Carbon Nanotube Migration in a Compatibilized Blend System, Leading to Kinetically Induced Enhancement in Electrical Conductivity and Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Blend Preparation

2.2. Sample Characterization and Testing

3. Results

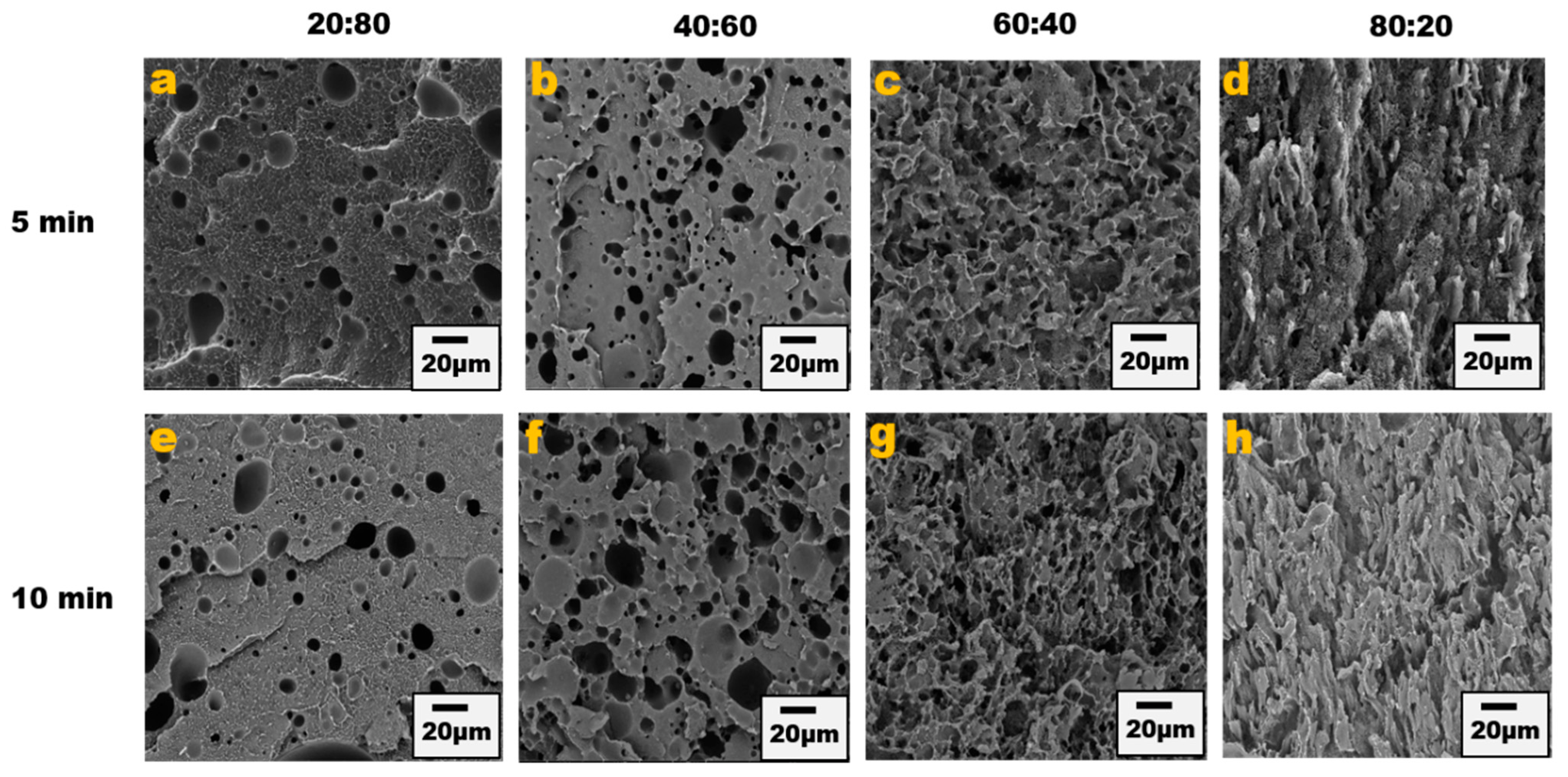

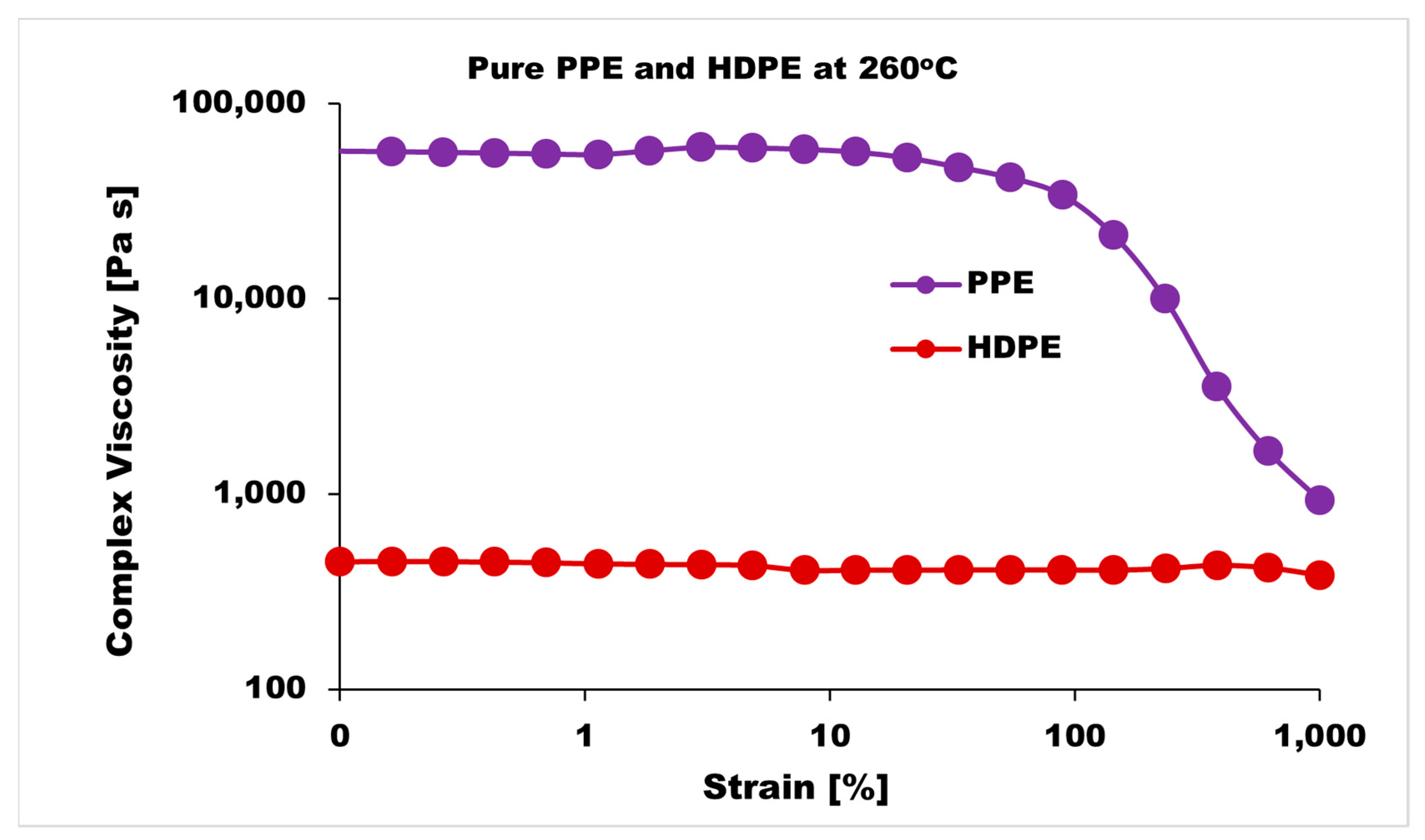

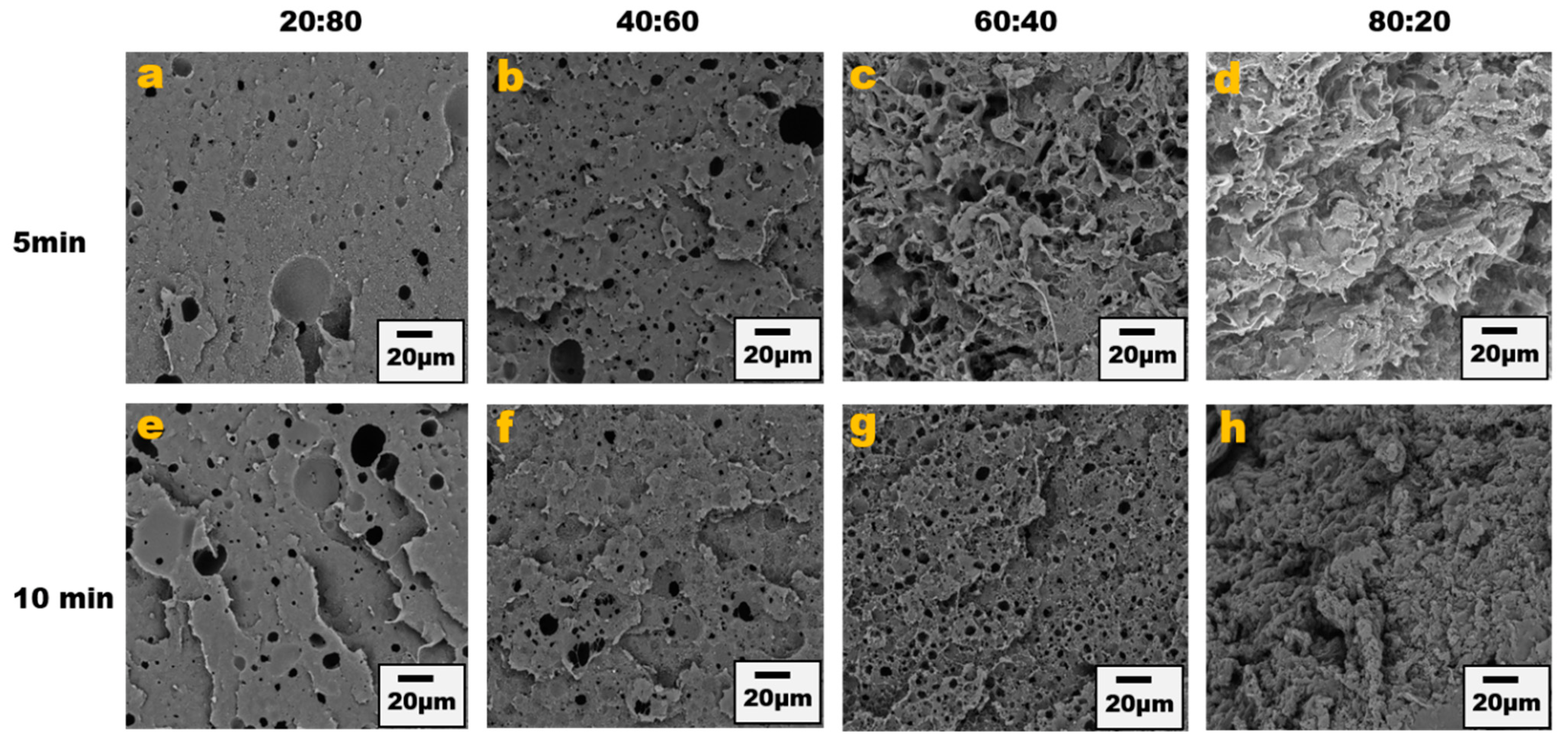

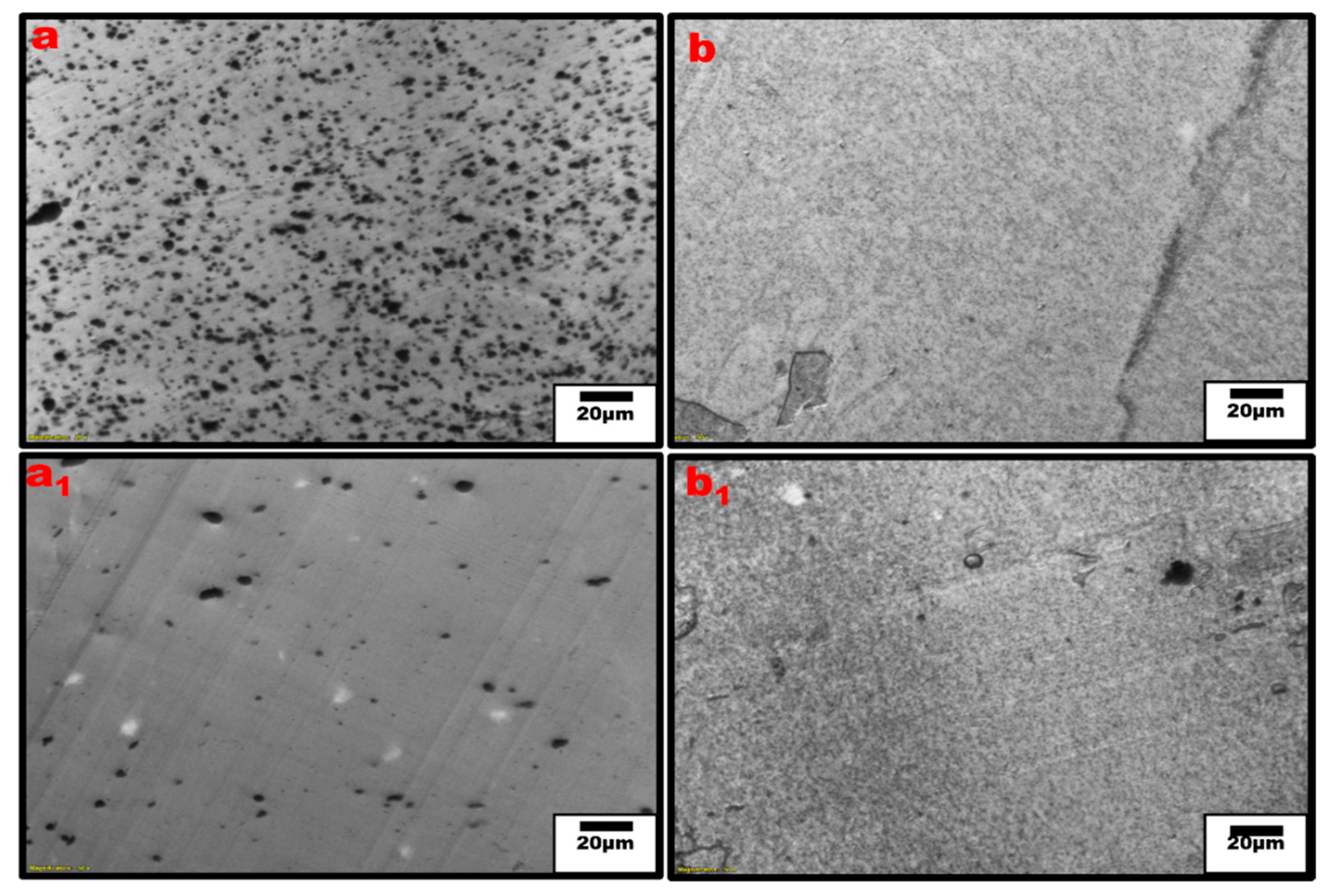

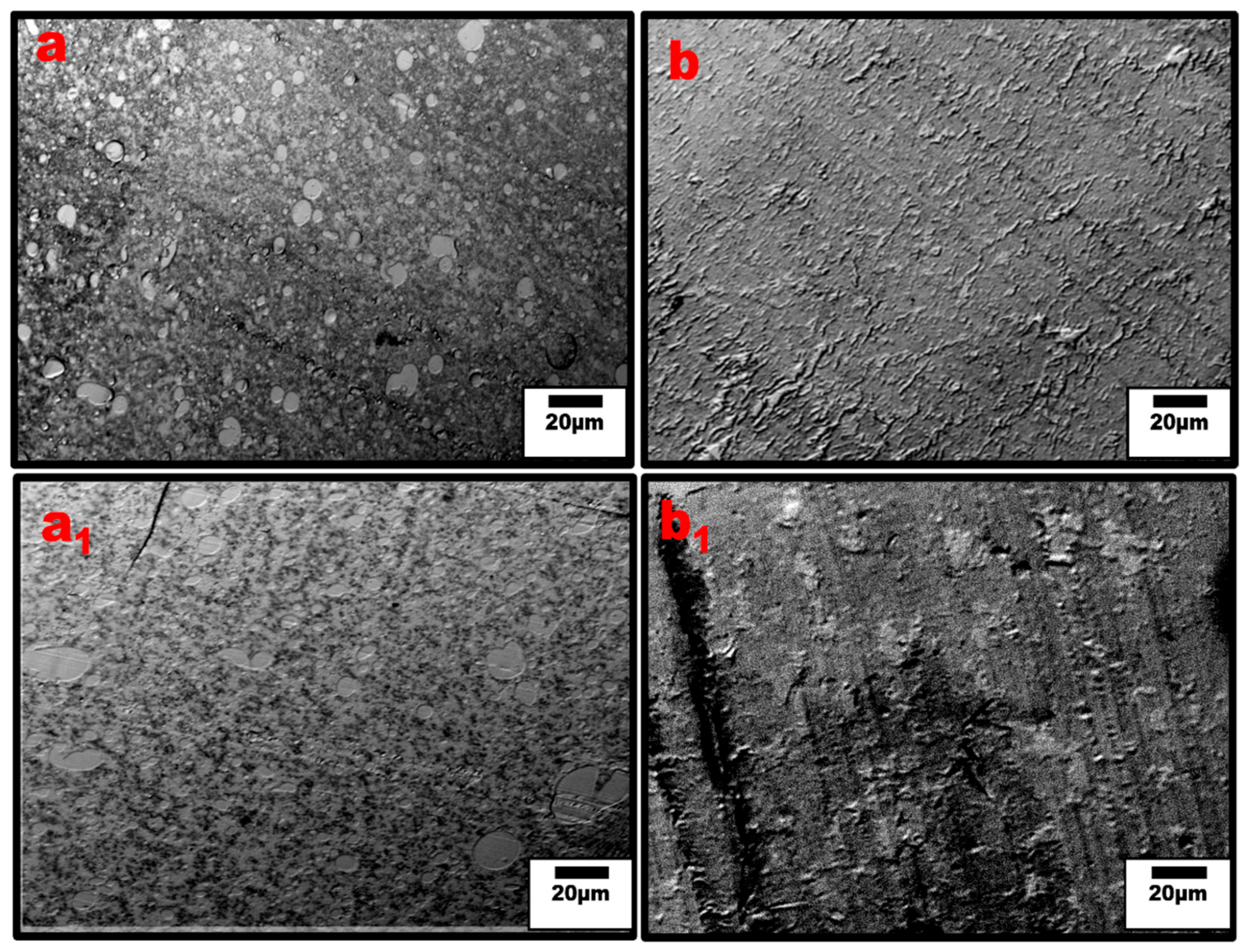

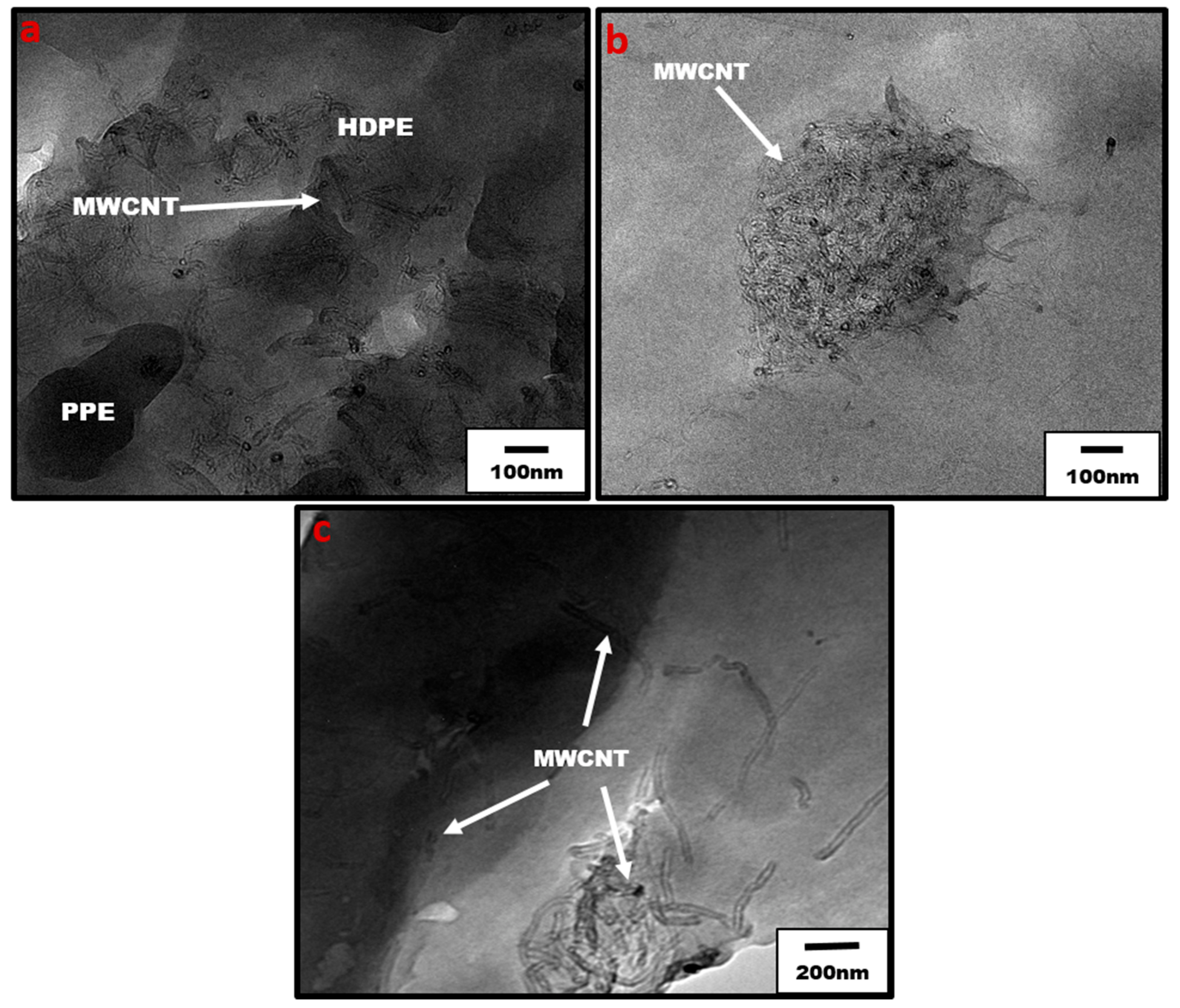

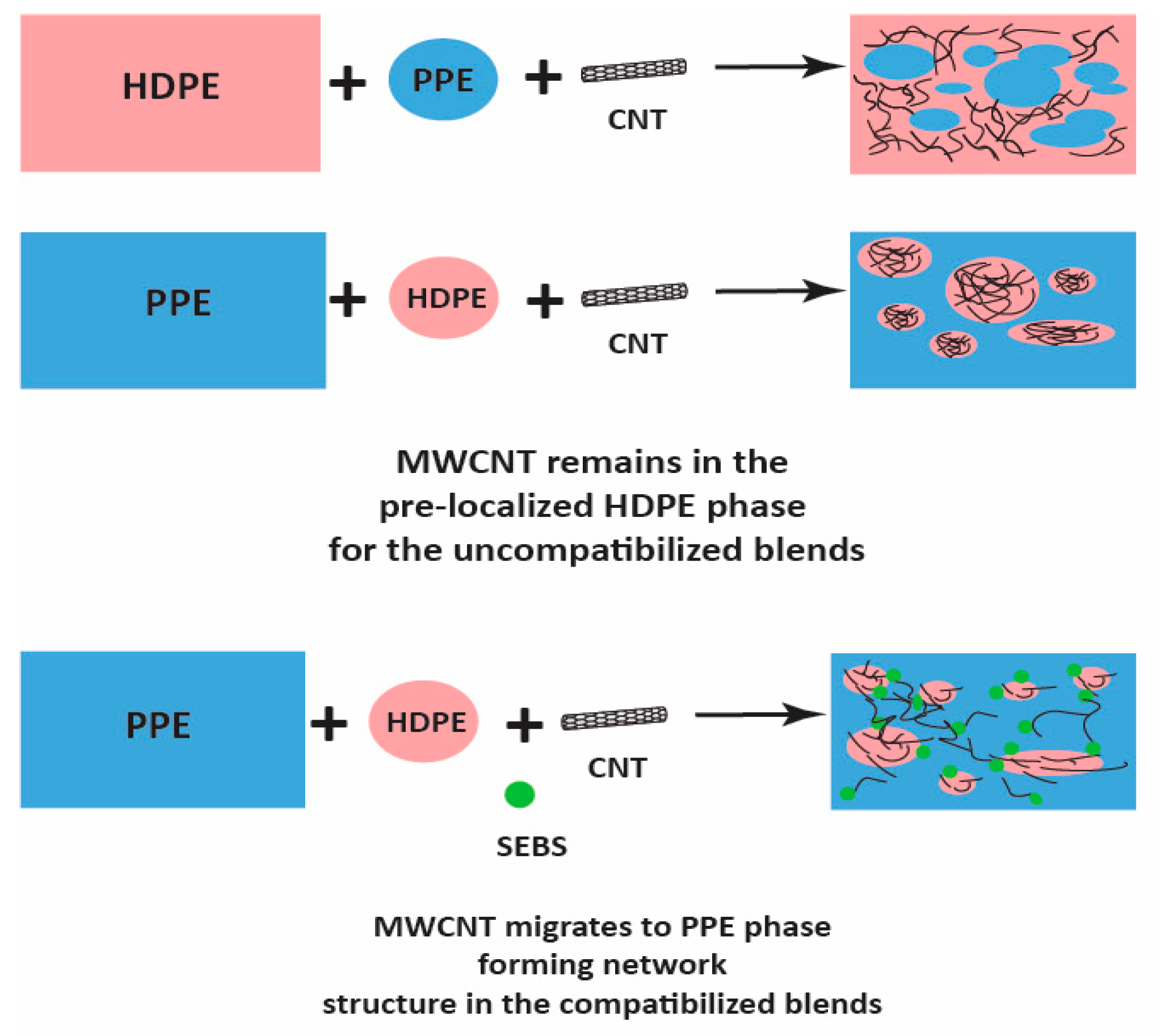

3.1. Blend Morphology

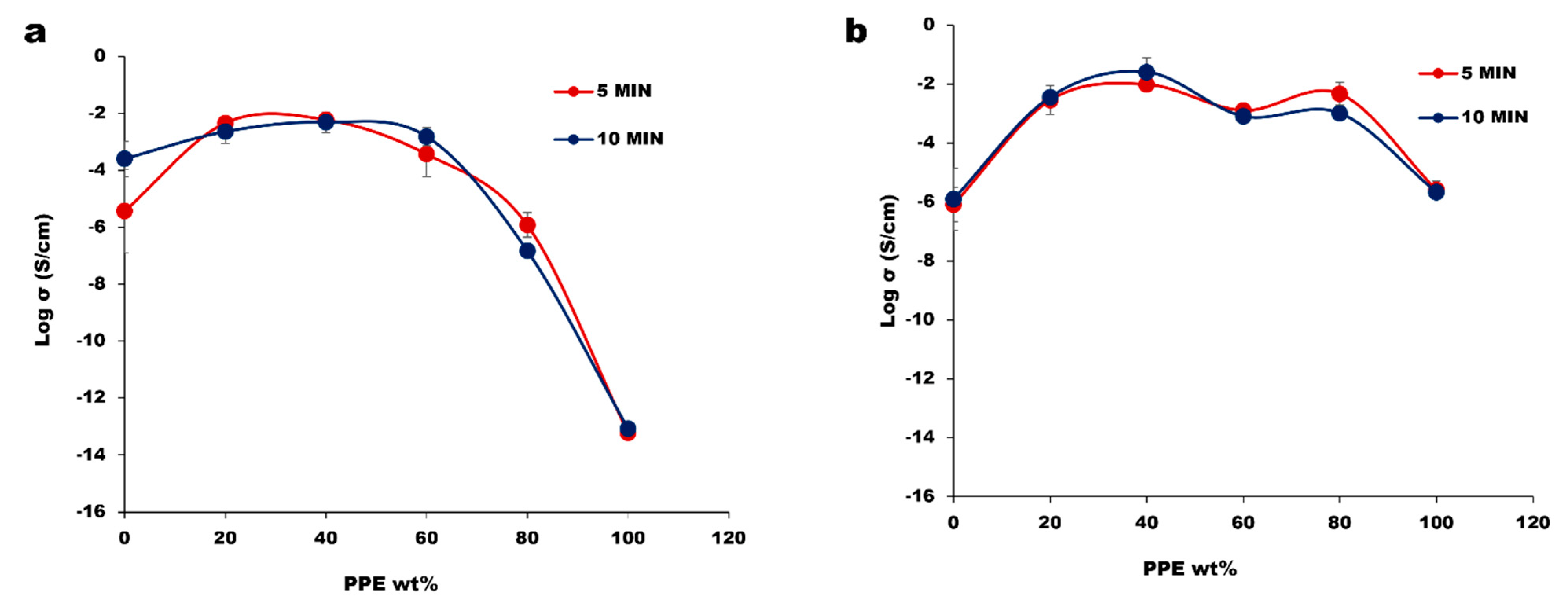

3.2. Electrical Conductivity

3.3. Mechanical Properties of the Blend System

