Manipulation and Applications of Hotspots in Nanostructured Surfaces and Thin Films

Abstract

1. Introduction

2. Experimental Section

2.1. NSL Technique and Physical Vapor Deposition Technique

2.2. Design of Nanostructured Surfaces and Thin Films and Manipulation of Hotspots

2.3. Applications of Hotspots in PEMS and PMCRs

3. Results and Discussion

3.1. Manipulation of Hotspots in Nanostructured Surfaces and Thin Films

3.2. Applications of Hotspots in Plasmonics

4. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kuznetsov, A.I.; Miroshnichenko, A.E.; Brongersma, M.L.; Kivshar, Y.S.; Luk’yanchuk, B. Optically resonant dielectric nanostructures. Science 2016, 354, 2472. [Google Scholar] [CrossRef]

- Ai, B.; Yu, Y.; Möhwald, H.; Zhang, G.; Yang, B. Plasmonic films based on colloidal lithography. Adv. Colloid Interface Sci. 2014, 206, 5. [Google Scholar] [CrossRef]

- Fan, F.R.; Tang, W.; Wang, Z.L. Flexible nanogenerators for energy harvesting and self-powered electronics. Adv. Mater. 2016, 28, 4283–4305. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Ai, B.; Möhwald, H.; Zhang, G. Colloidal lithography meets plasmonic nanochemistry. Adv. Opt. Mater. 2018, 6, 1800402. [Google Scholar] [CrossRef]

- Zhu, T.; Wang, H.; Zang, L.B.; Jin, S.L.; Guo, S.; Park, E.; Mao, Z.; Jung, Y.M. Flexible and reusable Ag coated TiO2 nanotube arrays for highly sensitive SERS detection of formaldehyde. Molecules 2020, 25, 1199. [Google Scholar] [CrossRef]

- Pellacani, P.; Morasso, C.; Picciolini, S.; Gallach, D.; Fornasari, L.; Marabelli, F.; Silvan, M.M. Plasma fabrication and SERS functionality of gold crowned silicon submicrometer pillars. Materials 2020, 13, 1244. [Google Scholar] [CrossRef]

- Ma, L.W.; Wang, J.K.; Huang, H.C.; Zhang, Z.J.; Li, X.G.; Fan, Y. Simultaneous thermal stability and ultrahigh sensitivity of heterojunction SERS substrates. Nanomaterials 2019, 9, 830. [Google Scholar] [CrossRef]

- Willets, K.A.; van Duyne, R.P. Localized surface plasmon resonance spectroscopy and sensing. Ann. Rev. Phys. Chem. 2007, 58, 267. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhao, X.Y.; Chen, L.; Chen, S.; Wei, M.B.; Gao, M.; Zhao, Y.; Wang, C.; Qu, X.; Zhang, Y.J.; et al. Ordered nanocap array composed of SiO2-isolated Ag islands as SERS platform. Langmuir 2014, 30, 15285. [Google Scholar] [CrossRef]

- Chen, Y.; Shu, Z.; Feng, Z.; Kong, L.; Liu, Y.; Duan, H. Reliable patterning, transfer printing and post-assembly of multiscale adhesion-free metallic structures for nanogap device applications. Adv. Funct. Mater. 2020, 2002549. [Google Scholar] [CrossRef]

- Chen, Y.; Bi, K.; Wang, Q.; Zheng, M.; Liu, Q.; Han, Y.; Yang, J.; Chang, S.; Zhang, G.; Duan, H. Rapid focused ion beam milling based fabrication of plasmonic nanoparticles and assemblies via“Sketch and Peel” strategy. ACS Nano 2016, 10, 11228–11236. [Google Scholar] [CrossRef]

- Chen, Y.; Xiang, Q.; Li, Z.; Wang, Y.; Meng, Y.; Duan, H. “Sketch and Peel” lithography for high-resolution multiscale patterning. Nano Lett. 2016, 16, 3253–3259. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Wen, J.H.; Li, L.W.; Wang, Y.X.; Wang, D.H.; Chen, L.; Zhang, Y.J.; Du, Y.W. Architecture design and applications of nanopatterned arrays based on colloidal Lithography. J. Appl. Phys. 2019, 126, 141101. [Google Scholar] [CrossRef]

