Optimum Design of InGaN Blue Laser Diodes with Indium-Tin-Oxide and Dielectric Cladding Layers

Abstract

:1. Introduction

2. LD Structure and Simulation Method

2.1. LD Structure

2.2. Simulation Method

3. Results and Discussion

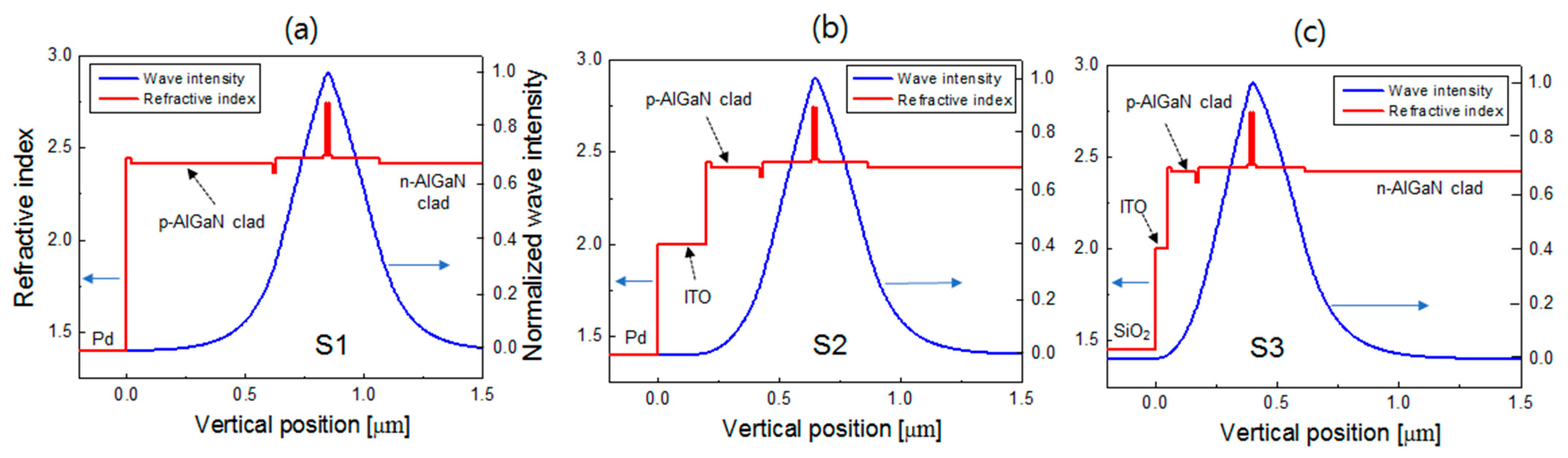

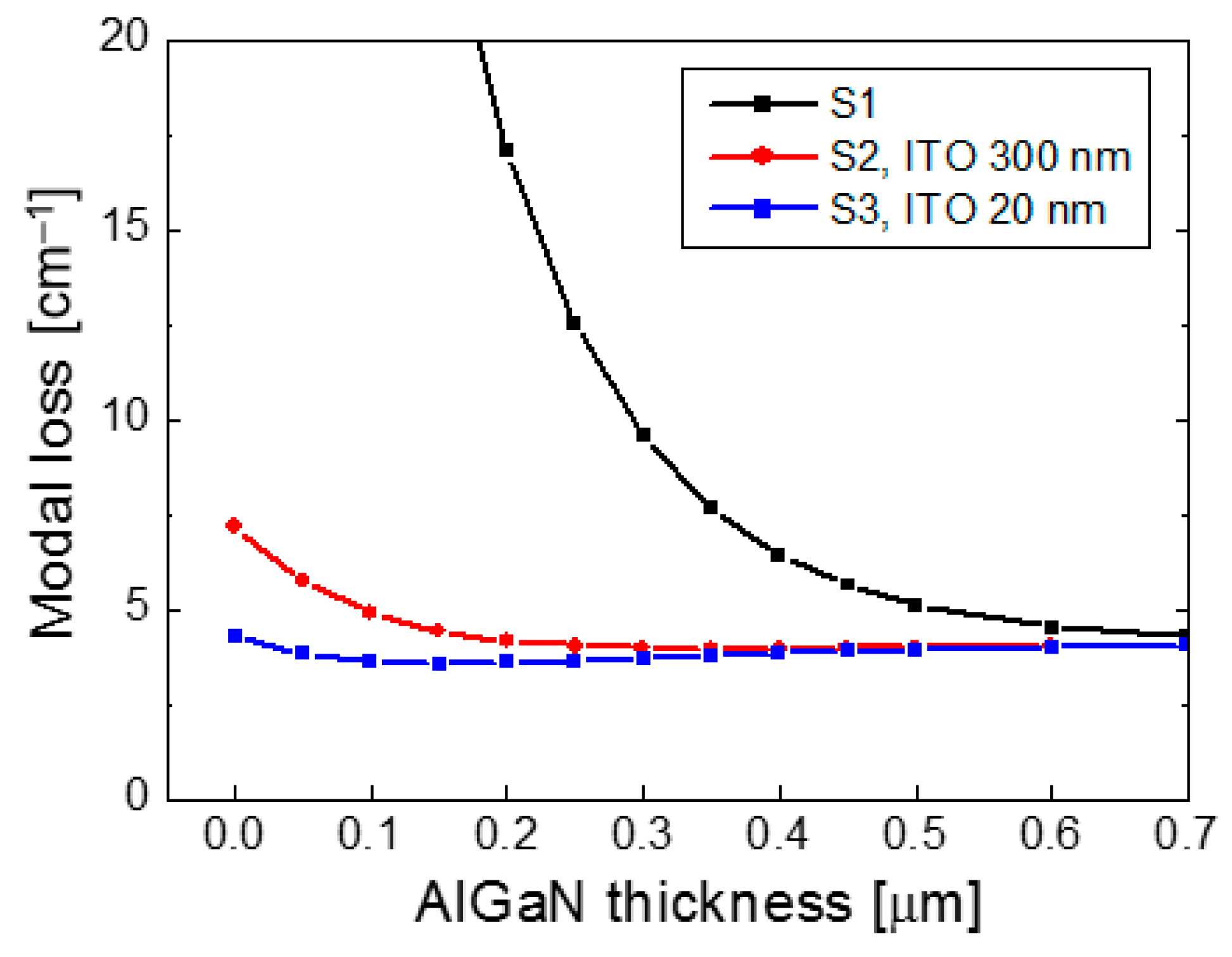

3.1. Modal Loss of Simulated Structures

3.2. Device Performance of Conventional LD Structure (S1)