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Utracki, L.A.; Wilkie, C.A. Polymer Blends Handbook; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar] [CrossRef]

- Olabisi, O.; Lloyd, M.R.; Montgomery, T.S. Polymer-Polymer Miscibility; Academic Press: New York, NY, USA, 1979. [Google Scholar] [CrossRef]

- Liu, N.C.; Baker, W.E. Reactive polymers for blend compatibilization. Adv. Polym. Technol. 1992, 11, 249–262. [Google Scholar] [CrossRef]

- Mostafapoor, F.; Khosravi, A.; Fereidoon, A.; Khalili, R.; Jafari, S.H.; Vahabi, H.; Formela, K.; Saeb, M.R. Interface Analysis of Compatibilized Polymer Blends; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 349–371. [Google Scholar] [CrossRef]

- Kar, G.P.; Biswas, S.; Bose, S. Tailoring the interface of an immiscible polymer blend by a mutually miscible homopolymer grafted onto graphene oxide: Outstanding mechanical properties. Phys. Chem. Chem. Phys. 2015, 17, 1811–1821. [Google Scholar] [CrossRef] [PubMed]

- Harvard, T.; Resource, I.S. All information taken from University Library. Univ. Sheff. 2010, 8, 1996–1999. [Google Scholar]

- Owens, K.D.; De Nemours, E.; Film, S. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Dubey, V.K.; Sisanth, K.; Jose, S.; Zachariah, A.K.; Siengchin, S.; Salim, N.V.; Hameed, N. Tailoring of interface of polypropylene/polystyrene/carbon nanofibre composites by polystyrene-block-poly(ethylene-ran-butylene)-block-polystyrene. Polym. Test. 2016, 51, 131–141. [Google Scholar] [CrossRef]

