Flexible Sandwich-Shaped Cellulose Nanocrystals/Silver Nanowires/MXene Films Exhibit Efficient Electromagnetic-Shielding Interference Performance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

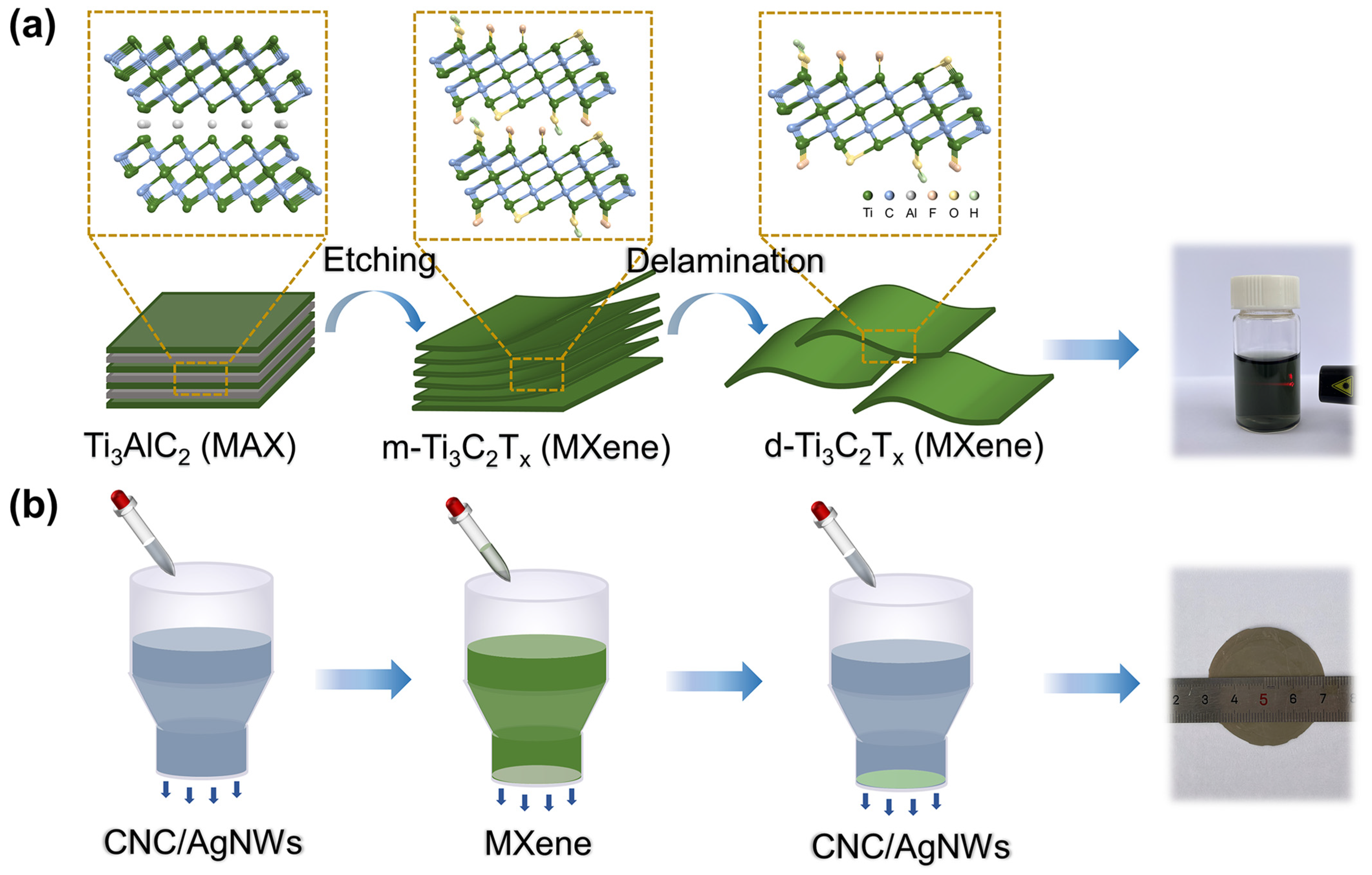

2.2. Synthesis of Ti3C2Tx MXene

2.3. Preparation of MX@AC Composite Films

2.4. Characterization

3. Results and Discussion

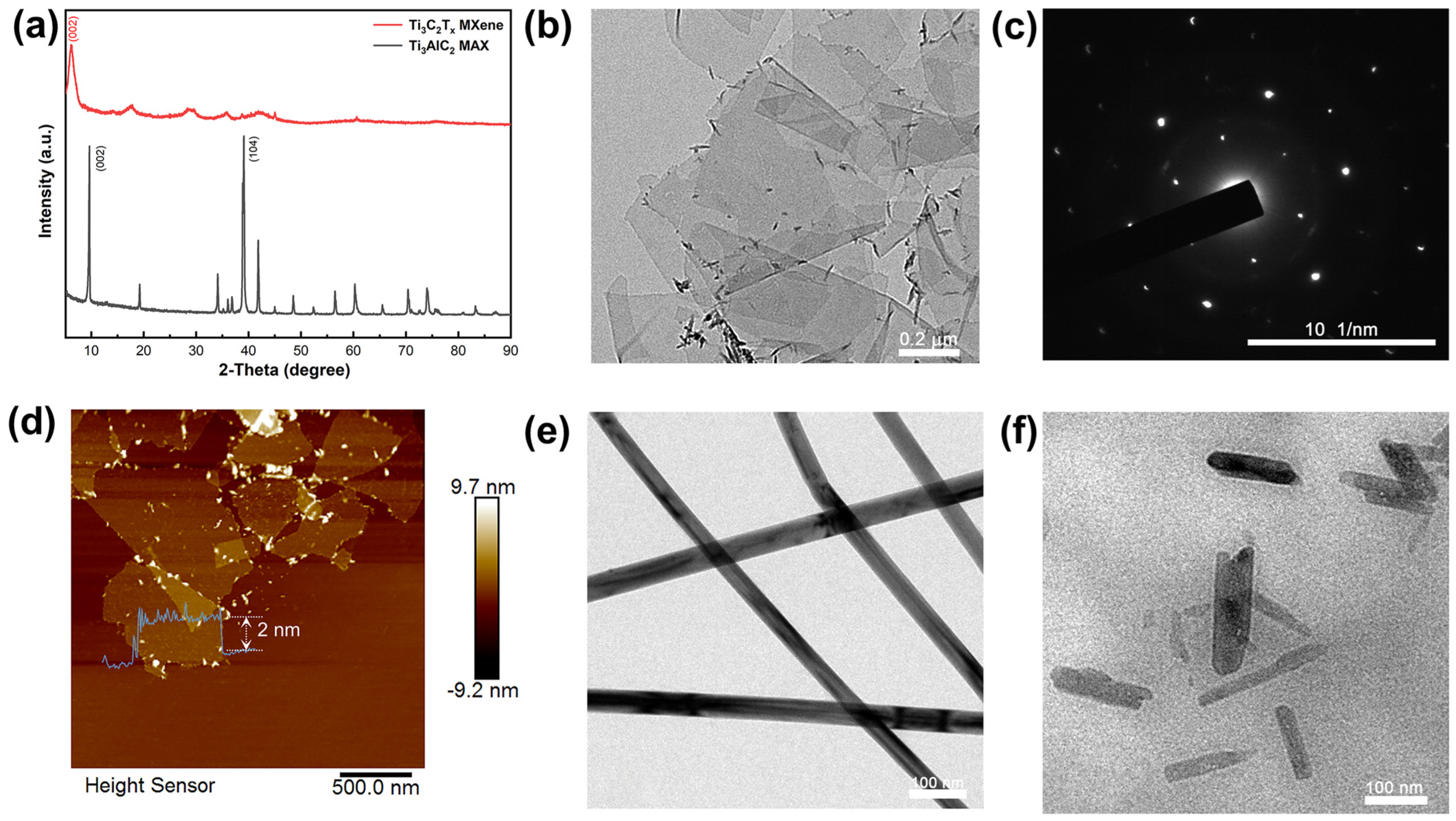

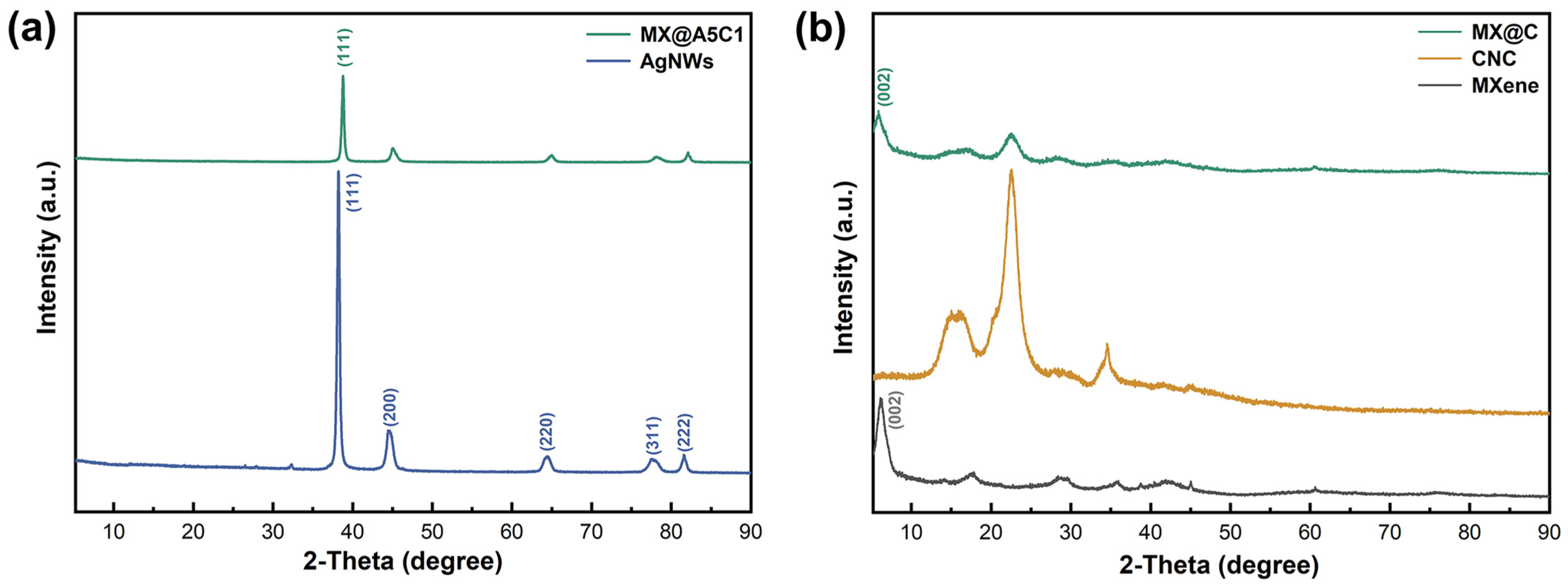

3.1. Morphological and Structural Characterization of MX@AC Composite Films

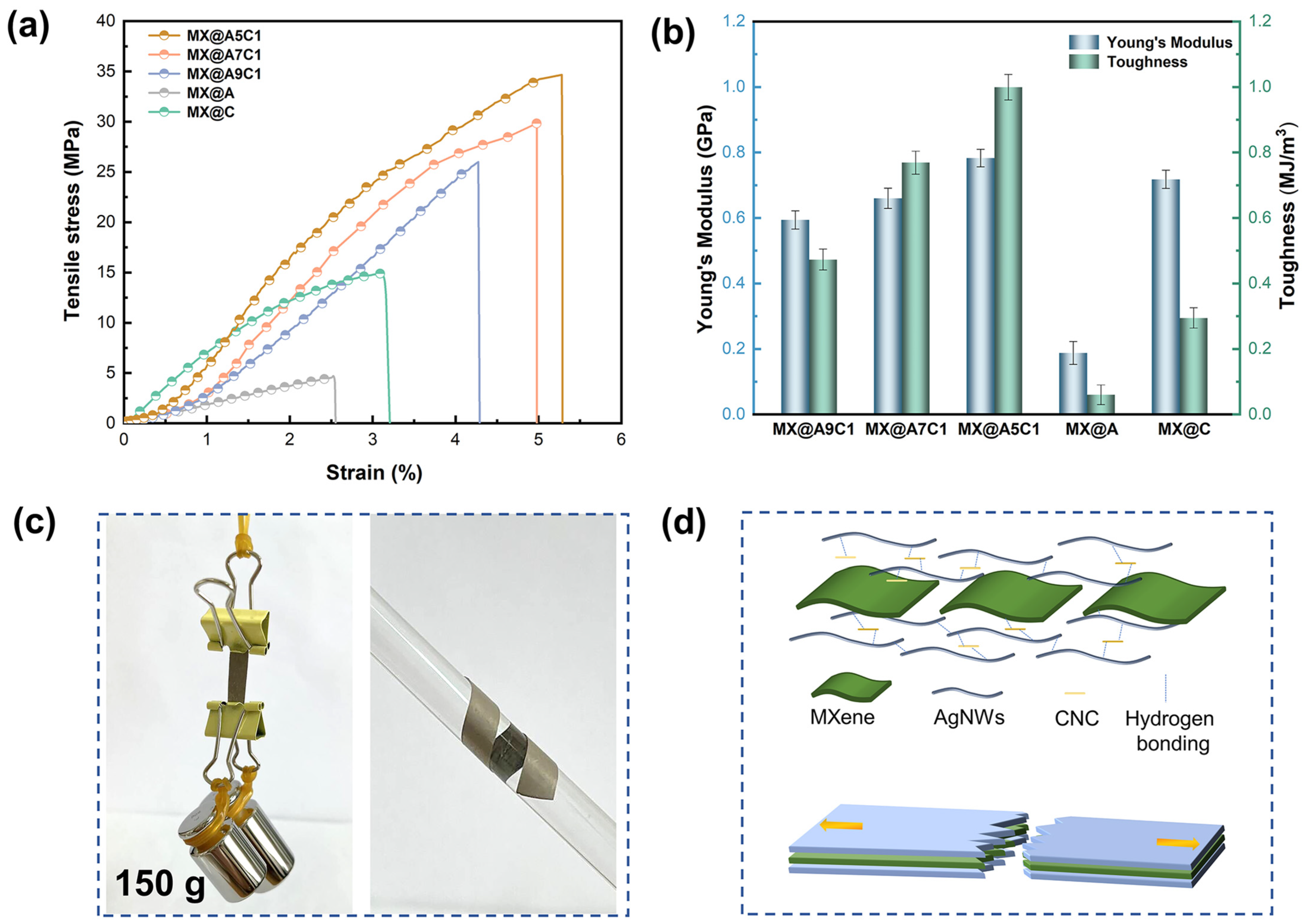

3.2. Mechanical Properties of MX@AC

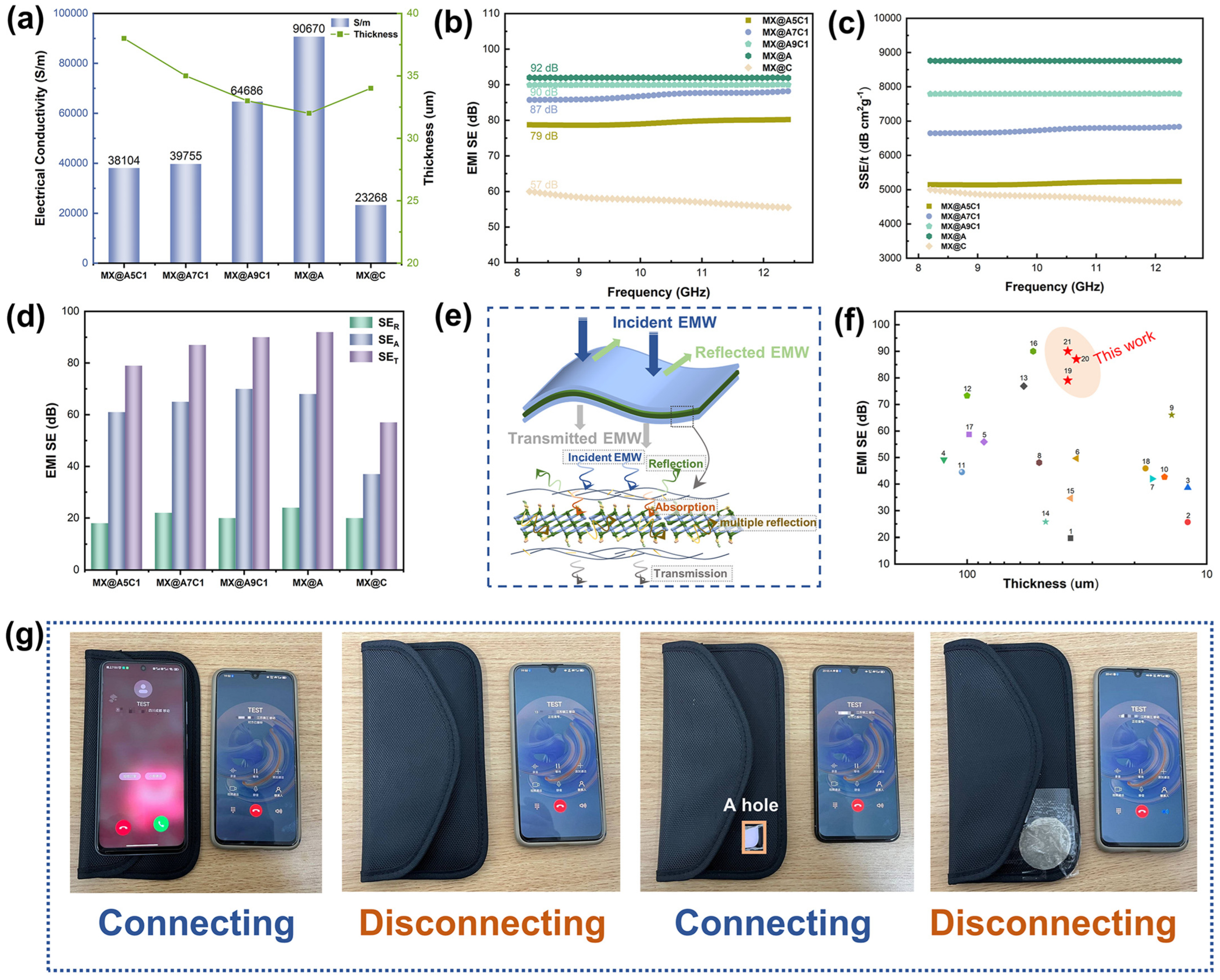