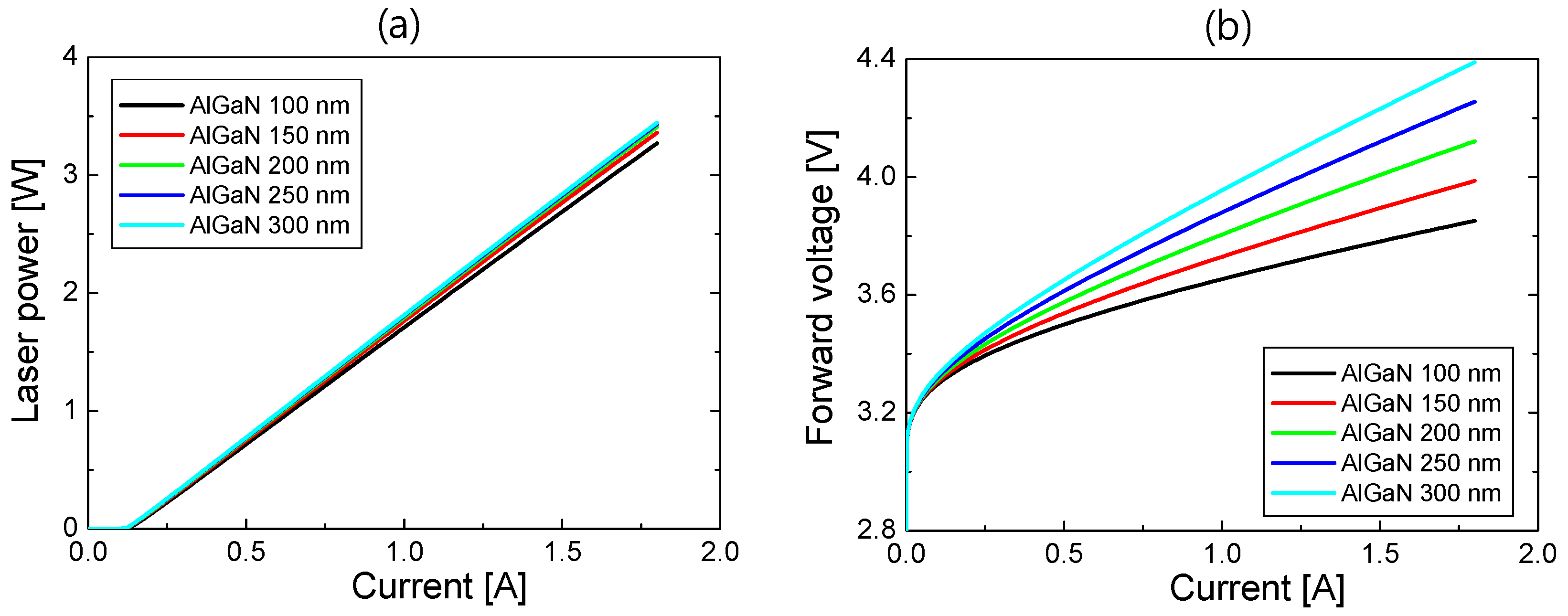

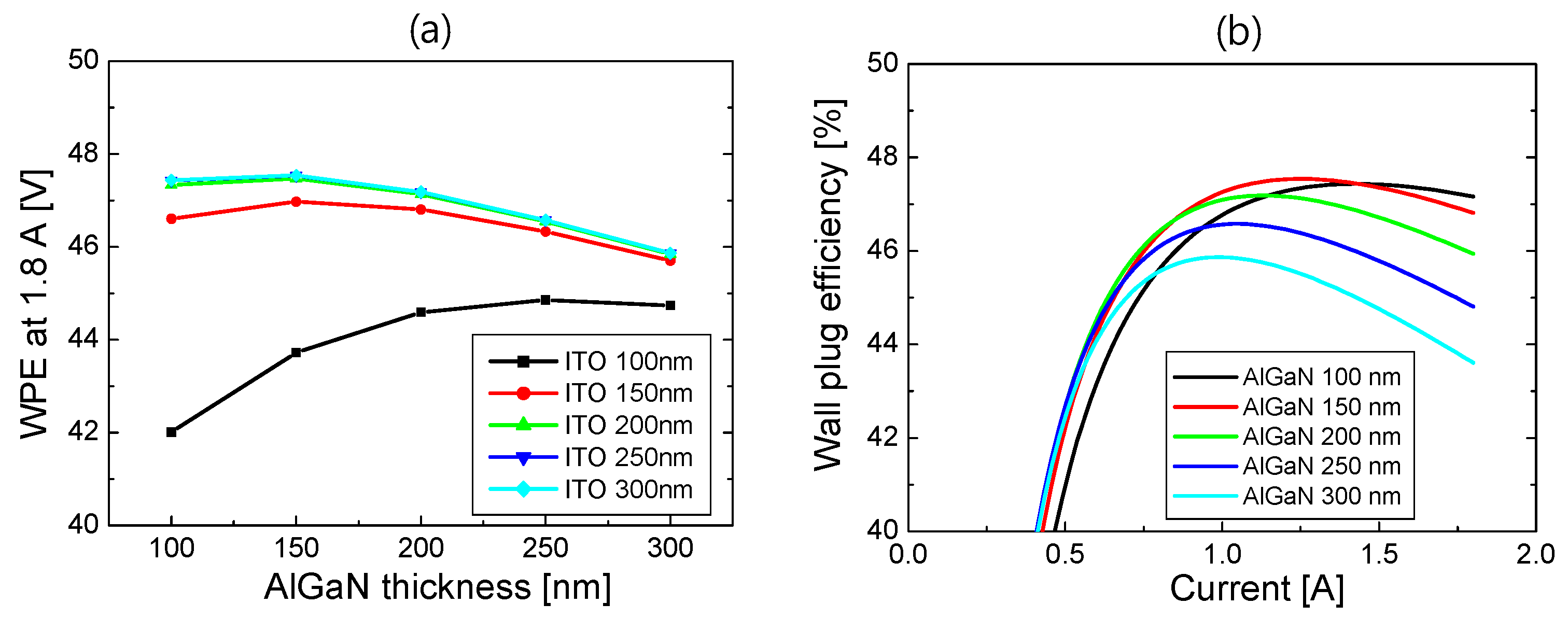

3.3. Device Performance of ITO/p-AlGaN Cladding Structure (S2)

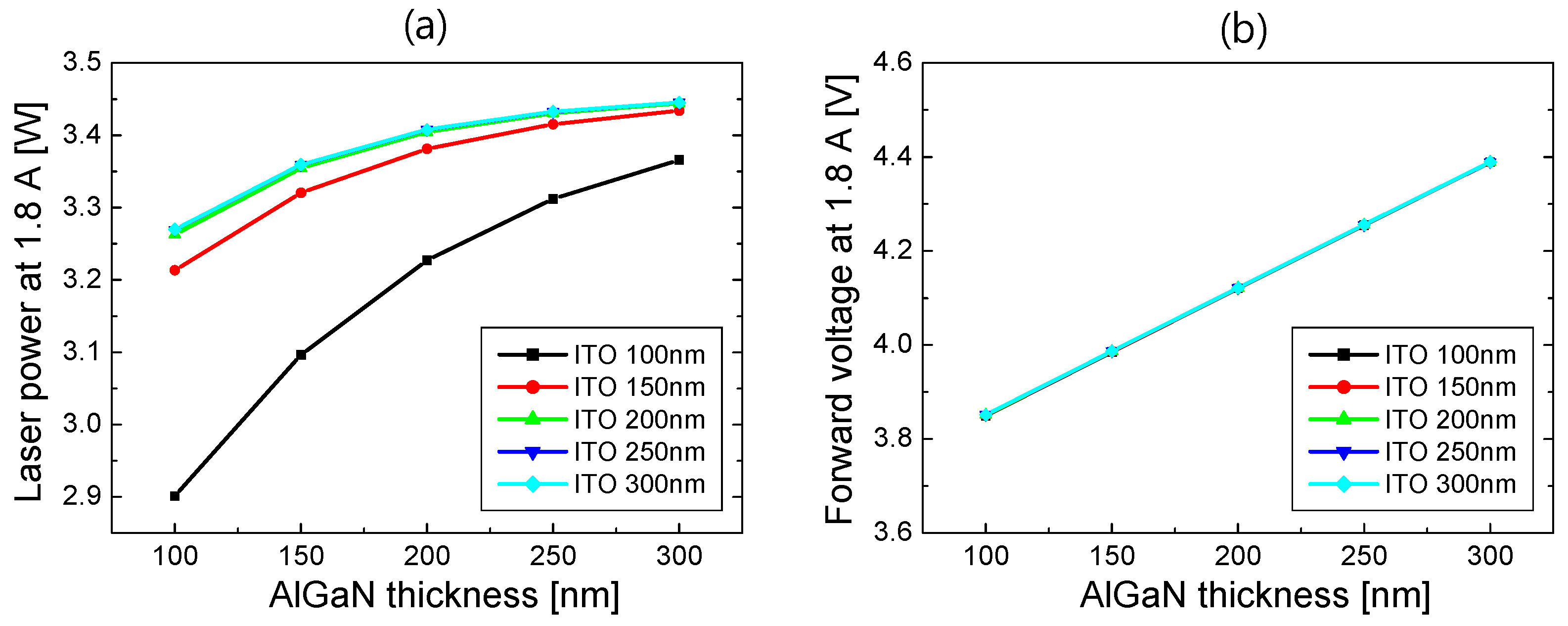

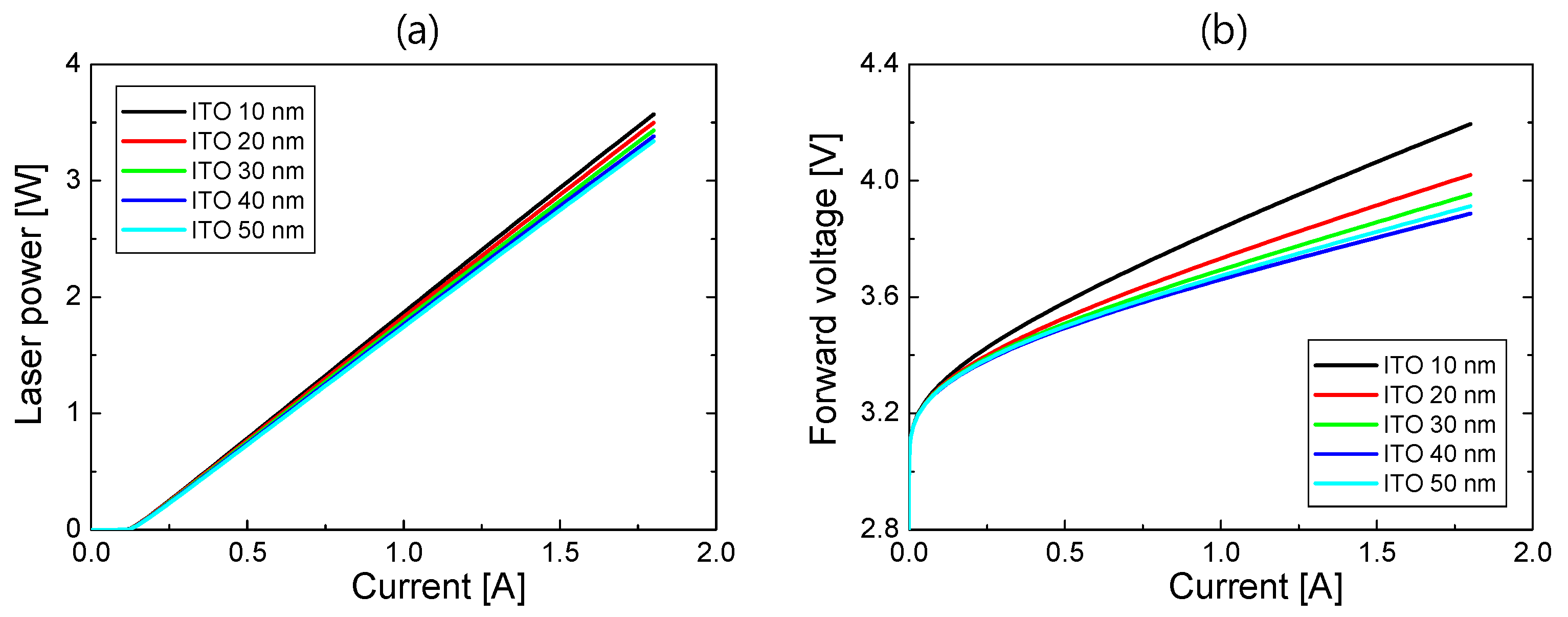

