Laser-Induced Graphene Based Flexible Electronic Devices

Abstract

:1. Introduction

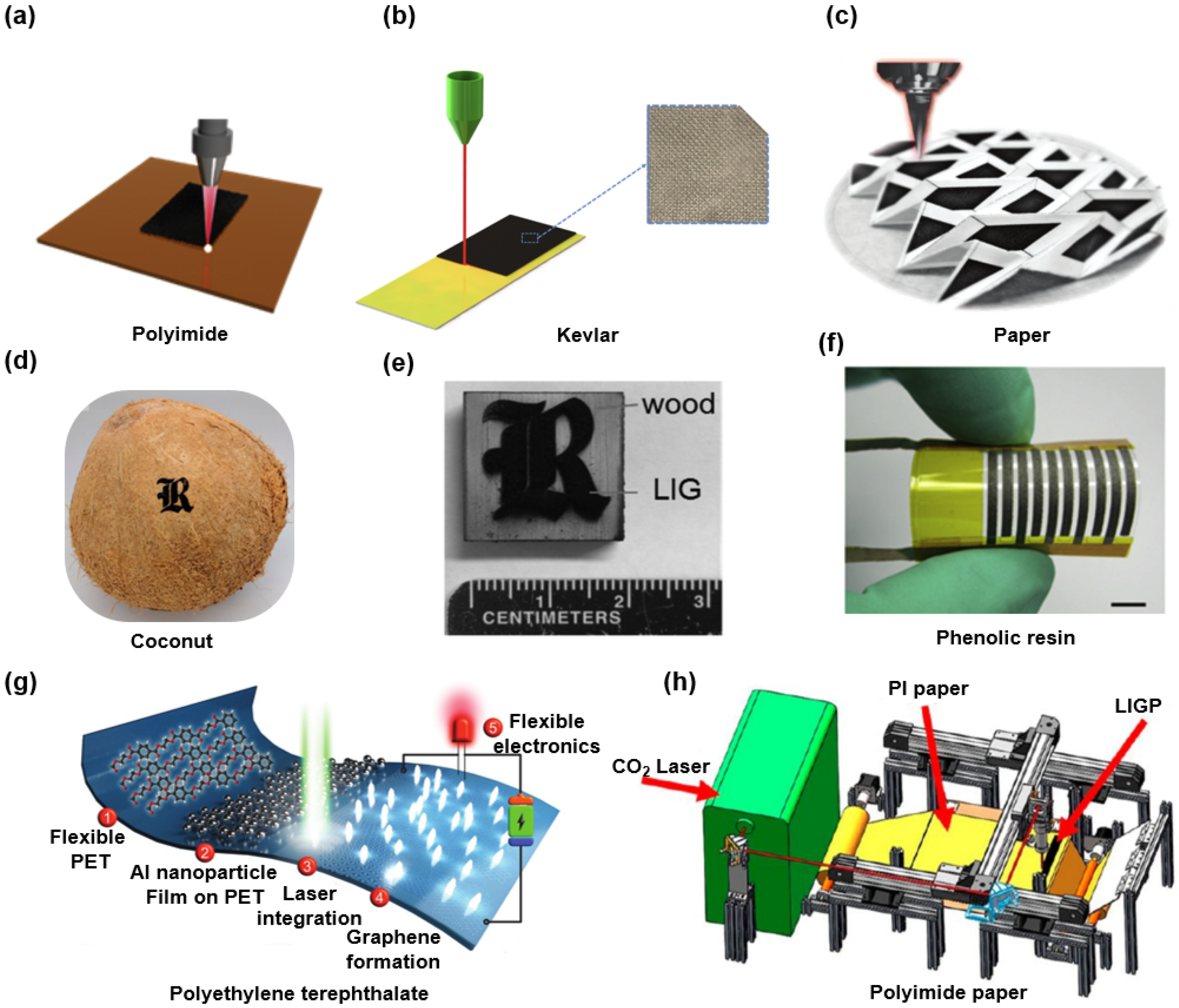

2. Fabrications of LIG

3. Application of LIG

3.1. LIG-Based Biosensors

3.1.1. LIG-Based Mechanical Sensors

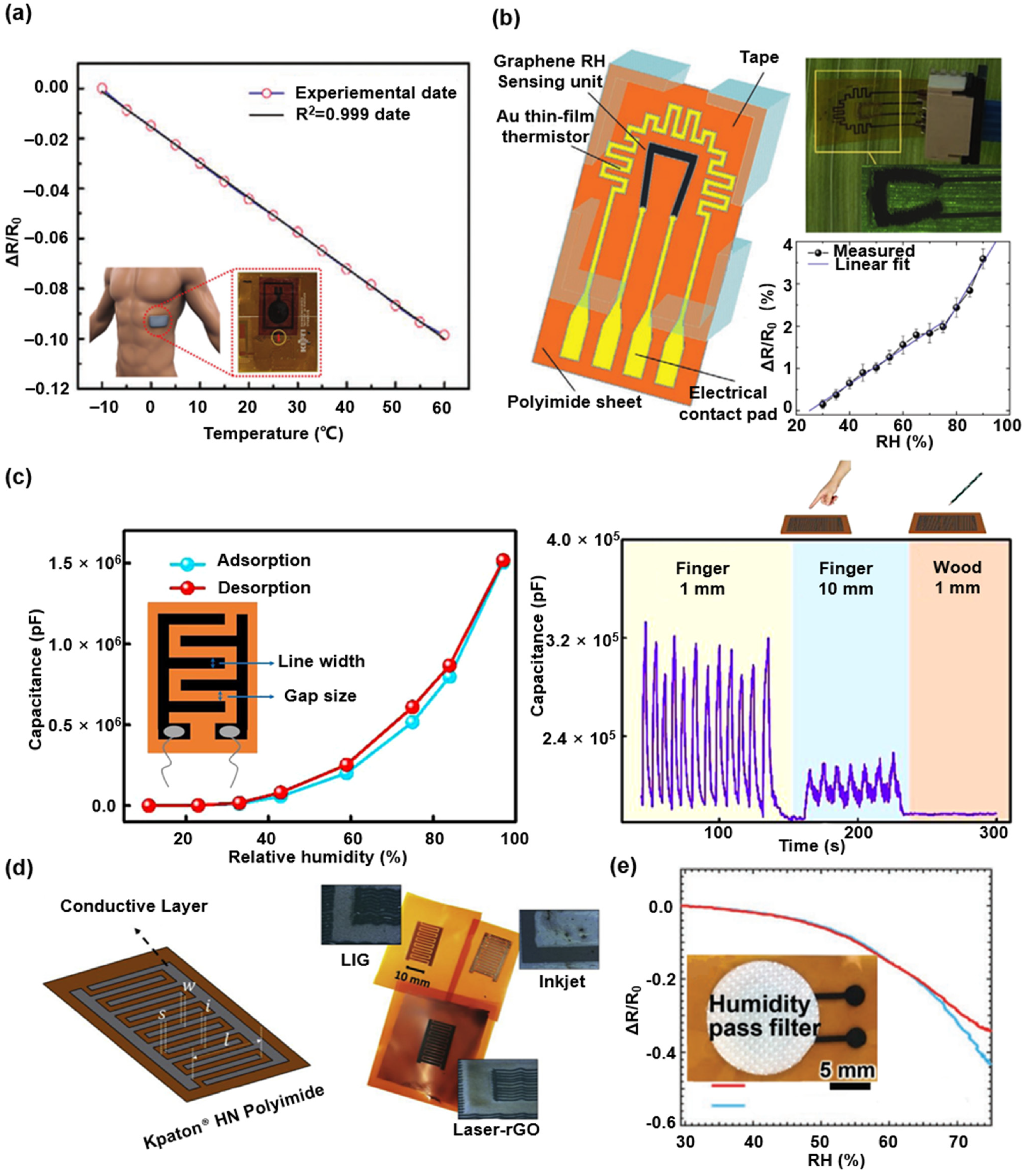

3.1.2. LIG-Based Temperature and Humidity Sensors

3.1.3. LIG-Based Electrochemical Sensors

3.1.4. LIG-Based Electrophysiological Sensors

3.2. LIG-Based Energy Storage Devices

3.2.1. LIG-Based Batteries

3.2.2. LIG-Based Supercapacitors

3.3. LIG-Based Heaters and Actuators

4. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geim, A.K. Graphene: Status and prospects. Science 2009, 324, 1530–1534. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Cai, W.; An, J.; Kim, S.; Nah, J.; Yang, D.; Piner, R.; Velamakanni, A.; Jung, I.; Tutuc, E.; et al. Large-area synthesis of high-quality and uniform graphene films on copper foils. Science 2009, 324, 1312–1314. [Google Scholar] [CrossRef] [Green Version]

- Chua, C.K.; Pumera, M. Chemical reduction of graphene oxide: A synthetic chemistry viewpoint. Chem. Soc. Rev. 2014, 43, 291–312. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Xu, Z.; Liu, Z.; Wei, Y.; Sun, H.; Li, Z.; Zhao, X.; Gao, C. An iron-based green approach to 1-h production of single-layer graphene oxide. Nat. Commun. 2015, 6, 5716. [Google Scholar] [CrossRef] [Green Version]

