Aluminum Micropillar Surfaces with Hierarchical Micro- and Nanoscale Features for Enhancement of Boiling Heat Transfer Coefficient and Critical Heat Flux

Abstract

:1. Introduction

Motivation and Goals of the Present Study

2. Materials and Methods

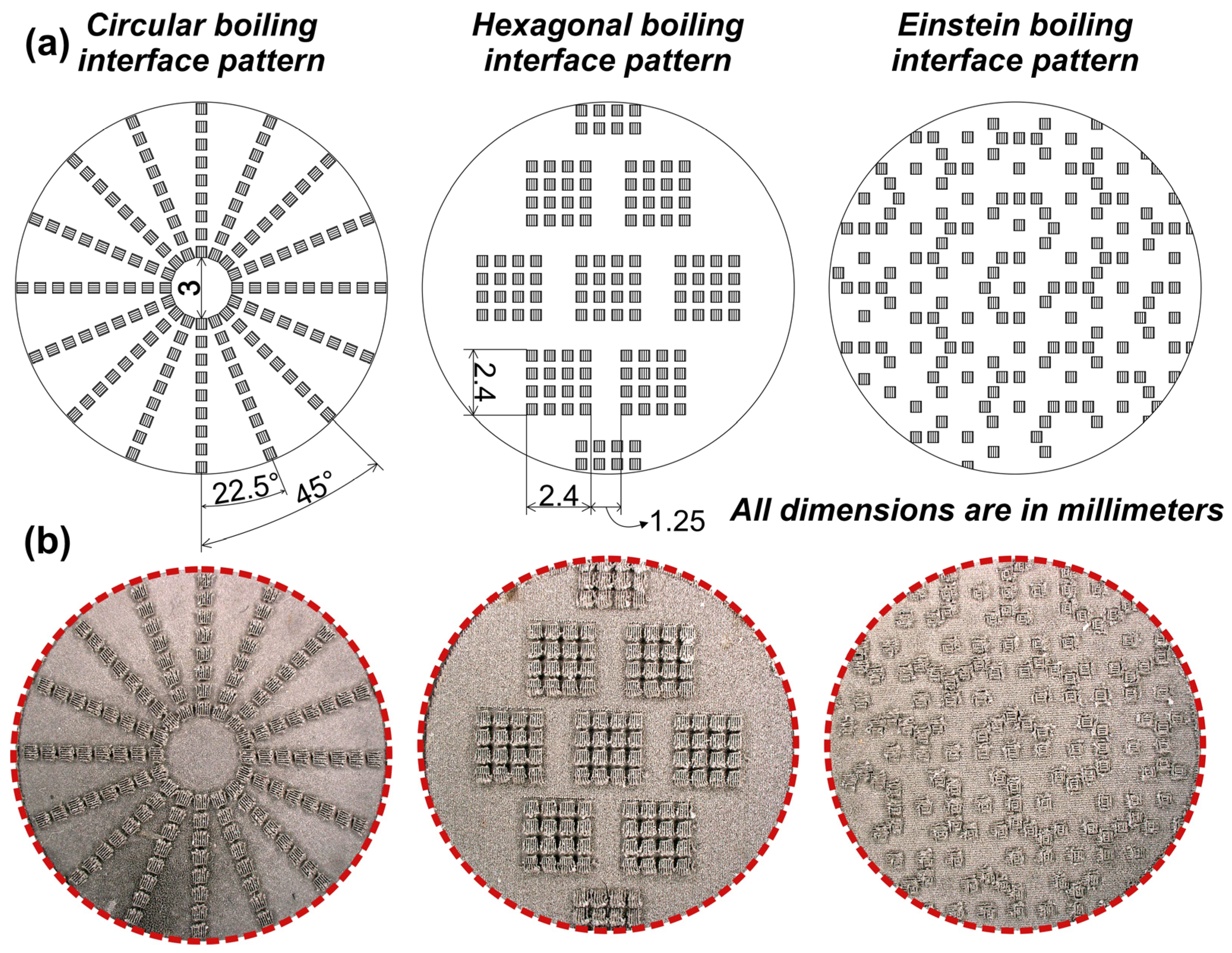

2.1. Samples

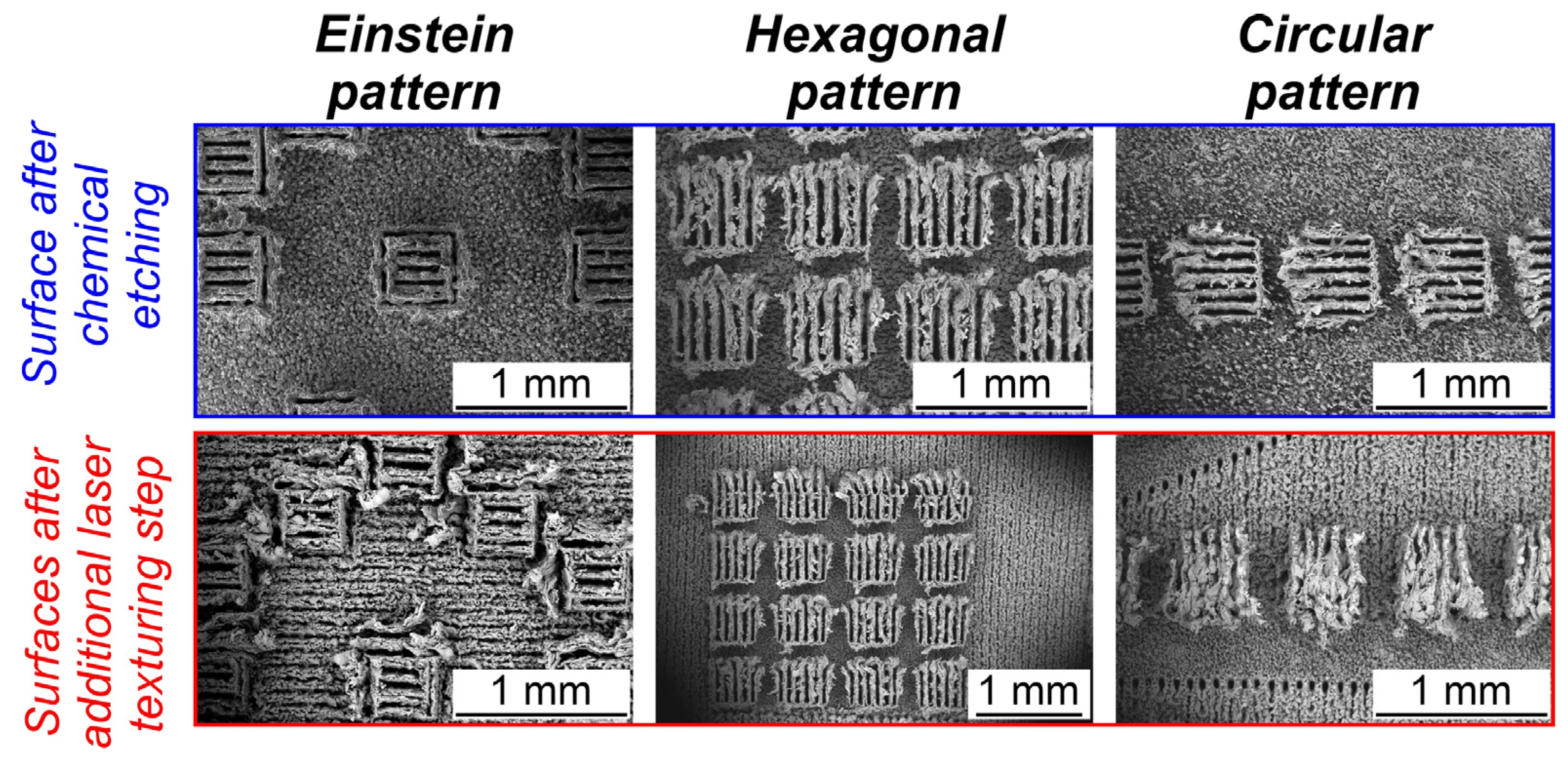

2.2. Fabrication of Micropillar Surfaces

2.3. Fabrication of Fully Laser-Functionalized Micropillar Surfaces

