Embedded Electronic Sensor for Monitoring of Breathing Activity, Fitting and Filter Clogging in Reusable Industrial Respirators

Abstract

:1. Introduction

2. Material and Methods

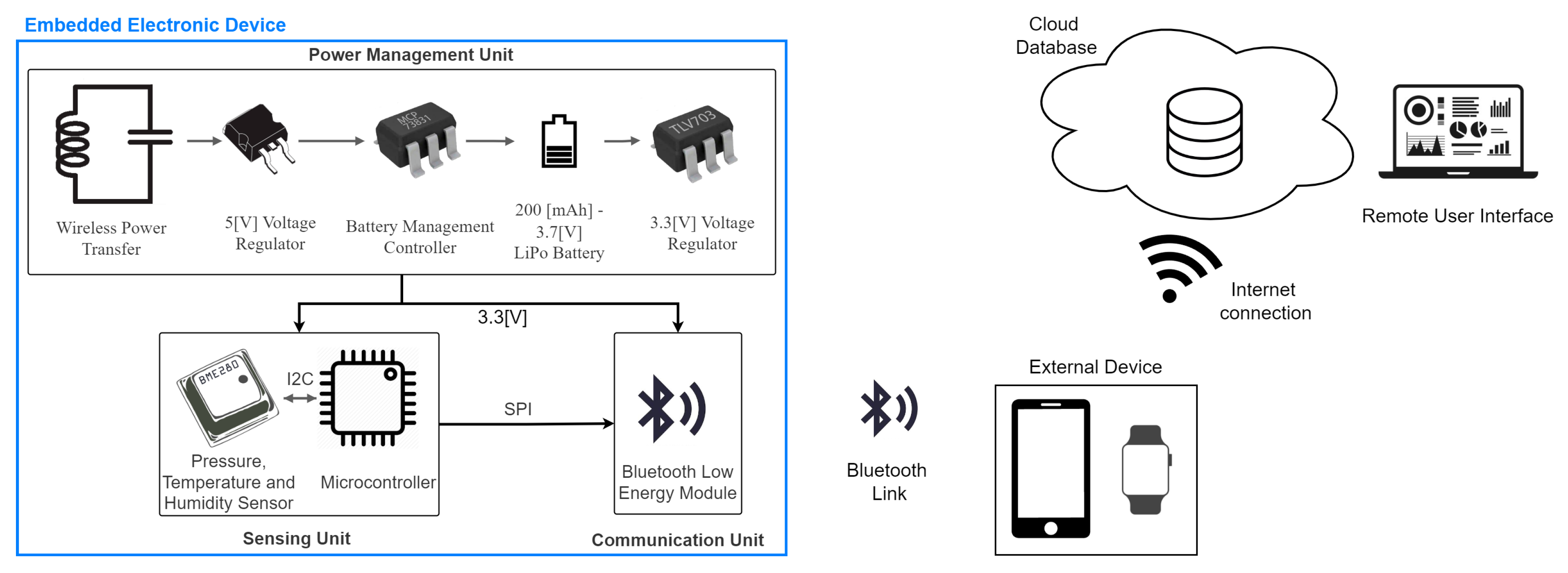

2.1. Electronic Design

2.1.1. Sensing Unit

- The MCU initialize the system and configure the BLE module for advertising mode, waiting for a connection attempt.

- The MCU uses a timer interruption, configured at 10 Hz for sampling P, T, and rH signals.

- In real-time, if there is a BLE connection, the MCU send the samples measured and the device battery level to an external device (P.C. or Smartphone).

- In case of any failure, the system continues working except in a power failure where the embedded electronic device is turned off.