- Ismail, H.H.; Nasir, M. The effect of various compatibilizers on mechanical properties of polystyrene/polypropylene blend. Polym. Test. 2002, 21, 163–170. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Pouliot, S.; Bousmina, M.; Utracki, L.A. Role of organically modified layered silicate as an active interfacial modifier in immiscible polystyrene/polypropylene blends. Polymer 2004, 45, 8403–8413. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.-Y.; Hu, S.-W.; Sheng, J. Evolution of phase dimensions and interfacial morphology of polypropylene/polystyrene compatibilized blends during mixing. Eur. Polym. J. 2007, 43, 561–572. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Joseph, G.; Jose, S.; Hameed, N. Phase morphology, thermomechanical, and crystallization behavior of uncompatibilized and PP-g-MAH compatibilized polypropylene/polystyrene blends. J. Appl. Polym. Sci. 2015, 132, 1–11. [Google Scholar] [CrossRef]

- Machado, J.M.; Lee, C.S. Compatibilization of immiscible blends with a mutually miscible third polymer. Polym. Eng. Sci. 1994, 34, 59–68. [Google Scholar] [CrossRef]

- Ader, F.; Sharifzadeh, E. Rheological and mechanical behavior of blend-based polymer nanocomposites containing Janus and non-Janus silica nanoparticles. Colloid Polym. Sci. 2021, 299, 1843–1852. [Google Scholar] [CrossRef]

- Vinckier, I.; Laun, H.M. Manifestation of spinodal decomposition in oscillatory shear measurement. Macromol. Symp. 2000, 149, 151–156. [Google Scholar] [CrossRef]

- Vinckier, I.; Laun, H.M. Manifestation of phase separation processes in oscillatory shear: Droplet-matrix systems versus co-continuous morphologies. Rheol. Acta 1999, 38, 274–286. [Google Scholar] [CrossRef]

- Weis, C.; Leukel, J.; Borkenstein, K.; Maier, D.; Gronski, W.; Friedrich, C.; Honerkamp, J. Morphological and rheological detection of the phase inversion of PMMA/PS polymer blends. Polym. Bull. 1998, 40, 235–241. [Google Scholar] [CrossRef]

- Li, R.; Yu, W.; Zhou, C. Phase Behavior and its Viscoelastic Responses of Poly(methyl methacrylate) and Poly(styrene-co-maleic anhydride) Blend Systems. Polym. Bull. 2006, 56, 455–466. [Google Scholar] [CrossRef]