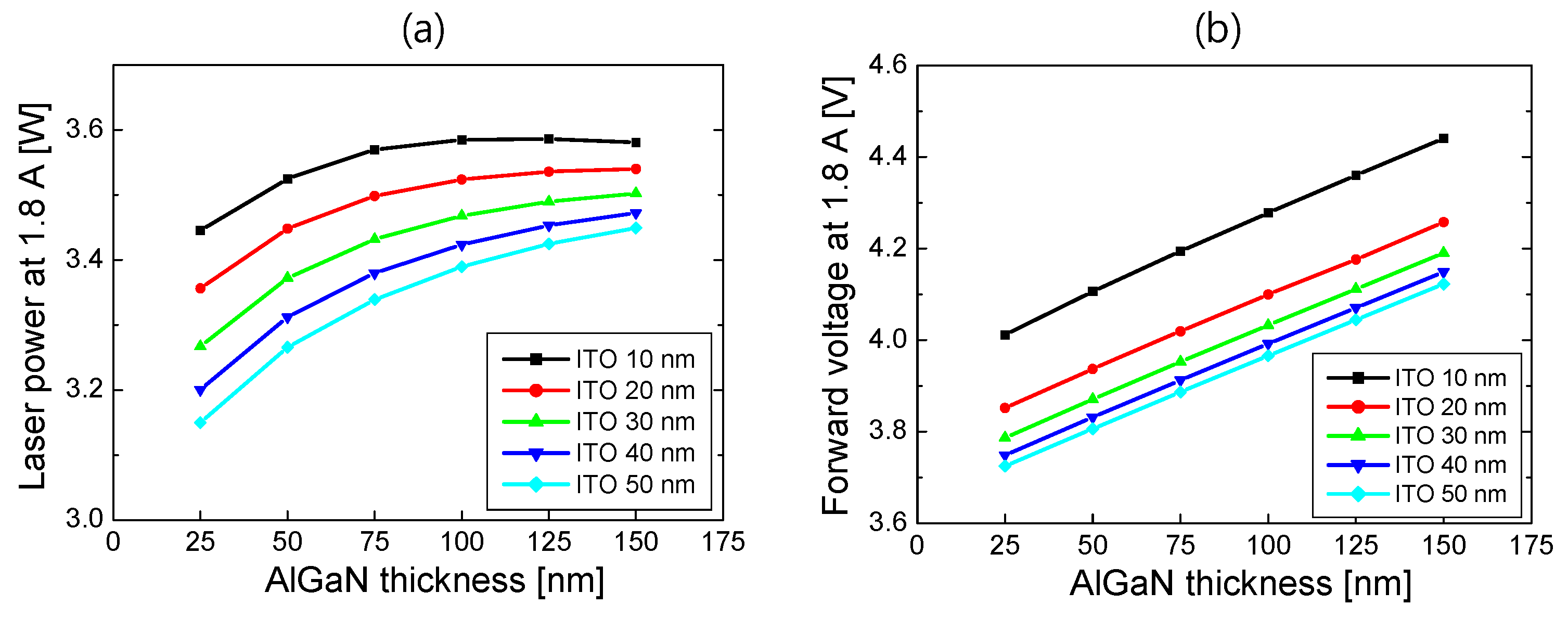

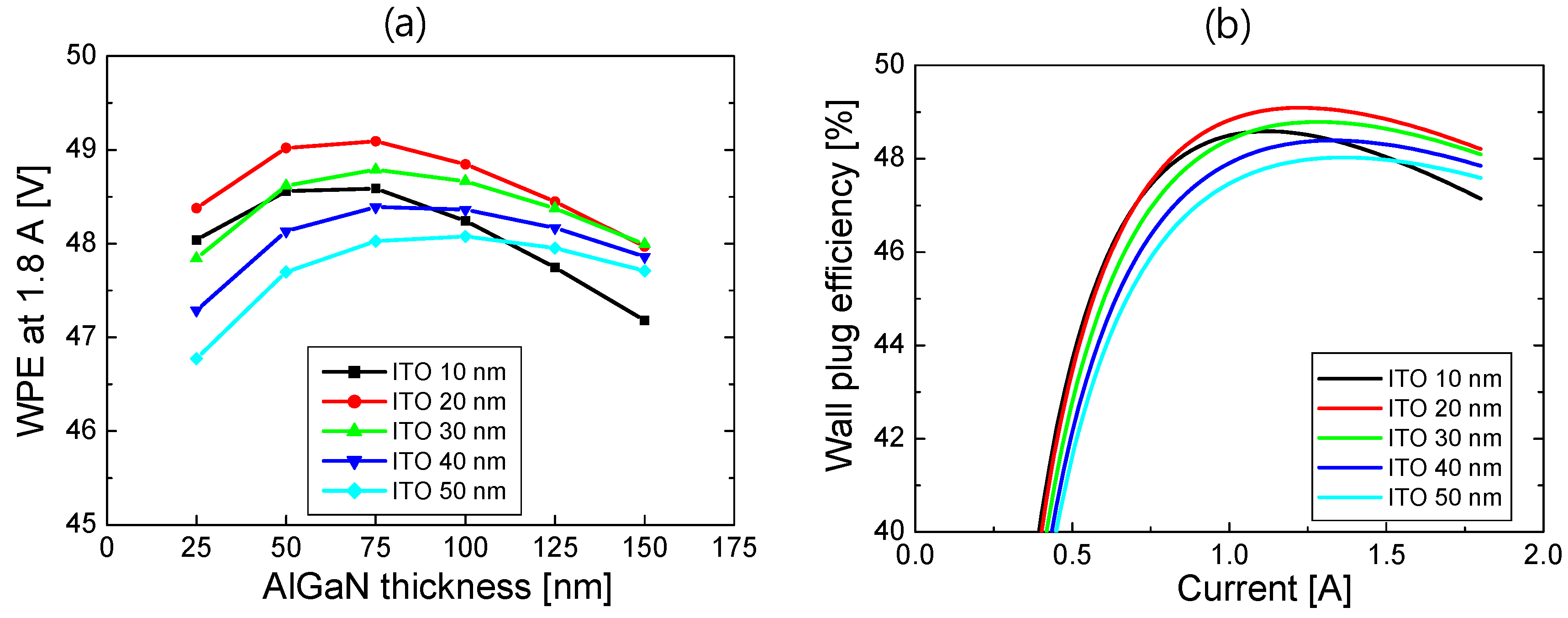

3.4. Device Performance of SiO2/ITO/p-AlGaN Cladding Structure (S3)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nakamura, S.; Senoh, M.; Nagahama, S.; Iwasa, N.; Yamada, T.; Matsushita, T.; Kiyoku, H.; Sugimoto, Y. InGaN-based multi-quantum-well-structure laser diodes. Jpn. J. Appl. Phys. 1996, 35, L74–L76. [Google Scholar] [CrossRef]

