The Positive Temperature Coefficient of Resistivity in BiFeO3 Films

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

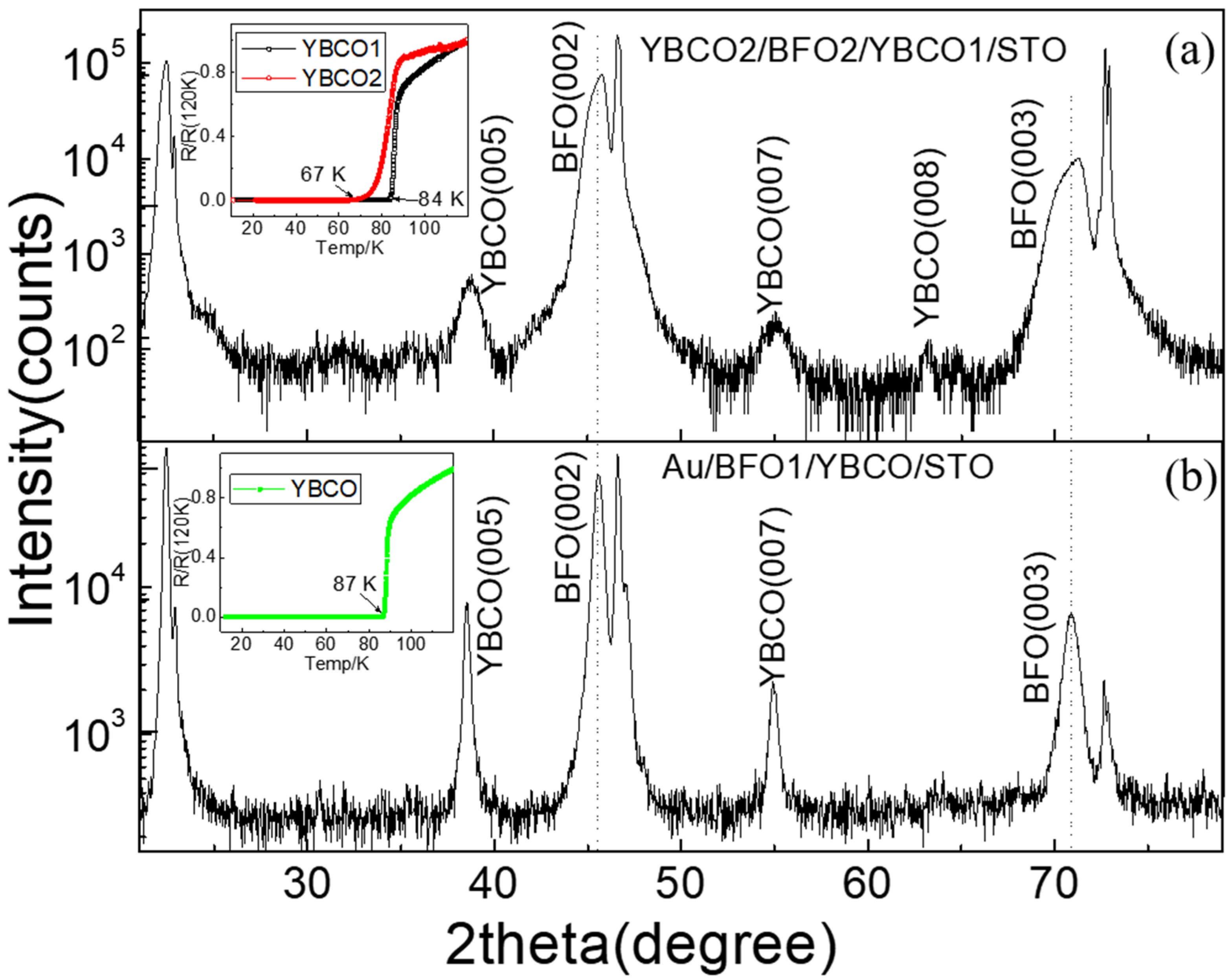

3.1. Structures in the BFO Capacitors

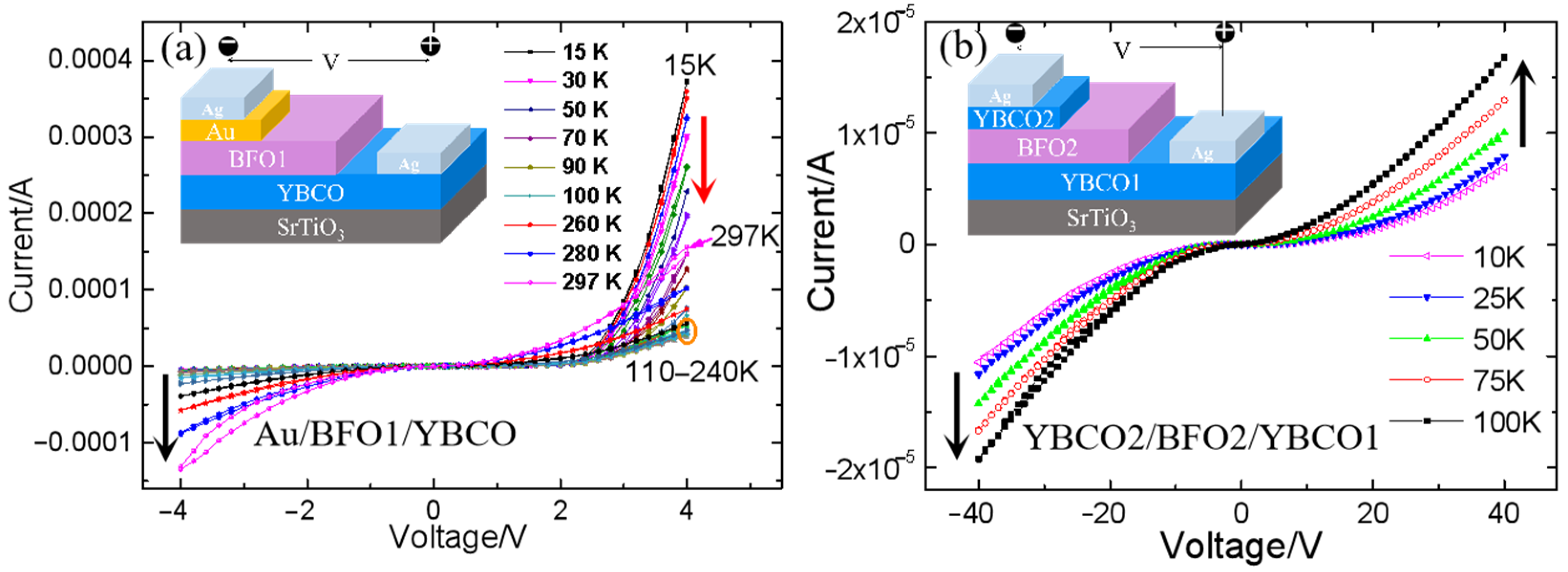

3.2. PTCR Effect

