Machine Learning Approach for Application-Tailored Nanolubricants’ Design

Abstract

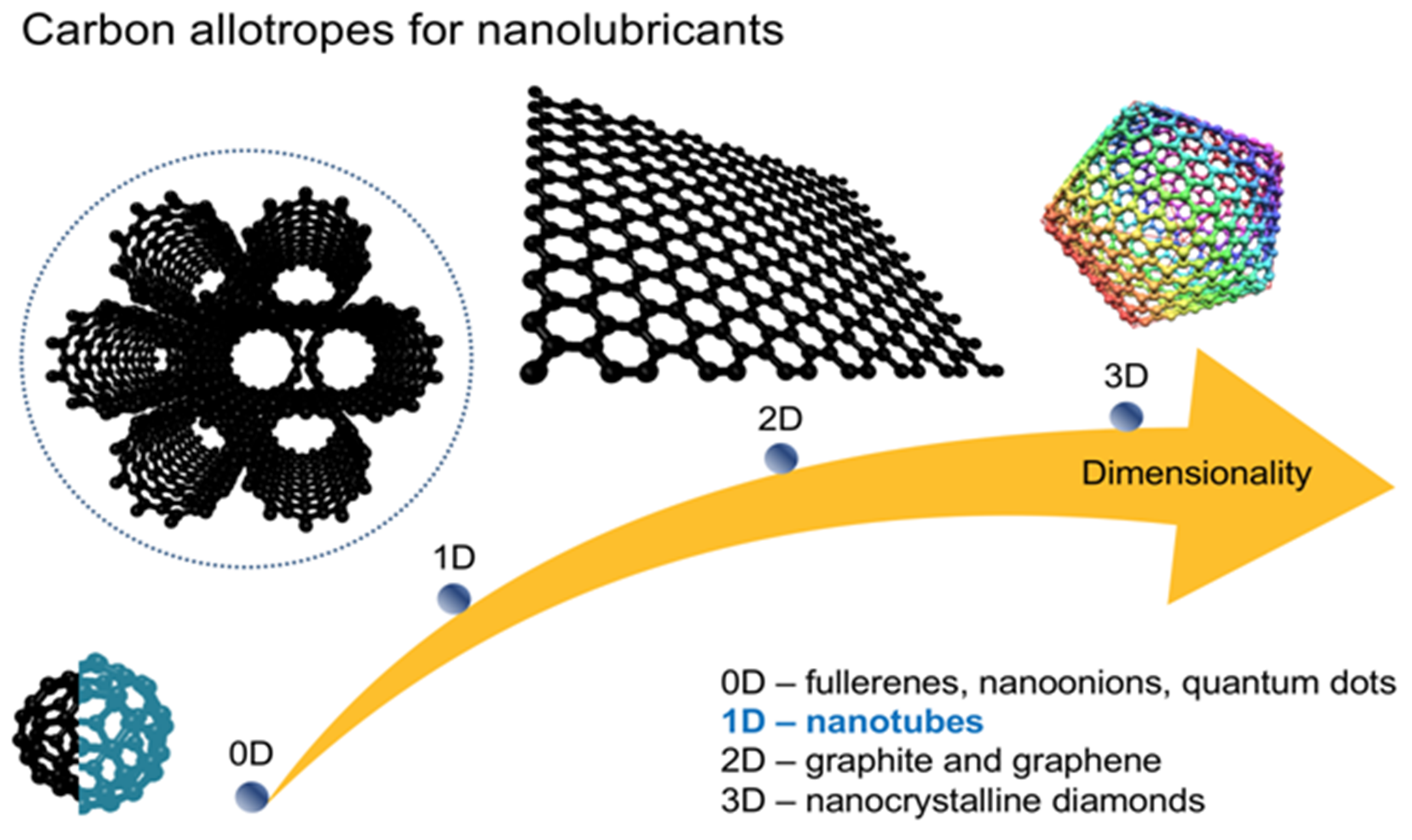

:1. Introduction

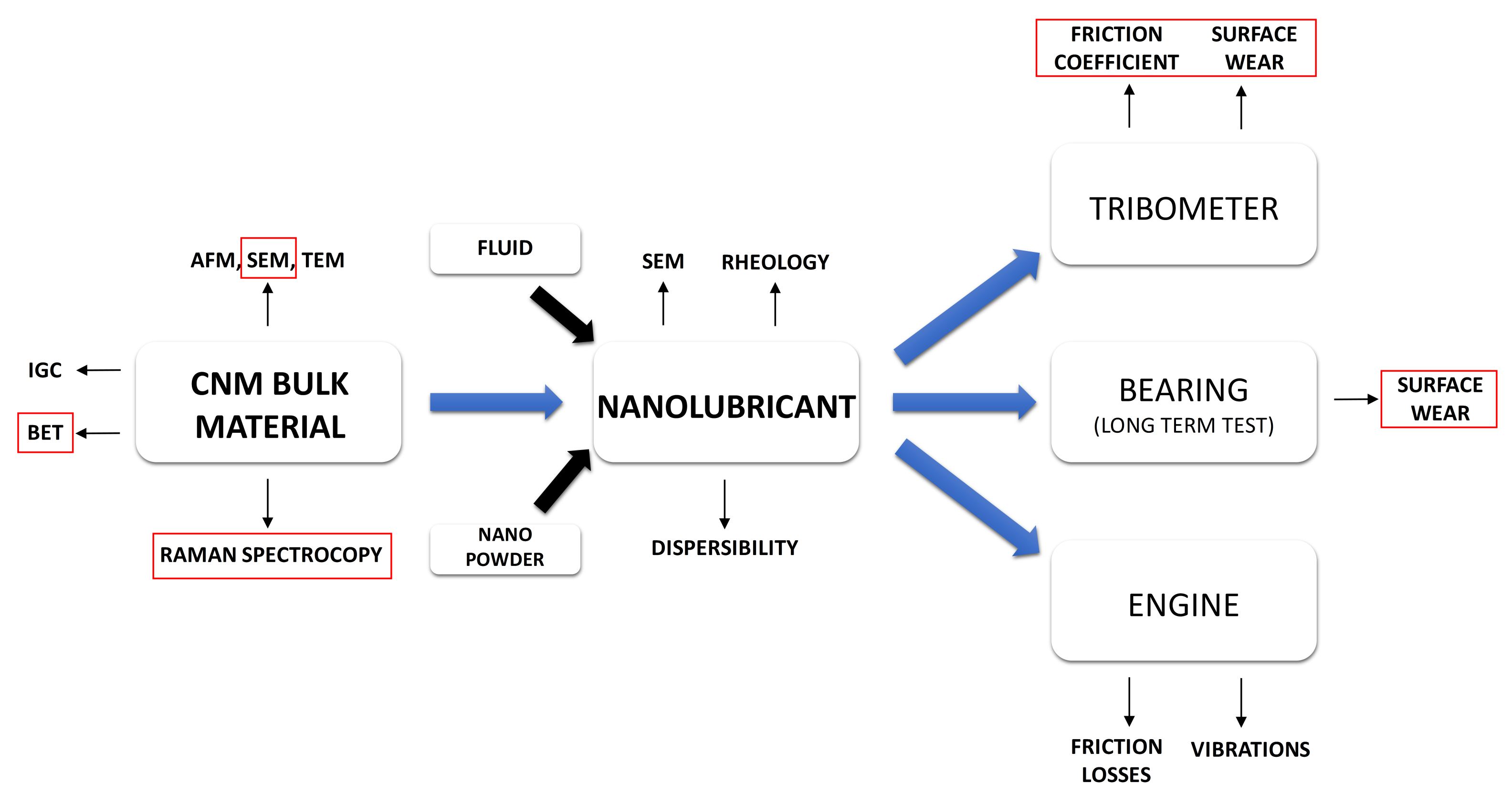

