In Situ Studies on the Influence of Surface Symmetry on the Growth of MoSe2 Monolayer on Sapphire Using Reflectance Anisotropy Spectroscopy and Differential Reflectance Spectroscopy

Abstract

:1. Introduction

2. Experimental Section

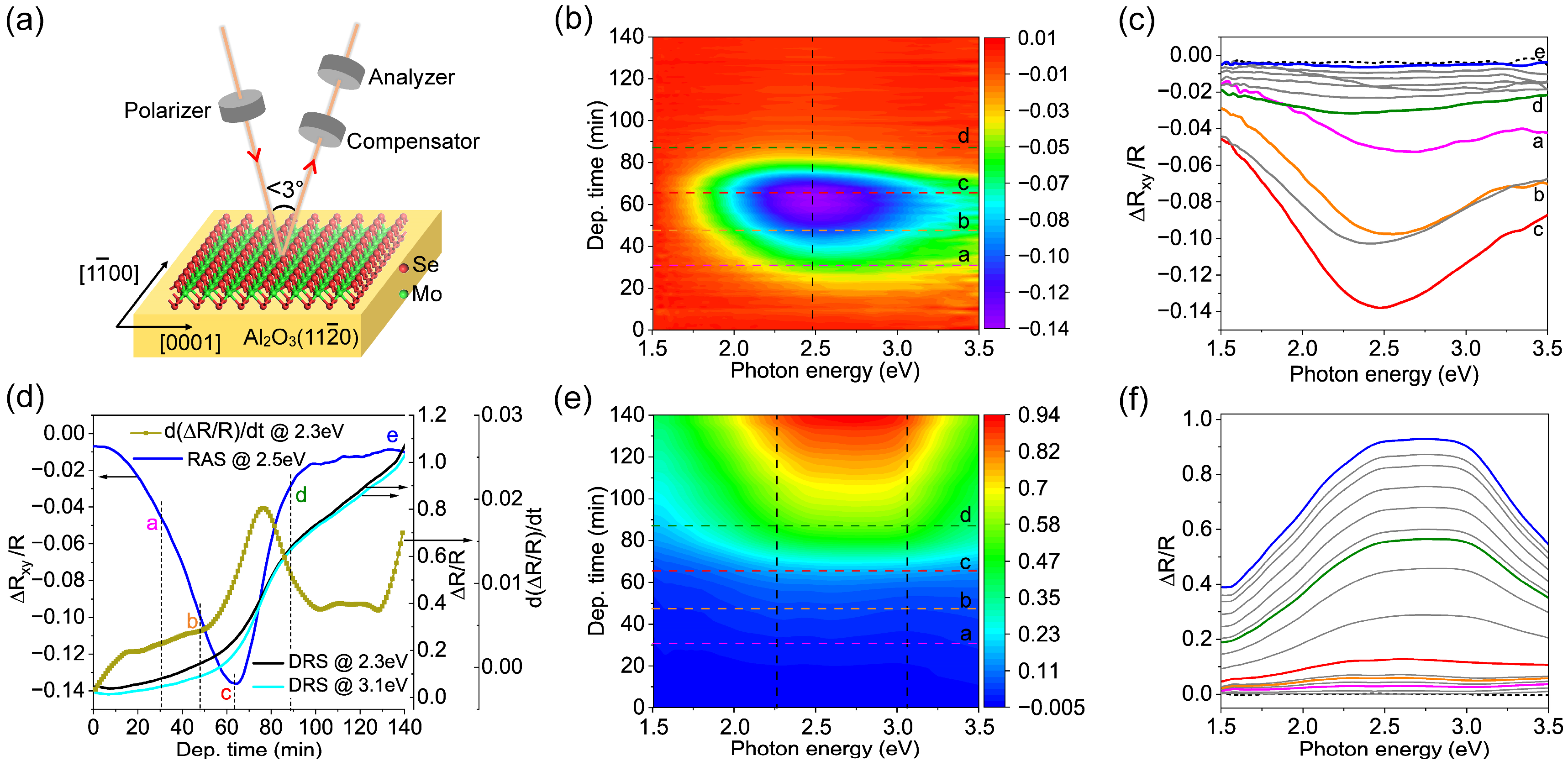

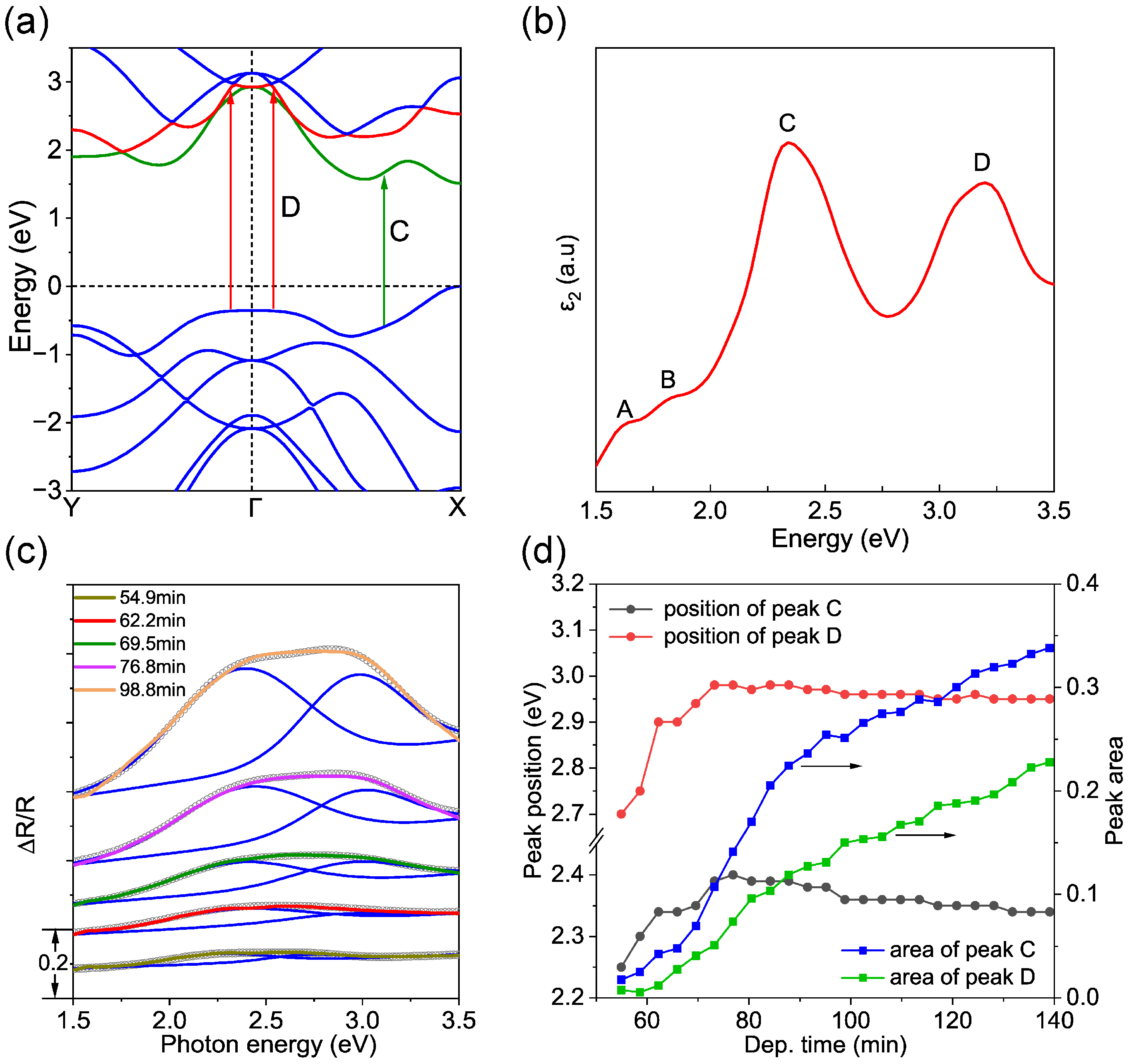

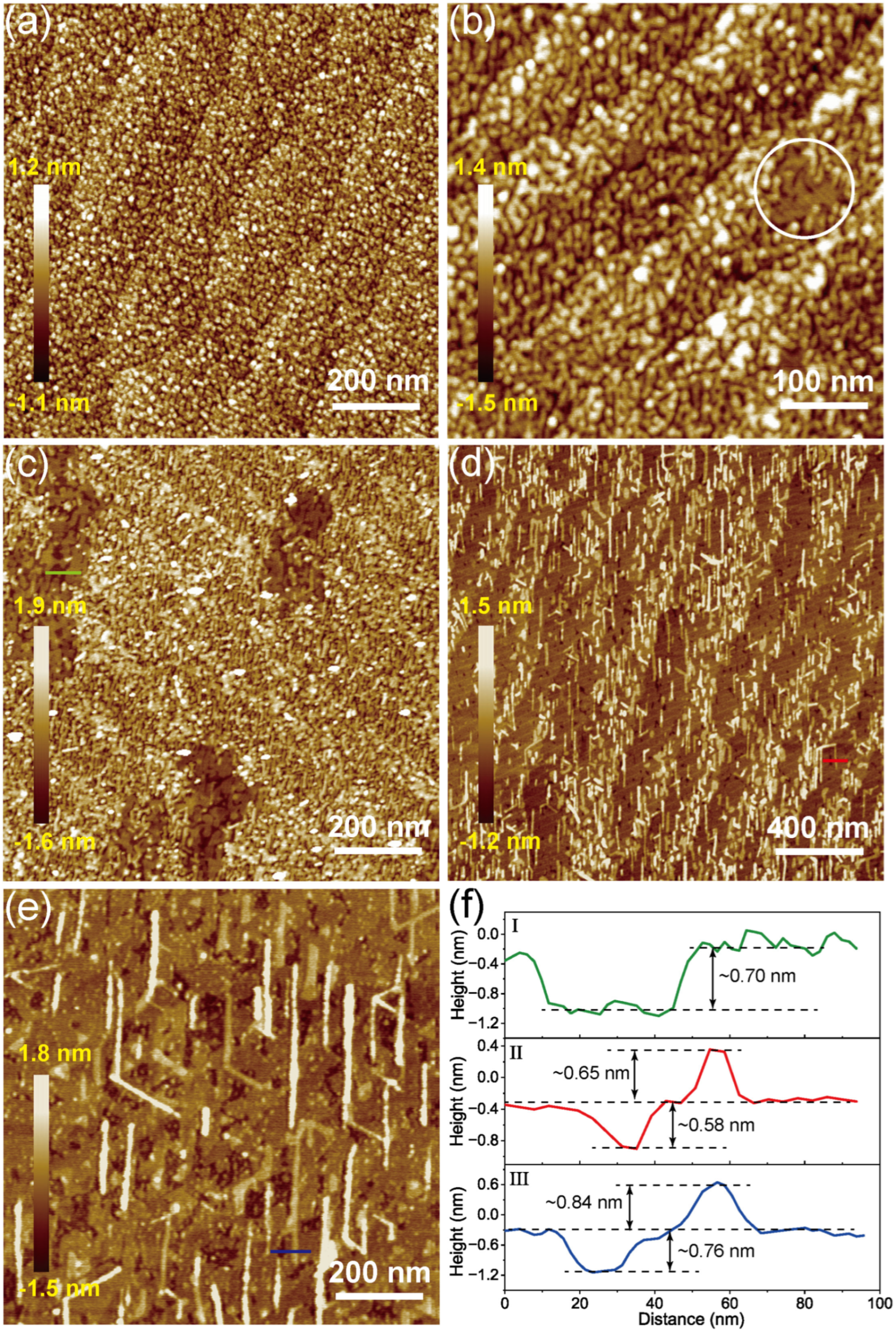

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics. Optoelectronics of Two-Dimensional Transition Metal Dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712. [Google Scholar] [CrossRef]

- Ahmed, S.; Yi, J. Two-Dimensional Transition Metal Dichalcogenides and Their Charge Carrier Mobilities in Field-Effect Transistors. Nano-Micro Lett. 2017, 9, 50. [Google Scholar] [CrossRef]