2.1.2. Wireless Communication Unit

2.1.3. Power Supply Management Unit

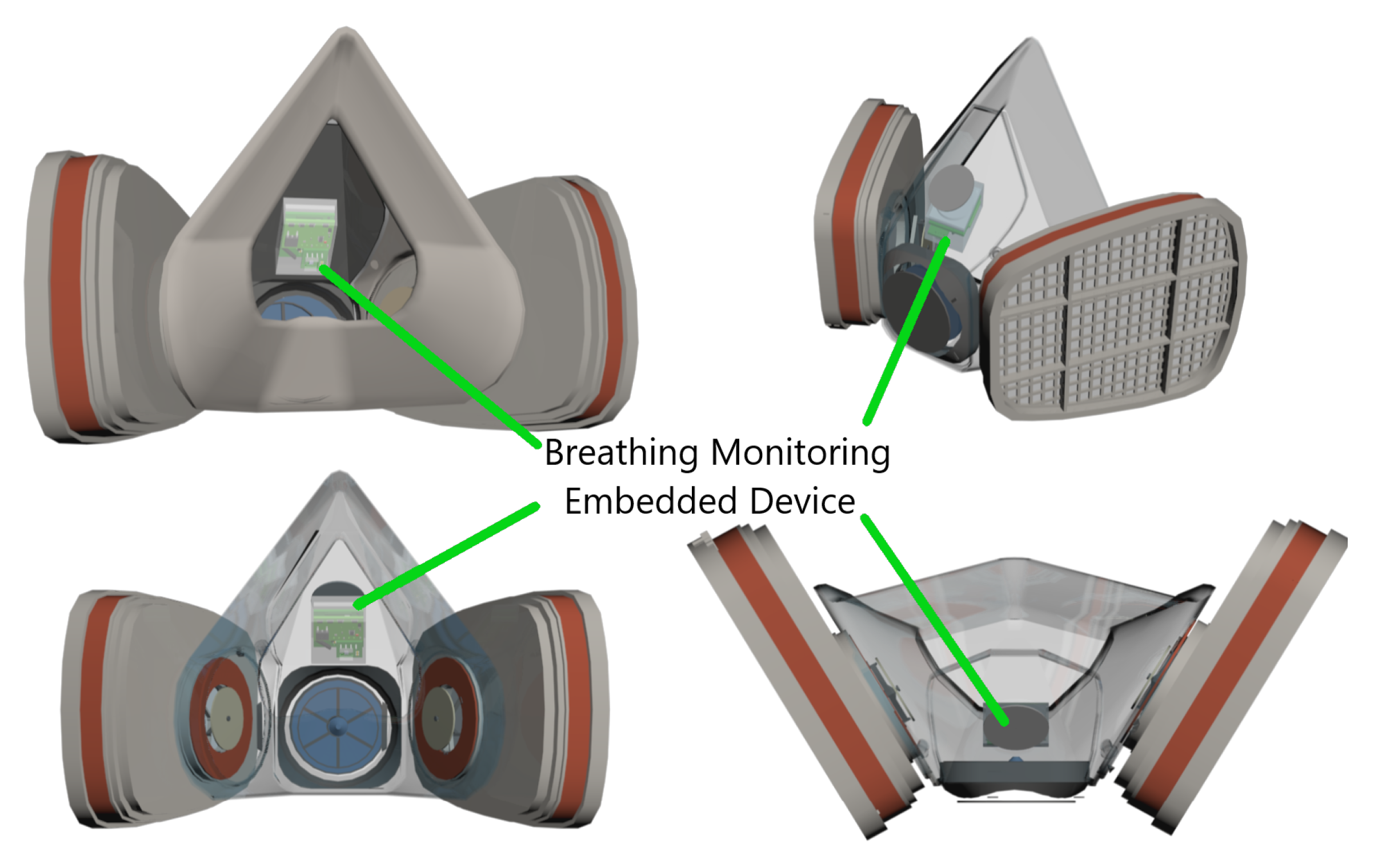

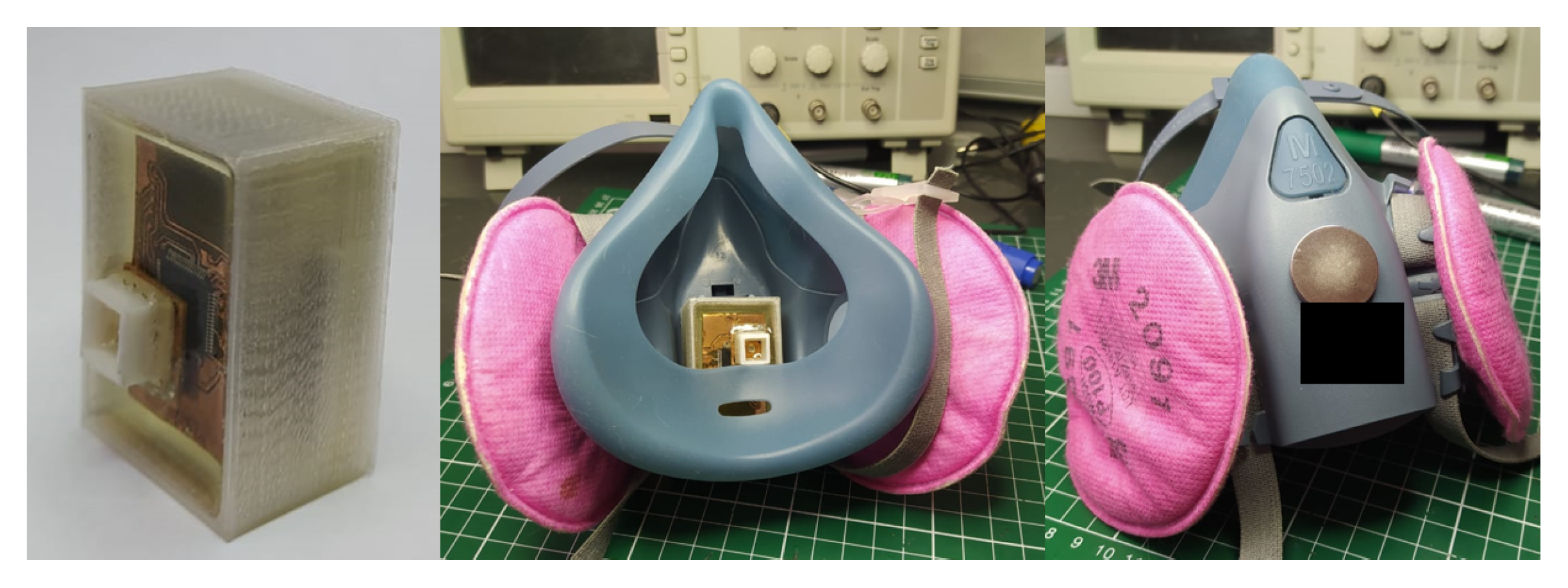

2.1.4. Electronic Sensor Implementation

2.2. Encapsulation Process

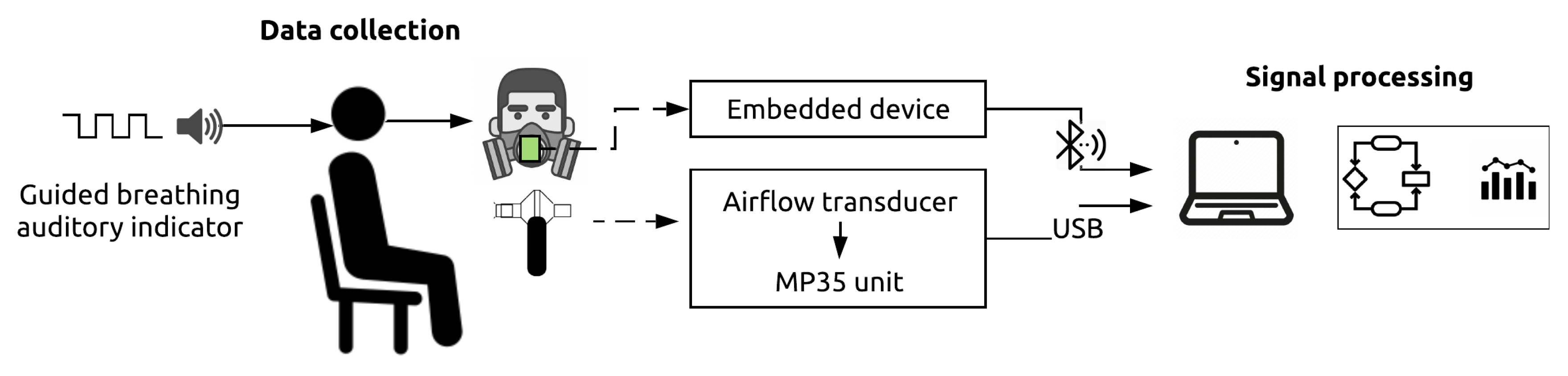

2.3. Experimental Validation

2.3.1. Participants

2.3.2. Materials

2.3.3. Data Recording Protocol

- Breathing rate evaluationThe participants remained seated in a relaxed position and synchronized their breathing with an auditory indicator, which marked the beginning and the end of inspiration and expiration. Rate values of 10, 13, 16, 19, and 22 BPM were used. The recording lasted for 5 minutes for each breathing rate.

