Abstract

Chemical vapor deposition (CVD) is a highly adaptable manufacturing technique used to fabricate high-quality thin films, making it essential across numerous industries. As materials fabrication processes progress, CVD has advanced to enable the precise deposition of both inorganic 2D materials, such as graphene and transition metal dichalcogenides, and high-quality polymeric thin films, offering excellent conformality and precise nanostructure control on a wide range of substrates. Conjugated conducting polymers have emerged as promising materials for next-generation electronic, optoelectronic, and energy storage devices due to their unique combination of electrical conductivity, optical transparency, ionic transport, and mechanical flexibility. Oxidative CVD (oCVD) involves the spontaneous reaction of oxidant and monomer vapors upon their adsorption onto the substrate surface, resulting in step-growth polymerization that commonly produces conducting or semiconducting polymer thin films. oCVD has gained significant attention for its ability to fabricate conjugated conducting polymers under vacuum conditions, allowing precise control over film thickness, doping levels, and nanostructure engineering. The low to moderate deposition temperature in the oCVD method enables the direct integration of conducting and semiconducting polymer thin films onto thermally sensitive substrates, including plants, paper, textiles, membranes, carbon fibers, and graphene. This review explores the fundamentals of the CVD process and vacuum-based manufacturing, while also highlighting recent advancements in the oCVD method for the fabrication of conjugated conducting and semiconducting polymer thin films.

1. Introduction

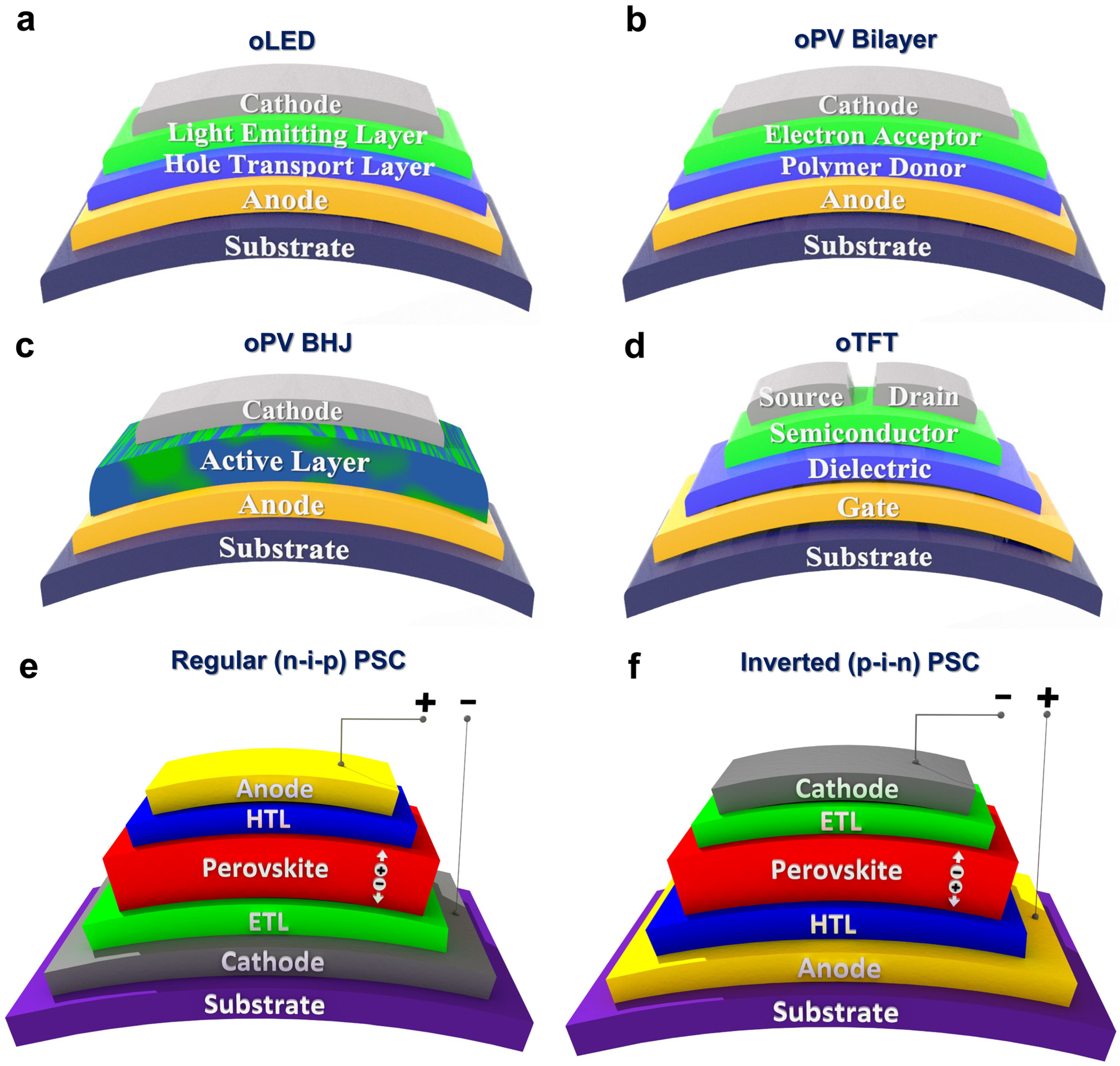

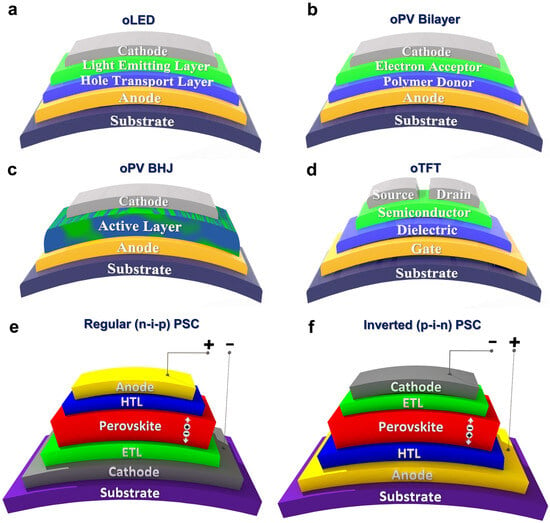

Conducting polymers exhibit desirable properties, such as electronic conductivity, ionic conductivity, optical transparency, and mechanical flexibility, making their fabrication into thin films essential for advancing next-generation technologies [1,2]. Potential applications of conducting polymers extend across multiple scientific and device domains, including optical displays, solar cells, electrochromic energy storage devices, catalytic processes, targeted drug delivery, tissue regeneration, memory and logic components, biomedical instruments, sensors, actuators, antistatic coatings, corrosion protection films, soft robotics, and widely accessible devices for the internet of things (IoT) [1,2,3,4,5,6].

Although conducting polymers offer significant potential for various applications, their integration into commercial and industrial markets remain limited. For successful commercialization, it is crucial to benchmark the performance of conducting polymer-based devices against those made with conventional materials. Their unique advantages, such as mechanical flexibility, lightweight nature, and suitability for wearable and stretchable technologies, position conducting polymers as promising candidates for integration into modern electronic and energy devices [3].

The chemical vapor deposition (CVD) method facilitates the deposition of insoluble polymers without the need for dissolution, ensuring uniform coating while preventing solvent-induced damage to solution-sensitive substrates [1,3,7,8]. Various CVD techniques have been developed to enable vapor-phase reactants to undergo polymerization mechanisms similar to those observed in solution-based synthesis. These methods include CVD polymerization through (i) chain growth initiated by free radicals or cations, primarily achieved in initiated CVD (iCVD) [9,10,11], and (ii) step-growth polymerization, which serves as the fundamental principle of oxidative CVD (oCVD) [3,7,12,13,14,15,16,17,18,19,20,21,22,23]. Step-growth polymerization, in contrast to chain-growth polymerization, involves the gradual formation of polymer chains through the reaction of multifunctional monomers. Unlike chain-growth mechanisms, where monomer addition occurs at an active site on a growing polymer chain, step-growth polymerization proceeds through the successive combination of smaller oligomers, eventually forming high-molecular-weight polymers. In oCVD, this mechanism is facilitated by the continuous exposure of monomers to a vapor-phase oxidant, allowing for controlled polymerization and thin film formation [3,12,24,25,26,27,28,29].

For most conjugated macromolecules, achieving optimal properties, such as high electrical conductivity, requires a CVD approach that replicates the step-growth polymerization mechanism. This necessity led to the development of oCVD, where vacuum chamber design, reactant vapor introduction strategies, and process conditions are specifically optimized for step-growth polymerization. The ability of oCVD to reliably fabricate conjugated conducting and semiconducting polymers with highly desirable characteristics is particularly significant for the fabrication of cutting-edge optoelectronic and renewable energy storage devices [2,12,17,22,30,31,32].

The oCVD process is a one-step approach that directly converts vapor-phase monomers and oxidant vapors into thin conjugated conducting and semiconducting polymer films [2,7,12,17,22,33,34,35,36,37,38]. At the substrate surface, step-growth polymerization and simultaneous doping occur in a single deposition step. The properties of oCVD-derived thin films can be precisely controlled by adjusting the flow rates of vapor-phase reactants [39,40], along with key process parameters, such as deposition temperature [30,34,41] and chamber pressure [12]. The oxidant saturation ratio (OSR) in the oCVD method is a critical process parameter that significantly impacts the texture and nanostructure of the deposited thin films, ultimately playing a crucial role in determining their electrical conductivity [1,39]. When multiple monomers are introduced, modifying their flow rate ratios allows for fine-tuning the composition and characteristics of the resulting copolymer films [3,11].

As a highly versatile deposition technique, oCVD offers several advantages for fabrication of conjugated conducting and semiconducting polymers, including conformal coating formation, low-temperature processing, solvent-free synthesis, uniform film growth, mechanical flexibility, scalability for industrial applications, and substrate independence [3]. Even when alternative thin film deposition methods are available, CVD is often preferred for achieving high-quality, reproducible layers essential for optoelectronic and biomedical device applications. The small-molecule reactants used in CVD can be purified to a high degree, ensuring superior material quality. Additionally, deposition in a controlled vacuum environment enhances interfacial integrity, while the all-dry processing approach eliminates the risk of residual solvents. This aspect is particularly crucial, as poor biocompatibility in polymer coatings is often linked to trapped small molecules rather than the macromolecular structure of the film itself [7,11].

