Study of the Reinforcement Effect in (0.5–x)TeO2–0.2WO3–0.1Bi2O3–0.1MoO3–0.1SiO2–xCNDs Glasses Doped with Carbon Nanodiamonds

Abstract

1. Introduction

2. Experimental Section

3. Results and Discussion

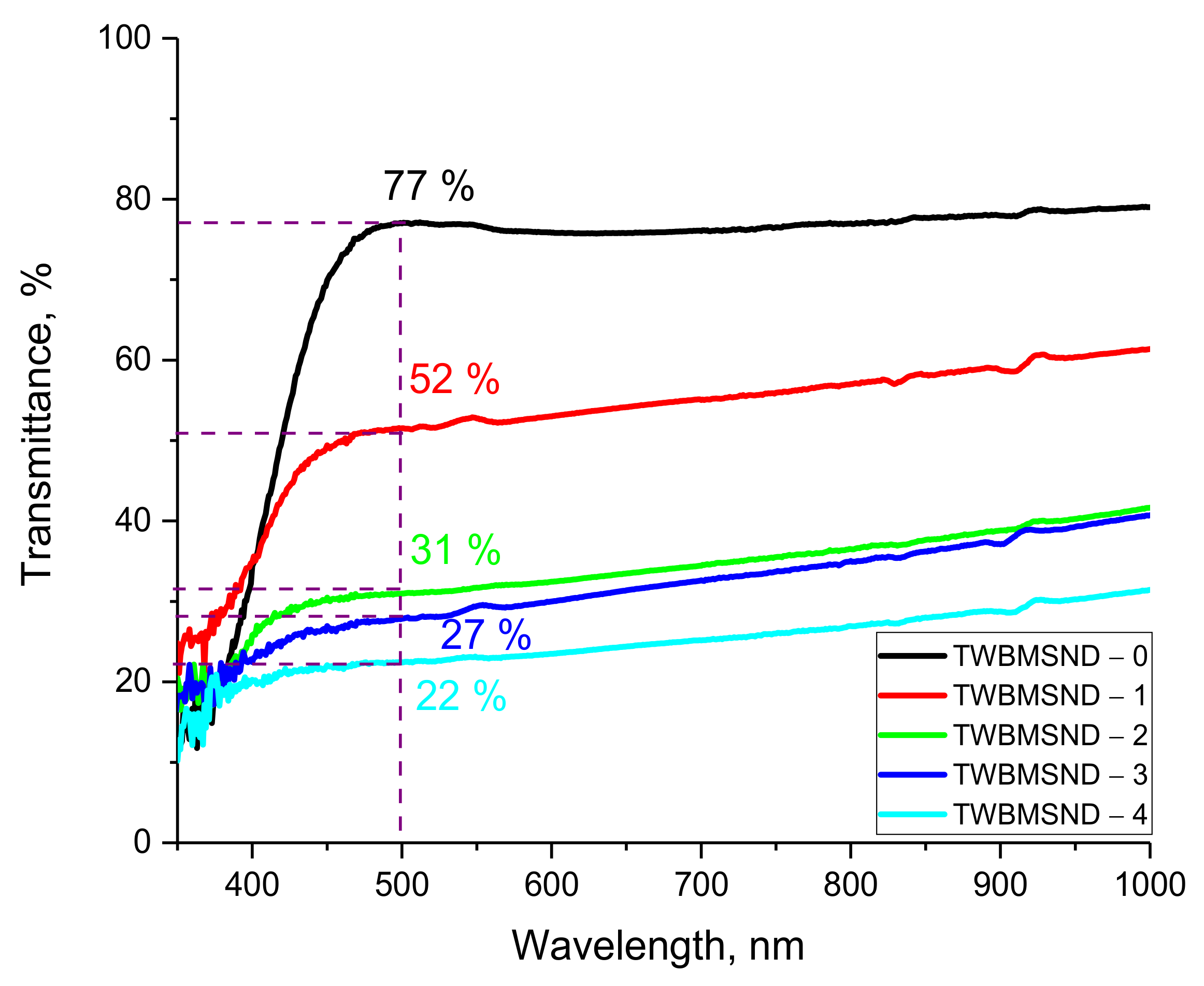

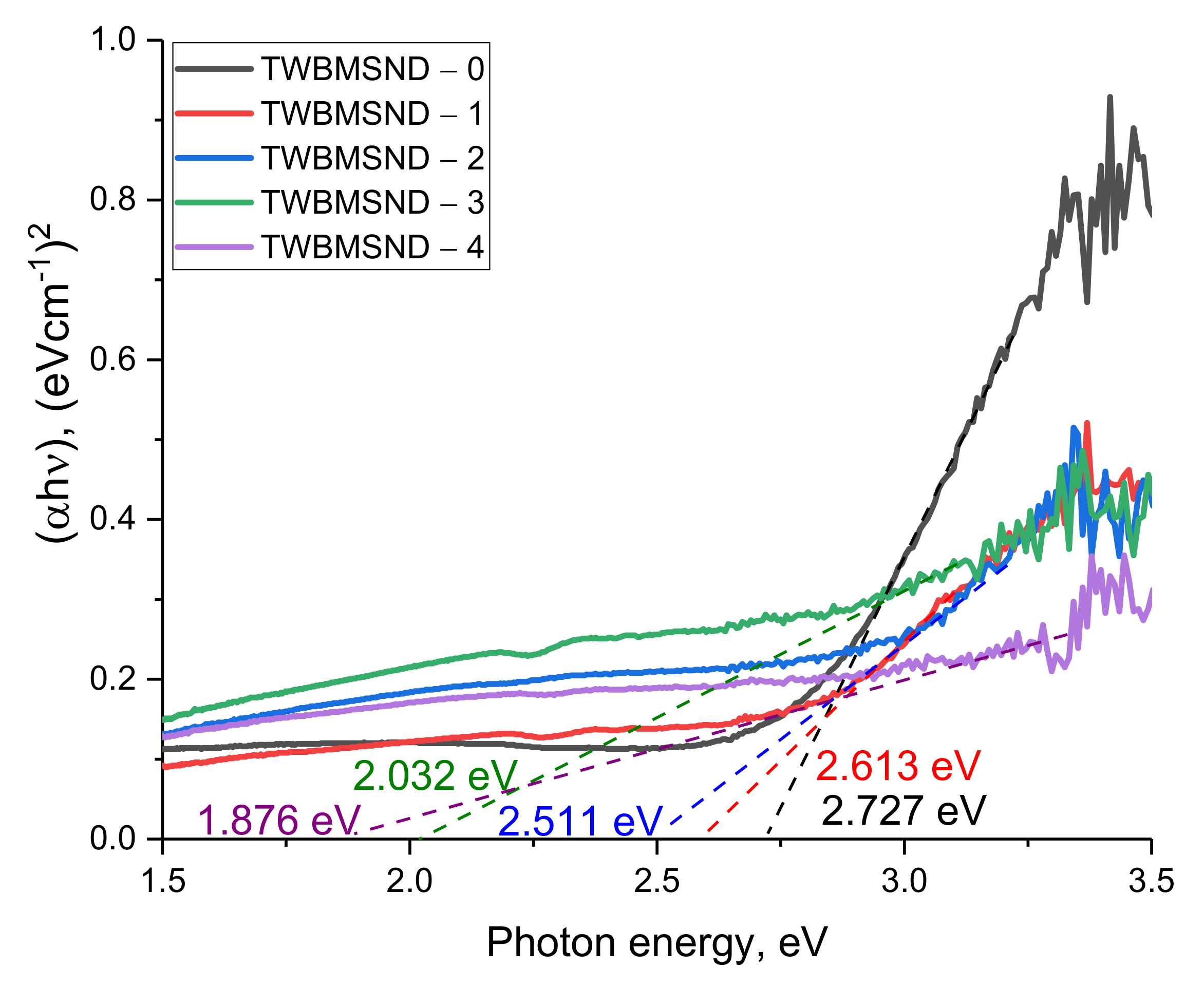