2.4. Pool Boiling Heat Transfer Evaluation

2.5. Data Reduction and Measurement Uncertainty

3. Results

3.1. Surface Analysis of Micropillar Surfaces

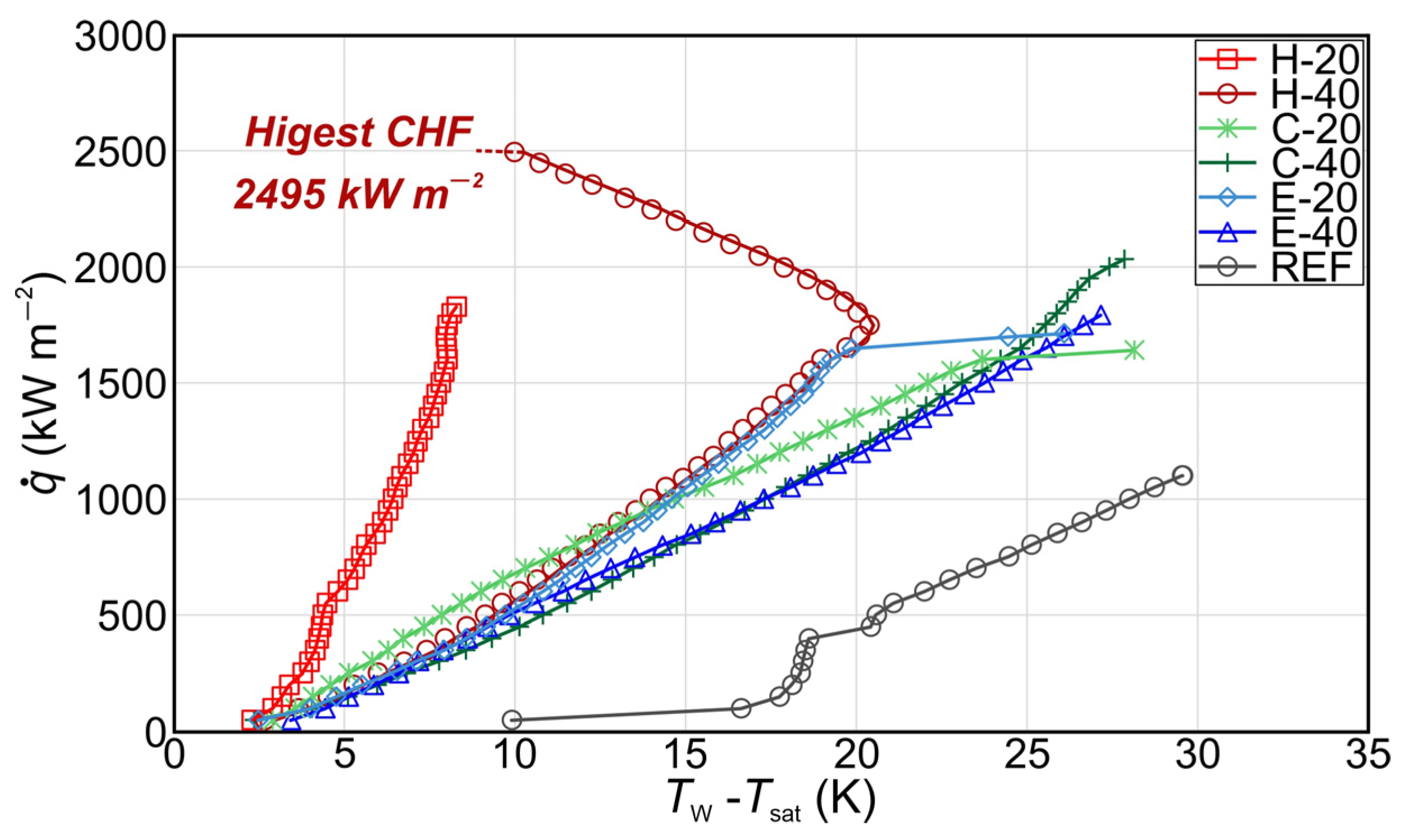

3.2. Pool Boiling Performance of Micropillar Surfaces

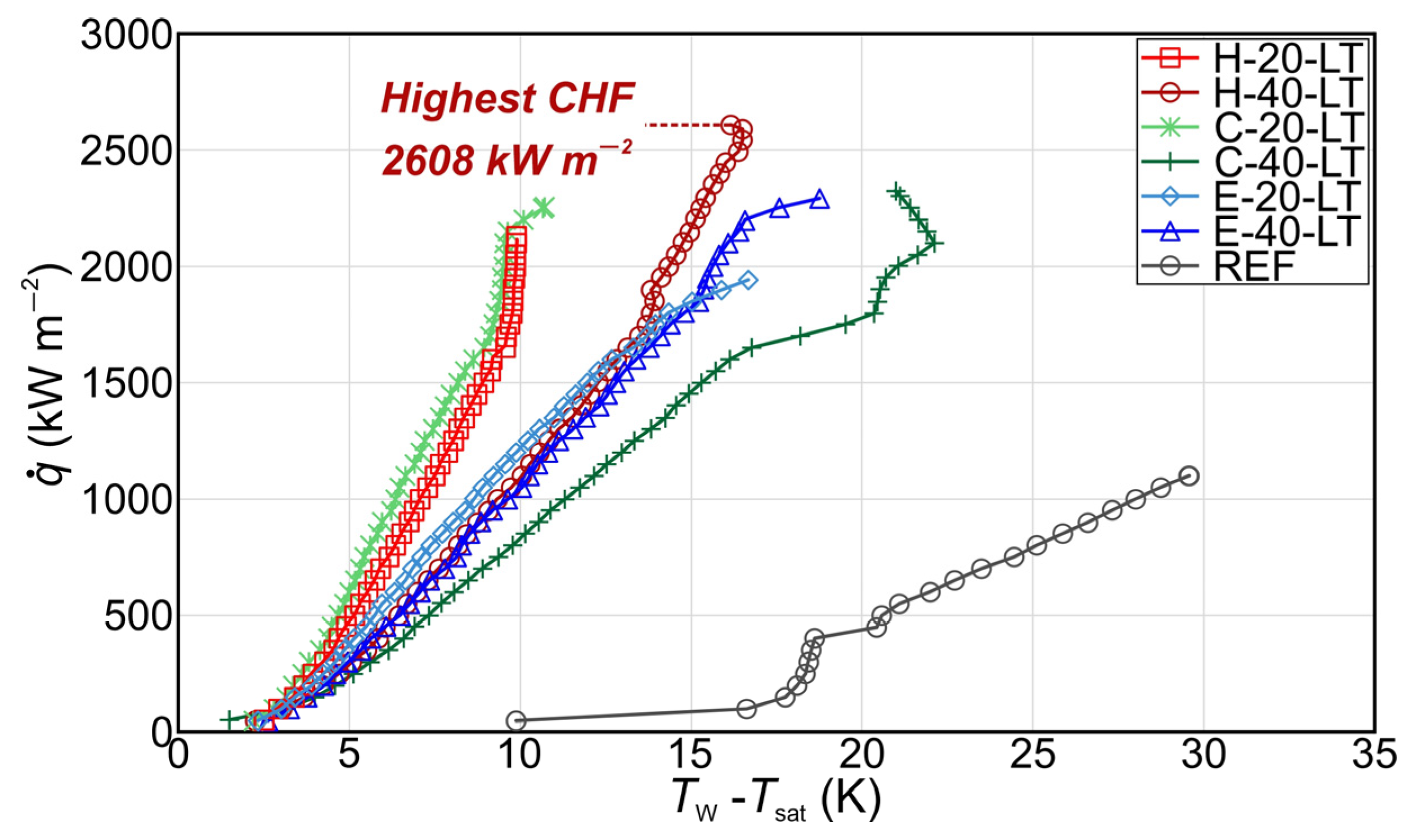

3.3. Pool Boiling Performance of Micropillar Surfaces Treated with Second Laser Texturing Step

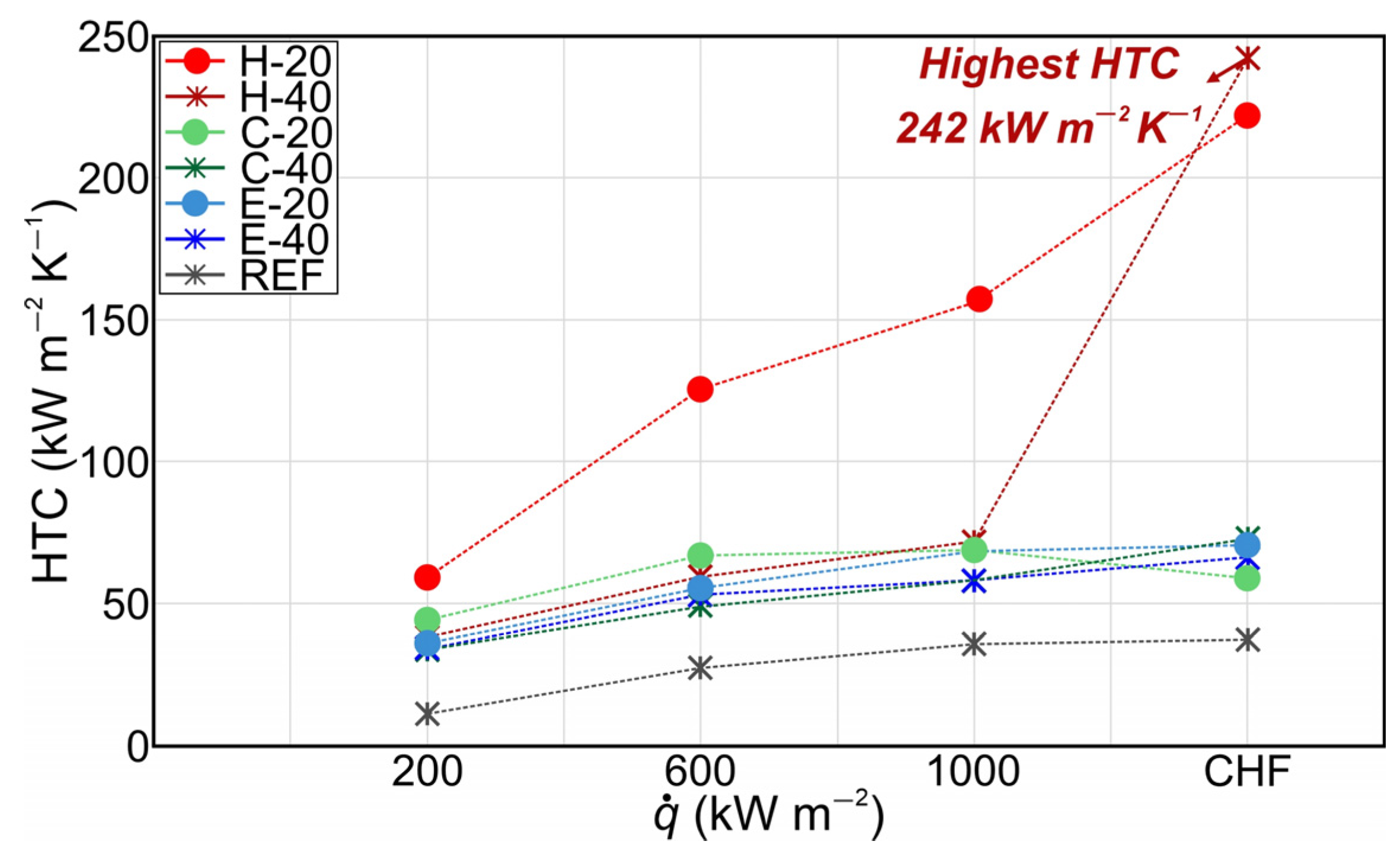