- Stiles, P.L.; Dieringer, J.A.; Shah, N.C.; van Duyne, R.P. Surface-enhanced Raman spectroscopy. Ann. Rev. Anal. Chem. 2011, 1, 601. [Google Scholar] [CrossRef]

- Farcău, C.; Aştilean, S. Silver half-shell arrays with controlled plasmonic response for fluorescence enhancement optimization. Appl. Phys. Lett. 2009, 95, 193110. [Google Scholar]

- Kreno, L.E.; Greeneltch, N.G.; Farha, O.K.; Hupp, J.T.; van Duyne, R.P. SERS of molecules that do not adsorb on Ag surfaces: A metal–organic framework-based functionalization strategy. Analyst 2014, 139, 4073. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhao, X.Y.; Gao, W.T.; Chen, L.; Chen, S.; Wei, M.B.; Gao, M.; Wang, C.; Zhang, Y.J.; Yang, J.H. Au/Ag bimetal nanogap arrays with tunable morphologies for surface-enhanced Raman scattering. RSC Adv. 2015, 5, 7454. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Wang, C.; Wang, J.P.; Chen, L.; Li, J.; Liu, Y.; Zhao, X.Y.; Wang, Y.X.; Yang, J.H. Nanocap array of Au:Ag composite for surface-enhanced Raman scattering. Spectrochim. Acta Part Mol. Biomol. Spectrosc. 2016, 152, 461. [Google Scholar] [CrossRef]

- Tabatabaei, M.; Sangar, A.; Kazemi-Zanjani, N.; Torchio, P.; Merlen, A.; Lagugne-Labarthet, F. Optical properties of silver and gold tetrahedral nanopyramid arrays prepared by nanosphere lithography. J. Phys. Chem. C 2013, 117, 14778. [Google Scholar] [CrossRef]

- Zrimsek, A.B.; Henry, A.-I.; van Duyne, R.P. Single molecule Surface-enhanced Raman spectroscopy without nanogaps. J. Phys. Chem. Lett. 2013, 4, 3206. [Google Scholar] [CrossRef]

- Jensen, T.R.; Malinsky, M.D.; Haynes, C.L.; van Duyne, R.P. Nanosphere Lithography: Tunable localized surface plasmon resonance spectra of silver nanoparticles. J. Phys. Chem. B 2000, 104, 10549. [Google Scholar] [CrossRef]

- Dickreuter, S.; Gleixner, J.; Kolloch, A.; Boneberg, J.; Scheer, E.; Leiderer, P. Mapping of plasmonic resonances in nanotriangles. Beil. J. Nanotechnol. 2013, 4, 588. [Google Scholar] [CrossRef]

- Vogel, N.; Belisle, R.A.; Hatton, B.; Wong, T.S.; Aizenberg, J. Transparency and damage tolerance of patternable omniphobic lubricated surfaces based on inverse colloidal monolayers. Nat. Commun. 2013, 4, 2176. [Google Scholar] [CrossRef]

- Yang, S.K.; Lapsley, M.L.; Cao, B.Q.; Zhao, C.L.; Zhao, Y.H.; Hao, Q.Z.; Kiraly, B.; Scott, J.; Li, W.Z.; Wang, L.; et al. Large-scale fabrication of three-dimensional surface patterns using template-defined electrochemical deposition. Adv. Funct. Mater. 2013, 23, 720. [Google Scholar] [CrossRef]

- Yang, S.K.; Cao, B.Q.; Kong, L.; Wang, Z.Y. Template-directed dewetting of a gold membrane to fabricate highly SERS-active substrates. J. Mater. Chem. 2011, 21, 14031. [Google Scholar] [CrossRef]

- Ai, B.; Basnet, P.; Larson, S.; Ingram, W.; Zhao, Y.P. Plasmonic sensor with high figure of merit based on differential polarization spectra of elliptical nanohole array. Nanoscale 2010, 9, 14710. [Google Scholar] [CrossRef]

- Lee, S.H.; Bantz, K.C.; Lindquist, N.C.; Oh, S.H.; Haynes, C.L. Self-assembled plasmonic nanohole arrays. Langmuir 2009, 25, 13685. [Google Scholar] [CrossRef]