3.3. EMI-Shielding Performance of MX@AC Composite Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cheng, J.; Li, C.; Xiong, Y.; Zhang, H.; Raza, H.; Ullah, S.; Wu, J.; Zheng, G.; Cao, Q.; Zhang, D.; et al. Recent Advances in Design Strategies and Multifunctionality of Flexible Electromagnetic Interference Shielding Materials. Nano-Micro Lett. 2022, 14, 80. [Google Scholar] [CrossRef] [PubMed]

- Jia, X.; Li, Y.; Shen, B.; Zheng, W. Evaluation, fabrication and dynamic performance regulation of green EMI-shielding materials with low reflectivity: A review. Compos. Part B Eng. 2022, 233, 109652. [Google Scholar] [CrossRef]

- Liang, C.; Gu, Z.; Zhang, Y.; Ma, Z.; Qiu, H.; Gu, J. Structural Design Strategies of Polymer Matrix Composites for Electromagnetic Interference Shielding: A Review. Nano-Micro Lett. 2021, 13, 181. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Cheng, Z.; Fang, C.; Hou, X.; Xie, L. Recent advances in MXenes composites for electromagnetic interference shielding and microwave absorption. Compos. Part A Appl. Sci. Manuf. 2020, 136, 105956. [Google Scholar] [CrossRef]

- Park, J.S.; Park, J.Y.; Lee, K.; Cho, Y.S.; Shin, H.; Jung, Y.; Park, C.R.; Kim, T.; Kim, J.H.; Yang, S.J. Large-scalable, ultrastable thin films for electromagnetic interference shielding. J. Mater. Chem. A 2023, 11, 18188–18194. [Google Scholar] [CrossRef]

- He, J.; Han, M.; Wen, K.; Liu, C.; Zhang, W.; Liu, Y.; Su, X.; Zhang, C.; Liang, C. Absorption-dominated electromagnetic interference shielding assembled composites based on modular design with infrared camouflage and response switching. Compos. Sci. Technol. 2023, 231, 109799. [Google Scholar] [CrossRef]

- Ma, C.; Ma, M.G.; Si, C.; Ji, X.X.; Wan, P. Flexible MXene-Based Composites for Wearable Devices. Adv. Funct. Mater. 2021, 31, 2009524. [Google Scholar] [CrossRef]

- Sang, M.; Liu, G.; Liu, S.; Wu, Y.; Xuan, S.; Wang, S.; Xuan, S.; Jiang, W.; Gong, X. Flexible PTFE/MXene/PI soft electrothermal actuator with electromagnetic-interference shielding property. Chem. Eng. J. 2021, 414, 128883. [Google Scholar] [CrossRef]

