Impact of the Interruption Duration on Photoluminescence Properties of MOCVD-Grown GaAsP/InAlGaAs Quantum Well Structures

Abstract

1. Introduction

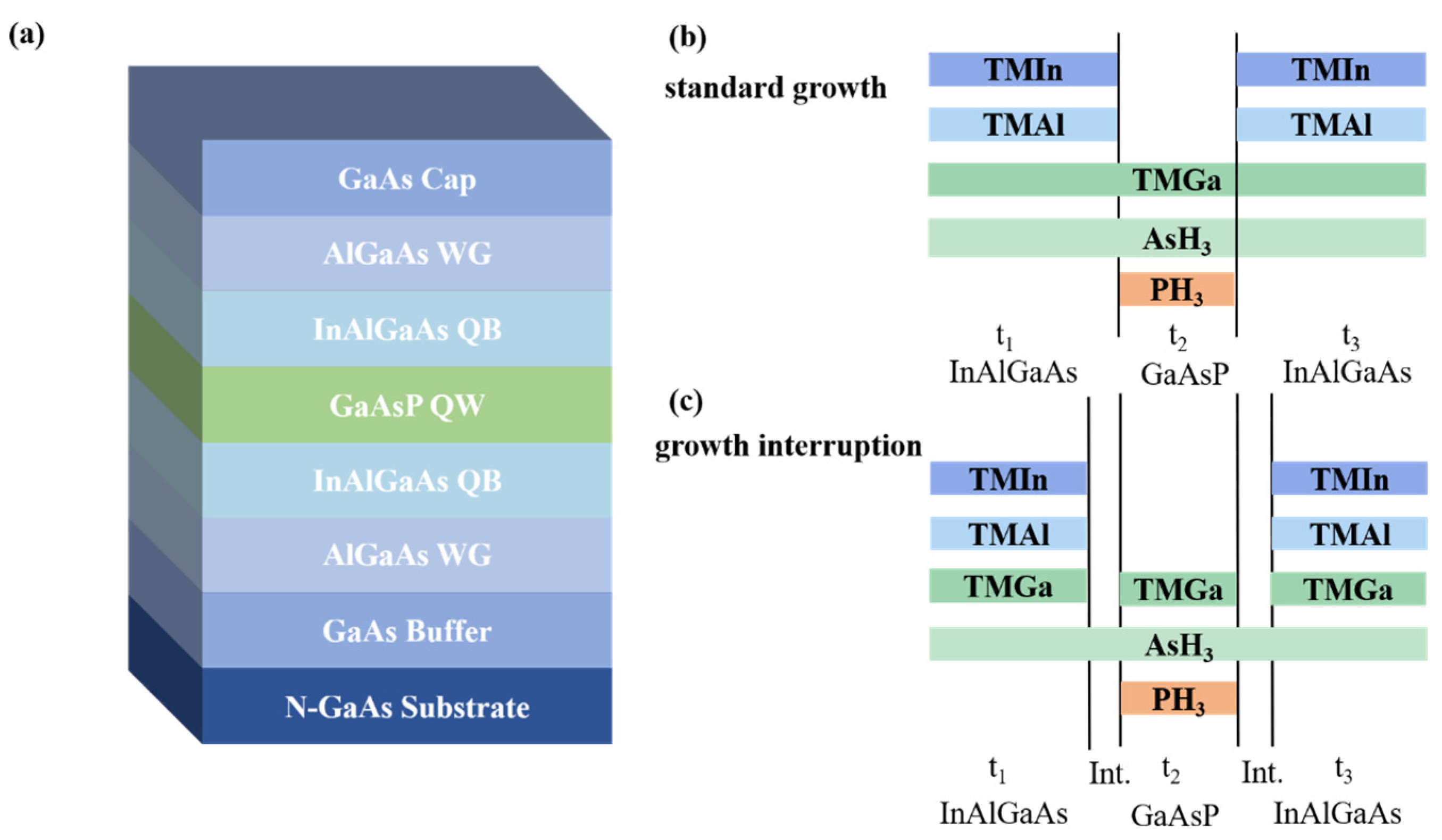

2. Materials and Methods

3. Results and Discussion

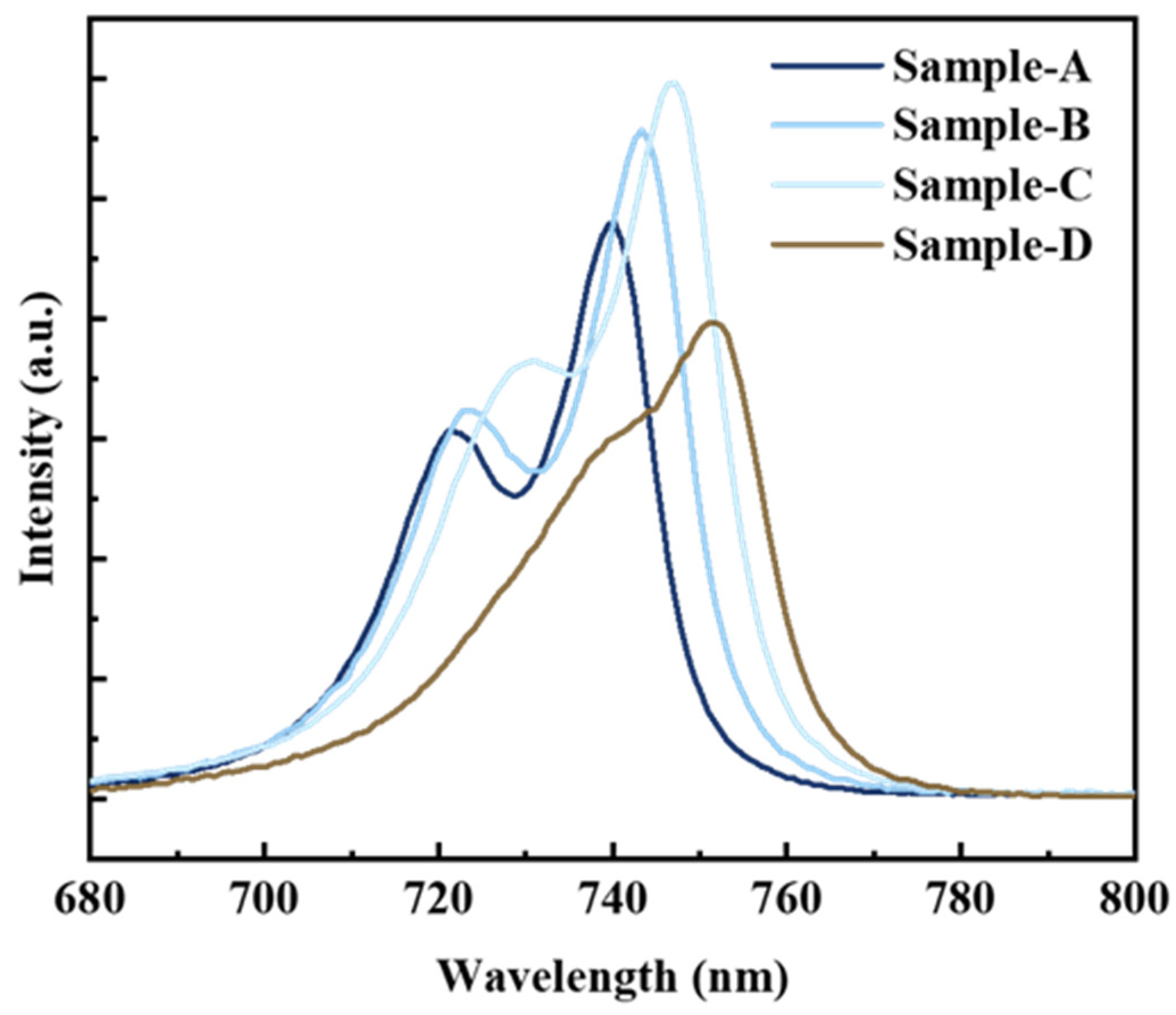

3.1. Photoluminescence at Room Temperature

3.2. The Simulation of Quantum Well Subband Levels and Analysis of RT-PL

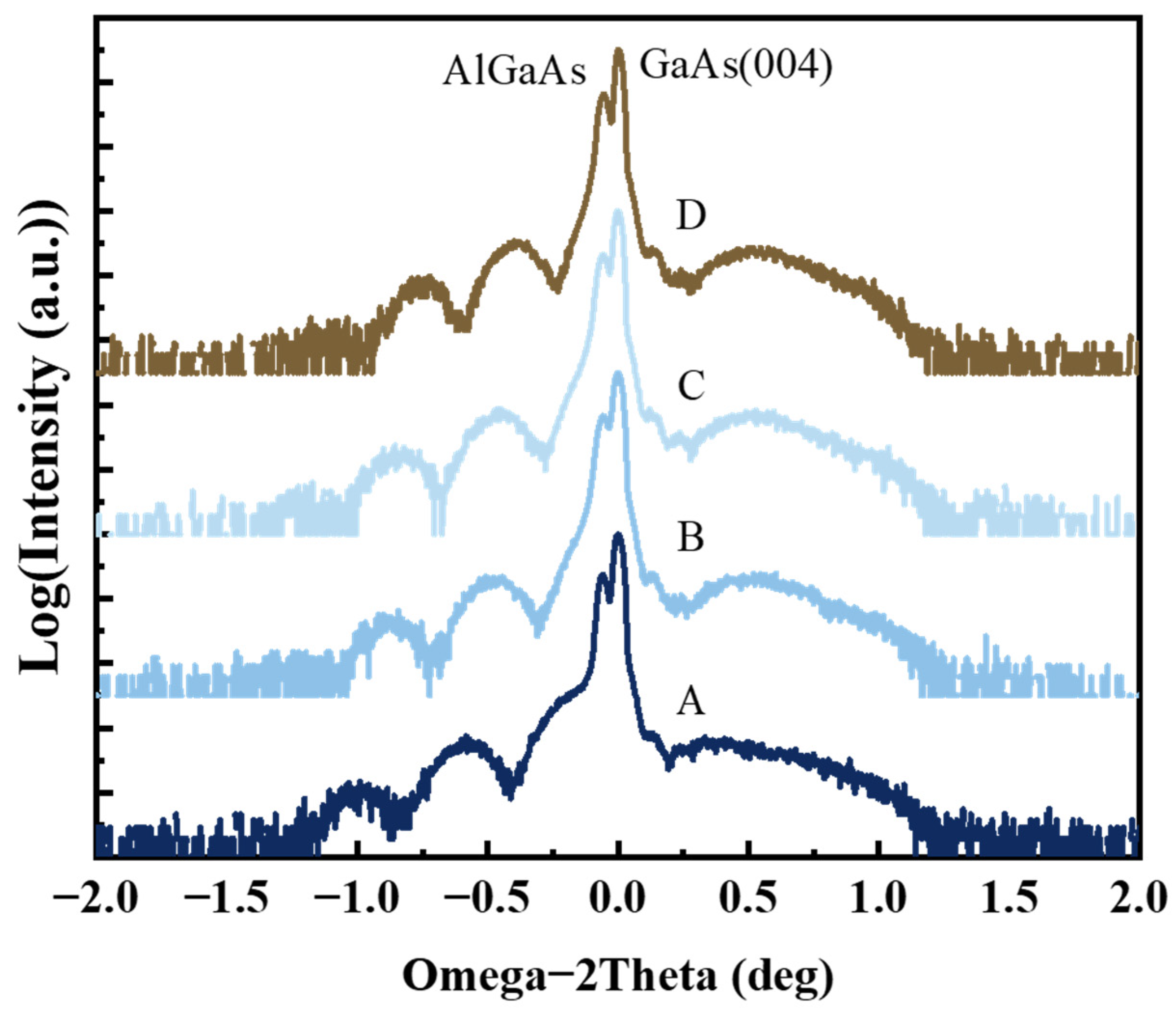

3.3. The X-ray Diffraction Results

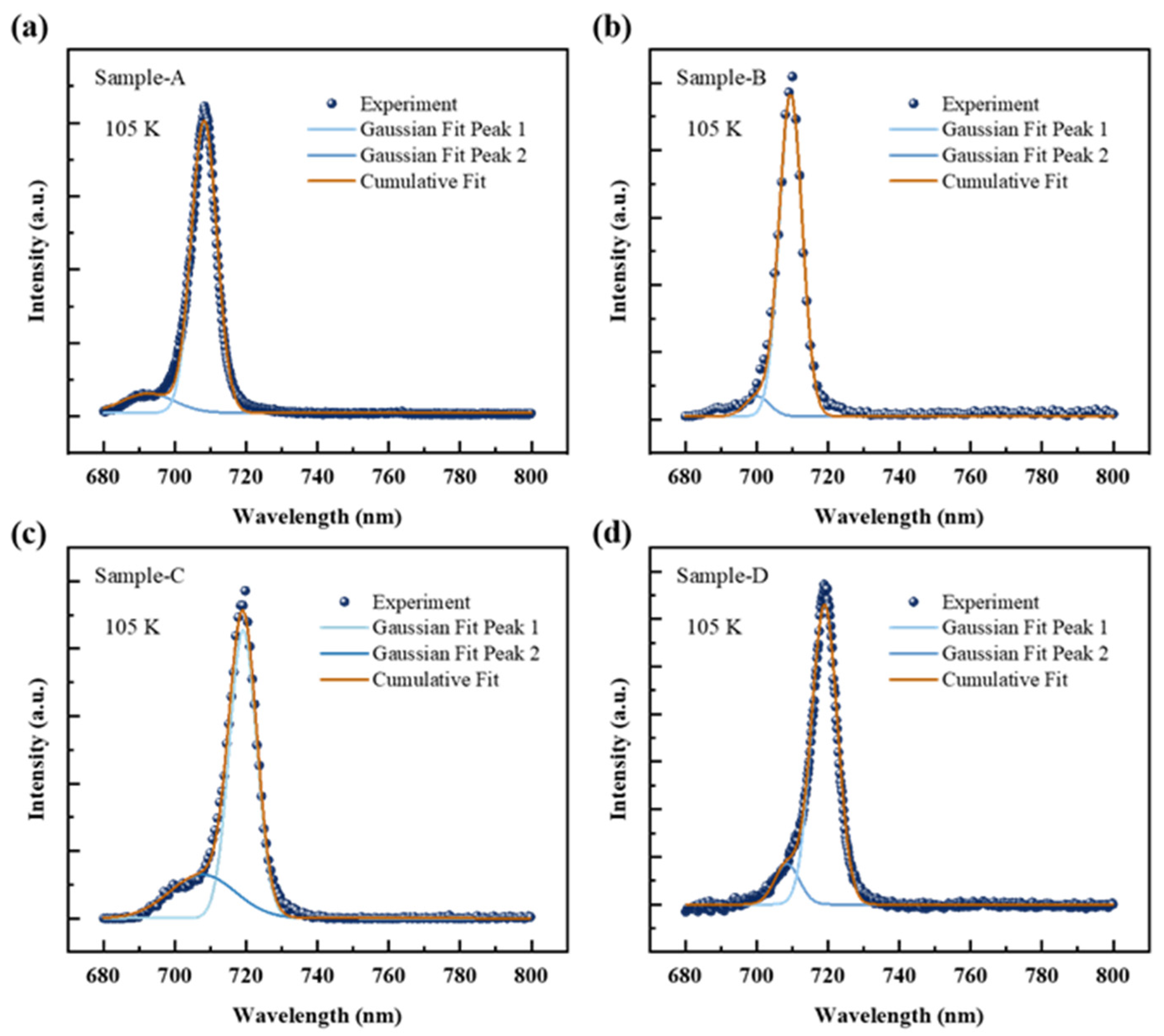

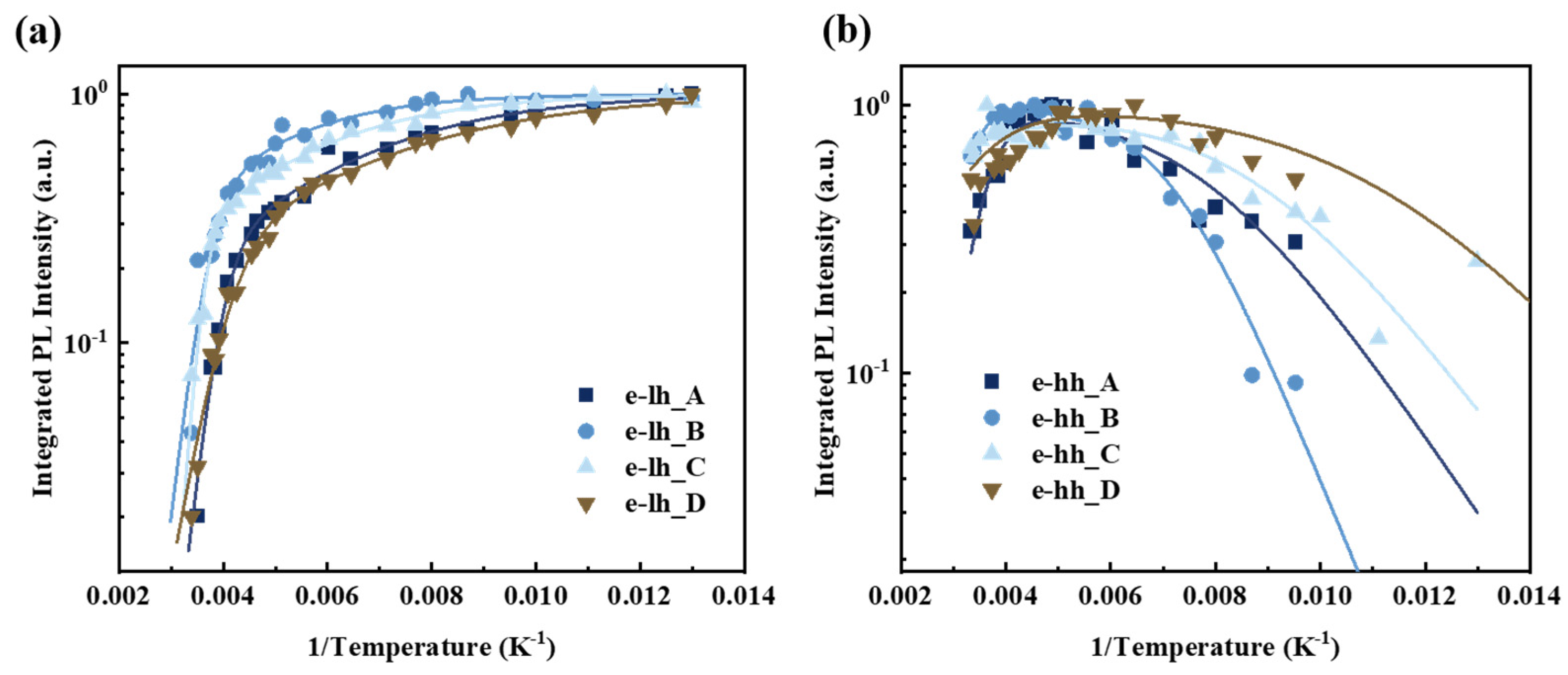