- Ponce, F.A.; Bour, D.P. Nitride-based semiconductors for blue and green light-emitting devices. Nature 1997, 386, 351–359. [Google Scholar] [CrossRef]

- Murayama, M.; Nakayama, Y.; Yamazaki, K.; Hoshina, Y.; Watanabe, H.; Fuutagawa, N.; Kawanishi, H.; Uemura, T.; Narui, H. Watt-class green (530 nm) and blue (465 nm) laser diodes. Phys. Status Solidi A 2018, 215, 1700513. [Google Scholar] [CrossRef]

- Nakatsu, Y.; Nagao, Y.; Hirao, T.; Hara, Y.; Masui, S.; Yamamoto, T.; Nagahama, S. Blue and green InGaN semiconductor lasers as light sources for displays. Proc. SPIE 2020, 11280, 112800S. [Google Scholar]

- Wierer, J.J.; Tsao, J.Y.; Sizov, D.S. Comparison between blue lasers and light-emitting diodes for future solid-state lighting. Laser Photonics Rev. 2013, 7, 963–993. [Google Scholar] [CrossRef]

- Chi, Y.C.; Hsieh, D.H.; Lin, C.Y.; Chen, H.Y.; Huang, C.Y.; He, J.H.; Ooi, B.; DenBaars, S.P.; Nakamura, S.; Kuo, H.C.; et al. Phosphorous diffuser diverged blue laser diode for indoor lighting and communication. Sci. Rep. 2015, 5, 18690. [Google Scholar] [CrossRef]

- Huang, Q.; Sui, P.; Huang, F.; Lin, H.; Wang, B.; Lin, S.; Wang, P.; Xu, J.; Cheng, Y.; Wang, Y. Toward high-quality laser-driven lightings: Chromaticity-tunable phosphor-in-glass film with phosphor pattern design. Laser Photon. Rev. 2022, 16, 2200040. [Google Scholar] [CrossRef]

- Sui, P.; Lin, H.; Lin, Y.; Lin, S.; Huang, J.; Xu, J.; Cheng, Y.; Wang, Y. Toward high-power-density laser-driven lighting: Enhancing heat dissipation in phosphor-in-glass film by introducing h-BN. Opt. Lett. 2022, 47, 3455–3458. [Google Scholar] [CrossRef]

- Watson, S.; Tan, M.; Najda, S.P.; Perlin, P.; Leszczynski, M.; Targowaski, G.; Grzanka, S.; Kelly, A.E. Visible light communications using a directly modulated 422 nm GaN laser diode. Opt. Lett. 2013, 38, 3792–3794. [Google Scholar] [CrossRef]

- Lee, C.; Zhang, C.; Cantore, M.; Farrell, R.M.; Oh, S.H.; Margalith, T.; Speck, J.S.; Nakamura, S.; Bowers, J.E.; DenBaars, S.P. 4 Gbps direct modulation of 450 nm GaN laser for high-speed visible light communication. Opt. Express 2015, 23, 16232–16237. [Google Scholar] [CrossRef]

- Wu, T.C.; Chi, Y.C.; Wang, H.Y.; Tsai, C.T.; Lin, G.R. Blue laser diode enables underwater communication at 12.4 Gbps. Sci. Rep. 2017, 7, 40480. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Kawahito, Y.; Yoshida, R.; Nakashima, Y.; Shiokawa, K. Development of a high-power blue laser (445 nm) for material processing. Opt. Lett. 2017, 42, 2151–2154. [Google Scholar] [CrossRef]

- Baumann, M.; Balck, A.; Malchus, J.; Chacko, R.V.; Marfels, S.; Witte, U.; Dinakaran, D.; Ocylok, S.; Weinbach, M.; Bachert, C.; et al. 1000 W blue fiber-coupled diode laser emitting at 450 nm. Proc. SPIE 2019, 10900, 1090005. [Google Scholar]

- Hagino, H.; Kawaguchi, M.; Nozaki, S.; Mochida, A.; Kano, T.; Takigawa, S.; Katayama, T.; Tanaka, T. High-power InGaN laser array with advanced lateral-corrugated waveguides. IEEE J. Quantum Electron. 2021, 57, 2600107. [Google Scholar] [CrossRef]

- Hatakeyama, K.; Tanahashi, Y.; Konishi, R.; Nakagaki, M.; Okuno, R.; Sugiyama, T.; Shibuya, S.; Okada, A.; Hayamizu, N. High-power and high-luminance blue laser module using GaN-based laser diodes. Proc. SPIE 2024, 12867, 128670B. [Google Scholar]