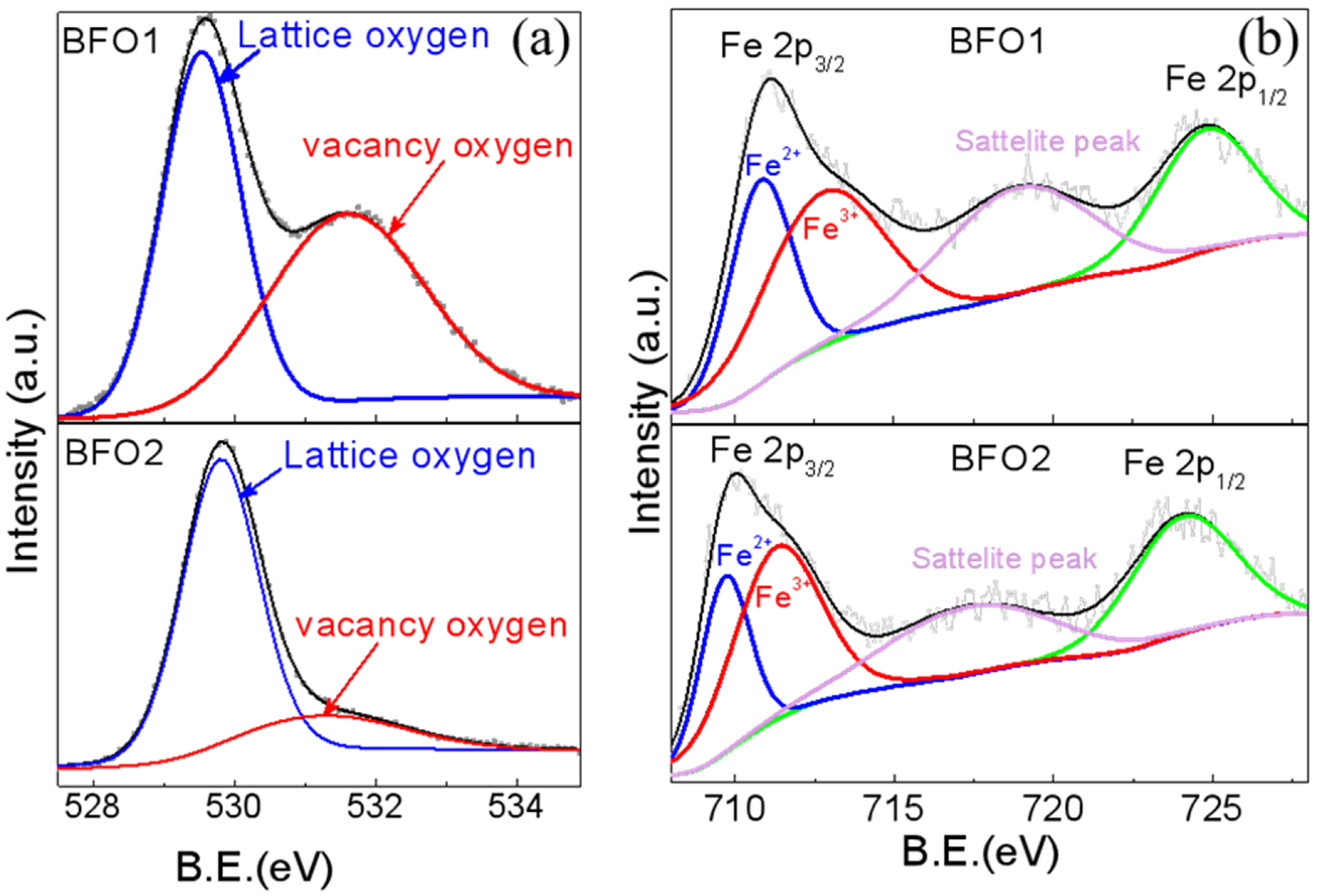

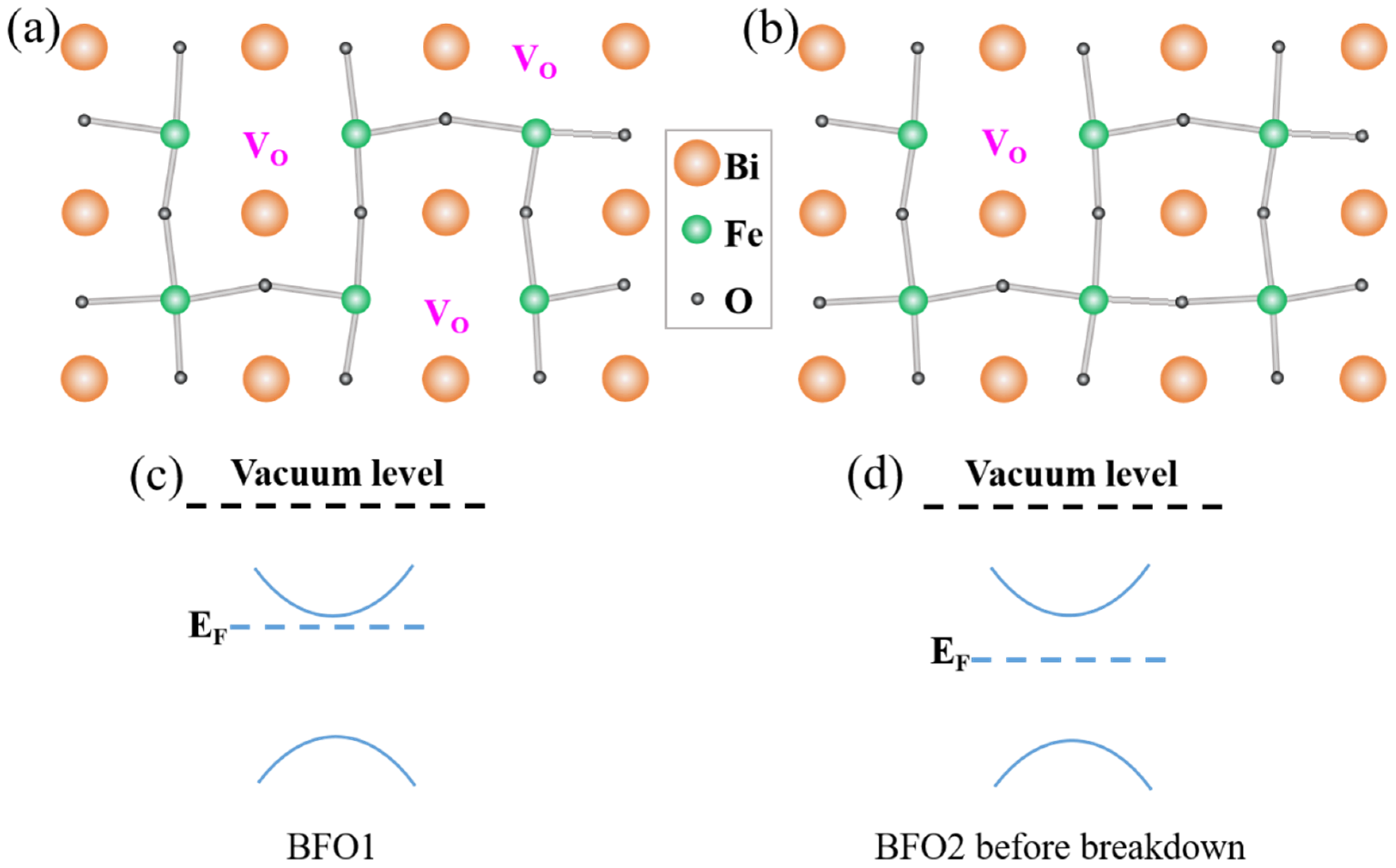

3.3. The Oxygen Vacancy Contents

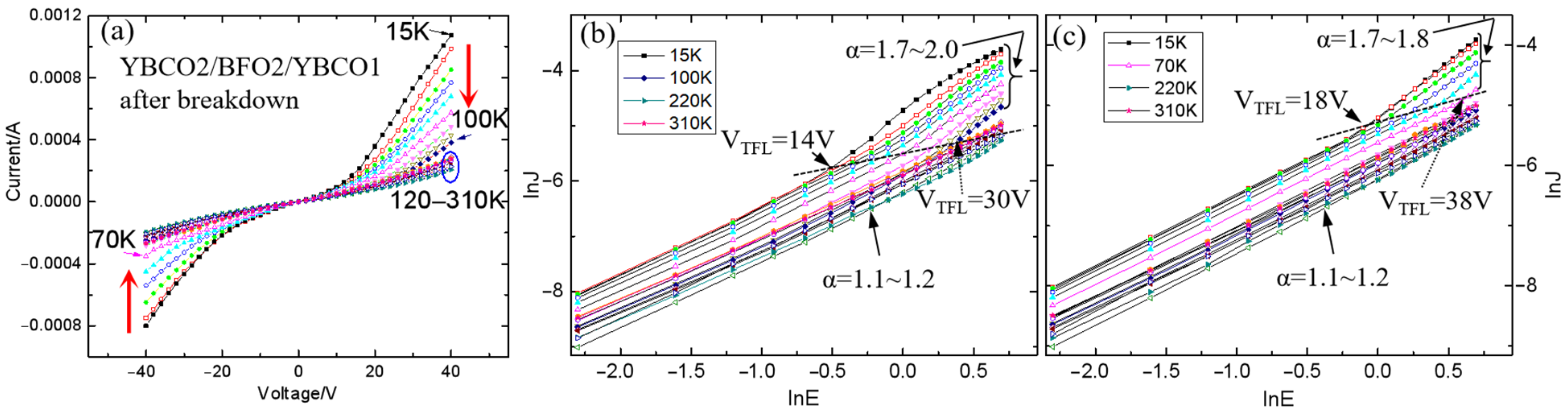

3.4. PTCR Effect in BFO/YBCO Capacitor after Breakdown

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Jiang, Q.-H.; He, H.-C.; Nan, C.-W. Multiferroic BiFeO3 thin films prepared via a simple sol-gel method. Appl. Phys. Lett. 2006, 88, 142503. [Google Scholar] [CrossRef]

- Pakalniškis, A.; Lukowiak, A.; Niaura, G.; Głuchowski, P.; Karpinsky, D.V.; Alikin, D.O.; Abramov, A.S.; Zhaludkevich, A.; Silibin, M.; Kholkin, A.L.; et al. Nanoscale ferroelectricity in pseudo-cubic sol-gel derived barium titanate–bismuth ferrite (BaTiO3–BiFeO3) solid solutions. J. Alloys Compd. 2020, 830, 154632. [Google Scholar] [CrossRef]