2. Characterisation of Materials—Structure of the Input Data for Machine Learning

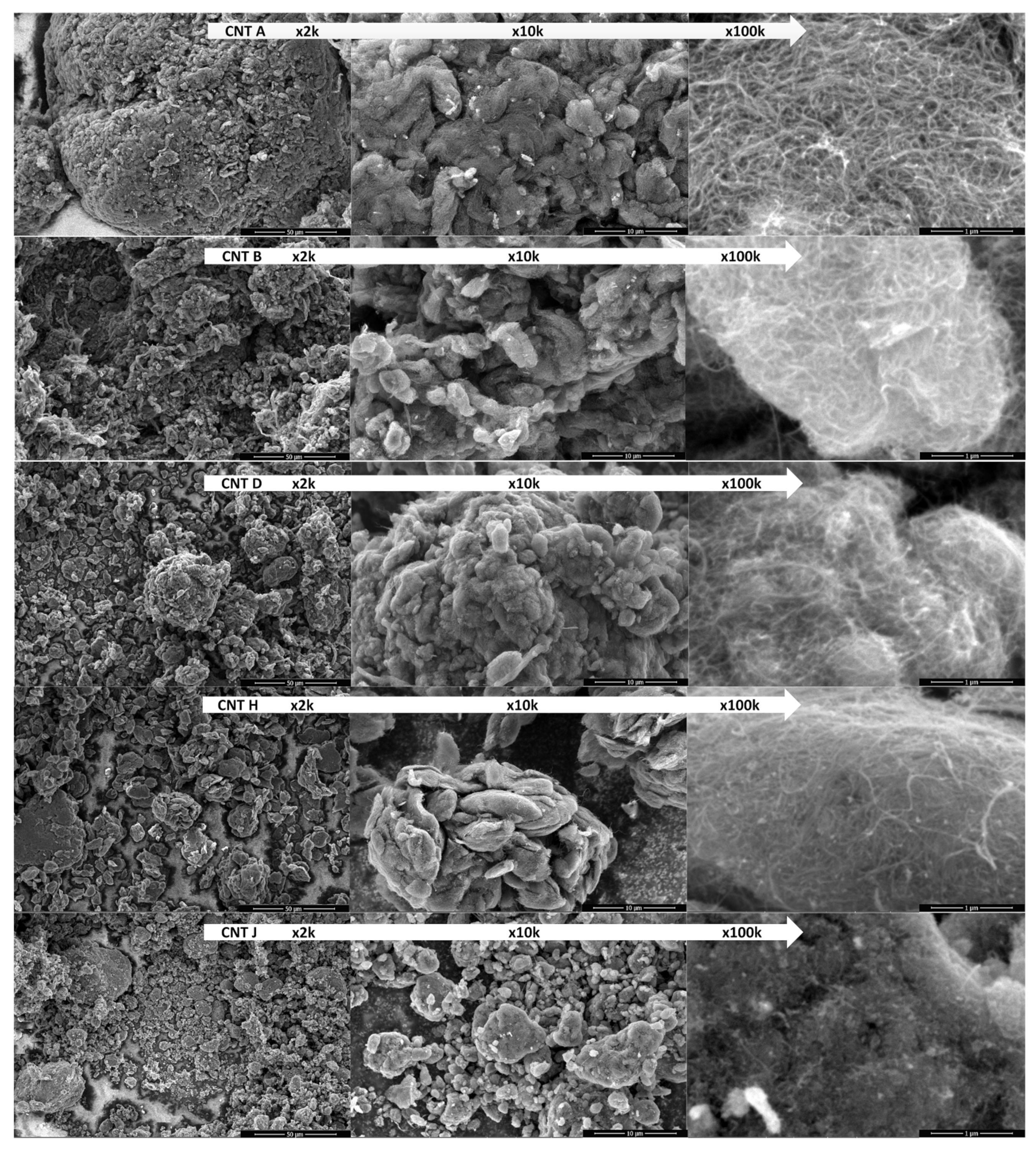

2.1. SEM Microscopy

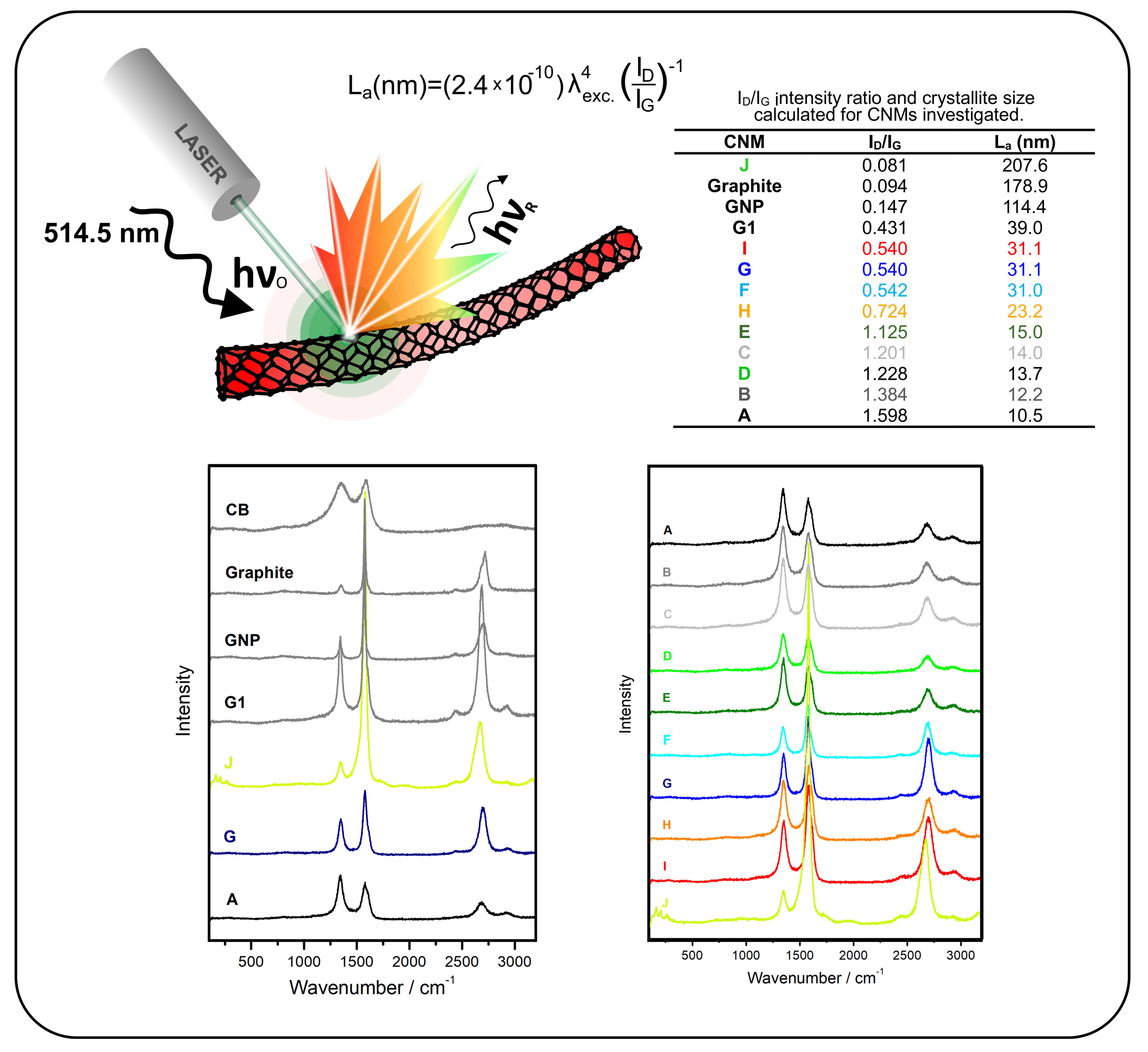

2.2. Raman Spectra

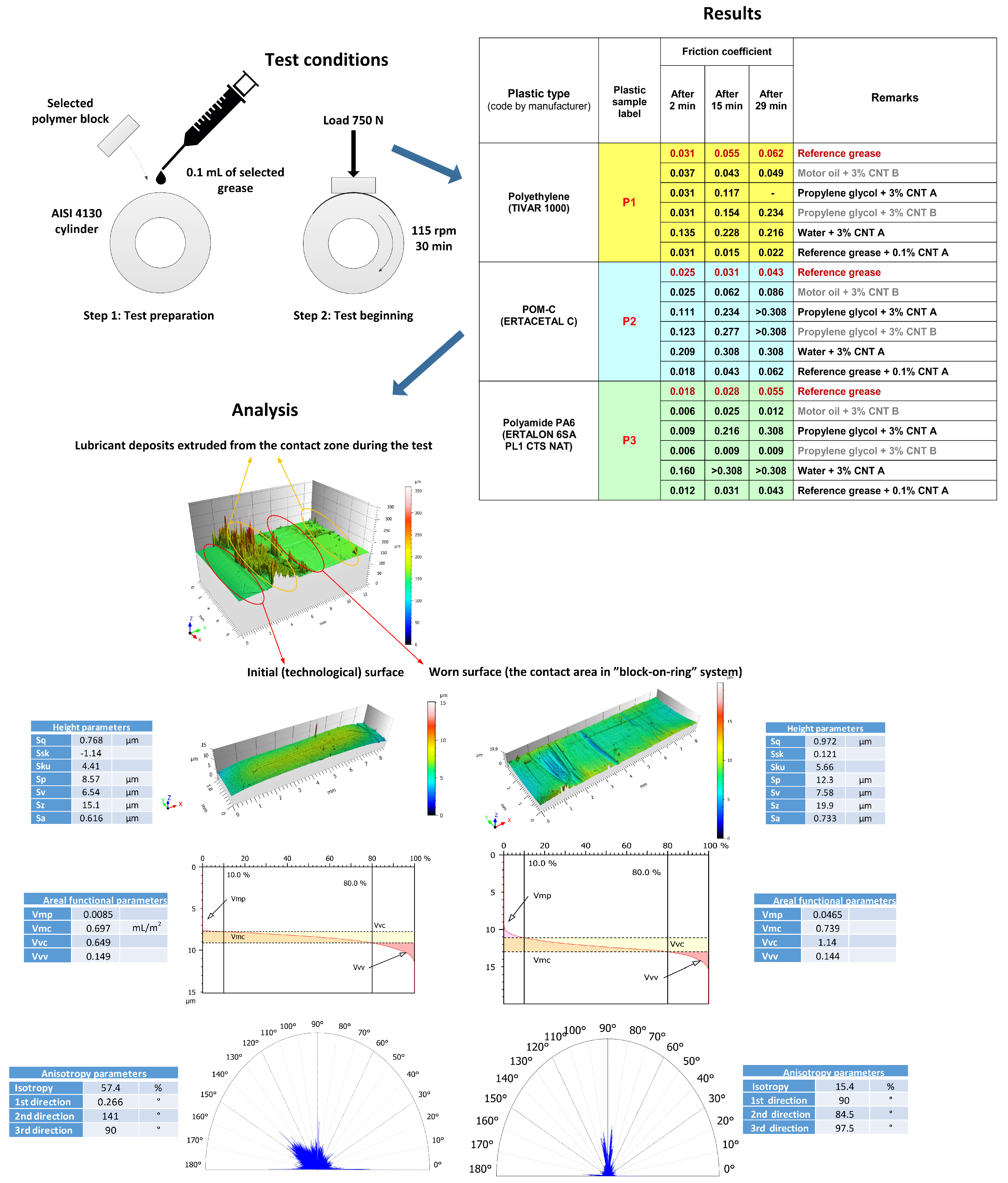