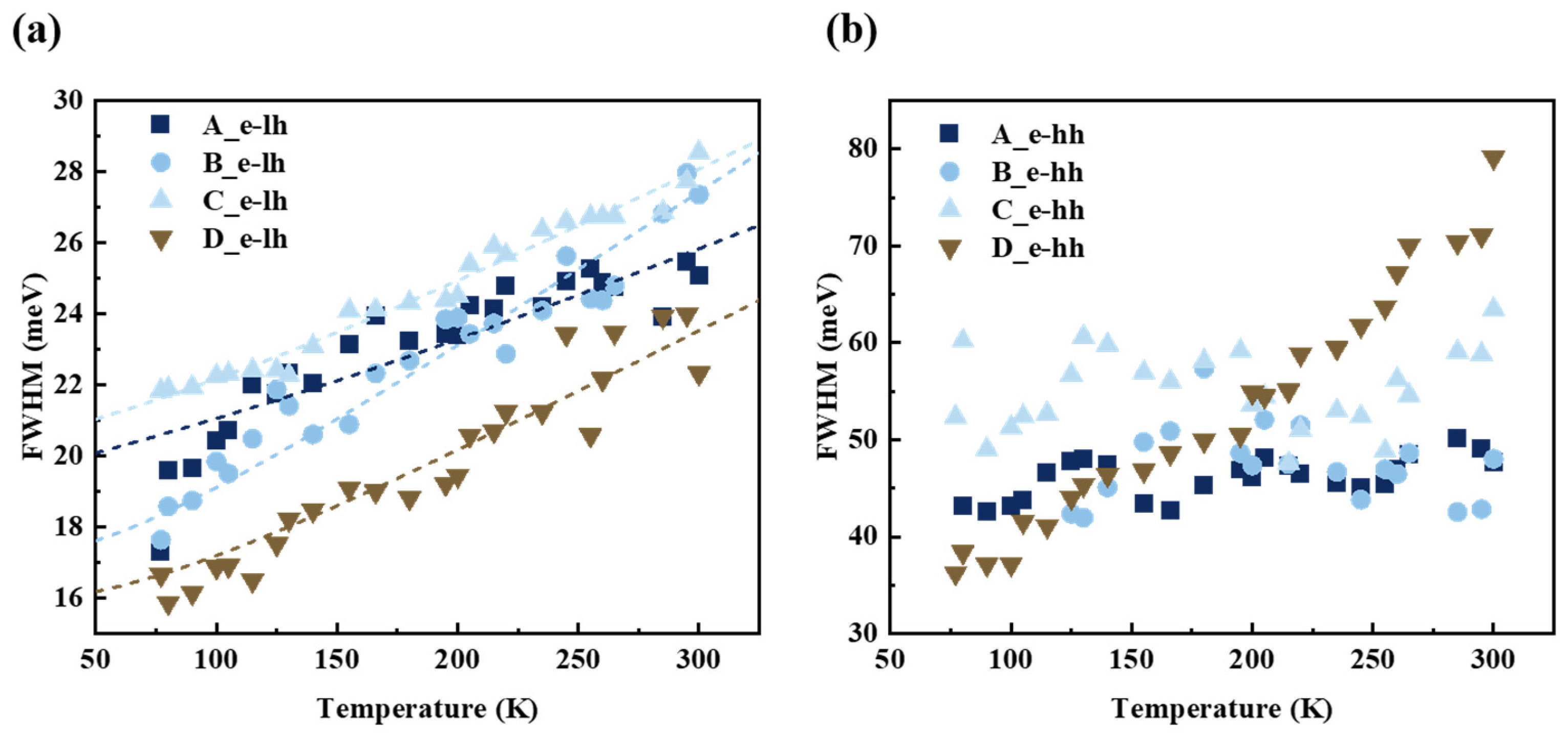

3.4. The Temperature-Dependent Photoluminescence Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Imamoto, H.; Sato, F.; Imanaka, K.; Shimura, M. AlGaAs/GaAs Superlattice Multi-Quantum-Well Laser Diode. Superlattices Microstruct. 1989, 5, 167–170. [Google Scholar] [CrossRef]

- Bour, D.P.; Treat, D.W.; Thornton, R.L.; Paoli, T.L.; Bringans, R.D.; Krusor, B.S.; Geels, R.S.; Welch, D.F.; Wang, T.Y. Low Threshold GaxIn1−XP/(AlyGa1−Y)0.5In0.5P Strained Quantum Well Lasers. J. Cryst. Growth 1992, 124, 751–756. [Google Scholar] [CrossRef]