- Jin, C.; Zhu, Y.; Han, W.; Liu, Q.; Hu, S.; Ji, Y.; Xu, Z.; Hu, S.; Ye, M.; Chen, L. Exchange bias in flexible freestanding La0.7Sr0.3MnO3/BiFeO3 membranes. Appl. Phys. Lett. 2020, 117, 252902. [Google Scholar] [CrossRef]

- Mo, Z.; Tian, G.; Yang, W.; Ning, S.; Ross, C.A.; Gao, X.; Liu, J. Magnetoelectric coupling in self-assembled BiFeO3–CoFe2O4 nanocomposites on (110)-LaAlO3 substrates. APL Mater. 2021, 9, 041109. [Google Scholar] [CrossRef]

- Liu, F.G.; Xie, L.; Liu, W. Anomalous capacitance response induced by the superconducting gap in an Au/BiFeO3/La1.84Sr0.16CuO4/LaSrAlO4 heterostructure. Appl. Phys. Lett. 2013, 103, 153507. [Google Scholar] [CrossRef]

- Rouco, V.; Hage, R.E.; Sander, A.; Grandal, J.; Seurre, K.; Palermo, X.; Briatico, J.; Collin, S.; Trastoy, J.; Bouzehouane, K.; et al. Quasiparticle tunnel electroresistance in superconducting junctions. Nat. Commun. 2020, 11, 658. [Google Scholar] [CrossRef]

- Crassous, A.; Bernard, R.; Fusil, S.; Bouzehouane, K.; Le Bourdais, D.; Enouz-Vedrenne, S.; Briatico, J.; Bibes, M.; Barthélémy, A.; Villegas, J.E. Nanoscale Electrostatic Manipulation of Magnetic Flux Quanta in Ferroelectric/Superconductor BiFeO3/YBa2Cu3O7-delta Heterostructures. Phys. Rev. Lett. 2011, 107, 247002. [Google Scholar] [CrossRef] [Green Version]

- Sinclair, D.C.; West, A.R. Impedance and modulus spectroscopy of semiconducting BaTiO3 showing positive temperature coefficient of resistance. J. Appl. Phys. 1989, 66, 3850–3856. [Google Scholar] [CrossRef]

- Slimani, Y.; Algarou, N.A.; Almessiere, M.A.; Sadaqat, A.; Vakhitov, M.G.; Klygach, D.S.; Tishkevich, D.I.; Trukhanov, A.V.; Güner, S.; Hakeem, A.S.; et al. Fabrication of exchange coupled hard/soft magnetic nanocomposites: Correlation between composition, magnetic, optical and microwave properties. Arabian J. Chem. 2021, 14, 102992. [Google Scholar] [CrossRef]

- Mächler, D.; Schmidt, R.; Töpfer, J. Synthesis, doping and electrical bulk response of (Bi1/2Na1/2)xBa1−xTiO3+CaO–based ceramics with positive temperature coefficient of resistivity (PTCR). J. Alloys Compd. 2018, 762, 209–215. [Google Scholar] [CrossRef]

- Rowlands, W.; Vaidhyanathan, B. Additive manufacturing of barium titanate based ceramic heaters with positive temperature coefficient of resistance (PTCR). J. Eur. Ceram. Soc. 2019, 39, 3475–3483. [Google Scholar] [CrossRef]

- Pu, Y.; Zhang, L.; Keil, P.; Novak, N.; Frömling, T. Impact of mechanical stress on barium titanate-based positive temperature coefficient resistive material. J. Mater. Sci. 2018, 53, 16243–16251. [Google Scholar] [CrossRef]

- Hou, Y.l.; Zhang, P.; Xie, M.m. Thermally induced double-positive temperature coefficients of electrical resistivity in combined conductive filler–doped polymer composites. J. Appl. Polym. Sci. 2017, 134, 44876. [Google Scholar] [CrossRef]

- Zhang, P.; Hou, Y.; Wang, B. VO2-enhanced double positive temperature coefficient effects of high density polyethylene/graphite composites. Mater. Res. Express 2018, 6, 035702. [Google Scholar] [CrossRef]

