Pixelated Micropolarizer Array Based on Carbon Nanotube Films

Abstract

:1. Introduction

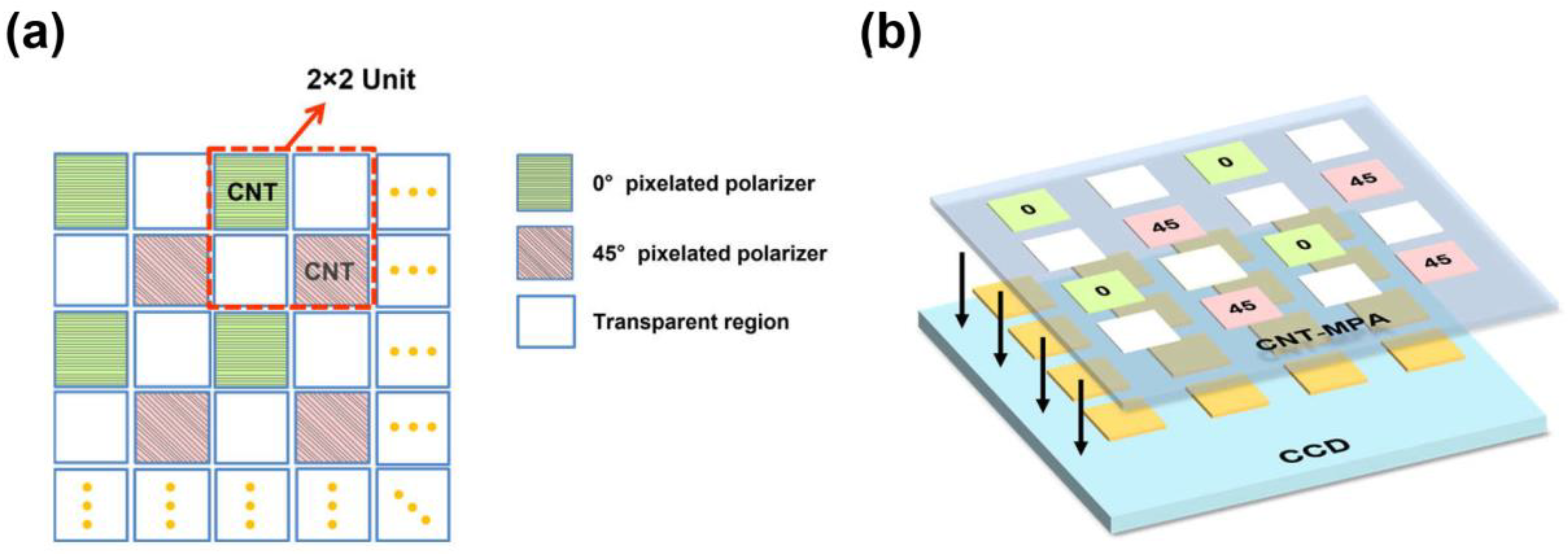

2. Structural Designs of MPA Based on Stokes Parameters

3. Fabrication of a CNT-MPA Based on a Semiconductor Process

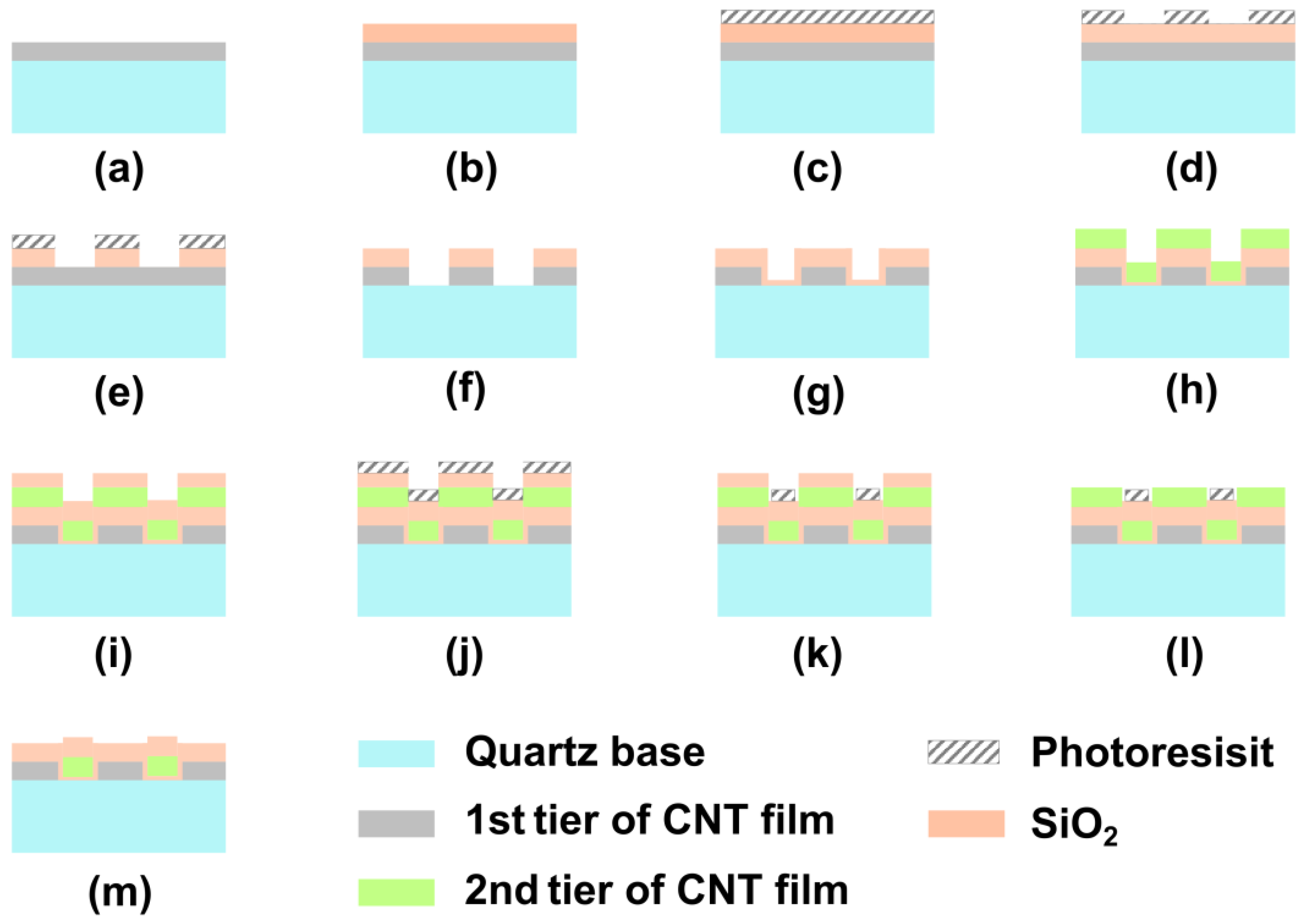

- (1)

- The self-assembled CNT film with a thickness of ~700 nm adheres to the quartz substrate tightly due to van der Waals forces (Figure 2a). The initial orientation of the film is defined as 0 degrees. The densified CNT film is baked in the air at 400 °C for 20 min to remove the amorphous carbon and improve the transmittance of the film [26].

- (2)

- Under plasma-enhanced chemical vapor deposition (PECVD, Plasma Pro System100, Oxford Instrument, UK), a layer of 200 nm SiO2 is deposited on the CNT film as a hard mask (Figure 2b);

- (3)

- The predesigned pixelated pattern is defined through the standard lithography method (Figure 2c,d), which is described in detail in Supplementary Document S2;

- (4)

- The hard mask is etched in reactive ion etching (RIE, Plasma Pro NGP 80, Oxford Instrument, UK) with CHF3 as the reaction gas (a detailed recipe can be found in Supplementary Document S2, Table S1). The preset pattern is transferred to the hard mask, as shown in Figure 2e;

- (5)

- Oxygen was used as the etching gas (a detailed recipe can be found in Supplementary Document S2, Table S2), and the CNT film was etched in an inductively coupled plasma metal etching machine (ICP, Plasma System 100 ICP180, Oxford Instrument, UK). Under the protection of the hard mask, the predesigned pixelated pattern is transferred to the CNT film, which can be seen in Figure 2f;

- (6)

- A layer of 200 nm PECVD SiO2 (a detailed recipe can be found in Supplementary Document S2, Table S3) is grown on the sample surface as a protective layer to protect the CNT arrays from the follow-up operations (Figure 2g);

- (7)