- Erbert, G.; Bugge, F.; Knauer, A.; Sebastian, J.; Thies, A.; Wenzel, H.; Weyers, M.; Trankle, G. High-Power Tensile-Strained GaAsP-AlGaAs Quantum-Well Lasers Emitting between 715 and 790 nm. IEEE J. Sel. Top. Quantum Electron. 1999, 5, 780–784. [Google Scholar] [CrossRef]

- Bai, Y.; Xu, Z.; Lin, Y.; Wisdom, J.; Scholz, C.; Weiss, E.S.; Chilla, J.; Diening, A. AlGaAs-Based Optically Pumped Semiconductor Lasers. In Vertical External Cavity Surface Emitting Lasers (VECSELs) VIII; SPIE: Bellingham, WA, USA, 2018; Volume 10515. [Google Scholar] [CrossRef]

- Mogensen, P.C.; Hall, S.A.; Smowton, P.M.; Bangert, U.; Blood, P.; Dawson, P. The Effect of High Compressive Strain on the Operation of AlGaInP Quantum-Well Lasers. IEEE J. Quantum Electron. 1998, 34, 1652–1659. [Google Scholar] [CrossRef]

- Shieh, H.M.; Fu, R.J.; Lu, T.-C.; Chen, L.-R. High-Performance GaInP/AlGaInP Visible Laser Diodes Grown by Multiwafer MOCVD. In Laser Diodes and LEDs in Industrial, Measurement, Imaging, and Sensors Applications II; Testing, Packaging, and Reliability of Semiconductor Lasers V; SPIE: Bellingham, WA, USA, 2000; p. 3945. [Google Scholar] [CrossRef]

- Kaspari, C.; Zorn, M.; Weyers, M.; Erbert, G. Growth Parameter Optimization of the GaInP/AlGaInP Active Zone of 635nm Red Laser Diodes. J. Cryst. Growth 2008, 310, 5175–5177. [Google Scholar] [CrossRef]

- Hu, H.M.; Zhao, J.; Wang, W.; Ho, J.; Kuang, L.; Liu, W. 12 W High Power InGaAsP/AlGaInP 755 Nm Quantum Well Laser. Chin. Opt. Lett. 2019, 17, 061403. [Google Scholar] [CrossRef]

- Mawsi, L.J.; Rusli, S.; Al-Muhanna, A.; Wade, J.K. Short-Wavelength (0.7 Μm>λ>0.78 Μm) High-Power InGaAsP-Active Diode Lasers. IEEE J. Sel. Top. Quantum Electron. 1999, 5, 785–791. [Google Scholar] [CrossRef]