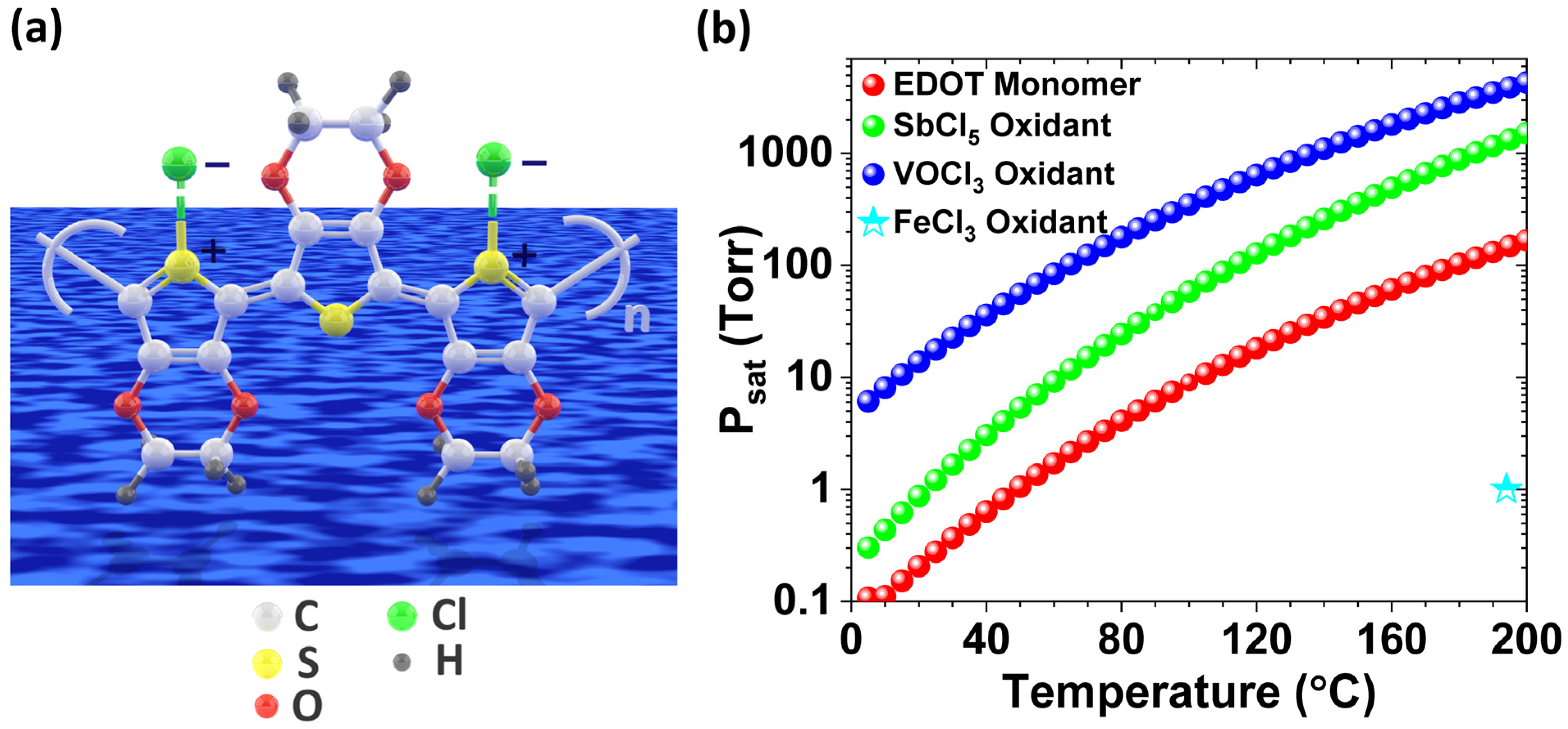

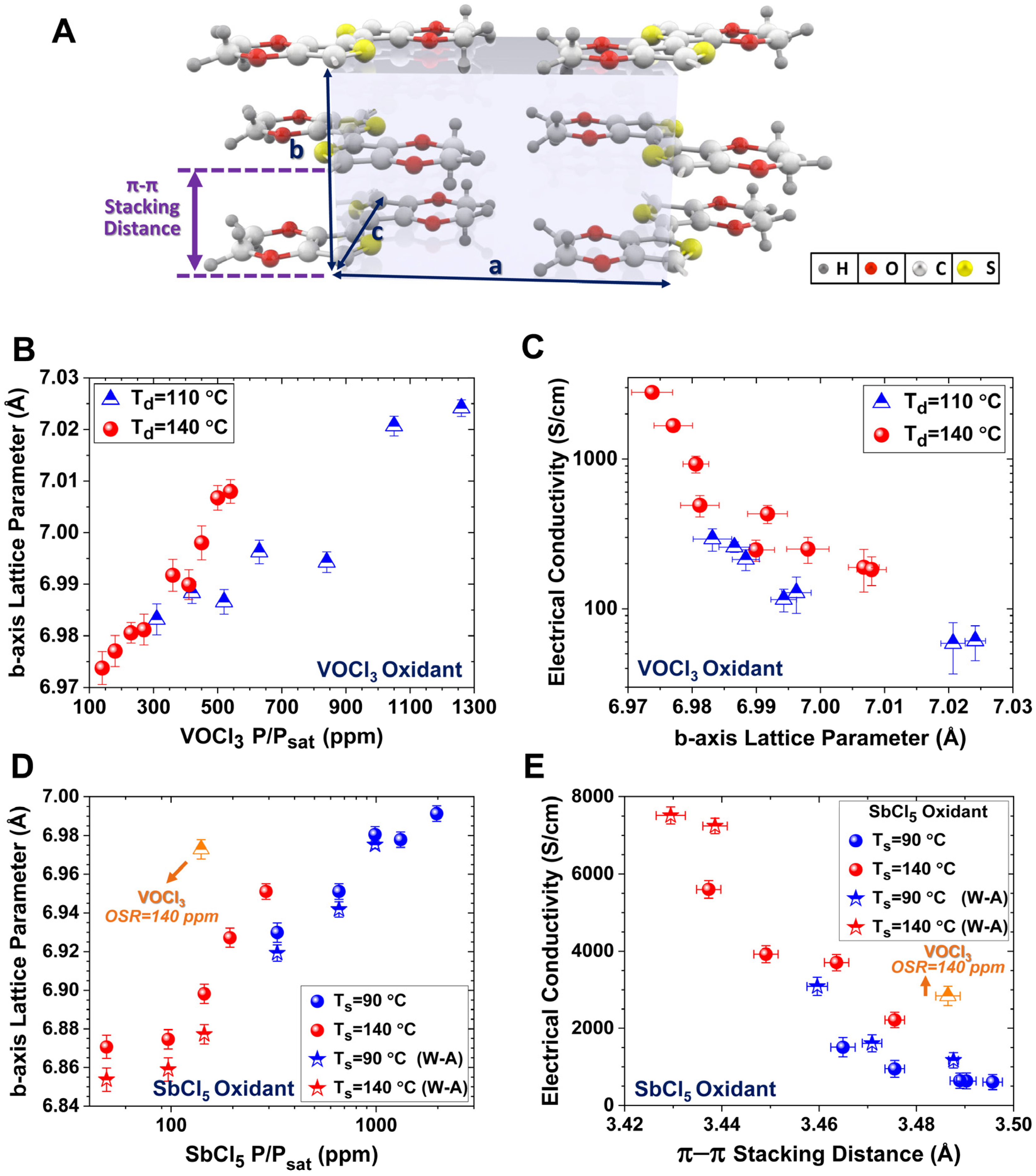

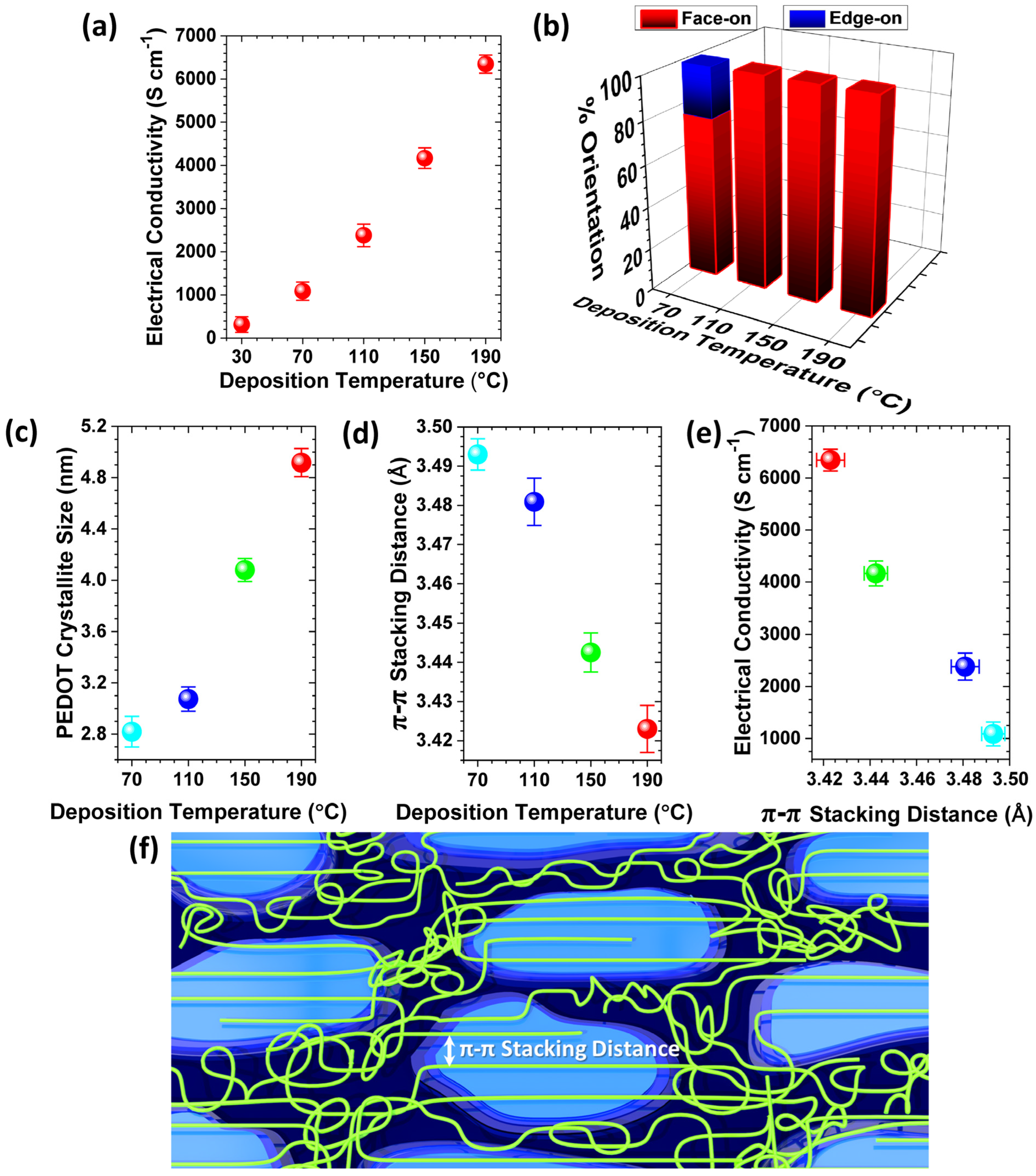

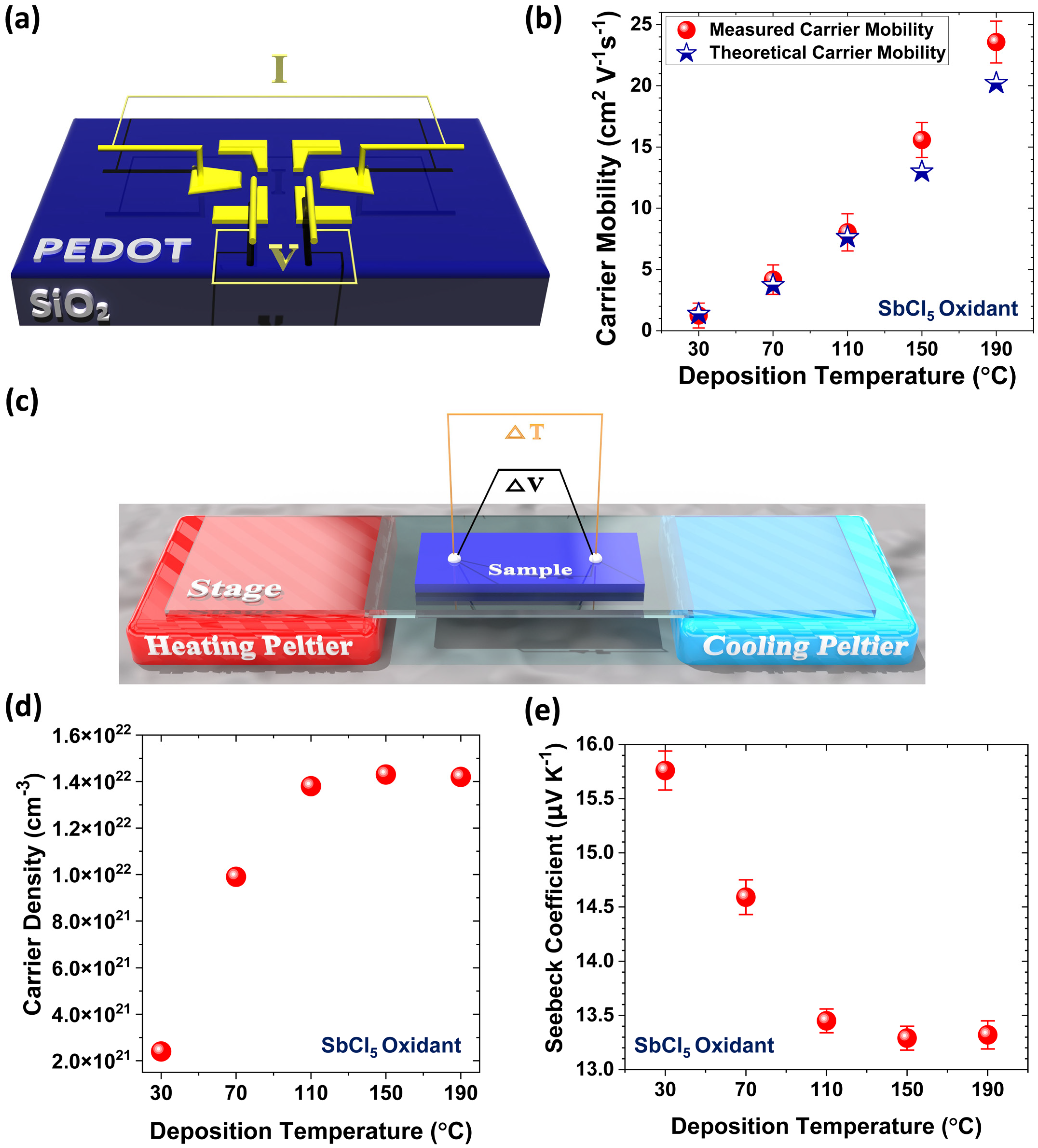

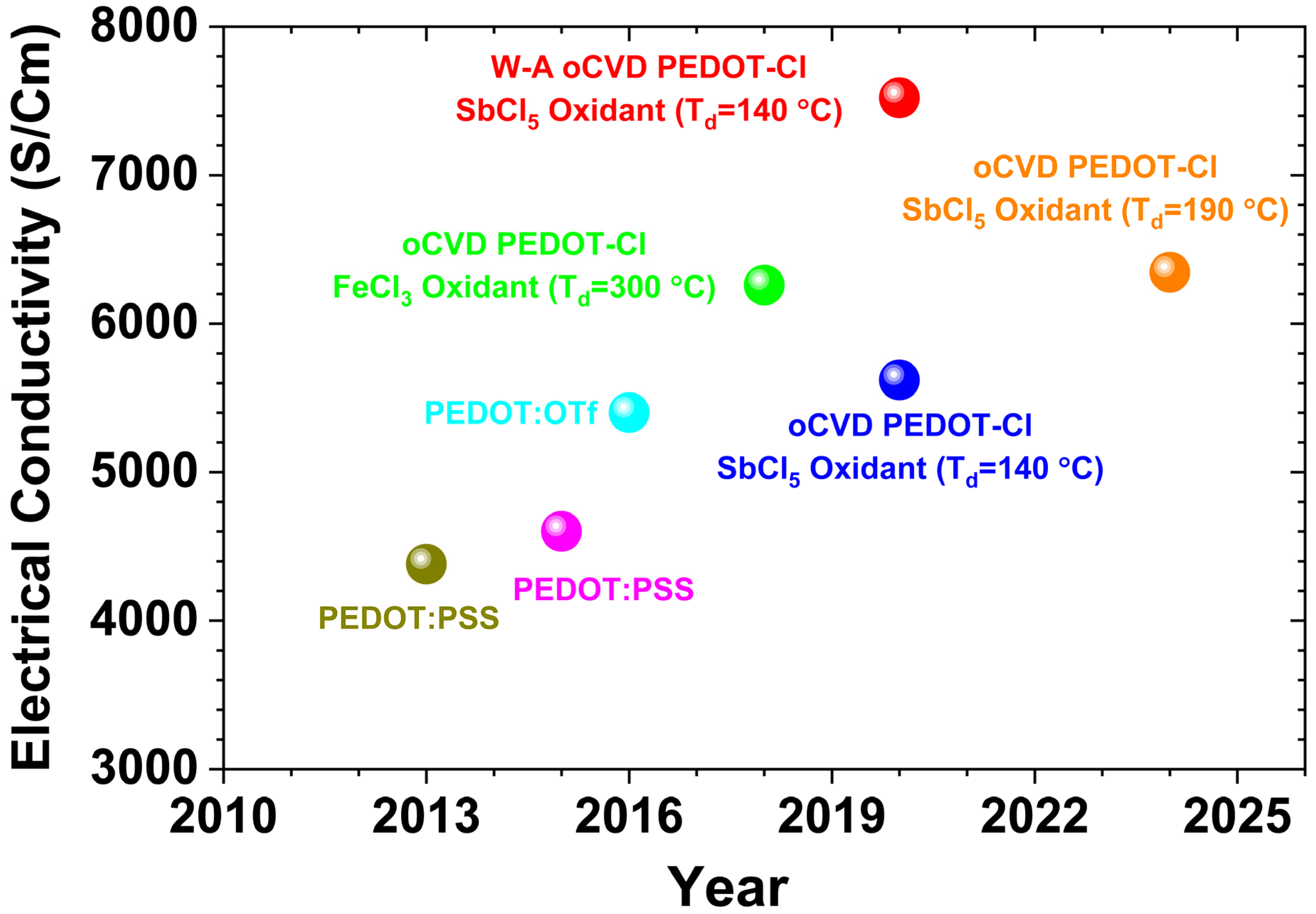

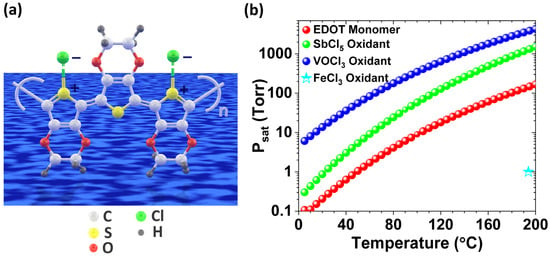

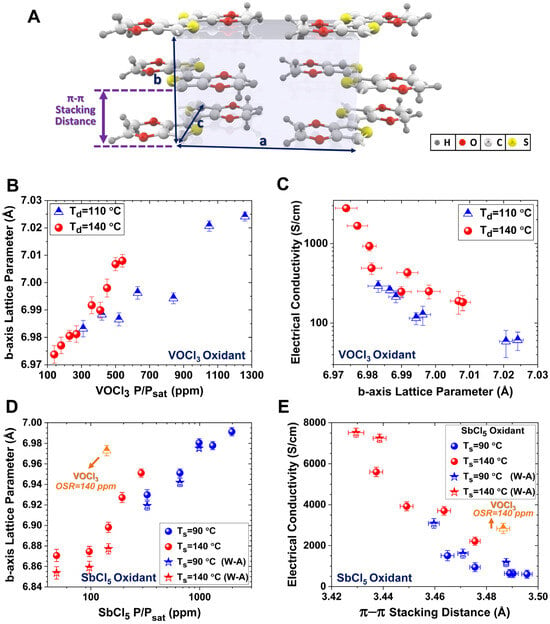

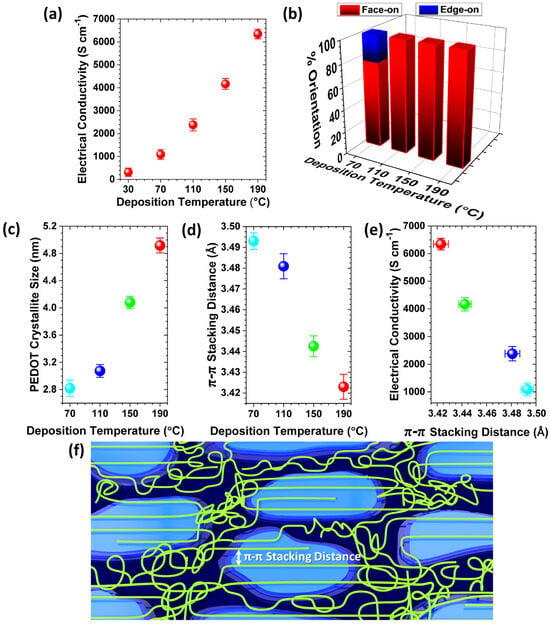

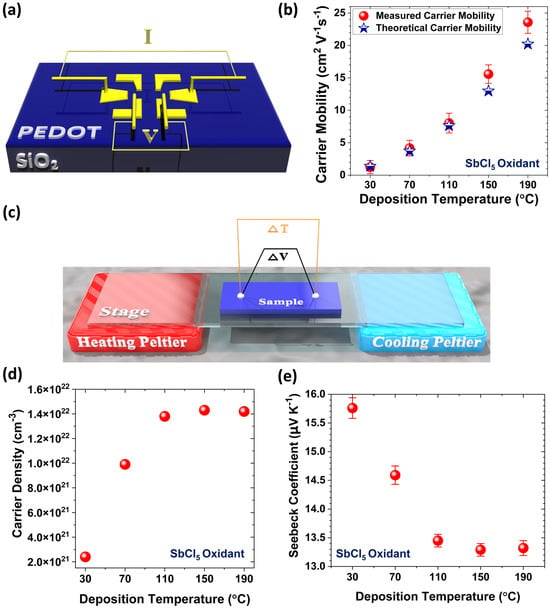

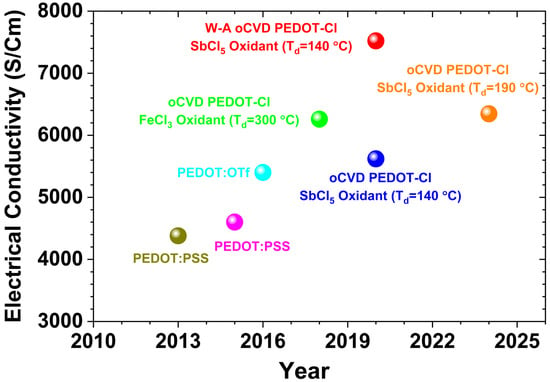

The first-generation oCVD reactors use solid oxidants, such as sublimated FeCl3 vapor [39]. The second-generation oCVD reactors utilize liquid oxidants, such as vanadium oxytrichloride (VOCl3) [31,39,40], and antimony pentachloride (SbCl5) [34,40,42]. Liquid oxidants remove the need for post-deposition rinsing, enabling a fully dry, one-step process that is cost-effective and suitable for solvent-sensitive and temperature-sensitive substrates [12]. Water-assisted oCVD (W-A oCVD) further enhances film crystallinity by improving oxidant decomposition with water vapor [40]. The W-A oCVD process enhances monomer interaction with dopants, leading to larger crystallite formation, greater ionic dopant incorporation, and reduced backbone chlorination. Additionally, water vapor scavenges protons during oxidation, promoting higher molecular weight polymer chains through equilibrium shifts favoring dimerization [12,40]. Using the W-A oCVD method with SbCl5 as an oxidant, PEDOT thin films have achieved a record electrical conductivity of 7520 ± 240 S/cm by optimizing oxidant saturation and π-π stacking distances [40]. Unlike vacuum reactors using solid oxidants, which require a large crucible-to-substrate distance, liquid oxidants allow for a reduced chamber volume, resulting in higher precursor yield and improved efficiency within a more compact reactor [30].

By eliminating the need for solvents, oCVD prevents de-wetting effects that often result in pinhole defects [43]. In solution-based processing, interfacial surface energy drives de-wetting, an issue that becomes more pronounced as film thickness decreases, making it particularly difficult to achieve uniform ultrathin coating [12,13]. In contrast, oCVD enables the deposition of pinhole-free conducting polymer films as thin as 10 nm [7,12,39,44]. Furthermore, the absence of solvents ensures that the substrate remains unaffected, eliminating risks of dissolution, swelling, or structural degradation [3,12]. The oCVD process allows polymer growth on a wide range of substrates, including common and cost-effective materials, without requiring specialized surface pretreatment [12]. This contrasts with substrate-specific surface modification techniques, such as electropolymerization, which necessitates an electrically conductive substrate or self-assembled monolayers (SAMs), which only form on specific surfaces, like gold [2]. A key advantage of oCVD is its ability to operate at low temperatures, making it suitable for direct deposition on fragile substrates. such as fabrics, paper, and membranes. In contrast, deposition techniques that require high temperatures often exceed the thermal stability of the intended substrate, necessitating an additional transfer step from a heat-resistant surface to the final substrate [4,12,34,45,46]. By enabling direct low-temperature deposition, oCVD eliminates the need for complex and expensive transfer processes, simplifying fabrication and improving efficiency.

The oCVD process enables the uniform deposition of conjugated conducting and semiconducting polymer thin films on complex substrates by eliminating surface tension effects and allowing non-directional diffusion of reactants [3,12,30,42]. In contrast, liquid-based fabrication methods, such as spin-coating, face challenges in achieving conformal coverage due to issues such as liquid bridging, limited uniformity, non-conformality at low thicknesses, and delamination [13,42,43]. The elimination of surface tension effects, a major drawback in solution-based fabrication techniques, like spin-coating, is a key advantage of the oCVD method, enabling the deposition of highly conformal coatings [30]. The ability to achieve uniform, conformal coatings of conducting polymers provides significant benefits for renewable energy applications. The fabrication of conjugated conducting polymer thin films by the oCVD method preserve electrode geometry, maintain active redox sites, and enhance ion transport, which is crucial for high-performance electrochemical energy storage devices, such as supercapacitors and batteries [2,42,43]. Beyond electrochemical energy storage devices, the oCVD method’s ability to fabricate highly conformal PEDOT coatings (the most applicable conjugated conducting polymers in optoelectronic devices) as a stable and efficient hole transport layer provides a key advantage for solar cell applications [34,39]. By applying conformal coatings to artificially textured surfaces, the available surface area is increased, enhancing light absorption in the photoactive layer [12,34]. Conformal coatings are also essential for everyday materials, such as paper, textiles, foams, electrospun mats, and membranes, allowing device fabrication while preserving breathability on fiber-based substrates [3,12]. Additionally, conformality ensures complete protection and functionalization of non-planar surfaces, making it valuable for medical devices, industrial components, and printed circuit boards [3].

This review article highlights the advantages of the CVD method, with a particular focus on the oCVD process for the fabrication of conjugated conducting and semiconducting polymers. The fundamentals of the CVD process were explored in detail, including key aspects, such as the gas delivery system, vacuum reaction chamber, vacuum system, and mean free path. Additionally, critical concepts related to conductance in vacuum systems, effective pump speed, and flow regimes were discussed, providing a comprehensive understanding of vacuum-based manufacturing technologies. Furthermore, this review highlights recent advancements in the oCVD process, particularly the use of liquid oxidants, and examines the impact of deposition temperature and oxidant saturation ratio on the fabrication of high-quality conjugated conducting polymers. These insights contribute to the optimization of thin-film manufacturing techniques and expand the potential applications of vacuum-based polymer deposition techniques in next-generation electronic, optoelectronic, and energy storage devices.

2. Chemical Vapor Deposition (CVD) Method

