Abstract

Molybdenum disulfide (MoS2), a typical layered material, has important applications in various fields, such as optoelectronics, catalysis, electronic devices, sensors, and supercapacitors. Extensive research has been carried out on few-layered MoS2 in the field of electrochemistry due to its large specific surface area, abundant active sites and short electron transport path. However, the preparation of few-layered MoS2 is a significant challenge. This work presents a simple one-pot hydrothermal method for synthesizing few-layered MoS2. Furthermore, it investigates the exfoliation effect of different amounts of sodium borohydride (NaBH4) as a stripping agent on the layer number of MoS2. Na+ ions, as alkali metal ions, can intercalate between layers to achieve the purpose of exfoliating MoS2. Additionally, NaBH4 exhibits reducibility, which can effectively promote the formation of the metallic phase of MoS2. Few-layered MoS2, as an electrode for supercapacitor, possesses a wide potential window of 0.9 V, and a high specific capacitance of 150 F g−1 at 1 A g−1. This work provides a facile method to prepare few-layered two-dimensional materials for high electrochemical performance.

1. Introduction

In recent decades, it has been essential to develop a new generation of energy storage devices that are eco-friendly, sustainable, and capable of meeting the evolving energy demands [1,2,3]. Supercapacitors have attracted significant attention due to their superior power density and energy density, excellent cycle performance, and fast charge–discharge characteristics [4,5,6]. Supercapacitors can be divided into two categories (electrostatic double layer capacitors (EDLCs) and pseudocapacitors) based on the energy storage mechanisms [7]. Regarding EDLCs, the double-layer capacitor on the surface of the electrode material is formed through the effect of electrostatic force [8]. Pseudocapacitors store energy through rapid and reversible redox reactions or intercalation in the electrode material [9]. Thus, the selection of electrode materials is crucial for the performance of supercapacitors.

Molybdenum disulfide (MoS2) is a two-dimensional material composed of molybdenum and sulfur atoms, belonging to the family of transition metal dichalcogenides [10,11]. In the structure of MoS2, a Mo atomic layer is sandwiched between two sulfur atomic layers, forming a two-dimensional layered structure similar to graphene [12,13,14]. This layer structure imparts unique properties to MoS2, such as excellent electrical, optical, and mechanical properties [15,16]. Within the interlayer space of molybdenum disulfide, electrolyte ions and molecules can diffuse, providing convenience for its electrochemical and catalytic applications [17,18,19]. The atomic-level thickness and two-dimensional structure of MoS2 make it an ideal choice for researching and developing advanced materials and devices [20]. Specifically, the central Mo atoms exhibit oxidation states ranging from +2 to +6, creating an interlayer space that allows for the diffusion of electrolyte ions into the interlayers for Faraday reactions [21]. These distinctive features play a critical role in enhancing charge storage capabilities, ultimately enabling MoS2 to achieve an impressive theoretical specific capacitance of approximately 1000 F g−1 [22]. The few-layered treatment of MoS2 is able to expose more active sites, increase contact area with the electrolyte, and shorten the ion diffusion distance to further effectively enhance its electrochemical performance [23]. However, due to the challenges in preparing few-layered MoS2 and the high technical requirements involved, the synthesis of few-layered MoS2 faces significant hurdles.

In this work, few-layered MoS2 is successfully prepared by the one-pot hydrothermal method with the effect of NaBH4. Furthermore, the influence of different NaBH4 dosages on few-layered MoS2 is studied. The presence of few-layered MoS2 after the NaBH4 treatment is obtained using scanning electron microscopy (SEM) and transmission electron microscopy (TEM). MoS2-0.3894 exhibits the excellent supercapacitor performance, including a wide potential window of 0.9 V and a high specific capacitance of 150 g−1 at 1 A g−1. This work provides a simple way to achieve few-layered MoS2, which has a significant impact on the development of two-dimensional layered materials.

2. Materials and Methods

2.1. Preparation of MoS2 Nanosheets

First, 0.8225 g of sodium molybdate dihydrate (Na2MoO4·2H2O) and 0.7370 g of thioacetamide (C2H5NS) were dissolved in deionized water (25 mL) and stirred for 30 min. After the mixture was transferred to a Teflon-lined stainless-steel autoclave (100 mL), it was heated to 200 °C and kept for 20 h. The resulting product was washed several times with deionized water and ethanol, and then the sample was dried. Finally, the dried sample was ground into powder in a mortar to obtain MoS2.

2.2. Preparation of MoS2 with Different Amounts of NaBH4

First, 0.2595, 0.3894 and 0.5192 g of sodium borohydride (NaBH4) was dissolved in homogeneous mixture composed of Na2MoO4·2H2O and C2H5NS, and then stirred for 30 min. The rest of the operation process was the same as for the preparation of MoS2 nanosheets. According to the various dosages of NaBH4, the product samples are named MoS2, MoS2-0.2595, MoS2-0.3894, and MoS2-0.5192.

2.3. Material Characterizations

XRD patterns were collected on X-ray diffraction (PANalytical Empyrean, Bruker, Germany) with Cu K radiation (λ = 0.154 nm). Raman spectra were obtained by a spectrometer (TACHI Regulus8220) with 532 nm laser excitation. Materials nanostructure characterizations come from Field emission scanning electron microscope (FE-SEM, HiTACHI Regulus8220) and Energy-dispersive X-ray spectroscopy (EDX, Oxford EDX, with INCA software, INCA V7.5), transmission electron microscope (TEM, JEM-2100) with configured EDX.