- Ciesielski, A.; Samori, P. Graphene via sonication assisted liquid-phase exfoliation. Chem. Soc. Rev. 2014, 43, 381–398. [Google Scholar] [CrossRef]

- El-Kady, M.F.; Strong, V.; Dubin, S.; Kaner, R.B. Laser scribing of high-performance and flexible graphene-based electrochemical capacitors. Science 2012, 335, 1326–1330. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Fei, Q.; Page, M.; Zhao, G.; Ling, Y.; Chen, D.; Yan, Z. Laser-induced graphene for bioelectronics and soft actuators. Nano Res. 2021, 14, 3033–3050. [Google Scholar] [CrossRef]

- Yin, K.; Wu, Z.; Wu, J.; Zhu, Z.; Zhang, F.; Duan, J.-A. Solar-driven thermal-wind synergistic effect on laser-textured superhydrophilic copper foam architectures for ultrahigh efficient vapor generation. Appl. Phys. Lett. 2021, 118, 211905. [Google Scholar] [CrossRef]

- Lin, J.; Peng, Z.; Liu, Y.; Ruiz-Zepeda, F.; Ye, R.; Samuel, E.L.; Yacaman, M.J.; Yakobson, B.I.; Tour, J.M. Laser-induced porous graphene films from commercial polymers. Nat. Commun. 2014, 5, 5714. [Google Scholar] [CrossRef] [PubMed]

- Inagaki, M.; Harada, S.; Sato, T.; Nakajima, T.; Horino, Y.; Morita, K. Carbonization of polyimide film “Kapton”. Carbon 1989, 27, 253–257. [Google Scholar] [CrossRef]