With advancements in materials fabrication, CVD technology has evolved to enable the precise deposition of both inorganic 2D materials, such as graphene [4,47], transition metal dichalcogenides (TMDs) [4,48,49,50,51,52], and high-quality polymeric thin films [3,7,12,53]. This progress offers exceptional conformality and precise nanostructure control across a diverse range of substrates. The large-scale fabrication of uniform conducting polymers using high-throughput roll-to-roll (R2R) processing is crucial for industrial applications. To facilitate this, chemical vapor deposition (CVD) and other vapor deposition techniques present promising solutions for accelerating the commercialization of conjugated conducting polymers in mass production [3,4,12]. CVD is a widely utilized technique for material processing, where thin films are fabricated on a heated substrate through chemical reactions of gaseous precursors [12]. Unlike physical vapor deposition (PVD) techniques (including thermal evaporation, electron beam (E-Beam) evaporation, direct current (DC) sputtering, radio frequency (RF) sputtering, magnetron sputtering), the CVD method relies on chemical reactions to enable tunable deposition rates and fabricate high-quality thin films with superior conformality. The growing demand for conjugated conducting polymers, organic semiconductors, and inorganic semiconductor thin films, played a crucial role in accelerating the development of CVD technology [3,54]. As the semiconductor industry advanced, the necessity for high-purity, defect-free, and precisely engineered thin films became paramount to enhance device performance and reliability [4,55].

CVD emerged as a transformative deposition method, offering superior conformality, precise thickness control, and the ability to tailor material properties at the atomic level [3,4,11,12]. Its versatility has been instrumental in shaping modern microelectronics, enabling the fabrication of integrated circuits, transistors, and nanostructured materials essential for next-generation computing, optoelectronics, flexible electronics, photonic devices, advanced energy systems, and quantum technologies. Strong vacuum pumps, like ion pumps (also known as ion getter pumps), can create an ultra-high vacuum (UHV) in the range of 10−6–10−9 Torr, or even an extreme high vacuum (XHV) below 10−9 Torr. In contrast, the CVD method does not require such extreme vacuum conditions, and it typically operates at process pressures in the range of 100 m Torr to 1 Torr, making it a widely used technique in electronics, optoelectronics, surface modification, and biomedical applications.

The adaptability of the CVD method enables precise control over material properties and structural characteristics, making it indispensable for next-generation electronic and optoelectronic applications. To meet the increasing demands of modern technologies, various specialized CVD techniques have been developed, each tailored for specific applications. Plasma-enhanced CVD (PECVD) enhances reaction kinetics and allows low-temperature processing, making it well-suited for temperature-sensitive substrates by providing plasma, which is made of ionized, high-energy gases [4,56]. In PECVD, plasma is generated using direct current (DC), radio-frequency (RF) voltage, or microwave sources, which are coupled to the reactor, leading to a significant reduction in the reaction temperature [4]. Metal organic CVD (MOCVD) involves the use of metal–organic precursors, typically volatile liquids, which are vaporized to form thin films. The MOCVD method is essential for depositing III–V compound semiconductors (comprised of elements from groups III and V of the periodic table) [4,57,58], high-temperature superconductors [59,60,61,62,63], and epitaxial layers [4], making it particularly valuable for the fabrication of advanced electronic and optoelectronic devices.

Oxidative CVD (oCVD) relies on the spontaneous reaction between oxidant and monomer vapors upon adsorption to the substrate, producing step-growth polymerization that typically yields conducting or semiconducting polymer films [3,12,30,43]. oCVD facilitates the fabrication of conjugated conducting and semiconducting polymers, offering new possibilities for flexible electronics and organic optoelectronics [3,12,13]. The initiated CVD (iCVD) method employs vapor-phase reactants, including an initiator and monomers, which undergo chain-growth polymerization upon adsorption onto a temperature-controlled substrate [9,64]. Utilizing an initiator allows for significantly lower filament temperatures, preserving the monomer’s organic functional groups. This retention of functional groups enables precise control over the film’s wettability and surface reactivity [11]. Meanwhile, iCVD enables the deposition of functional polymer films with controlled thickness and composition, expanding the use of CVD in surface coatings, biomedical applications, and nanostructured materials [4,9,11]. These advancements significantly enhance CVD’s capabilities, allowing for atomic-scale precision, high-quality film growth, and scalable manufacturing for next-generation devices. Other variations of CVD include photo-assisted CVD and laser-assisted CVD, where high-intensity light or a laser is used to stimulate and enhance the deposition process, promoting thin film formation [4].

The most common CVD configuration is the horizontal tube reactor, where substrates are positioned horizontally, vertically, or at a tilt to optimize gas flow. Vertical reactors often use showerhead mixers for improved material uniformity and growth rates [4]. In hot-wall CVD reactors, the entire vacuum chamber is uniformly heated using a heating filament or external furnace, whereas in cold-wall CVD reactors, only the substrate and its surrounding area are heated while the reactor walls remain cold, enabling rapid heating and cooling. Hot filament CVD (HFCVD) uses resistively heated filaments, often made from tungsten, tantalum, or molybdenum, to thermally decompose precursors that deposit onto cooler substrates, typically forming inorganic films, like amorphous silicon or silicon nitride [4,65,66,67].

The deposition rates in CVD techniques are highly influenced by process parameters, such as chamber pressure, precursor flow rates, and deposition temperature, as well as the specific approach used, such as low-pressure CVD (LPCVD), and PECVD. Typically, deposition rates in CVD methods range from 1 to 10 nm/min [30]. Lower deposition rates are associated with the formation of high-quality, highly conformal thin films, whereas higher deposition rates facilitate faster production but may compromise film quality. Table 1 provides a summary of the common precursors utilized and functional materials fabricated in various CVD methods. It outlines the typical precursor combinations used in different CVD techniques.

Table 1.

Common precursors utilized and materials fabricated in various CVD methods. This table summarizes the typical precursors used and common functional materials deposited via different CVD techniques, including 2D materials, conducting polymers, semiconductors, dielectrics, superconductors, and protective coatings.