- Pisco, M.; Galeotti, F.; Quero, G.; Grisci, G.; Micco, A.; Mercaldo, L.V.; Veneri, P.D.; Cutolo, A.; Cusano, A. Nanosphere lithography for optical fiber tip nanoprobes. Light Sci. Appl. 2017, 6, 1. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhang, M.N.; Yan, C.; Chen, L.; Liu, Y.; Li, J.; Zhang, Y.J.; Yang, J.H. Pillar-cap shaped arrays of Ag/SiO2 multilayers after annealing treatment as a SERS-active substrate. Colloids Surf. A Phys. Eng. Asp. 2016, 506, 96. [Google Scholar] [CrossRef]

- Gao, R.X.; Zhang, Y.J.; Zhang, F.; Guo, S.; Wang, Y.X.; Chen, L.; Yang, J.H. SERS polarization-dependent effects for an ordered 3D plasmonic tilted silver nanorod array. Nanoscale 2018, 10, 8106. [Google Scholar] [CrossRef]

- Ai, B.; Yu, Y.; Möhwald, H.; Wang, L.M.; Zhang, G. Resonant optical transmission through topologically continuous films. ACS Nano 2014, 8, 1566. [Google Scholar] [CrossRef]

- Ai, B.; Gu, P.P.; Wang, Z.Y.; Möhwald, H.; Wang, L.M.; Zhang, G. Light trapping in plasmonic nanovessels. Adv. Opt. Mater. 2017, 5, 1600980. [Google Scholar] [CrossRef]

- Ai, B.; Möhwald, H.; Zhang, G. Smart pattern display by tuning the surface plasmon resonance of hollow nanocone arrays. Nanoscale 2015, 7, 11525. [Google Scholar] [CrossRef]

- Yang, S.K.; Sun, N.; Stogin, B.B.; Wang, J.; Huang, Y.; Wong, T.S. Ultra-antireflective synthetic brochosomes. Nat. Commun. 2017, 8, 1285. [Google Scholar] [CrossRef]

- Yu, Y.; Zhou, Z.W.; Möhwald, H.; Ai, B.; Zhao, Z.Y.; Ye, S.S.; Zhang, G. Distorted colloidal arrays as designed template. Nanotechnology 2015, 26, 035301. [Google Scholar] [CrossRef]

- Ho, C.C.; Zhao, K.; Lee, T.Y. Quasi-3D gold nanoring cavity arrays with high-density hot-spots for SERS applications via nanosphere lithography. Nanoscale 2014, 6, 8606. [Google Scholar] [CrossRef]

