High-Performance Ultraviolet Photodetectors Based on Nanoporous GaN with a Ga2O3 Single-Crystal Layer

Abstract

1. Introduction

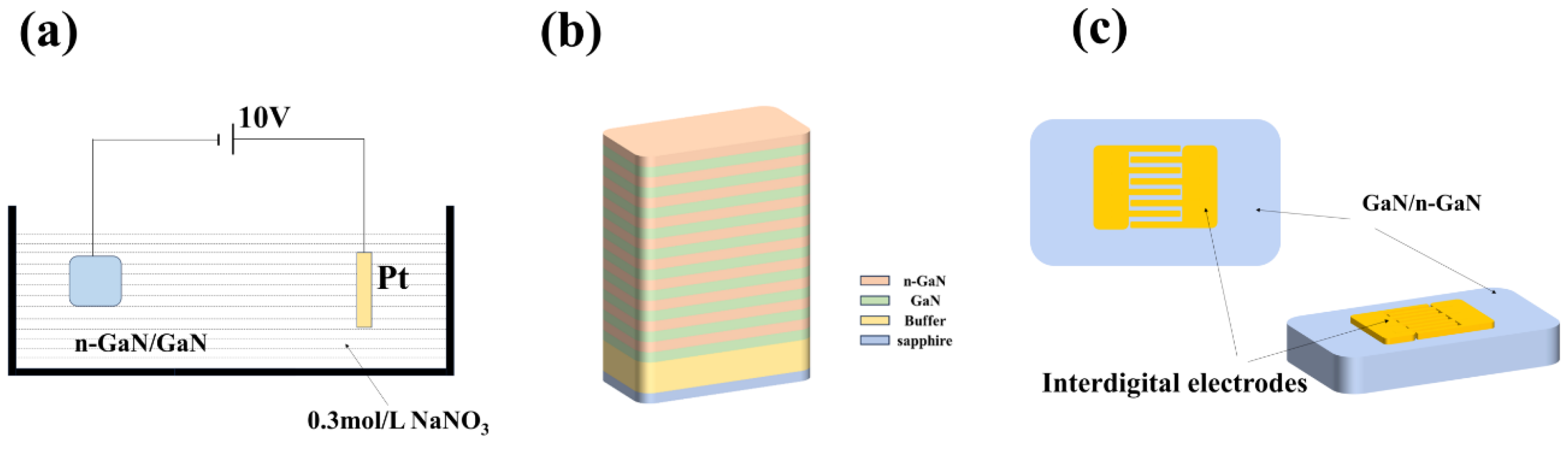

2. Materials and Methods

3. Results and Discussion

3.1. Potodetector Based on NP-GaN-DBR

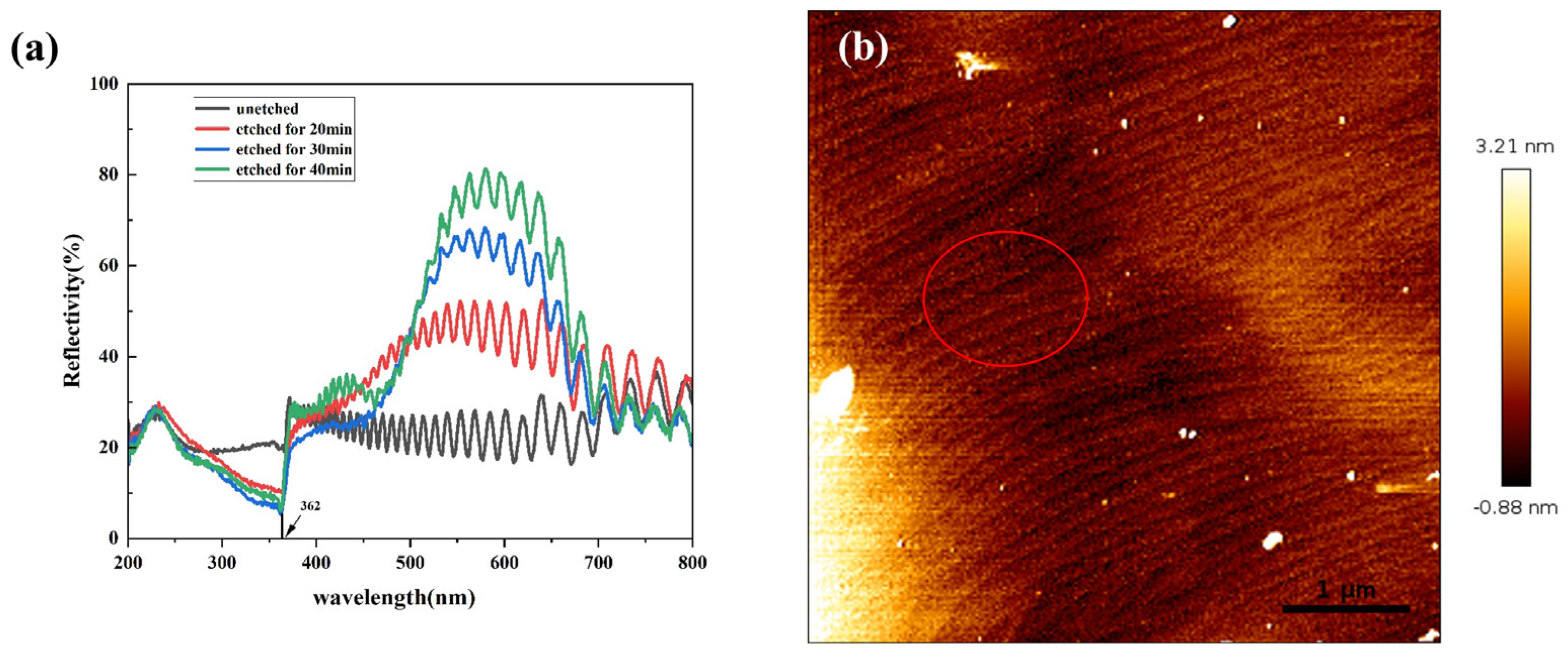

3.1.1. Etching Mechanism and Properties of NP-GaN DBR

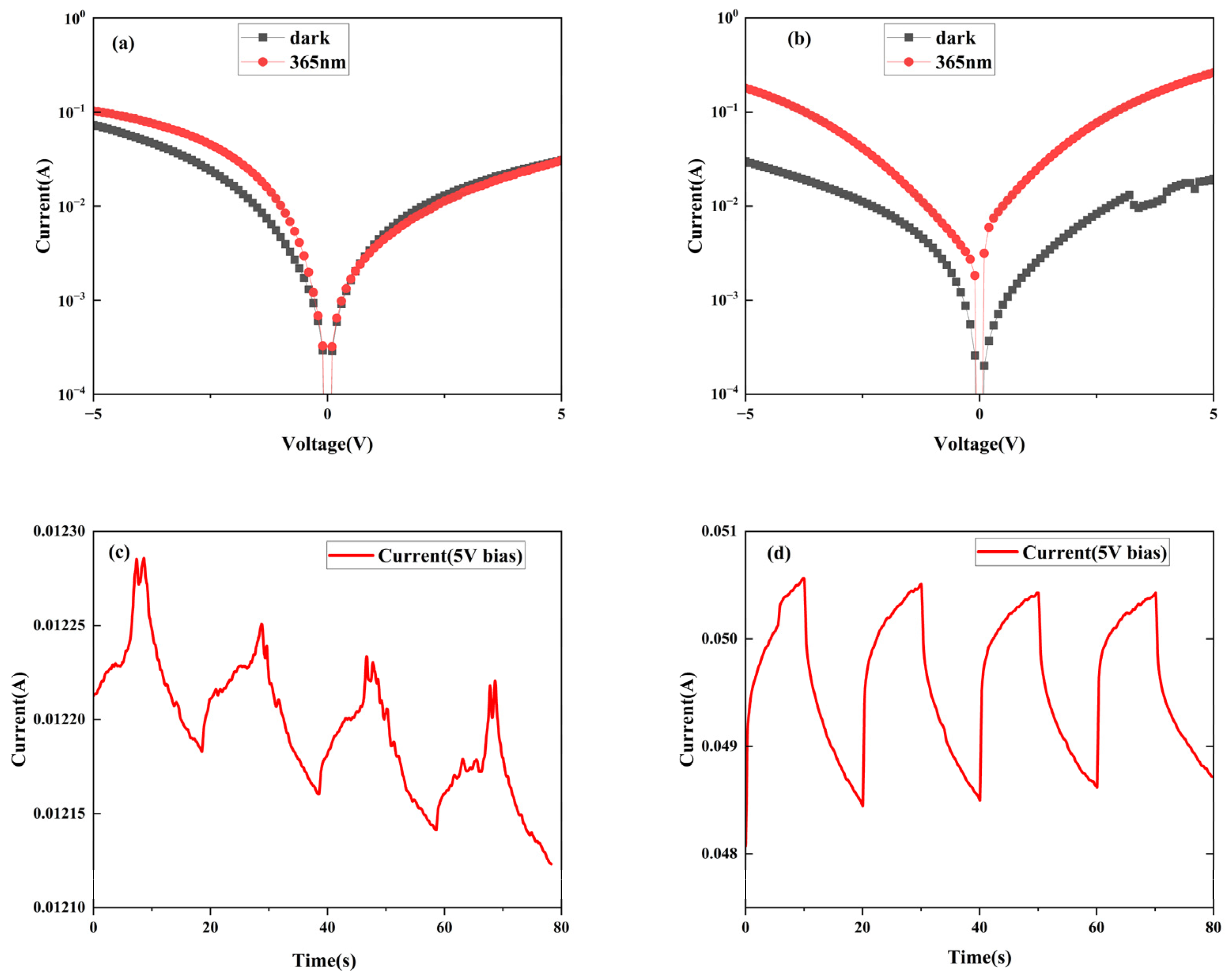

3.1.2. Photoresponse Properties of NP-GaN-DBR PD

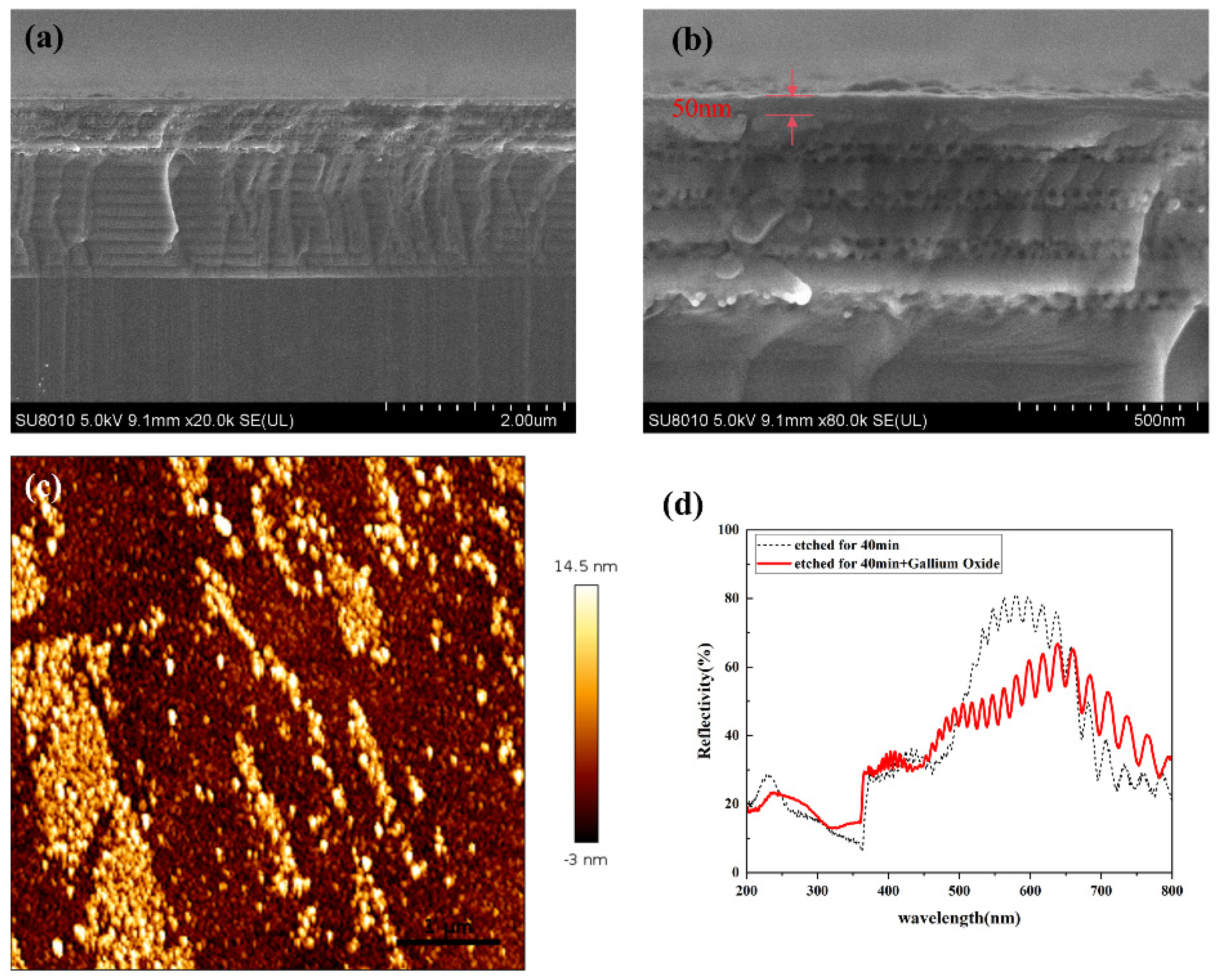

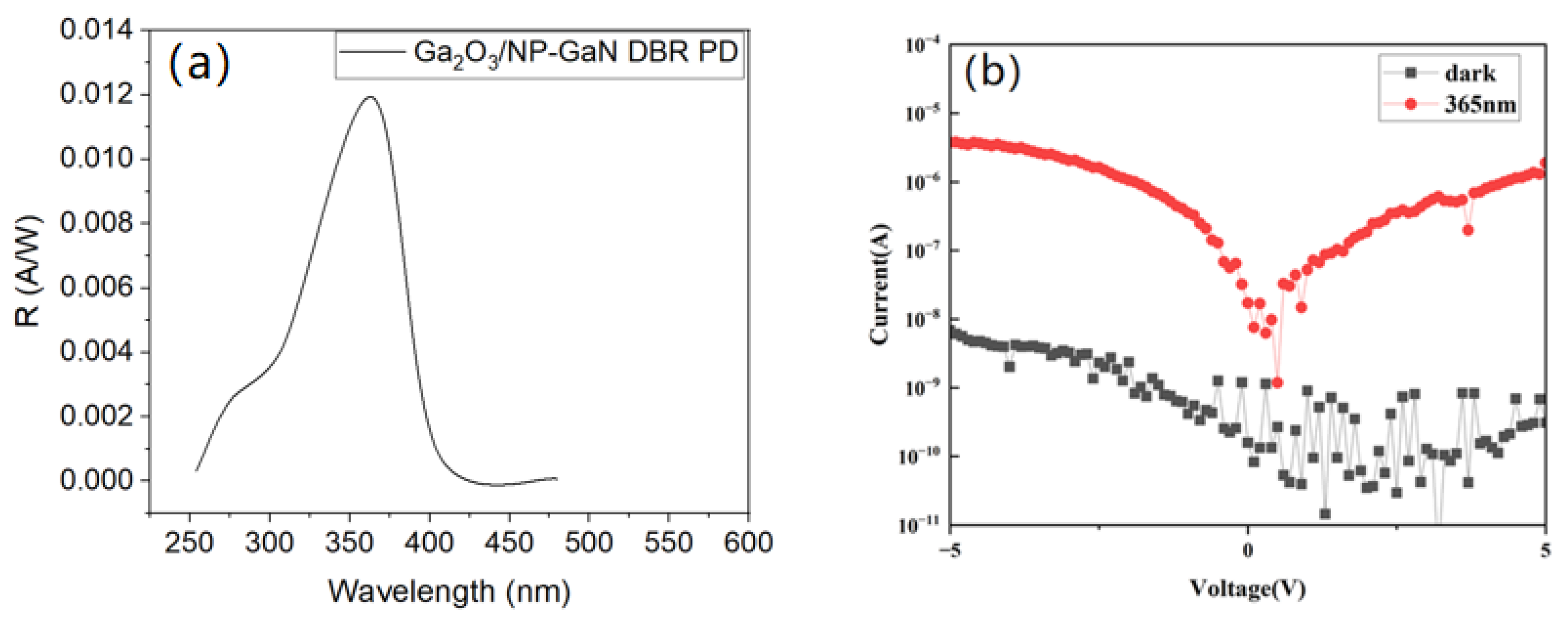

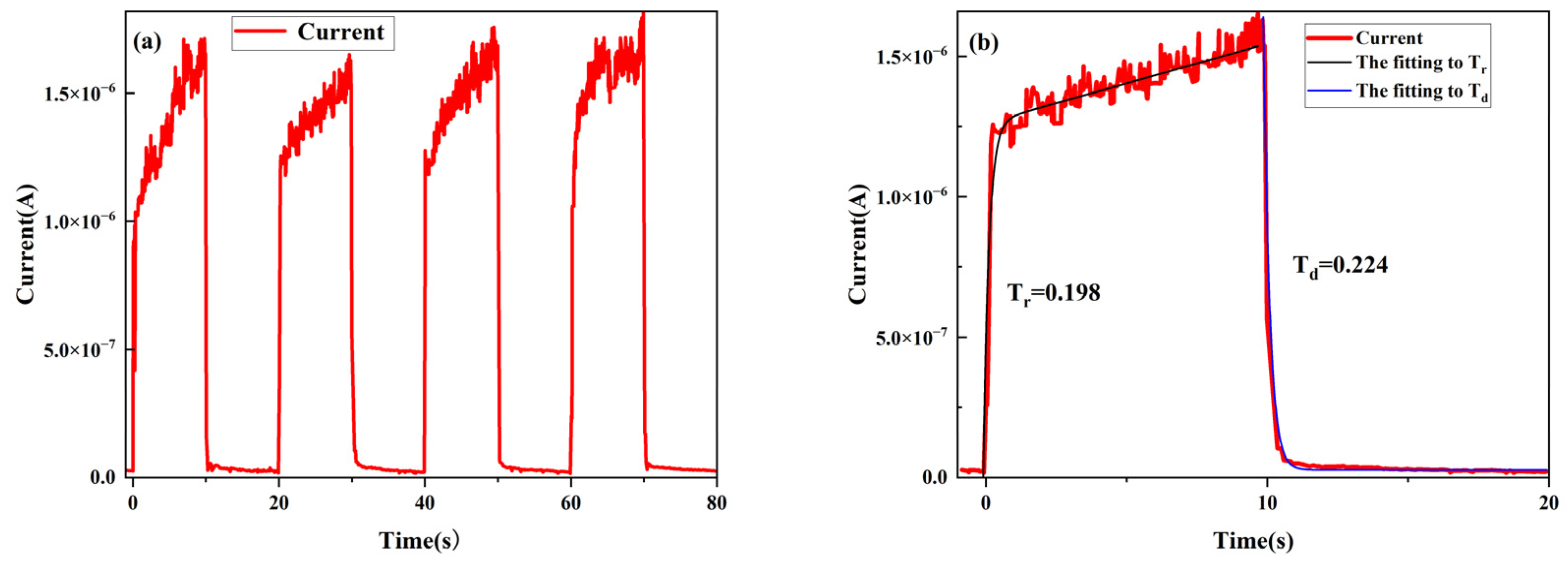