- Li, R.; Yu, W.; Zhou, C. Rheological characterization of droplet-matrix versus Co-continuous morphology. J. Macromol. Sci. Part B Phys. 2006, 45B, 889–898. [Google Scholar] [CrossRef]

- Pötschke, P.; Paul, D.R. Formation of Co-continuous Structures in Melt-Mixed Immiscible Polymer Blends. J. Macromol. Sci. Polym. Rev. 2003, 43, 87–141. [Google Scholar] [CrossRef]

- Hadaeghnia, M.; Ahmadi, S.; Ghasemi, I.; Wood-Adams, P.M. Manipulating the morphology of PA6/POE blends using graphene to achieve balanced electrical and mechanical properties. Compos. Sci. Technol. 2020, 200, 108412. [Google Scholar] [CrossRef]

- de Luna, M.S.; Filippone, G. Effects of nanoparticles on the morphology of immiscible polymer blends—Challenges and opportunities. Eur. Polym. J. 2016, 79, 198–218. [Google Scholar] [CrossRef]

- Chen, J.; Cui, X.; Zhu, Y.; Jiang, W.; Sui, K. Design of superior conductive polymer composite with precisely controlling carbon nanotubes at the interface of a co-continuous polymer blend via a balance of π-π interactions and dipole-dipole interactions. Carbon N. Y. 2017, 114, 441–448. [Google Scholar] [CrossRef]

- Bose, S.; Bhattacharyya, A.R.; Kulkarni, A.R.; Pötschke, P. Electrical, rheological and morphological studies in co-continuous blends of polyamide 6 and acrylonitrile–butadiene–styrene with multiwall carbon nanotubes prepared by melt blending. Compos. Sci. Technol. 2009, 69, 365–372. [Google Scholar] [CrossRef]

- Tol, R.T.; Groeninckx, G.; Vinckier, I.; Moldenaers, P.; Mewis, J. Phase morphology and stability of co-continuous (PPE/PS)/PA6 and PS/PA6 blends: Effect of rheology and reactive compatibilization. Polymer 2004, 45, 2587–2601. [Google Scholar] [CrossRef]

- Wang, J.; Tsou, A.; Passino, H.; Favis, B.D. PPE-g-HDPE in high-performance poly(p-phenylene ether)/polyethylene blends: Synthesis and compatibilization effects. Polymer 2018, 138, 92–102. [Google Scholar] [CrossRef]

- Akkapeddi, M.K.; Vanbuskirk, B. Compatibilization and toughening of PPE—PP blends with hydrogenated, styrene—Diene block copolymers. Adv. Polym. Technol. 1992, 11, 263–275. [Google Scholar] [CrossRef]

- Chiang, C.-R.; Chang, F.-C. Polymer blends of polyamide-6 (PA6) and poly(phenylene oxide) (PPO) compatibilized by styrene-maleic anhydride (SMA) copolymer. Polymer 1997, 38, 4807–4817. [Google Scholar] [CrossRef]

- Lee, C.J.; Salehiyan, R.; Ham, D.S.; Cho, S.K.; Lee, S.J.; Kim, K.J.; Yoo, Y.; Hyun, K.; Lee, J.H.; Choi, W.J. Influence of carbon nanotubes localization and transfer on electrical conductivity in PA66/(PS/PPE)/CNTs nanocomposites. Polymer 2016, 84, 198–208. [Google Scholar] [CrossRef]

- Lee, M.; Son, K.; Kim, J.; Kim, D.; Min, B.; Kim, J.H. Effect of PA6T on morphology and electrical conductivity in PA66/PA6T/PPE/multiwalled carbon nanotube nanocomposites. Compos. Sci. Technol. 2018, 164, 260–266. [Google Scholar] [CrossRef]

- Du, B.; Handge, U.A.; Majeed, S.; Abetz, V. Localization of functionalized MWCNT in SAN/PPE blends and their influence on rheological properties. Polymer 2012, 53, 5491–5501. [Google Scholar] [CrossRef] [Green Version]

- Breuer, O.; Sundararaj, U.; Toogood, R.W. The design and performance of a new miniature mixer for specialty polymer blends and nanocomposites. Polym. Eng. Sci. 2004, 44, 868–879. [Google Scholar] [CrossRef]

- Sundararaj, U.; Macosko, C.W.; Nakayama, A.; Inoue, T. Milligrams to kilograms: An evaluation of mixers for reactive polymer blending. Polym. Eng. Sci. 1995, 35, 100–114. [Google Scholar] [CrossRef]

- Breuer, O.; Chen, H.; Lin, B.; Sundararaj, U. Simulation and visualization of flow in a new miniature mixer for multiphase polymer systems. J. Appl. Polym. Sci. 2005, 97, 136–142. [Google Scholar] [CrossRef]

- Otero-Navas, I.; Arjmand, M.; Sundararaj, U. Carbon nanotube induced double percolation in polymer blends: Morphology, rheology and broadband dielectric properties. Polymer 2017, 114, 122–134. [Google Scholar] [CrossRef]

- Hoseini, A.H.A.; Arjmand, M.; Sundararaj, U.; Trifkovic, M. Significance of interfacial interaction and agglomerates on electrical properties of polymer-carbon nanotube nanocomposites. Mater. Des. 2017, 125, 126–134. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Norrrahim, F.; Sabaruddin, F.A.; Ilyas, R.A. Mechanical performance evaluation of bamboo fibre reinforced polymer composites and its applications: A. review. Funct. Compos. Struct. 2022, 4, 1–25. [Google Scholar] [CrossRef]

- Ma, P.-C.; Siddiqui, N.A.; Marom, G.; Kim, J.-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Sumita, M.; Sakata, K.; Asai, S.; Miyasaka, K.; Nakagawa, H. Dispersion of fillers and the electrical conductivity of polymer blends filled with carbon black. Polym. Bull. 1991, 25, 265–271. [Google Scholar] [CrossRef]