3.4. Comparison of the Boiling Performance of Developed Surfaces

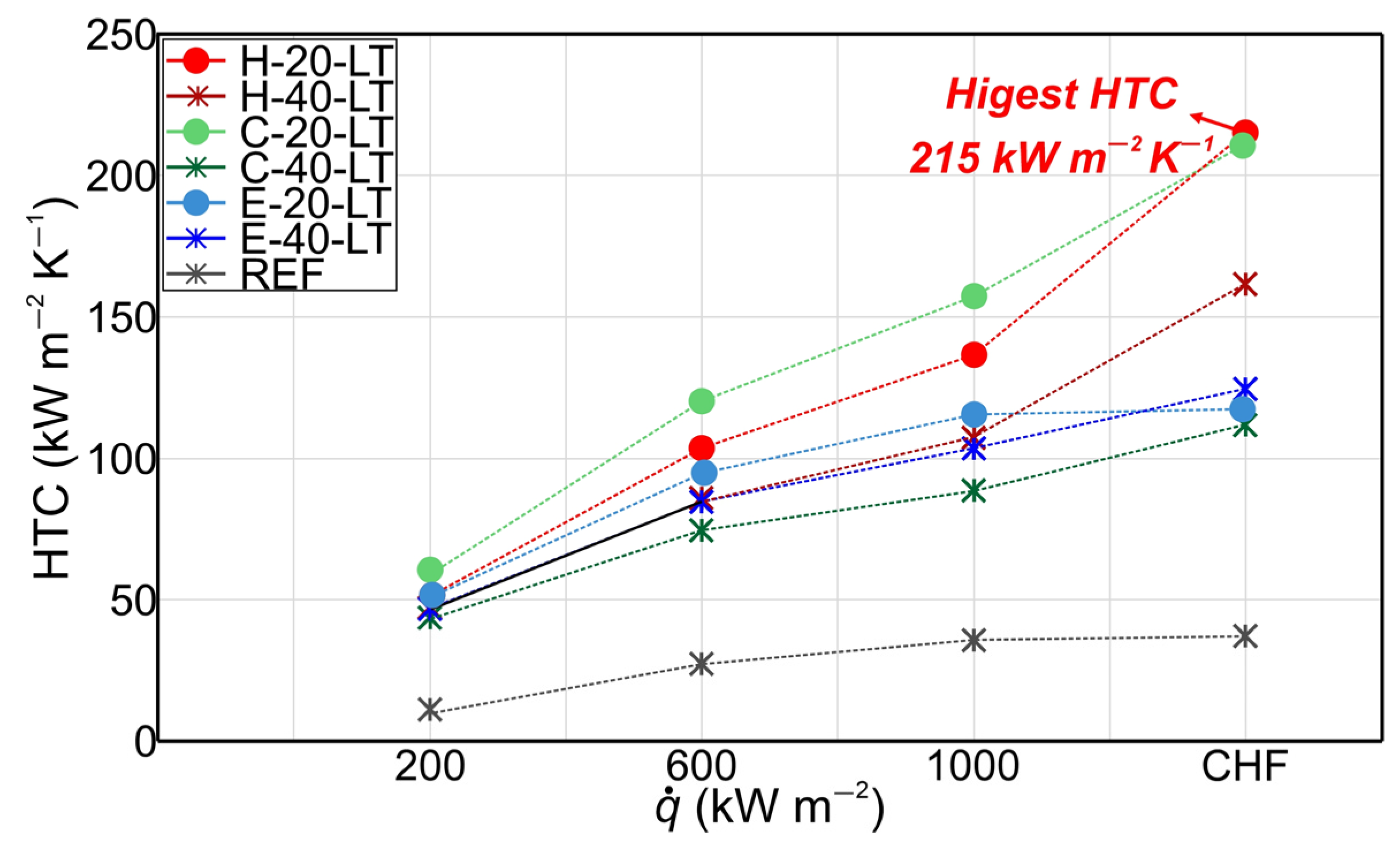

3.5. Evaluation of Heat Transfer Enhancement

4. Conclusions

- The surface with the hexagonal micropillar pattern of higher micropillars exhibited a CHF of 2495 kW m−2 and an HTC of 242 kW m−2 K−1. This configuration yielded enhancements of 126% and 554%, respectively, in comparison to the reference surface. Notably, the highest CHF value, reaching 2608 kW m−2, was observed on the hexagonal-patterned surface with additional laser texturing.

- The pronounced improvement in CHF on micropillar surfaces compared to the untreated reference surface is ascribed to the formation of an intra-pillar liquid layer and increased capillary liquid inflow facilitated by the interpillar wickable structure that supplies the latter, leading to the delayed formation of dry spots.