3.2. Photodetector Based on Ga2O3/NP-GaN-DBR

3.2.1. Characterization of Ga2O3 Thin Film

3.2.2. Photoresponse Properties of Ga2O3/NP-GaN-DBR PD Device

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Weisman, M.J.; Dagefu, F.T.; Moore, T.J.; Arslan, C.H.; Drost, R.J. Analysis of the low-probability-of-detection characteristics of ultraviolet communications. Opt. Express 2020, 28, 23640–23651. [Google Scholar] [CrossRef]

- Biswal, M.R.; Arya, S.; Chung, Y.H. Effect of turbulence and noise on ultraviolet and mid-infrared spectrum in optical wireless communications. Photonic Netw. Commun. 2020, 39, 181–186. [Google Scholar] [CrossRef]

- Nasiri, N.; Jin, D.; Tricoli, A. Nanoarchitechtonics of Visible-Blind Ultraviolet Photodetector Materials: Critical Features and Nano-Microfabrication. Adv. Opt. Mater. 2019, 7, 1800580. [Google Scholar] [CrossRef]

- Ouyang, W.; Teng, F.; He, J.H.; Fang, X. Enhancing the Photoelectric Performance of Photodetectors Based on Metal Oxide Semiconductors by Charge-Carrier Engineering. Adv. Funct. Mater. 2019, 29, 1807672. [Google Scholar] [CrossRef]