- Zhao, W.; Ribeiro, R.M.; Toh, M.; Carvalho, A.; Kloc, C.; Castro Neto, A.H.; Eda, G. Origin of Indirect Optical Transitions in Few-Layer MoS2, WS2, and WSe2. Nano Lett. 2013, 13, 5627–5634. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.J.; Krasnok, A.; Alu, A.; Yu, Y.L.; Neshev, D.; Miroshnichenko, A.E. Enhanced Light-Matter Interaction in Two-Dimensional Transition Metal Dichalcogenides. Rep. Prog. Phys. 2022, 85, 046401. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.Y.; Cheng, Y.C.; Schwingenschlögl, U. Giant Spin-Orbit-Induced Spin Splitting in Two-Dimensional Transition-Metal Dichalcogenide Semiconductors. Phys. Rev. B Condens. Matter Mater. Phys. 2011, 84, 153402. [Google Scholar] [CrossRef]

- Upadhyay, S.; Pandey, O.P. Studies on 2D-Molybdenum Diselenide (MoSe2) Based Electrode Materials for Supercapacitor and Batteries: A Critical Analysis. J. Energy Storage 2021, 40, 102809. [Google Scholar] [CrossRef]

- Gupta, U.; Naidu, B.S.; Maitra, U.; Singh, A.; Shirodkar, S.N.; Waghmare, U.V.; Rao, C.N.R. Characterization of Few-Layer 1T-MoSe2 and Its Superior Performance in the Visible-Light Induced Hydrogen Evolution Reaction. APL Mater. 2014, 2, 092802. [Google Scholar] [CrossRef]

- Chang, Y.H.; Zhang, W.; Zhu, Y.; Han, Y.; Pu, J.; Chang, J.K.; Hsu, W.T.; Huang, J.K.; Hsu, C.L.; Chiu, M.H.; et al. Monolayer MoSe2 Grown by Chemical Vapor Deposition for Fast Photodetection. ACS Nano 2014, 8, 8582–8590. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, H.; Chen, X.; Chu, G.; Chu, S.; Zhang, H. Wafer-Size and Single-Crystal MoSe2 Atomically Thin Films Grown on GaN Substrate for Light Emission and Harvesting. ACS Appl. Mater. Interfaces 2016, 8, 20267–20273. [Google Scholar] [CrossRef]

- Xia, Y.; Ding, D.; Xiao, K.; Zhang, J.; Xu, S.; He, D.; Yue, X.; Rao, Q.; Wang, X.; Ding, S.; et al. Wafer-scale Single-crystalline MoSe2 and WSe2 Monolayers Grown by Molecular-beam Epitaxy at Low-temperature—The Role of Island-substrate Interaction and Surface Steps. Nat. Sci. 2023, 3, 20220059. [Google Scholar] [CrossRef]

- Wang, X.; Gong, Y.; Shi, G.; Chow, W.L.; Keyshar, K.; Ye, G.; Vajtai, R.; Lou, J.; Liu, Z.; Ringe, E.; et al. Chemical Vapor Deposition Growth of Crystalline Monolayer MoSe2. ACS Nano 2014, 8, 5125–5131. [Google Scholar] [CrossRef] [PubMed]

- Picker, J.; Schaal, M.; Gan, Z.; Gruenewald, M.; Neumann, C.; George, A.; Otto, F.; Forker, R.; Fritz, T.; Turchanin, A. Structural and Electronic Properties of MoS2 and MoSe2 Monolayers Grown by Chemical Vapor Deposition on Au(111). Nanoscale Adv. 2023, 6, 92–101. [Google Scholar] [CrossRef]

- Shen, C.; Tian, F.; Qiu, P.; He, Y.; Wei, H.; Song, Y.; Li, Y.; Liu, H.; Zhu, X.; Zheng, X.; et al. Se Vacancy Modulation of Centimeter-Scale 2D MoSe2 Continuous Films via Se Evaporating Temperature. Mater. Today Commun. 2023, 35, 105528. [Google Scholar] [CrossRef]