- The second tier of self-assembled CNT film is grown directly on the protective layer (Figure 2h). The catalyst lines [24] of the second CNT film have a 45-degree angular offset from those of the first tier of CNT film. After the self-assembly process of the CNT film, the orientation of the second layer of the CNT film has a 45-degree angular offset from those in the first layer;

- (8)

4. Characterizations of the Dual-Tier MPA

4.1. The Structural Characterization of the Dual-Tier MPA

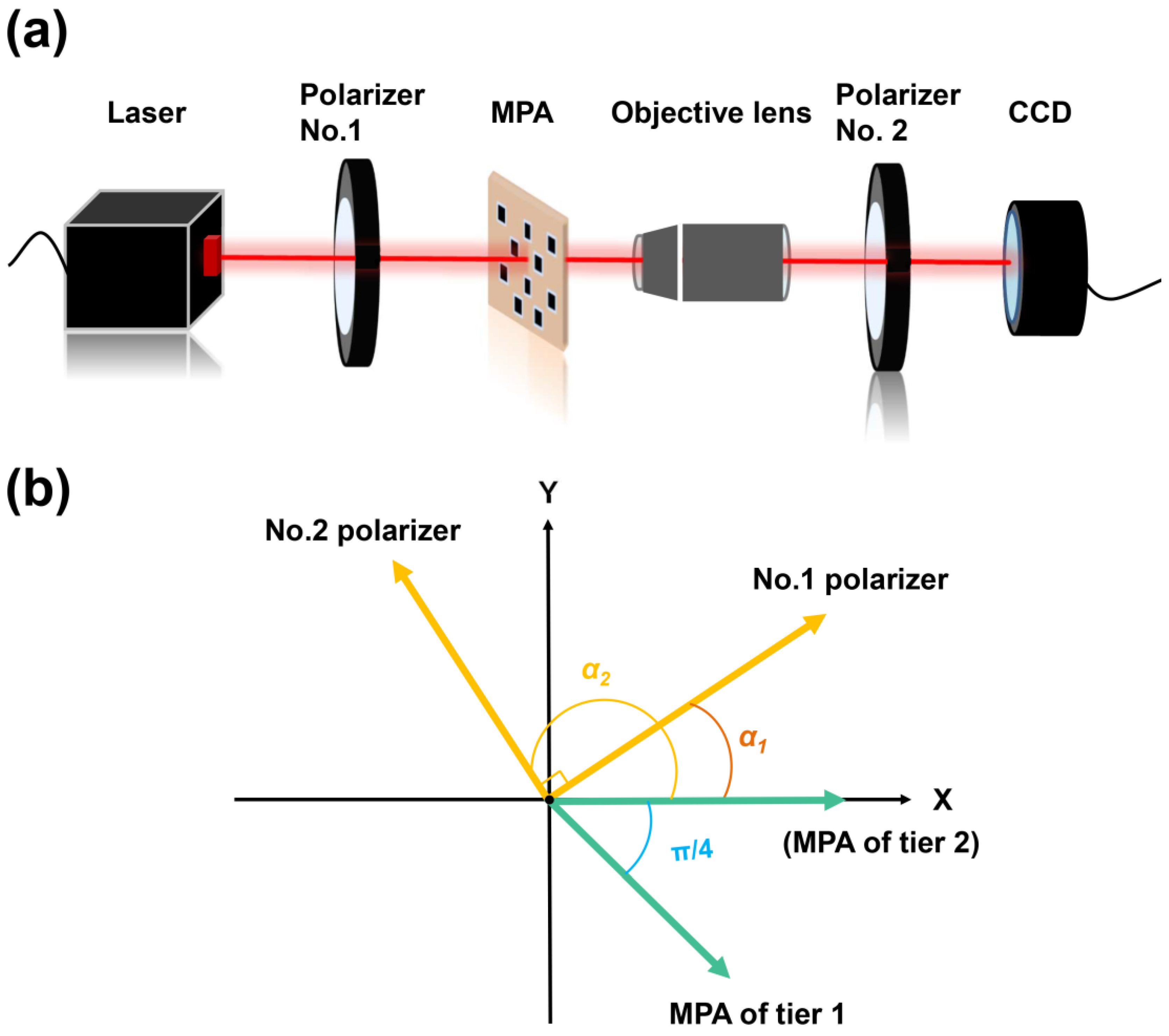

4.2. The Optical Properties of the Dual-Tier MPA

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bom, M.; Wolf, E. Principles of Optics, 3rd ed.; Section 4.8; Pergamon Press: Oxford, UK, 1965. [Google Scholar]