- Li, S.; Guo, D.; Li, P.; Wang, X.; Wang, Y.; Yan, Z.; Liu, Z.; Zhi, Y.; Huang, Y.; Wu, Z.; et al. Ultrasensitive, Superhigh Signal-to-Noise Ratio, Self-Powered Solar-Blind Photodetector Based on n-Ga2O3/p-CuSCN Core–Shell Microwire Heterojunction. ACS Appl. Mater. Interfaces 2019, 11, 35105–35114. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, B.; Liu, Q.; Yang, W.; Xiong, C.; Li, J.; Jiang, X. Ultrasensitive and Highly Selective Photodetections of UV-A Rays Based on Individual Bicrystalline GaN Nanowire. ACS Appl. Mater. Interfaces 2017, 9, 2669–2677. [Google Scholar] [CrossRef] [PubMed]

- Rabiee Golgir, H.; Li, D.W.; Keramatnejad, K.; Zou, Q.M.; Xiao, J.; Wang, F.; Jiang, L.; Silvain, J.-F.; Lu, Y.F. Fast Growth of GaN Epilayers via Laser-Assisted Metal–Organic Chemical Vapor Deposition for Ultraviolet Photodetector Applications. ACS Appl. Mater. Interfaces 2017, 9, 21539–21547. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.-R.; Jiang, Q.-M.; Hou, F.; Wang, Z.-G.; Pan, G.-B. Fabrication of high aspect ratio gallium nitride nanostructures by photochemical etching for enhanced photocurrent and photoluminescence property. Scr. Mater. 2018, 146, 115–118. [Google Scholar] [CrossRef]

- Guo, X.Y.; Williamson, T.L.; Bohn, P.W. Enhanced ultraviolet photoconductivity in porous GaN prepared by metal-assisted electroless etching. Solid State Commun. 2006, 140, 159–162. [Google Scholar] [CrossRef]

- Meng, R.; Ji, X.; Lou, Z.; Yang, J.; Zhang, Y.; Zhang, Z.; Bi, W.; Wang, J.; Wei, T. High-performance nanoporous-GaN metal-insulator-semiconductor ultraviolet photodetectors with a thermal oxidized β-Ga2O3 layer. Opt. Lett. 2019, 44, 2197–2200. [Google Scholar] [CrossRef]