- Inagaki, M.; Meng, L.-J.; Ibuki, T.; Sakai, M.; Hishiyama, Y. Carbonization and graphitization of polyimide film “Novax”. Carbon 1991, 29, 1239–1243. [Google Scholar] [CrossRef]

- Duy, L.X.; Peng, Z.; Li, Y.; Zhang, J.; Ji, Y.; Tour, J.M. Laser-induced graphene fibers. Carbon 2018, 126, 472–479. [Google Scholar] [CrossRef]

- You, R.; Liu, Y.Q.; Hao, Y.L.; Han, D.D.; Zhang, Y.L.; You, Z. Laser fabrication of graphene-based flexible electronics. Adv. Mater. 2020, 32, e1901981. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Su, J.; Song, Y.; Ye, R. Laser-induced graphene: En route to smart sensing. Nanomicro Lett. 2020, 12, 157. [Google Scholar] [CrossRef] [PubMed]

- Tao, L.Q.; Tian, H.; Liu, Y.; Ju, Z.Y.; Pang, Y.; Chen, Y.Q.; Wang, D.Y.; Tian, X.G.; Yan, J.C.; Deng, N.Q.; et al. An intelligent artificial throat with sound-sensing ability based on laser induced graphene. Nat. Commun. 2017, 8, 14579. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, L.; Zhu, S.; Pan, B.; Dai, X.; Zhao, W.; Liu, Y.; Xie, W.; Kuang, Y.; Liu, X. Stable and durable laser-induced graphene patterns embedded in polymer substrates. Carbon 2020, 163, 85–94. [Google Scholar] [CrossRef]

- Carvalho, A.F.; Fernandes, A.J.S.; Leitão, C.; Deuermeier, J.; Marques, A.C.; Martins, R.; Fortunato, E.; Costa, F.M. Laser-induced graphene strain sensors produced by ultraviolet irradiation of polyimide. Adv. Funct. Mater. 2018, 28, 1805271. [Google Scholar] [CrossRef]

- Santos, N.F.; Pereira, S.O.; Moreira, A.; Girão, A.V.; Carvalho, A.F.; Fernandes, A.J.S.; Costa, f.m. ir and uv laser-induced graphene: Application as dopamine electrochemical sensors. Adv. Mater. Technol. 2021, 6, 2100007. [Google Scholar] [CrossRef]

- Chen, Y.; Long, J.; Zhou, S.; Shi, D.; Huang, Y.; Chen, X.; Gao, J.; Zhao, N.; Wong, C.P. UV laser-induced polyimide-to-graphene conversion: Modeling, fabrication, and application. Small Methods 2019, 3, 1900208. [Google Scholar] [CrossRef]

- Mikheev, K.G.; Zonov, R.G.; Mogileva, T.N.; Fateev, A.E.; Mikheev, G.M. Optical anisotropy of laser-induced graphene films. Opt. Laser Technol. 2021, 141, 107143. [Google Scholar] [CrossRef]

- Ye, R.; Chyan, Y.; Zhang, J.; Li, Y.; Han, X.; Kittrell, C.; Tour, J.M. Laser-induced graphene formation on wood. Adv. Mater. 2017, 29, 1702211. [Google Scholar] [CrossRef]

- Le, T.S.D.; Park, S.; An, J.; Lee, P.S.; Kim, Y.J. Ultrafast laser pulses enable one-step graphene patterning on woods and leaves for green electronics. Adv. Funct. Mater. 2019, 29, 1902771. [Google Scholar] [CrossRef]

- Chyan, Y.; Ye, R.; Li, Y.; Singh, S.P.; Arnusch, C.J.; Tour, J.M. Laser-induced graphene by multiple lasing: Toward electronics on cloth, paper, and food. ACS Nano 2018, 12, 2176–2183. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, H.; Wang, Y.; Su, X.; Wang, C.; Zhang, M.; Jian, M.; Xia, K.; Liang, X.; Lu, H.; et al. Laser writing of Janus graphene/kevlar textile for intelligent protective clothing. ACS Nano 2020, 14, 3219–3226. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Z.; Lu, L.; Xie, Y.; Wang, W.; Lin, Z.; Tang, B.; Lin, N. Preparation of laser-induced graphene fabric from silk and its application examples for flexible sensor. Adv. Eng. Mater. 2021, 23, 2100195. [Google Scholar] [CrossRef]

- Nasser, J.; Groo, L.; Zhang, L.; Sodano, H. Laser induced graphene fibers for multifunctional aramid fiber reinforced composite. Carbon 2020, 158, 146–156. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Liu, F.; Luo, S. Laser-induced graphene paper heaters with multimodally patternable electrothermal performance for low-energy manufacturing of composites. ACS Appl. Mater. Interfaces 2020, 12, 23284–23297. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Zhang, P.; Liu, F.; Luo, S. Laser-induced freestanding graphene papers: A new route of scalable fabrication with tunable morphologies and properties for multifunctional devices and structures. Small 2018, 14, 1802350. [Google Scholar] [CrossRef]

- Zang, X.; Shen, C.; Chu, Y.; Li, B.; Wei, M.; Zhong, J.; Sanghadasa, M.; Lin, L. Laser-induced molybdenum carbide-graphene composites for 3d foldable paper electronics. Adv. Mater. 2018, 30, 1800062. [Google Scholar] [CrossRef]