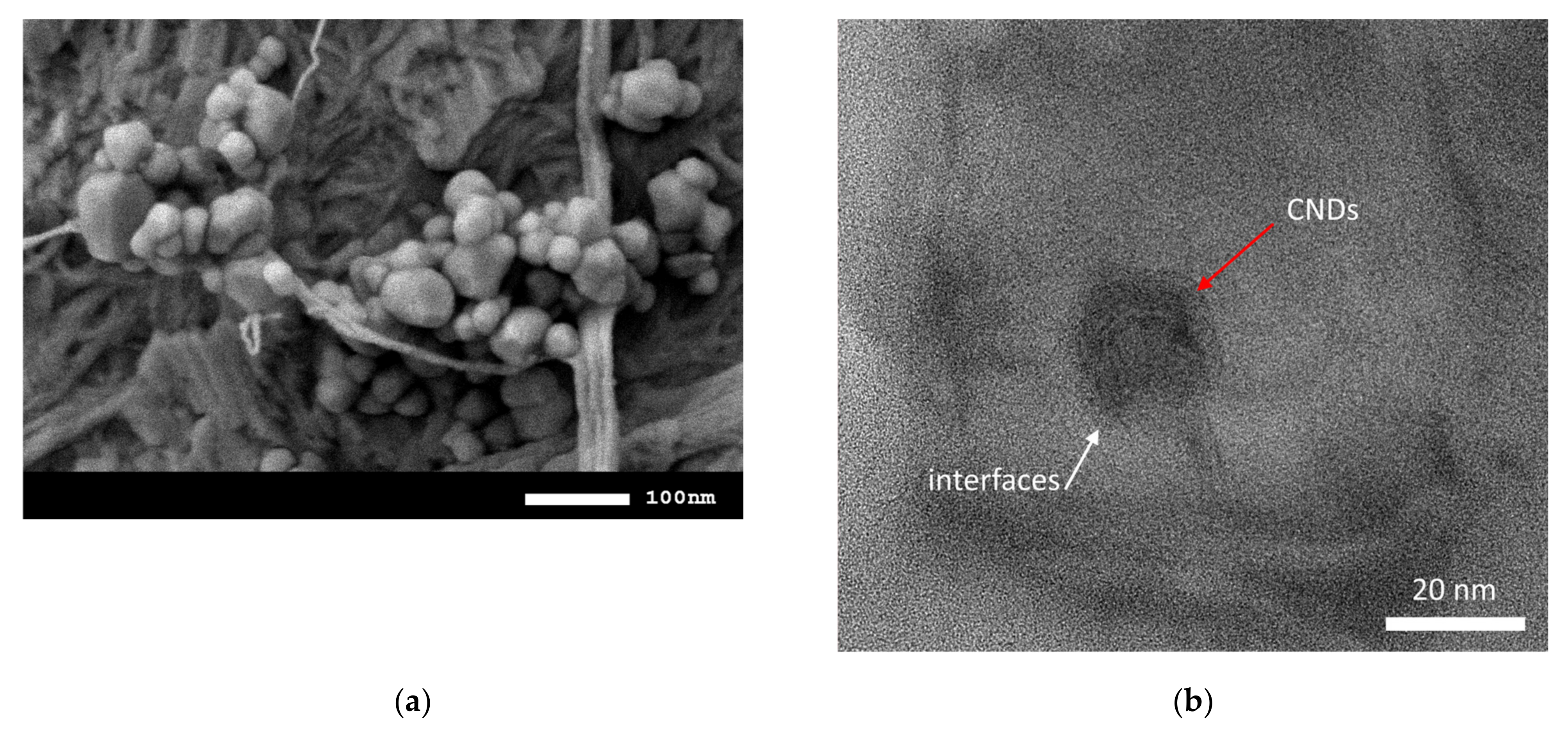

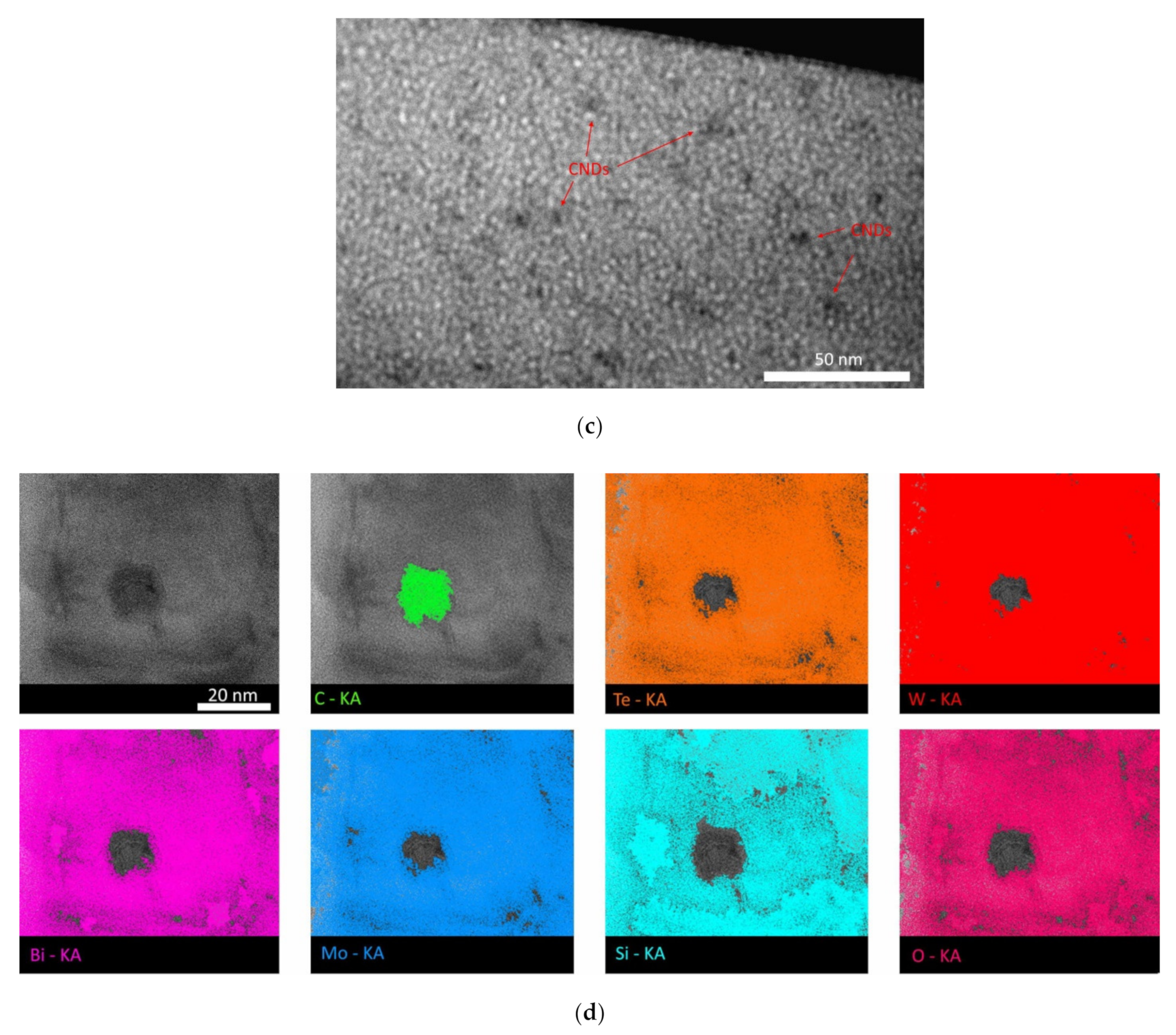

3.1. Study of the Structural and Optical Properties of Synthesized Glasses