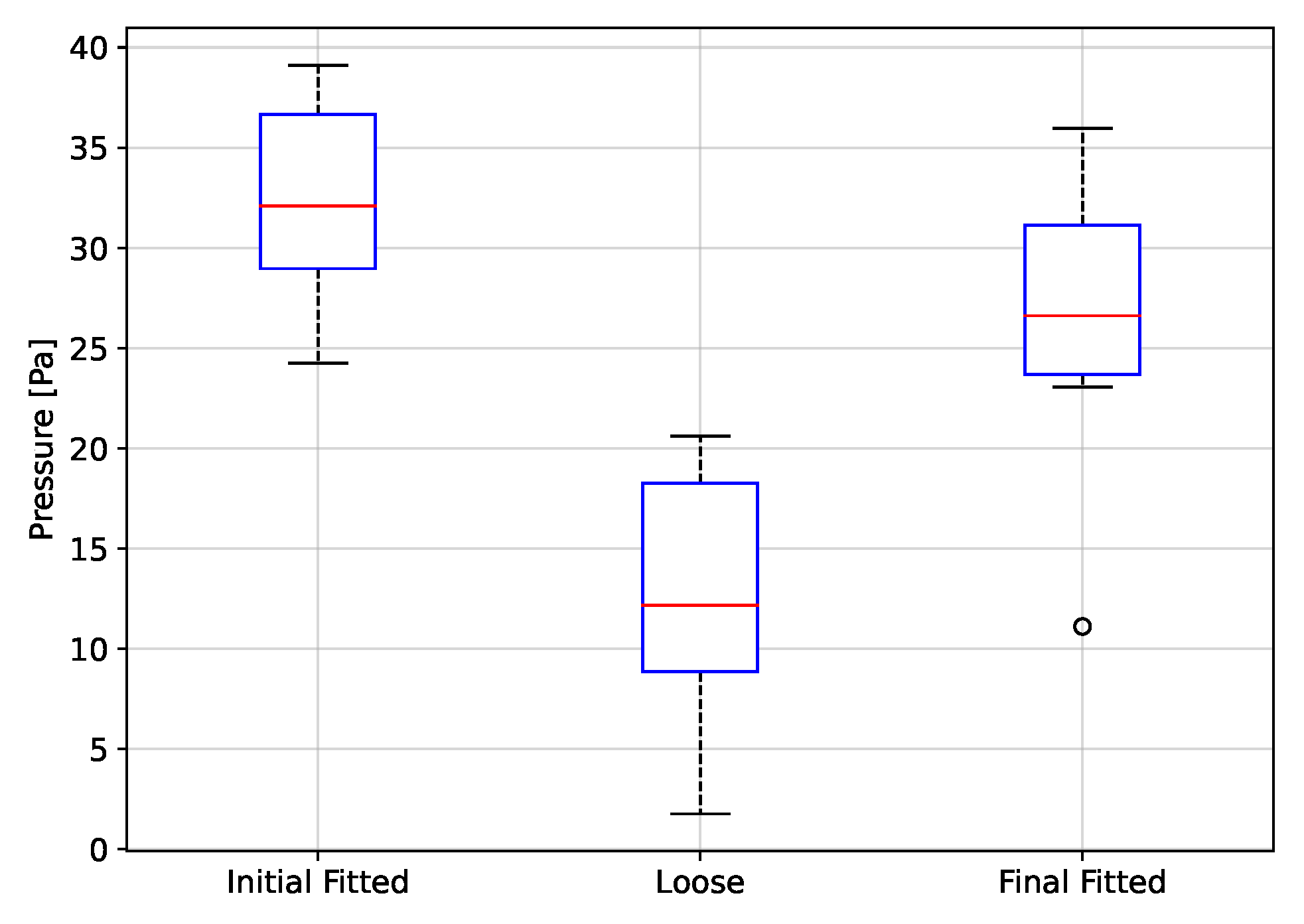

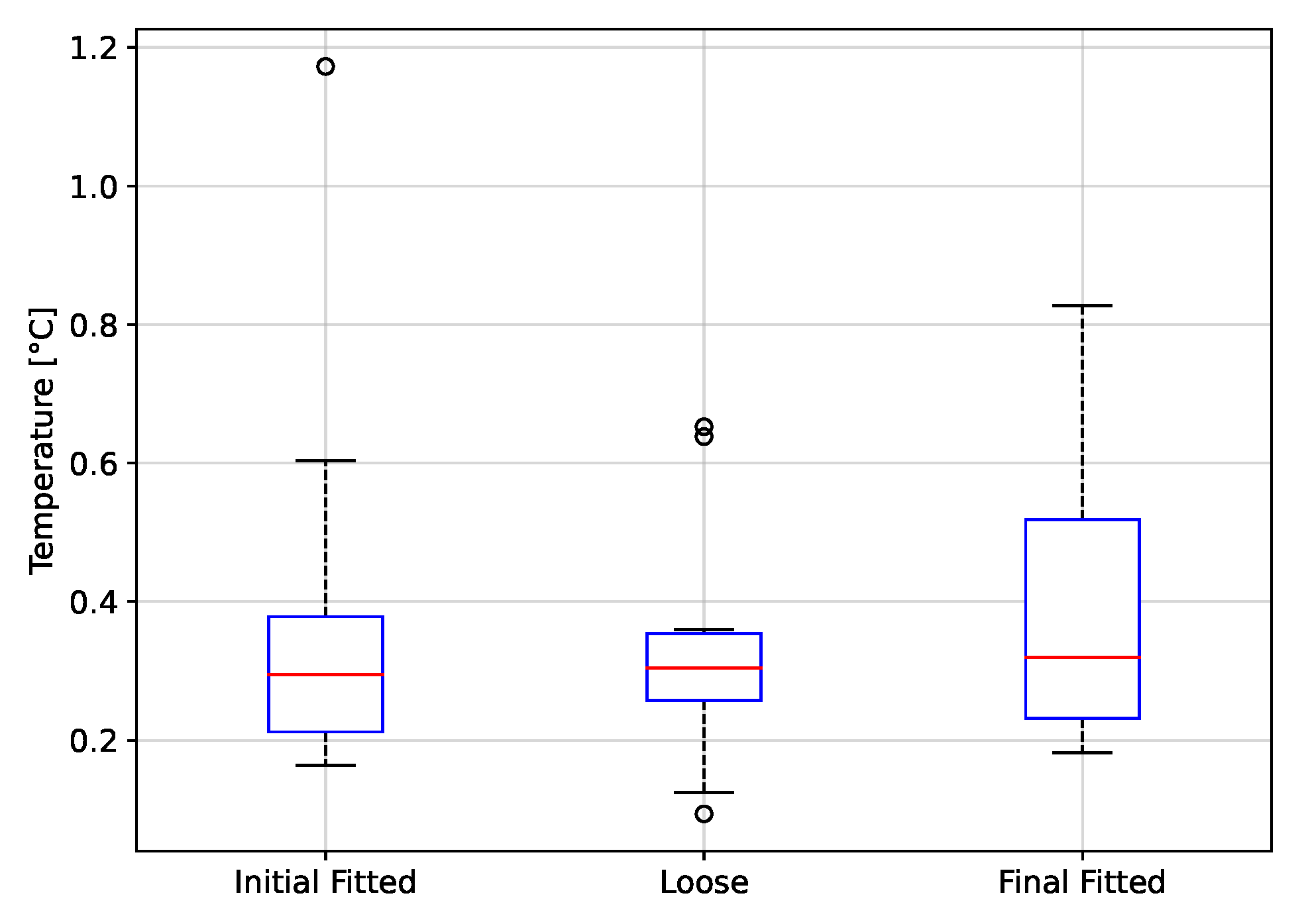

- Fitting condition evaluationThe participants remained seated in a relaxed position. The subjects were asked to breathe using a fitted respirator, named as Initial Fitted condition. After 5 min of recording, the respirator stripes were loosened (See Figure 7). Ten minutes after, the respirator stripes were tightened again, named as Final Fitted condition. The spontaneous breathing of the participant was acquired during 15 minutes.

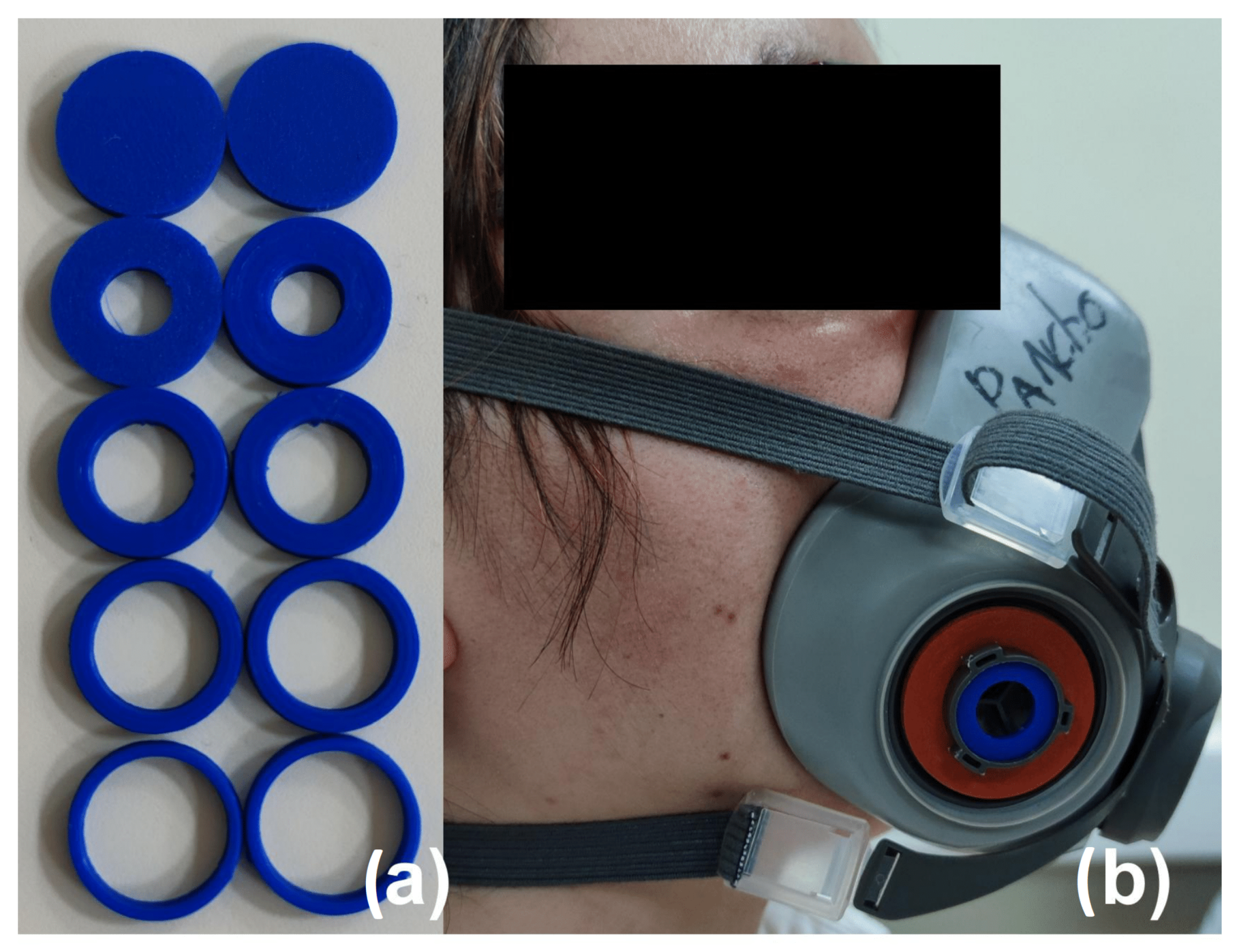

- Filter clogging evaluationThe participants remained seated in a relaxed position. This protocol was applied six times per subject. Each time, a 3D printed PLA piece was put in the filter fixations, in the external part of the respirator. Each plastic piece represents a level of clogging (0, 20, 40, 60, 80, and 100%). Figure 8 shows the plastic pieces and an example of a plastic piece located in the respirator. The spontaneous breathing of the participant was acquired during 5 minutes for each clogging level.

