Enhancing Polymethyl Methacrylate Prostheses for Cranioplasty with Ti mesh Inlays

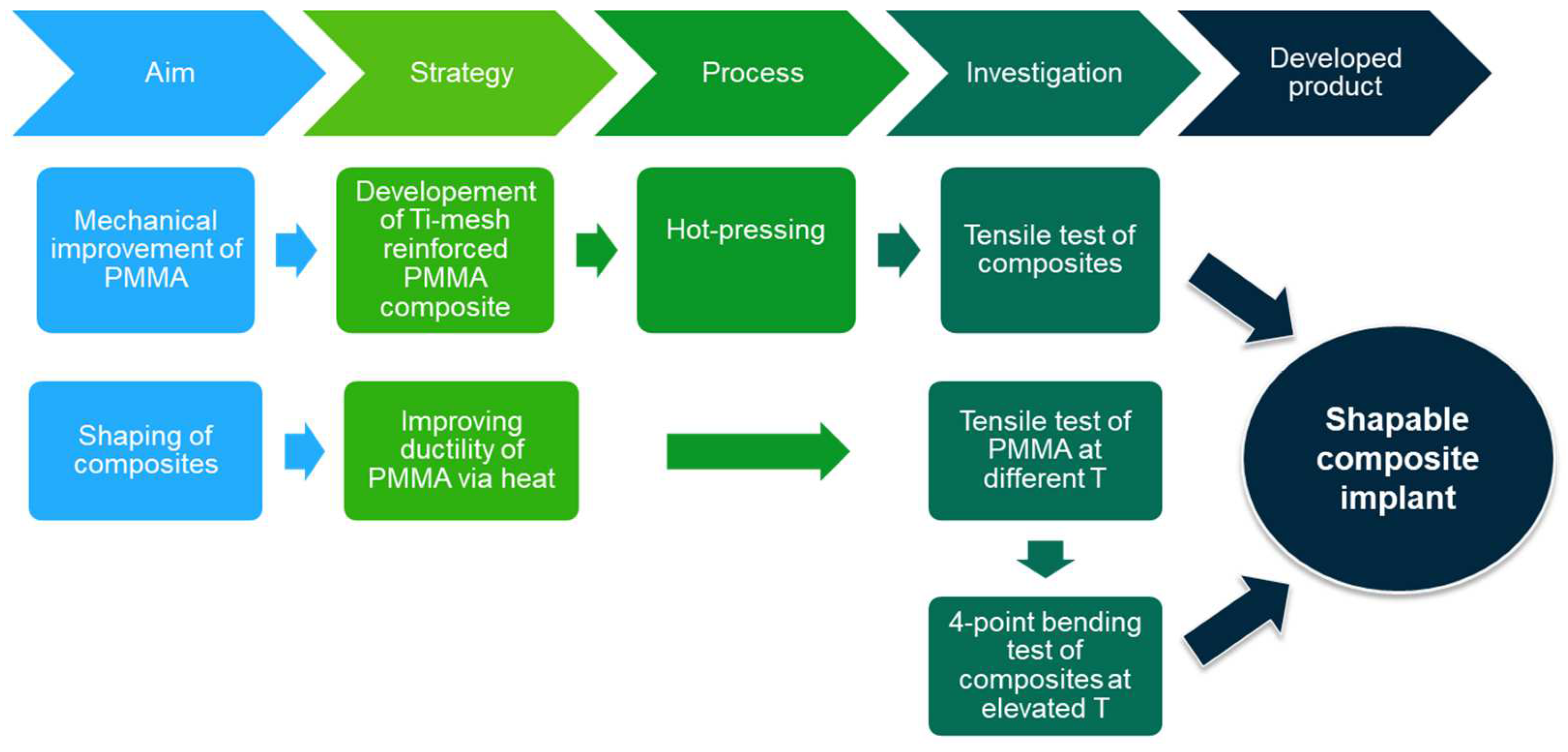

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Used

2.2. Sample Preparation

2.3. Performed Tests

2.4. Shaping at Elevated Temperatures

3. Results and Discussion

3.1. Cross-Section Analysis

3.2. Tensile Test

3.3. Tensile Tests of PMMA at Different Temperatures

3.4. Bending Tests

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, H.; Liang, B.; Jiang, H.; Deng, Z.; Yu, K. Magnesium-based biomaterials as emerging agents for bone repair and regeneration: From mechanism to application. J. Magnes. Alloys 2021, 9, 779–804. [Google Scholar] [CrossRef]