2.1. Fundamental of CVD Method

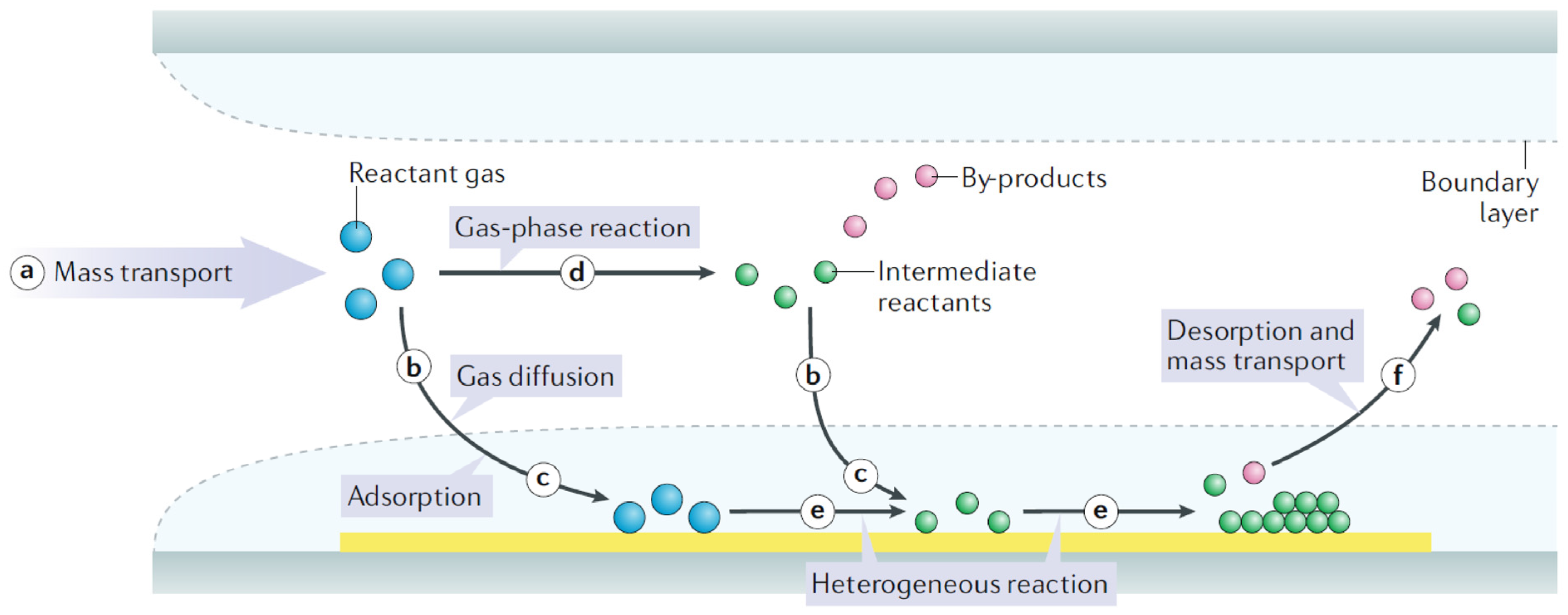

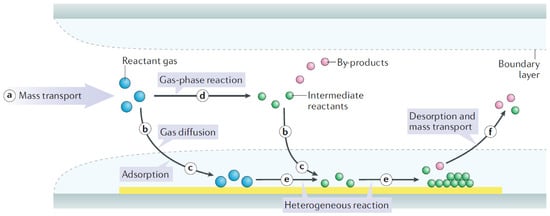

Despite the diversity of CVD techniques, the fundamental process remains consistent and follows several key steps, as illustrated in Figure 1 [4]. Initially, reactant gases are delivered into the vacuum reactor chamber, where their flow rate is regulated through a mass flow controller (MFC) or a needle valve to ensure precise mass transport (Figure 1a). The reactant gases may either diffuse across the boundary layer to reach the substrate surface, enabling gas diffusion (Figure 1b) or undergo gas-phase reactions, leading to the formation of intermediate reactants and gaseous by-products (Figure 1d). In both scenarios, the reactant gases and intermediate reactants adsorb onto the heated substrate’s surface and spread across it (Figure 1c). The subsequent reactions at the gas–solid interface result in the steady formation of a thin film through processes of heterogenous nucleation and growth (Figure 1e). Eventually, any gaseous by-products and unreacted species desorb from the substrate’s surface and are evacuated from the reaction area (Figure 1f). Gas-phase reactions typically occur when temperatures are sufficiently high or when additional energy, like plasma, is applied. It is important to highlight that heterogeneous nucleation and growth play a critical role when deposition relies on surface catalysis by the substrate [4].

Figure 1.

Schematic illustration of the CVD process. (a) Reactant gases enter the reactor. (b,c) Gases either diffuse through the boundary layer and adsorb onto the substrate or (d) undergo gas-phase reactions, forming intermediates and by-products, which then deposit via diffusion and adsorption. (e) Surface diffusion and heterogeneous reactions occur, leading to thin film formation. (f) Unreacted species and by-products desorb and exit as exhaust [4]. Reproduced with permission [4]. Copyright 2021, Nature.

Heterogeneous nucleation and growth are a key process in the formation of thin films, particularly in the CVD method, where a reaction occurs at the interface between two distinct phases, typically between the gas phase and a solid substrate [1,4]. During heterogeneous nucleation, gas-phase reactants undergo surface processes, such as adsorption and surface diffusion, before nucleating as solid-phase clusters on the substrate. These nucleation sites serve as initial points for further growth, eventually forming a continuous thin film. The characteristics of the heterogenous nucleation and growth process depend on factors like substrate temperature, precursor properties, and surface energy, which collectively influence thin film morphology, grain size, and uniformity.

The growth of thin films during heterogeneous nucleation can occur through various mechanisms, including island growth (also known as Volmer–Weber grow), layer-by-layer growth (also known as Frank–van der Merwe growth), and layer-plus-island growth modes [85,86]. Island growth occurs when atoms or molecules aggregate into isolated clusters on the substrate surface due to stronger interactions between deposited atoms compared to their interactions with the substrate, resulting in discrete island formation [86]. In contrast, layer-by-layer growth involves the sequential addition of atomic or molecular layers on the substrate surface, driven by stronger interactions between the film atoms and the substrate compared to interactions between adjacent film atoms. A combination of these mechanisms, known as layer-plus-island growth, involves initial layer formation followed by island growth, creating a more complex film morphology [86,87].

Achieving desired thin film characteristics involves challenges, such as minimizing defects, ensuring uniformity, and optimizing grain size, as defects, like dislocations, voids, and grain boundaries, can degrade electrical, mechanical, and optical properties [87]. Uniform growth is critical for consistent performance, while grain size affects conductivity, crystallinity, and overall behavior. Therefore, careful optimization of parameters, like substrate temperature, precursor flux, and deposition time, is essential to produce high-quality thin films for applications in microelectronics, optoelectronics, and energy devices.

The CVD system must fulfill several essential requirements to ensure efficient and controlled high quality thin film deposition. First, it must enable the precise and adjustable delivery of gas-phase reactants, allowing for accurate control over film composition and growth rates. Second a well-sealed vacuum reaction chamber with a leak rate below 10 mTorr/min is crucial for maintaining a stable environment, minimizing contamination, and ensuring precise control over reaction pressure, which directly influences thin film morphology, uniformity, and overall material quality [12]. Furthermore, the system must incorporate a reliable energy source, such as thermal, plasma, or optical excitation, to drive the chemical reactions essential for thin film deposition [4,12,88]. Proper exhaust gas treatment through the use of an appropriate vacuum pump is essential to safely neutralize oxidants and gaseous by-products while effectively removing them from the chemical reaction zone to maintain process stability and prevent contamination. Lastly, an advanced automatic process control system is required to enhance deposition stability, reproducibility, and efficiency, reducing human intervention while optimizing thin film characteristics. By meeting these fundamental criteria, a CVD system can achieve precise and scalable material synthesis for various industrial and research applications.

2.2. Gas Delivery System in the CVD Method

The volatile gaseous reactants used in the CVD processes are typically stored in high-pressure gas cylinders, which are placed in temperature-controlled environments at a constant negative pressure [4]. The gas supply system begins at the outlet of these high-pressure cylinders, where mechanical pressure regulators are installed to precisely control the output pressure before the gases are transported through the delivery lines to the reaction vacuum chamber. To regulate the mass flow rate of reactant gases into the reactor, various types of valves are integrated into the delivery line, including ball valves for quick shut-off, needle valves for fine flow adjustments, and pneumatic valves for automated control in high-precision applications. The vacuum coupling radiation (VCR) gaskets are commonly used in the gas delivery system to ensure leak-free, high-purity connections between components, maintaining system integrity and preventing contamination during thin film deposition.

In CVD processes, gas throughput () plays a critical role in controlling reaction conditions, ensuring uniform thin film deposition, and maintaining process stability. The gas throughput is typically measured in standard cubic centimeters per minute (SCCM), where 1 SCCM corresponds to 1 cm3 of gas at a standard temperature and pressure (0 °C and 1 atm (760 Torr)). The relationship between gas throughput (, system pressure (), and vacuum pump speed ( is expressed by the following equation [89,90]:

where represents the gas throughput in a unit of , is the system pressure in a unit of , and is the vacuum pump speed, measured in .

Proper control over throughput ensures stable deposition conditions, and maintaining a steady gas influx and exhaust helps prevent unwanted pressure fluctuations that may lead to thin film inhomogeneity. In practical applications, is often converted to SCCM for easier gas flow measurements and adjustments. The approximate conversion factor is: . By carefully regulating gas throughput, engineers and researchers can fine-tune deposition parameters to achieve high-quality thin films with desired composition, thickness uniformity, and structural integrity.

Mass flow controllers (MFCs) play a critical role in regulating gas delivery to the reactor chamber by automatically adjusting the gas flow rate in the SCCM through feedback control based on the mass of the gas in transit. For liquid-phase precursors, a carrier gas is typically employed to transport the vaporized precursor through a bubbling process [12,30,40]. In contrast, solid precursors with low volatility are introduced into the reaction chamber either by dissolving them in a suitable solvent for vaporization or by sublimating them directly from a crucible into the gas phase, ensuring precise and efficient delivery for thin film deposition [4,12].

2.3. Vacuum Reaction Chamber in CVD Method

The two primary configurations of the vacuum reaction chamber in CVD systems are horizontal and vertical designs, each suited for different deposition requirements and scalability [4]. Horizontal reaction chambers are commonly used for batch processing, where substrates are placed on a boat inside a quartz tube and exposed to the reactant gases. Vertical reaction chambers are preferred in high-throughput processes, such as semiconductor wafer fabrication, where substrates are loaded onto susceptor plates or rotating platforms to ensure uniform gas exposure.

In CVD reactors, stainless steel 304 (SS 304) and 316 (SS 316) are commonly used for the chamber walls due to their excellent corrosion resistance, thermal stability, and mechanical strength. The reaction chamber is also constructed from quartz, a material widely employed in tube shape reactors in semiconductor manufacturing due to its high-temperature tolerance and resistance to rapid thermal cycling. The chamber is connected to a gas inlet injector via a metal flange, which is often equipped with cooling components to prevent thermal damage and maintain system integrity. To ensure laminar gas flow and uniform precursor distribution, a gas distributor with precision-engineered through-holes is typically integrated into the system [11,90].

The CVD systems may incorporate hot-wall or cold-wall reactor designs. In hot-wall reactors, the chamber walls are heated to maintain a uniform temperature distribution, reducing unwanted deposition on chamber surfaces. In contrast, cold-wall reactors use localized heating for the substrate to minimize contamination and improve deposition selectivity on the substrate. The substrate is typically placed on a substrate holder, commonly referred to as a boat or susceptor, which is designed to withstand the high temperatures and reactive environments of the CVD process. These holders are generally made from quartz or graphite, materials known for their excellent chemical stability, thermal resistance, and minimal interaction with the deposited films [4,91,92]. In high-temperature applications, particularly in MOCVD epitaxial growth processes, Inconel (a nickel-based superalloy), is also used due to its superior oxidation resistance, mechanical strength, and durability under extreme thermal conditions [59,60,62,63,78].

2.4. Heating Source in the CVD Method

In the CVD process, the heating source is a crucial component that drives the chemical reactions necessary for thin film formation on the substrate. The heating source must supply adequate thermal energy to decompose precursor gases into reactive species, promoting their reaction and subsequent deposition as a solid thin film [4,11,12]. The choice and configuration of the heating source significantly affect the deposition rate, thin film morphology, crystallinity, and overall material characteristics. Common heating sources in CVD include resistive heating, induction heating, infrared (IR) heating, and plasma-assisted methods, each offering distinct advantages based on specific application needs [4]. For instance, resistive heating is widely favored due to its ability to deliver uniform heat distribution across the substrate, while induction heating provides rapid temperature control, making it ideal for processes requiring elevated temperatures. Various thermocouples (such as types B, J, K, R, and S) are employed for precise temperature monitoring in different operational environments.

In plasma-enhanced CVD (PECVD), plasma generated through electrical discharge in a gaseous medium (e.g., argon) serves as an energy source, enabling thin film deposition at lower temperatures, which is particularly advantageous for temperature-sensitive substrates, like flexible electronics [4]. Notably, oCVD and iCVD techniques have enabled the fabrication of conducting and functional polymers at significantly lower deposition temperatures, ranging from room temperature to 150 °C, making them ideal for applications involving temperature-sensitive and flexible substrates while broadening their applicability across various fields [3,12,30,42]. The deposition temperature in various CVD methods is highly dependent on the specific technique and the materials being fabricated. For instance, metal organic chemical vapor deposition (MOCVD), commonly used in the fabrication of high-temperature superconductors, typically requires deposition temperatures in the range of 700 °C to 1000 °C [59,60,61,62,63,77,78]. Additionally, the geometry and materials of the substrate holder influence heat transfer efficiency. Radiant heating techniques involving halide lamps, electric induction, or lasers can be utilized to selectively heat the substrate. In cylindrical CVD reactors, commonly known as furnace reactors, resistance heating systems featuring three distinct heating zones and aluminum silicate insulating cotton are often employed to ensure a uniform temperature field over an extended length. This uniformity is crucial for consistent film quality and reproducibility in high-performance applications [4].

2.5. Vacuum System and Mean Free Path

Purging the deposition vacuum chamber to start the deposition process and obtaining the necessary pressure for transport of the reactants relies on the vacuum system, where measurement and control of the vacuum are essential and complement one another. The primary reasons for utilizing a vacuum system in the fabrication of functional materials through CVD methods are to ensure a contamination-free process and to achieve a high mean free path for precursor vapors [4]. In a vacuum environment, the mean free path, which is defined as the average distance that a vapor molecule travels before colliding with another molecule, is significantly increased due to the reduced gas density. This minimizes gas-phase scattering, thereby reducing unwanted side reactions and improving the uniformity and purity of the deposited thin film. Additionally, a higher mean free path allows precursor molecules to reach the substrate surface more efficiently, leading to an enhanced deposition rate and improved film quality, which is crucial for applications in electronics, optoelectronics, and advanced material coatings.

The behavior of low-pressure gases is generally described by kinetic gas theory, which treats gases as a system of individual molecules with negligible intermolecular van der Waals forces, allowing their motion and interactions to be analyzed statistically. According to kinetic gas theory, gas molecules travel at thermal velocity, determined by temperature, and undergo collisions that define their motion. There is an inverse relation between the process pressure in the vacuum reactor and mean free path (), as in the following equation [93,94]:

where represents Boltzmann’s constant, denotes the absolute temperature, is the diameter of the gas molecule, and refers to the reactor pressure during deposition.

To accurately measure the pressure within a vacuum system, a variety of pressure transducer gauges are employed, each offering unique measurement principles and advantages. Among the most commonly used mechanical gauges are piezo sensors, capacitance manometers, and diaphragm manometers, which detect vacuum levels by measuring physical changes in strain or electrical capacitance. While the Bourdon gauge is a cost-effective and durable option, it lacks an electronic output, making it unsuitable for automated feedback control systems. In contrast, the capacitance manometer is a widely preferred choice due to its high accuracy and broad measurement range, typically spanning four orders of magnitude. The capacitance manometer gauge is highly versatile, as it provides precise readings for nearly any gas and allows seamless integration with electronic displays and automated feedback controllers, enabling real-time pressure monitoring and process optimization in CVD and other vacuum-based deposition systems.