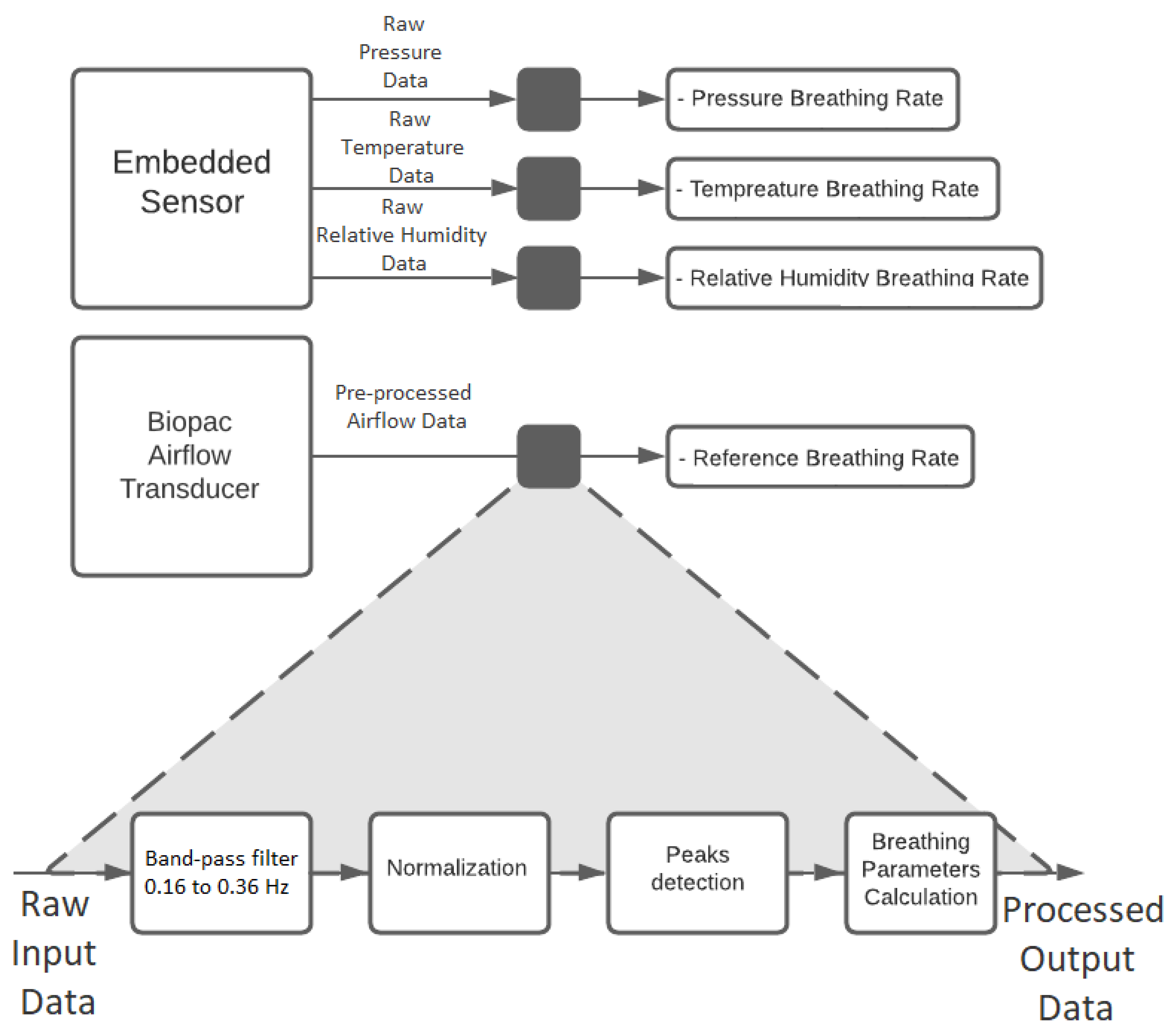

2.4. Data Analysis

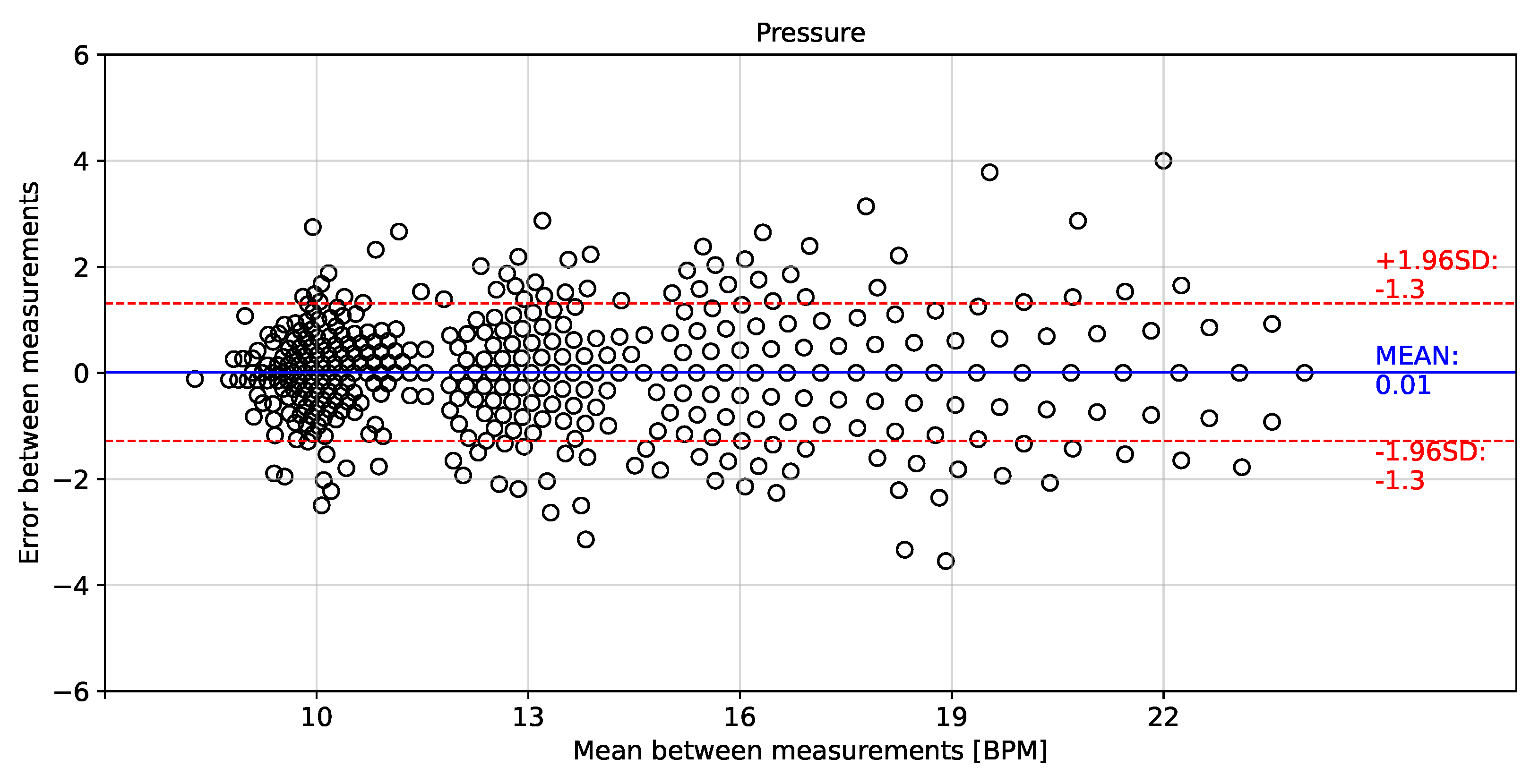

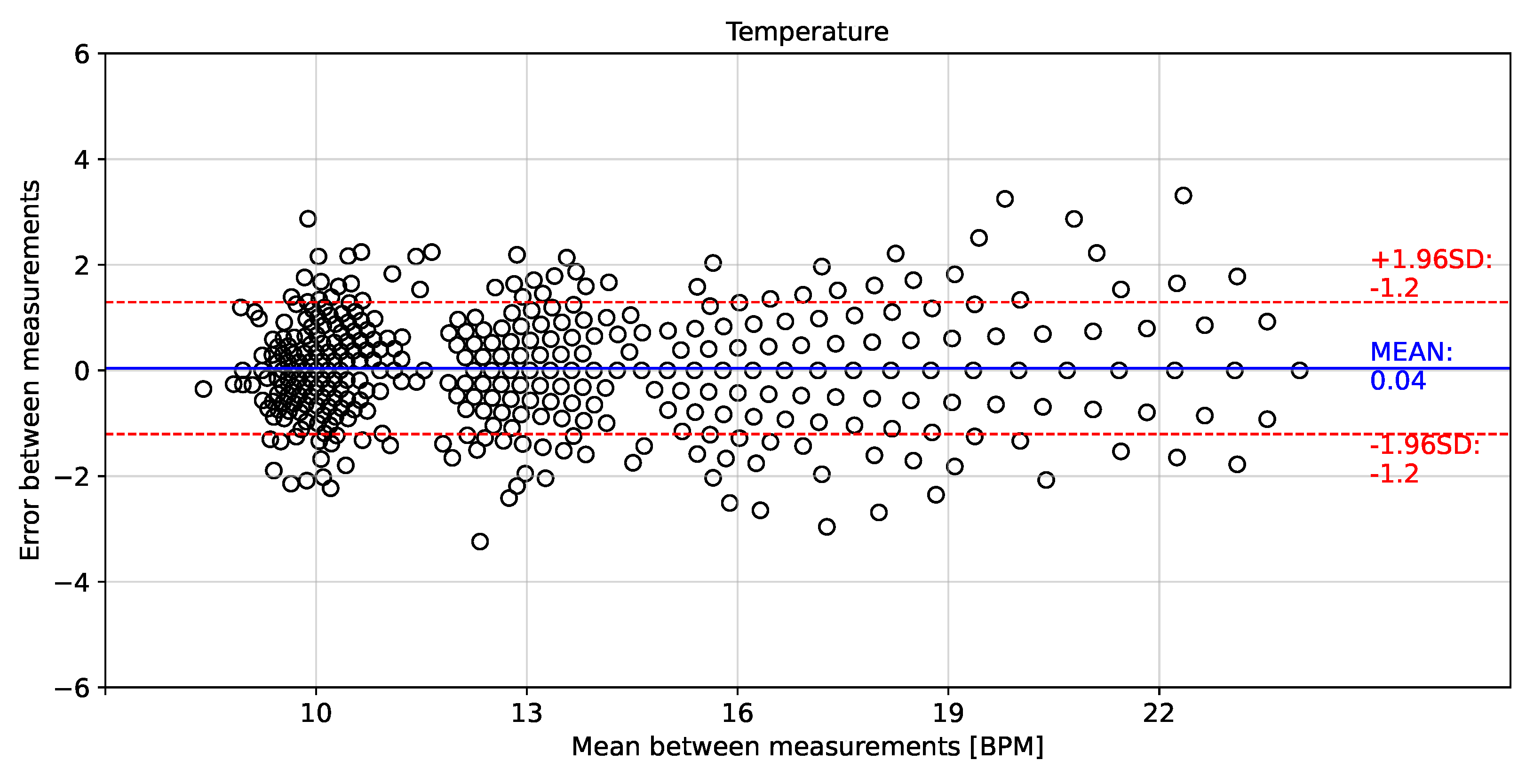

- Breathing rate evaluation.Firstly, the P, T, and rH signals were filtered by a zero-phase 4th order band-pass Butterworth filter from 0.16 Hz to 0.36 Hz. The variation pattern of the sensors while recording breathing differs between them. The beggining of an inspiration (inspiratory event) for P and A.F. is given by the falling inflection point of a cycle, whereas the start of an expiration (expiratory event), by the rising inflection point. On the other hand, for T and rH the inspiratory and expiratory event correspond to the local maxima and minima of a cycle, respectively. Therefore, two algorithms were implemented to determine the inspiratory and expiratory events. A peak-detection-based algorithm was used [37] to identify the inspiratory and expiratory events on the AF and P signals’ first derivative and on the T and rH signals. Then, instantaneous breathing rate () was obtained calculating the inverse of the difference between the time of occurrence of local maxima () in seconds multiplied by 60 (see Equation (1)).where (i) corresponds to the number of the detected local maxima.

- Fitting condition evaluation.Data were segmented for three conditions: (A) Initial Fitted condition, (B) Loose condition, and (C) Final Fitted condition. To assess the separability between the three conditions, a two-sided paired t-test was performed ( = 0.05) after checking normal distributions with the Shapiro–Wilk test. The T-test was applied three times. First, to assess if the initial fitted condition can be discriminated from the loose condition. Second, to assess if the loose condition can be discriminated from the final fitted condition. Third, to assess if the data distribution is the same (or similar) during the initial and final fitted conditions. For reliability and repetitivity of the fitting condition evaluation, it is expected to obtain the same data distribution during the initial fitted condition and the final fitted condition.