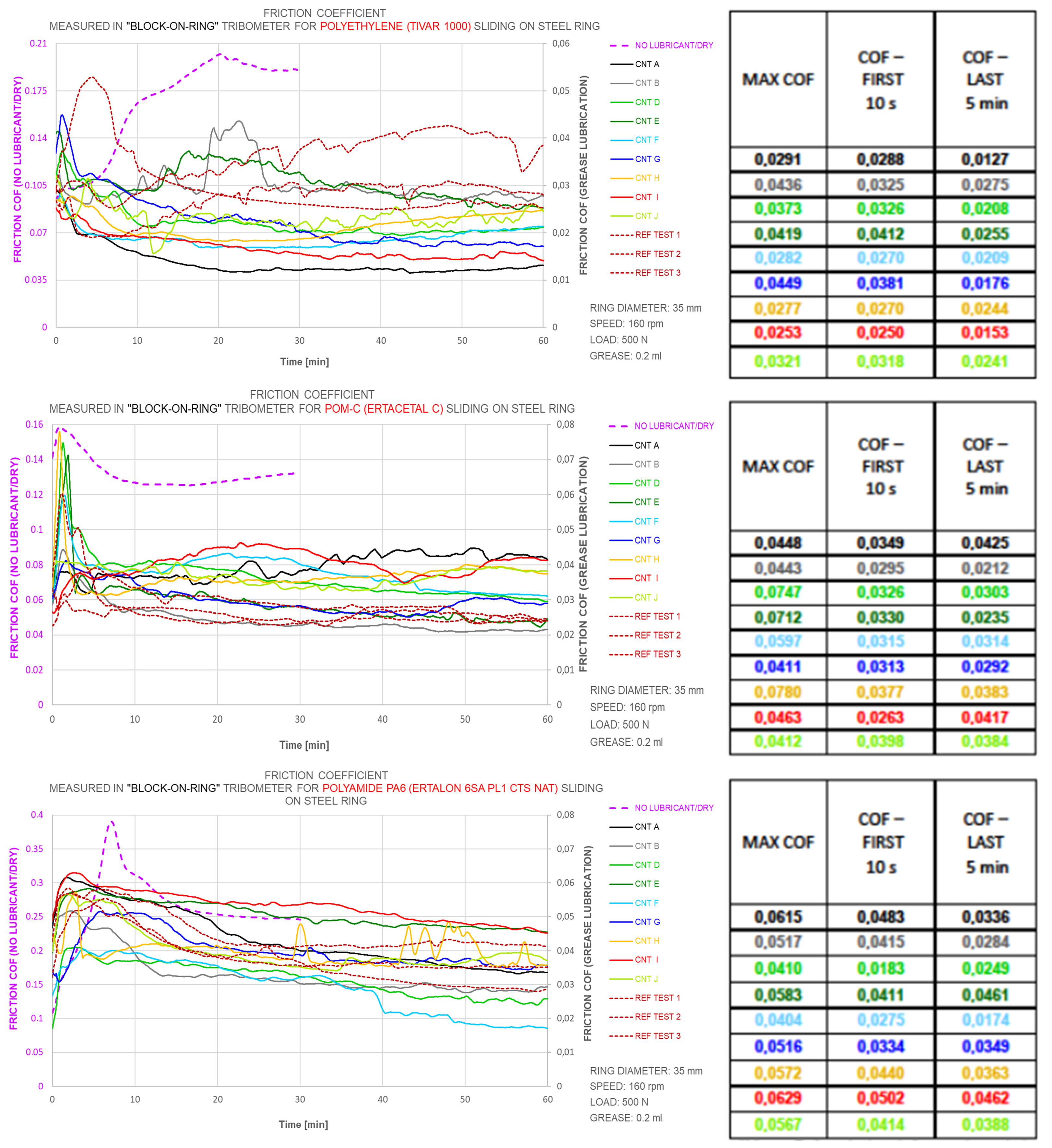

3. Tribological Tests of CNT-Based Nanolubricants

3.1. CNT-Based and CNT-Enriched Greases in “Block-on-Ring” Tribometers

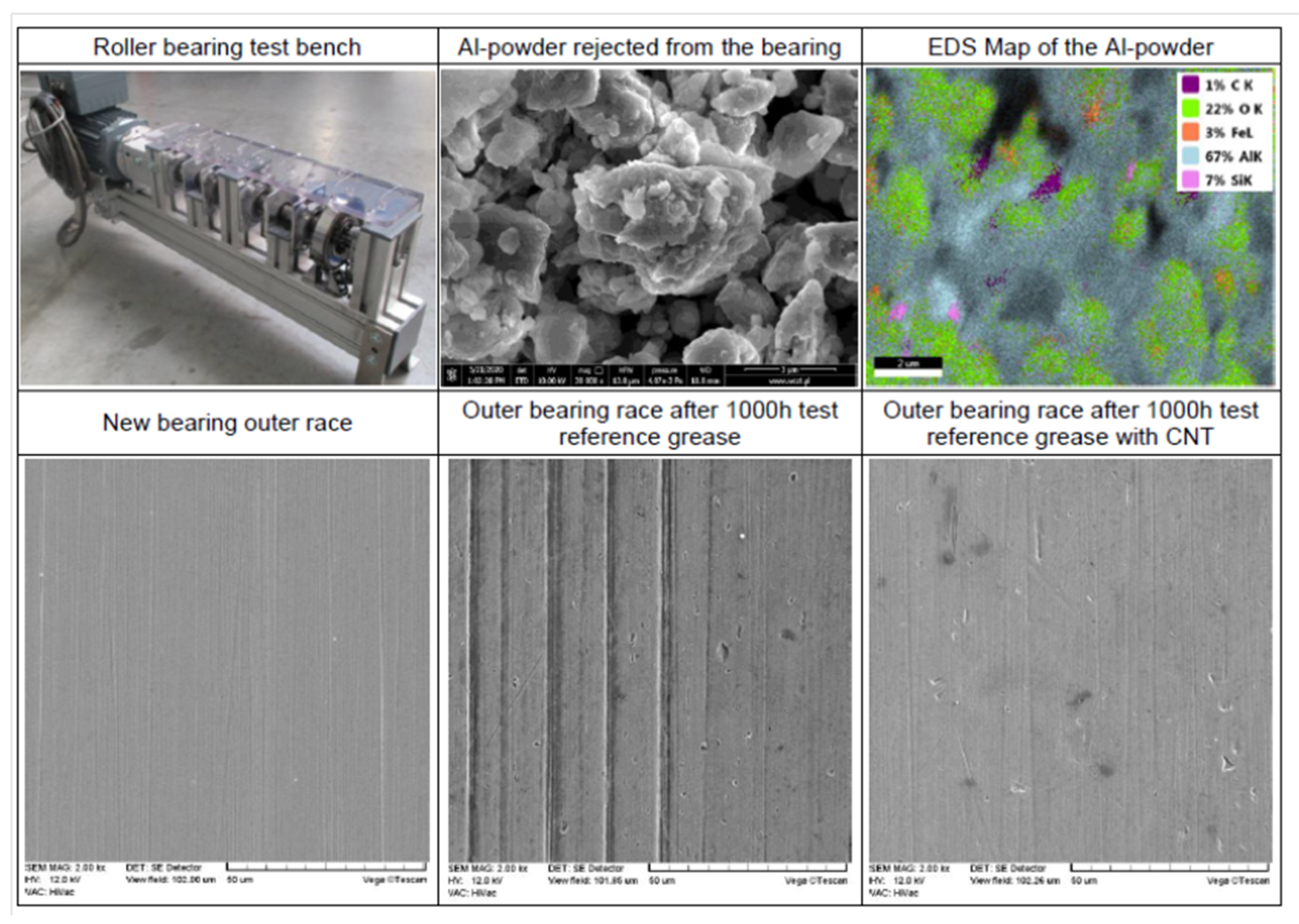