- Rodriguez, R.D.; Shchadenko, S.; Murastov, G.; Lipovka, A.; Fatkullin, M.; Petrov, I.; Tran, T.H.; Khalelov, A.; Saqib, M.; Villa, N.E.; et al. Ultra-robust flexible electronics by laser-driven polymer-nanomaterials integration. Adv. Funct. Mater. 2021, 31, 2008818. [Google Scholar] [CrossRef]

- Zhang, Z.; Song, M.; Hao, J.; Wu, K.; Li, C.; Hu, C. Visible light laser-induced graphene from phenolic resin: A new approach for directly writing graphene-based electrochemical devices on various substrates. Carbon 2018, 127, 287–296. [Google Scholar] [CrossRef]

- Yazdi, A.Z.; Navas, I.O.; Abouelmagd, A.; Sundararaj, U. Direct creation of highly conductive laser-induced graphene nanocomposites from polymer blends. Macromol. Rapid. Comm. 2017, 38, 1700176. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhao, Z.; Liu, P.; Guo, X. Laser-induced porous graphene on Polyimide/PDMS composites and its kirigami-inspired strain sensor. Theor. App. Mech. Lett. 2021, 11, 100240. [Google Scholar] [CrossRef]

- Behrent, A.; Griesche, C.; Sippel, P.; Baeumner, A.J. Process-property correlations in laser-induced graphene electrodes for electrochemical sensing. Mikrochim. Acta 2021, 188, 159. [Google Scholar] [CrossRef]

- Abdulhafez, M.; Tomaraei, G.N.; Bedewy, M. Fluence-dependent morphological transitions in laser-induced graphene electrodes on polyimide substrates for flexible devices. ACS Appl. Nano Mater. 2021, 4, 2973–2986. [Google Scholar] [CrossRef]

- Kaidarova, A.; Alsharif, N.; Oliveira, B.N.M.; Marengo, M.; Geraldi, N.R.; Duarte, C.M.; Kosel, J. Laser-printed, flexible graphene pressure sensors. Glob. Chall. 2020, 4, 2000001. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Han, B.; Zhang, Y.; Li, Q.; Zhang, Y.L.; Han, D.D.; Sun, H.B. Laser-induced graphene tapes as origami and stick-on labels for photothermal manipulation via marangoni effect. Adv. Funct. Mater. 2020, 31, 2006179. [Google Scholar] [CrossRef]

- Nasser, J.; Lin, J.; Zhang, L.; Sodano, H.A. Laser induced graphene printing of spatially controlled super-hydrophobic/hydrophilic surfaces. Carbon 2020, 162, 570–578. [Google Scholar] [CrossRef]

- Li, Y.; Luong, D.X.; Zhang, J.; Tarkunde, Y.R.; Kittrell, C.; Sargunaraj, F.; Ji, Y.; Arnusch, C.J.; Tour, J.M. Laser-induced graphene in controlled atmospheres: From superhydrophilic to superhydrophobic surfaces. Adv. Mater. 2017, 29, 1700496. [Google Scholar] [CrossRef]

- Deshmukh, S.; Banerjee, D.; Marin Quintero, J.S.; Fishlock, S.J.; McLaughlin, J.; Waghmare, P.R.; Roy, S.S. Polarity dependent electrowetting for directional transport of water through patterned superhydrophobic laser induced graphene fibers. Carbon 2021, 182, 605–614. [Google Scholar] [CrossRef]

- Luong, D.X.; Subramanian, A.K.; Silva, G.A.L.; Yoon, J.; Cofer, S.; Yang, K.; Owuor, P.S.; Wang, T.; Wang, Z.; Lou, J.; et al. Laminated object manufacturing of 3D-printed laser-induced graphene foams. Adv. Mater. 2018, 30, e1707416. [Google Scholar] [CrossRef]

- Shi, X.; Zhou, F.; Peng, J.; Wu, R.A.; Wu, Z.S.; Bao, X. One-step scalable fabrication of graphene-integrated micro-supercapacitors with remarkable flexibility and exceptional performance uniformity. Adv. Funct. Mater. 2019, 29, 1902860. [Google Scholar] [CrossRef]

- Zhao, C.; Liu, Y.; Beirne, S.; Razal, J.; Chen, J. Recent development of fabricating flexible micro-supercapacitors for wearable devices. Adv. Mater. Technol. 2018, 3, 1800028. [Google Scholar] [CrossRef]

- Zhang, W.; Lei, Y.; Jiang, Q.; Ming, F.; Costa, P.M.F.J.; Alshareef, H.N. 3D laser scribed graphene derived from carbon nanospheres: An ultrahigh-power electrode for supercapacitors. Small Methods 2019, 3, 1900005. [Google Scholar] [CrossRef] [Green Version]

- Zeng, J.; Xu, C.; Gao, T.; Jiang, X.; Wang, X.B. Porous monoliths of 3D graphene for electric double-layer supercapacitors. Carbon Energy 2021, 3, 193–224. [Google Scholar] [CrossRef]

- Song, W.; Zhu, J.; Gan, B.; Zhao, S.; Wang, H.; Li, C.; Wang, J. Flexible, stretchable, and transparent planar microsupercapacitors based on 3d porous laser-induced graphene. Small 2018, 14, 1702249. [Google Scholar] [CrossRef] [PubMed]

- Lu, B.; Jin, X.; Han, Q.; Qu, L. Planar graphene-based microsupercapacitors. Small 2021, 17, 2006827. [Google Scholar] [CrossRef]