- Wu, S. Calculation of interfacial tension in polymer systems. J. Polym. Sci. Part C Polym. Symp. 2007, 34, 19–30. [Google Scholar] [CrossRef]

- Taguet, A.; Cassagnau, P.; Taguet, A.; Cassagnau, P.; Structuration, J.L. Structuration, selective dispersion and compatibilizing effect of (nano) fillers in polymer blend. Prog. Polym. Sci. 2014, 39, 1526–1563. [Google Scholar] [CrossRef]

- Everaert, V.; Groeninckx, G.; Pionteck, J.; Favis, B.; Aerts, L.; Moldenaers, P.; Mewis, J. Miscible PS/PPE compounds: An alternative for blend phase morphology studies? Influence of the PPE content on the surface tension of PS/PPE and on the interfacial tension in PP/(PS/PPE) and POM/(PS/PPE) blends. Polymer 2000, 41, 1011–1025. [Google Scholar] [CrossRef]

- Wang, J.; Tsou, A.H.; Favis, B.D. Effects of Polyethylene Molecular Weight Distribution on Phase Morphology Development in Poly(p-phenylene ether) and Polyethylene Blends. Macromolecules 2018, 51, 9165–9176. [Google Scholar] [CrossRef]

- Kia, M.M.; Paydayesh, A.; Azar, A.A. Morphology and Mechanical Properties of Polyamide 6/Acrylonitrile-Butadiene-Styrene Blends Containing Carbon Nanotubes. J. Macromol. Sci. Part B Phys. 2019, 58, 355–370. [Google Scholar]

- Zhang, M.; Sundararaj, U. Thermal, Rheological, and Mechanical Behaviors of LLDPE/PEMA/Clay Nanocomposites: Effect of Interaction Between Polymer, Compatibilizer, and Nanofiller. Macromol. Mater. Eng. 2006, 291, 697–706. [Google Scholar] [CrossRef]

| Samples | Blend Compositions | Filler | Copolymer | Mixing Time |

|---|---|---|---|---|

| HDPE-MB | 0:100 | 10 wt% | - | - |

| PPE/HDPE/CNT | 80:20, 20:80 | 1 wt% | - | 5, 10 min |

| PPE/HDPE/CNT/SEBS | 20:80, 40:60, 60:40, 80:20 | 1 wt% | 1, 2, 3 wt% | 5, 10 min |

| Pure PPE/HDPE | 20:80, 80:20 | - | - | 5, 10 min |

| PPE/HDPE | 20:80, 80:20 | - | 2 | 5, 10 min |

| Materials | Total Surface Tension (mN/m) | Dispersive Surface Tension (mN/m) | Polar Surface Tension (mN/m) | References |

|---|---|---|---|---|

| PPE | 28.4 | 22.2 | 6.2 | [41,42] |

| HDPE | 22 | 22 | 0 | [43] |

| MWCNTs | 27.8 | 17.6 | 10.2 | [41] |

| Samples | Tensile Strength at Break (MPa) | Young’s Modulus (MPa) | Elongation at Break (%) |

|---|---|---|---|

| PPE/HDPE 80/20 | 15.40 ± 0.7 | 1029.45 ± 24.7 | 3.00 ± 1.9 |

| PPE/HDPE/SEBS/80/20/2 | 28.30 ± 4.9 | 1557.18 ± 119.0 | 2.90 ± 0.3 |

| PPE/HDPE/CNT/80/20/1 | 21.25 ± 2.2 | 1285.70 ± 54.2 | 3.46 ± 0.7 |

| PPE/HDPE/SEBS/CNT/80/20/2/1 | 38.27± 0.2 | 1784.26 ± 99.9 | 5.97 ± 0.5 |

| PPE/HDPE 20/80 | 11.49 ± 1.9 | 210.4 ± 36.4 | 15.27 ± 3.4 |

| PPE/HDPE/SEBS/20/80/2 | 15.40 ± 0.6 | 275.06 ± 20.6 | 25.2 ± 2.6 |

| PPE/HDPE/CNT/20/80/1 | 14.05 ± 2.9 | 356.04 ± 92.3 | 5.73 ± 0.7 |

| PPE/HDPE/SEBS/CNT/20/80/2/1 | 16.86 ± 0.6 | 399.39 ± 27.1 | 9.51 ± 1.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azubuike, L.; Wang, J.; Sundararaj, U. Carbon Nanotube Migration in a Compatibilized Blend System, Leading to Kinetically Induced Enhancement in Electrical Conductivity and Mechanical Properties. Nanomaterials 2023, 13, 1039. https://doi.org/10.3390/nano13061039

Azubuike L, Wang J, Sundararaj U. Carbon Nanotube Migration in a Compatibilized Blend System, Leading to Kinetically Induced Enhancement in Electrical Conductivity and Mechanical Properties. Nanomaterials. 2023; 13(6):1039. https://doi.org/10.3390/nano13061039

Chicago/Turabian StyleAzubuike, Lilian, Jun Wang, and Uttandaraman Sundararaj. 2023. "Carbon Nanotube Migration in a Compatibilized Blend System, Leading to Kinetically Induced Enhancement in Electrical Conductivity and Mechanical Properties" Nanomaterials 13, no. 6: 1039. https://doi.org/10.3390/nano13061039

APA StyleAzubuike, L., Wang, J., & Sundararaj, U. (2023). Carbon Nanotube Migration in a Compatibilized Blend System, Leading to Kinetically Induced Enhancement in Electrical Conductivity and Mechanical Properties. Nanomaterials, 13(6), 1039. https://doi.org/10.3390/nano13061039