The operating pressure during thin film deposition is precisely maintained and regulated using a throttle valve, which continuously adjusts in response to real-time pressure readings from a capacitance manometer gauge [3,12]. This dynamic feedback mechanism ensures stable process pressure throughout the deposition process, optimizing film uniformity and quality.

Vacuum pumps serve as the primary mechanism for generating vacuum conditions and facilitating mass transport within a system. Different types of vacuum pumps operate across a range of vacuum levels, classified as follows:

- (i)

- Rough vacuum: Pressure range of 760 Torr to 1 mTorr;

- (ii)

- Medium vacuum: Pressure range of 1 mTorr to 10−6 Torr;

- (iii)

- High vacuum: Pressure range of 10−6 to 10−9 Torr;

- (iv)

- Ultra-high vacuum (UHV): Pressure range of 10−9 to 10−12 Torr;

- (v)

- Extreme high vacuum (XHV): Pressure range of below than 10−12 Torr;

- (vi)

- Rough vacuum conditions can be achieved using a variety of pumps, including rotary piston mechanical pumps, dry mechanical pumps, sorption pumps, and blower/booster pumps, each suited for different industrial and laboratory applications. For high vacuum environments, turbo molecular pumps, cryogenic pumps, and diffusion pumps are commonly utilized, providing efficient gas removal and maintaining stable vacuum levels. Achieving an ultra-high vacuum requires specialized pumps, such as ion pumps, which rely on ionization and electrostatic trapping to remove residual gas molecules, making them essential for high-precision applications, like space research, and particle accelerators. In a CVD system, mechanical pumps are sufficient for many processes and can achieve vacuum levels down to 1 mTorr. While oil-sealed pumps are more cost-effective compared to dry pumps of similar capacity, they introduce potential contamination due to oil back streaming, which may affect film purity and process stability. For systems with large reaction vacuum chambers, a rotary pump (with a pumping speed ranging from 0.5 to 325 L/s) combined with a Roots pump (capable of 50 to 35,000 L/s) is an effective solution for rapid gas evacuation, enhancing process efficiency and maintaining stable vacuum conditions [4].

2.6. Pump-Down in Vacuum Systems

The pump-down process in a vacuum system refers to the gradual reduction of pressure as gases are removed from the reactor chamber. Initially, the pressure drop follows an exponential decay, as governed by the equation [95]:

where is the pressure at time , denotes the initial pressure (which is atmospheric pressure ), signifies the pump speed in unit of L/s, and is the volume of reactor chamber in liters.

During the initial pump down process, gas molecules are rapidly evacuated from the reactor chamber, leading to a sharp pressure drop. However, as the pressure decreases, the effect of outgassing from chamber walls and internal components becomes more significant, slowing down the pump-down rate. Outgassing, which includes desorption of water vapor and volatile contaminants, becomes the dominant factor in achieving high or ultra-high vacuum conditions. To minimize the effect of outgassing, techniques such as baking the reactor chamber, plasma cleaning, or using cryogenic traps are often employed in the vacuum systems.

2.7. Conductance in Vacuum Systems

In vacuum technology, conductance refers to the ability of a vacuum component or system to facilitate the flow of gas. Conductance is a key parameter that influences the efficiency of vacuum pumping and gas transport within the system [96]. Conductance can be considered the inverse of flow resistance, meaning that higher conductance allows gases to move more freely, while lower conductance restricts flow. Conductance () is defined as the ratio of gas throughput or molecular flux () to the pressure drop () across a vacuum system [90]:

where C is conductance (typically in Liters per Second, L/s), Q is the molecular flux or gas throughput (Torr·L/s), and is the pressure drop between reactor side and vacuum pump side in the unit of Torr.

2.8. Effective Pump Speed in Vacuum Systems

The effective pump speed in vacuum technology is a critical parameter that determines the rate of gas removal from the vacuum reactor chamber and the ability to maintain the desired pressure in a CVD reactor. The effective pump speed () is defined as the actual pumping speed at the reactor chamber and is influenced by both the intrinsic/nominal pumping speed (of the vacuum pump and the conductance of the connecting vacuum lines. The effective pump speed ( is generally lower than the nominal pump speed () due to gas flow restrictions and pressure drops in the connecting filter trap, vacuum tubing, roughing valve, and throttle valve. As a result, optimizing the vacuum system layout is crucial for achieving efficient gas removal and maintaining stable deposition conditions in CVD processes.

The conductance of the vacuum tube connecting the vacuum reactor to the vacuum pump plays a key role in determining the effective pump speed and the relationship between the effective pump speed (, nominal pump speed (), and conductance () is given by the following equation [97]:

As can be noted from the above equation, the low conductance in the vacuum line significantly reduces the effective pumping speed, limiting the gas removal rate from the vacuum reactor. To enhance pumping efficiency, shorter and wider vacuum tubes with smooth inner surfaces should be used to minimize flow resistance.

2.9. Flow Regimes in the Vacuum Systems

In general, to enhance the conductance of the vacuum system, larger diameter vacuum tubing, shorter pump lines, and high-conductance valves are often used. Proper system design ensures that vacuum pumps operate efficiently, leading to improved process stability and thin film quality. It is important to note that conductance in a vacuum system varies significantly depending on the flow regime, which can be categorized into viscous flow, molecular flow, and transition flow. The classification of flow regimes in the vacuum system is determined by the Knudsen number (), which describes the relationship between the mean free path () of gas molecules and the smallest characteristic dimension of the vacuum system’s geometry (L), as described by the following definition [98]:

where is the Boltzmann constant, represents the temperature, denotes the diameter of the gas molecule, and is the pressure of the system.

Flow regimes in the vacuum system are classified as follows [99]:

- (i)

- Molecular flow (Gas molecules move independently, with collisions occurring more frequently with chamber walls than with other molecules, typical in high and ultra-high vacuum and high mean free path.

- (ii)

- Viscous flow (): Gas molecules interact predominantly with each other, behaving like a continuous fluid, common at higher pressures and low mean free path.

- (iii)

- Transition flow (): Intermediate regime where both molecular and viscous flow characteristics are present, occurring in medium vacuum conditions.

Under atmospheric pressure, gas diffusion in mesoporous materials predominantly occurs in the Knudsen regime, where the mean free path of gas molecules is comparable to or larger than the pore size, leading to molecular collisions with the pore walls rather than intermolecular collisions. In contrast, the ultra-high vacuum diffusion setup enables the generation of significantly high Knudsen numbers at macroscopic scales by operating under ultra-high vacuum conditions, where molecular flow is dominated by wall interactions rather than bulk gas dynamics [100].

3. Methods for the Fabrication of Conjugated Conducting and Semiconducting Polymers

Conjugated conducting and semiconducting polymers are classified based on charge carrier polarity as p-type (hole-dominant), n-type (electron-dominant), or ambipolar (both carriers) [5,6]. In p-type doping, an oxidizing agent extracts an electron from the highest occupied molecular orbital (HOMO) of the polymer matrix, leaving behind a positive hole along the conjugated backbone. In contrast, n-type doping involves a reducing agent injecting an electron into the lowest occupied molecular orbital (LUMO) of a polymer matrix, resulting in a negative charge carrier along the conjugated polymer chain [2,5,101,102]. Ionization energy (IE) and electron affinity (EA) are key parameters that determine p-type and n-type doping characteristics in semiconductors. For p-type doping, the EA of the acceptor dopant must be equal to or greater than the IE of the organic polymer host, facilitating electron transfer from the HOMO of the polymer to the LUMO of the dopant. In other words, p-type doping occurs when the LUMO of the dopant is positioned near or below the HOMO of the polymer host [5]. In n-type doping, the HOMO of the dopant is positioned near or above the LUMO of the organic polymer host [5,6,103].

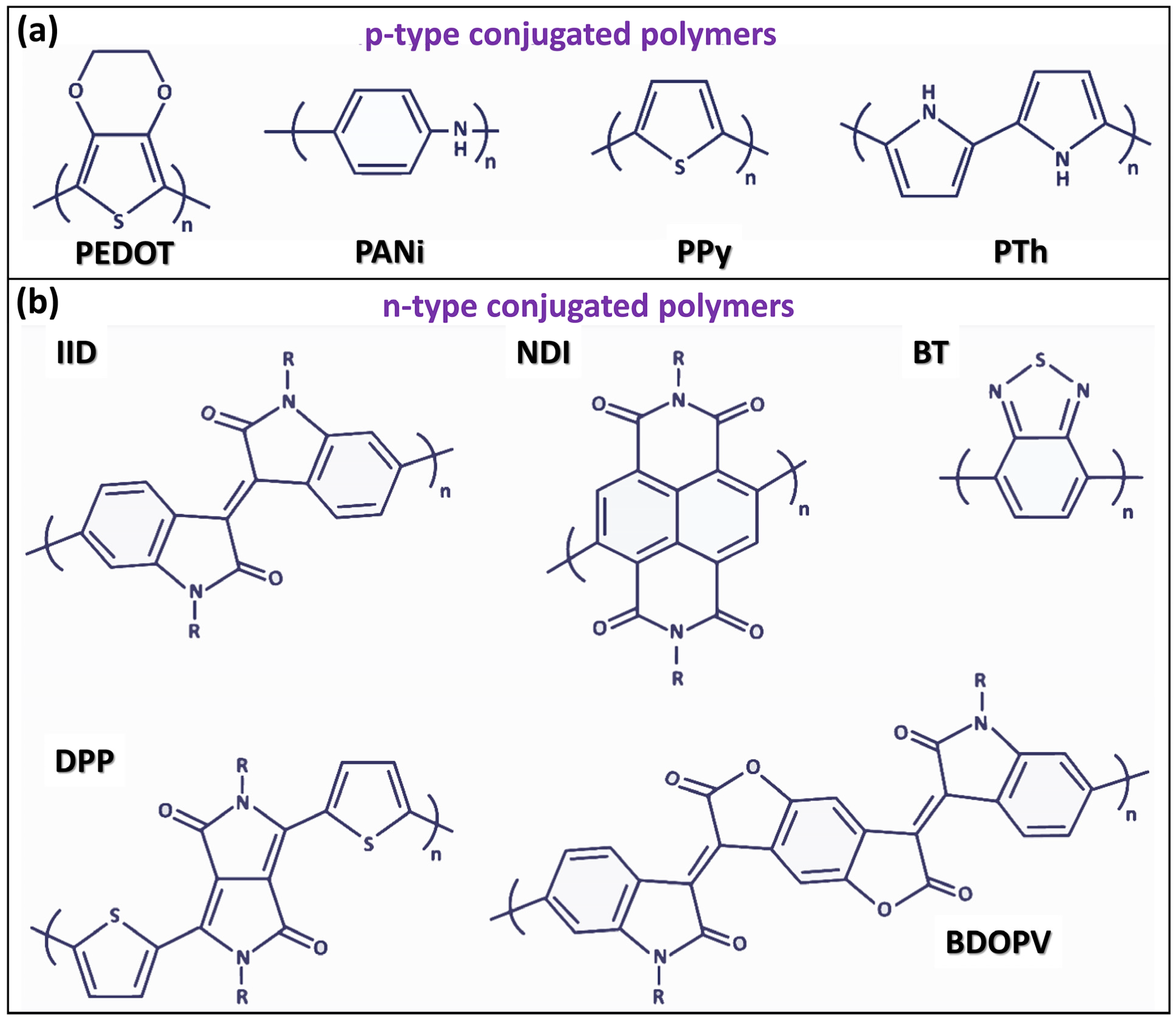

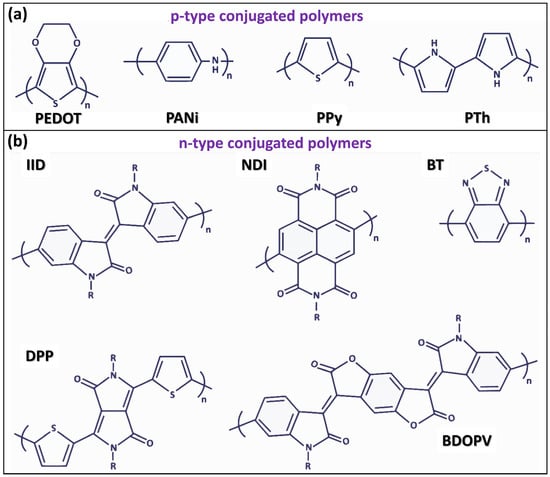

Among p-type conjugated conducting polymers, the most widely studied and applicable are poly(3,4-ethylenedioxythiophene) (PEDOT) [30,34,40,42,43,104,105,106], polyaniline (PANI) [6,17,107,108], polypyrrole (PPy) [2,109,110], polythiophene (PT) [18,29,111], and their derivatives. In contrast, high-mobility n-type conjugated conducting polymers are relatively rare, unstable under ambient conditions, and prone to oxidation [5,6]. The most reported n-type conjugated conducting polymers include naphthalene diimide (NDI), benzodifurandione-based oligo(p-phenylene vinylene) (BDOPV), diketopyrrolopyrrole (DPP), isoindigo (IID), and benzothiadiazole (BT) [2,5]. The chemical structures of the most widely used p-type and n-type conjugated conducting and semiconducting polymers are shown in Figure 2a and Figure 2b, respectively [6].

Figure 2.

Chemical structures of key p-type and n-type conducting and semiconducting polymers. (a) Structures of widely studied p-type conjugated polymers, including PEDOT, PANI, PPy, and PTh [6]. (b) Structures of prominent n-type conjugated polymers, such as IID, NDI, BT, and DPP BDOPV [6]. (a,b) Reproduced with permission [6]. Copyright 2022, MDPI.