3. Results and Discussion

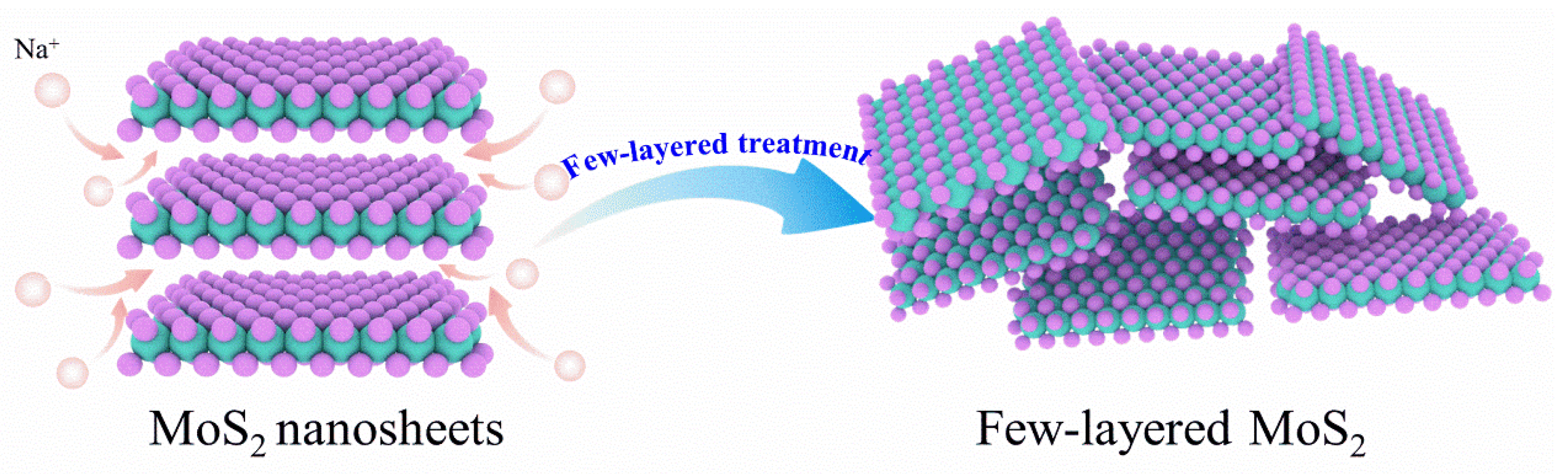

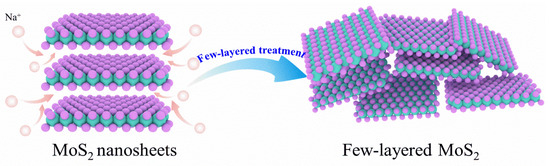

As shown in Figure 1, the layered-material MoS2 can be prepared into few-layered MoS2 with the effect of NaBH4. NaBH4 is an excellent exfoliating and reducing agent. The alkali metal Na+ ions have a significant exfoliating effect during synthesis processing. The group of BH4− exhibits strong reducing properties. In addition, various NaBH4 have different effects on the exfoliation of MoS2 layers [24,25]. The products are named MoS2, MoS2-0.2595, MoS2-0.3894, and MoS2-0.5192.

Figure 1.

Schematic diagram of few-layered MoS2 preparation.