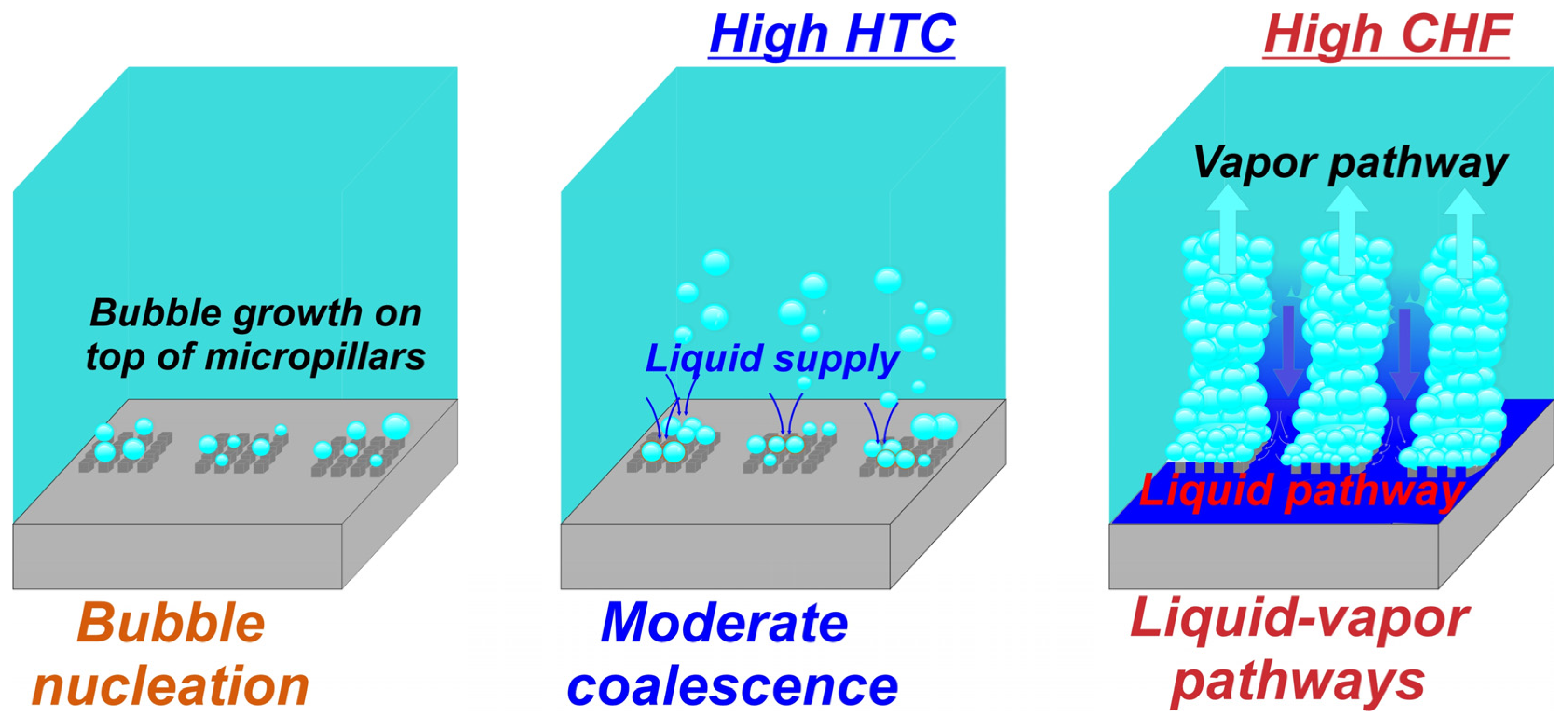

- The hexagonal micropillar pattern turned out to be the most effective, displaying moderate bubble coalescence, thereby improving the HTC. In high heat flux regions, the hexagonal pattern facilitated the generation of distinct vapor–liquid pathways, mitigating the formation of dryout spots and consequently yielding the highest CHF values in this study.

- An exploration of two distinct micropillar heights revealed that higher micropillars result in a greater improvement in boiling heat transfer parameters, which is attributed to the heightened ability of taller micropillars to capture a greater intra-pillar liquid layer and facilitate improved liquid supply inflow toward the micropillars, leading to the delay of the formation of dry spots.

- The presented study marks a meaningful foundation for efficient and scalable manufacturing of high-performing boiling interfaces on aluminum substrates, raising important future challenges of micropillar pattern optimization for achieving even higher simultaneous improvements in the critical heat flux and boiling heat transfer coefficient.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rishi, A.M.; Kandlikar, S.G.; Rozati, S.A.; Gupta, A. Effect of Ball Milled and Sintered Graphene Nanoplatelets–Copper Composite Coatings on Bubble Dynamics and Pool Boiling Heat Transfer. Adv. Eng. Mater. 2020, 22, 1901562. [Google Scholar] [CrossRef]

- Jaikumar, A.; Kandlikar, S.G. Ultra-High Pool Boiling Performance and Effect of Channel Width with Selectively Coated Open Microchannels. Int. J. Heat Mass Transf. 2016, 95, 795–805. [Google Scholar] [CrossRef]

- Figueiredo, V.; Elangovan, E.; Gonçalves, G.; Barquinha, P.; Pereira, L.; Franco, N.; Alves, E.; Martins, R.; Fortunato, E. Effect of Post-Annealing on the Properties of Copper Oxide Thin Films Obtained from the Oxidation of Evaporated Metallic Copper. Appl. Surf. Sci. 2008, 254, 3949–3954. [Google Scholar] [CrossRef]

- Li, W.; Dai, R.; Zeng, M.; Wang, Q. Review of Two Types of Surface Modification on Pool Boiling Enhancement: Passive and Active. Renew. Sustain. Energy Rev. 2020, 130, 109926. [Google Scholar] [CrossRef]

- Rahimian, A.; Kazeminejad, H.; Khalafi, H.; Akhavan, A.; Mirvakili, S.M. Boiling Heat Transfer and Critical Heat Flux Enhancement Using Electrophoretic Deposition of SiO2 Nanofluid. Sci. Technol. Nucl. Install. 2019, 2019, 1272156. [Google Scholar] [CrossRef]

- Bian, H.; Kurwitz, C.; Sun, Z.; Cheng, K.; Chen, K. Enhanced Nucleate Boiling on 3D-Printed Micro-Porous Structured Surface. Appl. Therm. Eng. 2018, 141, 422–434. [Google Scholar] [CrossRef]

- Smakulski, P.; Pietrowicz, S. A Review of the Capabilities of High Heat Flux Removal by Porous Materials, Microchannels and Spray Cooling Techniques. Appl. Therm. Eng. 2016, 104, 636–646. [Google Scholar] [CrossRef]

- Liang, G.; Mudawar, I. Review of Pool Boiling Enhancement with Additives and Nanofluids. Int. J. Heat Mass Transf. 2018, 124, 423–453. [Google Scholar] [CrossRef]

- Mudawar, I. Recent Advances in High-Flux, Two-Phase Thermal Managment. J. Therm. Sci. Eng. Appl. 2013, 5, 021012. [Google Scholar] [CrossRef]

- Tang, K.; Jia, M.; Zhong, G.; Chen, S.; Zhang, S.; Yuan, W.; Chen, G. Pool Boiling Heat Transfer of Dual-Scale Porous Microchannel for High-Power Electronics Cooling. Int. Commun. Heat Mass Transf. 2022, 138, 106339. [Google Scholar] [CrossRef]

- Chen, J.; Ahmad, S.; Cai, J.; Liu, H.; Lau, K.T.; Zhao, J. Latest Progress on Nanotechnology Aided Boiling Heat Transfer Enhancement: A Review. Energy 2021, 215, 119114. [Google Scholar] [CrossRef]

- Duan, L.; Liu, B.; Qi, B.; Zhang, Y.; Wei, J. Pool Boiling Heat Transfer on Silicon Chips with Non-Uniform Micro-Pillars. Int. J. Heat Mass Transf. 2020, 151, 119456. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Hormozi, F.; Peyghambarzadeh, S.M. Pool Boiling Heat Transfer to Aqueous Alumina Nano-Fluids on the Plain and Concentric Circular Micro-Structured (CCM) Surfaces. Exp. Therm. Fluid Sci. 2016, 72, 125–139. [Google Scholar] [CrossRef]