- Zhang, Y.; Ruan, K.; Zhou, K.; Gu, J. Controlled Distributed Ti3C2Tx Hollow Microspheres on Thermally Conductive Polyimide Composite Films for Excellent Electromagnetic Interference Shielding. Adv. Mater. 2023, 35, e2211642. [Google Scholar] [CrossRef]

- Zhuo, L.; Cai, Y.; Shen, D.; Gou, P.; Wang, M.; Hu, G.; Xie, F. Anti-oxidation polyimide-based hybrid foams assembled with bilayer coatings for efficient electromagnetic interference shielding. Chem. Eng. J. 2023, 451, 138808. [Google Scholar] [CrossRef]

- Jia, F.; Lu, Z.; Liu, Y.; Li, J.; Xie, F.; Dong, J. Carboxylate-Decorated Multiwalled Carbon Nanotube/Aramid Nanofiber Film for Tunable Electromagnetic Interference Shielding Performance and Rapid Electric Heating Capacity. ACS Appl. Polym. Mater. 2022, 4, 6342–6353. [Google Scholar] [CrossRef]

- Jia, L.-C.; Sun, W.-J.; Zhou, C.-G.; Yan, D.-X.; Zhang, Q.-C.; Li, Z.-M. Integrated strength and toughness in graphene/calcium alginate films for highly efficient electromagnetic interference shielding. J. Mater. Chem. C 2018, 6, 9166–9174. [Google Scholar] [CrossRef]

- Wei, Q.; Pei, S.; Qian, X.; Liu, H.; Liu, Z.; Zhang, W.; Zhou, T.; Zhang, Z.; Zhang, X.; Cheng, H.M.; et al. Superhigh Electromagnetic Interference Shielding of Ultrathin Aligned Pristine Graphene Nanosheets Film. Adv. Mater. 2020, 32, e1907411. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Dong, J.; Li, X.; Zhao, X.; Ji, C.; Zhang, Q. Interlayer decoration of expanded graphite by polyimide resins for preparing highly thermally conductive composites with superior electromagnetic shielding performance. Carbon 2022, 198, 1–10. [Google Scholar] [CrossRef]

- Zhang, Y.; Ruan, K.; Shi, X.; Qiu, H.; Pan, Y.; Yan, Y.; Gu, J. Ti3C2Tx/rGO porous composite films with superior electromagnetic interference shielding performances. Carbon 2021, 175, 271–280. [Google Scholar] [CrossRef]

- Cao, M.-S.; Cai, Y.-Z.; He, P.; Shu, J.-C.; Cao, W.-Q.; Yuan, J. 2D MXenes: Electromagnetic property for microwave absorption and electromagnetic interference shielding. Chem. Eng. J. 2019, 359, 1265–1302. [Google Scholar] [CrossRef]

- Iqbal, A.; Sambyal, P.; Koo, C.M. 2D MXenes for Electromagnetic Shielding: A Review. Adv. Funct. Mater. 2020, 30, 2000883. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Z.; Zhang, H.B.; Chen, W.; Zhao, Z.; Wang, Q.W.; Yu, Z.Z. Ultrastrong and Highly Conductive MXene-Based Films for High-Performance Electromagnetic Interference Shielding. Adv. Electron. Mater. 2019, 6, 1901094. [Google Scholar] [CrossRef]

- Wang, J.Q.; Qian, P.F.; Lou, T.J.; Wang, W.; Geng, W.H.; Jing, L.C.; Bao, Z.L.; Wang, T.; Geng, H.Z. Vacuum-Assisted Layer-by-Layer Carbon Nanotube/Ti3C2TX MXene Films for Detecting Human Movements. Adv. Mater. Technol. 2021, 7, 2101096. [Google Scholar] [CrossRef]

- Qian, K.; Wu, H.; Fang, J.; Yang, Y.; Miao, M.; Cao, S.; Shi, L.; Feng, X. Yarn-ball-shaped CNF/MWCNT microspheres intercalating Ti3C2Tx MXene for electromagnetic interference shielding films. Carbohydr. Polym. 2021, 254, 117325. [Google Scholar] [CrossRef]

- Liu, H.; Fu, R.; Su, X.; Wu, B.; Wang, H.; Xu, Y.; Liu, X. MXene confined in shape-stabilized phase change material combining enhanced electromagnetic interference shielding and thermal management capability. Compos. Sci. Technol. 2021, 210, 108835. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Y.; Li, Z.; Ma, J.; Zhou, K.; Liu, C.; Shen, C.; Feng, Y. Fire/heat-resistant, anti-corrosion and folding Ti2C3Tx MXene/single-walled carbon nanotube films for extreme-environmental EMI shielding and solar-thermal conversion applications. J. Mater. Chem. C 2021, 9, 10425–10434. [Google Scholar] [CrossRef]

- Seredych, M.; Shuck, C.E.; Pinto, D.; Alhabeb, M.; Precetti, E.; Deysher, G.; Anasori, B.; Kurra, N.; Gogotsi, Y. High-Temperature Behavior and Surface Chemistry of Carbide MXenes Studied by Thermal Analysis. Chem. Mater. 2019, 31, 3324–3332. [Google Scholar] [CrossRef]