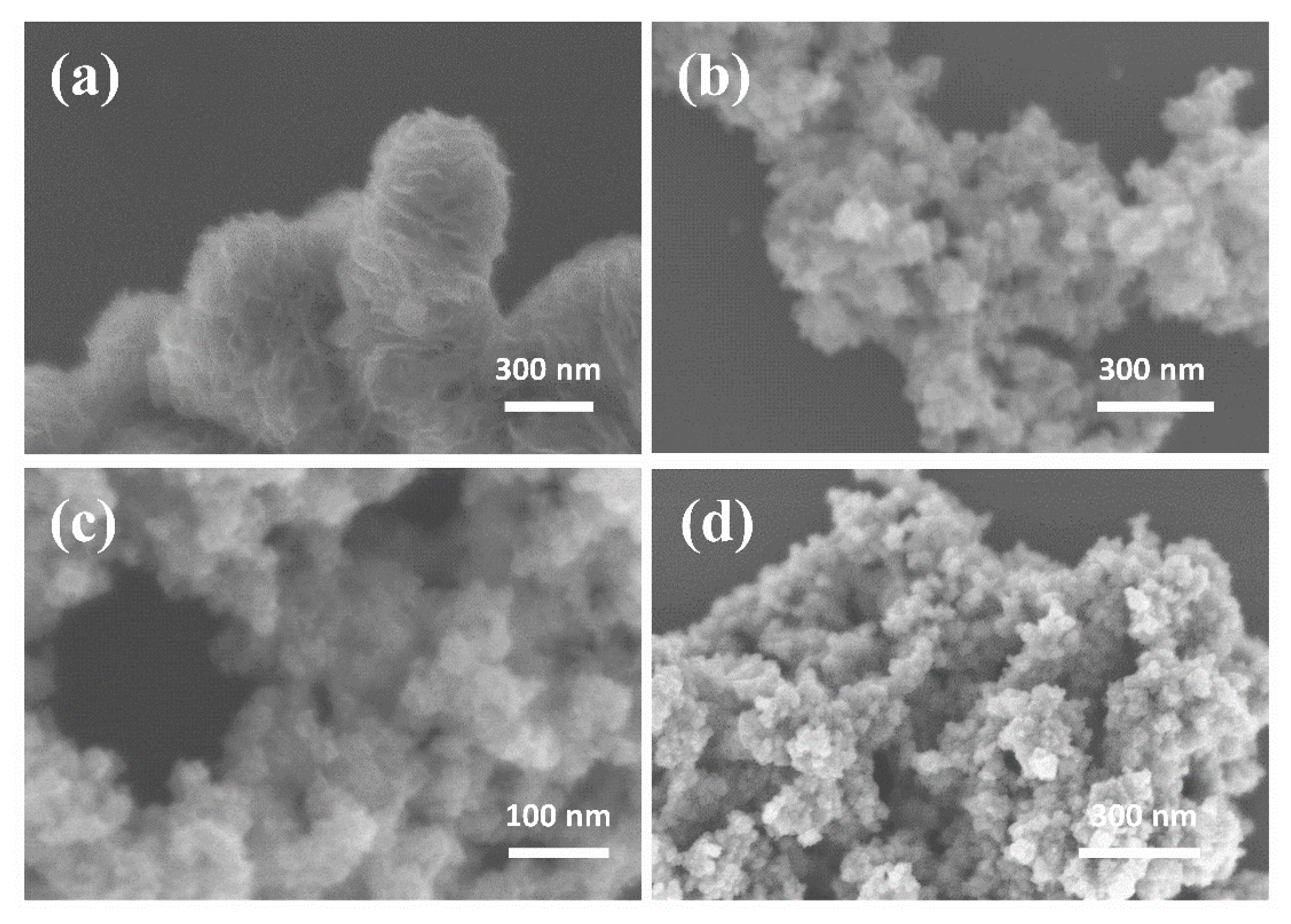

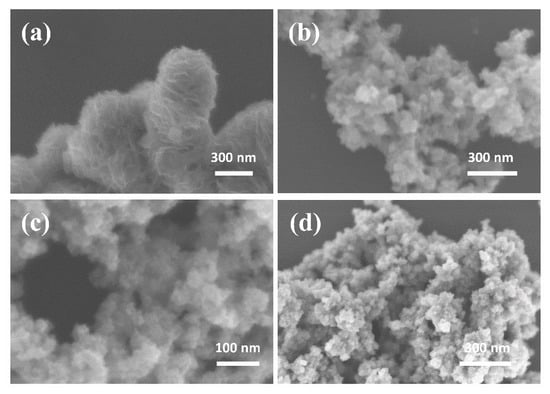

The microscopic morphologies of all the samples obtained using scanning electron microscopy (SEM) are illustrated in Figure 2. As shown in the SEM images for MoS2, MoS2-0.2595, MoS2-0.3894, and MoS2-0.5192, it is clear that the nanoflowers of MoS2 gradually disintegrated and agglomerated with an increase in the NaBH4 dosage, which reflects the significant effect of NaBH4 on MoS2 morphology.

Figure 2.

(a–d) The SEM images of MoS2, MoS2-0.2595, MoS2-0.3894 and MoS2-0.5192.