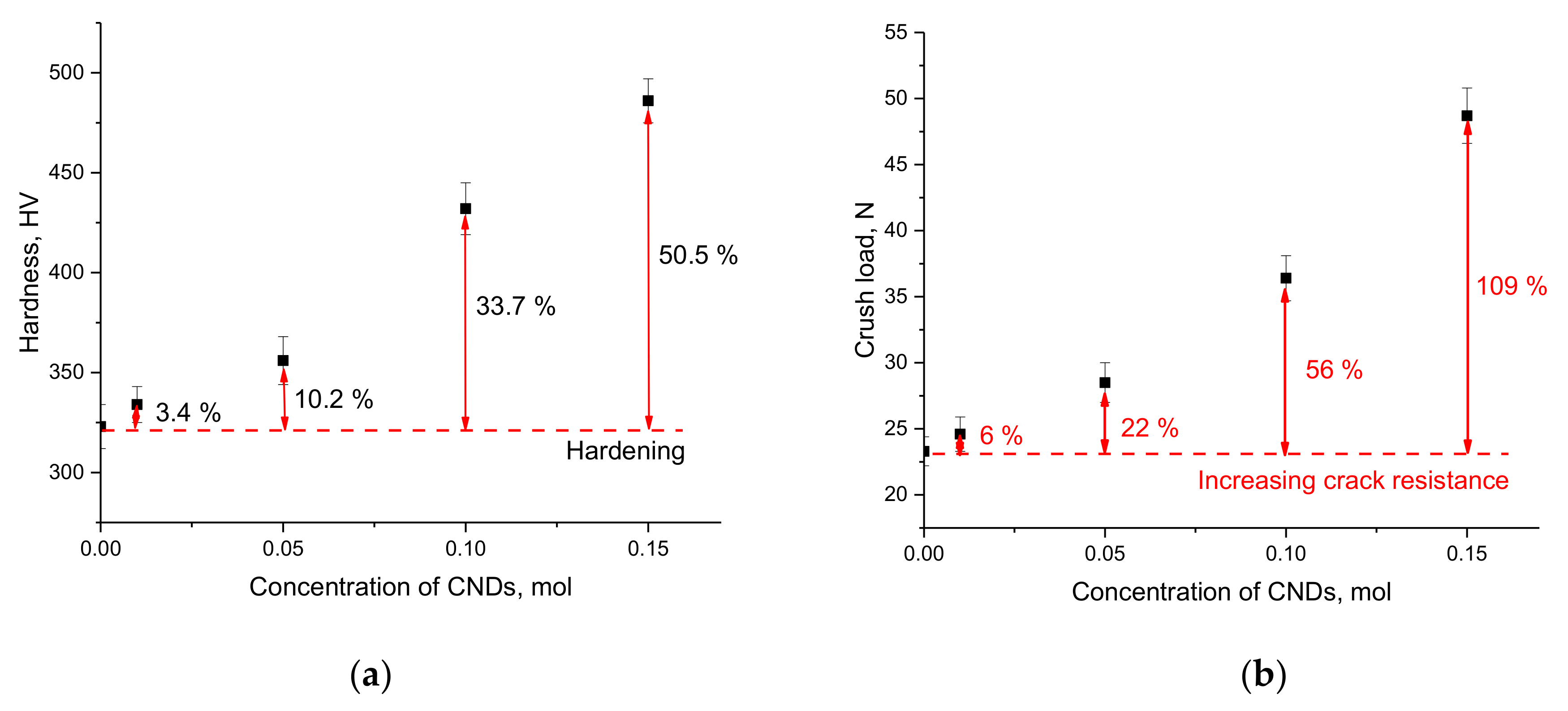

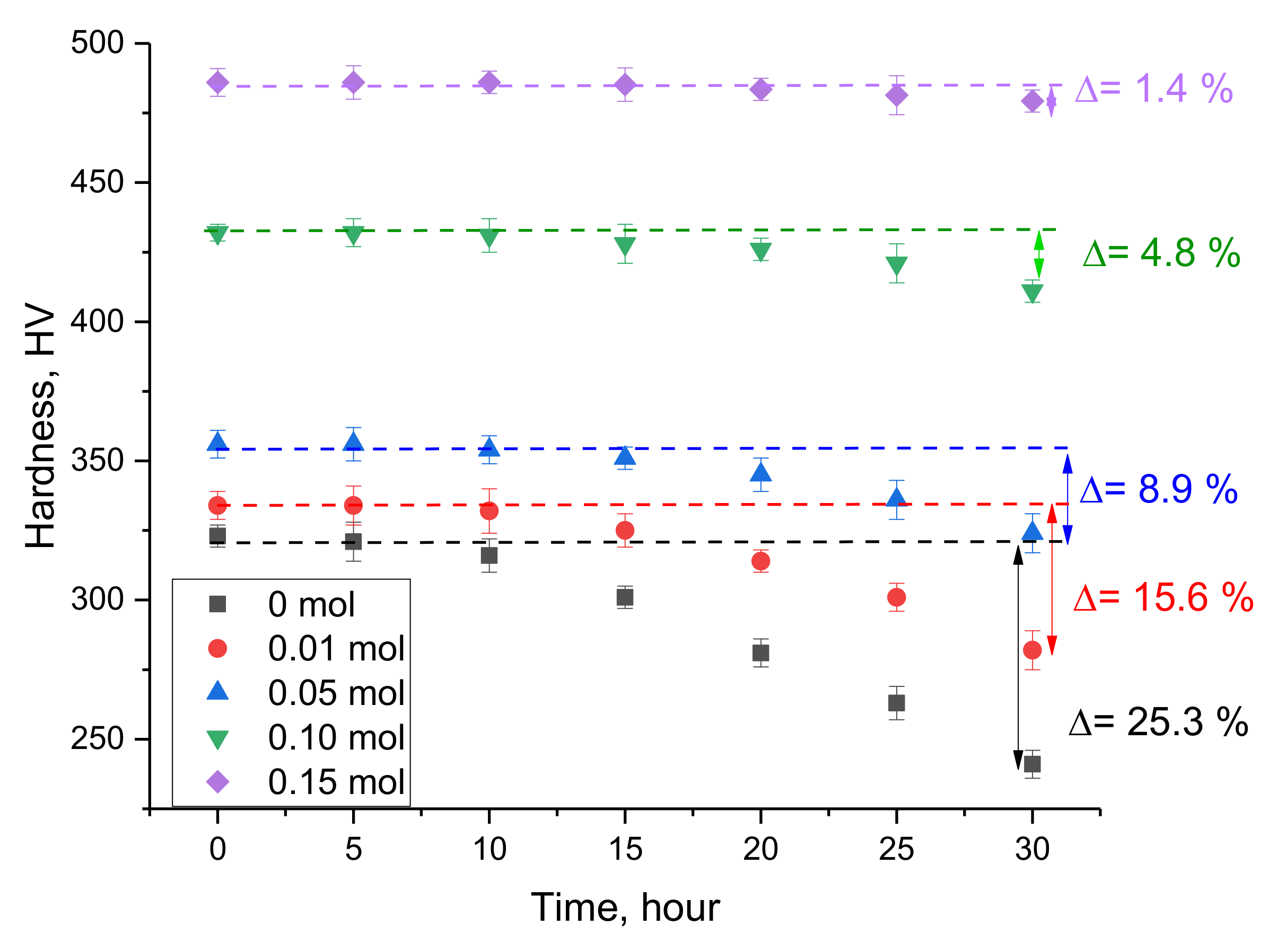

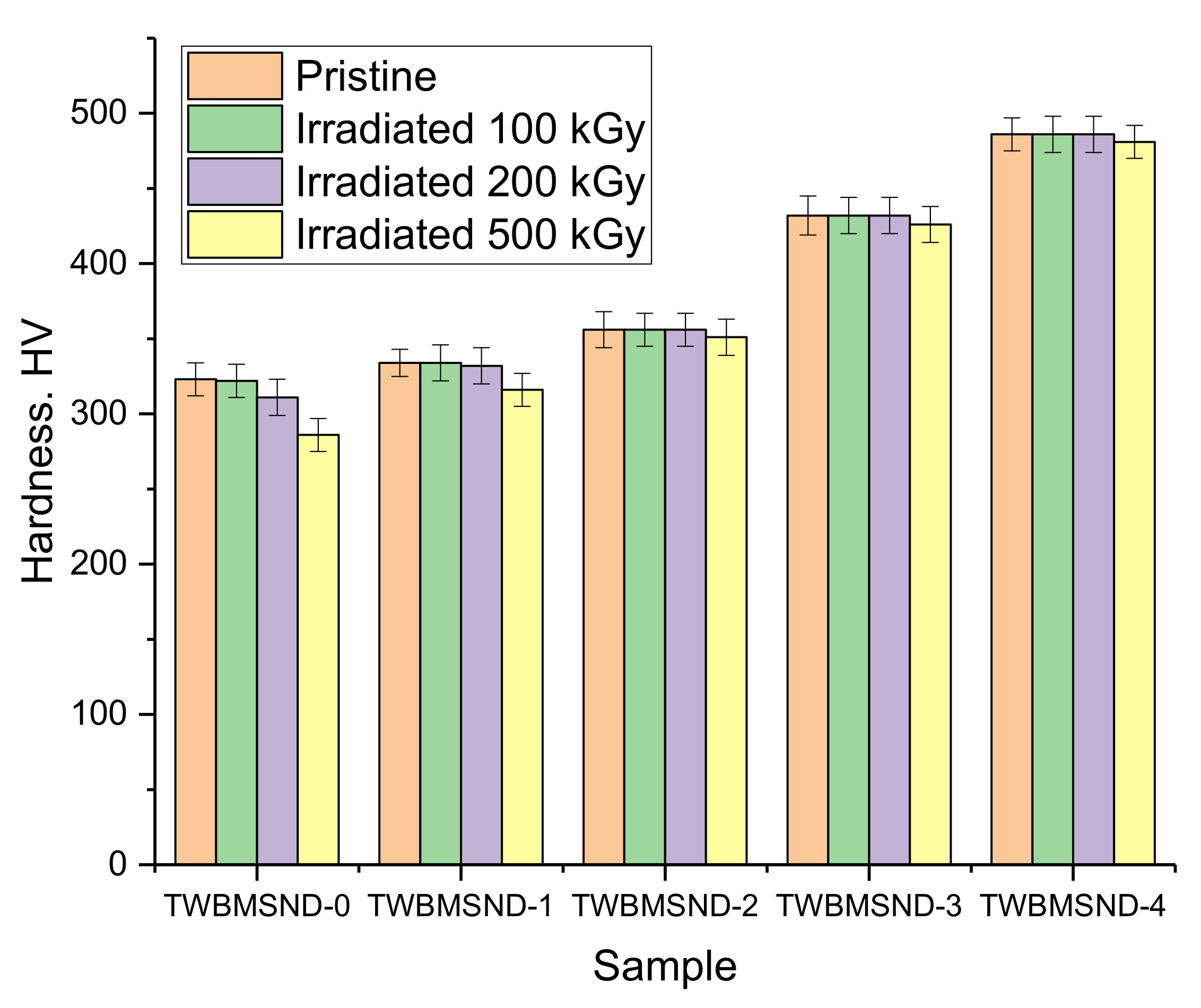

3.2. Study of the Strength Properties of Glasses and Their Resistance to External Influences, including Radiation Resistance to Irradiation with Gamma Rays