- Li, L.; Zhang, J.; Peng, Z.; Li, Y.; Gao, C.; Ji, Y.; Ye, R.; Kim, N.D.; Zhong, Q.; Yang, Y.; et al. High-performance pseudocapacitive microsupercapacitors from laser-induced graphene. Adv. Mater. 2016, 28, 838–845. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Secor, E.B.; Chen, K.S.; Zhu, J.; Liu, X.; Gao, T.Z.; Seo, J.W.T.; Zhao, Y.; Hersam, M.C. High-performance solid-state supercapacitors and microsupercapacitors derived from printable graphene inks. Adv. Energy Mater. 2016, 6, 1600909. [Google Scholar] [CrossRef]

- Lee, J.B.; Jang, J.; Zhou, H.; Lee, Y.; In, J.B. Densified laser-induced graphene for flexible microsupercapacitors. Energies 2020, 13, 6567. [Google Scholar] [CrossRef]

- Kim, K.Y.; Choi, H.; Tran, C.V.; In, J.B. Simultaneous densification and nitrogen doping of laser-induced graphene by duplicated pyrolysis for supercapacitor applications. J. Power Sources 2019, 441, 227199. [Google Scholar] [CrossRef]

- He, M.; Wang, G.; Zhu, Y.; Wang, Y.; Liu, F.; Luo, S. In-situ joule heating-triggered nanopores generation in laser-induced graphene papers for capacitive enhancement. Carbon 2022, 186, 215–226. [Google Scholar] [CrossRef]

- Zhang, C.; Peng, Z.; Huang, C.; Zhang, B.; Xing, C.; Chen, H.; Cheng, H.; Wang, J.; Tang, S. High-energy all-in-one stretchable micro-supercapacitor arrays based on 3D laser-induced graphene foams decorated with mesoporous ZnP nanosheets for self-powered stretchable systems. Nano Energy 2021, 81, 105609. [Google Scholar] [CrossRef]

- Luo, J.; Fan, F.R.; Jiang, T.; Wang, Z.; Tang, W.; Zhang, C.; Liu, M.; Cao, G.; Wang, Z.L. Integration of micro-supercapacitors with triboelectric nanogenerators for a flexible self-charging power unit. Nano Res. 2015, 8, 3934–3943. [Google Scholar] [CrossRef]

- Hatta, F.F.; Mohammad Haniff, M.A.S.; Mohamed, M.A. A review on applications of graphene in triboelectric nanogenerators. Int. J. Ener. Res. 2021, 1–33. [Google Scholar] [CrossRef]

- Zhao, P.; Bhattacharya, G.; Fishlock, S.J.; Guy, J.G.M.; Kumar, A.; Tsonos, C.; Yu, Z.; Raj, S.; McLaughlin, J.A.; Luo, J.; et al. Replacing the metal electrodes in triboelectric nanogenerators: High-performance laser-induced graphene electrodes. Nano Energy 2020, 75, 104958. [Google Scholar] [CrossRef]

- Yan, Z.; Wang, L.; Xia, Y.; Qiu, R.; Liu, W.; Wu, M.; Zhu, Y.; Zhu, S.; Jia, C.; Zhu, M.; et al. Flexible high-resolution triboelectric sensor array based on patterned laser-induced graphene for self-powered real-time tactile sensing. Adv. Funct. Mater. 2021, 31, 2100709. [Google Scholar] [CrossRef]

- Stanford, M.G.; Li, J.T.; Chyan, Y.; Wang, Z.; Wang, W.; Tour, J.M. Laser-induced graphene triboelectric nanogenerators. ACS Nano 2019, 13, 7166–7174. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Li, X.; Yao, Y.; Lan, L.; Shao, Y.; Zhao, F.; Ying, Y.; Ping, J. A multifunctional and highly flexible triboelectric nanogenerator based on MXene-enabled porous film integrated with laser-induced graphene electrode. Nano Energy 2019, 66, 104121. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, B.; Long, J.; Kuang, Y.; Chen, X.; Hou, M.; Gao, J.; Zhou, S.; Fan, B.; He, Y.; et al. Interfacial laser-induced graphene enabling high-performance liquid−solid triboelectric nanogenerator. Adv. Mater. 2021, 33, 2104290. [Google Scholar] [CrossRef]

- Stanford, M.G.; Li, J.T.; Chen, Y.; McHugh, E.A.; Liopo, A.; Xiao, H.; Tour, J.M. Self-sterilizing laser-induced graphene bacterial air filter. ACS Nano 2019, 13, 11912–11920. [Google Scholar] [CrossRef] [PubMed]

- Maqbool, I.; Rehman, F.; Soomro, F.; Bhatti, Z.; Ali, U.; Jatoi, A.H.; Lal, B.; Iqbal, M.; Phulpoto, S.; Ali, A.; et al. Graphene-based materials for fighting coronavirus disease 2019: Challenges and opportunities. ChemBioEng Rev. 2021, 8, 67–77. [Google Scholar] [CrossRef]

- Liu, F.; Wang, G.; Ding, X.; Luo, S. Multifunctional laser-induced graphene enabled polymeric composites. Compos. Commun. 2021, 25, 100714. [Google Scholar] [CrossRef]

