Tribol. Int. 2017, 116, 295–302. [Google Scholar] [CrossRef]

- Sharma, V.; Gupta, R.K.; Kailas, S.; Basu, B. Probing lubricated sliding wear properties of HDPE/UHMWPE hybrid bionanocomposite. J. Biomater. Appl. 2022, 37, 204–218. [Google Scholar] [CrossRef]

- Bhusari, S.A.; Sharma, V.; Bose, S.; Basu, B. HDPE/UHMWPE hybrid nanocomposites with surface functionalized graphene oxide towards improved strength and cytocompatibility. J. R. Soc. Interface 2019, 16, 20180273. [Google Scholar] [CrossRef] [Green Version]

- Amirapu, S.L.; Nelapati, G.S.; Yalamanchili, H.; Badgayan, N.D.; Sahu, S.K. HDPE based polymeric nanodiamond nanocomposite for total knee arthoplasty: A finite element based approach. Mater. Today Proc. 2022, 56, 1622–1628. [Google Scholar] [CrossRef]

- Badgayan, N.D.; Sahu, S.K.; Samanta, S.; Sreekanth, P.S. Evaluation of dynamic mechanical and thermal behavior of HDPE reinforced with MWCNT/h-BNNP: An attempt to find possible substitute for a metallic knee in transfemoral prosthesis. Int. J. Thermophys. 2019, 40, 93. [Google Scholar] [CrossRef]

- Dimple, D.; Shruti, M.; Badgayan, N.D.; Sahu, S.K. Finite element analysis of hdpe-based hybrid nanocomposite for potential use as liner material for total hip prosthesis. In Advances in Engineering Design; Springer: Berlin/Heidelberg, Germany, 2021; pp. 305–313. [Google Scholar]

- Nabhan, A.; Ameer, A.K.; Rashed, A. Tribological and Mechanical Properties of HDPE Reinforced by Al2O3 Nanoparticles for Bearing Materials. Int. J. Adv. Sci. Technol. 2019, 28, 481–489. [Google Scholar]

- Dabees, S.; Tirth, V.; Mohamed, A.; Kamel, B.M. Wear performance and mechanical properties of MWCNT/HDPE nanocomposites for gearing applications. J. Mater. Res. Technol. 2021, 12, 2476–2488. [Google Scholar] [CrossRef]

- Dabees, S.; Kamel, B.M.; Tirth, V.; Elshalakny, A.B. Experimental design of Al2O3/MWCNT/HDPE hybrid nanocomposites for hip joint replacement. Bioengineered 2020, 11, 679–692. [Google Scholar] [CrossRef]

- Lin, J.-H.; Pan, Y.-J.; Liu, C.-F.; Huang, C.-L.; Hsieh, C.-T.; Chen, C.-K.; Lin, Z.-I.; Lou, C.-W. Preparation and compatibility evaluation of polypropylene/high density polyethylene polyblends. Materials 2015, 8, 8850–8859. [Google Scholar] [CrossRef] [Green Version]

- Maheswari, C.U.; Reddy, K.O.; Muzenda, E.; Shukla, M.; Rajulu, A.V. A comparative study of modified and unmodified high-density polyethylene/borassus fiber composites. Int. J. Polym. Anal. Charact. 2013, 18, 439–450. [Google Scholar] [CrossRef]

- de Morais, J.A.; Gadioli, R.; De Paoli, M.-A. Curaua fiber reinforced high-density polyethylene composites: Effect of impact modifier and fiber loading. Polímeros 2016, 26, 115–122. [Google Scholar] [CrossRef] [Green Version]

- Benabid, F.Z.; Kharchi, N.; Zouai, F.; Mourad, A.-H.I.; Benachour, D. Impact of co-mixing technique and surface modification of ZnO nanoparticles using stearic acid on their dispersion into HDPE to produce HDPE/ZnO nanocomposites. Polym. Polym. Compos. 2019, 27, 389–399. [Google Scholar] [CrossRef]