- Može, M.; Senegačnik, M.; Gregorčič, P.; Hočevar, M.; Zupančič, M.; Golobič, I. Laser-Engineered Microcavity Surfaces with a Nanoscale Superhydrophobic Coating for Extreme Boiling Performance. ACS Appl. Mater. Interfaces 2020, 12, 24419–24431. [Google Scholar] [CrossRef] [PubMed]

- Hadžić, A.; Može, M.; Zupančič, M.; Golobič, I. Superbiphilic Laser-Microengineered Surfaces with A Self-Assembled Monolayer Coating for Exceptional Boiling Performance. Adv. Funct. Mater. 2023, 34, 202310662. [Google Scholar] [CrossRef]

- Mori, S.; Mt Aznam, S.; Okuyama, K. Enhancement of the Critical Heat Flux in Saturated Pool Boiling of Water by Nanoparticle-Coating and a Honeycomb Porous Plate. Int. J. Heat Mass Transf. 2015, 80, 1–6. [Google Scholar] [CrossRef]

- Pham, Q.N.; Zhang, S.; Hao, S.; Montazeri, K.; Lin, C.H.; Lee, J.; Mohraz, A.; Won, Y. Boiling Heat Transfer with a Well-Ordered Microporous Architecture. ACS Appl. Mater. Interfaces 2020, 12, 19174–19183. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Mo, D.; Zhao, H.; Ding, N.; Lu, S. Pool Boiling on the Superhydrophilic Surface with TiO2 Nanotube Arrays. Sci. China Ser. E Technol. Sci. 2009, 52, 1596–1600. [Google Scholar] [CrossRef]

- Park, S.S.; Kim, Y.H.; Jeon, Y.H.; Hyun, M.T.; Kim, N.J. Effects of Spray-Deposited Oxidized Multi-Wall Carbon Nanotubes and Graphene on Pool-Boiling Critical Heat Flux Enhancement. J. Ind. Eng. Chem. 2015, 24, 276–283. [Google Scholar] [CrossRef]

- Li, J.Q.; Mou, L.W.; Zhang, J.Y.; Zhang, Y.H.; Fan, L.W. Enhanced Pool Boiling Heat Transfer during Quenching of Water on Superhydrophilic Porous Surfaces: Effects of the Surface Wickability. Int. J. Heat Mass Transf. 2018, 125, 494–505. [Google Scholar] [CrossRef]

- Shin, S.; Choi, G.; Rallabandi, B.; Lee, D.; Shim, D.I.; Kim, B.S.; Kim, K.M.; Cho, H.H. Enhanced Boiling Heat Transfer Using Self-Actuated Nanobimorphs. Nano Lett. 2018, 18, 6392–6396. [Google Scholar] [CrossRef]

- Sujith Kumar, C.S.; Udaya Kumar, G.; Mata Arenales, M.R.; Hsu, C.C.; Suresh, S.; Chen, P.H. Elucidating the Mechanisms behind the Boiling Heat Transfer Enhancement Using Nano-Structured Surface Coatings. Appl. Therm. Eng. 2018, 137, 868–891. [Google Scholar] [CrossRef]

- Rahman, M.M.; McCarthy, M. Effect of Length Scales on the Boiling Enhancement of Structured Copper Surfaces. J. Heat Transfer 2017, 139, 111508. [Google Scholar] [CrossRef]

- Kong, D.; Kang, M.; Kim, K.Y.; Jang, J.; Cho, J.; In, J.B.; Lee, H. Hierarchically Structured Laser-Induced Graphene for Enhanced Boiling on Flexible Substrates. ACS Appl. Mater. Interfaces 2020, 12, 37784–37792. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhao, Y.; Ma, J.; Fu, W.; Yan, X.; Rabbi, K.F.; Miljkovic, N. Superior Antidegeneration Hierarchical Nanoengineered Wicking Surfaces for Boiling Enhancement. Adv. Funct. Mater. 2022, 32, 202108836. [Google Scholar] [CrossRef]

- Kaniowski, R.; Pastuszko, R.; Nowakowski, L. Effect of Geometrical Parameters of Open Microchannel Surfaces on Pool Boiling Heat Transfer. EPJ Web Conf. 2017, 143, 02049. [Google Scholar] [CrossRef]

- Gouda, R.K.; Pathak, M.; Khan, M.K. Pool Boiling Heat Transfer Enhancement with Segmented Finned Microchannels Structured Surface. Int. J. Heat Mass Transf. 2018, 127, 39–50. [Google Scholar] [CrossRef]

- Patil, C.M.; Kandlikar, S.G. Review of the Manufacturing Techniques for Porous Surfaces Used in Enhanced Pool Boiling. Heat Transf. Eng. 2014, 35, 887–902. [Google Scholar] [CrossRef]

- Mehdikhani, A.; Moghadasi, H.; Saffari, H. An Experimental Investigation of Pool Boiling Augmentation Using Four-Step Electrodeposited Micro/Nanostructured Porous Surface in Distilled Water. Int. J. Mech. Sci. 2020, 187, 105924. [Google Scholar] [CrossRef]

- Može, M.; Zupančič, M.; Golobič, I. Investigation of the Scatter in Reported Pool Boiling CHF Measurements Including Analysis of Heat Flux and Measurement Uncertainty Evaluation Methodology. Appl. Therm. Eng. 2020, 169, 114938. [Google Scholar] [CrossRef]

- Hadžić, A.; Može, M.; Arhar, K.; Zupančič, M.; Golobič, I. Effect of Nanoparticle Size and Concentration on Pool Boiling Heat Transfer with TiO2 Nanofluids on Laser-Textured Copper Surfaces. Nanomaterials 2022, 12, 2611. [Google Scholar] [CrossRef] [PubMed]

- Može, M.; Vajc, V.; Zupančič, M.; Golobič, I. Hydrophilic and Hydrophobic Nanostructured Copper Surfaces for Efficient Pool Boiling Heat Transfer with Water, Water/Butanol Mixtures and Novec 649. Nanomaterials 2021, 11, 3216. [Google Scholar] [CrossRef] [PubMed]

- Takata, Y.; Hidaka, S.; Masuda, M.; Ito, T. Pool Boiling on a Superhydrophilic Surface. Int. J. Energy Res. 2003, 27, 111–119. [Google Scholar] [CrossRef]

- Može, M.; Zupančič, M.; Golobič, I. Pattern Geometry Optimization on Superbiphilic Aluminum Surfaces for Enhanced Pool Boiling Heat Transfer. Int. J. Heat Mass Transf. 2020, 161, 120265. [Google Scholar] [CrossRef]