- Zhong, Z.; Lu, S.; Li, J.; Lin, W.; Huang, K.; Li, S.; Cai, D.; Kang, J. Design and fabrication of high power InGaN blue laser diode over 8 W. Opt. Laser Technol. 2021, 139, 106985. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, J.; Liang, F.; Chen, P.; Liu, Z.; Zhao, D. Low threshold current density and high power InGaN-based blue-violet laser diode with an asymmetric waveguide structure. Opt. Express 2023, 31, 7839–7849. [Google Scholar] [CrossRef]

- Piprek, J. Comparative efficiency analysis of GaN-based light-emitting diodes and laser diodes. Appl. Phys. Lett. 2016, 109, 021104. [Google Scholar] [CrossRef]

- Hurni, C.A.; David, A.; Cich, M.J.; Aldaz, R.I.; Ellis, B.; Huang, K.; Tyagi, A.; Delille, R.A.; Craven, M.D.; Steranka, F.M.; et al. Bulk GaN flip-chip violet light-emitting diodes with optimized efficiency for high-power operation. Appl. Phys. Lett. 2015, 106, 31101. [Google Scholar] [CrossRef]

- Crump, P.; Erbert, G.; Wenzel, H.; Frevert, C.; Schultz, C.M.; Hasler, K.H.; Staske, R.; Sumpf, B.; Maassdorf, A.; Bugge, F.; et al. Efficient High-Power Laser Diodes. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 1501211. [Google Scholar] [CrossRef]

- Nagahama, S.; Yanamoto, T.; Sano, M.; Mukai, T. Wavelength dependence of InGaN laser diode characteristics. Jpn. J. Appl. Phys. 2001, 40, 3075–3081. [Google Scholar] [CrossRef]

- Kim, J.; Kim, H.; Lee, S.N. Thermal degradation in InGaN quantum wells in violet and blue GaN-based laser diodes. Curr. Appl. Phys. 2011, 11, S167–S170. [Google Scholar] [CrossRef]

- Piprek, J. Analysis of efficiency limitations in high-power InGaN/GaN laser diodes. Opt. Quantum Electron. 2016, 48, 471. [Google Scholar] [CrossRef]

- Hardy, M.T.; Holder, C.O.; Feezell, D.F.; Nakamura, S.; Speck, J.S.; Cohen, D.A.; DenBaars, S.P. Indium-tin-oxide clad blue and rue green semipolar InGaN/GaN laser diodes. Appl. Phys. Lett. 2013, 103, 081103. [Google Scholar] [CrossRef]

- Pourhashemi, A.; Farrell, R.M.; Cohen, D.A.; Speck, J.S.; DenBaars, S.P.; Nakamura, S. High-power blue laser diodes with indium tin oxide cladding on semipolar (2021) GaN substrates. Appl. Phys. Lett. 2015, 106, 111105. [Google Scholar] [CrossRef]

- Myzaferi, A.; Reading, A.H.; Cohen, D.A.; Farrell, R.M.; Nakamura, S.; Speck, J.S.; DenBaars, S.P. Transparent conducting oxide clad limited area epitaxy semipolar III-nitride laser diodes. Appl. Phys. Lett. 2016, 109, 061109. [Google Scholar] [CrossRef]

- Hu, L.; Ren, X.; Liu, J.; Tian, A.; Jiang, L.; Huang, S.; Zhou, W.; Zhang, L.; Yang, H. High-power hybrid GaN-based green laser diodes with ITO cladding layer. Photonics Res. 2020, 8, 279–285. [Google Scholar] [CrossRef]

- Kuc, M.; Piskorski, Ł.; Dems, M.; Wasiak, M.; Sokół, A.K.; Sarzała, R.P.; Czyszanowski, T. Numerical investigation of the impact of ITO, AlInN, plasmonic GaN and top gold metalization on semipolar green EELs. Materials 2020, 13, 1444. [Google Scholar] [CrossRef]

- Kuc, M.; Sokół, A.K.; Piskorski, Ł.; Dems, M.; Wasiak, M.; Sarzała, R.P.; Czyszanowski, T. ITO layer as an optical confinement for nitride edge-emitting lasers. Bull. Pol. Acad. Sci. 2020, 68, 147–154. [Google Scholar] [CrossRef]

- Granqvist, C.B.; Hultaker, A. Transparent and conducting ITO films: New developments and applications. Thin Solid Films 2002, 411, 1–5. [Google Scholar] [CrossRef]

- Crosslight. LASTIP; Crosslight Software Inc.: Burnaby, BC, Canada. Available online: http://crosslight.com (accessed on 1 August 2024).