3.2. CNT-Based Nanolubricants in Roller Bearings

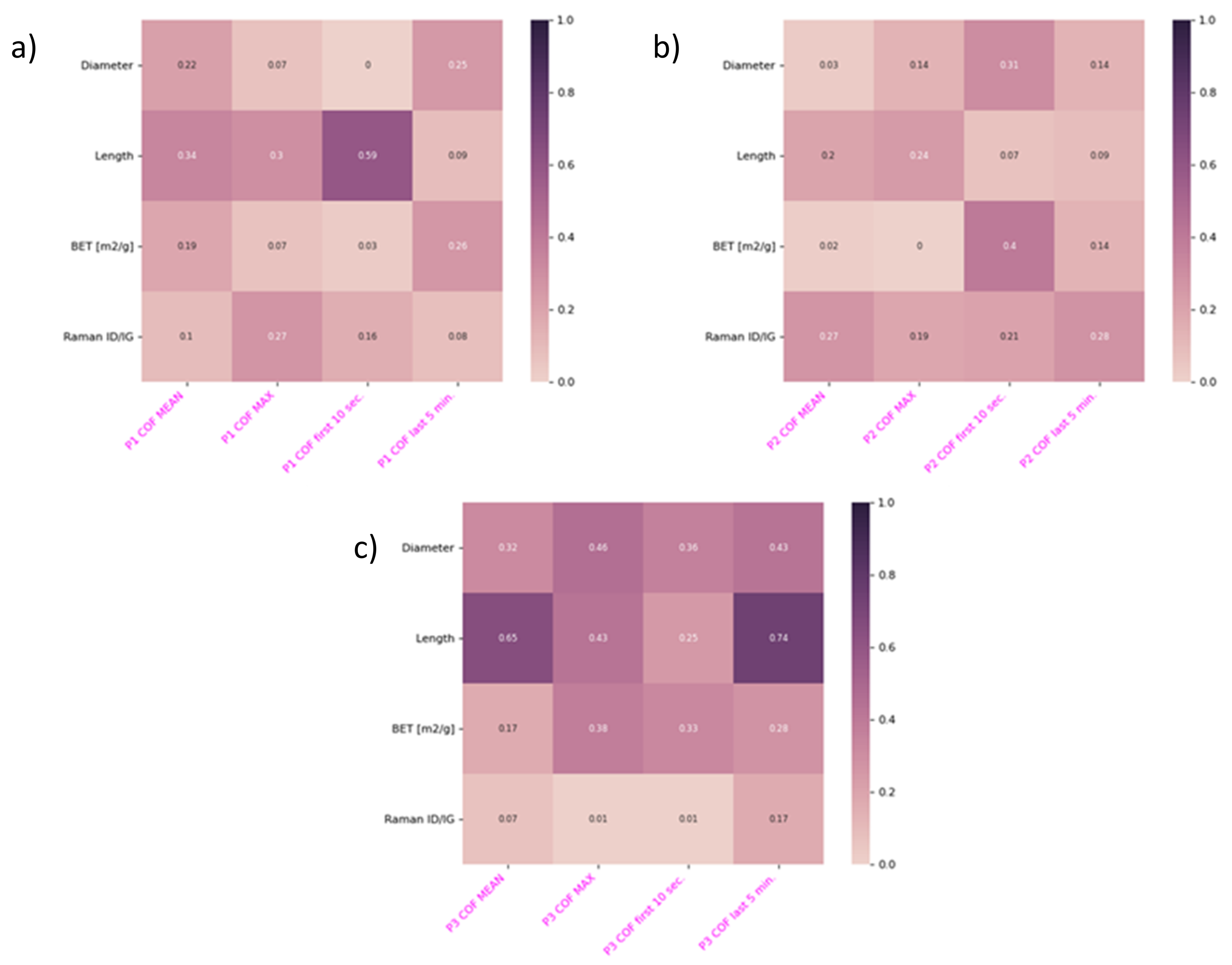

4. Neural Network for the Nanolubricant Design

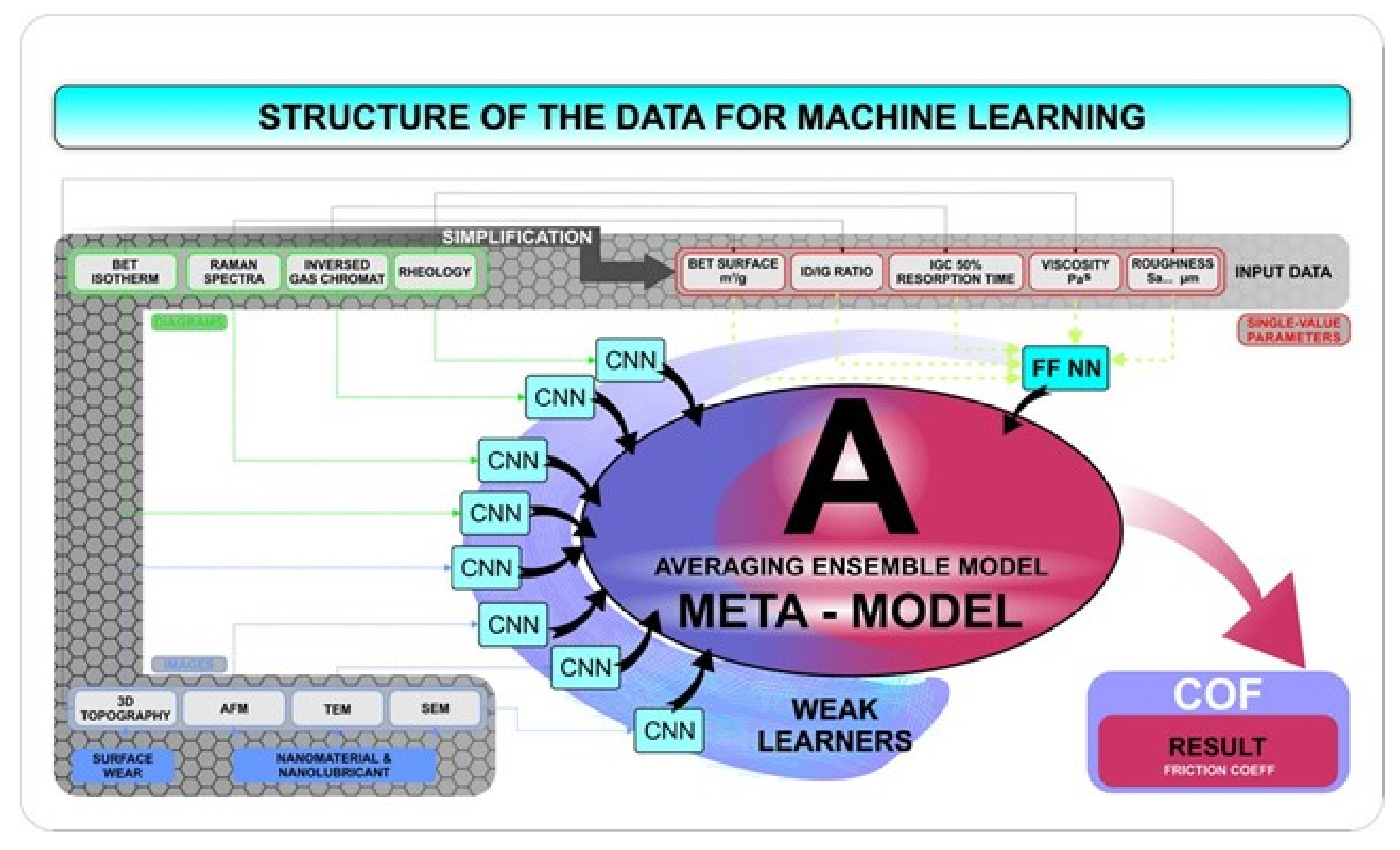

- Images of the topography of a friction track on the block have visually similar properties to maps, so trying to apply similar ML methods seems to be appropriate, that is mainly deep neural networks. Such an example solution can be found in, for example, [55].