- Li, X.; Yang, M.; Qin, W.; Gu, C.; Feng, L.; Tian, Z.; Qiao, H.; Chen, J.; Chen, J.; Yin, S. MXene-based multilayered flexible strain sensor integrating electromagnetic shielding and Joule heat. Colloids Surf. A Physicochem. Eng. Asp. 2023, 658, 130706. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, S.J.; Kim, Y.-J.; Lim, Y.; Chae, Y.; Lee, B.-J.; Kim, Y.-T.; Han, H.; Gogotsi, Y.; Ahn, C.W. Oxidation-resistant titanium carbide MXene films. J. Mater. Chem. A 2020, 8, 573–581. [Google Scholar] [CrossRef]

- Xu, D.; Huang, Q.; Yang, L.; Chen, Y.; Lu, Z.; Liu, H.; Han, P.; Guo, L.; Wang, C.; Liu, C. Experimental design of composite films with thermal management and electromagnetic shielding properties based on polyethylene glycol and MXene. Carbon 2023, 202, 1–12. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, Q.; Sheng, X.; Zhang, S.; Chen, J.; Ma, Y.; Qin, J.; Zhao, Y.; Shi, X.; Zhang, G. Flexible, robust, sandwich structure polyimide composite film with alternative MXene and Ag NWs layers for electromagnetic interference shielding. J. Mater. Sci. Technol. 2023, 159, 194–203. [Google Scholar] [CrossRef]

- Lan, C.; Jia, H.; Qiu, M.; Fu, S. Ultrathin MXene/Polymer Coatings with an Alternating Structure on Fabrics for Enhanced Electromagnetic Interference Shielding and Fire-Resistant Protective Performances. ACS Appl. Mater. Interfaces 2021, 13, 38761–38772. [Google Scholar] [CrossRef]

- Sha, Z.; He, H.; Ma, H.; Hong, B.; Lu, J.; Fei, X.; Zhu, M. All-in-one integrated flexible PE@PET/MXene films for high-performance electromagnetic shields with self-reinforced conductivity and mechanical properties. Carbon 2024, 216, 118595. [Google Scholar] [CrossRef]

- Cheng, H.; Pan, Y.; Chen, Q.; Che, R.; Zheng, G.; Liu, C.; Shen, C.; Liu, X. Ultrathin flexible poly(vinylidene fluoride)/MXene/silver nanowire film with outstanding specific EMI shielding and high heat dissipation. Adv. Compos. Hybrid Mater. 2021, 4, 505–513. [Google Scholar] [CrossRef]

- Zhang, W.; Ji, X.-X.; Ma, M.-G. Emerging MXene/cellulose composites: Design strategies and diverse applications. Chem. Eng. J. 2023, 458, 141402. [Google Scholar] [CrossRef]

- Ma, Z.; Kang, S.; Ma, J.; Shao, L.; Zhang, Y.; Liu, C.; Wei, A.; Xiang, X.; Wei, L.; Gu, J. Ultraflexible and Mechanically Strong Double-Layered Aramid Nanofiber–Ti3C2Tx MXene/Silver Nanowire Nanocomposite Papers for High-Performance Electromagnetic Interference Shielding. ACS Nano 2020, 14, 8368–8382. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Mai, T.; Wang, P.-L.; Guo, W.-Y.; Ma, M.-G. Flexible MXene/Nanocellulose Composite Aerogel Film with Cellular Structure for Electromagnetic Interference Shielding and Photothermal Conversion. ACS Appl. Mater. Interfaces 2023, 15, 47425–47433. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Chen, K.; Dang, B.; Wang, C.; Chen, Y.; Liu, M.; Li, Y.; Zhang, X.; Sun, Q. Flexible and mechanically strong MXene/cellulose-lamellae sheets for electromagnetic interference shielding. Chem. Eng. J. 2023, 468, 143661. [Google Scholar] [CrossRef]

- Wu, N.; Li, B.; Pan, F.; Zhang, R.; Liu, J.; Zeng, Z. Ultrafine cellulose nanocrystal-reinforced MXene biomimetic composites for multifunctional electromagnetic interference shielding. Sci. China Mater. 2023, 66, 1597–1606. [Google Scholar] [CrossRef]

- Cao, W.-T.; Chen, F.-F.; Zhu, Y.-J.; Zhang, Y.-G.; Jiang, Y.-Y.; Ma, M.-G.; Chen, F. Binary Strengthening and Toughening of MXene/Cellulose Nanofiber Composite Paper with Nacre-Inspired Structure and Superior Electromagnetic Interference Shielding Properties. ACS Nano 2018, 12, 4583–4593. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Z.; Wang, C.; Siqueira, G.; Han, D.; Huch, A.; Abdolhosseinzadeh, S.; Heier, J.; Nüesch, F.; Zhang, C.; Nyström, G. Nanocellulose-MXene Biomimetic Aerogels with Orientation-Tunable Electromagnetic Interference Shielding Performance. Adv. Sci. 2020, 7, 2000979. [Google Scholar] [CrossRef] [PubMed]

- Ma, M.; Liao, X.; Chu, Q.; Chen, S.; Shi, Y.; He, H.; Wang, X. Construction of gradient conductivity cellulose nanofiber/MXene composites with efficient electromagnetic interference shielding and excellent mechanical properties. Compos. Sci. Technol. 2022, 226, 109540. [Google Scholar] [CrossRef]