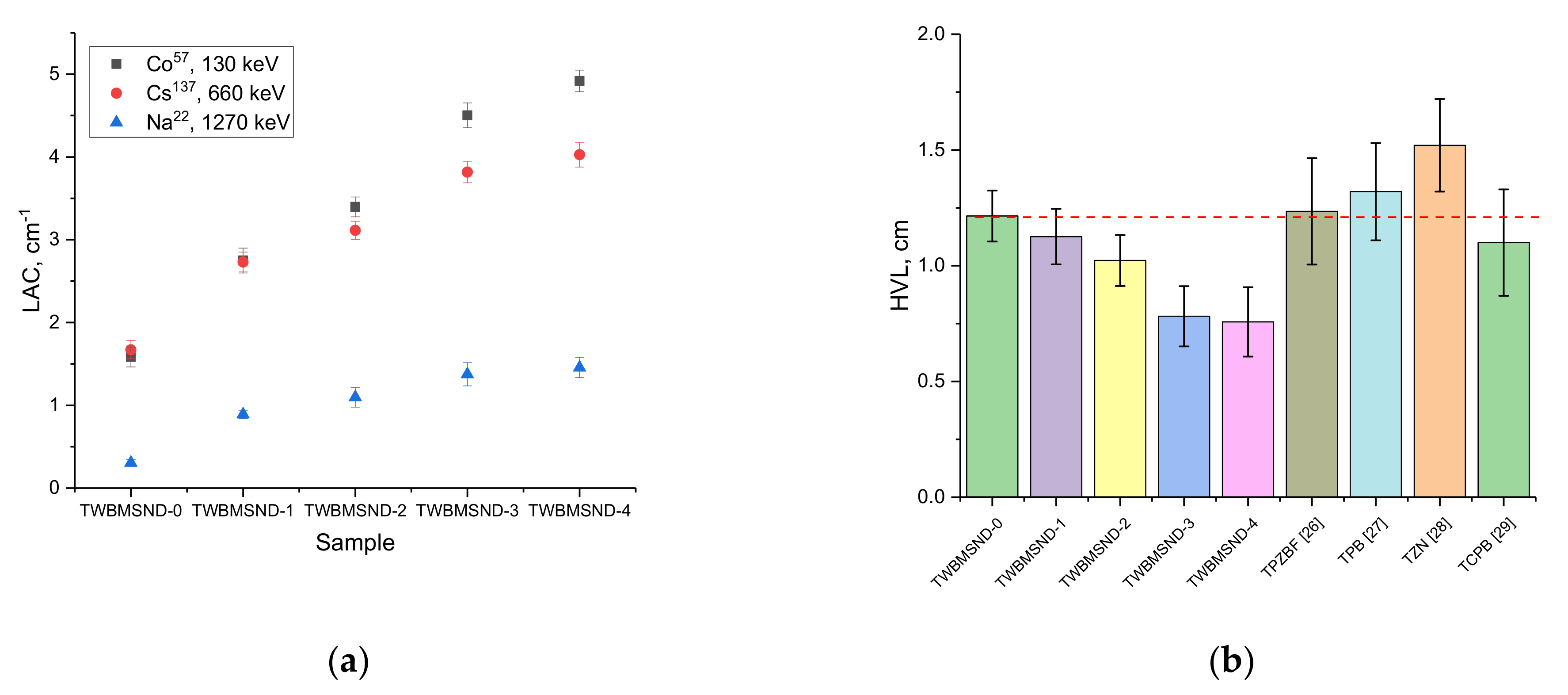

3.3. Study of the Gamma Radiation Shielding Efficiency of Synthesized Glasses Depending on the CND Dopant Concentration

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Glyva, V.; Natalia, K.; Nazarenko, V.; Burdeina, N.; Karaieva, N.; Levchenko, L.; Khodakovskyy, O. Development and study of protective properties of the composite materials for shielding the electromagnetic fields of a wide frequency range. East.-Eur. J. Enterp. Technol. 2020, 2, 104. [Google Scholar] [CrossRef]

- Elsafi, M.; El-Nahal, M.A.; Alrashedi, M.F.; Olarinoye, O.I.; Sayyed, M.I.; Khandaker, M.U.; Abbas, M.I. Shielding properties of some marble types: A comprehensive study of experimental and XCOM results. Materials 2021, 14, 4194. [Google Scholar] [CrossRef]

- Brzeziński, S.; Rybicki, T.; Karbownik, I.; Malinowska, G.; Śledzińska, K. Textile materials for electromagnetic field shielding made with the use of nano-and micro-technology. Open Phys. 2012, 10, 1190–1196. [Google Scholar] [CrossRef]

- Ciesielska-Wróbel, I.; Grabowska, K. Estimation of the EMR shielding effectiveness of knit structures. Fibres Text. East. Eur. 2012, 20, 53–60. [Google Scholar]

- Jia, Z.; Zhang, M.; Liu, B.; Wang, F.; Wei, G.; Su, Z. Graphene foams for electromagnetic interference shielding: A review. ACS Appl. Nano Mater. 2020, 3, 6140–6155. [Google Scholar] [CrossRef]

- Blachowicz, T.; Ehrmann, A. Shielding of Cosmic Radiation by Fibrous Materials. Fibers 2021, 9, 60. [Google Scholar] [CrossRef]

- Spillantini, P.; Casolino, M.; Durante, M.; Mueller-Mellin, R.; Reitz, G.; Rossi, L.; Sorbi, M. Shielding from cosmic radiation for interplanetary missions: Active and passive methods. Radiat. Meas. 2007, 42, 14–23. [Google Scholar] [CrossRef]

- Borggräfe, A.; Quatmann, M.; Nölke, D. Radiation protective structures on the base of a case study for a manned Mars mission. Acta Astronaut. 2009, 65, 1292–1305. [Google Scholar] [CrossRef]

- Mahltig, B.; Leisegang, T.; Jakubik, M.; Haufe, H. Hybrid sol-gel materials for realization of radiation protective coatings—A review with emphasis on UV protective materials. J. Sol-Gel Sci. Technol. 2021, 1, 1–12. [Google Scholar] [CrossRef]

- Di Trolio, R.; Di Lorenzo, G.; Fumo, B.; Ascierto, P.A. Cosmic radiation and cancer: Is there a link? Future Oncol. 2015, 11, 1123–1135. [Google Scholar] [CrossRef]

- Thibeault, S.A.; Kang, J.H.; Sauti, G.; Park, C.; Fay, C.C.; King, G.C. Nanomaterials for radiation shielding. Mrs Bull. 2015, 40, 836–841. [Google Scholar] [CrossRef]

- Lochard, J.; Bartlett, D.T.; Rühm, W.; Yasuda, H.; Bottollier-Depois, J.F. ICRP publication 132: Radiological protection from cosmic radiation in aviation. Ann. ICRP 2016, 45, 5–48. [Google Scholar] [CrossRef]

- Zhong, W.H.; Sui, G.; Jana, S.; Miller, J. Cosmic radiation shielding tests for UHMWPE fiber/nano-epoxy composites. Compos. Sci. Technol. 2009, 69, 2093–2097. [Google Scholar] [CrossRef]