- Wu, Q.; Fu, X.; Yang, K.; Wu, H.; Liu, L.; Zhang, L.; Tian, Y.; Yin, L.J.; Huang, W.Q.; Zhang, W.; et al. Promoting a Weak Coupling of Monolayer MoSe2 Grown on (100)-Faceted Au Foil. ACS Nano 2021, 15, 4481–4489. [Google Scholar] [CrossRef]

- Ji, R.; Liao, J.; Li, L.; Wen, R.; Liu, M.; Ren, Y.; Wu, J.; Song, Y.; Qi, M.; Qiao, Z.; et al. Step-Edge Controlled Fast Growth of Wafer-Scale MoSe2 Films by MOCVD. Nano Res. 2023, 16, 9577–9583. [Google Scholar] [CrossRef]

- Hwang, Y.; Shin, N. Hydrogen-Assisted Step-Edge Nucleation of MoSe2 Monolayers on Sapphire Substrates. Nanoscale 2019, 11, 7701–7709. [Google Scholar] [CrossRef]

- Li, T.; Guo, W.; Ma, L.; Li, W.; Yu, Z.; Han, Z.; Gao, S.; Liu, L.; Fan, D.; Wang, Z.; et al. Epitaxial Growth of Wafer-Scale Molybdenum Disulfide Semiconductor Single Crystals on Sapphire. Nat. Nanotechnol. 2021, 16, 1201–1207. [Google Scholar] [CrossRef]

- Roy, A.; Movva, H.C.P.; Satpati, B.; Kim, K.; Dey, R.; Rai, A.; Pramanik, T.; Guchhait, S.; Tutuc, E.; Banerjee, S.K. Structural and Electrical Properties of MoTe2 and MoSe2 Grown by Molecular Beam Epitaxy. ACS Appl. Mater. Interfaces 2016, 8, 7396–7402. [Google Scholar] [CrossRef]

- Dau, M.T.; Vergnaud, C.; Marty, A.; Rortais, F.; Beigné, C.; Boukari, H.; Bellet-Amalric, E.; Guigoz, V.; Renault, O.; Alvarez, C.; et al. Millimeter-Scale Layered MoSe2 Grown on Sapphire and Evidence for Negative Magnetoresistance. Appl. Phys. Lett. 2017, 110, 011909. [Google Scholar] [CrossRef]

- Dong, J.; Zhang, L.; Dai, X.; Ding, F. The Epitaxy of 2D Materials Growth. Nat. Commun. 2020, 11, 5862. [Google Scholar] [CrossRef]

- Wang, J.; Xu, X.; Cheng, T.; Gu, L.; Qiao, R.; Liang, Z.; Ding, D.; Hong, H.; Zheng, P.; Zhang, Z.; et al. Dual-Coupling-Guided Epitaxial Growth of Wafer-Scale Single-Crystal WS2 Monolayer on Vicinal a-Plane Sapphire. Nat. Nanotechnol. 2022, 17, 33–38. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Wang, S.; Deng, Q.; Hou, Z.; Zhou, X.; Li, X.; Cui, F.; Si, H.; Zhai, T.; Xu, H. Epitaxial Growth of Rectangle Shape MoS2 with Highly Aligned Orientation on Twofold Symmetry A-Plane Sapphire. Small 2020, 16, 2000596. [Google Scholar] [CrossRef]

- Huang, Y.; Wei, Y.; Li, Y.; Hu, C.; Shen, W.; Zhang, K.; Xu, Z.; Sun, L. Growth of Singly Orientated MoSe2 Monolayer on Al2O3(). Appl. Surf. Sci. 2023, 628, 157352. [Google Scholar] [CrossRef]

- Sutter, P.; Sutter, E. Microscopy of Graphene Growth, Processing, and Properties. Adv. Funct. Mater. 2013, 23, 2617–2634. [Google Scholar] [CrossRef]

- Felter, J.; Raths, M.; Franke, M.; Kumpf, C. In Situ Study of Two-Dimensional Dendritic Growth of Hexagonal Boron Nitride. 2D Mater. 2019, 6, 045005. [Google Scholar] [CrossRef]