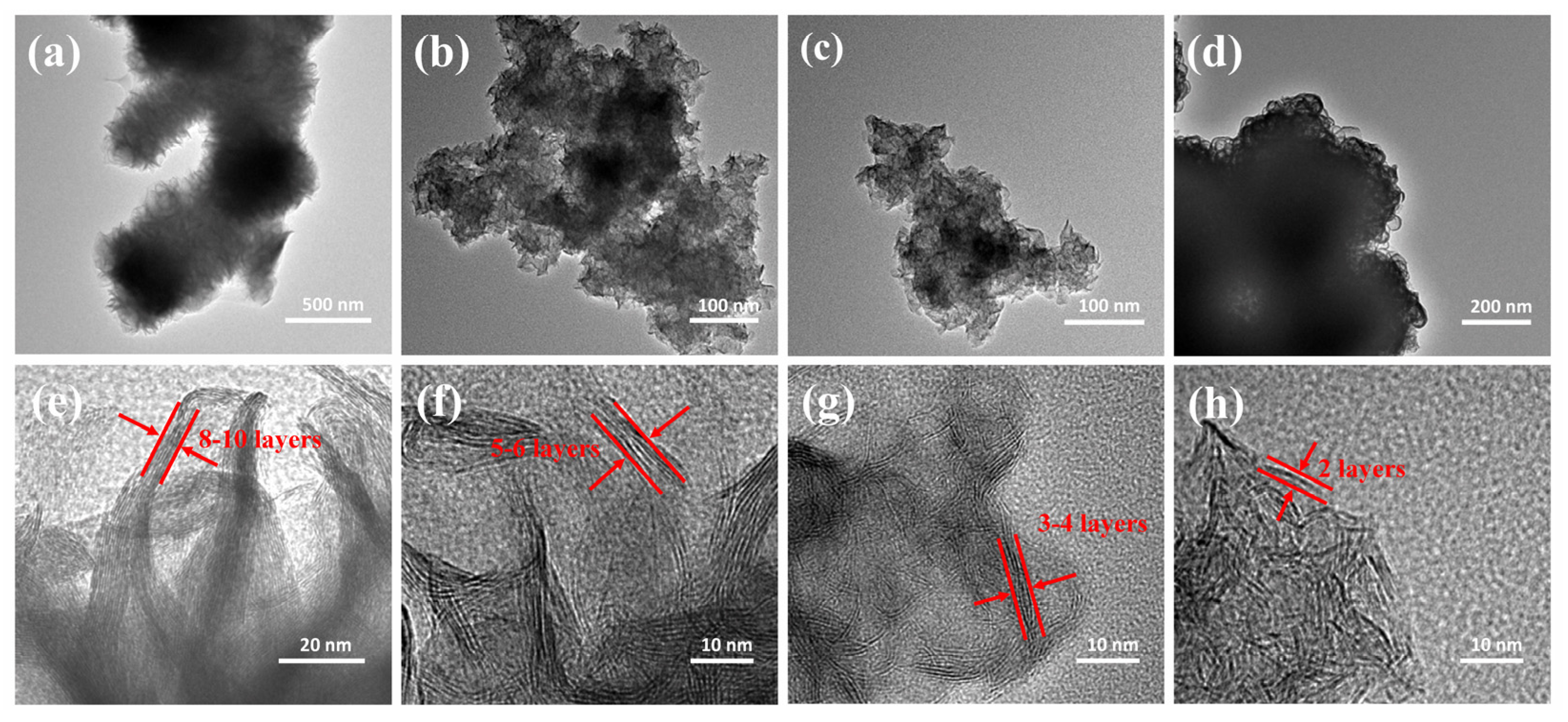

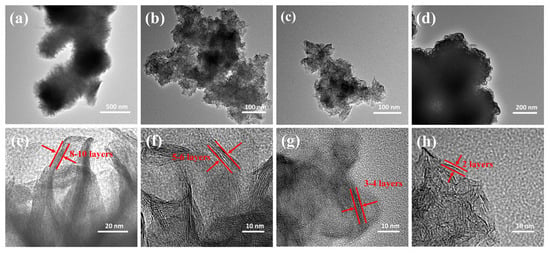

In order to clearly demonstrate this result, the morphology of MoS2 treated with NaBH4 was also observed using transmission electron microscopy (TEM). As shown in Figure 3a, the nanoflowers of MoS2 are composed of a large number of nanosheets. Interestingly, for MoS2-0.2595 and MoS2-0.3894, the diameters of the nanoflowers are reduced, and their thickness is noticeably decreased. However, for MoS2-0.5192, the nanosheets are much stacked, which resulted from the nanosheets of MoS2 re-agglomerating after severe few-layered exfoliation. The layered structure of MoS2 was observed using high-resolution transmission electron microscopy (HRTEM), and the characteristics of the multiple layers are shown in Figure 3e. As depicted in Figure 3f–h, MoS2-0.2595 consists of approximately 5–6 layers, MoS2-0.3894 contains around 3–4 layers, and MoS2-0.5192 only exhibits 2 layers, indicating that NaBH4 significantly influences the exfoliation process. Alkali metal Na+ ions can intercalate into the interlayers of MoS2 and achieve exfoliation of the layered materials during the hydrothermal process. The TEM results indicate that the amount of NaBH4 is crucially related to the exfoliation effect. A significant amount of NaBH4 can lead to evident fragmentation of MoS2, ultimately resulting in its re-aggregation. The microstructure of materials plays a critical role in determining its electrochemical performance. Upon exfoliation of MoS2, its increased interlayer spacing allows for improved ion transport and accessibility, leading to enhanced electrochemical reactions. Furthermore, the expanded specific surface area provides more active sites for electrochemical processes, ultimately boosting the material’s performance in energy storage applications. Additionally, the presence of more defects can promote electrolyte penetration and enhance charge transfer kinetics, further optimizing the electrochemical properties of electrode materials. However, the re-aggregation of few-layered MoS2 can inhibit its electrochemical performance.

Figure 3.

(a–d) The TEM images of MoS2, MoS2-0.2595, MoS2-0.3894 and MoS2-0.5192. (e–h) The HRTEM images of MoS2, MoS2-0.2595, MoS2-0.3894 and MoS2-0.5192.

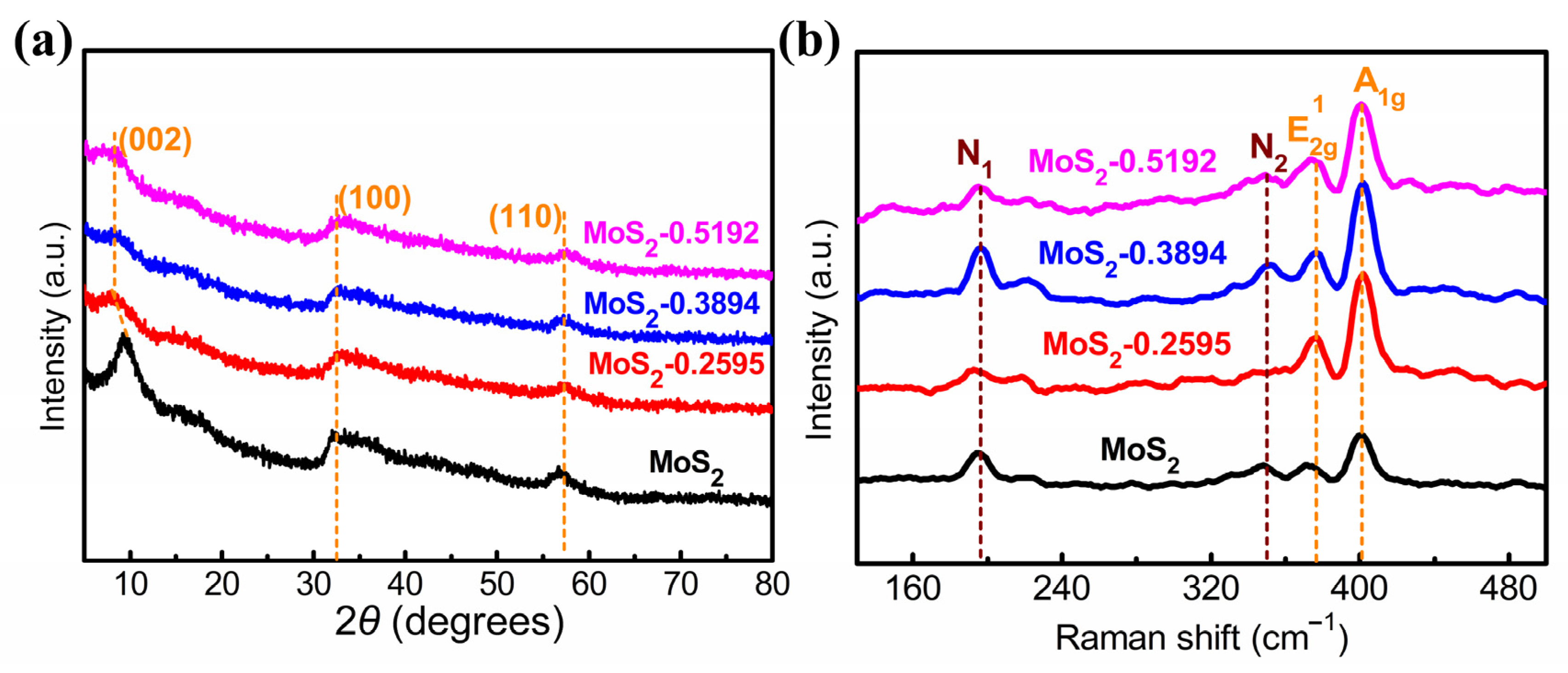

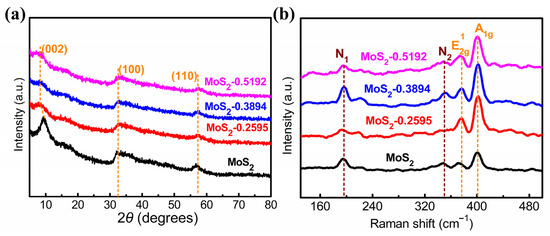

To investigate the crystal structure of all samples, X-ray diffraction (XRD) was applied. As shown in Figure 4a, there are three characteristic peaks located at 9.3°, 32.2°, and 56.9°, which correspond to the (002), (100), and (110) planes of MoS2 (JCPDS no. 37-1492), respectively [26]. The interlayer spacing was about 0.94 nm after calculation using the Bragg formula [27]. The wide interlayer spacing results from the intercalation of alkali metal Na+ ions. On the one hand, the (002) peak of MoS2 shifts from 9.4° to 8.2°, indicating the exfoliation of MoS2 into few layers with the increase in the amount of NaBH4. On the other hand, the (002) peak intensity of MoS2 weakens after exfoliation, which resulted in defects that affected its X-ray diffraction and weaken the intensity of the characteristic peak. Large interlayer spacing and numerous defects can have a significant impact on the electrochemical performance of electrode materials. A large interlayer spacing helps to improve ion diffusion within the material, enhances electrolyte permeability, and facilitates more effective charge–discharge processes. An increased number of defects can provide additional active sites, thereby promoting ion and electron transfer, and enhancing the reactivity and electrochemical performance of the electrode [28]. Therefore, the few-layered treatment is often considered key technology for improving electrochemical performance.