- Guo, Z.; Ren, P.; Lu, Z.; Hui, K.; Yang, J.; Zhang, Z.; Chen, Z.; Jin, Y.; Ren, F. Multifunctional CoFe2O4@MXene-AgNWs/Cellulose Nanofiber Composite Films with Asymmetric Layered Architecture for High-Efficiency Electromagnetic Interference Shielding and Remarkable Thermal Management Capability. ACS Appl. Mater. Interfaces 2022, 14, 41468–41480. [Google Scholar] [CrossRef]

- Liu, K.; Du, H.; Liu, W.; Zhang, M.; Wang, Y.; Liu, H.; Zhang, X.; Xu, T.; Si, C. Strong, flexible, and highly conductive cellulose nanofibril/PEDOT:PSS/MXene nanocomposite films for efficient electromagnetic interference shielding. Nanoscale 2022, 14, 14902–14912. [Google Scholar] [CrossRef]

- Chen, W.; Liu, L.-X.; Zhang, H.-B.; Yu, Z.-Z. Flexible, Transparent, and Conductive Ti3C2Tx MXene–Silver Nanowire Films with Smart Acoustic Sensitivity for High-Performance Electromagnetic Interference Shielding. ACS Nano 2020, 14, 16643–16653. [Google Scholar] [CrossRef]

- Tang, H.; Feng, H.; Wang, H.; Wan, X.; Liang, J.; Chen, Y. Highly Conducting MXene–Silver Nanowire Transparent Electrodes for Flexible Organic Solar Cells. ACS Appl. Mater. Interfaces 2019, 11, 25330–25337. [Google Scholar] [CrossRef]

- Shi, Y.; Xiang, Z.; Cai, L.; Pan, F.; Dong, Y.; Zhu, X.; Cheng, J.; Jiang, H.; Lu, W. Multi-interface Assembled N-Doped MXene/HCFG/AgNW Films for Wearable Electromagnetic Shielding Devices with Multimodal Energy Conversion and Healthcare Monitoring Performances. ACS Nano 2022, 16, 7816–7833. [Google Scholar] [CrossRef]

- Cheng, R.; Wang, B.; Zeng, J.; Li, J.; Xu, J.; Gao, W.; Chen, K. Janus-inspired flexible cellulose nanofiber-assisted MXene/Silver nanowire papers with fascinating mechanical properties for efficient electromagnetic interference shielding. Carbon 2023, 202, 314–324. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Q.; Xu, P.; Feng, Y.; Ma, J.; Liu, C.; Shen, C. An asymmetric sandwich structural cellulose-based film with self-supported MXene and AgNW layers for flexible electromagnetic interference shielding and thermal management. Nanoscale 2021, 13, 2378–2388. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Zhang, P.; Soomro, R.A.; Zhu, Q.; Xu, B. Advances in the Synthesis of 2D MXenes. Adv. Mater. 2021, 33, 2103148. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Zhang, H.; Li, L.; Fu, Q.; Ge, X. Flexible and Recyclable MXene Nanosheet/Ag Nanowire/Cellulose Nanocrystal Composite Films for Electromagnetic Interference Shielding. ACS Appl. Nano Mater. 2024, 7, 2702–2710. [Google Scholar] [CrossRef]

- Li, Y.; Xue, B.; Yang, S.; Cheng, Z.; Xie, L.; Zheng, Q. Flexible multilayered films consisting of alternating nanofibrillated cellulose/Fe3O4 and carbon nanotube/polyethylene oxide layers for electromagnetic interference shielding. Chem. Eng. J. 2021, 410, 128356. [Google Scholar] [CrossRef]

- Wang, Y.; Peng, H.-K.; Li, T.-T.; Shiu, B.-C.; Zhang, X.; Lou, C.-W.; Lin, J.-H. Layer-by-layer assembly of low-temperature in-situ polymerized pyrrole coated nanofiber membrane for high-efficiency electromagnetic interference shielding. Prog. Org. Coat. 2020, 147, 105861. [Google Scholar] [CrossRef]

- Fan, M.; Li, S.; Wu, L.; Li, L.; Qu, M.; Nie, J.; Zhang, R.; Tang, P.; Bin, Y. Natural rubber toughened carbon nanotube buckypaper and its multifunctionality in electromagnetic interference shielding, thermal conductivity, Joule heating and triboelectric nanogenerators. Chem. Eng. J. 2022, 433, 133499. [Google Scholar] [CrossRef]

- Zhang, Q.; Cui, J.; Zhao, S.; Zhang, G.; Gao, A.; Yan, Y. Development of Electromagnetic-Wave-Shielding Polyvinylidene Fluoride–Ti3C2Tx MXene–Carbon Nanotube Composites by Improving Impedance Matching and Conductivity. Nanomaterials 2023, 13, 417. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhang, B.; Wang, Q.; Yu, G.; Liu, W.; Bai, X.; Dong, L. Thin, Flexible, and High-Strength Graphene Films Modified with CoFe2O4 Nanoparticle–Carbon Nanotubes Composites for Electromagnetic Interference Shielding. ACS Appl. Nano Materials 2023, 6, 17031–17039. [Google Scholar] [CrossRef]

- Miao, M.; Liu, R.; Thaiboonrod, S.; Shi, L.; Cao, S.; Zhang, J.; Fang, J.; Feng, X. Silver nanowires intercalating Ti3C2Tx MXene composite films with excellent flexibility for electromagnetic interference shielding. J. Mater. Chem. C 2020, 8, 3120–3126. [Google Scholar] [CrossRef]