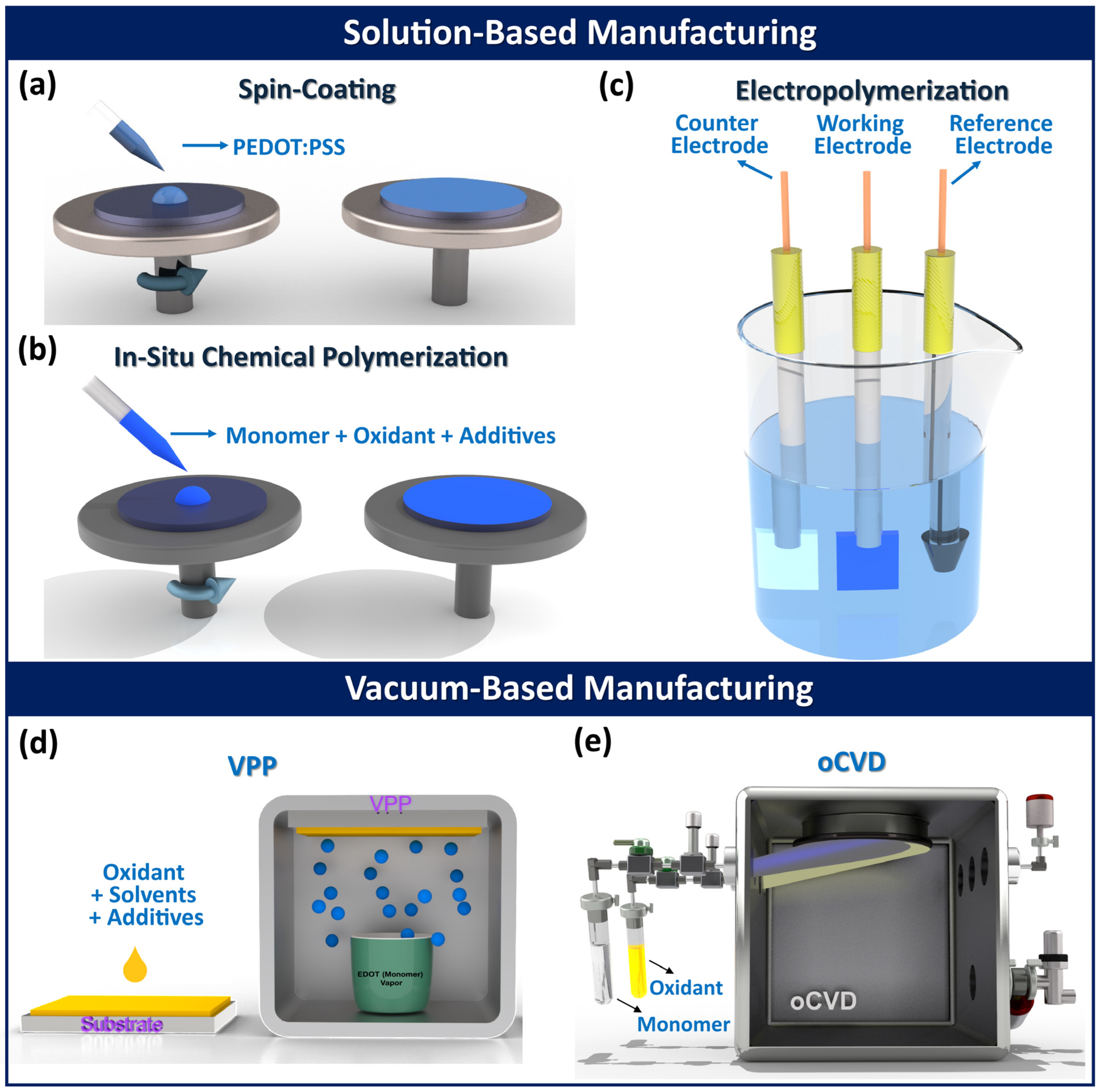

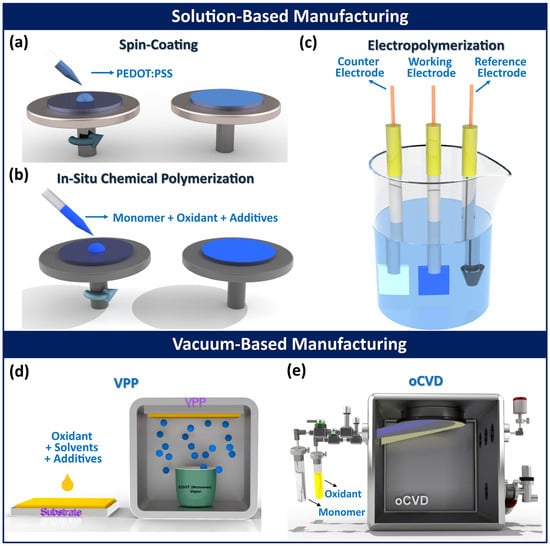

While the CVD method is a highly versatile manufacturing technique for fabricating high quality conducting polymers, semiconducting polymers, and functional polymers, particularly through approaches, like oCVD [3,7,12,30,42,112] and iCVD [9,10,11,64,88,113,114], other fabrication techniques are also exhibited in Figure 3 [2]. Solution-based methods utilize liquid-phase processing techniques, such as spin-coating [115,116], in situ chemical polymerization (ICP) [117,118,119], and electropolymerization [120,121]. In contrast, vapor-phase deposition methods enable polymerization from gaseous reactants, including vapor phase polymerization (VPP) [122,123,124,125], and oCVD [3,11,12,14,33,42,43,54,126,127,128,129,130]. Additionally, alternative polymerization strategies, like hydrothermal synthesis [131], electrospinning [132], self-assembly [133], interfacial polymerization [134], and plasma polymerization [135], have been explored for fabricating conducting polymer thin films and composites, broadening their application potential.

Figure 3.

Overview of common fabrication methods for conjugated conducting polymers. Solution-based techniques include (a) spin-coating [3], (b) in situ chemical polymerization (ICP) [2], and (c) electrochemical polymerization [2], while vapor-based methods consist of (d) vapor phase polymerization (VPP) [2], and (e) oxidative chemical vapor deposition (oCVD) [39]. (a) Reproduced with permission [3]. Copyright 2019, Wiley. (b–d) Reproduced with permission [2]. Copyright 2024, Royal Society of Chemistry. (e) Reproduced with permission [39]. Copyright 2019, Science.

Spin-coating is a common solution-based method for depositing polymer thin films and involves four steps: (i) dispensing the solution, (ii) spinning the substrate, (iii) removing excess solution, and (iv) thermal annealing (Figure 3a) [2]. Polymeric thin film quality in spin-coating depends on factors like spin speed, polymer molecular weight, viscosity, solvent volatility, and surface interactions [2,136]. Electrical conductivity in spin-coated conducting polymer films improves with high-boiling-point polar solvents, such as dimethyl sulfoxide (DMSO), N,N-dimethyl formamide (DMF), N,N-dimethyl acetamide (DMAc), sorbitol, glycerol, ethylene glycol (EG), and dichloromethane (DMC) [2,5,6,137]. In in situ chemical polymerization (ICP), a monomer, oxidant, and additives are spin-coated onto a substrate, enabling simultaneous polymerization and doping (Figure 3b) [2]. Properties of conjugated polymer thin films fabricated by the ICP depend on molecular weight, oxidant type, solvent, additives, and morphology, while oxidant characteristics influence oxidation rate, affecting film structure and conductivity [2,138]. Electropolymerization deposits conjugated conducting polymer films on a conductive electrode via anodic oxidation in a three-electrode setup (Figure 3c) [2]. Applying a deposition potential oxidizes the monomer, forming radical cations that polymerize into oligomers, leading to conjugated polymer thin film formation [2,139]. Counterions integrate into the polymer, influencing conductivity in electropolymerization. Solvent and electrolyte selection are crucial for ionic conductivity and stability [2,140,141].

Vapor phase polymerization (VPP) is a two-step process for fabricating conducting polymer films, where a low-volatility oxidant is first applied via spin-coating, dried, and then exposed to monomer vapor in a vacuum chamber, initiating polymerization at the oxidant–monomer interface (Figure 3d) [2]. VPP operates at an ambient or moderate vacuum (5–30 Torr), while recently, vacuum-assisted methods have become common [2,125,142,143]. The polymerization rate in VPP can be adjusted using polar organic solvents (e.g., DMSO, NMP, DMF) and chelating ligands (e.g., EDTA) to modify oxidant reactivity [2,5,6,144]. Base inhibitors (e.g., imidazole, PEI, and pyridine) raise the pH, minimize side reactions, and improve the conductivity of fabricated conjugated polymers by the VPP method [145,146,147]. The use of surfactants (e.g., PEG-PPG-PEG) improve electrical properties of conducting polymers fabricated by the VPP method through controlling the polymerization rate and preventing oxidant crystallization [148]. Key fabricated factors in the VPP method include monomer exposure time, deposition pressure, deposition temperature, humidity, oxidant acidity, and post-deposition acidic rinsing treatments [2].

The oCVD method is a solvent-free and scalable manufacturing technique for depositing conducting and semiconducting polymers as highly conformal thin films, with tunable nanostructures achieved by engineering dopant levels and process parameters [4,7,12,13,15,30,33,34,40,42,43,53]. In the oCVD process, a monomer and oxidant are delivered as vapors into a hot-wall vacuum chamber, where the oxidant vapor initiates step-growth polymerization on a temperature-regulated substrate, resulting in the formation of high-quality conductive polymer films (Figure 3e) [2]. The oCVD method enables direct polymerization of vapor-phase monomers and oxidants in a controlled vacuum environment, offering a single-step, truly dry process. Key parameters in the oCVD method, such as oxidant saturation ratio (OSR) [39,40], deposition temperature [25,30,41,42] chamber pressure [3,11,12,149], choice of oxidant [2,12,39], and water-assisted growth techniques [33,40], tailor properties of fabricated conducting polymers. The oCVD method is largely substrate independent, enabling deposition of conjugated conducting polymers on a wide range of surfaces, including organic and inorganic, planar and non-planar, as well as porous and dense materials, while forming covalently grafted films without the need for linker molecules [2,3,12]. Unlike solution-based techniques, oCVD offers solvent-free processing, low-temperature deposition, and scalability, making it well-suited for roll-to-roll (R2R) production of large-area, high-performance conducting polymer thin films [4,11,12,54]. The highest reported electrical conductivity of 7520 ± 240 S/cm in PEDOT thin films was achieved using the oCVD method with water-assisted growth and SbCl5 as an oxidant, resulting in excellent optoelectronic properties [40].

The key advantages and disadvantages of each fabrication method for conjugated polymers have been summarized based on recent literature [2,3,7,12,53,125,136,146,149,150,151,152,153] and are provided in Table 2. Various factors, including quality of thin film, conformality, substrate compatibility, and process scalability have been considered to assess their suitability for applications in electronic, optoelectronic, and energy-related devices. In general, the oCVD method is a highly versatile manufacturing technique for fabricating ultrathin, highly conformal coatings of conducting and semiconducting polymers, enabling large-scale production through roll-to-roll (R2R) processing [3,7,12,53].

Table 2.

Summary of key advantages and disadvantages of various fabrication methods for conjugated conducting and semiconducting polymers. Various factors, including thin film quality, conformality, substrate compatibility, and process scalability, are summarized for different fabrication methods.

Unlike solution-based methods, oCVD is a solvent-free technique that minimizes the generation of hazardous liquid waste. However, the choice of oxidant significantly influences the process’s overall environmental footprint. Recent advancements in oCVD, particularly the use of liquid oxidants, such as SbCl5 and VOCl3, along with optimized process parameters (mainly oxidant saturation ratio and deposition temperature) enable the fabrication of conductive polymers with minimal oxidant by-products. This development transforms oCVD into a true single-step, dry process, eliminating the need for acidic rinsing post-treatment steps. Additionally, any volatile by-products can be effectively controlled through appropriate exhaust and filtration systems.

4. Oxidative Chemical Vapor Deposition (oCVD) Method

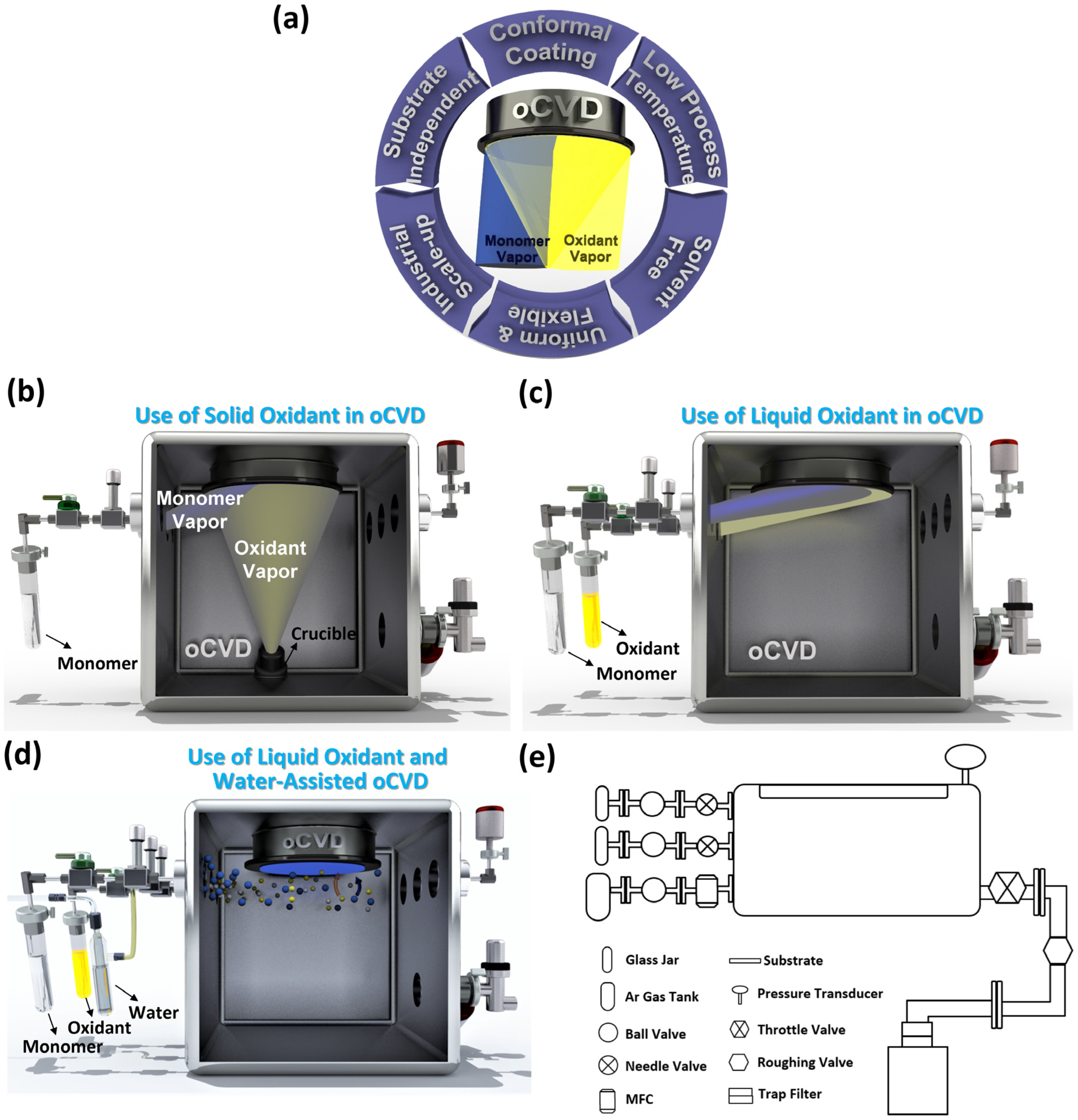

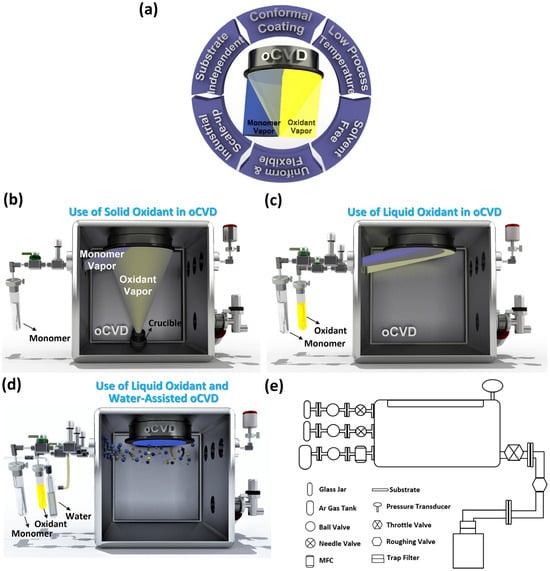

The oCVD method has emerged as a highly effective roll-to-roll (R2R) manufacturing technique, enabling the simultaneous polymerization, doping, and thin film formation to achieve conformal coatings on complex nanostructured substrates [12]. Its low to moderate deposition temperature allows the direct integration of conducting and semiconducting polymer thin films onto thermally sensitive substrates, such as plants [154], papers [7,155], textiles [112], membranes [156], carbon fibers [13,42,43], and graphene [1,15]. For commercial-scale applications, the oCVD technique offers the advantage of fabricating uniform, defect-free, and ultra-thin (<100 nm) conjugated conducting polymers over large-area substrates (>600 cm2), making it a promising method for scalable manufacturing [3,12,112]. As a versatile deposition method, oCVD provides key benefits for fabricating conjugated conducting and semiconducting polymers, such as conformal coatings, low-temperature processing, solvent-free synthesis, uniform film growth, mechanical flexibility, scalability, and substrate independence (Figure 4a) [3]. Even when alternative deposition techniques exist, CVD is often favored for producing high-quality, reproducible layers critical for optoelectronic and biomedical devices.