- Reichert, J.C.; Wullschleger, M.E.; Cipitria, A.; Lienau, J.; Cheng, T.K.; Schütz, M.A.; Duda, G.N.; Nöth, U.; Eulert, J.; Hutmacher, D.W. Custom-made composite scaffolds for segmental defect repair in long bones. Int. Orthop. 2011, 35, 1229–1236. [Google Scholar] [CrossRef] [PubMed]

- Cheng, B.C.; Koduri, S.; Wing, C.A.; Woolery, N.; Cook, D.J.; Spiro, R.C. Porous titanium-coated polyetheretherketone implants exhibit an improved bone–implant interface: An in vitro and in vivo biochemical, biomechanical, and histological study. Med. Devices Évid. Res. 2018, 11, 391–402. [Google Scholar] [CrossRef] [PubMed]

- Polo-Corrales, L.; Latorre-Esteves, M.; Ramirez-Vick, J.E. Scaffold Design for Bone Regeneration. J. Nanosci. Nanotechnol. 2014, 14, 15–56. [Google Scholar] [CrossRef]

- Jagodzinski, M.; Krettek, C. Effect of mechanical stability on fracture healing—An update. Injury 2007, 38, S3–S10. [Google Scholar] [CrossRef] [PubMed]

- Foster, A.L.; Moriarty, T.F.; Zalavras, C.; Morgenstern, M.; Jaiprakash, A.; Crawford, R.; Burch, M.-A.; Boot, W.; Tetsworth, K.; Miclau, T.; et al. The influence of biomechanical stability on bone healing and fracture-related infection: The legacy of Stephan Perren. Injury 2021, 52, 43–52. [Google Scholar] [CrossRef] [PubMed]

- Fouda, N.; Mostafa, R.; Saker, A. Numerical study of stress shielding reduction at fractured bone using metallic and composite bone-plate models. Ain Shams Eng. J. 2019, 10, 481–488. [Google Scholar] [CrossRef]

- Raffa, M.L.; Nguyen, V.H.; Hernigou, P.; Flouzat-Lachaniette, C.H.; Haiat, G. Stress shielding at the bone-implant interface: Influence of surface roughness and of the bone-implant contact ratio. J. Orthop. Res. 2021, 39, 1174–1183. [Google Scholar] [CrossRef]

- Bahraminasab, M.; Sahari, B.; Edwards, K.; Farahmand, F.; Arumugam, M. Aseptic loosening of femoral components—Materials engineering and design considerations. Mater. Des. 2012, 44, 155–163. [Google Scholar] [CrossRef]

- Thomas, S.; Balakrishnan, P.; Sreekala, M. Fundamental Biomaterials: Ceramics; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar]

- Chen, Q.; Zhu, C.; Thouas, G.A. Progress and challenges in biomaterials used for bone tissue engineering: Bioactive glasses and elastomeric composites. Prog. Biomater. 2012, 1, 2. [Google Scholar] [CrossRef]

- Song, R.; Murphy, M.; Li, C.; Ting, K.; Soo, C.; Zheng, Z. Current development of biodegradable polymeric materials for biomedical applications. Drug Des. Dev. Ther. 2018, 12, 3117–3145. [Google Scholar] [CrossRef] [PubMed]

- Bahrami, M.; Fathi, M.; Ahmadian, M. The effect of nanobioceramic reinforcement on mechanical and biological properties of Co-base alloy/hydroxyapatite nanocomposite. Mater. Sci. Eng. C 2015, 48, 572–578. [Google Scholar] [CrossRef] [PubMed]

- Ahlhelm, M.; Günther, P.; Scheithauer, U.; Schwarzer, E.; Günther, A.; Slawik, T.; Moritz, T.; Michaelis, A. Innovative and novel manufacturing methods of ceramics and metal-ceramic composites for biomedical applications. J. Eur. Ceram. Soc. 2016, 36, 2883–2888. [Google Scholar] [CrossRef]

- Kim, H.C.; Kim, D.; Lee, J.Y.; Zhai, L.; Kim, J. Effect of Wet Spinning and Stretching to Enhance Mechanical Properties of Cellulose Nanofiber Filament. Int. J. Precis. Eng. Manuf. Technol. 2019, 6, 567–575. [Google Scholar] [CrossRef]

- Kasai, D.; Chougale, R.; Masti, S.; Chalannavar, R.; Malabadi, R.B.; Gani, R. Influence of Syzygium cumini leaves extract on morphological, thermal, mechanical, and antimicrobial properties of PVA and PVA/chitosan blend films. J. Appl. Polym. Sci. 2018, 135, 46188. [Google Scholar] [CrossRef]