- Al-Hadeethi, Y.; Sayyed, M.I. BaO—Li2O—B2O3 glass systems: Potential utilization in gamma radiation protection. Prog. Nucl. Energy 2020, 129, 103511. [Google Scholar] [CrossRef]

- Al-Buriahi, M.S.; Tamam, N.; Somaily, H.H.; Alrowaili, Z.A.; Saleh, H.H.; Olarinoye, I.O.; Tonguc, B.T. Estimation of radiation protection ability of borate glass system doped with CdO, PbO, and TeO2. Radiat. Phys. Chem. 2022, 193, 109996. [Google Scholar] [CrossRef]

- Mostafa, A.M.A.; Zakaly, H.M.; Al-Ghamdi, S.A.; Issa, S.A.; Al-Zaibani, M.; Ramadan, R.M.; El Agammy, E.F. PbO—Sb2O3—B2O3—CuO glassy system: Evaluation of optical, gamma and neutron shielding properties. Mater. Chem. Phys. 2021, 258, 123937. [Google Scholar] [CrossRef]

- Zadehrafi, M.; Olaru, C.; Ciobanu, S.A.; Ormenisan, G.V. Characteristics of lead glass for radiation protection purposes: A Monte Carlo study. Int. J. Radiat. Res. 2020, 18, 907–912. [Google Scholar]

- Kamislioglu, M. Research on the effects of bismuth borate glass system on nuclear radiation shielding parameters. Results Phys. 2021, 22, 103844. [Google Scholar] [CrossRef]

- Chen, Q.; Naseer, K.A.; Marimuthu, K.; Kumar, P.S.; Miao, B.; Mahmoud, K.A.; Sayyed, M.I. Influence of modifier oxide on the structural and radiation shielding features of Sm3+-doped calcium telluro-fluoroborate glass systems. J. Aust. Ceram. Soc. 2021, 57, 275–286. [Google Scholar] [CrossRef]

- Alothman, M.A.; Olarinoye, I.O.; Sriwunkum, C.; Alomairy, S.; Alzahrani, J.S.; Al-Buriahi, M.S. Study of the radiation attenuation properties of MgO—Al2O3—SiO2—Li2O—Na2O glass system. J. Aust. Ceram. Soc. 2022, 58, 267–273. [Google Scholar] [CrossRef]

- Woo, D.J.; Heer, F.C.; Brewer, L.N.; Hooper, J.P.; Osswald, S. Synthesis of nanodiamond-reinforced aluminum metal matrix composites using cold-spray deposition. Carbon 2015, 86, 15–25. [Google Scholar] [CrossRef]

- Davidov, S.V.; Gorlenko, A.O. Friction surface modification by nanodiamonds of denotational synthesis. IOP Conf. Ser. Mater. Sci. Eng. 2016, 124, 012122. [Google Scholar] [CrossRef]

- Zakaly, H.M.; Abouhaswa, A.S.; Issa, S.A.; Mostafa, M.Y.; Pyshkina, M.; El-Mallawany, R. Optical and nuclear radiation shielding properties of zinc borate glasses doped with lanthanum oxide. J. Non-Cryst. Solids 2020, 543, 120151. [Google Scholar] [CrossRef]

- Abouhaswa, A.S.; Zakaly, H.M.; Issa, S.A.; Pyshkina, M.; El-Mallawany, R.; Mostafa, M.Y. Lead borate glasses and synergistic impact of lanthanum oxide additive: Optical and nuclear radiation shielding behaviors. J. Mater. Sci. Mater. Electron. 2020, 31, 14494–14501. [Google Scholar] [CrossRef]

- Elazaka, A.I.; Zakaly, H.M.; Issa, S.A.; Rashad, M.; Tekin, H.O.; Saudi, H.A.; Mostafa, A.G. New approach to removal of hazardous Bypass Cement Dust (BCD) from the environment: 20Na2O-20BaCl2-(60-x) B2O3-(x) BCD glass system and Optical, mechanical, structural and nuclear radiation shielding competences. J. Hazard. Mater. 2021, 403, 123738. [Google Scholar] [CrossRef] [PubMed]

- Saddeek, Y.B.; Issa, S.A.; Alharbi, T.; Elsaman, R.; Mostafa, A.M.A.; Aly, K.; Ahmad, M. Synthesis and characterization of lead borate glasses comprising cement kiln dust and Bi2O3 for radiation shielding protection. Mater. Chem. Phys. 2020, 242, 122510. [Google Scholar] [CrossRef]

- Mostafa, A.M.A.; Issa, S.A.; Zakaly, H.M.; Zaid, M.H.M.; Tekin, H.O.; Matori, K.A.; Elsaman, R. The influence of heavy elements on the ionizing radiation shielding efficiency and elastic properties of some tellurite glasses: Theoretical investigation. Results Phys. 2020, 19, 103496. [Google Scholar] [CrossRef]

- Kilic, G.; Ilik, E.; Issa, S.A.M.; Issa, B.; Al-Buriahi, M.S.; Issever, U.G.; Zakaly, H.M.H.; Tekin, H.O. Ytterbium (III) oxide reinforced novel TeO2–B2O3–V2O5 glass system: Synthesis and optical, structural, physical and thermal properties. Ceram. Int. 2021, 47, 18517–18531. [Google Scholar] [CrossRef]

- Saudi, H.A.; Tekin, H.O.; Zakaly, H.M.; Issa, S.A.; Susoy, G.; Zhukovsky, M. The impact of samarium (III) oxide on structural, optical and radiation shielding properties of thallium-borate glasses: Experimental and numerical investigation. Opt. Mater. 2021, 114, 110948. [Google Scholar] [CrossRef]