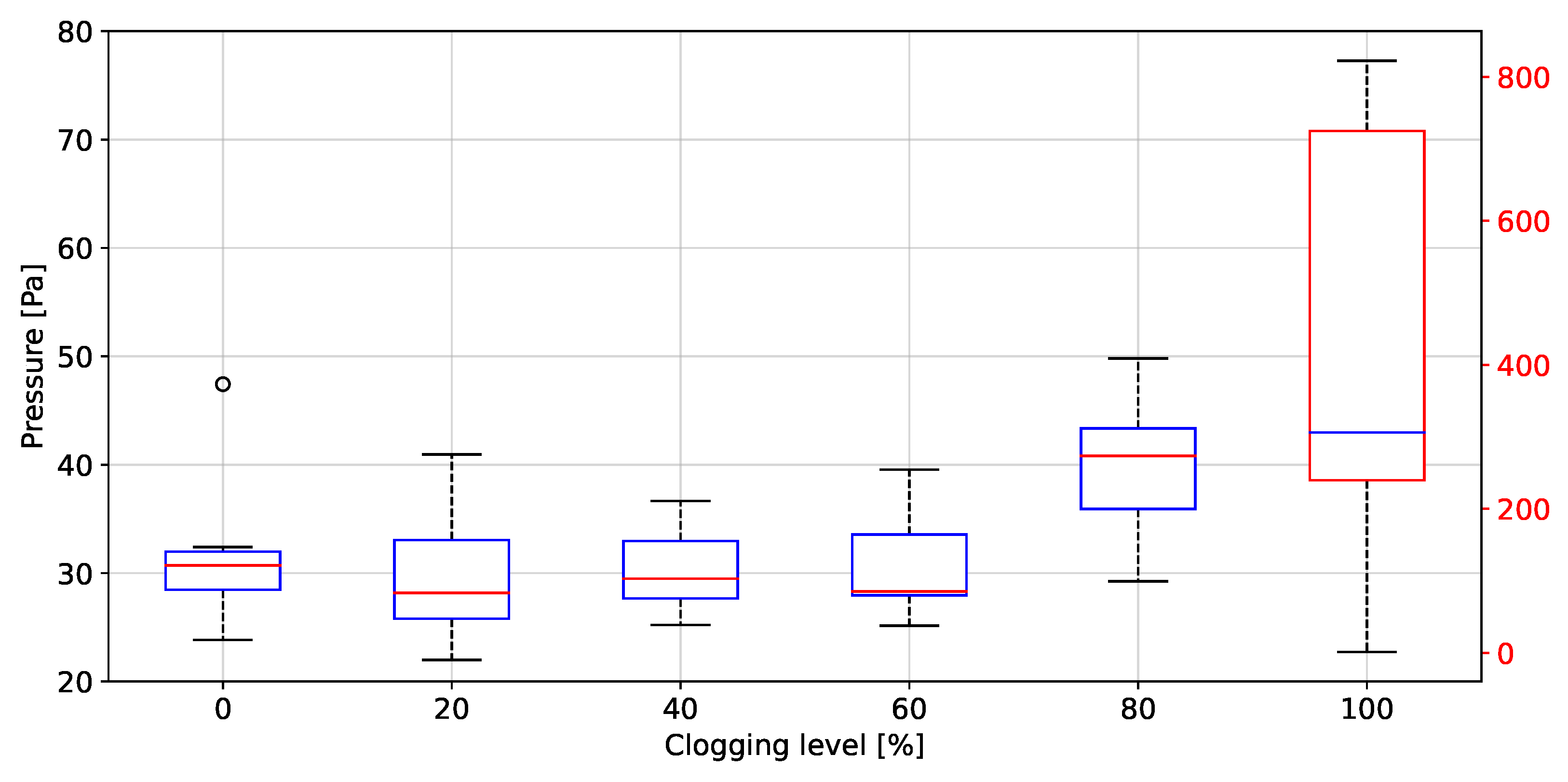

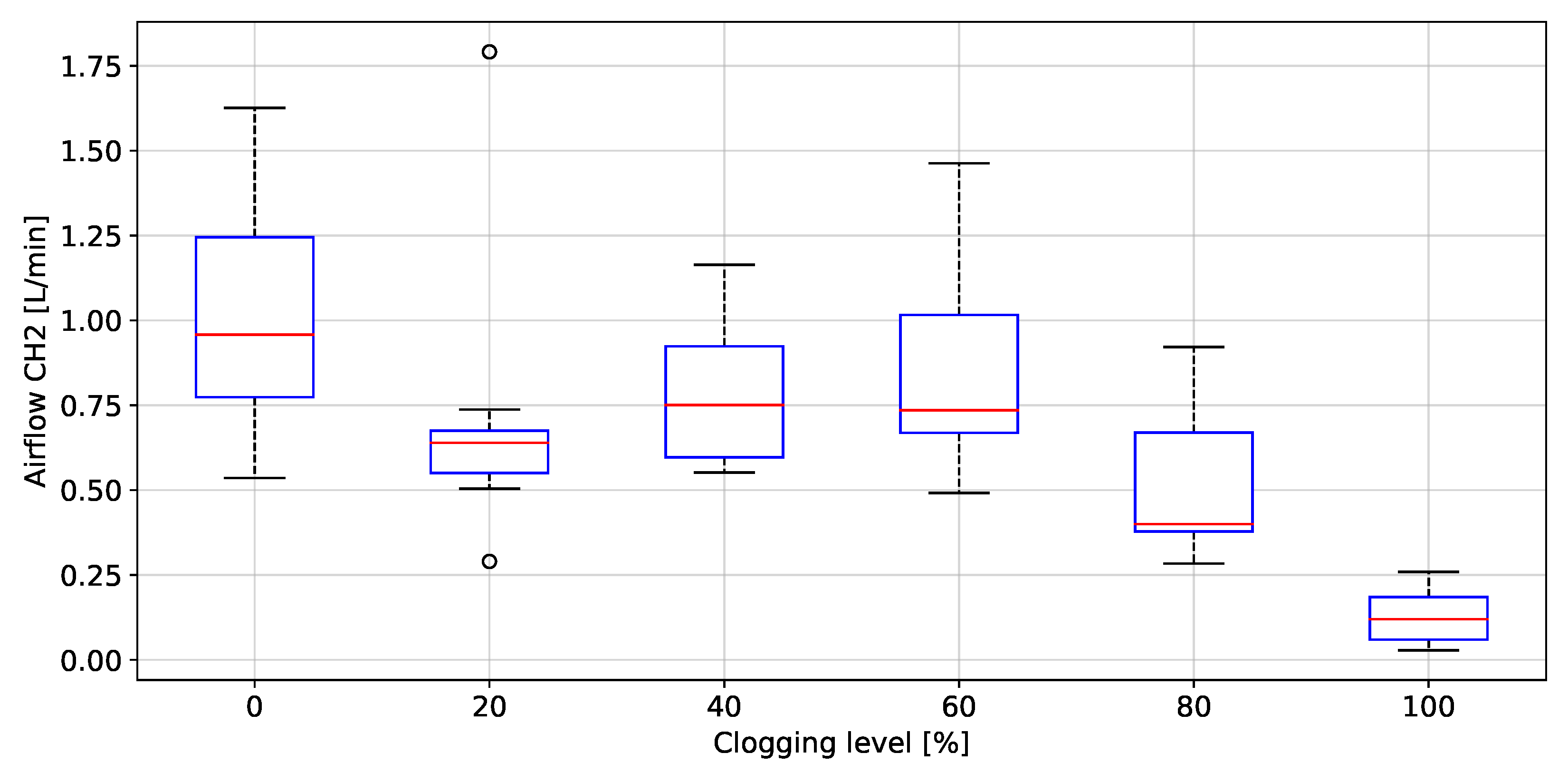

- Filter clogging evaluationData were grouped by clogging level: 0, 20, 40, 60, 80, and 100%. To evaluate the effect of clogging level on the peak-to-peaks values of the different signals, multiple comparisons were performed with one-way Analysis of Variance (ANOVA) followed by a post hoc comparison ( = 0.05) using Tukey’s method.