- Madhu, G.; Bhunia, H.; Bajpai, P.K.; Chaudhary, V. Mechanical and morphological properties of high-density polyethylene and polylactide blends. J. Polym. Eng. 2014, 34, 813–821. [Google Scholar] [CrossRef]

- Kaczmarek, H.; Chylińska, M.; Królikowski, B.; Klimiec, E.; Bajer, D.; Kowalonek, J. Influence of glass beads filler and orientation process on piezoelectric properties of polyethylene composites. J. Mater. Sci. Mater. Electron. 2019, 30, 21032–21047. [Google Scholar] [CrossRef] [Green Version]

- Wypych, G. Handbook of Fillers; ChemTec Pub.: Toronto, ON, Canada, 2010; Volume 92. [Google Scholar]

- Sui, G.; Zhong, W.H.; Ren, X.; Wang, X.Q.; Yang, X.P. Structure, mechanical properties and friction behavior of UHMWPE/HDPE/carbon nanofibers. Mater. Chem. Phys. 2009, 115, 404–412. [Google Scholar] [CrossRef]

- Pelto, J.; Heino, V.; Karttunen, M.; Rytöluoto, I.; Ronkainen, H. Tribological performance of high-density polyethylene (HDPE) composites with low nanofiller loading. Wear 2020, 460, 203451. [Google Scholar] [CrossRef]

- Pelto, J.; Verho, T.; Ronkainen, H.; Kaunisto, K.; Metsäjoki, J.; Seitsonen, J.; Karttunen, M. Matrix morphology and the particle dispersion in HDPE nanocomposites with enhanced wear resistance. Polym. Test. 2019, 77, 105897. [Google Scholar] [CrossRef]

| Sample No | HDPE | TiO2 NPs | Gr |

|---|---|---|---|

| Sample O | 100% | - | - |

| Sample A | 99.5% | 0.25% | 0.25% |

| Sample B | 99% | 0.5% | 0.5% |

| Sample C | 98.5% | 0.75% | 0.75% |

| Sample D | 98% | 1.0% | 1.0% |

| Sample No | Tensile Strength (MPa) | Elastic Modulus (GPa) | %Breaking Strain |

|---|---|---|---|

| Sample O | 23.4 ± 2.7 | 409.4 ± 6.1 | 13.6 ± 1.3 |

| Sample A | 24.2 ± 2.5 | 419.4 ± 6.9 | 14.4 ± 1.6 |

| Sample B | 25.0 ± 2.6 | 425.9 ± 7.3 | 14.9 ± 1.5 |

| Sample C | 26.8 ± 3.3 | 431.5 ± 6.3 | 14.4 ± 1.9 |

| Sample D | 28.4 ± 3.1 | 447.9 ± 8.1 | 14.1 ± 2.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nabhan, A.; Sherif, G.; Abouzeid, R.; Taha, M. Mechanical and Tribological Performance of HDPE Matrix Reinforced by Hybrid Gr/TiO2 NPs for Hip Joint Replacement. J. Funct. Biomater. 2023, 14, 140. https://doi.org/10.3390/jfb14030140

Nabhan A, Sherif G, Abouzeid R, Taha M. Mechanical and Tribological Performance of HDPE Matrix Reinforced by Hybrid Gr/TiO2 NPs for Hip Joint Replacement. Journal of Functional Biomaterials. 2023; 14(3):140. https://doi.org/10.3390/jfb14030140

Chicago/Turabian StyleNabhan, Ahmed, Galal Sherif, Ragab Abouzeid, and Mohamed Taha. 2023. "Mechanical and Tribological Performance of HDPE Matrix Reinforced by Hybrid Gr/TiO2 NPs for Hip Joint Replacement" Journal of Functional Biomaterials 14, no. 3: 140. https://doi.org/10.3390/jfb14030140