- Rogne, T.J.; Smith, F.G.; Rice, J.E. Passive target detection using polarized components of infrared signatures. In Polarimetry: Radar, Infrared, Visible, Ultraviolet, and X-ray, 1990; International Society for Optics and Photonics: Washington, DC, USA, 1990; pp. 242–251. [Google Scholar]

- Garcia, M.; Edmiston, C.; Marinov, R.; Vail, A.; Gruev, V. Bio-inspired color-polarization imager for real-time in situ imaging. Optica 2017, 4, 1263–1271. [Google Scholar] [CrossRef]

- Nordin, G.P.; Meier, J.T.; Deguzman, P.C.; Jones, M.W. Micropolarizer array for infrared imaging polarimetry. JOSA A 1999, 16, 1168–1174. [Google Scholar] [CrossRef] [Green Version]

- Chu, J.; Zhao, K.; Zhang, Q.; Wang, T. Construction and performance test of a novel polarization sensor for navigation. Sens. Actuators A Phys. 2008, 148, 75–82. [Google Scholar] [CrossRef]

- Nayar, S.K.; Fang, X.-S.; Boult, T. Separation of reflection components using color and polarization. Int. J. Comput. Vis. 1997, 21, 163–186. [Google Scholar] [CrossRef]

- Kuncic, Z.; McNamara, A.; Wu, K.; Boardman, D. Polarization enhanced X-ray imaging for biomedicine. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2011, 648, S208–S210. [Google Scholar] [CrossRef]

- Guo, J.; Brady, D. Fabrication of thin-film micropolarizer arrays for visible imaging polarimetry. Appl. Opt. 2000, 39, 1486–1492. [Google Scholar] [CrossRef]

- Gruev, V.; Ortu, A.; Lazarus, N.; Van der Spiegel, J.; Engheta, N. Fabrication of a dual-tier thin film micropolarization array. Opt. Express 2007, 15, 4994–5007. [Google Scholar] [CrossRef] [Green Version]

- Yongqiang, Z.; Wuteng, L.; Seong, G.K.; Yong, L.; Quan, P. Design and performance analysis of infrared micro-polarizer array. In Proceedings of the 2015 34th Chinese Control Conference (CCC), Hangzhou, China, 28–30 July 2015; pp. 4574–4580. [Google Scholar]

- Zhang, Z.; Dong, F.; Cheng, T.; Qiu, K.; Zhang, Q.; Chu, W.; Wu, X. Nano-fabricated pixelated micropolarizer array for visible imaging polarimetry. Rev. Sci. Instrum. 2014, 85, 105002. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Boussaid, F.; Bermak, A.; Chigrinov, V.G. High-resolution thin “guest-host” micropolarizer arrays for visible imaging polarimetry. Opt. Express 2011, 19, 5565–5573. [Google Scholar] [CrossRef]

- De Heer, W.A.; Bacsa, W.; Chatelain, A.; Gerfin, T.; Humphrey-Baker, R.; Forro, L.; Ugarte, D. Aligned carbon nanotube films: Production and optical and electronic properties. Science 1995, 268, 845–847. [Google Scholar] [CrossRef]

- Jiang, K.; Li, Q.; Fan, S. Spinning continuous carbon nanotube yarns. Nature 2002, 419, 801. [Google Scholar] [CrossRef] [PubMed]

- Dresselhaus, G.; Dresselhaus, M.S.; Saito, R. Physical Properties of Carbon Nanotubes; World Scientific: Hackensack, NJ, USA, 1998. [Google Scholar]

- Murakami, Y.; Einarsson, E.; Edamura, T.; Maruyama, S. Polarization dependence of the optical absorption of single-walled carbon nanotubes. Phys. Rev. Lett. 2005, 94, 087402. [Google Scholar] [CrossRef] [Green Version]

- Ajiki, H.; Ando, T. Aharonov-Bohm effect in carbon nanotubes. Phys. B Condens. Matter 1994, 201, 349–352. [Google Scholar] [CrossRef]

- Ando, T.; Uryu, S. Theory of excitons in carbon nanotubes. physica status solidi c 2009, 6, 173–180. [Google Scholar] [CrossRef]