- It seems that the easiest task would be to design an artificial neural network that would determine the COF on the basis of all kinds of parameters describing nanotubes, such as the BET area or ICG. The feed-forward neural network concept immediately comes to mind for such defined numerical inputs.

- Ultimately, nanotubes can be characterised via different graphs, such as a Raman spectrum or nitrogen adsorption isotherm, which we believe will be the greatest challenge for MLAs. As we have already mentioned, the most reasonable approach at this point is to use images of these graphs, as was done in, for example [58,59,60,61], or graphs generally in [62]. Another approach may be to create a feed-forward or convolutional neural network where pairs of coordinates marked on such a graph would be given as the input for this network. Perhaps the use of a convolutional neural network, where the matrix of these coordinates is treated as an image, would also be appropriate. We found no such solutions in the literature; thus, a study of such charts would be interesting.

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Slepičková Kasálková, N.; Slepička, P.; Švorčík, V. Carbon nanostructures, nanolayers, and their composites. Nanomaterials 2021, 11, 2368. [Google Scholar] [CrossRef] [PubMed]

- Hirsch, A. The era of carbon allotropes. Nat. Mater. 2010, 9, 868–871. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Nan, H.Y.; Ni, Z.H.; Wang, J.; Zafar, Z.; Shi, Z.X.; Wang, Y.Y. The thermal stability of graphene in air investigated by Raman spectroscopy. J. Raman Spectrosc. 2013, 44, 1018–1021. [Google Scholar] [CrossRef]

- Chen, X.; Li, J. Superlubricity of carbon nanostructures. Carbon 2020, 158, 1–23. [Google Scholar] [CrossRef]

- Song, Y.; Mandelli, D.; Hod, O.; Urbakh, M.; Ma, M.; Zheng, Q. Robust microscale superlubricity in graphite/hexagonal boron nitride layered heterojunctions. Nat. Mater. 2018, 17, 894–899. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Ge, X.; Yi, S.; Wang, H.; Liu, Y.; Luo, J. Macroscale superlubricity achieved on the hydrophobic graphene coating with glycerol. ACS Appl. Mater. Interfaces 2020, 12, 18859–18869. [Google Scholar] [CrossRef]

- Zhang, B.; Xue, Y.; Qiang, L.; Gao, K.; Liu, Q.; Yang, B.; Liang, A.; Zhang, J. Robust microscale superlubricity in graphite/hexagonal boron nitride layered heterojunctions. Appl. Nanosci. 2017, 7, 835–842. [Google Scholar] [CrossRef] [Green Version]

- Erdemir, A.; Ramirez, G.; Eryilmaz, O.L.; Narayanan, B.; Liao, Y.; Kamath, G.; Sankaranarayanan, S.K.R.S. Carbon-based tribofilms from lubricating oils. Nature 2016, 536, 67–71. [Google Scholar] [CrossRef]

- Li, S.; Li, Q.; Carpick, R.W.; Gumbsch, P.; Liu, X.Z.; Ding, X.; Sun, J.; Li, J. The evolving quality of frictional contact with graphene. Nature 2016, 539, 541–545. [Google Scholar] [CrossRef]

- Garcia, I.; Guerra, S.; de Damborenea, J.; Conde, A. Reduction of the coefficient of friction of steel-steel tribological contacts by novel graphene-deep eutectic solvents (DESs) lubricants. Lubricants 2019, 7, 37. [Google Scholar] [CrossRef] [Green Version]

- Zhou, F.; Liang, Y.; Liu, W. Ionic liquid lubricants: Designed chemistry for engineering applications. Chem. Soc. Rev. 2009, 38, 2590–2599. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, X.; Li, J. Graphene lubrication. Appl. Mater. Today 2020, 20, 100662. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, M.; Li, X.; Jin, L.; Su, G.; Mo, Y.; Li, L.; Zhu, H.; Tian, Y. Research progress in application of 2D materials in liquid-phase lubrication system. Materials 2018, 11, 1314. [Google Scholar] [CrossRef] [Green Version]

- Dong, Y.; Duan, Z.; Tao, Y.; Wei, Z.; Gueye, B.; Zhang, Y.; Chen, Y. Friction evolution with transition from commensurate to incommensurate contacts between graphene layers. Tribol. Int. 2019, 136, 259–266. [Google Scholar] [CrossRef]

- Vanossi, A.; Manini, N.; Urbakh, M.; Zapperi, S.; Tosatti, E. Colloquium: Modeling friction: From nanoscale to mesoscale. Rev. Mod. Phys. 2013, 85, 529–552. [Google Scholar] [CrossRef] [Green Version]

- Holt, J.K.; Park, H.G.; Wang, Y.; Stadermann, M.; Artyukhin, A.B.; Grigoropoulos, C.P.; Noy, A.; Bakajin, O. Fast mass transport through sub-2-nanometer carbon nanotubes. Science 2006, 312, 1034–1037. [Google Scholar] [CrossRef]

- Whitby, M.; Cagnon, L.; Thanou, M.; Quirke, N. Enhanced fluid low through Nanoscale Carbon Pipes. Nano Lett. 2008, 8, 2632–2637. [Google Scholar] [CrossRef]

- Secchi, E.; Marbach, S.; Niguès, A.; Stein, D.; Siria, A.; Bocquet, L. Massive radius-dependent flow slippage in carbon nanotubes. Nature 2016, 537, 210–213. [Google Scholar] [CrossRef]

- Xie, Q.; Alibakhshi, M.A.; Jiao, S.; Xu, Z.; Hempel, M.; Kong, J.; Park, H.G.; Duan, C. Fast water transport in graphene nanofluidic channels. Nat. Nanotechnol. 2018, 13, 238–245. [Google Scholar] [CrossRef]

- Kavokine, N.; Bocquet, M.L.; Bocquet, L. Fluctuation-induced quantum friction in nanoscale water flows. Nature 2022, 602, 84–90. [Google Scholar] [CrossRef]