- Hibino, H.; Wang, S.; Orofeo, C.M.; Kageshima, H. Growth and Low-Energy Electron Microscopy Characterizations of Graphene and Hexagonal Boron Nitride. Prog. Cryst. Growth Charact. Mater. 2016, 62, 155–176. [Google Scholar] [CrossRef]

- Losurdo, M.; Giangregorio, M.M.; Capezzuto, P.; Bruno, G. Ellipsometry as a Real-Time Optical Tool for Monitoring and Understanding Graphene Growth on Metals. J. Phys. Chem. C 2011, 115, 21804–21812. [Google Scholar] [CrossRef]

- Ma, G.; Shen, W.; Sanchez, S.D.; Yu, Y.; Hu, C.; Sun, L. Synthesis and Ellipsometric Characterizations of Large-Scale MoS2 Sub-Monolayer. Thin Solid Films 2022, 762, 139562. [Google Scholar] [CrossRef]

- Forker, R.; Gruenewald, M.; Fritz, T. Optical Differential Reflectance Spectroscopy on Thin Molecular Films. Annu. Reports Prog. Chem. Sect. C 2012, 108, 34–68. [Google Scholar] [CrossRef]

- Zhang, L.; Fu, X.; Hu, C.G.; Yao, Y.; Xu, Z.Y.; Hu, X.T.; Hohage, M.; Zeppenfeld, P.; Sun, L.D. Optical and Structural Properties of the Pentacene/Quartz (0001) Interface. Phys. Rev. B 2016, 93, 075443. [Google Scholar] [CrossRef]

- Li, Y.; Wei, Y.; Shen, W.; Wu, S.; Hu, C.; Hu, X.; Zimmerleiter, R.; Hohage, M.; Sun, L. Reflectance and Fluorescence Spectroscopy of Ultrathin PTCDI-C5 Films on Muscovite Mica. Synth. Met. 2017, 228, 105–110. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Yang, W.; Lv, S.; Su, C.; Xiao, H.; Zhang, F.; Sui, Q.; Jia, L.; Jiang, M. An in Situ Reflectance Spectroscopic Investigation to Monitor Two-Dimensional Mos2 Flakes on a Sapphire Substrate. Materials 2020, 13, 5794. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Shen, W.; Roth, D.; Wu, S.; Hu, C.; Li, Y.; Hu, X.; Hohage, M.; Bauer, P.; Sun, L. Real-Time Monitoring of 2D Semiconductor Film Growth with Optical Spectroscopy. Nanotechnology 2017, 28, 465601. [Google Scholar] [CrossRef]

- Wei, Y.; Hu, C.; Li, Y.; Hu, X.; Hohage, M.; Sun, L. Growth Oscillation of MoSe2 Monolayers Observed by Differential Reflectance Spectroscopy. J. Phys. Condens. Matter 2020, 32, 155001. [Google Scholar] [CrossRef] [PubMed]

- López-Posadas, C.B.; Wei, Y.; Shen, W.; Kahr, D.; Hohage, M.; Sun, L. Direct Observation of the CVD Growth of Monolayer MoS2 Using in Situ Optical Spectroscopy. Beilstein J. Nanotechnol. 2019, 10, 557–564. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, L.; Su, C.; Xiao, H.; Lv, S.; Zhang, F.; Sui, Q.; Jia, L.; Jiang, M. Direct Observation of Monolayer MoS2 Prepared by CVD Using In-Situ Differential Reflectance Spectroscopy. Nanomaterials 2019, 9, 1640. [Google Scholar] [CrossRef]

- Weightman, P.; Martin, D.S.; Cole, R.J.; Farrell, T. Reflection Anisotropy Spectroscopy. Rep. Prog. Phys. 2005, 68, 1251–1341. [Google Scholar] [CrossRef]

- Sun, L.; Berkebile, S.; Weidlinger, G.; Denk, M.; Denk, R.; Hohage, M.; Koller, G.; Netzer, F.P.; Ramsey, M.G.; Zeppenfeld, P. Layer Resolved Evolution of the Optical Properties of α-Sexithiophene Thin Films. Phys. Chem. Chem. Phys. 2012, 14, 13651–13655. [Google Scholar] [CrossRef]