3. Experimental Results Analysis

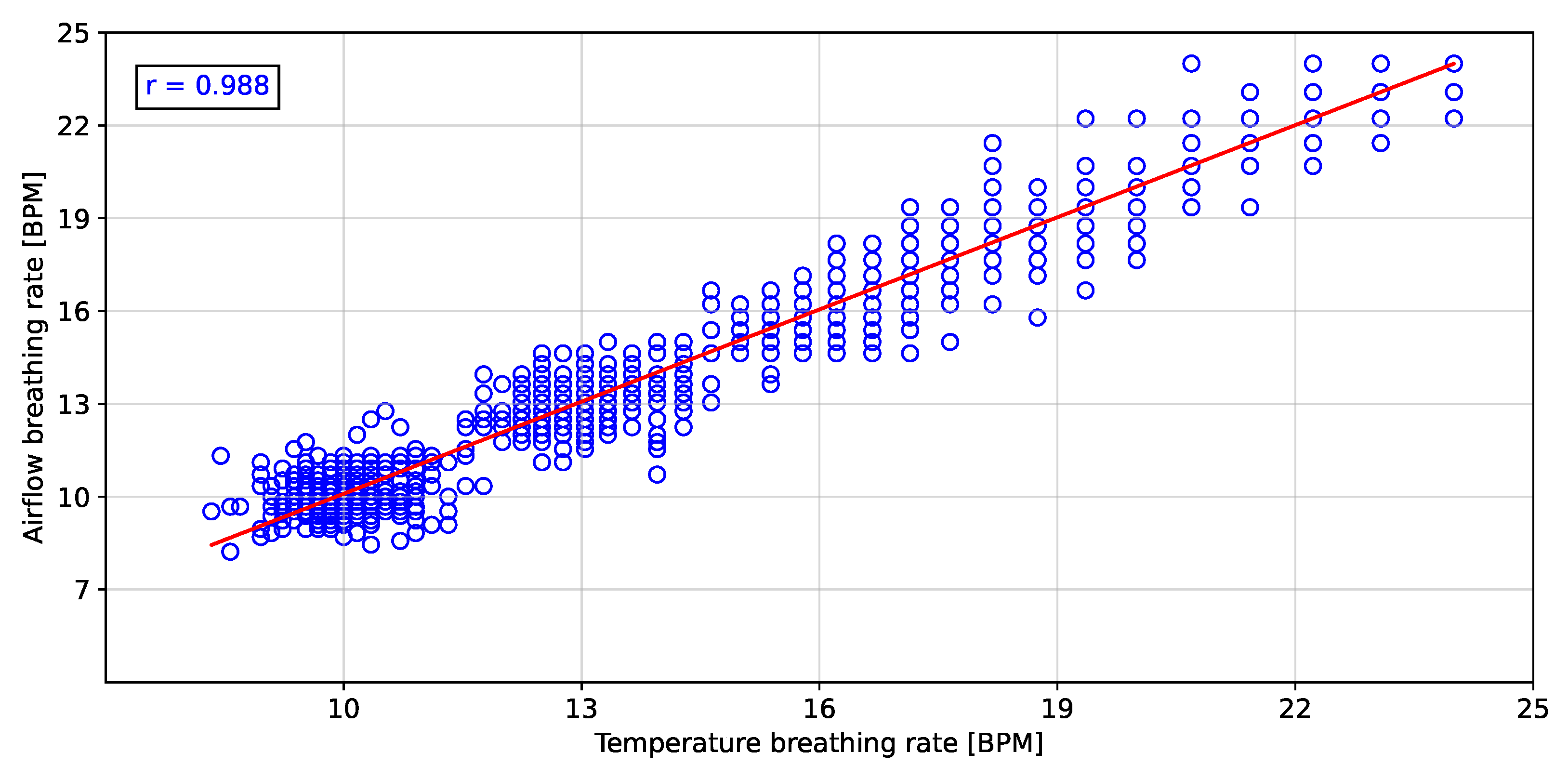

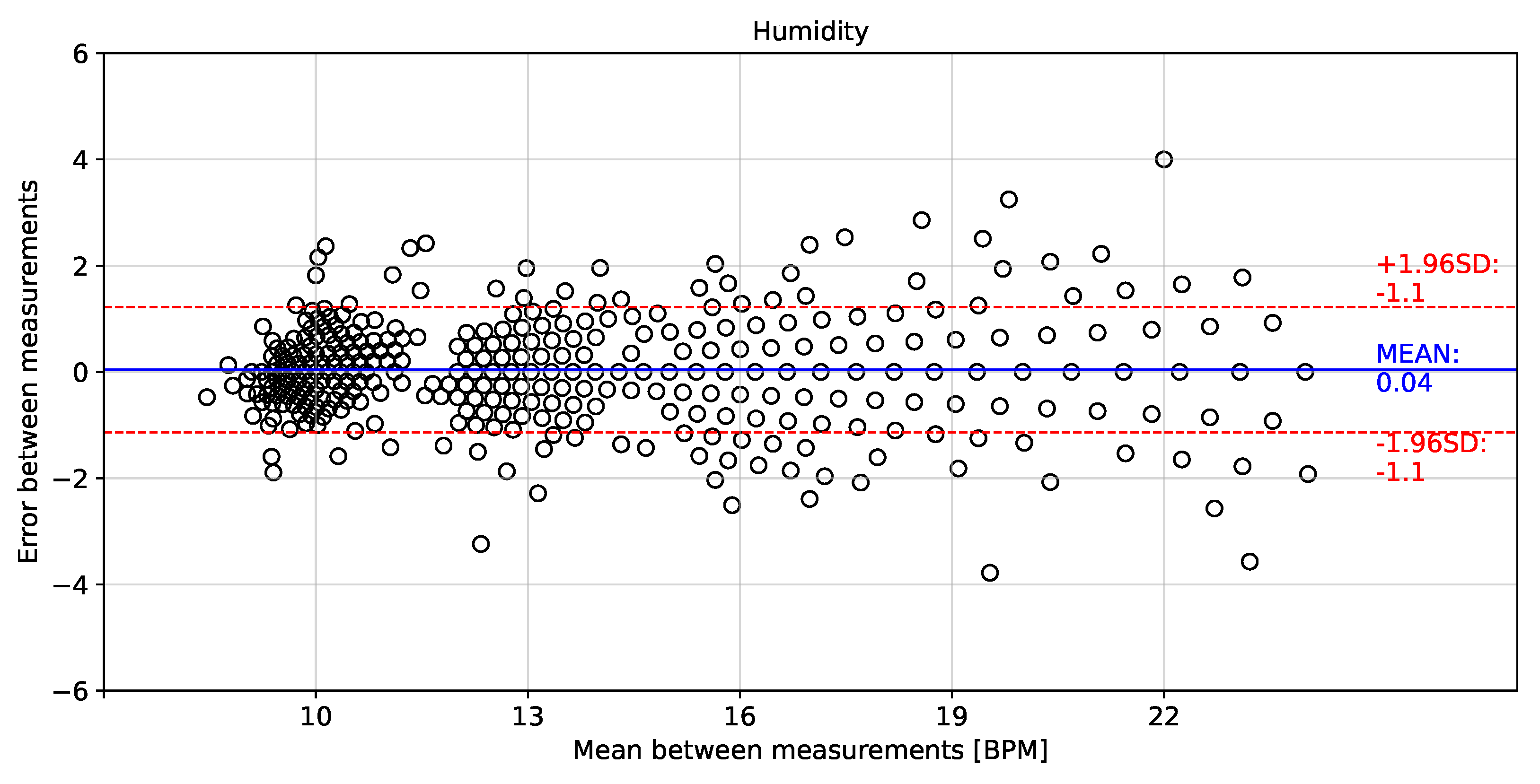

3.1. Breathing Rate Evaluation

3.2. Fitting Condition Evaluation

3.3. Filter Clogging Evaluation

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- NIOSH. Work-Related Respiratory Diseases. Available online: https://wwwn.cdc.gov/eworld/Set/Work-Related_Respiratory_Diseases/88 (accessed on 7 May 2020).

- BLS. Occupational Safety and Health Definitions. Available online: https://www.bls.gov/iif/oshdef.htm (accessed on 5 October 2020).

- NIOSH. Worker Medical Monitoring. Available online: https://www.cdc.gov/niosh/topics/surveillance/ords/workermedicalmonitoring.html (accessed on 7 May 2020).

- U.S. Bureau of Labor Statistics Industry Injury and Illness Data—SNR07. Illness Cases by Category of Illness—Rates, Counts, and Percent—Industry Division—2020. Available online: https://www.bls.gov/iif/oshsum.htm#01Illness_Data (accessed on 25 September 2022).

- U.S. Bureau of Labor Statistics Census of Fatal Occupational Injuries (CFOI)—Current and Revised Data—Industry by Event or Exposure. 2020. Available online: https://www.bls.gov/iif/oshcfoi1.htm (accessed on 25 September 2022).

- TSI. Incorporated Quantitative Respirator Fit Testing. Available online: https://tsi.com/solutions/solutions-by-application/quantitative-respirator-fit-testing/ (accessed on 4 October 2020).

- OSHA. Respiration Protection VII. Fit Testing. Available online: https://www.osha.gov/dts/osta/otm/otm_viii/otm_viii_2.html#7 (accessed on 4 October 2020).

- Zheng, Y.N.; Yu, Z.; Mao, G.; Li, Y.; Pravarthana, D.; Asghar, W.; Liu, Y.; Qu, S.; Shang, J.; Li, R.W. A Wearable Capacitive Sensor Based on Ring/Disk-Shaped Electrode and Porous Dielectric for Noncontact Healthcare Monitoring. Glob. Chall. 2020, 4, 1900079. [Google Scholar] [CrossRef] [PubMed]

- Kundu, S.K.; Kumagai, S.; Sasaki, M. A Wearable Capacitive Sensor for Monitoring Human Respiratory Rate. Jpn. J. Appl. Phys. 2013, 52, 04CL05. [Google Scholar] [CrossRef]

- Luis, J.; Roa Romero, L.; Gómez-Galán, J.; Hernández, D.; Estudillo-Valderrama, M.; Barbarov-Rostán, G.; Rubia-Marcos, C. Design and Implementation of a Smart Sensor for Respiratory Rate Monitoring. Sensors 2014, 14, 3019–3032. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Al-Halhouli, A.; Al-Ghussain, L.; Bouri, S.; Liu, H.; Zheng, D. Clinical evaluation of stretchable and wearable inkjet-printed strain gauge sensor for respiratory rate monitoring at different measurements locations. J. Clin. Monit. Comput. 2021, 35, 453–462. [Google Scholar] [CrossRef] [PubMed]

- Massaroni, C.; Di Tocco, J.; Bravi, M.; Carnevale, A.; Lo Presti, D.; Sabbadini, R.; Miccinilli, S.; Sterzi, S.; Formica, D.; Schena, E. Respiratory Monitoring during Physical Activities With a Multi-Sensor Smart Garment and Related Algorithms. IEEE Sens. J. 2020, 20, 2173–2180. [Google Scholar] [CrossRef]