- Hu, T.; Zhao, L.; Wang, Y.; Lin, H.; Xie, S.; Hu, Y.; Liu, C.; Zhu, W.; Wei, Z.; Liu, J.; et al. High-Sensitivity and Fast-Speed UV Photodetectors Based on Asymmetric Nanoporous-GaN/Graphene Vertical Junction. ACS Nano 2023, 17, 8411–8419. [Google Scholar] [CrossRef]

- Liu, H.Y.; Hsu, W.C.; Chou, B.Y.; Wang, Y.H.; Sun, W.C.; Wei, S.Y.; Yu, S.M.; Chiang, M.H. Growing Al2O3 by Ultrasonic Spray Pyrolysis for Al2O3/AlGaN/GaN Metal-Insulator-Semiconductor Ultraviolet Photodetectors. IEEE Trans. Electron Devices 2014, 61, 4062–4069. [Google Scholar]

- Hwang, J.-D.; Lin, C.J. High 366/254-nm Rejection Contrast GaN MIS Photodetectors Using Nano Spin-Oxide. IEEE Electron Device Lett. 2009, 30, 27–29. [Google Scholar] [CrossRef]

- Lee, M.L.; Mue, T.S.; Huang, F.W.; Yang, J.H.; Sheu, J.K. High-performance GaN metal-insulator-semiconductor ultraviolet photodetectors using gallium oxide as gate layer. Opt. Express 2011, 19, 12658–12663. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.-H. GaN-Based Metal–Insulator–Semiconductor Ultraviolet Photodetectors with HfO2 Insulators. Jpn. J. Appl. Phys. 2013, 52, 08JF08. [Google Scholar] [CrossRef]

- Lupan, O.; Braniste, T.; Deng, M.; Ghimpu, L.; Paulowicz, I.; Mishra, Y.K.; Kienle, L.; Adelung, R.; Tiginyanu, I. Rapid switching and ultra-responsive nanosensors based on individual shell-core Ga2O3/GaN:Ox@ SnO2 nanobelt with nanocrystalline shell in mixed phases. Sens. Actuators B Chem. 2015, 221, 544–555. [Google Scholar] [CrossRef]

- Song, Y.K.; Zhou, H.; Diagne, M.; Ozden, I.; Vertikov, A.; Nurmikko, A.V.; Carter-Coman, C.; Kern, R.S.; Kish, F.A.; Krames, M.R. A vertical cavity light emitting InGaN quantum well heterostructure. Appl. Phys. Lett. 1999, 74, 3441–3443. [Google Scholar] [CrossRef]

- Naranjo, F.B.; Fernández, S.; Sánchez-García, M.A.; Calle, F.; Calleja, E. Resonant-cavity InGaN multiple-quantum-well green light-emitting diode grown by molecular-beam epitaxy. Appl. Phys. Lett. 2002, 80, 2198–2200. [Google Scholar] [CrossRef]

- Someya, T.; Werner, R.; Forchel, A.; Catalano, M.; Cingolani, R.; Arakawa, Y. Room Temperature Lasing at Blue Wavelengths in Gallium Nitride Microcavities. Science 1999, 285, 1905–1906. [Google Scholar] [CrossRef]

- Lu, T.-C.; Kao, C.-C.; Kuo, H.-C.; Huang, G.-S.; Wang, S.-C. CW lasing of current injection blue GaN-based vertical cavity surface emitting laser. Appl. Phys. Lett. 2008, 92, 141102. [Google Scholar] [CrossRef]

- Zhang, C.; Park, S.H.; Chen, D.; Lin, D.-W.; Xiong, W.; Kuo, H.-C.; Lin, C.-F.; Cao, H.; Han, J. Mesoporous GaN for Photonic Engineering—Highly Reflective GaN Mirrors as an Example. ACS Photonics 2015, 2, 980–986. [Google Scholar] [CrossRef]