- Tran, T.; Hamid, Z.; Cheong, K. A Review of Mechanical Properties of Scaffold in Tissue Engineering: Aloe Vera Composites. J. Physics Conf. Ser. 2018, 1082, 012080. [Google Scholar] [CrossRef]

- Reggente, M.; Harhash, M.; Kriegel, S.; He, W.; Masson, P.; Faerber, J.; Pourroy, G.; Palkowski, H.; Carradò, A. Resin-free three-layered Ti/PMMA/Ti sandwich materials: Adhesion and formability study. Compos. Struct. 2019, 218, 107–119. [Google Scholar] [CrossRef]

- Kucko, N.W.; Schickert, S.d.L.; Marques, T.S.; Herber, R.-P.; Beuken, J.J.J.P.v.D.; Zuo, Y.; Leeuwenburgh, S.C.G. Tough and Osteocompatible Calcium Phosphate Cements Reinforced with Poly(vinyl alcohol) Fibers. ACS Biomater. Sci. Eng. 2019, 5, 2491–2505. [Google Scholar] [CrossRef]

- Huang, H.; Wang, J.; Liu, W. Mechanical properties and reinforced mechanism of the stainless steel wire mesh–reinforced Al-matrix composite plate fabricated by twin-roll casting. Adv. Mech. Eng. 2017, 9, 1687814017716639. [Google Scholar] [CrossRef]

- Karataş, M.A.; Gökkaya, H. A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def. Technol. 2018, 14, 318–326. [Google Scholar] [CrossRef]

- Hamidi, A.; Tadesse, Y. Single step 3D printing of bioinspired structures via metal reinforced thermoplastic and highly stretchable elastomer. Compos. Struct. 2018, 210, 250–261. [Google Scholar] [CrossRef]

- Jose, A.S.; Athijayamani, A.; Jani, S. A review on the mechanical properties of bio waste particulate reinforced polymer composites. Mater. Today Proc. 2020, 37, 1757–1760. [Google Scholar] [CrossRef]

- Ali, N.H.; Shihab, S.K.; Mohamed, M.T. Influence of Ceramic Particles Additives on the Mechanical Properties and Machinability of Carbon Fiber/Polymer Composites. Silicon 2023. [Google Scholar] [CrossRef]

- Ageorges, C.; Ye, L. Fusion Bonding of Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Awaja, F. Autohesion of polymers. Polymer 2016, 97, 387–407. [Google Scholar] [CrossRef]

- Martineau, L.; Chabert, F.; Boniface, B.; Bernhart, G. Effect of interfacial crystalline growth on autohesion of PEEK. Int. J. Adhes. Adhes. 2019, 89, 82–87. [Google Scholar] [CrossRef]

- Awaja, F.; Wong, T.-T.; Arhatari, B. Lab-on-a-chip device made by autohesion-bonded polymers. Biomed. Microdevices 2017, 20, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Weidmann, F.C. On the In-Situ Manufacture of Thermoplastic Sandwich Structures with Continuous Fibre Reinforced Facesheets and Integral Foam Cores. Doctoral Thesis, Clausthal University of Technology, Clausthal, Germany, 2020. [Google Scholar]

- Newaz, G.M. Advances in Thermoplastic Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 1987. [Google Scholar]

- Grouve, W.J.B. Weld Strength of Laser-Assisted Tape-Placed Thermoplastic Composites; University of Twente: Enschede, The Netherlands, 2012. [Google Scholar] [CrossRef]

- Barocio, E.; Brenken, B.; Favaloro, A.; Ramirez, J.; Kunc, V.; Pipes, R.B. Fusion bonding simulations of semi-crystalline polymer composites in the extrusion deposition additive manufacturing process. In Proceedings of the 32nd Technical Conference of the American Society for Composites, West Lafayette, IN, USA, 23–25 October 2017; Volume 4, pp. 2875–2889. [Google Scholar] [CrossRef]

- Liao, G.; Li, Z.; Cheng, Y.; Xu, D.; Zhu, D.; Jiang, S.; Guo, J.; Chen, X.; Xu, G.; Zhu, Y. Properties of oriented carbon fiber/polyamide 12 composite parts fabricated by fused deposition modeling. Mater. Des. 2018, 139, 283–292. [Google Scholar] [CrossRef]

- Voll, N.; Meichsner, A.; Maier, M. Metal Mesh reinforced long Glass Fiber Thermoplastics (M-LFRT)-Comparison of Experiment and Simulation. Edinb. ICCM 17 Proc. 2009. Available online: https://iccm-central.org/Proceedings/ICCM17proceedings/papers/ID5.1%20Voll.pdf (accessed on 15 April 2023).