- Huang, L.; Gu, M.; Wang, Z.; Tang, T.W.; Zhu, Z.; Yuan, Y.; Wang, D.; Shen, C.; Tang, B.Z.; Ye, R. Highly efficient and rapid inactivation of coronavirus on non-metal hydrophobic laser-induced graphene in mild conditions. Adv. Funct. Mater. 2021, 31, 2101195. [Google Scholar] [CrossRef]

- Stanford, M.G.; Yang, K.; Chyan, Y.; Kittrell, C.; Tour, J.M. Laser-induced graphene for flexible and embeddable gas sensors. ACS Nano 2019, 13, 3474–3482. [Google Scholar] [CrossRef] [PubMed]

- Peng, Z.; Tao, L.-Q.; Zou, S.; Zhu, C.; Wang, G.; Sun, H.; Ren, T.-L. A multi-functional NO2 gas monitor and self-alarm based on laser-induced graphene. Chem. Eng. J. 2022, 428, 131079. [Google Scholar] [CrossRef]

- Ren, M.; Zhang, J.; Fan, M.; Ajayan, P.M.; Tour, J.M. Li-breathing air batteries catalyzed by MnNiFe/laser-induced graphene catalysts. Adv. Mater. Interfaces 2019, 6, 1901035. [Google Scholar] [CrossRef]

- Ren, M.; Zhang, J.; Tour, J.M. Laser-induced graphene hybrid catalysts for rechargeable Zn-air batteries. ACS Appl. Energy Mater. 2019, 2, 1460–1468. [Google Scholar] [CrossRef]

- Ren, M.; Zhang, J.; Zhang, C.; Stanford, M.G.; Chyan, Y.; Yao, Y.; Tour, J.M. Quasi-solid-state Li–O2 batteries with laser-induced graphene cathode catalysts. ACS Appl. Energy Mater. 2020, 3, 1702–1709. [Google Scholar] [CrossRef]

- Han, X.; Ye, R.; Chyan, Y.; Wang, T.; Zhang, C.; Shi, L.; Zhang, T.; Zhao, Y.; Tour, J.M. Laser-induced graphene from wood impregnated with metal salts and use in electrocatalysis. ACS Appl. Nano Mater. 2018, 1, 5053–5061. [Google Scholar] [CrossRef]

- Ren, M.; Zhang, J.; Tour, J.M. Laser-induced graphene synthesis of Co3O4 in graphene for oxygen electrocatalysis and metal-air batteries. Carbon 2018, 139, 880–887. [Google Scholar] [CrossRef]

- Ling, Y.; Pang, W.; Li, X.; Goswami, S.; Xu, Z.; Stroman, D.; Liu, Y.; Fei, Q.; Xu, Y.; Zhao, G.; et al. Laser-induced graphene for electrothermally controlled, mechanically guided, 3D assembly and human-soft actuators interaction. Adv. Mater. 2020, 32, 1908475. [Google Scholar] [CrossRef]

- Oh, J.H.; Anas, M.; Barnes, E.; Moores, L.C.; Green, M.J. Site-specific selective bending of actuators using radio frequency heating. Adv. Eng. Mater. 2021, 23, 2000873. [Google Scholar] [CrossRef]

- Zhang, C.; Deng, H.; Xie, Y.; Zhang, C.; Su, J.W.; Lin, J. Stimulus responsive 3D assembly for spatially resolved bifunctional sensors. Small 2019, 15, 1904224. [Google Scholar] [CrossRef] [PubMed]

- Alhajji, E.; Zhang, F.; Alshareef, H.N. Status and prospects of laser-induced graphene for battery applications. Energy Technol. 2021, 9, 2100454. [Google Scholar] [CrossRef]

- Yi, J.; Chen, J.; Yang, Z.; Dai, Y.; Li, W.; Cui, J.; Ciucci, F.; Lu, Z.; Yang, C. Facile patterning of laser-induced graphene with tailored li nucleation kinetics for stable lithium-metal batteries. Adv. Energy Mater. 2019, 9, 1901796. [Google Scholar] [CrossRef]

- Luo, S.; Hoang, P.T.; Liu, T. Direct laser writing for creating porous graphitic structures and their use for flexible and highly sensitive sensor and sensor arrays. Carbon 2016, 96, 522–531. [Google Scholar] [CrossRef]

- Zhao, J.; Luo, J.; Zhou, Z.; Zheng, C.; Gui, J.; Gao, J.; Xu, R. Novel multi-walled carbon nanotubes-embedded laser-induced graphene in crosslinked architecture for highly responsive asymmetric pressure sensor. Sensors Actuat. A-Phys. 2021, 323, 112658. [Google Scholar] [CrossRef]

- Xu, K.; Fujita, Y.; Lu, Y.; Honda, S.; Shiomi, M.; Arie, T.; Akita, S.; Takei, K. A wearable body condition sensor system with wireless feedback alarm functions. Adv. Mater. 2021, 33, 2008701. [Google Scholar] [CrossRef]

- Gandla, S.; Naqi, M.; Lee, M.; Lee, J.J.; Won, Y.; Pujar, P.; Kim, J.; Lee, S.; Kim, S. Highly linear and stable flexible temperature sensors based on laser-induced carbonization of polyimide substrates for personal mobile monitoring. Adv. Mater. Technol. 2020, 5, 2000014. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, N.; Xiang, Y.; Wang, D.; Zhang, P.; Wang, Y.; Lu, S.; Xu, R.; Zhao, J. A flexible non-enzymatic glucose sensor based on copper nanoparticles anchored on laser-induced graphene. Carbon 2020, 156, 506–513. [Google Scholar] [CrossRef]