- Fagan, J.; Simpson, J.R.; Landi, B.; Richter, L.; Mandelbaum, I.; Bajpai, V.; Ho, D.; Raffaelle, R.; Walker, A.H.; Bauer, B. Dielectric response of aligned semiconducting single-wall nanotubes. Phys. Rev. Lett. 2007, 98, 147402. [Google Scholar] [CrossRef] [Green Version]

- Jung, M.; Noh, Y.; Suh, D.; Ahn, S.E. Flexible and thermally stable optical polarizers based on highly aligned carbon nanotube sheets for the visible spectral range. Adv. Mater. Technol. 2018, 3, 1800203. [Google Scholar] [CrossRef]

- Kyoung, J.; Jang, E.Y.; Lima, M.D.; Park, H.-R.; Robles, R.O.; Lepró, X.; Kim, Y.H.; Baughman, R.H.; Kim, D.-S. A reel-wound carbon nanotube polarizer for terahertz frequencies. Nano Lett. 2011, 11, 4227–4231. [Google Scholar] [CrossRef]

- Hayamizu, Y.; Yamada, T.; Mizuno, K.; Davis, R.C.; Futaba, D.N.; Yumura, M.; Hata, K. Integrated three-dimensional microelectromechanical devices from processable carbon nanotube wafers. Nat. Nanotechnol. 2008, 3, 289–294. [Google Scholar] [CrossRef]

- Fan, S.; Chapline, M.G.; Franklin, N.R.; Tombler, T.W.; Cassell, A.M.; Dai, H. Self-oriented regular arrays of carbon nanotubes and their field emission properties. Science 1999, 283, 512–514. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Zhang, P.; Hou, H.; Zhao, Y. Investigation and optimization of polarization properties of self-assembled carbon nanotube films. Nanotechnology 2022, 33, 195702. [Google Scholar] [CrossRef]

- Stokes, G.G. On the Composition and Resolution of Streams of Polarized Light from different Sources. Trans. Camb. Philos. Soc. 1851, 9, 399. [Google Scholar]

- Osswald, S.; Havel, M.; Gogotsi, Y. Monitoring oxidation of multiwalled carbon nanotubes by Raman spectroscopy. J. Raman Spectrosc. 2007, 38, 728–736. [Google Scholar] [CrossRef]

- Ghosh, D.S.; Martinez, L.; Giurgola, S.; Vergani, P.; Pruneri, V. Widely transparent electrodes based on ultrathin metals. Opt. Lett. 2009, 34, 325–327. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lozanova, V.; Lalova, A.; Soserov, L.; Todorov, R. Optical and electrical properties of very thin chromium films for optoelectronic devices. J. Phys. Conf. Ser. 2014, 514, 012003. [Google Scholar] [CrossRef] [Green Version]

- Jones, M.W.; Persons, C.M. Performance predictions for micro-polarizer array imaging polarimeters. In Polarization Science and Remote Sensing III; SPIE: Washington, DC, USA, 2007; pp. 51–61. [Google Scholar]

- York, T.; Gruev, V. Characterization of a visible spectrum division-of-focal-plane polarimeter. Appl. Opt. 2012, 51, 5392–5400. [Google Scholar] [CrossRef] [PubMed]

- Powell, S.B.; Gruev, V. Calibration methods for division-of-focal-plane polarimeters. Opt. Express 2013, 21, 21039–21055. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, H.; Hui, B.; Chang, Z. Non-uniformity correction for division of focal plane polarimeters with a calibration method. Appl. Opt. 2016, 55, 7236–7240. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Yi, Y.; Wang, Y.; Hou, H.; Meng, T.; Zhang, P.; Zhao, Y. Pixelated Micropolarizer Array Based on Carbon Nanotube Films. Nanomaterials 2023, 13, 391. https://doi.org/10.3390/nano13030391

Zhang H, Yi Y, Wang Y, Hou H, Meng T, Zhang P, Zhao Y. Pixelated Micropolarizer Array Based on Carbon Nanotube Films. Nanomaterials. 2023; 13(3):391. https://doi.org/10.3390/nano13030391

Chicago/Turabian StyleZhang, Hui, Yanji Yi, Yibin Wang, Huwang Hou, Ting Meng, Peng Zhang, and Yang Zhao. 2023. "Pixelated Micropolarizer Array Based on Carbon Nanotube Films" Nanomaterials 13, no. 3: 391. https://doi.org/10.3390/nano13030391