- Gall, J.; Zhang, L.; Fu, X.; Zeppenfeld, P.; Sun, L.D. Perfluoropentacene Adsorption on Cu(110). Phys. Rev. B 2017, 96, 125424. [Google Scholar] [CrossRef]

- Ogata, S.; Ohno, S.; Tanaka, M.; Mori, T.; Horikawa, T.; Yasuda, T. Vacuum-Ultraviolet Reflectance Difference Spectroscopy for Characterizing Dielectrics-Semiconductor Interfaces. Thin Solid Films 2011, 519, 2830–2833. [Google Scholar] [CrossRef]

- Papadimitriou, D.; Richter, W. Highly Sensitive Strain Detection in Silicon by Reflectance Anisotropy Spectroscopy. Phys. Rev. B Condens. Matter Mater. Phys. 2005, 72, 075212. [Google Scholar] [CrossRef]

- Wyss, A.; Schamel, M.; Sologubenko, A.S.; Denk, R.; Hohage, M.; Zeppenfeld, P.; Spolenak, R. Reflectance Anisotropy Spectroscopy as a Tool for Mechanical Characterization of Metallic Thin Films. J. Phys. D. Appl. Phys. 2015, 48, 415303. [Google Scholar] [CrossRef]

- Weightman, P.; Harrison, P.; Lucas, C.A.; Grunder, Y.; Smith, C.I. The Reflection Anisotropy Spectroscopy of the Au(110) Surface Structures in Liquid Environments. J. Phys. Condens. Matter 2015, 27, 475005. [Google Scholar] [CrossRef]

- Yang, S.; Hu, C.; Wu, M.; Shen, W.; Tongay, S.; Wu, K.; Wei, B.; Sun, Z.; Jiang, C.; Huang, L.; et al. In-Plane Optical Anisotropy and Linear Dichroism in Low-Symmetry Layered TlSe. ACS Nano 2018, 12, 8798–8807. [Google Scholar] [CrossRef] [PubMed]

- Denk, R.; Hohage, M.; Zeppenfeld, P.; Cai, J.; Pignedoli, C.A.; Söde, H.; Fasel, R.; Feng, X.; Müllen, K.; Wang, S.; et al. Exciton-Dominated Optical Response of Ultra-Narrow Graphene Nanoribbons. Nat. Commun. 2014, 5, 4253. [Google Scholar] [CrossRef] [PubMed]

- Shen, W.; Wei, Y.; Hu, C.; López-Posadas, C.B.; Hohage, M.; Sun, L. Substrate Induced Optical Anisotropy in Monolayer MoS2. J. Phys. Chem. C 2020, 124, 15468–15473. [Google Scholar] [CrossRef]

- Huang, Y.; Li, M.; Wang, H.; Wang, P.; Shen, W.; Hu, C.; Li, Y.; Sun, L.; Hu, Z.; Gao, H.Y. In-Plane Optical Anisotropy in a MoSe2/Au (110) Moiré Superstructure. J. Phys. Chem. C 2024, 128, 13493–13499. [Google Scholar] [CrossRef]

- Hingerl, K.; Aspnes, D.E.; Kamiya, I.; Florez, L.T. Relationship among Reflectance-Difference Spectroscopy, Surface Photoabsorption, and Spectroellipsometry. Appl. Phys. Lett. 1993, 63, 885–887. [Google Scholar] [CrossRef]

- Palummo, M.; Witkowski, N.; Pluchery, O.; Del Sole, R.; Borensztein, Y. Reflectance-Anisotropy Spectroscopy and Surface Differential Reflectance Spectra at the Si(100) Surface: Combined Experimental and Theoretical Study. Phys. Rev. B Condens. Matter Mater. Phys. 2009, 79, 035327. [Google Scholar] [CrossRef]

- Hu, C.G.; Sun, L.D.; Flores-Camacho, J.M.; Hohage, M.; Liu, C.Y.; Hu, X.T.; Zeppenfeld, P. A Rotating-Compensator Based Reflectance Difference Spectrometer for Fast Spectroscopic Measurements. Rev. Sci. Instrum. 2010, 81, 043108. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficient Iterative Schemes for Ab Initio Total-Energy Calculations Using a Plane-Wave Basis Set. Phys. Rev. B Condens. Matter Mater. Phys. 1996, 54, 11169–11186. [Google Scholar] [CrossRef] [PubMed]