- Al-Muhanna, A.; Wade, J.K.; Earles, T.; Lopez, J.; Mawst, L.J. High-Performance, Reliable, 730-Nm-Emitting Al-Free Active Region Diode Lasers. Appl. Phys. Lett. 1998, 73, 2869–2871. [Google Scholar] [CrossRef][Green Version]

- Ono, K. Masayoshi Takemi Anomalous Behavior of Phase Separation of InGaAsP on GaAs Substrates Grown by MOVPE. J. Cryst. Growth 2007, 298, 41–45. [Google Scholar] [CrossRef]

- Ono, K.; Takemi, M. Investigation of Anomalous Optical Characteristics of InGaAsP Layers on GaAs Substrates Grown by Metalorganic Vapor Phase Epitaxy. J. Appl. Phys. 2008, 47, 1484–1490. (In Japanese) [Google Scholar] [CrossRef]

- Ono, K.; Takemi, M.; Fujiwara, Y. Metalorganic Vapor Phase Epitaxial Growth Parameter Dependence of Phase Separation in Miscibility Gap of InGaAsP. J. Appl. Phys. 2008, 47, 896–898. (In Japanese) [Google Scholar] [CrossRef]

- Konaka, Y.; Ono, K.; Terai, Y.; Fujiwara, Y. Coexistence Properties of Phase Separation and CuPt-Ordering in InGaAsP Grown on GaAs Substrates by Organometallic Vapor Phase Epitaxy. J. Cryst. Growth 2010, 312, 2056–2059. [Google Scholar] [CrossRef]

- Knauer, A.; Bugge, F.; Erbert, G.; Wenzel, H.; Vogel, K.; Zeimer, U.; Meyers, M.M. Optimization of GaAsP/AlGaAs-Based QW Laser Structures for High Power 800 Nm Operation. J. Electron. Mater. 2000, 29, 53–56. [Google Scholar] [CrossRef]

- Knauer, A.; Erbert, G.; Wenzel, H.; Bhattacharya, A.; Bugge, F.; Maege, J.; Pittroff, W.; Sebastian, J. 7W CW Power from Tensile-Strained GaAsyP1-y/AlGaAs (=735 nm) QW Diode Lasers. Electron. Lett. 1999, 35, 638. [Google Scholar] [CrossRef]

- Sebastian, J.; Beister, G.; Bugge, F.; Buhrandt, E.; Erbert, G.; Hansel, H.G.; Hulsewede, R.; Knauer, A.; Pittroff, W.; Staske, R.; et al. High-Power 810-nm GaAsP-AlGaAs Diode Lasers with Narrow Beam Divergence. IEEE J. Sel. Top. Quantum Electron. 2000, 7, 334–339. [Google Scholar] [CrossRef]

- Sumpf, B.; Beister, G.; Erbert, G.; Fricke, J.; Knauer, A.; Pittroff, W.; Ressel, P.; Sebastian, J.; Wenzel, H.; Tra, G. 2 W Reliable Operation of =735 nm GaAsP/AlGaAs Laser Diodes. Electron. Lett. 2001, 37, 351. [Google Scholar] [CrossRef]

- Sumpf, B.; Hu, R.; Erbert, G.; Dzionk, C.; Fricke, J.; Knauer, A.; Pittroff, W.; Ressel, P.; Sebastian, J.; Wenzel, H.; et al. High-Brightness 735 Nm Tapered Diode Lasers. Electron. Lett. 2002, 38, 183. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, L.; Tan, S.; Liu, W.; Deng, G.; Wang, J. 71% Wall-Plug Efficiency from 780 Nm-Emitting Laser Diode with GaAsP Quantum Well. Opt. Laser Technol. 2024, 168, 109867. [Google Scholar] [CrossRef]

- Ota, K.; Yaguchi, H.; Onabe, K.; Ito, R.; Shiraki, Y. Effect of Growth Interruption on the Interface Flatness in Metalorganic Vapor Phase Epitaxy-Grown GaAs/GaAsP Heterostructures. J. Cryst. Growth 1994, 145, 819–823. [Google Scholar] [CrossRef]

- Antolini, A.; Fornuto, G.; Papuzza, C.; Soldani, D.; Taiariol, F. Growth and Characterization of InGaAsP/InGaAs MQW Structures Grown by MOCVD. Technique. Mater. Sci. Forum 1996, 203, 103–108. [Google Scholar] [CrossRef]

- Pan, J.; Huan, B.; Zhang, X.; Yue, J.; Yu, Y.; Wei, J. Effect of Growth Interruption and Strain Buffer Layer on PL Performance of AlGaAs/GaAs/InGaAs Quantum Well for 1065 nm Wavelength Lasers. Rare Met. 2004, 23, 64–67. [Google Scholar]

- Demir, I.; Elagoz, S. Interruption Time Effects on InGaAs/InAlAs Superlattices of Quantum Cascade Laser Structures Grown by MOCVD. Superlattices Microstruct. 2016, 100, 723–729. [Google Scholar] [CrossRef]

- Bru-Chevallier, C.; Baltagi, Y.; Guillot, G.; Hong, K.; Pavlidis, D. Impact of Growth Interruption on Interface Roughness of MOCVD Grown InGaAs/InAlAs Studied by Photoreflectance Spectroscopy. In Proceedings of the Compound Semiconductors 1997. Proceedings of the IEEE Twenty-Fourth International Symposium on Compound Semiconductors, San Diego, CA, USA, 8–11 September 1997; p. 156. [Google Scholar] [CrossRef]