- Okano, M.; Watanabe, Y.; Cheong, S.-W. Nonlinear positive temperature coefficient of resistance of BaTiO3 film. Appl. Phys. Lett. 2003, 82, 1923–1925. [Google Scholar] [CrossRef]

- Kumar, A.; Katiyar, R.S.; Scott, J. Positive temperature coefficient of resistivity and negative differential resistivity in lead iron tunstate-lead zirconate titate. Appl. Phys. Lett. 2009, 94, 212903. [Google Scholar] [CrossRef]

- Hwang, C.S.; Lee, B.T.; Cho, H.-J.; Lee, K.H.; Kang, C.S.; Hideki, H.; Lee, S.I.; Lee, M.Y. A positive temperature coefficient of resistivity effect from a paraelectric Pt/(Ba0.5, Sr0.5)TiO3/IrO2 thin-film capacitor. Appl. Phys. Lett. 1997, 71, 371–373. [Google Scholar] [CrossRef]

- Yang, H.; Chen, B.; Miao, J.; Zhao, L.; Xu, B.; Dong, X.; Cao, L.; Qiu, X.; Zhao, B. Positive temperature coefficient of resistivity in Pt/(Ba0.7Sr0.3)TiO3/YBa2Cu3O7-x capacitors. Appl. Phys. Lett. 2004, 85, 5019–5021. [Google Scholar] [CrossRef]

- Watanabe, Y. Tunneling current through a possible all-perovskite oxide p-n junction. Phys. Rev. B 1998, 57, R5563–R5566. [Google Scholar] [CrossRef]

- Vanga, P.R.; Mangalaraja, R.; Giridharan, N.; Ashok, M. PTCR behavior of BiFeO3 synthesized by the solvothermal method. Mater. Lett. 2015, 143, 230–232. [Google Scholar] [CrossRef]

- Giraldo, D.; Almodóvar, P.; López, M.L.; Rodríguez-Aguado, E.; Rodríguez-Castellón, E.; Galdámez, A.; Álvarez-Serrano, I. Exploring multiferroicity in BiFeO3-NaNbO3 thermistor electroceramics. J. Eur. Ceram. Soc. 2021, 41, 7069–7076. [Google Scholar] [CrossRef]

- Gupta, P.; Mahapatra, P.K.; Choudhary, R.N.P. Structural, dielectric, impedance, and modulus spectroscopy of BaSnO3-Modified BiFeO3. J. Phys. Chem. Solids 2020, 137, 109217. [Google Scholar] [CrossRef]

- Saad, Y.; Álvarez-Serrano, I.; López, M.L.; Hidouri, M. Dielectric response and thermistor behavior of lead-free x NaNbO3–(1-x) BiFeO3 electroceramics. Ceram. Int. 2018, 44, 18560–18570. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, H.; Dai, Q.; Nie, R.; Wang, F. The abnormal temperature-dependent rectification effect in BiFeO3/YBa2Cu3Ox heterostructures. J. Phys.: Conf. Ser. 2014, 507, 012052. [Google Scholar] [CrossRef]

- Yang, Q.; Deng, J.; Wang, G.; Deng, Q.; Zhao, J.; Dai, Y.; Duan, P.; Cui, M.; Kong, L.; Gao, H.; et al. The physical properties and microstructure of BiFeO3/YBCO heterostructures. Vacuum 2019, 167, 313–318. [Google Scholar] [CrossRef]

- Redfern, S.A.T.; Wang, C.; Hong, J.W.; Catalan, G.; Scott, J.F. Elastic and electrical anomalies at low-temperature phase transitions in BiFeO3. J. Phys.: Condens. Matter 2008, 20, 452205. [Google Scholar] [CrossRef] [Green Version]

- Zubair, M.A.; Leach, C. Modeling the resistance-temperature characteristic of a positive temperature coefficient thermistor, using experimentally determined permittivity data. Appl. Phys. Lett. 2007, 91, 082105. [Google Scholar] [CrossRef]

- Das, R.; Choudhary, R.N.P. Studies of electrical, magnetic and leakage-current characteristics of double perovskite: Dy2CoMnO6. J. Alloys Compd. 2021, 853, 157240. [Google Scholar] [CrossRef]

- Li, P.; Han, Z.; Jia, X.; Mei, Z.; Han, X.; Wang, Z. Comparative analysis of an organic Rankine cycle with different turbine efficiency models based on multi-objective optimization. Energy Convers. Manage. 2019, 185, 130–142. [Google Scholar] [CrossRef]