Figure 4.

(a,b) The XRD patterns and Raman spectra of MoS2, MoS2-0.2595, MoS2-0.3894, and MoS2-0.5192.

Further phase analysis of MoS2, MoS2-0.2595, MoS2-0.3894, and MoS2-0.5192 was conducted using Raman spectroscopy, and the results are shown in Figure 4b, revealing characteristic peaks of 1T-MoS2 and 2H-MoS2 [29]. Two typical vibration modes of 2H-MoS2, E2g1 and A1g, can be observed at 377.0 cm−1 and 401.8 cm−1, respectively. Interestingly, the characteristic peaks corresponding to 1T exhibited blue shifts toward the shortwave region. Peaks such as j1, j2, j3, and E1g shifted, accompanied by the appearance of two new peaks, N1 at 195.2 cm−1 and N2 at 352.0 cm−1. The blue shift phenomenon often coincides with the generation of new peaks, highlighting structural changes within the material. According to the Raman spectroscopy results, the sample contained part of 1T-MoS2. NaBH4 provided additional electrons for the formation of 1T-MoS2 due to its certain reduction properties during the exfoliation process of MoS2. 1T-MoS2 possesses high electrical conductivity, facilitating electron and ion transport to improve the response rate and charge–discharge efficiency of the electrode.