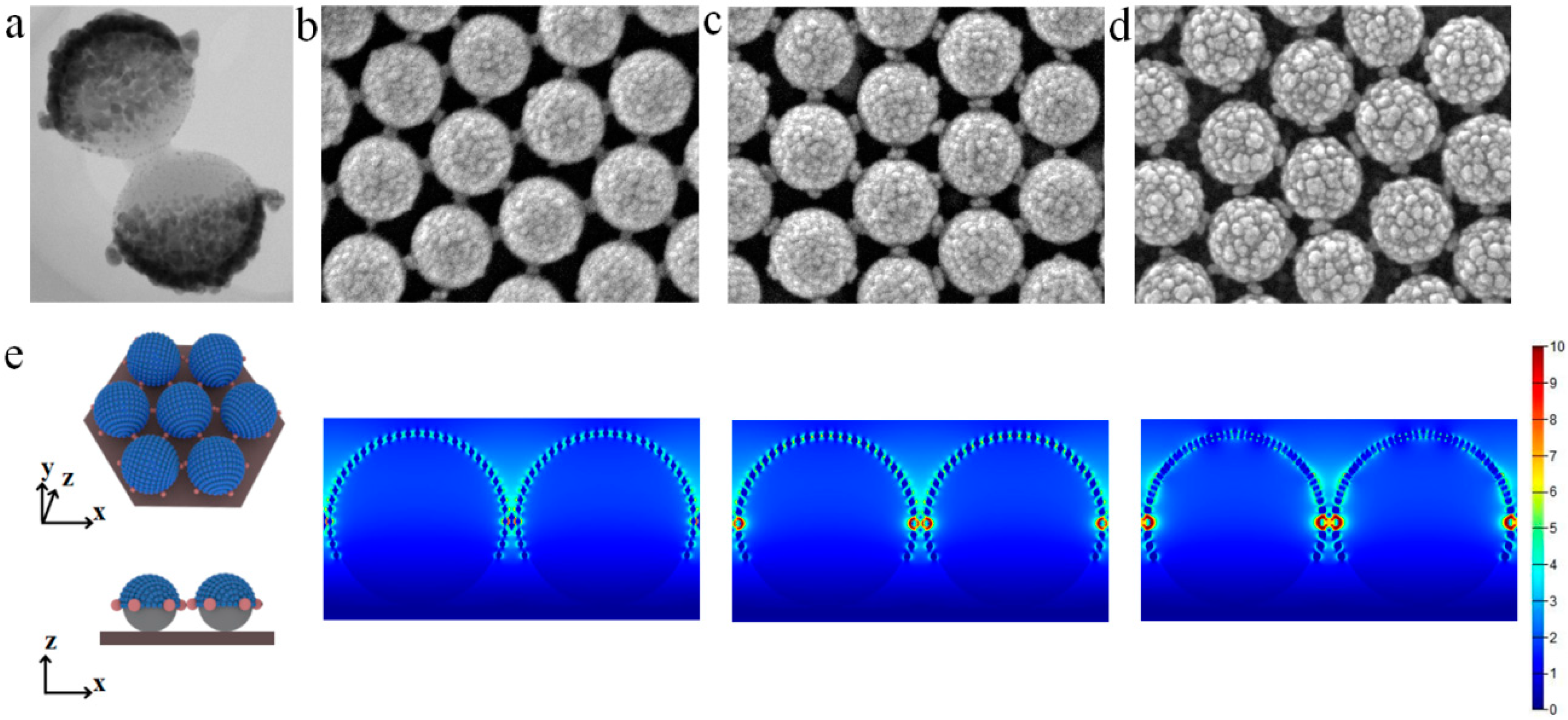

- Zhao, X.Y.; Wen, J.H.; Zhang, M.N.; Wang, D.H.; Wang, Y.X.; Chen, L.; Zhang, Y.J.; Yang, J.H.; Du, Y.W. Design of hybrid nanostructural arrays to manipulate SERS-active substrates by nanosphere lithography. ACS Appl. Mater. Interfaces 2017, 9, 7710. [Google Scholar] [CrossRef]