- Motezakker, A.R.; Sadaghiani, A.K.; Çelik, S.; Larsen, T.; Villanueva, L.G.; Koşar, A. Optimum Ratio of Hydrophobic to Hydrophilic Areas of Biphilic Surfaces in Thermal Fluid Systems Involving Boiling. Int. J. Heat Mass Transf. 2019, 135, 164–174. [Google Scholar] [CrossRef]

- Song, Y.; Díaz-Marín, C.D.; Zhang, L.; Cha, H.; Zhao, Y.; Wang, E.N. Three-Tier Hierarchical Structures for Extreme Pool Boiling Heat Transfer Performance. Adv. Mater. 2022, 34, e2200899. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Yang, X.; Jie, Z.; Wei, J.; Li, Q. Enhanced Pool Boiling on Micro-Nano Composited Surfaces with Nanostructures on Micro-Pin-Fins. Int. J. Heat Mass Transf. 2022, 190, 122812. [Google Scholar] [CrossRef]

- Lee, D.; Lee, N.; Shim, D.I.; Kim, B.S.; Cho, H.H. Enhancing Thermal Stability and Uniformity in Boiling Heat Transfer Using Micro-Nano Hybrid Surfaces (MNHS). Appl. Therm. Eng. 2018, 130, 710–721. [Google Scholar] [CrossRef]

- Shim, D.I.; Hsu, W.-T.; Yun, M.; Lee, D.; Kim, B.S.; Cho, H.H. Superbiphilic Patterned Nanowires with Wicking for Enhanced Pool Boiling Heat Transfer. Int. J. Mech. Sci. 2023, 249, 108280. [Google Scholar] [CrossRef]

- Wang, X.; Xu, J.; Jiang, H.; Liu, Y.; Li, X.; Shan, D.; Guo, B. Achieving Robust and Enhanced Pool Boiling Heat Transfer Using Micro–Nano Multiscale Structures. Appl. Therm. Eng. 2023, 227, 120441. [Google Scholar] [CrossRef]

- Kim, S.H.; Lee, G.C.; Kang, J.Y.; Moriyama, K.; Kim, M.H.; Park, H.S. Boiling Heat Transfer and Critical Heat Flux Evaluation of the Pool Boiling on Micro Structured Surface. Int. J. Heat Mass Transf. 2015, 91, 1140–1147. [Google Scholar] [CrossRef]

- Song, Y.; Gong, S.; Vaartstra, G.; Wang, E.N. Microtube Surfaces for the Simultaneous Enhancement of Efficiency and Critical Heat Flux during Pool Boiling. ACS Appl. Mater. Interfaces 2021, 13, 12629–12635. [Google Scholar] [CrossRef] [PubMed]

- Cho, H.R.; Park, S.C.; Kim, D.; Joo, H.M.; Yu, D.I. Experimental Study on Pool Boiling on Hydrophilic Micro/Nanotextured Surfaces with Hydrophobic Patterns. Energies 2021, 14, 7543. [Google Scholar] [CrossRef]

- Sun, X.Z.; Li, Q.; Li, W.X.; Wen, Z.X.; Liu, B. Enhanced Pool Boiling on Microstructured Surfaces with Spatially-Controlled Mixed Wettability. Int. J. Heat Mass Transf. 2022, 183, 122164. [Google Scholar] [CrossRef]

- Godinez, J.C.; Fadda, D.; Lee, J.; You, S.M. Development of a Stable Boehmite Layer on Aluminum Surfaces for Improved Pool Boiling Heat Transfer in Water. Appl. Therm. Eng. 2019, 156, 541–549. [Google Scholar] [CrossRef]

- Liang, G.; Mudawar, I. Review of Pool Boiling Enhancement by Surface Modification. Int. J. Heat Mass Transf. 2019, 128, 892–933. [Google Scholar] [CrossRef]

- Gao, L.; Bai, M.; Lv, J.; Li, Y.; Lv, X.; Liu, X.; Li, Y. Experimental Studies for the Combined Effects of Micro-Cavity and Surface Wettability on Saturated Pool Boiling. Exp. Therm. Fluid Sci. 2023, 140, 110769. [Google Scholar] [CrossRef]

- Shim, D.I.; Choi, G.; Lee, N.; Kim, T.; Kim, B.S.; Cho, H.H. Enhancement of Pool Boiling Heat Transfer Using Aligned Silicon Nanowire Arrays. ACS Appl. Mater. Interfaces 2017, 9, 17595–17602. [Google Scholar] [CrossRef]

- Wei, J.J.; Honda, H. Effects of Fin Geometry on Boiling Heat Transfer from Silicon Chips with Micro-Pin-Fins Immersed in FC-72. Int. J. Heat Mass Transf. 2003, 46, 4059–4070. [Google Scholar] [CrossRef]

- Sarkar, D.K.; Farzaneh, M.; Paynter, R.W. Superhydrophobic Properties of Ultrathin Rf-Sputtered Teflon Films Coated Etched Aluminum Surfaces. Mater. Lett. 2008, 62, 1226–1229. [Google Scholar] [CrossRef]

- Escobar, A.M.; Llorca-Isern, N. Superhydrophobic Coating Deposited Directly on Aluminum. Appl. Surf. Sci. 2014, 305, 774–782. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, X.; Zhou, J.; Lei, Z.; Wei, J. Experimental Investigation of Pool Boiling Heat Transfer on the Radial Micro-Pillar Surfaces. Appl. Therm. Eng. 2022, 214, 118843. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, C.; Su, G.; Kossolapov, A.; Matana Aguiar, G.; Hyun Seong, J.; Chavagnat, F.; Phillips, B.; Mahamudur Rahman, M.; Bucci, M. A Unifying Criterion of the Boiling Crisis. Nat. Commun. 2023, 14, 2321. [Google Scholar] [CrossRef]

- Zhang, L.; Seong, J.H.; Bucci, M. Percolative Scale-Free Behavior in the Boiling Crisis. Phys. Rev. Lett. 2019, 122, 134501. [Google Scholar] [CrossRef]

- Može, M.; Vajc, V.; Zupančič, M.; Šulc, R.; Golobič, I. Pool Boiling Performance of Water and Self-Rewetting Fluids on Hybrid Functionalized Aluminum Surfaces. Processes 2021, 9, 1058. [Google Scholar] [CrossRef]

- Katarkar, A.S.; Majumder, B.; Pingale, A.D.; Belgamwar, S.U.; Bhaumik, S. A Review on the Effects of Porous Coating Surfaces on Boiling Heat Transfer. Mater. Today Proc. 2021, 44, 362–367. [Google Scholar] [CrossRef]