Figure 4.

Schematic representation of oCVD reactors. (a) Key features and benefits of the oCVD method for fabricating conjugated conducting polymers [3]. The oCVD process using (b) a solid oxidant [39], (c) a liquid oxidant [39], and (d) a liquid oxidant with water-assisted growth [40]. (e) Diagram illustrating the oCVD setup with a reduced reactor volume enabled by liquid oxidants, including dedicated delivery lines for monomers and oxidant species, along with exhaust configurations [30]. (a) Reproduced with permission [3]. Copyright 2019, Wiley. (b,c) Reproduced with permission [39]. Copyright 2019, Science. (d) Reproduced with permission [40]. Copyright 2021, Wiley. (e) Reproduced with permission [30]. Copyright 2024, Wiley.

First-generation oCVD reactors use solid oxidants, like sublimated FeCl3 vapor (Figure 4b) [39], while second-generation reactors employ liquid oxidants, such as VOCl3 and SbCl5, enabling a fully dry, cost-effective one-step process suitable for solvent-sensitive and temperature-sensitive substrates (Figure 4c) [39]. Water-assisted oCVD (W-A oCVD) enhances thin film crystallinity by reducing the π-π stacking distance through improved oxidant decomposition and increased monomer–dopant interactions, achieving a record electrical conductivity of 7520 ± 240 S/cm for PEDOT thin films fabricated with the SbCl5 oxidant (Figure 4d) [40]. In contrast to vacuum reactors that use solid oxidants and require a large crucible-to-substrate distance, liquid oxidants enable a reduced chamber volume, leading to higher precursor yield and greater efficiency in a more compact reactor design, as shown in Figure 4e [30].

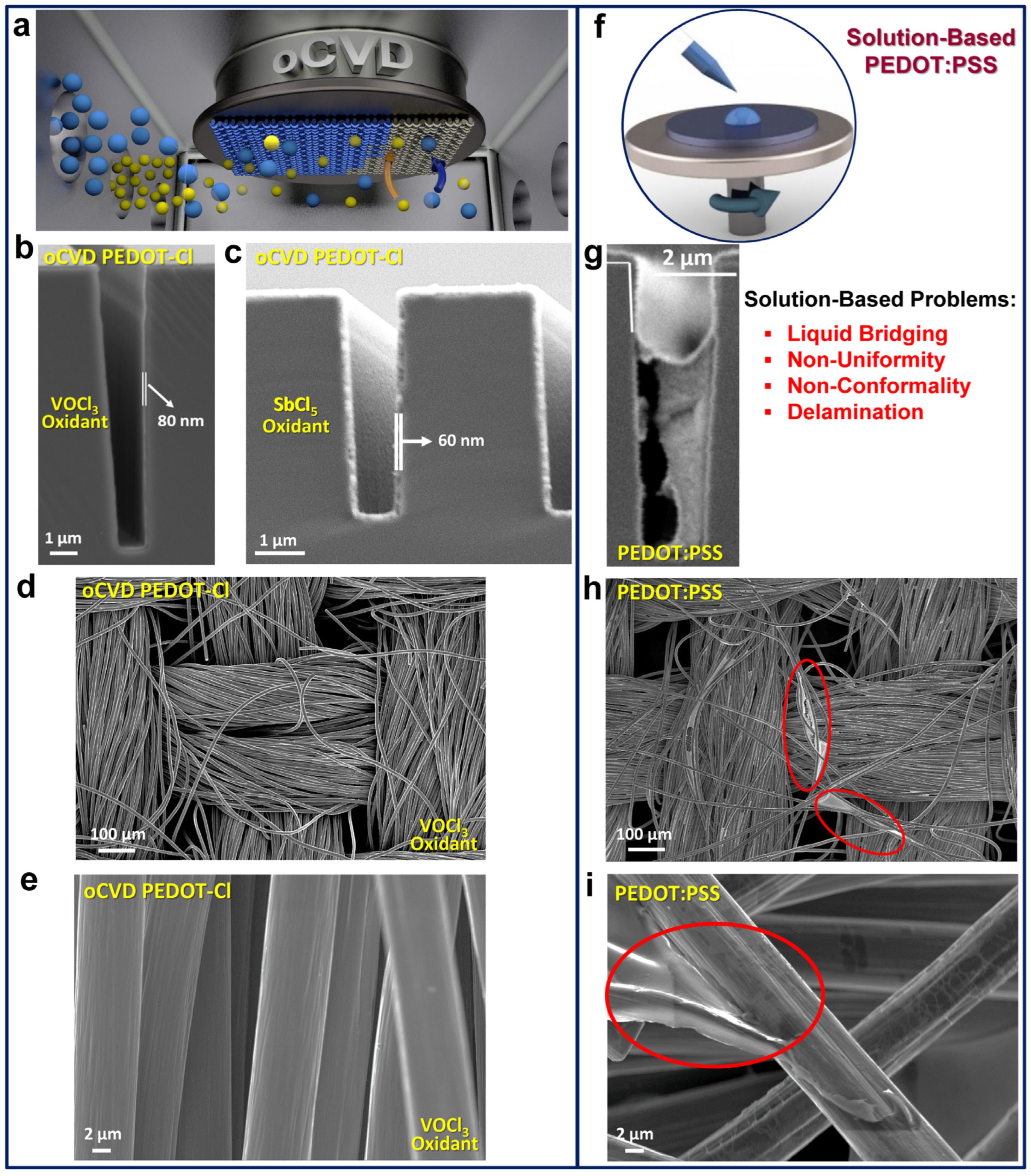

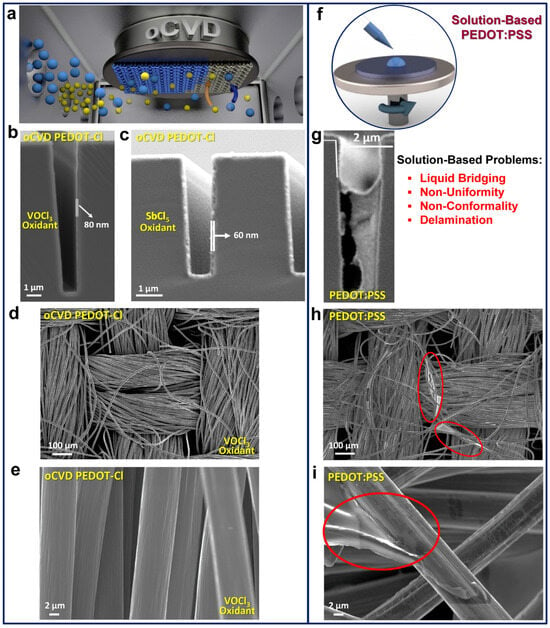

The oCVD process allows uniform deposition of conjugated conducting and semiconducting polymer thin films on complex substrates by removing surface tension effects and enabling non-directional reactant diffusion (Figure 5a–e) [34,39,43]. Unlike liquid-based methods, like spin-coating, which face issues, like liquid bridging, poor uniformity, and delamination (Figure 5f,i) [3,43], oCVD’s key advantage lies in its ability to fabricate highly conformal coatings, overcoming these limitations [30]. Achieving uniform, conformal coatings of conducting polymers offers substantial advantages for renewable energy applications. The oCVD method enables the fabrication of thin films of conjugated conducting polymers that preserve electrode geometry, sustain active redox sites, and enhance ion transport, which is essential for high-performance electrochemical energy storage devices such as supercapacitors and batteries [2,12,42,43]. In addition, the oCVD process’s ability to produce highly conformal PEDOT coatings, a widely used conjugated polymer in optoelectronics, offers a crucial advantage as a stable and efficient hole transport layer in solar cell applications, where high surface area on trenched substrates enhances light absorption by the photoactive layer [34,39].

Figure 5.

High Conformality of Conjugated Polymers Fabricated by the oCVD Method. (a) Schematic of the oCVD process, where monomer vapor (represented by blue spheres) and oxidant vapor (represented by yellow spheres) are introduced into a vacuum chamber [43]. Ultrathin, highly conformal PEDOT thin films deposited via oCVD on silicon trench wafers using (b) VOCl3 [39], and (c) SbCl5 oxidants [34]. (d,e) Highly conformal oCVD PEDOT coatings on carbon cloth electrodes for redox flow batteries [43]. (f) Schematic of the spin-coating method [3]. (g) Spin-coating method demonstrating its non-uniform coverage on silicon trench wafers [130]. (h,i) SEM images of PEDOT:PSS on carbon cloths show issues with spin-coating, including liquid bridging, non-uniformity, poor conformality, and delamination due to surface tension effects [43]. (a,d,e,h,i) Reproduced with permission [43]. Copyright 2020, Wiley. (b) Reproduced with permission [39]. Copyright 2019, Science. (c) Reproduced with permission [34]. Copyright 2024, ACS. (f) Reproduced with permission [3]. Copyright 2019, Wiley. (g) Reproduced with permission [130]. Copyright 2008, ACS.

In the oCVD process, a monomer (e.g., EDOT) and an oxidant (e.g., SbCl5) are introduced as vapors into a hot-wall vacuum chamber, where the oxidant vapor triggers step-growth polymerization on a temperature-controlled stage, forming high-quality conductive polymer films [12,30,34,43]. Deposition rates in CVD methods vary widely depending on process parameters such as chamber pressure, precursor flow rates, and deposition temperature, as well as the specific technique employed, including low-pressure CVD (LPCVD), plasma-enhanced CVD (PECVD), and oxidative CVD (oCVD). The deposition rates typically range from 1 to 10 nm/min in the oCVD method [30]. Lower deposition rates (e.g., in the range of 1–2 nm/min) produce high-quality, highly conformal thin films, while higher rates enable faster production, often at the expense of film quality [30]. Unlike solution-based methods, oCVD processes eliminate surface tension effects, preventing pinhole formation in ultra-thin polymer films, even below 10 nm [3,4,39].

The key factor for the commercial viability of conjugated conducting and semiconducting polymers fabricated by the oCVD method is the ability to produce high-quality thin films at low deposition temperatures, ensuring compatibility with various plastic substrates. Simultaneously, there is a strong demand for a one-step, fully dry process to minimize fabrication costs [12]. Flexible substrates such as polyethylene terephthalate (PET), polyethylene naphthalate (PEN), and their blends (PEN/PET) can tolerate temperatures up to approximately 150 °C [30,157]. Optimizing oCVD parameters, such as oxidant and monomer flow rates, allows the fabrication of PEDOT films using SbCl5 without the need for post-deposition acidic treatment, making it well-suited for flexible, temperature-sensitive, and solution-sensitive substrates [12]. Additionally, incorporating water vapor during deposition further enhances the performance of oCVD-deposited conducting polymers while maintaining a fully dry fabrication process [40].

4.1. Monomers Used in the oCVD Method

So far, oCVD-based homo-polymerization and co-polymerization have been successfully demonstrated for over a dozen monomers, highlighting the versatility of vapor-phase fabrication for conjugated conducting and semiconducting polymers. A key requirement for oCVD monomers is sufficient volatility, ensuring their transition into the vapor phase for effective deposition [3,54]. Unlike solution-based methods, oCVD eliminates the need for solubility-enhancing functional groups, as neither the monomers nor the resulting polymers require dissolution [3]. The elimination of solubility requirements for monomers enables the direct polymerization of unsubstituted monomers, such as thiophene [35,111], selenophene [158], and aniline [107], all of which are liquid at ambient conditions, allowing their efficient integration into the oCVD process [3].

Modified monomers have been investigated to enhance the properties of conjugated conducting polymers fabricated by the oCVD method, particularly for bandgap tuning [3,39]. Specifically, substituting thiophene at the 3- and 4-positions restricts polymerization to the 2- and 5-positions, enabling the selective formation of linear polymer chains with high stereoregularity, which enhances π-conjugation, thereby improving charge transport efficiency and electrical conductivity [3,159]. The first successfully demonstrated conjugated polymer fabricated by the oCVD method was synthesized from 3,4-ethylenedioxythiophene (EDOT) [159], which continues to be the most extensively studied oCVD chemistry to this day [3,30,34,42].

The majority of monomers utilized in the oCVD method for fabricating conjugated conducting and semiconducting polymers exist as liquids at ambient conditions [3]. However, it is important to note that solid-state monomers (such as 3,4-propylenedioxythiophene, 2,2-dimethyl-3,4-propylenedioxythiophene, 2,2′-bithiophene, 2′:5′3″-terthiophene, and thieno 3,2-b thiophene(TT)) have also been successfully employed in oCVD polymerization, demonstrating the versatility of this deposition technique [3,160]. The incorporation of functional groups into conjugated polymer thin films fabricated via the oCVD method has been successfully achieved using various monomers, enabling post-deposition functionalization with nanoparticles or biomolecules, a feature particularly advantageous for chemical sensing, biochemical detection, and smart biomaterials applications [36].

4.2. Oxidants Used in the oCVD Method

In the oCVD method, step-growth polymerization is facilitated by an oxidant, typically an evaporated metal halogen salt or halogen gas [3,11,12]. Delivering oxidants, particularly solid-phase oxidants, into the oCVD reactor via the vapor phase presents a greater challenge compared to monomer vapor delivery, primarily due to the low volatility of many solid oxidants [3]. Commonly used solid oxidants in the oCVD method include iron(III) chloride (FeCl3) [2,13,29,31,37,39,40,54,129,161,162,163] and copper(II) chloride (CuCl2) [2,3,130]. Conducting polymers deposited via the oCVD method using CuCl2 as an oxidant displayed a porous structure, primarily due to the lower oxidizing power of CuCl2, which affects the polymerization process and film formation [3]. The effectiveness of an oxidant in the polymerization process is directly influenced by its standard electrode potential, which determines its ability to facilitate electron transfer through step-growth polymerization [3,162]. CuCl2, with a standard electrode potential (also known as the redox potential of oxidant) of 0.33 V, acts as a weaker oxidant in comparison to FeCl3, which has a higher standard electrode potential of 0.77 V, leading to differences in oxidation efficiency and film morphology [3,162].