- Shvonski, A.; Kong, J.; Kempa, K. Plasmon-polaron of the topological metallic surface states. Phys. Rev. B 2019, 99, 125148. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Pan, R.; Cai, M.; Luo, X.; Chen, C.; Jiang, G.; Hu, X.; Zhang, H.; Zhong, M. Oil-triggered switchable wettability on patterned alternating air/lubricant-infused superamphiphobic surfaces. J. Mater. Chem. A 2020, 8, 6647–6660. [Google Scholar] [CrossRef]

- Kałużny, J.; Merkisz-Guranowska, A.; Giersig, M.; Kempa, K. Lubricating performance of carbon nanotubes in internal combustion engines-engine test results for CNT enriched oil. Int. J. Automot. Technol. 2017, 18, 1047–1059. [Google Scholar] [CrossRef]

- Kałużny, J.; Merkisz, J.; Kempa, K.; Gapiński, B.; Wróblewski, E.; Stepanenko, A.; Al-Karawi, M. Friction reducing performance of carbon nanotubes covered pistons in internal combustion engines—Engine test results. Combust. Engines 2018, 172, 14–24. [Google Scholar] [CrossRef]

- Kałużny, J.; Waligórski, M.; Szymański, G.M.; Merkisz, J.; Różański, J.; Nowicki, M.; Al Karawi, M.; Kempa, K. Reducing friction and engine vibrations with trace amounts of carbon nanotubes in the lubricating oil. Tribol. Int. 2020, 151, 106484. [Google Scholar] [CrossRef]

- Kałużny, J.; Kulczycki, A.; Dzięgielewski, W.; Piasecki, A.; Gapiński, B.; Mendak, M.; Runka, T.; Łukawski, D.; Stepanenko, O.; Merkisz, J.; et al. The indirect tribological role of carbon nanotubes stimulating zinc dithiophosphate anti-wear film formation. Nanomaterials 2020, 10, 1330. [Google Scholar] [CrossRef]

- Bukrajewski, P.; Deliś, M.; Desaniuk, T.; Dzięgielewski, W.; Kałużny, J.; Kulczycki, A.; Ozimina, D. The influence of ordered carbon structures on the mechanism of tribocatalysis. Tribol. Int. 2020, 151, 106518. [Google Scholar] [CrossRef]

- Guo, W.; Yin, J.; Qiu, H.; Guo, Y.; Wu, H.; Xue, M. Friction of low-dimensional nanomaterial systems. Friction 2014, 2, 209–225. [Google Scholar] [CrossRef] [Green Version]

- Kolmogorov, A.N.; Crespi, V.H. Smoothest bearings: Interlayer sliding in multiwalled carbon nanotubes. Phys. Rev. Lett. 2000, 85, 4727–4730. [Google Scholar] [CrossRef] [PubMed]

- De Laurentis, N.; Kadiric, A.; Lugt, P.; Cann, P. The influence of bearing grease composition on friction in rolling/sliding concentrated contacts. Tribol. Int. 2016, 94, 624–632. [Google Scholar] [CrossRef] [Green Version]

- Vengudusamy, B.; Enekes, C.; Spallek, R. On the film forming and friction behaviour of greases in rolling/sliding contacts. Tribol. Int. 2019, 129, 323–337. [Google Scholar] [CrossRef]

- De Laurentis, N.; Cann, P.; Lugt, P.M.; Kadiric, A. The influence of base oil properties on the friction behaviour of lithium greases in rolling/sliding concentrated contacts. Tribol. Lett. 2017, 65, 128. [Google Scholar] [CrossRef] [Green Version]

- Lugt, P.M. A review on grease lubrication in rolling bearings. Tribol. Trans. 2009, 52, 470–480. [Google Scholar] [CrossRef]

- Dorgham, A.; Azam, A.; Parsaeian, P.; Wang, C.; Morina, A.; Neville, A. Nanoscale viscosity of triboreactive interfaces. Nano Energy 2021, 79, 105447. [Google Scholar] [CrossRef]

- Vyavhare, K.; Aswath, P.B. Tribological properties of novel multi-walled carbon nanotubes and phosphorus containing ionic liquid hybrids in grease. Front. Mech. Eng. 2019, 5, 15. [Google Scholar] [CrossRef]

- Kamel, B.M.; Mohamed, A.; El Sherbiny, M.; Abed, K.A. Tribological behaviour of calcium grease containing carbon nanotubes additives. Ind. Lubr. Tribol. 2016, 68, 723–728. [Google Scholar] [CrossRef]

- Dai, W.; Kheireddin, B.; Gao, H.; Liang, H. Roles of nanoparticles in oil lubrication. Tribol. Int. 2016, 102, 88–98. [Google Scholar] [CrossRef]

- Huang, Y.Y.; Terentjev, E.M. Dispersion of carbon nanotubes: Mixing, sonication, stabilization, and composite properties. Polymers 2012, 4, 275–295. [Google Scholar] [CrossRef] [Green Version]

- Xie, H.; Lee, H.; Youn, W.; Choi, M. Nanofluids containing multiwalled carbon nanotubes and their enhanced thermal conductivities. J. Appl. Phys. 2003, 94, 4967–4971. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Marian, M.; Profito, F.J.; Aragon, N.; Shah, R. The use of artificial intelligence in tribology—A perspective. Lubricants 2021, 9, 2. [Google Scholar] [CrossRef]

- Marian, M.; Tremmel, S. Current Trends and Applications of Machine Learning in Tribology—A Review. Lubricants 2021, 9, 86. [Google Scholar] [CrossRef]

- Modarres, M.H.; Aversa, R.; Cozzini, S.; Ciancio, R.; Leto, A.; Brandino, G.P. Neural network for nanoscience scanning electron microscope image recognition. Sci. Rep. 2017, 7, 13282. [Google Scholar] [CrossRef] [Green Version]

- Chauveau, V. Le Pouvoir Lubrifiant des Nanotubes de Carbone. Ph.D. Thesis, Ecole Centrale de Lyon, Lyon, France, 2010. [Google Scholar]

- Gouadec, G.; Colomban, P. Raman Spectroscopy of nanomaterials: How spectra relate to disorder, particle size and mechanical properties. Prog. Cryst. Growth Charact. Mater. 2007, 53, 1–56. [Google Scholar] [CrossRef] [Green Version]

- Pitt, G. Engineering aspects and applications of the new Raman instrumentation. IEE Proc. Sci. Meas. Technol. 2005, 152, 241–318. [Google Scholar] [CrossRef]

- Dieing, T.; Hollricher, O.; Toporski, J. Confocal Raman Microscopy; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef] [Green Version]

- Cançado, L.G.; Takai, K.; Enoki, T.; Endo, M.; Kim, Y.A.; Mizusaki, H.; Jorio, A.; Coelho, L.N.; Magalhães-Paniago, R.; Pimenta, M.A. General equation for the determination of the crystallite size La of nanographite by Raman spectroscopy. Appl. Phys. Lett. 2006, 88, 163106. [Google Scholar] [CrossRef]