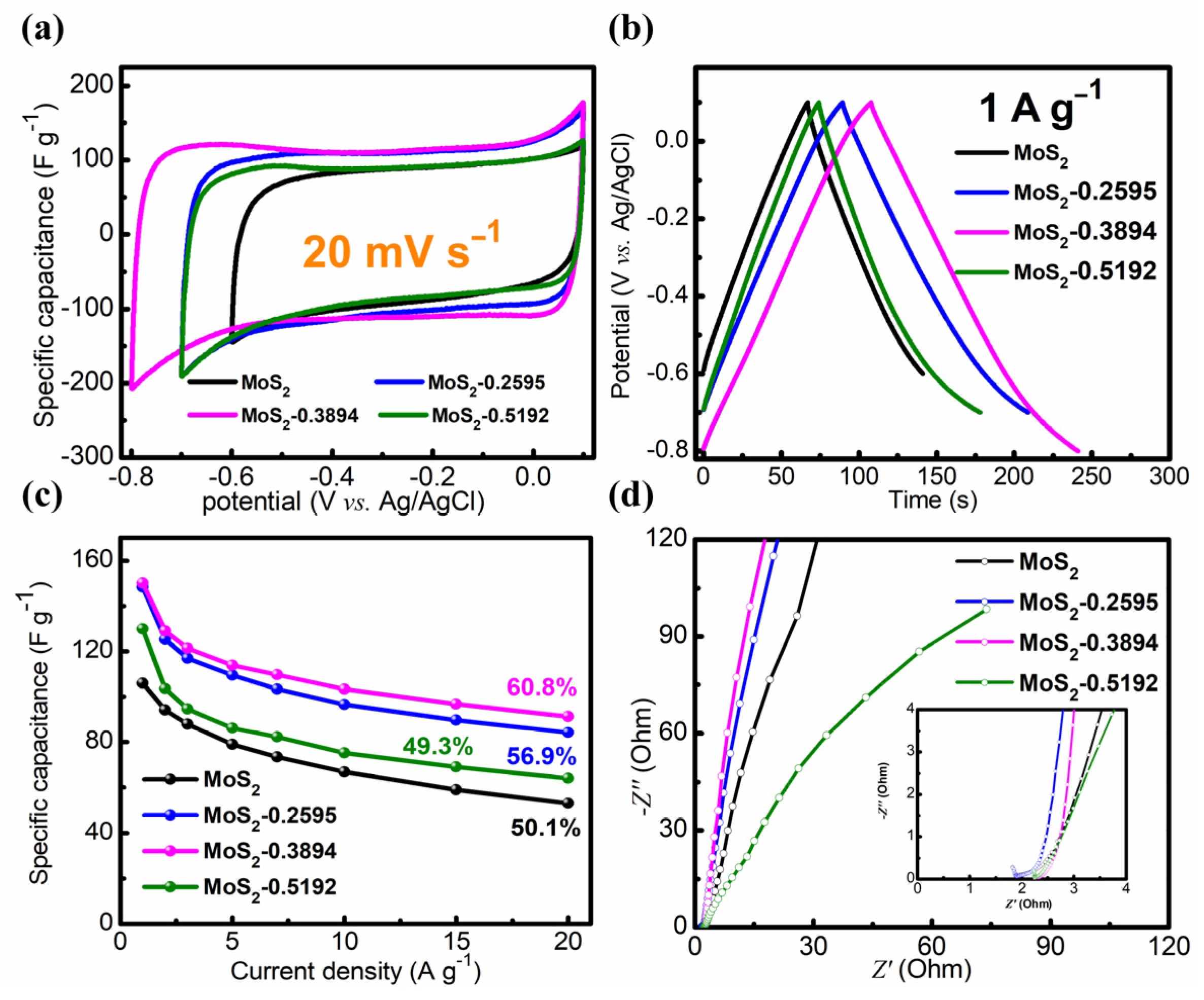

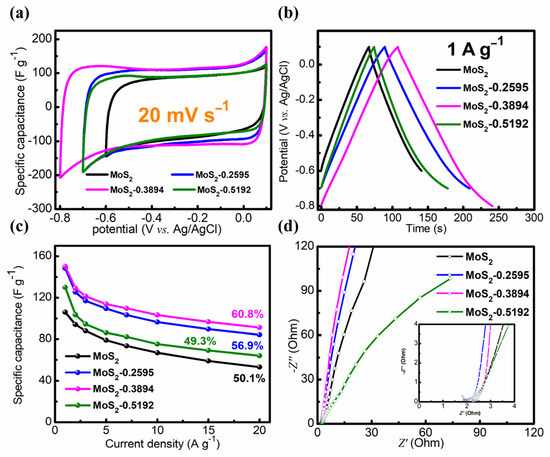

To display the supercapacitor performance of all samples, cyclic voltammetry (CV), galvanostatic charge–discharge (GCD), and electrochemical impedance spectroscopy (EIS) were evaluated using the three-electrode configuration. As shown in Figure 5a, the potential windows for MoS2, MoS2-0.2595, MoS2-0.3894, and MoS2-0.5192 are at 0.7, 0.8 and 0.9 V. Furthermore, as shown in Figure S1, the potential window for MoS2-0.3894 is from −0.8 to 0.1 V, which implies that MoS2-0.3894 has the largest potential window. Expanding the potential window not only enhances the capacitance capacity, contributing to the improved energy density and power density of supercapacitors, but also boosts response rates, enhancing the electrochemical kinetics performance of electrode materials. The expanded potential window was derived from the formation of the partial metallic phase of MoS2 during the exfoliation process, thereby enhancing the conductivity, and contributing to the properties of electrode materials. Additionally, the areas surrounded by the CV curves represent the capacitance of the electrode materials. It is clear that MoS2-0.3894 has the largest area of the CV curve compared to the other electrode materials, indicating the highest specific capacitance.

Figure 5.

(a–d) The cyclic voltammetry (CV) curves, galvanostatic charge–discharge (GCD) curves, rate performance and electrochemical impedance spectroscopy (EIS) of MoS2, MoS2-0.2595, MoS2-0.3894 and MoS2-0.5192.

In order to more accurately reflect the specific capacitance, the GCD curves of each electrode are displayed in Figure 5b. There were some specific capacitances of 105.9, 148.2, 150 and 129.8 F g−1 for MoS2, MoS2-0.2595, MoS2-0.3894 and MoS2-0.5192, respectively, at a current density of 1 A g−1. Obviously, the specific capacitance of MoS2 was improved with the assistance of NaBH4. As shown in Figure 5c, the rate performances of MoS2, MoS2-0.2595, MoS2-0.3894, and MoS2-0.5192 are displayed as 50.1%, 56.9%, 60.8%, and 49.3%, respectively, with a current density from 1 to 20 A g−1. As the amount of NaBH4 increased, the exfoliation of few-layered MoS2 becomes more pronounced, leading to the formation of a larger specific surface area and an increased presence of metallic phase MoS2, which enhanced the rate performance. However, in the case of MoS2-0.5192, the re-stacking of exfoliated few-layered nanosheets resulted in a reduction in the specific surface area, impeding the diffusion of ions. As depicted in Table 1, following treatment with NaBH4, the voltage window of MoS2 was expanded, the specific capacitance of MoS2 was enhanced, and the rate performance of MoS2 was improved. These results adequately demonstrate that few-layered MoS2 displays outstanding electrochemical performance.

Table 1.

The potential windows, specific capacitance and rate performance of MoS2, MoS2-0.2595, MoS2-0.3894, and MoS2-0.5192.

The EIS of each sample was measured, and the results are shown in Figure 5d. The EIS consists of high frequency and low frequency regions. In the high-frequency range, it typically represents the double-layer capacitance of the electrolyte at the electrode surface and the charge transfer process. In the low-frequency range, it usually represents the pseudocapacitance effect of the electrode material and the charge transfer process between the electrode and the electrolyte. MoS2-0.3894 had the smallest radius, indicating the lowest charge transfer resistance in the high-frequency region. Furthermore, the slope of MoS2-0.3894 was the biggest in the low frequency range compared to the other electrode materials, implying its capacitive-like behavior. Therefore, this indicates that MoS2-0.3894 has low equivalent series resistance (ESR) and high conductivity.

As shown in Figure S2, the CV and GCD curves of MoS2, MoS2-0.2595, MoS2-0.3894 and MoS2-0.5192 are shown as a series of scan rates and current densities. It is clear that the CV curves are all rectangle-like, while the GCD curves are all triangle-like, which indicates the capacitive-like behavior of all electrodes. To determine the dynamics of each electrode, the b-value fitting of each electrode is shown. The CV curves of MoS2-0.3894 electrode at various scan rates of 5, 10, 20, 30, 50, 70 and 100 mV s−1 were selected. The b-value fitting was calculated with the formula i(v) = avb, where i represents the current density (A g−1), v represents the scan rate (V s−1), a and b are both constant, respectively [30]. When the b-value is close to 0.5, it indicates semi-diffusion-controlled behavior, whereas a b-value close to 1 indicates capacitance-controlled behavior [31]. According to Figure S3, the b-value had a range from 0.75 to 1, suggesting capacitive-like behavior for the MoS2-0.3894 electrode. To clarify the contribution of capacitance behavior, the formula of i(v) = k1v + k2v1/2 was used for fitting, where k1v represents the contribution of capacitance behavior, while k2v1/2 represents the contribution of semi-diffusion behavior [32]. Figure S4 shows the fitting calculations of the capacitance contribution at different scan rates of 10, 20, 30, 50, 70, and 100 mV s−1. Moreover, the capacitance contributions increased from 77.1% to 90.3% at scan rate of 10, 20, 30, 50, 70 and 100 mV s−1, indicating high capacitance behavior.

4. Conclusions

In summary, few-layered MoS2 was successfully prepared using the one-pot hydrothermal method with the assistance of NaBH4. The exfoliation effects of different dosages of NaBH4 were also demonstrated in the results of the SEM and TEM images. Furthermore, a part of metallic phase MoS2 was obtained in the process of exfoliation. In terms of the electrochemical performance, the optimal sample of MoS2-0.3894 had a wide potential window of 0.9 V, the specific capacitance 150 F g−1 at 1 A g−1, and a high rate performance of 60.8%. NaBH4 plays an important role in the preparation of few-layered MoS2. This work provides a simple and effective solution for the preparation of few-layered two-dimensional materials.