- Cui, C.; Xiang, C.; Geng, L.; Lai, X.; Guo, R.; Zhang, Y.; Xiao, H.; Lan, J.; Lin, S.; Jiang, S. Flexible and ultrathin electrospun regenerate cellulose nanofibers and d-Ti3C2Tx (MXene) composite film for electromagnetic interference shielding. J. Alloys Compd. 2019, 788, 1246–1255. [Google Scholar] [CrossRef]

- Liu, F.; Li, Y.; Hao, S.; Cheng, Y.; Zhan, Y.; Zhang, C.; Meng, Y.; Xie, Q.; Xia, H. Well-aligned MXene/chitosan films with humidity response for high-performance electromagnetic interference shielding. Carbohydr. Polym. 2020, 243, 116467. [Google Scholar] [CrossRef] [PubMed]

- Ji, H.; Zhao, R.; Zhang, N.; Jin, C.; Lu, X.; Wang, C. Lightweight and flexible electrospun polymer nanofiber/metal nanoparticle hybrid membrane for high-performance electromagnetic interference shielding. NPG Asia Mater. 2018, 10, 749–760. [Google Scholar] [CrossRef]

- Qian, J.; Zhang, Z.M.; Bao, R.Y.; Liu, Z.Y.; Yang, M.B.; Yang, W. Lightweight poly (vinylidene fluoride)/silver nanowires hybrid membrane with different conductive network structure for electromagnetic interference shielding. Polym. Compos. 2020, 42, 522–531. [Google Scholar] [CrossRef]

- Yang, S.; Wang, Y.-Y.; Song, Y.-N.; Jia, L.-C.; Zhong, G.-J.; Xu, L.; Yan, D.-X.; Lei, J.; Li, Z.-M. Ultrathin, flexible and sandwich-structured PHBV/silver nanowire films for high-efficiency electromagnetic interference shielding. J. Mater. Chem. C 2021, 9, 3307–3315. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Zhang, J.; Song, P.; Xiao, Z.; Liang, C.; Qiu, H.; Kong, J.; Gu, J. Fabrication and investigation on the ultra-thin and flexible Ti3C2Tx/co-doped polyaniline electromagnetic interference shielding composite films. Compos. Sci. Technol. 2019, 183, 107833. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, R.; Zhang, J.; Miao, M.; Feng, X. Vulcanization of Ti3C2T MXene/natural rubber composite films for enhanced electromagnetic interference shielding. Appl. Surf. Sci. 2021, 546, 149143. [Google Scholar] [CrossRef]

- Ren, W.; Zhu, H.; Yang, Y.; Chen, Y.; Duan, H.; Zhao, G.; Liu, Y. Flexible and robust silver coated non-woven fabric reinforced waterborne polyurethane films for ultra-efficient electromagnetic shielding. Compos. Part B Eng. 2020, 184, 107745. [Google Scholar] [CrossRef]

- Liao, S.-Y.; Wang, X.-Y.; Li, X.-M.; Wan, Y.-J.; Zhao, T.; Hu, Y.-G.; Zhu, P.-L.; Sun, R.; Wong, C.-P. Flexible liquid metal/cellulose nanofiber composites film with excellent thermal reliability for highly efficient and broadband EMI shielding. Chem. Eng. J. 2021, 422, 129962. [Google Scholar] [CrossRef]

- Fan, M.; Song, J.; Qu, M.; Li, S.; Chen, R.; Ma, Y.; Tang, P.; Yuezhen, B. Bacterial-Cellulose-Reinforced Graphite Nanoplate Films for Electromagnetic Interference Shielding, Heat Conduction, and Joule Heating. ACS Appl. Nano Mater. 2023, 6, 10202–10212. [Google Scholar] [CrossRef]

- Wang, T.; Kong, W.-W.; Yu, W.-C.; Gao, J.-F.; Dai, K.; Yan, D.-X.; Li, Z.-M. A Healable and Mechanically Enhanced Composite with Segregated Conductive Network Structure for High-Efficient Electromagnetic Interference Shielding. Nano-Micro Lett. 2021, 13, 162. [Google Scholar] [CrossRef]

- Zhao, W.; Zhao, B.; Wu, Z.; Pei, K.; Qian, Y.; Luo, K.; Xu, C.; Liu, M.; Wang, M.; Zhang, J.; et al. Dopant Engineering of Flexible MNPs/TPU/PPy Core–Shell Films for Controllable Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2023, 15, 28410–28420. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, S.; Li, L.; Zhang, H.; Fu, Q.; Ge, X. Flexible Sandwich-Shaped Cellulose Nanocrystals/Silver Nanowires/MXene Films Exhibit Efficient Electromagnetic-Shielding Interference Performance. Nanomaterials 2024, 14, 647. https://doi.org/10.3390/nano14070647

Yan S, Li L, Zhang H, Fu Q, Ge X. Flexible Sandwich-Shaped Cellulose Nanocrystals/Silver Nanowires/MXene Films Exhibit Efficient Electromagnetic-Shielding Interference Performance. Nanomaterials. 2024; 14(7):647. https://doi.org/10.3390/nano14070647

Chicago/Turabian StyleYan, Shasha, Ling Li, Hong Zhang, Qiubo Fu, and Xingbo Ge. 2024. "Flexible Sandwich-Shaped Cellulose Nanocrystals/Silver Nanowires/MXene Films Exhibit Efficient Electromagnetic-Shielding Interference Performance" Nanomaterials 14, no. 7: 647. https://doi.org/10.3390/nano14070647