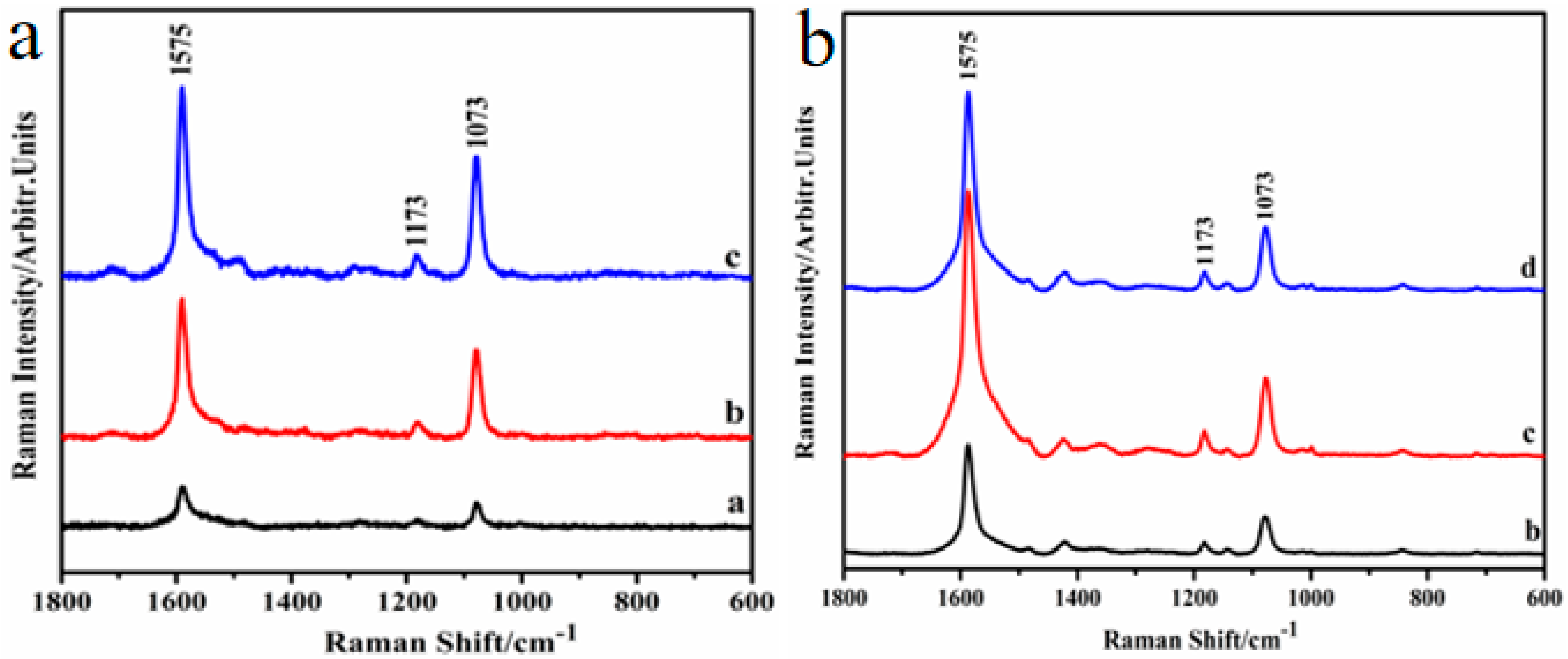

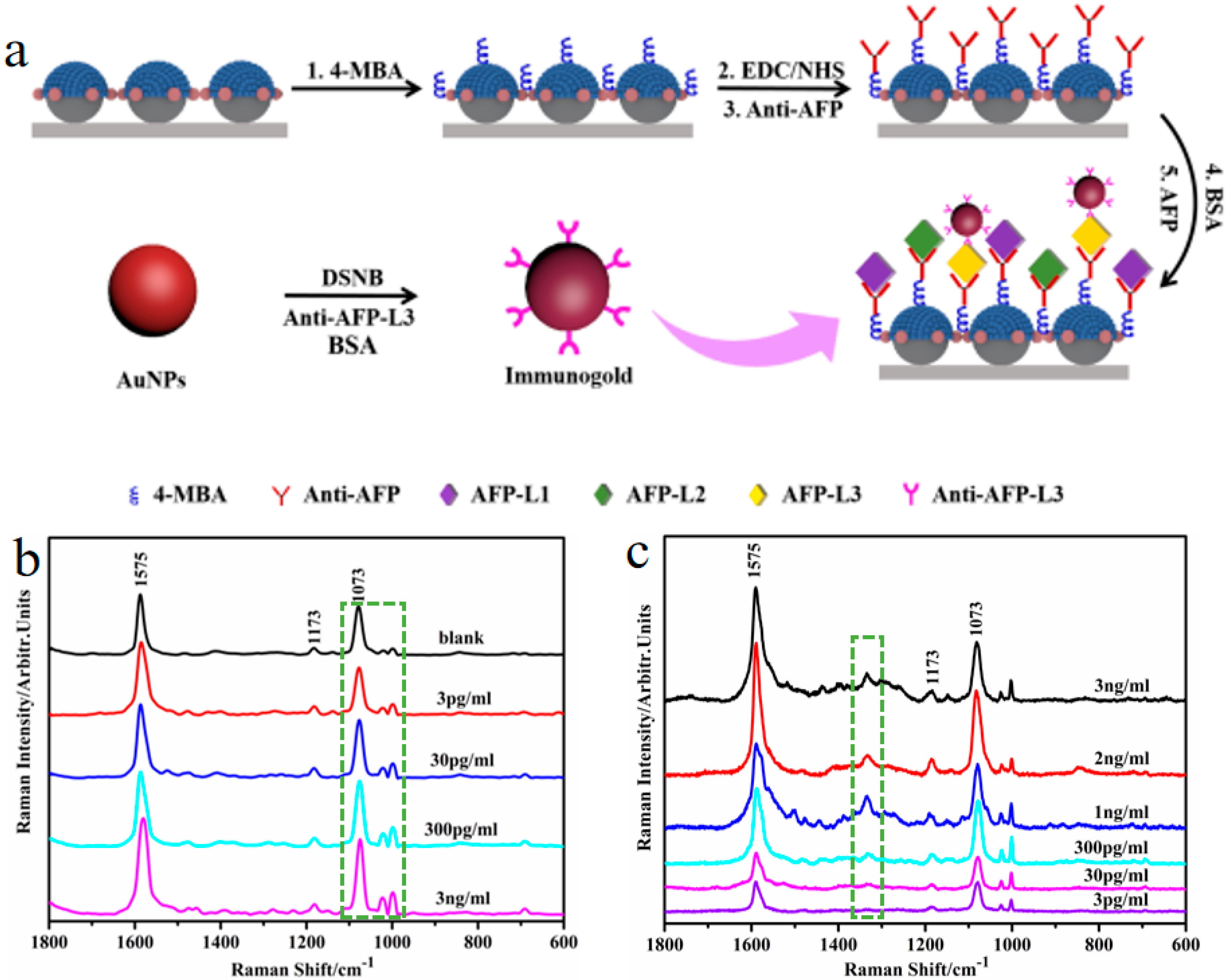

- Zhu, A.N.; Zhao, X.Y.; Cheng, M.Y.; Chen, L.; Wang, Y.X.; Zhang, X.L.; Zhang, Y.J.; Zhang, X.F. Nanohoneycomb Surface-enhanced Raman spectroscopy-active chip for the determination of biomarkers of hepatocellular carcinoma. ACS Appl. Mater. Interfaces 2019, 11, 44617–44623. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Zhang, F.; Zhu, A.N.; Zhang, X.L.; Wang, Y.X.; Zhao, X.Y.; Chen, L.; Hua, Z.; Zhang, Y.J.; Zhang, X.F. Bridging the neighbor plasma coupling on curved surface array for early hepatocellular carcinoma detection. Sens. Actuators B Chem. 2020, 309, 127759. [Google Scholar] [CrossRef]

- Zhu, K.; Wang, Z.Y.; Zong, S.F.; Liu, Y.; Yang, K.; Li, N.; Wang, Z.L.; Li, L.; Tang, H.L.; Cui, Y.P. Hydrophobic plasmonic nanoacorn array for a label-free and uniform SERS-based biomolecular assay. ACS Appl. Mater. Interfaces 2020, 12, 29917–29927. [Google Scholar]

- Yang, S.K.; Lei, Y. Recent progress on surface pattern fabrications based on monolayer colloidal crystal templates and related applications. Nanoscale 2011, 3, 2768. [Google Scholar] [CrossRef]