- Strömberg, A.; Omanakuttan, G.; Liu, Y.; Mu, T.; Xu, Z.; Lourdudoss, S.; Sun, Y.-T. Heteroepitaxy of GaAsP and GaP on GaAs and Si by low pressure hydride vapor phase epitaxy. J. Cryst. Growth 2020, 540, 125623. [Google Scholar] [CrossRef]

- Wagner, J.; Peter, M.; Winkler, K.; Bachem, K.-H. Interfacial Intermixing and Arsenic Incorporation in Thin InP Barriers Embedded in In0.53Ga0.47As. J. Appl. Phys. 1998, 83, 4299–4302. [Google Scholar] [CrossRef]

- Spurdens, P.C.; Taylor, M.R.; Hockly, M.; Yates, M.J. The Influence of Growth Conditions on the Planarity of MOVPE Grown GaInAs(P) Interfaces. J. Cryst. Growth 1991, 107, 215–220. [Google Scholar] [CrossRef]

- Schwedler, R.; Gallmann, B.; Wolter, K.; Kohl, A.; Leo, K.; Kurz, H.; Juillaguet, S.; Massone, E.; Camassel, J.; Laurenti, J.P.; et al. Interface Characterization of Strained InGaAs/InP Quantum Wells after a Growth Interruption Sequence. Appl. Surf. Surf. Sci. 1993, 63, 187–190. [Google Scholar] [CrossRef]

- Jordan, A.S.; Robertson, A. Thermodynamic Analysis of AsH3 and PH3 Decomposition Including Subhydrides. J. Vac. Sci. Technol. A 1994, 12, 204–215. [Google Scholar] [CrossRef]

- Zhong, L.; Ma, X. Photoluminescence Properties of Tensile-Strained GaAsP/GaInP Single Quantum Wells Grown by Metal Organic Chemical Vapor Deposition. J. Appl. Phys. 2008, 47, 7026. (In Japanese) [Google Scholar] [CrossRef]

- Bertolet, D.C.; Hsu, J.-K.; Lau, K.M. Tailoring of Hole Eigenenergies in Strained GaAsP/AlGaAs Single Quantum Wells Grown by Atmospheric Pressure Organometallic Chemical Vapor Deposition. Appl. Phys. Lett. 1988, 53, 2501–2503. [Google Scholar] [CrossRef]

- Nakano, T.; Shioda, T.; Abe, E.; Sugiyama, M.; Enomoto, N.; Nakano, Y.; Shimogaki, Y. Abrupt InGaP∕GaAs Heterointerface Grown by Optimized Gas-Switching Sequence in Metal Organic Vapor Phase Epitaxy. Appl. Phys. Lett. 2008, 92, 112106. [Google Scholar] [CrossRef]

- Seifert, W.; Liu, X.; Samuelson, L. Influence of Arsenic Adsorption Layers on Heterointerfaces in GaInAs/InP Quantum Well Structures. Appl. Phys. Lett. 1993, 62, 949–951. [Google Scholar] [CrossRef]

- López-Escalante, M.C.; Gabás, M.; García, I.; Barrigón, E.; Rey-Stolle, I.; Algora, C.; Palanco, S.; Ramos-Barrado, J.R. Differences between GaAs/GaInP and GaAs/AlInP Interfaces Grown by Movpe Revealed by Depth Profiling and Angle-Resolved X-Ray Photoelectron Spectroscopies. Appl. Surf. Sci. 2016, 360, 477–484. [Google Scholar] [CrossRef]

- Kúdela, R.; Kučera, M.; Olejnı, B.; Eliáš, P.; Hasenöhrl, S.; Novák, J. Formation of Interfaces in InGaP/GaAs/InGaP Quantum Wells. J. Cryst. Growth 2000, 212, 21–28. [Google Scholar] [CrossRef]

- Zhang, X.B.; Ryou, J.H.; Dupuis, R.D.; Walter, G.; Holonyak, N. Metalorganic Chemical Vapor Deposition Growth and Characterization of InGaP/GaAs Superlattices. J. Electron. Mater. 2006, 35, 705–710. [Google Scholar] [CrossRef]

- Hou, C.; Zou, Y.; Wang, H.; Wang, X.; Xu, Y.; Wang, Q.; He, Z.; Fan, J.; Shi, L.; Xu, L.; et al. Tailoring Strain and Lattice Relaxation Characteristics in InGaAs/GaAsP Multiple Quantum Wells Structure with Phosphorus Doping Engineering. J. Alloys Compd. 2019, 770, 517–522. [Google Scholar] [CrossRef]

- Fan, H.Y. Temperature Dependence of the Energy Gap in Semiconductors. Phys. Rev. 1951, 82, 900–905. [Google Scholar] [CrossRef]

- Dong, H.; Sun, J.; Ma, S.; Liang, J.; Lu, T.; Liu, X.; Xu, B. Influence of Substrate Misorientation on the Photoluminescence and Structural Properties of InGaAs/GaAsP Multiple Quantum Wells. Nanoscale 2016, 8, 6043–6056. [Google Scholar] [CrossRef]

- Liu, L.; Wang, L.; Li, D.; Liu, N.; Li, L.; Cao, W.; Yang, W.; Wan, C.; Chen, W.; Du, W.; et al. Influence of Indium Composition in the Prestrained InGaN Interlayer on the Strain Relaxation of InGaN/GaN Multiple Quantum Wells in Laser Diode Structures. J. Appl. Phys. 2011, 109, 073106. [Google Scholar] [CrossRef]