- Tekin, H.O.; Issa, S.A.; Kilic, G.; Zakaly, H.M.; Tarhan, N.; Sidek, H.A.A.; Zaid, M.H.M. A systematical characterization of TeO2–V2O5 glass system using boron (III) oxide and neodymium (III) oxide substitution: Resistance behaviors against ionizing radiation. Appl. Sci. 2021, 11, 3035. [Google Scholar] [CrossRef]

- Abou Hussein, E.M.; Maksoud, M.A.; Fahim, R.A.; Awed, A.S. Unveiling the gamma irradiation effects on linear and nonlinear optical properties of CeO2—Na2O—SrO—B2O3 glass. Opt. Mater. 2021, 114, 111007. [Google Scholar] [CrossRef]

- Abdel Maksoud, M.I.A.; Abou Hussein, E.M.; Kassem, S.M.; Fahim, R.A.; Awed, A.S. Effect of CeO2 addition on structural, optical, and radiation shielding properties of B2O3–Na2O–SrO glass system. J. Mater. Sci. Mater. Electron. 2021, 32, 18931–18950. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, S.; Zhao, P.; Liu, T.; Sun, J. Titanium/nanodiamond nanocomposites: Effect of nanodiamond on microstructure and mechanical properties of titanium. Mater. Des. 2017, 131, 144–155. [Google Scholar] [CrossRef]

- Yin, S.; Wang, H.; Li, A.; Ma, Z.; He, Y. Study on Radiation Shielding Properties of New Barium-Doped Zinc Tellurite Glass. Materials 2022, 15, 2117. [Google Scholar] [CrossRef]

- Yin, S.; Wang, H.; Wang, S.; Zhang, J.; Zhu, Y. Effect of B2O3 on the Radiation Shielding Performance of Telluride Lead Glass System. Crystals 2022, 12, 178. [Google Scholar] [CrossRef]

- Al-Buriahi, M.; Alrowaili, Z.; Eke, C.; Alzahrani, J.S.; Olarinoye, I.; Sriwunkum, C. Optical and radiation shielding studies on tellurite glass system containing ZnO and Na2O. Optik 2022, 257, 168821. [Google Scholar] [CrossRef]

- Alotaibi, B.M.; Alotiby, M.; Kumar, A.; Mahmoud, K.A.; Sayyed, M.I.; Al-Yousef, H.A.; Al-Hadeethi, Y. Gamma-ray shielding, physical, and structural characteristics of TeO2—CdO—PbO—B2O3 glasses. Opt. Mater. 2021, 119, 111333. [Google Scholar] [CrossRef]

| Sample | Concentration, mol | |||||

|---|---|---|---|---|---|---|

| TeO2 | WO3 | Bi2O3 | MoO3 | SiO2 | CNDs | |

| TWBMSND-0 | 0.5 | 0.2 | 0.1 | 0.1 | 0.1 | - |

| TWBMSND-1 | 0.49 | 0.2 | 0.1 | 0.1 | 0.1 | 0.01 |

| TWBMSND-2 | 0.45 | 0.2 | 0.1 | 0.1 | 0.1 | 0.05 |

| TWBMSND-3 | 0.4 | 0.2 | 0.1 | 0.1 | 0.1 | 0.10 |

| TWBMSND-4 | 0.35 | 0.2 | 0.1 | 0.1 | 0.1 | 0.15 |

| Sample | Refractive Index (noptical) | Reflection Loss (RL) | Optical Transmission (Toptical) | Static Dielectric Constants (εstatic) |

|---|---|---|---|---|

| TWBMSND-0 | 2.474 | 0.180 | 0.694 | 6.12 |

| TWBMSND-1 | 2.509 | 0.185 | 0.687 | 6.29 |

| TWBMSND-2 | 2.543 | 0.189 | 0.681 | 6.46 |

| TWBMSND-3 | 2.722 | 0.214 | 0.647 | 7.41 |

| TWBMSND-4 | 2.792 | 0.223 | 0.635 | 7.79 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozlovskiy, A.L.; Tleulessova, I.; Borgekov, D.B.; Uglov, V.V.; Anishchik, V.M.; Zdorovets, M.V.; Shlimas, D.I. Study of the Reinforcement Effect in (0.5–x)TeO2–0.2WO3–0.1Bi2O3–0.1MoO3–0.1SiO2–xCNDs Glasses Doped with Carbon Nanodiamonds. Nanomaterials 2022, 12, 3310. https://doi.org/10.3390/nano12193310

Kozlovskiy AL, Tleulessova I, Borgekov DB, Uglov VV, Anishchik VM, Zdorovets MV, Shlimas DI. Study of the Reinforcement Effect in (0.5–x)TeO2–0.2WO3–0.1Bi2O3–0.1MoO3–0.1SiO2–xCNDs Glasses Doped with Carbon Nanodiamonds. Nanomaterials. 2022; 12(19):3310. https://doi.org/10.3390/nano12193310

Chicago/Turabian StyleKozlovskiy, Artem L., Indira Tleulessova, Daryn B. Borgekov, Vladimir V. Uglov, Viktor M. Anishchik, Maxim V. Zdorovets, and Dmitriy I. Shlimas. 2022. "Study of the Reinforcement Effect in (0.5–x)TeO2–0.2WO3–0.1Bi2O3–0.1MoO3–0.1SiO2–xCNDs Glasses Doped with Carbon Nanodiamonds" Nanomaterials 12, no. 19: 3310. https://doi.org/10.3390/nano12193310

APA StyleKozlovskiy, A. L., Tleulessova, I., Borgekov, D. B., Uglov, V. V., Anishchik, V. M., Zdorovets, M. V., & Shlimas, D. I. (2022). Study of the Reinforcement Effect in (0.5–x)TeO2–0.2WO3–0.1Bi2O3–0.1MoO3–0.1SiO2–xCNDs Glasses Doped with Carbon Nanodiamonds. Nanomaterials, 12(19), 3310. https://doi.org/10.3390/nano12193310