- Ai, B.; Möhwald, H.; Wang, D.Y.; Zhang, G. Advanced colloidal lithography beyond surface patterning. Adv. Mater. Interfaces 2016, 4, 1600271. [Google Scholar] [CrossRef]

- Chen, L.; Sun, H.H.; Zhao, Y.; Gao, R.X.; Wang, Y.X.; Liu, Y.; Zhang, Y.J.; Hua, Z.; Yang, J.H. Iron layer-dependent surface-enhanced Raman scattering of hierarchical nanocap arrays. Appl. Surf. Sci. 2017, 423, 1124. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Chen, L.; Wang, Y.X.; Zhang, Y.J.; Yang, J.H.; Choi, H.C.; Jung, Y.M. Design of tunable ultraviolet (UV) absorbance by controlling the Ag-Al co-sputtering deposition. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2018, 197, 37. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Sun, H.H.; Gao, R.X.; Zhang, F.; Zhu, A.N.; Chen, L.; Wang, Y.X. Facile SERS-active chip (PS@Ag/SiO2/Ag) for the determination of HCC biomarker. Sens. Actuators B Chem. 2018, 272, 34. [Google Scholar] [CrossRef]

- Yang, S.K.; Hricko, P.J.; Huang, P.H.; Li, S.X.; Zhao, Y.H.; Xie, Y.L.; Guo, F.; Wang, L.; Huang, T.J. Superhydrophobic surface enhanced Raman scattering sensing using janus particle arrays realized by site-specific electrochemical growth. J. Mater. Chem. C 2014, 2, 542. [Google Scholar] [CrossRef]