- Shen, C.L.; Huang, T.h.; Hsu, P.C.; Ko, Y.C.; Chen, F.L.; Wang, W.C.; Kao, T.; Chan, C.T. Respiratory Rate Estimation by Using ECG, Impedance, and Motion Sensing in Smart Clothing. J. Med. Biol. Eng. 2017, 37, 826–842. [Google Scholar] [CrossRef] [PubMed]

- Lo Presti, D.; Massaroni, C.; D’Abbraccio, J.; Massari, L.; Caponero, M.; Longo, U.G.; Formica, D.; Oddo, C.M.; Schena, E. Wearable System Based on Flexible FBG for Respiratory and Cardiac Monitoring. IEEE Sens. J. 2019, 19, 7391–7398. [Google Scholar] [CrossRef]

- Harbour, E.; Lasshofer, M.; Genitrini, M.; Schwameder, H. Enhanced Breathing Pattern Detection during Running Using Wearable Sensors. Sensors 2021, 21, 5606. [Google Scholar] [CrossRef] [PubMed]

- Hurtado, D.; Abusleme, A.; Chávez, J. Non-invasive continuous respiratory monitoring using temperature-based sensors. J. Clin. Monit. Comput. 2019, 34, 223–231. [Google Scholar] [CrossRef]

- Jiang, P.; Zhao, S.; Zhu, R. Smart Sensing Strip Using Monolithically Integrated Flexible Flow Sensor for Noninvasively Monitoring Respiratory Flow. Sensors 2015, 15, 31738–31750. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Q.; Tang, Z.; Liu, J.; Xiang, B. Towards Accurate, Cost-Effective, Ultra-Low-Power and Non-Invasive Respiration Monitoring: A Reusable Wireless Wearable Sensor for an Off-the-Shelf KN95 Mask. Sensors 2021, 21, 6698. [Google Scholar] [CrossRef] [PubMed]

- Presti, D.L.; Massaroni, C.; Zaltieri, M.; Sabbadini, R.; Carnevale, A.; Di Tocco, J.; Longo, U.G.; Caponero, M.A.; D’Amato, R.; Schena, E.; et al. A Magnetic Resonance-Compatible Wearable Device Based on Functionalized Fiber Optic Sensor for Respiratory Monitoring. IEEE Sens. J. 2021, 21, 14418–14425. [Google Scholar] [CrossRef]

- Burton, D. Bio-Mask. U.S. Patent US7204250B1, 17 April 2007. [Google Scholar]

- John Mumford, R.K.; Wu, J. Mask Assembly with Integrated Sensors. U.S. Patent US20050268916A1, 8 December 2005. [Google Scholar]

- Wearable Mask Fit Monitor. U.S. Patent US11358014B2, 14 June 2022.

- Brochard, L.; Martin, G.S.; Blanch, L.; Pelosi, P.; Belda, F.J.; Jubran, A.; Gattinoni, L.; Mancebo, J.; Ranieri, V.M.; Richard, J.C.M.; et al. Clinical review: Respiratory monitoring in the ICU—A consensus of 16. Crit Care 2012, 16, 219–233. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peetz, D.; Murray, G.; Muurlink, O. Work and Hours amongst Mining and Energy Workers; Centre for work, Griffith University: Queensland, Australia, 2012. [Google Scholar]

- Energía, C.M. Jornadas Laborales y Salud del Trabajador: Factor de Cuidado. Available online: https://www.construccionminera.cl/jornadas-laborales-y-salud-del-trabajador-factor-de-cuidado/#.YDqQ36tR2Uk (accessed on 1 February 2020).