Supplementary Materials

The supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/nano14110968/s1, Text S1: Experimental Section; Text S2: Electrochemical measurements and evaluations; Figure S1: The different potential windows of MoS2-0.3894 for the cyclic voltammetry (CV) and galvanostatic charge–discharge (GCD) curves at a same scan rate of 20 mV s−1 and current density of 1 A g−1; Figure S2: The CV and GCD curves of MoS2-0.3894 at a series of scan rates and current densities; Figure S3: b-value for MoS2-0.3894 electrode; Figure S4: CV partition analysis showing the capacitive contribution to the total current at select scan rates of 10, 20, 30, 50, 70 and 100 mV s−1; Figure S5: Normalized contribution ratio of capacitive capacitance at different scan rates.

Author Contributions

Conceptualization, Q.J., H.L. and Y.Z. (Yongxing Zhang); methodology, H.L., H.C. and Y.Z. (Yongxing Zhang); software, Q.W., L.M., Y.Z. (Yujie Zhao) and J.X.; validation, H.L., H.C. and Y.Z. (Yongxing Zhang); formal analysis, H.L., H.C. and Y.Z. (Yongxing Zhang); investigation, Y.Z. (Yujie Zhao), J.X., M.S. and Z.L.; resources, H.L. and Y.Z. (Yongxing Zhang); data curation, Q.J. and H.L.; writing—original draft, Q.J. and H.L.; writing—review and editing, Q.J., H.L. and Y.Z. (Yongxing Zhang); visualization, Q.J., Q.W. and L.M; supervision, Y.Z. (Yongxing Zhang); project administration, H.L., H.C. and Y.Z. (Yongxing Zhang); funding acquisition, H.L. and Y.Z. (Yongxing Zhang). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Key Natural Science Research Project for Colleges and Universities of Anhui Province (Grant No. 2022AH050384, KJ2021ZD0056), the University Enterprise Joint Research and Development Project (Grant No. 22100227, 22100229), the Excellent scientific research and innovation team of Education Department of Anhui Province (No. 2023AH010044), the University Synergy Innovation Program of Anhui Province (Grant No. GXXT-2023-098), the University Enterprise Joint Research and Development Project: Development of mod-ern spectral data mining and signal extraction techniques (Grant No. 2024340603000066).

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Noori, A.; El-Kady, M.F.; Rahmanifar, M.S.; Kaner, R.B.; Mousavi, M.F. Towards establishing standard performance metrics for batteries, supercapacitors and beyond. Chem. Soc. Rev. 2019, 48, 1272–1341. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.G.; Song, Y.F.; Xia, Y.Y. Electrochemical capacitors: Mechanism, materials, systems, characterization and applications. Chem. Soc. Rev. 2016, 45, 5925–5950. [Google Scholar] [CrossRef] [PubMed]

- Maqsood, M.F.; Latif, U.; Sheikh, Z.A.; Abubakr, M.; Rehman, S.; Khan, K.; Khan, M.A.; Kim, H.; Ouladsmane, M.; Rehman, M.A.; et al. A comprehensive study of Bi2Sr2Co2Oy misfit layered oxide as a supercapacitor electrode material. Inorg. Chem. Commun. 2023, 158, 111487. [Google Scholar] [CrossRef]

- Wei, Y.; Tang, B.; Liang, X.; Zhang, F.; Tang, Y. An ultrahigh-mass-loading integrated free-standing functional all-carbon positive electrode prepared using an architecture tailoring strategy for high-energy-density dual-ion batteries. Adv. Mater. 2023, 35, 2302086. [Google Scholar] [CrossRef] [PubMed]

- Dubal, D.P.; Chodankar, N.R.; Kim, D.H.; Gomez-Romero, P. Towards flexible solid-state supercapacitors for smart and wearable electronics. Chem. Soc. Rev. 2018, 47, 2065–2129. [Google Scholar] [CrossRef] [PubMed]

- Guo, T.Z.; Zhou, D.; Pang, L.X.; Sun, S.K.; Zhou, T.; Su, J.Z. Perspectives on working voltage of aqueous supercapacitors. Small 2022, 18, 2106360. [Google Scholar] [CrossRef] [PubMed]

- Mu, H.C.; Wang, W.Q.; Yang, L.F.; Chen, J.; Li, X.W.; Yuan, Y.Z.; Tian, X.H.; Wang, G.C. Fully integrated design of intrinsically stretchable electrodes for stretchable. Energy Storage Mater. 2021, 39, 130–138. [Google Scholar] [CrossRef]

- Lukatskaya, M.R.; Dunn, B.; Gogotsi, Y. Multidimensional materials and device architectures for future hybrid energy storage. Nat. Commun. 2016, 7, 12647. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, S.; Kumar, R.; Joanni, E.; Singh, R.K.; Shim, J.J. Advances in pseudocapacitive and battery-like electrode materials for high performance supercapacitors. J. Mater. Chem. A 2022, 10, 13190–13240. [Google Scholar] [CrossRef]

- Heine, T. Transition metal chalcogenides: Ultrathin inorganic materials with tunable electronic properties. Acc. Chem. Res. 2015, 48, 65–72. [Google Scholar] [CrossRef]

- Butler, S.Z.; Hollen, S.M.; Cao, L.Y.; Cui, Y.; Gupta, J.A.; Gutiérrez, H.R.; Heinz, T.F.; Hong, S.S.; Huang, J.X.; Ismach, A.F.; et al. Progress, Challenges, and opportunities in two-dimensional materials beyond graphene. ACS Nano 2013, 7, 2898–2926. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.X.; Lei, W.; Zhang, S.W.; Liu, Y.Q.; Wallace, G.G.; Chen, J. Two-dimensional transition metal dichalcogenides in supercapacitors and secondary batteries. Energy Storage Mater. 2019, 19, 408–423. [Google Scholar] [CrossRef]

- Peng, L.L.; Zhu, Y.; Li, H.S.; Yu, G.H. Chemically integrated inorganic-graphene two-dimensional hybrid materials for flexible energy storage devices. Small 2016, 12, 6183–6199. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.F.; Sun, H.N.; Bai, X. Two-dimensional transition metal dichalcogenides: Synthesis, biomedical applications and biosafety evaluation. Front. Bioeng. Biotechnol. 2020, 8, 236. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.L.; Walker, W.R.; Xu, L.Z.; Krysiak, O.; She, Z.M.; Pope, M.A. Intrinsic capacitance of molybdenum disulfide. ACS Nano 2020, 14, 5636–5648. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Liu, Y.P.; Yu, J.; Ye, Q.T.; Yang, L.; Li, Y.; Fan, H.J. Biaxially strained MoS2 nanoshells with controllable layers boost alkaline hydrogen evolution. Adv. Mater. 2022, 34, 2202195. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wang, L.L.; Cai, T.; Zhang, S.Q.; Liu, Y.T.; Song, Y.Z.; Dong, X.R.; Hu, L. Glucose-assisted synthesize 1D/2D nearly vertical CdS/MoS2 heterostructures for efficient photocatalytic hydrogen evolution. Chem. Eng. J. 2017, 321, 366–374. [Google Scholar] [CrossRef]