- Klimeš, J.; Bowler, D.R.; Michaelides, A. Van Der Waals Density Functionals Applied to Solids. Phys. Rev. B 2011, 83, 195131. [Google Scholar] [CrossRef]

- Dion, M.; Rydberg, H.; Schröder, E.; Langreth, D.C.; Lundqvist, B.I. Van Der Waals Density Functional for General Geometries. Phys. Rev. Lett. 2004, 92, 246401. [Google Scholar] [CrossRef]

- Forker, R.; Fritz, T. Optical Differential Reflectance Spectroscopy of Ultrathin Epitaxial Organic Films. Phys. Chem. Chem. Phys. 2009, 11, 2142–2155. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Chernikov, A.; Zhang, X.; Rigosi, A.; Hill, H.M.; Van Der Zande, A.M.; Chenet, D.A.; Shih, E.M.; Hone, J.; Heinz, T.F. Measurement of the Optical Dielectric Function of Monolayer Transition-Metal Dichalcogenides: MoS2, MoSe2, WS2, and WSe2. Phys. Rev. B Condens. Matter Mater. Phys. 2014, 90, 205422. [Google Scholar] [CrossRef]

- Choi, B.K.; Kim, M.; Jung, K.H.; Kim, J.; Yu, K.S.; Chang, Y.J. Temperature Dependence of Band Gap in MoSe2 Grown by Molecular Beam Epitaxy. Nanoscale Res. Lett. 2017, 12, 492. [Google Scholar] [CrossRef]

- Liu, H.L.; Yang, T.; Chen, J.H.; Chen, H.W.; Guo, H.; Saito, R.; Li, M.Y.; Li, L.J. Temperature-Dependent Optical Constants of Monolayer MoS2, MoSe2, WS2, and WSe2: Spectroscopic Ellipsometry and First-Principles Calculations. Sci. Rep. 2020, 10, 15282. [Google Scholar]

- Tonndorf, P.; Schmidt, R.; Bottger, P.; Zhang, X.; Borner, J.; Liebig, A.; Albrecht, M.; Kloc, C.; Gordan, O.; Zahn, D.R.T.; et al. Photoluminescence Emission and Raman Response of Monolayer MoS2, MoSe2, and WSe2. Opt. Express 2013, 21, 4908–4916. [Google Scholar] [CrossRef]

- Lu, X.; Utama, M.I.B.; Lin, J.; Gong, X.; Zhang, J.; Zhao, Y.; Pantelides, S.T.; Wang, J.; Dong, Z.; Liu, Z.; et al. Large-Area Synthesis of Monolayer and Few-Layer MoSe2 Films on SiO2 Substrates. Nano Lett. 2014, 14, 2419–2425. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Li, M.; Hu, Z.; Hu, C.; Shen, W.; Li, Y.; Sun, L. In Situ Studies on the Influence of Surface Symmetry on the Growth of MoSe2 Monolayer on Sapphire Using Reflectance Anisotropy Spectroscopy and Differential Reflectance Spectroscopy. Nanomaterials 2024, 14, 1457. https://doi.org/10.3390/nano14171457

Huang Y, Li M, Hu Z, Hu C, Shen W, Li Y, Sun L. In Situ Studies on the Influence of Surface Symmetry on the Growth of MoSe2 Monolayer on Sapphire Using Reflectance Anisotropy Spectroscopy and Differential Reflectance Spectroscopy. Nanomaterials. 2024; 14(17):1457. https://doi.org/10.3390/nano14171457

Chicago/Turabian StyleHuang, Yufeng, Mengjiao Li, Zhixin Hu, Chunguang Hu, Wanfu Shen, Yanning Li, and Lidong Sun. 2024. "In Situ Studies on the Influence of Surface Symmetry on the Growth of MoSe2 Monolayer on Sapphire Using Reflectance Anisotropy Spectroscopy and Differential Reflectance Spectroscopy" Nanomaterials 14, no. 17: 1457. https://doi.org/10.3390/nano14171457