- Ahmad, I.; Balkhyour, M. Occupational exposure and respiratory health of workers at small scale industries. Saudi J. Biol. Sci. 2020, 27, 985–990. [Google Scholar] [CrossRef] [PubMed]

- Chehri, A.; Saadane, R.; Hakem, N.; Chaibi, H. Enhancing Energy Efficiency of Wireless Sensor Network for Mining Industry Applications. Procedia Comput. Sci. 2020, 176, 261–270. [Google Scholar] [CrossRef]

- Molaei, F.; Rahimi, E.; Siavoshi, H.; Ghaychi Afrouz, S.; Tenorio, V. A Comprehensive Review on Internet of Things (IoT) and its Implications in the Mining Industry. Am. J. Eng. Appl. Sci. 2020, 13, 499–515. [Google Scholar] [CrossRef]

- STMicroelectronics. STM32L422xx Ultra-Low-Power Arm ® Cortex ®-M4 32-bit MCU + FPU, 100 DMIPS, 128 KB Flash, 40 KB SRAM, analog, AES Datasheet. Available online: https://datasheetspdf.com/pdf/1364006/STMicroelectronics/STM32L422CB/1 (accessed on 27 September 2020).

- Sensortec, B. Humidity Sensor BME280. Available online: https://www.bosch-sensortec.com/products/environmental-sensors/humidity-sensors-bme280/ (accessed on 27 September 2020).

- STMicroelectronics. BlueNRG-M2—Very Low Power Application Processor Module for Bluetooth® Low Energy v5.0. Datasheet. Available online: https://www.st.com/resource/en/datasheet/bluenrg-m2.pdf (accessed on 27 September 2020).

- Mutashar, S.; Hannan, M.A.; Samad, S.A.; Hussain, A. Analysis of transcutaneous inductive powering links. In Proceedings of the 2012 4th International Conference on Intelligent and Advanced Systems (ICIAS2012), Kuala Lumpur, Malaysia, 12–14 June 2012; Volume 1, pp. 64–67. [Google Scholar] [CrossRef]

- Vandevoorde, G.; Puers, R. Wireless energy transfer for stand-alone systems: A comparison between low and high power applicability. Sens. Actuators A Phys. 2001, 92, 305–311. [Google Scholar] [CrossRef]

- QUANQING, Y.; RUI, X.; CHUAN, L.; PECHT, M. Water-Resistant Smartphone Technologies. IEEE Access 2019, 7, 499–515. [Google Scholar] [CrossRef]

- American National Standards Institute (ANSI). NEMA ANSI/IEC 60529:2004. Available online: https://webstore.ansi.org/Standards/NEMA/NEMAANSIIEC605292004?source=preview (accessed on 8 March 2020).

- Wheatley, I. Respiratory Rate 3: How to Take an Accurate Measurement. Available online: https://www.nursingtimes.net/clinical-archive/respiratory-clinical-archive/respiratory-rate-3-how-to-take-an-accurate-measurement-25-06-2018/ (accessed on 27 September 2020).

- Duarte, M. Detecta: A Python Module to Detect Events in Data. Available online: https://zenodo.org/record/4598962#.Y2tYzeRByUk (accessed on 6 February 2022).

| Initial Fitted to Loose | Loose to Final Fitted | Initial Fitted to Final Fitted | |||||||

|---|---|---|---|---|---|---|---|---|---|

| T | p-Value | df | T | p-Value | df | T | p-Value | df | |

| Humidity | 3.29 | 0.0094 | 9 | −5.44 | 0.00041 | 9 | −0.23 | 0.82 | 9 |

| Pressure | 6.82 | 9 | −5.27 | 0.00052 | 9 | 2.51 | 0.033 | 9 | |

| Temperature | 0.66 | 0.52 | 9 | −1.42 | 0.19 | 9 | −0.24 | 0.81 | 9 |

| df between Groups | F | p-Value | |

|---|---|---|---|

| Humidity | 5 | 0.176 | 0.971 |

| Pressure | 4 | 18.30 | |

| Temperature | 5 | 0.47 | 0.79 |

| Airflow CH1 | 5 | 4.38 | 0.0020 |

| Airflow CH2 | 5 | 12.11 |

| 0 | 20 | 40 | 60 | 80 | |

|---|---|---|---|---|---|

| 0 | 1.000000 | 0.900 | 0.900000 | 0.900000 | 0.005402 |

| 20 | 0.900000 | 1.000 | 0.900000 | 0.900000 | 0.001000 |

| 40 | 0.900000 | 0.900 | 1.000000 | 0.900000 | 0.002096 |

| 60 | 0.900000 | 0.900 | 0.900000 | 1.000000 | 0.002156 |

| 80 | 0.005402 | 0.001 | 0.002096 | 0.002156 | 1.000000 |

| 0 | 20 | 40 | 60 | 80 | 100 | |

|---|---|---|---|---|---|---|

| 0 | 1.000000 | 0.900000 | 0.900000 | 0.900000 | 0.90000 | 0.008029 |

| 20 | 0.900000 | 1.000000 | 0.900000 | 0.900000 | 0.90000 | 0.012144 |

| 40 | 0.900000 | 0.900000 | 1.000000 | 0.900000 | 0.90000 | 0.011862 |

| 60 | 0.900000 | 0.900000 | 0.900000 | 1.000000 | 0.90000 | 0.004099 |

| 80 | 0.900000 | 0.900000 | 0.900000 | 0.900000 | 1.00000 | 0.008440 |

| 100 | 0.008029 | 0.012144 | 0.011862 | 0.004099 | 0.00844 | 1.000000 |

| 0 | 20 | 40 | 60 | 80 | 100 | |

|---|---|---|---|---|---|---|

| 0 | 1.000000 | 0.151323 | 0.416844 | 0.801411 | 0.002737 | 0.001000 |

| 20 | 0.151323 | 1.000000 | 0.900000 | 0.787558 | 0.641409 | 0.001000 |

| 40 | 0.416844 | 0.900000 | 1.000000 | 0.900000 | 0.312879 | 0.001000 |

| 60 | 0.801411 | 0.787558 | 0.900000 | 1.000000 | 0.081196 | 0.001000 |

| 80 | 0.002737 | 0.641409 | 0.312879 | 0.081196 | 1.000000 | 0.042081 |

| 100 | 0.001000 | 0.001000 | 0.001000 | 0.001000 | 0.042081 | 1.000000 |

| System | Performance Metric | Value (Best) | Error [BPM] | Reference |

|---|---|---|---|---|

| Our Proposal | Regression Coefficient | 98.9% | 0.01 ± 1.3 | Biopac Flowmeter |

| Kundu et al. [9] | % of breathes detected | 100% | Non reported | Spirometer |

| Al-Halhouli et al. [11] | Regression Coefficient | 99.22% | 0.082 ± 0.109 | Nasal e-Health sensor |

| Massaroni et al. [12] | % of breathes detected | 97% | <±3 | SpiroQuant system |

| Harbour et al. [15] | % of breathes detected | 99.8% | Non reported | Cosmed Quark system |

| Hurtado et al. [16] | % of breathes detected | 95% | 0.4 ± 0.45 | Thermistor based |

| Xu et al. [18] | % of breathes detected | 99.7% | 0.449 ± 0.620 | Self counted breathes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aqueveque, P.; Díaz, M.; Gomez, B.; Osorio, R.; Pastene, F.; Radrigan, L.; Morales, A. Embedded Electronic Sensor for Monitoring of Breathing Activity, Fitting and Filter Clogging in Reusable Industrial Respirators. Biosensors 2022, 12, 991. https://doi.org/10.3390/bios12110991

Aqueveque P, Díaz M, Gomez B, Osorio R, Pastene F, Radrigan L, Morales A. Embedded Electronic Sensor for Monitoring of Breathing Activity, Fitting and Filter Clogging in Reusable Industrial Respirators. Biosensors. 2022; 12(11):991. https://doi.org/10.3390/bios12110991

Chicago/Turabian StyleAqueveque, Pablo, Macarena Díaz, Britam Gomez, Rodrigo Osorio, Francisco Pastene, Luciano Radrigan, and Anibal Morales. 2022. "Embedded Electronic Sensor for Monitoring of Breathing Activity, Fitting and Filter Clogging in Reusable Industrial Respirators" Biosensors 12, no. 11: 991. https://doi.org/10.3390/bios12110991

APA StyleAqueveque, P., Díaz, M., Gomez, B., Osorio, R., Pastene, F., Radrigan, L., & Morales, A. (2022). Embedded Electronic Sensor for Monitoring of Breathing Activity, Fitting and Filter Clogging in Reusable Industrial Respirators. Biosensors, 12(11), 991. https://doi.org/10.3390/bios12110991