- Uflyand, I.E.; Zhinzhilo, V.A.; Burlakova, V.E. Metal-containing nanomaterials as lubricant additives: State-of-the-art and future development. Friction 2019, 7, 93–116. [Google Scholar] [CrossRef] [Green Version]

- Peigney, A.; Laurent, C.; Flahaut, E.; Bacsa, R.; Rousset, A. Specific surface area of carbon nanotubes and bundles of carbon nanotubes. Carbon 2001, 39, 507–514. [Google Scholar] [CrossRef] [Green Version]

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2015, arXiv:1409.1556. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. arXiv 2015, arXiv:1512.03385. [Google Scholar]

- Szegedy, C.; Liu, W.; Jia, Y.; Sermanet, P.; Reed, S.; Anguelov, D.; Erhan, D.; Vanhoucke, V.; Rabinovich, A. Going deeper with convolutions. arXiv 2014, arXiv:1409.4842. [Google Scholar]

- Zhou, X.; Li, W.; Arundel, S.T.; Liu, J. Deep convolutional neural networks for map-type classification. arXiv 2018, arXiv:1805.10402. [Google Scholar]

- Minelli, E.; Ciasca, G.; Sassun, T.E.; Antonelli, M.; Palmieri, V.; Papi, M.; Maulucci, G.; Santoro, A.; Giangaspero, F.; Delfini, R.; et al. A fully-automated neural network analysis of AFM force-distance curves for cancer tissue diagnosis. Appl. Phys. Lett. 2017, 111, 143701. [Google Scholar] [CrossRef] [Green Version]

- Ede, J.M.; Beanland, R. Partial scanning transmission electron microscopy with deep learning. Sci. Rep. 2020, 10, 8332. [Google Scholar] [CrossRef]

- Fukuhara, M.; Fujiwara, K.; Maruyama, Y.; Itoh, H. Feature visualization of Raman spectrum analysis with deep convolutional neural network. Anal. Chim. Acta 2019, 1087, 11–19. [Google Scholar] [CrossRef]

- Moawad, A.A.; Silge, A.; Bocklitz, T.; Fischer, K.; Rösch, P.; Roesler, U.; Elschner, M.C.; Popp, J.; Neubauer, H. A machine learning-based Raman spectroscopic assay for the identification of Burkholderia mallei and related species. Molecules 2019, 24, 4516. [Google Scholar] [CrossRef] [Green Version]

- Mandrell, C.T.; Holland, T.E.; Wheeler, J.F.; Esmaeili, S.M.A.; Amar, K.; Chowdhury, F.; Sivakumar, P. Machine learning approach to Raman spectrum analysis of MIA PaCa-2 pancreatic cancer tumor repopulating cells for classification and feature analysis. Life 2020, 10, 181. [Google Scholar] [CrossRef]

- Liu, J.; Osadchy, M.; Ashton, L.; Foster, M.; Solomon, C.J.; Gibson, S.J. Deep convolutional neural networks for Raman spectrum recognition: A unified solution. Analyst 2017, 142, 4067–4074. [Google Scholar] [CrossRef] [Green Version]

- Dai, W.; Dai, C.; Qu, S.; Li, J.; Das, S. Very deep convolutional neural networks for raw waveforms. In Proceedings of the 2017 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), New Orleans, LA, USA, 5–9 March 2017; pp. 421–425. [Google Scholar] [CrossRef] [Green Version]

- Wolpert, D.H. Stacked generalization. Neural Netw. 1992, 5, 241–259. [Google Scholar] [CrossRef]

- Zhou, Z.H.; Wu, J.; Tang, W. Ensembling neural networks: Many could be better than all. Artif. Intell. 2002, 137, 239–263. [Google Scholar] [CrossRef] [Green Version]

- Chen, T.; Guestrin, C. XGBoost: A scalable tree boosting system. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining. Association for Computing Machinery, 2016, KDD ’16, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar] [CrossRef] [Green Version]

| Color | CNT Sample | Manufacturer | Label | Diameter * [nm] | Length * [m] | BET [m/g] |

|---|---|---|---|---|---|---|

| A | Nanocyl, Sambreville, Belgium | NC 7000 | 9.5 | 1.5 | 300 | |

| B | Nanocyl, Sambreville, Belgium | NC 7000 purified (Al2O3) batch 1 | 9.5 | 1.5 | 295 | |

| C | Nanocyl, Sambreville, Belgium | NC 7000 purified (Al2O3) batch 2 | 9.5 | 1.5 | 213 | |

| D | Cheap Tubes Inc., Grafton, VT, USA | MWCNT > 95% | <8 | 0.5…2.0 | 273 | |

| E | Cheap Tubes Inc., Grafton, VT, USA | MWCNT > 95% | <8 | 10…30 | 261 | |

| F | Cheap Tubes Inc., Grafton, VT, USA | MWCNT > 95% | >50 | 0.5…2.0 | 110 | |

| G | Cheap Tubes Inc., Grafton, VT, USA | MWCNT > 95% | >50 | 10…20 | 84 | |

| H | NanoLab, Waltham, MA, USA | PD15 L1-3 | 15 | 1…3 | 231 | |

| I | NanoLab, Waltham, MA, USA | PD15 L5-20 | 15 | 5…20 | 220 | |

| J | Cheap Tubes Inc., Grafton, VT, USA | SWCNT/DWCNT 60% | 1–4 | 5…30 | 340 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kałużny, J.; Świetlicka, A.; Wojciechowski, Ł.; Boncel, S.; Kinal, G.; Runka, T.; Nowicki, M.; Stepanenko, O.; Gapiński, B.; Leśniewicz, J.; et al. Machine Learning Approach for Application-Tailored Nanolubricants’ Design. Nanomaterials 2022, 12, 1765. https://doi.org/10.3390/nano12101765

Kałużny J, Świetlicka A, Wojciechowski Ł, Boncel S, Kinal G, Runka T, Nowicki M, Stepanenko O, Gapiński B, Leśniewicz J, et al. Machine Learning Approach for Application-Tailored Nanolubricants’ Design. Nanomaterials. 2022; 12(10):1765. https://doi.org/10.3390/nano12101765

Chicago/Turabian StyleKałużny, Jarosław, Aleksandra Świetlicka, Łukasz Wojciechowski, Sławomir Boncel, Grzegorz Kinal, Tomasz Runka, Marek Nowicki, Oleksandr Stepanenko, Bartosz Gapiński, Joanna Leśniewicz, and et al. 2022. "Machine Learning Approach for Application-Tailored Nanolubricants’ Design" Nanomaterials 12, no. 10: 1765. https://doi.org/10.3390/nano12101765

APA StyleKałużny, J., Świetlicka, A., Wojciechowski, Ł., Boncel, S., Kinal, G., Runka, T., Nowicki, M., Stepanenko, O., Gapiński, B., Leśniewicz, J., Błaszkiewicz, P., & Kempa, K. (2022). Machine Learning Approach for Application-Tailored Nanolubricants’ Design. Nanomaterials, 12(10), 1765. https://doi.org/10.3390/nano12101765