- Lei, F.; Sun, Y.; Liu, K.; Gao, S.; Liang, L.; Pan, B.; Xie, Y. Oxygen vacancies confined in ultrathin indium oxide porous sheets for promoted visible-light water splitting. J. Am. Chem. Soc. 2014, 136, 6826–6829. [Google Scholar] [CrossRef]

- Wang, S.; Chen, D.; Niu, F.; Zhang, N.; Qin, L.; Huang, Y. Hydrogenation-induced surface oxygen vacancies in BiFeO3 nanoparticles for enhanced visible light photocatalytic performance. J. Alloys Compd. 2016, 688, 399–406. [Google Scholar] [CrossRef]

- Sun, T.; Lu, M. Band-structure modulation of SrTiO3 by hydrogenation for enhanced photoactivity. Appl. Phys. A 2012, 108, 171–175. [Google Scholar] [CrossRef]

- Tan, H.; Zhao, Z.; Zhu, W.-b.; Coker, E.N.; Li, B.; Zheng, M.; Yu, W.; Fan, H.; Sun, Z. Oxygen Vacancy Enhanced Photocatalytic Activity of Pervoskite SrTiO3. ACS Appl. Mater. Interfaces 2014, 6, 19184–19190. [Google Scholar] [CrossRef] [PubMed]

- Bouscher, S.; Kang, Z.; Balasubramanian, K.; Panna, D.; Yu, P.; Chen, X.; Hayat, A. High-Tc Cooper-pair injection in a semiconductor–superconductor structure. J. Phys.: Condens. Matter 2020, 32, 475502. [Google Scholar] [CrossRef]

- Panna, D.; Balasubramanian, K.; Bouscher, S.; Wang, Y.; Yu, P.; Chen, X.; Hayat, A. Nanoscale High-Tc YBCO/GaN Super-Schottky Diode. Sci. Rep. 2018, 8, 5597. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, H.; Linghu, K.; Chen, X.; Zhang, J.; Nie, R.; Wang, F.; Deng, J.; Wang, J. The transport properties in BiFeO3/YBCO heterostructures. J. Alloys Compd. 2015, 646, 1133–1138. [Google Scholar] [CrossRef]

- Kolodiazhnyi, T.; Petric, A.; Johari, G.P. Models of the current–voltage dependence of BaTiO3 with positive temperature coefficient of resistivity. J. Appl. Phys. 2001, 89, 3939–3946. [Google Scholar] [CrossRef]

- Huang, A.; Shannigrahi, S.R. Effect of bottom electrode and resistive layer on the dielectric and ferroelectric properties of sol–gel derived BiFeO3 thin films. J. Alloys Compd. 2011, 509, 2054–2059. [Google Scholar] [CrossRef]

- Jain, A.; Kumar, P.; Jain, S.C.; Kumar, V.; Kaur, R.; Mehra, R.M. Trap filled limit voltage (VTFL) and V2 law in space charge limited currents. J. Appl. Phys. 2007, 102, 094505. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Wang, X.; Yang, K.; Deng, J.; Nie, R.; Deng, Q.; Chen, X.; Yang, H.; Xu, K.; Wang, F. The Positive Temperature Coefficient of Resistivity in BiFeO3 Films. Nanomaterials 2022, 12, 892. https://doi.org/10.3390/nano12060892

Yang Q, Wang X, Yang K, Deng J, Nie R, Deng Q, Chen X, Yang H, Xu K, Wang F. The Positive Temperature Coefficient of Resistivity in BiFeO3 Films. Nanomaterials. 2022; 12(6):892. https://doi.org/10.3390/nano12060892

Chicago/Turabian StyleYang, Qianqian, Xiaolei Wang, Kaihua Yang, Jinxiang Deng, Ruijuan Nie, Qingsong Deng, Xuegang Chen, Hongwei Yang, Kailin Xu, and Furen Wang. 2022. "The Positive Temperature Coefficient of Resistivity in BiFeO3 Films" Nanomaterials 12, no. 6: 892. https://doi.org/10.3390/nano12060892

APA StyleYang, Q., Wang, X., Yang, K., Deng, J., Nie, R., Deng, Q., Chen, X., Yang, H., Xu, K., & Wang, F. (2022). The Positive Temperature Coefficient of Resistivity in BiFeO3 Films. Nanomaterials, 12(6), 892. https://doi.org/10.3390/nano12060892