A tall reactor is commonly utilized in the oCVD technique to facilitate the sublimation of solid oxidants, such as FeCl3, within the vacuum chamber [3,11,12,161]. Within the oCVD reactor, a heated crucible sublimes the solid oxidant, directing it toward the downward-facing substrate surface [12]. To ensure the complete removal of unreacted FeCl3 and its oxidation by-products, a post-deposition acidic rinsing step is typically performed, involving rinsing with hydrochloric acid (HCl), sulfuric acid (H2SO4), and methanol (MeOH) [2,12,30]. The acidic treatment effectively dissolves residual FeCl3 while also eliminating any undesired oxidant by-products that affect the electrical conductivity and structural integrity of conducting polymers. It is important to note that the sticking probability of the oxidant, which is influenced by its volatility, plays a crucial role in determining the conformality of the deposited conjugated polymer thin films fabricated by the oCVD method. For instance, conjugated polymer thin films fabricated by the oCVD method using bromine (Br) gas as an oxidant exhibit higher conformality compared to films produced using evaporated solid oxidants, such as FeCl3 [3].

More recently, liquid oxidants reported for the oCVD process include vanadium oxytrichloride (VOCl3) [2,12,15,39,43] and antimony pentachloride (SbCl5) [12,30,33,40,42]. Liquid oxidants are often preferred over solid counterparts in the oCVD method due to their higher volatility, improved flow control, and minimal residue formation, eliminating the need for post-deposition acidic rinsing [3,12,39]. The properties of conjugated conducting and semiconducting polymers fabricated via oCVD can be tailored by adjusting key process parameters, such as oxidant saturation ratio (OSR) [39,40], deposition temperature [25,30,41,42], chamber pressure [2,3,11,12], water-assisted growth techniques [12,33,40], and the choice of oxidant [3,12,39]. The effectiveness of an oxidant in the oCVD process is primarily determined by its volatility, thermal stability, and ability to drive the polymerization reaction forward [2,12,164]. The variation in oxidizing strength influences polymerization kinetics, film density, and the overall structural characteristics of the resulting conducting polymer, resulting in distinct morphological differences depending on the chosen oxidizing agent [3]. A summary of the commonly utilized oxidants in different fabrication processes for the conjugated conducting polymers is presented in Table 3.

Table 3.

Overview of common oxidants in conjugated conducting polymer fabrication. This table highlights widely used oxidants in the synthesis of conjugated conducting polymers, covering both solution-based and vacuum-based fabrication techniques [2]. Reproduced with permission [2]. Copyright 2024, Royal Society of Chemistry.

4.3. Step-Growth Polymerization Mechanism in the oCVD Method

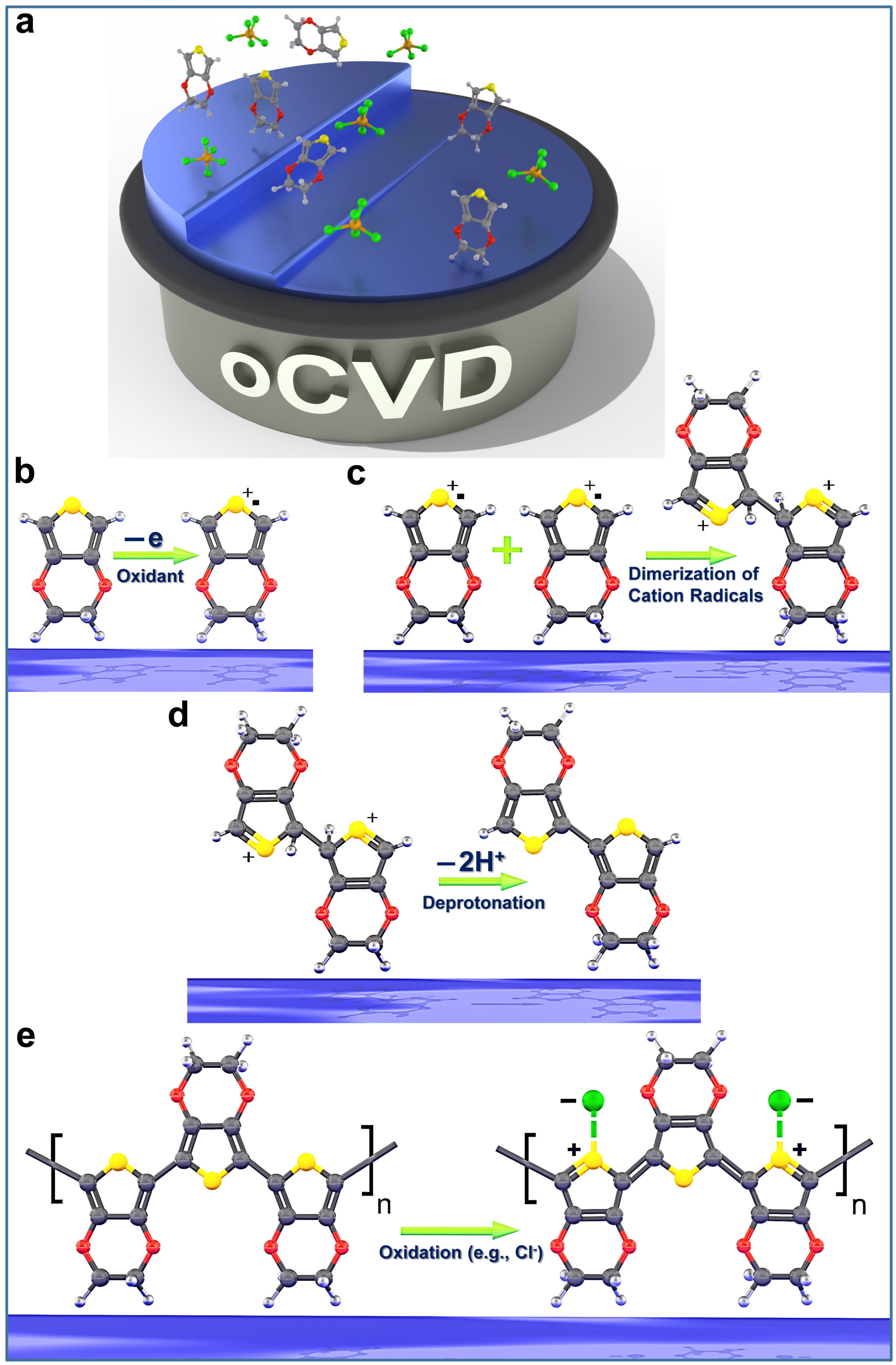

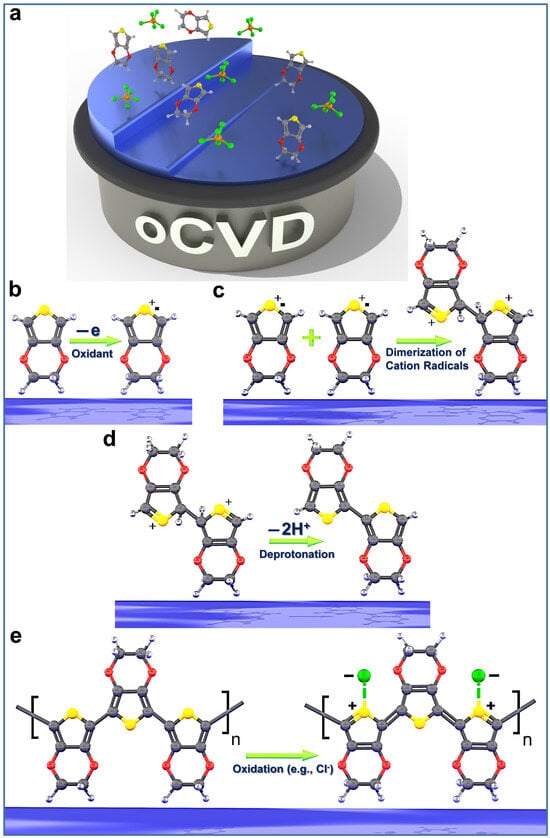

In the oCVD process, vapor phases of monomer and oxidant species are introduced into the deposition chamber, where they are directed onto a temperature-controlled substrate, as illustrated in Figure 6a [12]. Upon contact of precursor vapors with the substrate, adsorption occurs, followed by spontaneous surface polymerization reactions. This eliminates the need for external excitation sources, such as plasma or photonic energy, allowing the polymerization to proceed efficiently under controlled conditions [3,12].

Figure 6.

Schematic representation of step-growth polymerization in the oCVD process. (a) Vapor phases of the monomer (e.g., EDOT) and oxidant (e.g., SbCl5) are introduced onto a temperature-controlled substrate [12]. The polymerization follows a sequential process: (b) Oxidation of the EDOT monomer to generate radical cations, (c) Formation of dimers through radical coupling, (d) Deprotonation of the dimer to establish conjugation, and (e) Incorporation of counterion dopants into the PEDOT backbone. The spheres in different colors represent specific elements: dark gray for carbon, yellow for sulfur, red for oxygen, white for hydrogen, and green for chlorine [12]. (a–e) Reproduced with permission [12]. Copyright 2024, Springer.

The kinetics of polymerization in oCVD involves multiple sequential steps, including the adsorption of monomer and oxidant vapors onto the substrate, their surface diffusion, heterogeneous nucleation, and subsequent film growth through step-growth polymerization [53]. The polymerization rate (deposition rate) is significantly influenced by key parameters, such as oxidant concentration (also known as the oxidant saturation ratio), monomer reactivity, and deposition temperature, all of which collectively determine the growth rate, molecular weight distribution, and uniformity of the polymer film [12]. Higher deposition temperatures generally result in a lower deposition rate [30,34], while an increased oxidant concentration (or equivalently, a higher oxidant saturation ratio), leads to an increased deposition rate in conductive polymers fabricated by the oCVD method [12,39]. While higher oxidant concentrations accelerate the reaction rate by enhancing monomer oxidation, an excessive amount of oxidant vapors, quantified by the oxidant saturation ratio, can induce overoxidation and conjugated backbone chlorination, disrupting the semi-crystalline characteristics and degrading charge carrier mobility and overall electrical conductivity [40,42].

From a thermodynamic perspective, the polymerization reaction in oCVD is believed to be governed by the Gibbs free energy change (), which dictates whether the reaction occurs spontaneously ( where, is the enthalpy change, is the absolute temperature, and is the entropy change). For a favorable polymerization process, ΔG should be negative. The redox potential of the oxidant (), which reflects its tendency to gain electrons and thereby its ability to oxidize the monomer, plays a crucial role in determining the feasibility of monomer oxidation [3,162]. Generally, the oxidant’s redox potential must be sufficiently high to effectively accept electrons from the monomer, ensuring efficient oxidation and subsequent polymerization. Furthermore, the enthalpy change (ΔH) associated with bond dissociation and formation impacts the exothermic or endothermic nature of the reaction, while entropy (ΔS) accounts for the disorder introduced in the deposited thin film during vapor-phase polymerization.

The formation of polymer thin films in oCVD follows a step-growth polymerization mechanism, which occurs through the following sequential steps [3,12]:

- (1)

- Oxidation of Monomer: The oxidizing agent reacts with the EDOT monomer, generating radical cations through electron transfer (Figure 6b) [12]. This initiates the polymerization process by creating highly reactive species.

- (2)

- Dimerization: The radical cations undergo coupling, leading to the formation of stable dimer structures (Figure 6c) [12]. This step is crucial for chain elongation and determines the growth kinetics of the polymer film.

- (3)

- Proton Scavenging and Dimer Stabilization: The oxidizing agent’s anions act as proton scavengers, neutralizing excess protons from the dimer and stabilizing the newly formed structure (Figure 6d) [12]. This step enhances polymer integrity and prevents unwanted side reactions.

- (4)

- Propagation: The oxidizing agent continues to react with the stabilized dimer, producing additional radical cations. This process repeats continuously, allowing the polymer chains to grow in a controlled manner across the substrate surface.

- (5)

- Doping and Structural Stabilization: Some positively charged heterocyclic rings within the polymer backbone undergo stabilization through interactions with counter-ion dopants. This final step enhances the electrical conductivity and structural integrity of the polymer film, completing the polymerization process (Figure 6e) [12].

The doping process (exhibited in Figure 6e), results in the delocalization of charges along the conjugated polymer backbone, enabling efficient charge transport and facilitating electrical conductivity. The degree of conductivity in the polymer is directly influenced by the extent of charge delocalization and the integration of counter-ion dopants within the structure [5,12]. The counter-ion dopants stabilize the positive charges on the polymer chains, effectively modulating the electronic properties of the conjugated conducting polymers with the p-type semiconducting characteristics [30]. Unlike chain-growth polymerization, where molecular weight gradually increases as monomers are added sequentially, step-growth polymerization in the oCVD method follows an exponential progression [11]. The step-growth polymerization occurs through sequential coupling reactions, leading to the formation of progressively larger molecular units—dimers, tetramers, octomers, and eventually high-molecular-weight 2N-mers [3,11,12]. The step-growth polymerization mechanism enables the rapid formation of long polymer chains, resulting in thin films with well-defined morphology and enhanced conductivity.

A key theoretical assumption in PEDOT polymerization is that the maximum theoretical dopant-to-monomer unit ratio is 1:3, meaning one dopant ion is incorporated for every three monomer units [1,3,11,12,165]. However, experimental evidence has revealed deviations from this theoretical limit, with some reports indicating heavily doped PEDOT conjugated backbones, where the dopant-to-monomer unit ratio reaches 1:2 [12,39,40,42]. This increased doping level suggests enhanced charge carrier density, which can significantly impact the electrical properties and stability of the polymer, making it crucial to optimize doping conditions for specific applications.

4.4. Precursor Flow Rates and Partial Pressure in the oCVD Method

Achieving precise control over the flow rates of monomers and oxidants in the oCVD system is crucial for optimizing deposition conditions, ensuring uniform thin-film formation, and maintaining process stability. In the oCVD method, regulating the flow rates of monomer and oxidant species differs from the conventional use of mass flow controllers (MFCs) designed for standard gases. Since dedicated MFCs for reactive species used in the oCVD method are not always available, an alternative approach to flow rate control and extraction is implemented during the deposition process. Converting the reactant flow rate into standard cubic centimeters per minute (SCCM) requires degassing the oCVD reactor and applying fundamental principles of flow regulation and vacuum deposition design. The initial step in calculating the flow rates of precursor vapors in SCCM for the oCVD method is defining the reactor volume. The reactor volume (V) is determined using the well-known Boyle–Mariotte law , which establishes the relationship between pressure and volume under ideal gas conditions within the reactor [12]. Once the oCVD reactor volume is determined, the flow rates of monomer and oxidant precursor vapors can be derived in SCCM by analyzing the rate of vapor pressure change over time (), as described in the following equation [30,39,40]:

where represents the reactor volume, is the pressure recorded by the pressure transducer, denotes the rate of vapor pressure change over time for the reactants, is set at 0 °C (273.15 K) as a reference temperature, while denotes to the temperature of the inner wall of the vacuum reactor.

Once the monomer and oxidant flow rates are determined in SCCM units and the deposition pressure is known, the partial pressure of each reactant can be calculated. The partial pressure represents the individual contribution of each species to the total pressure within the deposition chamber, providing essential insight into the reactant concentration and its effect on thin film growth dynamics [12]. The partial pressure of the reactant species can be calculated using the following equation [12]:

The above equation ensures that the proportion of oxidant and monomer in the reaction environment is accurately defined, which is critical for controlling oxidation levels, doping efficiency, and overall thin film properties.

4.5. Saturation Precursor of Reactant Species in the oCVD Method

The saturation pressure () of the monomer and oxidant species at a given deposition temperature can be calculated using the Clausius–Clapeyron equation [12,39,40]:

where signifies the known pressure of reactants at approximately room temperature, represents the enthalpy of vaporization, and denotes for the gas constant.