- Nie, K.K.; Qu, X.Y.; Gao, D.W.; Li, B.J.; Yuan, Y.L.; Liu, Q.; Li, X.H.; Chong, S.K.; Liu, Z.Q. Engineering phase stability of semimetallic MoS2 monolayers for sustainable electrocatalytic hydrogen production. ACS Appl. Mater. Interfaces 2022, 14, 19847–19856. [Google Scholar] [CrossRef]

- Wan, Y.; Zhang, Z.Y.; Xu, X.L.; Zhang, Z.H.; Li, P.; Fang, X.; Zhang, K.; Yuan, K.; Liu, K.H.; Ran, G.Z.; et al. Engineering active edge sites of fractal-shaped single-layer MoS2 catalysts for high-efficiency hydrogen evolution. Nano Energy 2018, 51, 786–792. [Google Scholar] [CrossRef]

- Liu, M.Q.; Wang, J.A.; Klysubun, W.; Wang, G.G.; Sattayaporn, S.; Li, F.; Cai, Y.W.; Zhang, F.C.; Yu, J.; Yang, Y. Interfacial electronic structure engineering on molybdenum sulfide for robust dual-pH hydrogen evolution. Nat. Commun. 2021, 12, 5260. [Google Scholar] [CrossRef]

- Yang, X.; Mao, J.J.; Niu, H.; Wang, Q.; Zhu, K.; Ye, K.; Wang, G.L.; Cao, D.X.; Yan, J. NiS2/MoS2 mixed phases with abundant active edge sites induced by sulfidation and graphene introduction towards high-rate supercapacitors. Chem. Eng. J. 2021, 406, 126713. [Google Scholar] [CrossRef]

- Ma, G.F.; Peng, H.; Mu, J.J.; Huang, H.H.; Zhou, X.Z.; Lei, Z.Q. In situ intercalative polymerization of pyrrole in graphene analogue of MoS2 as advanced electrode material in supercapacitor. J. Power Sources 2013, 229, 72–78. [Google Scholar] [CrossRef]

- Wang, H.Y.; Ren, D.Y.; Zhu, Z.J.; Saha, P.; Jiang, H.; Li, C.Z. Few-layer MoS2 nanosheets incorporated into hierarchical porous carbon for lithium-ion batteries. Chem. Eng. J. 2016, 288, 179–184. [Google Scholar] [CrossRef]

- Qi, K.; Cui, X.Q.; Gu, L.; Yu, S.S.; Fan, X.F.; Luo, M.C.; Xu, S.; Li, N.B.; Zheng, L.R.; Zhang, Q.H.; et al. Single-atom cobalt array bound to distorted 1T MoS2 with ensemble effect for hydrogen evolution catalysis. Nat. Commun. 2019, 10, 5231. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Liu, Y.C.; Liu, H.Q.; Kang, H.Y.; Cao, K.Z.; Wang, Q.H.; Zhang, C.L.; Wang, Y.J.; Yuan, H.T.; Jiao, L.F. Improved dehydrogenation performance of LiBH4 by 3D hierarchical flower-like MoS2 spheres additives. J. Power Sources 2015, 300, 358–364. [Google Scholar] [CrossRef]

- Li, J.D.; Listwan, A.; Liang, J.X.; Shi, F.; Li, K.; Jia, J.P. High proportion of 1 T phase MoS2 prepared by a simple solvothermal method for high-efficiency electrocatalytic hydrogen evolution. Chem. Eng. J. 2021, 422, 130100. [Google Scholar] [CrossRef]

- Zhou, J.; Guo, M.; Wang, L.L.; Ding, Y.B.; Zhang, Z.Z.; Tang, Y.H.; Liu, C.B.; Luo, S.L. 1T-MoS2 nanosheets confined among TiO2 nanotube arrays for high performance supercapacitor. Chem. Eng. J. 2019, 366, 163–171. [Google Scholar] [CrossRef]

- Gao, G.P.; Jiao, Y.; Ma, F.X.; Jiao, Y.L.; Waclawik, E.; Du, A.J. Charge mediated semiconducting-to-metallic phase transition in molybdenum disulfide monolayer and hydrogen evolution reaction in new 1T’ phase. J. Phys. Chem. C 2015, 119, 13124–13128. [Google Scholar] [CrossRef]

- Hong, Z.A.; Hong, W.T.; Wang, B.C.; Cai, Q.; He, X.; Liu, W. Stable 1T-2H MoS2 heterostructures for efficient electrocatalytic hydrogen evolution. Chem. Eng. J. 2023, 460, 141858. [Google Scholar] [CrossRef]

- Feng, N.; Meng, R.J.; Zu, L.H.; Feng, Y.T.; Peng, C.X.; Huang, J.M.; Liu, G.L.; Chen, B.J.; Yang, J.H. A polymer-direct-intercalation strategy for MoS2/carbon-derived heteroaerogels with ultrahigh pseudocapacitance. Nat. Commun. 2019, 10, 1372. [Google Scholar] [CrossRef]

- Thiyagarajan, K.; Song, W.J.; Park, H.; Selvaraj, V.; Moon, S.; Oh, J.; Kwak, M.J.; Park, G.; Kong, M.; Pal, M.; et al. Electroactive 1T-MoS2 fluoroelastomer ink for intrinsically stretchable solid-state in-plane supercapacitors. ACS Appl. Mater. Interfaces 2021, 13, 26870–26878. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, P.; Janas, D.; Chandra, R. Self-standing MoS2/CNT and MnO2/CNT one dimensional core shell heterostructures for asymmetric supercapacitor applications. Carbon 2021, 177, 291–303. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).