- Sun, B.; McCay, R.N.; Goswami, S.; Xu, Y.; Zhang, C.; Ling, Y.; Lin, J.; Yan, Z. Gas-permeable, multifunctional on-skin electronics based on laser-induced porous graphene and sugar-templated elastomer sponges. Adv. Mater. 2018, 30, 1804327. [Google Scholar] [CrossRef] [PubMed]

- Duan, S.; Wang, B.; Lin, Y.; Li, Y.; Zhu, D.; Wu, J.; Xia, J.; Lei, W.; Wang, B. Waterproof mechanically robust multifunctional conformal sensors for underwater interactive human–machine interfaces. Adv. Intell. Syst. 2021, 3, 2100056. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, K.; Yu, J.; Zhang, S.; He, L.; Wu, S.; Liu, C.; Deng, Y. Facile fabrication of robust and reusable pdms supported graphene dry electrodes for wearable electrocardiogram monitoring. Adv. Mater. Technol. 2021, 6, 2100262. [Google Scholar] [CrossRef]

- Yoo, J.-H.; Park, J.B.; Ahn, S.; Grigoropoulos, C.P. Laser-induced direct graphene patterning and simultaneous transferring method for graphene sensor platform. Small 2013, 9, 4269–4275. [Google Scholar] [CrossRef]

- Groo, L.; Nasser, J.; Inman, D.J.; Sodano, H.A. Transfer printed laser induced graphene strain gauges for embedded sensing in fiberglass composites. Compos. Part B-Eng. 2021, 219, 108932. [Google Scholar] [CrossRef]

- Li, J.T.; Stanford, M.G.; Chen, W.; Presutti, S.E.; Tour, J.M. Laminated laser-induced graphene composites. ACS Nano 2020, 14, 7911–7919. [Google Scholar] [CrossRef] [PubMed]

- Rahimi, R.; Ochoa, M.; Yu, W.; Ziaie, B. Highly stretchable and sensitive unidirectional strain sensor via laser carbonization. ACS Appl. Mater. Interfaces 2015, 7, 4463–4470. [Google Scholar] [CrossRef]

- Dallinger, A.; Keller, K.; Fitzek, H.; Greco, F. Stretchable and skin-conformable conductors based on polyurethane/laser-induced graphene. ACS Appl. Mater. Interfaces 2020, 12, 19855–19865. [Google Scholar] [CrossRef]

- Ma, Y.; Choi, J.; Hourlier-Fargette, A.; Xue, Y.; Chung, H.U.; Lee, J.Y.; Wang, X.; Xie, Z.; Kang, D.; Wang, H.; et al. Relation between blood pressure and pulse wave velocity for human arteries. Proc. Natl. Acad. Sci. USA 2018, 115, 11144–11149. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Zhu, F.; Jang, K.I.; Feng, X.; Rogers, J.A.; Zhang, Y.; Huang, Y.; Ma, Y. The equivalent medium of cellular substrate under large stretching, with applications to stretchable electronics. J. Mech. Phys. Solids 2018, 120, 199–207. [Google Scholar] [CrossRef]

- Zhu, F.; Xiao, H.; Li, H.; Huang, Y.-S.; Ma, Y. Irregular hexagonal cellular substrate for stretchable electronics. J. Appl. Mech. 2018, 86, 034501. [Google Scholar] [CrossRef]

- Kulyk, B.; Silva, B.F.R.; Carvalho, A.F.; Silvestre, S.; Fernandes, A.J.S.; Martins, R.; Fortunato, E.; Costa, F.M. Laser-induced graphene from paper for mechanical sensing. ACS Appl. Mater. Interfaces 2021, 13, 10210–10221. [Google Scholar] [CrossRef]

- Kaidarova, A.; Khan, M.A.; Marengo, M.; Swanepoel, L.; Przybysz, A.; Muller, C.; Fahlman, A.; Buttner, U.; Geraldi, N.R.; Wilson, R.P.; et al. Wearable multifunctional printed graphene sensors. NPJ Flex. Electron. 2019, 3, 15. [Google Scholar] [CrossRef] [Green Version]

- Groo, L.; Nasser, J.; Inman, D.; Sodano, H. Fatigue damage tracking and life prediction of fiberglass composites using a laser induced graphene interlayer. Compos. Part B-Eng. 2021, 218, 108935. [Google Scholar] [CrossRef]

- Shao, Q.; Liu, G.; Teweldebrhan, D.; Balandin, A.A. High-temperature quenching of electrical resistance in graphene interconnects. App. Phys. Lett. 2008, 92, 202108. [Google Scholar] [CrossRef] [Green Version]

- Zhu, C.; Tao, L.-Q.; Wang, Y.; Zheng, K.; Yu, J.; Xiandong, L.; Chen, X.; Huang, Y. Graphene oxide humidity sensor with laser-induced graphene porous electrodes. Sens. Actuat. B-Chem. 2020, 325, 128790. [Google Scholar] [CrossRef]

- Yin, S.; Ibrahim, H.; Schnable, P.S.; Castellano, M.J.; Dong, L. A Field-deployable, wearable leaf sensor for continuous monitoring of vapor-pressure deficit. Adv. Mater. Technol. 2021, 6, 2001246. [Google Scholar] [CrossRef]