- da Silva, J.D.; Moreira, D.C.; Ribatski, G. An Overview on the Role of Wettability and Wickability as a Tool for Enhancing Pool Boiling Heat Transfer, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2021; Volume 53, ISBN 9780128245965. [Google Scholar]

- Kruse, C.; Tsubaki, A.; Zuhlke, C.; Anderson, T.; Alexander, D.; Gogos, G.; Ndao, S. Secondary Pool Boiling Effects. Appl. Phys. Lett. 2016, 108, 051602. [Google Scholar] [CrossRef] [PubMed]

- Rishi, A.M.; Kandlikar, S.G.; Gupta, A. Improved Wettability of Graphene Nanoplatelets (GNP)/Copper Porous Coatings for Dramatic Improvements in Pool Boiling Heat Transfer. Int. J. Heat Mass Transf. 2019, 132, 462–472. [Google Scholar] [CrossRef]

- Wang, Q.; Shi, Y.; Chen, R. Transition between Thin Film Boiling and Evaporation on Nanoporous Membranes near the Kinetic Limit. Int. J. Heat Mass Transf. 2020, 154, 119673. [Google Scholar] [CrossRef]

- Wang, C.; Rahman, M.M.; Bucci, M. Decrypting the Mechanisms of Wicking and Evaporation Heat Transfer on Micro-Pillars during the Pool Boiling of Water Using High-Resolution Infrared Thermometry. Phys. Fluids 2023, 35, 037112. [Google Scholar] [CrossRef]

- Wei, J.J.; Guo, L.J.; Honda, H. Experimental Study of Boiling Phenomena and Heat Transfer Performances of FC-72 over Micro-Pin-Finned Silicon Chips. Heat Mass Transf. Stoffuebertragung 2005, 41, 744–755. [Google Scholar] [CrossRef]

- Chen, H.X.; Sun, Y.; Li, L.H.; Wang, X.D. Bubble Dynamics and Heat Transfer Performance on Micro-Pillars Structured Surfaces with Various Pillars Heights. Int. J. Heat Mass Transf. 2020, 163, 120502. [Google Scholar] [CrossRef]

- Kim, J.; Jun, S.; Lee, J.; Godinez, J.; You, S.M. Effect of Surface Roughness on Pool Boiling Heat Transfer of Water on a Superhydrophilic Aluminum Surface. J. Heat Transfer 2017, 139, 101501. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, J.; Sun, X.; Liu, B. Experimental Investigation of Pool Boiling Heat Transfer on Pillar-Structured Surfaces with Different Wettability Patterns. Appl. Therm. Eng. 2022, 215, 118924. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, M.C.; Xu, D. The Suppression Effect of Easy-to-Activate Nucleation Sites on the Critical Heat Flux in Pool Boiling. Int. J. Therm. Sci. 2018, 129, 231–237. [Google Scholar] [CrossRef]

- Vajc, V.; Može, M.; Hadžić, A.; Šulc, R.; Golobič, I. Saturated and Subcooled Pool Boiling Heat Transfer in Mixtures of Water and Glycerin. Exp. Heat Transf. 2022, 36, 283–311. [Google Scholar] [CrossRef]

- Fang, R.; Zhang, X.; Zheng, J.; Pan, Z.; Yang, C.; Deng, L.; Li, R.; Lai, C.; Yan, W.; Maisotsenko, V.S.; et al. Superwicking Functionality of Femtosecond Laser Textured Aluminum at High Temperatures. Nanomaterials 2021, 11, 1–19. [Google Scholar] [CrossRef]

- Tran, N.G.; Chun, D.M. Green Manufacturing of Extreme Wettability Contrast Surfaces with Superhydrophilic and Superhydrophobic Patterns on Aluminum. J. Mater. Process. Technol. 2021, 297, 117245. [Google Scholar] [CrossRef]

- Freitas, E.; Pontes, P.; Cautela, R.; Bahadur, V.; Miranda, J.; Ribeiro, A.P.C.; Souza, R.R.; Oliveira, J.D.; Copetti, J.B.; Lima, R.; et al. Article Pool Boiling of Nanofluids on Biphilic Surfaces: An Experimental and Numerical Study. Nanomaterials 2021, 11, 125. [Google Scholar] [CrossRef]

| Heat Flux Level [kW m−2] | Surface Superheat [K] | Heat Flux [%] | Heat Transfer Coefficient [%] |

|---|---|---|---|

| 200 | 0.7 | 9.4–10.9 | 11–12.1 |

| 800 | 1.1 | 4–15 | 8.8–13.2 |

| 2000 | 1.3 | 12–16 | 14–18.8 |

| Sample Name | Micropillar Average Height (µm) | Etching Time (Minutes) | Boiling Interface Pattern | Fabrication Step |

|---|---|---|---|---|

| REF | / | / | / | / |

| H-20 | 369 ± 15 | 20 | Hexagonal | Laser texturing + Chemical etching |

| H-40 | 569 ± 28 | 40 | ||

| C-20 | 369 ± 15 | 20 | Circular | |

| C-40 | 569 ± 28 | 40 | ||

| E-20 | 369 ± 15 | 20 | Einstein | |

| E-40 | 569 ± 28 | 40 | ||

| H-20-LT | 369 ± 15 | 20 | Hexagonal | Laser texturing + Chemical etching + Additional laser texturing |

| H-40-LT | 569 ± 28 | 40 | ||

| C-20-LT | 369 ± 15 | 20 | Circular | |

| C-40-LT | 569 ± 28 | 40 | ||

| E-20-LT | 369 ± 15 | 20 | Einstein | |

| E-40-LT | 569 ± 28 | 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hadžić, A.; Može, M.; Zupančič, M.; Golobič, I. Aluminum Micropillar Surfaces with Hierarchical Micro- and Nanoscale Features for Enhancement of Boiling Heat Transfer Coefficient and Critical Heat Flux. Nanomaterials 2024, 14, 667. https://doi.org/10.3390/nano14080667

Hadžić A, Može M, Zupančič M, Golobič I. Aluminum Micropillar Surfaces with Hierarchical Micro- and Nanoscale Features for Enhancement of Boiling Heat Transfer Coefficient and Critical Heat Flux. Nanomaterials. 2024; 14(8):667. https://doi.org/10.3390/nano14080667

Chicago/Turabian StyleHadžić, Armin, Matic Može, Matevž Zupančič, and Iztok Golobič. 2024. "Aluminum Micropillar Surfaces with Hierarchical Micro- and Nanoscale Features for Enhancement of Boiling Heat Transfer Coefficient and Critical Heat Flux" Nanomaterials 14, no. 8: 667. https://doi.org/10.3390/nano14080667