- Wang, Z.; Zhou, Y.; Mallick, P.K. Effects of temperature and strain rate on the tensile behavior of short fiber reinforced polyamide-6. Polym. Compos. 2002, 23, 858–871. [Google Scholar] [CrossRef]

- Zhou, Y.; Mallick, P. A non-linear damage model for the tensile behavior of an injection molded short E-glass fiber reinforced polyamide-6,6. Mater. Sci. Eng. A 2005, 393, 303–309. [Google Scholar] [CrossRef]

- Morgan, E.F.; Unnikrisnan, G.U.; Hussein, A.I. Bone Mechanical Properties in Healthy and Diseased States. Annu. Rev. Biomed. Eng. 2018, 20, 119–143. [Google Scholar] [CrossRef] [PubMed]

- Magyar, B.; Czigany, T.; Szebényi, G. Metal-alike polymer composites: The effect of inter-layer content on the pseudo-ductile behaviour of carbon fibre/epoxy resin materials. Compos. Sci. Technol. 2021, 215, 109002. [Google Scholar] [CrossRef]

- Casadei, P.; Nanni, A. Steel-Reinforced Polymer: An Innovative and Promising Material for Strengthening Infrastructures. Concr. Eng. Int. 2014, 9, 54–56. [Google Scholar]

- Ibrahim, S.A.; Lafta, S.H.; Hussain, W.A. Impact strength of surface treated SS316L wires reinforced PMMA. J. Mech. Behav. Mater. 2021, 30, 272–278. [Google Scholar] [CrossRef]

- Mousa, W.F.; Kobayashi, M.; Shinzato, S.; Kamimura, M.; Neo, M.; Yoshihara, S.; Nakamura, T. Biological and mechanical properties of PMMA-based bioactive bone cements. Biomaterials 2000, 21, 2137–2146. [Google Scholar] [CrossRef]

- Frazer, R.Q.; Byron, R.T.; Osborne, P.B.; West, K.P. PMMA: An Essential Material in Medicine and Dentistry. J. Autom. Inf. Sci. 2005, 15, 629–639. [Google Scholar] [CrossRef] [PubMed]

- Nayak, G.S.; Mouillard, F.; Masson, P.; Pourroy, G.; Palkowski, H.; Carradò, A. Adhesion Behavior of Ti–PMMA–Ti Sandwiches for Biomedical Applications. JOM 2021, 74, 96–101. [Google Scholar] [CrossRef]

- Abdel-Wahab, A.A.; Ataya, S.; Silberschmidt, V.V. Temperature-dependent mechanical behaviour of PMMA: Experimental analysis and modelling. Polym. Test. 2016, 58, 86–95. [Google Scholar] [CrossRef]

- Beter, J.; Schrittesser, B.; Meier, G.; Fuchs, P.F.; Pinter, G. Influence of Fiber Orientation and Adhesion Properties On Tailored Fiber-reinforced Elastomers. Appl. Compos. Mater. 2020, 27, 149–164. [Google Scholar] [CrossRef]

- Salviato, M.; Zappalorto, M.; Quaresimin, M. Plastic shear bands and fracture toughness improvements of nanoparticle filled polymers: A multiscale analytical model. Compos. Part A: Appl. Sci. Manuf. 2013, 48, 144–152. [Google Scholar] [CrossRef]

- Subhedar, K.M.; Chauhan, G.S.; Singh, B.P.; Dhakate, S.R. Effect of fibre orientation on mechanical properties of carbon fibre composites. Indian J. Eng. Mater. Sci. 2020, 27, 1100–1103. [Google Scholar]

- Deb, S.; Mitra, N.; Majumder, S.B.; Maitra, S. Improvement in tensile and flexural ductility with the addition of different types of polypropylene fibers in cementitious composites. Constr. Build. Mater. 2018, 180, 405–411. [Google Scholar] [CrossRef]

- Parmiggiani, A.; Prato, M.; Pizzorni, M. Effect of the fiber orientation on the tensile and flexural behavior of continuous carbon fiber composites made via fused filament fabrication. Int. J. Adv. Manuf. Technol. 2021, 114, 2085–2101. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Effects of fiber orientation and anisotropy on tensile strength and elastic modulus of short fiber reinforced polymer composites. Compos. Part B Eng. 2015, 72, 116–129. [Google Scholar] [CrossRef]