- Tham, N.C.Y.; Sahoo, P.K.; Kim, Y.; Hegde, C.; Lee, S.W.; Kim, Y.J.; Murukeshan, V.M. Thermally controlled localized porous graphene for integrated graphene-paper electronics. Adv. Mater. Technol. 2021, 6, 2001156. [Google Scholar] [CrossRef]

- Romero, F.J.; Rivadeneyra, A.; Salinas-Castillo, A.; Ohata, A.; Morales, D.P.; Becherer, M.; Rodriguez, N. Design, fabrication and characterization of capacitive humidity sensors based on emerging flexible technologies. Sens. Actuat. B-Chem. 2019, 287, 459–467. [Google Scholar] [CrossRef]

- Chen, R.; Luo, T.; Geng, D.; Shen, Z.; Zhou, W. Facile fabrication of a fast-response flexible temperature sensor via laser reduced graphene oxide for contactless human-machine interface. Carbon 2022, 187, 35–46. [Google Scholar] [CrossRef]

- Aparicio-Martínez, E.; Ibarra, A.; Estrada-Moreno, I.A.; Osuna, V.; Dominguez, R.B. Flexible electrochemical sensor based on laser scribed Graphene/Ag nanoparticles for non-enzymatic hydrogen peroxide detection. Sens. Actuat. B-Chem. 2019, 301, 127101. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, H.; Sun, P.; Sun, C.K.; Huang, H.; Guan, S.; Liu, H.; Zhang, H.; Zhang, C.; Qin, K.R. Laser-induced graphene-based non-enzymatic sensor for detection of hydrogen peroxide. Electroanalysis 2019, 31, 1334–1341. [Google Scholar] [CrossRef]

- Kurra, N.; Jiang, Q.; Nayak, P.; Alshareef, H.N. Laser-derived graphene: A three-dimensional printed graphene electrode and its emerging applications. Nano Today 2019, 24, 81–102. [Google Scholar] [CrossRef]

- Yoon, H.; Nah, J.; Kim, H.; Ko, S.; Sharifuzzaman, M.; Barman, S.C.; Xuan, X.; Kim, J.; Park, J.Y. A chemically modified laser-induced porous graphene based flexible and ultrasensitive electrochemical biosensor for sweat glucose detection. Sens. Actuat. B-Chem. 2020, 311, 127866. [Google Scholar] [CrossRef]

- Nam, K.-H.; Abdulhafez, M.; Castagnola, E.; Tomaraei, G.N.; Cui, X.T.; Bedewy, M. Laser direct write of heteroatom-doped graphene on molecularly controlled polyimides for electrochemical biosensors with nanomolar sensitivity. Carbon 2022, 188, 209–219. [Google Scholar] [CrossRef]

- Ren, M.; Zheng, H.; Lei, J.; Zhang, J.; Wang, X.; Yakobson, B.I.; Yao, Y.; Tour, J.M. CO2 to formic acid using Cu-Sn on laser-induced graphene. ACS Appl. Mater. Interfaces 2020, 12, 41223–41229. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Yan, D.; Zhang, Y. Mechanics of unusual soft network materials with rotatable structural nodes. J. Mech. Phys. Solids 2021, 146, 104210. [Google Scholar] [CrossRef]

- Yan, D.; Chang, J.; Zhang, H.; Liu, J.; Song, H.; Xue, Z.; Zhang, F.; Zhang, Y. Soft three-dimensional network materials with rational bio-mimetic designs. Nat. Commun. 2020, 11, 1180. [Google Scholar] [CrossRef] [Green Version]

- Stanford, M.G.; Zhang, C.; Fowlkes, J.D.; Hoffman, A.; Ivanov, I.N.; Rack, P.D.; Tour, J.M. High-resolution laser-induced graphene. flexible electronics beyond the visible limit. ACS Appl. Mater. Interfaces 2020, 12, 10902–10907. [Google Scholar] [CrossRef]

- Pang, W.; Cheng, X.; Zhao, H.; Guo, X.; Ziyao, J.; Ji, G.; Liang, Y.; Xue, Z.; Honglie, S.; Zhang, F.; et al. Electro-mechanically controlled assembly of reconfigurable 3D mesostructures and electronic devices based on dielectric elastomer platforms. Natl. Sci. Rev. 2019, 7, 342–354. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, F.; Yan, Z.; Ma, Q.; Li, X.; Huang, Y.; Rogers, J.A. Printing, folding and assembly methods for forming 3D mesostructures in advanced materials. Nat. Rev. Mater. 2017, 2, 17019. [Google Scholar] [CrossRef]

- Bai, K.; Cheng, X.; Xue, Z.; Song, H.; Sang, L.; Zhang, F.; Liu, F.; Luo, X.; Huang, W.; Huang, Y.; et al. Geometrically reconfigurable 3D mesostructures and electromagnetic devices through a rational bottom-up design strategy. Sci. Adv. 2020, 6, eabb7417. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zhao, Z.; Liu, P.; Guo, X. Laser-Induced Graphene Based Flexible Electronic Devices. Biosensors 2022, 12, 55. https://doi.org/10.3390/bios12020055

Wang H, Zhao Z, Liu P, Guo X. Laser-Induced Graphene Based Flexible Electronic Devices. Biosensors. 2022; 12(2):55. https://doi.org/10.3390/bios12020055

Chicago/Turabian StyleWang, Hao, Zifen Zhao, Panpan Liu, and Xiaogang Guo. 2022. "Laser-Induced Graphene Based Flexible Electronic Devices" Biosensors 12, no. 2: 55. https://doi.org/10.3390/bios12020055