- Yuan, H.; Li, L.; Zhang, J.; Li, Z.; Zeng, L.; Wang, Y.; Qu, Y.; Ma, X.; Liu, G. Optical Properties Improvement of InGaAs/GaInP Single Quantum Well Grown by Metal-Organic Chemical Vapor Deposition. Optik 2019, 176, 295–301. [Google Scholar] [CrossRef]

- Mickevičius, J.; Nomeika, K.; Dmukauskas, M.; Kadys, A.; Nargelas, S.; Aleksiejūnas, R. Comparison of Growth Interruption and Temperature Variation Impact on Emission Efficiency in Blue InGaN/GaN MQWs. Vacuum 2021, 183, 109871. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, L.; Sun, Q.; Lu, T.; Deng, Z.; Ma, Z.; Jiang, Y.; Jia, H.; Wang, W.; Zhou, J.; et al. Investigation of Temperature-Dependent Photoluminescence in Multi-Quantum Wells. Sci. Rep. 2015, 5, 12718. [Google Scholar] [CrossRef] [PubMed]

- Rudin, S.; Reinecke, T.L. Temperature-Dependent Exciton Linewidths in Semiconductor Quantum Wells. Phys. Rev. B 1990, 41, 3017–3027. [Google Scholar] [CrossRef] [PubMed]

| Sample | Peak 1 (nm) | Peak 2 (nm) | e-lh1 (nm) | e-hh1 (nm) | QW Thickness (nm) | QW As Concentration (%) | QB Ga/Al Concentration (%) |

|---|---|---|---|---|---|---|---|

| A | 740.24 | 721.86 | 740.37 | 720.79 | 6.5 | 73 | 47/47 |

| B | 743.3 | 723.39 | 743.24 | 722.42 | 6.9 | 73 | 47/48 |

| C | 746.35 | 731.06 | 746.18 | 733.04 | 6.2 | 77 | 48/48 |

| D | 749.41 | 738.71 | 749.89 | 738.8 | 6.2 | 78.5 | 48/48 |

| Sample | Transition | Eg(0) (eV) | α (eV/K) | β (K) |

|---|---|---|---|---|

| A | e-lh | 1.769 | 4.955 × 10−4 | 195.396 |

| e-hh | 1.814 | 4.011 × 10−4 | 84.572 | |

| B | e-lh | 1.765 | 5.643 × 10−4 | 252.426 |

| e-hh | 1.824 | 4.846 × 10−4 | 103.768 | |

| C | e-lh | 1.738 | 4.688 × 10−4 | 273.293 |

| e-hh | 1.757 | 2.672 × 10−4 | 4.728 × 104 | |

| D | e-lh | 1.741 | 5.910 × 10−4 | 278.405 |

| e-hh | 1.746 | 4.742 × 10−4 | 325.895 |

| Sample | C1 | EA1 (meV) | C2 | EA2 (meV) |

|---|---|---|---|---|

| A | 8.08 × 107 | 363.83 | 18.25 | 40.86 |

| B | 1.1 × 107 | 355.74 | 14.83 | 55.39 |

| C | 6.95 × 1010 | 565.74 | 15.20 | 46.73 |

| D | 2.88 × 105 | 235.82 | 13.15 | 34.21 |

| Sample | Γ0 (meV) | σ (meV/K) | γ (meV) | ħωLO (meV) |

|---|---|---|---|---|

| A | 19.121 | 0.019 | 5.484 | 49.137 |

| B | 16.925 | 0.011 | 6.677 | 17.111 |

| C | 19.976 | 0.021 | 5.771 | 37.583 |

| D | 15.599 | 0.011 | 6.616 | 23.009 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Zeng, Y.; Yu, X.; Gao, W.; Chen, W.; Shen, H.; Qin, L.; Ning, Y.; Wang, L. Impact of the Interruption Duration on Photoluminescence Properties of MOCVD-Grown GaAsP/InAlGaAs Quantum Well Structures. Nanomaterials 2024, 14, 1469. https://doi.org/10.3390/nano14181469

Wang B, Zeng Y, Yu X, Gao W, Chen W, Shen H, Qin L, Ning Y, Wang L. Impact of the Interruption Duration on Photoluminescence Properties of MOCVD-Grown GaAsP/InAlGaAs Quantum Well Structures. Nanomaterials. 2024; 14(18):1469. https://doi.org/10.3390/nano14181469

Chicago/Turabian StyleWang, Bin, Yugang Zeng, Xuezhe Yu, Weijie Gao, Wei Chen, Haoyu Shen, Li Qin, Yongqiang Ning, and Lijun Wang. 2024. "Impact of the Interruption Duration on Photoluminescence Properties of MOCVD-Grown GaAsP/InAlGaAs Quantum Well Structures" Nanomaterials 14, no. 18: 1469. https://doi.org/10.3390/nano14181469

APA StyleWang, B., Zeng, Y., Yu, X., Gao, W., Chen, W., Shen, H., Qin, L., Ning, Y., & Wang, L. (2024). Impact of the Interruption Duration on Photoluminescence Properties of MOCVD-Grown GaAsP/InAlGaAs Quantum Well Structures. Nanomaterials, 14(18), 1469. https://doi.org/10.3390/nano14181469