- Swolfs, Y.; Meerten, Y.; Hine, P.; Ward, I.; Verpoest, I.; Gorbatikh, L. Introducing ductility in hybrid carbon fibre/self-reinforced composites through control of the damage mechanisms. Compos. Struct. 2015, 131, 259–265. [Google Scholar] [CrossRef]

- Hsieh, T.; Kinloch, A.; Masania, K.; Taylor, A.; Sprenger, S.; Hsieh, T.; Kinloch, A.; Masania, K.; Taylor, A.; Sprenger, S. The mechanisms and mechanics of the toughening of epoxy polymers modified with silica nanoparticles. Polymer 2010, 51, 6284–6294. [Google Scholar] [CrossRef]

- Hosseinnezhad, R.; Vozniak, I.; Morawiec, J.; Galeski, A.; Dutkiewicz, S. In situ generation of sustainable PLA-based nanocomposites by shear induced crystallization of nanofibrillar inclusions. RSC Adv. 2019, 9, 30370–30380. [Google Scholar] [CrossRef] [PubMed]

- Yan, Q.; Zhang, W.; Wu, T.; Lin, Y.; Wang, D.; Meng, L.; Chen, W.; Li, L. Understanding the brittle-ductile transition of glass polymer on mesoscopic scale by in-situ small angle X-ray scattering. Polymer 2020, 209, 122985. [Google Scholar] [CrossRef]

- Farotti, E.; Mancini, E.; Lattanzi, A.; Utzeri, M.; Sasso, M. Effect of temperature and strain rate on the formation of shear bands in polymers under quasi-static and dynamic compressive loadings: Proposed constitutive model and numerical validation. Polymer 2022, 245, 124690. [Google Scholar] [CrossRef]

- Wu, S. Secondary relaxation, brittle–ductile transition temperature, and chain structure. J. Appl. Polym. Sci. 1992, 46, 619–624. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, L. Mechanisms of the Complex Thermo-Mechanical Behavior of Polymer Glass Across a Wide Range of Temperature Variations. Polymers 2018, 10, 1153. [Google Scholar] [CrossRef] [PubMed]

- Ostapiuk, M.; Bieniaś, J.; Surowska, B. Analysis of the bending and failure of fiber metal laminates based on glass and carbon fibers. Sci. Eng. Compos. Mater. 2017, 25, 1095–1106. [Google Scholar] [CrossRef]

| Specimen Abbreviation | Ti Mesh vol.% | No. of Layer(s) Ti Mesh | Mesh Orientation (°) |

|---|---|---|---|

| Tim1-PMMA (45) | 6 | 1 | 45 |

| Tim2-PMMA (45) | 12 | 2 | 45 |

| Tim3-PMMA (45) | 18 | 3 | 45 |

| Tim4-PMMA (45) | 24 | 4 | 45 |

| Tim4-PMMA (0/90) | 24 | 4 | 0/90 |

| Material/ Combination | Thickness (mm) | E (GPa) | UTS (MPa) | ER (%) |

|---|---|---|---|---|

| PMMA | 1.5 | 3.1 ± 0.2 | 26.7 ± 5.0 | 0.8 |

| Tim4-PMMA (0/90°) | 1.5 | 4.8 ± 0.3 | 37.5 ± 6.0 | 3.4 |

| Tim4-PMMA (45) | 1.5 | 2.5 ± 0.2 | 21.5 ± 3.0 | 11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nayak, G.S.; Palkowski, H.; Carradò, A. Enhancing Polymethyl Methacrylate Prostheses for Cranioplasty with Ti mesh Inlays. J. Funct. Biomater. 2023, 14, 420. https://doi.org/10.3390/jfb14080420

Nayak GS, Palkowski H, Carradò A. Enhancing Polymethyl Methacrylate Prostheses for Cranioplasty with Ti mesh Inlays. Journal of Functional Biomaterials. 2023; 14(8):420. https://doi.org/10.3390/jfb14080420

Chicago/Turabian StyleNayak, Gargi Shankar, Heinz Palkowski, and Adele Carradò. 2023. "Enhancing Polymethyl Methacrylate Prostheses for Cranioplasty with Ti mesh Inlays" Journal of Functional Biomaterials 14, no. 8: 420. https://doi.org/10.3390/jfb14080420

APA StyleNayak, G. S., Palkowski, H., & Carradò, A. (2023). Enhancing Polymethyl Methacrylate Prostheses for Cranioplasty with Ti mesh Inlays. Journal of Functional Biomaterials, 14(8), 420. https://doi.org/10.3390/jfb14080420