- Correia-Ledo, D.; Gibson, K.F.; Dhawan, A.; Couture, M.; Vo-Dinh, T.; Graham, D.; Masson, J.F. Assessing the location of surface plasmons over nanotriangle and nanohole arrays of different size and periodicity. J. Phys. Chem. C 2012, 116, 6884. [Google Scholar] [CrossRef]

- Ai, B.; Wang, L.M.; Möhwald, H.; Yu, Y.; Zhang, G. Asymmetric half-cone/nanohole array films with structural and directional reshaping of extraordinary optical transmission. Nanoscale 2014, 6, 8997. [Google Scholar] [CrossRef]

- Haynes, C.L.; van Duyne, R.P. Nanosphere lithography: A versatile nanofabrication tool for studies of size-dependent nanoparticle optics. J. Phys. Chem. B 2001, 105, 5599. [Google Scholar] [CrossRef]

- Wang, Y.X.; Yan, C.; Chen, L.; Zhang, Y.J.; Yang, J.H. Controllable charge transfer in Ag-TiO2 composite structure for SERS application. Nanomaterials 2017, 7, 159. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, Y.X.; Zhang, Y.J.; Chen, L.; Liu, Y.; Yang, J.H. Ag nanotwin-assisted grain growth-induced by stress in SiO2/Ag/SiO2 nanocap arrays. Nanomaterials 2018, 8, 436. [Google Scholar] [CrossRef]

- Zhang, F.; Guo, S.; Liu, Y.; Chen, L.; Wang, Y.X.; Gao, R.X.; Zhu, A.N.; Zhang, X.L.; Zhang, Y.J. Controlling the 3D electromagnetic coupling in co-sputtered Ag-SiO2 nanomace arrays by lateral sizes. Nanomaterials 2018, 8, 493. [Google Scholar] [CrossRef]

- Zhu, A.N.; Gao, R.X.; Zhao, X.Y.; Zhang, F.; Zhang, X.Y.; Yang, J.H.; Zhang, Y.J.; Chen, L.; Wang, Y.X. Site-selective growth of Ag nanoparticles controlled by localized surface plasmon resonance of nanobowl arrays. Nanoscale 2019, 11, 6576. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, Y.J.; Wang, Y.X.; Zhao, X.Y. Composition-dependent LSPR shifts for co-sputtered TiS2 -Ag. Opt. Commun. 2020, 473, 125935. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhang, X.L.; Wang, Y.X.; Zhu, A.N.; Gao, R.X.; Zhao, X.Y.; Zhang, Y.J.; Chen, L. Controlling the growth locations of Ag nanoparticles at nanoscale by shifting LSPR hotspots. Nanomaterials 2019, 9, 1553. [Google Scholar] [CrossRef]

- Ellinas, K.; Smyrnakis, A.; Malainou, A.; Tserepi, A.; Gogolides, E. ‘‘Mesh-assisted’’ colloidal lithography and plasma etching: A route to large-area, uniform, ordered nano-pillar and nanopost fabrication on versatile substrates. Microelectron. Eng. 2011, 88, 2547. [Google Scholar] [CrossRef]

- Yang, S.M.; Jang, S.G.; Choi, D.G.; Kim, S.; Yu, H.K. Nanomachining by Colloidal Lithography. Small 2006, 2, 458. [Google Scholar] [CrossRef]

- Gao, P.Q.; He, J.; Zhou, S.Q.; Yang, X.; Li, S.Z.; Sheng, J.; Wang, D.; Yu, T.B.; Ye, J.C. Large-area nanosphere self-assembly by a micro-propulsive injection method for high throughput periodic surface nanotexturing. Nano Lett. 2015, 15, 4591. [Google Scholar] [CrossRef]

- Li, Y.; Cai, W.P.; Duan, G.T. Ordered micro/nanostructured arrays based on the monolayer colloidal crystals. Chem. Mater. 2008, 20, 615. [Google Scholar] [CrossRef]

- Skehan, C.; Ai, B.; Larson, S.R.; Stone, K.M.; Dennis, W.M.; Zhao, Y.P. Plasmonic and SERS performances of compound nanohole arrays fabricated by shadow sphere lithography. Nanotechnology 2018, 29, 095301. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, D.Y.; Möhwald, H. Patterning microsphere surfaces by templating colloidal crystals. Nano Lett. 2005, 5, 143. [Google Scholar] [CrossRef]