- Yang, X.; Du, X.; He, L.; Wang, D.; Zhao, C.; Liu, J.; Ma, J.; Xiao, H. Fabrication and optoelectronic properties of Ga2O3/Eu epitaxial films on nanoporous GaN distributed Bragg reflectors. J. Mater. Sci. 2020, 55, 8231–8240. [Google Scholar] [CrossRef]

- Zhu, H.; Chen, R.; Han, X.; Wang, Y.; Luan, C.; Ma, J.; Xiao, H. Fabrication of ZnSnO3 single crystal films on sapphire substrates by pulsed laser deposition for solar-blind photodetectors. Appl. Phys. Lett. 2024, 124, 122104. [Google Scholar] [CrossRef]

- Zangooie, S.; Jansson, R.; Arwin, H. Ellipsometric characterization of anisotropic porous silicon Fabry-Pérot filters and investigation of temperature effects on capillary condensation efficiency. J. Appl. Phys. 1999, 86, 850–858. [Google Scholar] [CrossRef]

- Cao, D.; Yang, X.; Shen, L.; Zhao, C.; Luan, C.; Ma, J.I.N.; Xiao, H. Fabrication and properties of high quality InGaN-based LEDs with highly reflective nanoporous GaN mirrors. Photonics Res. 2018, 6, 1144–1150. [Google Scholar] [CrossRef]

- Chen, R.; Wang, D.; Liu, J.; Feng, B.; Zhu, H.; Han, X.; Luan, C.; Ma, J.; Xiao, H. Ta-Doped Ga2O3 Epitaxial Films on Porous p-GaN Substrates: Structure and Self-Powered Solar-Blind Photodetectors. Cryst. Growth Des. 2022, 22, 5285–5292. [Google Scholar] [CrossRef]

- Liu, H.; Meng, J.; Zhang, X.; Chen, Y.; Yin, Z.; Wang, D.; Wang, Y.; You, J.; Gao, M.; Jin, P. High-performance deep ultraviolet photodetectors based on few-layer hexagonal boron nitride. Nanoscale 2018, 10, 5559–5565. [Google Scholar] [CrossRef] [PubMed]

- Vajpeyi, A.P.; Tripathy, S.; Shannigrahi, S.R.; Foo, B.C.; Wang, L.S.; Chua, S.J.; Alves, E. Influence of rapid thermal annealing on the luminescence properties of nanoporous GaN films. Electrochem. Solid-State Lett. 2006, 9, G150–G154. [Google Scholar] [CrossRef]

- Kim, S.; Kadam, M.; Kang, J.-H.; Ryu, S.-W. Optical characteristics of wet-thermally oxidized bulk and nanoporous GaN. Electron. Mater. Lett. 2016, 12, 596–602. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, J.; Wang, Y.; Zhang, B.; Chen, R.; Zhu, H.; Han, X.; Xiao, H. High-Performance Ultraviolet Photodetectors Based on Nanoporous GaN with a Ga2O3 Single-Crystal Layer. Nanomaterials 2024, 14, 1165. https://doi.org/10.3390/nano14131165

Wen J, Wang Y, Zhang B, Chen R, Zhu H, Han X, Xiao H. High-Performance Ultraviolet Photodetectors Based on Nanoporous GaN with a Ga2O3 Single-Crystal Layer. Nanomaterials. 2024; 14(13):1165. https://doi.org/10.3390/nano14131165

Chicago/Turabian StyleWen, Junjie, Yuankang Wang, Biao Zhang, Rongrong Chen, Hongyan Zhu, Xinyu Han, and Hongdi Xiao. 2024. "High-Performance Ultraviolet Photodetectors Based on Nanoporous GaN with a Ga2O3 Single-Crystal Layer" Nanomaterials 14, no. 13: 1165. https://doi.org/10.3390/nano14131165

APA StyleWen, J., Wang, Y., Zhang, B., Chen, R., Zhu, H., Han, X., & Xiao, H. (2024). High-Performance Ultraviolet Photodetectors Based on Nanoporous GaN with a Ga2O3 Single-Crystal Layer. Nanomaterials, 14(13), 1165. https://doi.org/10.3390/nano14131165