- Onwukaeme, C.; Ryu, H.Y. Investigation of the optimum Mg doping concentration in p-type-doped layers of InGaN blue laser diode structures. Crystals 2021, 11, 1335. [Google Scholar] [CrossRef]

- Lee, B.; Ryu, H. Investigation into the temperature dependence of electron leakage in GaN-based blue laser diode structures by numerical simulation. Opt. Quantum Electron. 2023, 55, 154–1115. [Google Scholar] [CrossRef]

- Liang, F.; Zhao, D.; Jiang, D.; Liu, Z.; Zhu, J.; Chen, P.; Yang, J.; Liu, W.; Li, X.; Liu, S.; et al. New design of upper waveguide with unintentionally doped InGaN layer for InGaN-based laser diode. Opt. Laser Technol. 2017, 97, 284–289. [Google Scholar] [CrossRef]

- Fiorentini, V.; Bernardini, F.; Ambacher, O. Evidence for nonlinear macroscopic polarization in III-V nitride alloy heterostructures. Appl. Phys. Lett. 2002, 80, 1204–1206. [Google Scholar] [CrossRef]

- Wang, W.; Li, D.; Liu, N.; Chen, Z.; Wang, L.; Liu, L.; Li, L.; Wan, C.; Chen, W.; Hu, X.; et al. Improvement of hole injection and electron overflow by a tapered AlGaN electron blocking layer in InGaN-based blue laser diodes. Appl. Phys. Lett. 2012, 100, 031105. [Google Scholar]

- Li, X.; Zhao, D.G.; Jiang, D.S.; Chen, P.; Liu, Z.S.; Zhu, J.J.; Yang, J.; Liu, W.; He, X.G.; Li, X.J.; et al. The effectiveness of electron blocking layer in InGaN-based laser diodes with different indium content. Phys. Status Solidi A 2016, 213, 2223–2228. [Google Scholar] [CrossRef]

- Hou, Y.; Zhao, D.; Liang, F.; Liu, Z.; Yang, J.; Chen, P. Enhancing the efficiency of GaN-based laser diodes by the designing of a p-AlGaN cladding layer and an upper waveguide layer. Opt. Mater. Express 2021, 11, 1780. [Google Scholar] [CrossRef]

- Farahmand, M.; Garetto, C.; Bellotti, E.; Brennan, K.F.; Goano, M.; Ghillino, E.; Ghione, G.; Albrecht, J.D.; Ruden, P.P. Monte Carlo simulation of electron transport in the III-nitride wurtzite phase materials system: Binaries and ternaries. IEEE Trans. Electron. Devices 2001, 48, 535–542. [Google Scholar] [CrossRef]

- Piprek, J. Semiconductor Optoelectronic Devices; Academic Press: London, UK, 2003; pp. 187–211. [Google Scholar]

- Chen, J.R.; Wu, Y.C.; Ling, S.C.; Ko, T.S.; Lu, T.C.; Kuo, H.C.; Kuo, Y.K.; Wang, S.C. Investigation of wavelength-dependent efficiency droop in InGaN light-emitting diodes. Appl. Phys B 2010, 98, 779–789. [Google Scholar] [CrossRef]

- Bergmann, M.J.; Casey, H.C., Jr. Optical-field calculations for lossy multiple-layer AlxGa1-xN/InxGa1-xN laser diodes. J. Appl. Phys. 1998, 84, 1196–1203. [Google Scholar] [CrossRef]

- Laws, G.M.; Larkins, E.C.; Harrison, I.; Molloy, C.; Somerford, D. Improved refractive index formulas for the AlxGa1-xN and InyGa1-yN alloys. J. Appl. Phys. 2001, 89, 1108–1115. [Google Scholar] [CrossRef]

- Kioupakis, E.; Rinke, P.; Van de Walle, C.G. Determination of internal loss in nitride lasers from first principles. Appl. Phys. Express 2010, 3, 082101. [Google Scholar] [CrossRef]

- Huang, C.Y.; Lin, Y.D.; Tyagi, A.; Chakraborty, A.; Ohta, H.; Speck, J.S.; DenBaars, S.P.; Nakamura, S. Optical waveguide simulations for the optimization of InGaN-based green laser diodes. J. Appl. Phys. 2010, 107, 023101. [Google Scholar] [CrossRef]

- Ryu, H.Y. Investigation into the anomalous temperature characteristics of InGaN double quantum well blue laser diodes using numerical simulation. Nanoscale Res. Lett. 2017, 12, 366. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onwukaeme, C.; Ryu, H.-Y. Optimum Design of InGaN Blue Laser Diodes with Indium-Tin-Oxide and Dielectric Cladding Layers. Nanomaterials 2024, 14, 1409. https://doi.org/10.3390/nano14171409

Onwukaeme C, Ryu H-Y. Optimum Design of InGaN Blue Laser Diodes with Indium-Tin-Oxide and Dielectric Cladding Layers. Nanomaterials. 2024; 14(17):1409. https://doi.org/10.3390/nano14171409

Chicago/Turabian StyleOnwukaeme, Chibuzo, and Han-Youl Ryu. 2024. "Optimum Design of InGaN Blue Laser Diodes with Indium-Tin-Oxide and Dielectric Cladding Layers" Nanomaterials 14, no. 17: 1409. https://doi.org/10.3390/nano14171409

APA StyleOnwukaeme, C., & Ryu, H.-Y. (2024). Optimum Design of InGaN Blue Laser Diodes with Indium-Tin-Oxide and Dielectric Cladding Layers. Nanomaterials, 14(17), 1409. https://doi.org/10.3390/nano14171409