- Ellinas, K.; Tserepi, A.; Gogolides, E. From superamphiphobic to amphiphilic polymeric surfaces with ordered hierarchical roughness fabricated with colloidal lithography and plasma nanotexturing. Langmuir 2011, 27, 3960. [Google Scholar] [CrossRef]

- Malainou, A.; Tsougeni, K.; Ellinas, K.; Petrou, P.S.; Constantoudis, V.; Sarantopoulou, E.; Awsiuk, K.; Bernasik, A.; Budkowski, A.; Markou, A.; et al. Plasma-assisted nanoscale protein patterning on si substrates via colloidal lithography. J. Phys. Chem. A 2013, 117, 13743. [Google Scholar] [CrossRef]

- Markou, A.; Beltsios, K.G.; Gergidis, L.N.; Panagiotopoulos, I.; Bakas, T.; Ellinas, K.; Tserepi, A.; Stoleriu, L.; Tanasa, R.; Stancu, A. Magnetization reversal in triangular L10-FePt nanoislands. J. Magn. Magn. Mater. 2013, 344, 224. [Google Scholar] [CrossRef]

- Zhou, S.Q.; Yang, Z.H.; Gao, P.Q.; Li, X.F.; Yang, X.; Wang, D.; He, J.; Ying, Z.Q.; Ye, J.C. Wafer-scale integration of inverted nanopyramid arrays for advanced light trapping in crystalline silicon thin film solar cells. Nanoscale Res. Lett. 2016, 11, 194. [Google Scholar] [CrossRef]

- Yang, X.; Zhou, S.Q.; Wang, D.; He, J.; Zhou, J.; Li, X.F.; Gao, P.Q.; Ye, J.C. Light trapping enhancement in a thin film with 2D conformal periodic hexagonal arrays. Nanoscale Res. Lett. 2015, 10, 284. [Google Scholar] [CrossRef][Green Version]

- Toma, M.; Loget, G.; Corn, R.M. Fabrication of broadband antireflflective plasmonic gold nanocone arrays on flexible polymer films. Nano Lett. 2013, 13, 6164. [Google Scholar] [CrossRef]

- Fan, W.; Zeng, J.; Gan, Q.Q.; Ji, D.X.; Song, H.M.; Liu, W.Z.; Shi, L.; Wu, L.M. Iridescence-controlled and flexibly tunable retroreflective structural color film for smart displays. Sci. Adv. 2019, 5, 8755. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Xia, J.; Lai, Z.; Tian, G.; Zhang, X.; Hou, Z.P.; Gao, X.S.; Mi, W.B.; Feng, C.; et al. Electric-field-driven non-volatile multi-state switching of individual skyrmions in a multiferroic heterostructure. Nat. Commun. 2020, 11, 3577. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Wen, J.; Zhu, A.; Cheng, M.; Zhu, Q.; Zhang, X.; Wang, Y.; Zhang, Y. Manipulation and Applications of Hotspots in Nanostructured Surfaces and Thin Films. Nanomaterials 2020, 10, 1667. https://doi.org/10.3390/nano10091667

Zhao X, Wen J, Zhu A, Cheng M, Zhu Q, Zhang X, Wang Y, Zhang Y. Manipulation and Applications of Hotspots in Nanostructured Surfaces and Thin Films. Nanomaterials. 2020; 10(9):1667. https://doi.org/10.3390/nano10091667

Chicago/Turabian StyleZhao, Xiaoyu, Jiahong Wen, Aonan Zhu, Mingyu Cheng, Qi Zhu, Xiaolong Zhang, Yaxin Wang, and Yongjun Zhang. 2020. "Manipulation and Applications of Hotspots in Nanostructured Surfaces and Thin Films" Nanomaterials 10, no. 9: 1667. https://doi.org/10.3390/nano10091667

APA StyleZhao, X., Wen, J., Zhu, A., Cheng, M., Zhu, Q., Zhang, X., Wang, Y., & Zhang, Y. (2020). Manipulation and Applications of Hotspots in Nanostructured Surfaces and Thin Films. Nanomaterials, 10(9), 1667. https://doi.org/10.3390/nano10091667