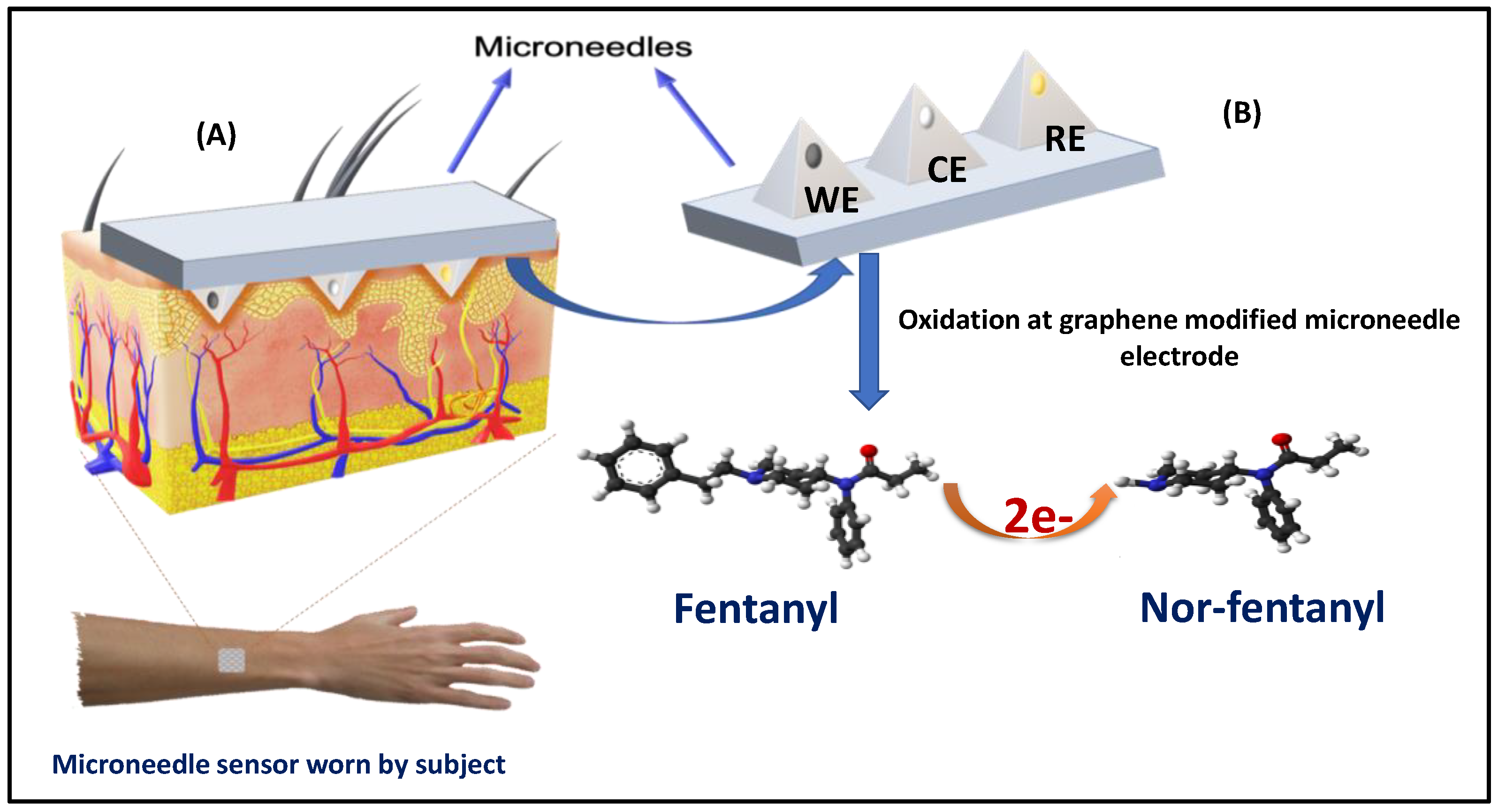

Transdermal Polymeric Microneedle Sensing Platform for Fentanyl Detection in Biofluid

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Microneedle Fabrication

2.3. Electrochemical Characterization

3. Results

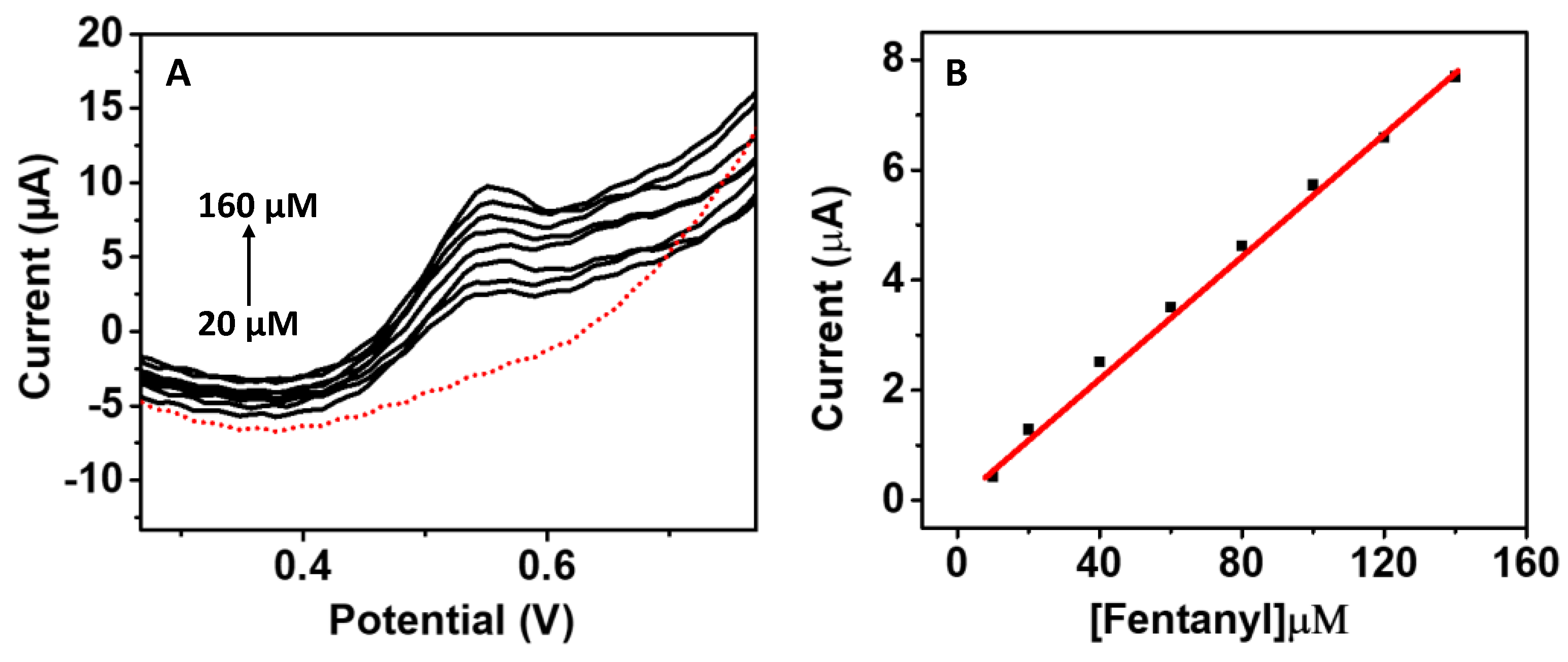

3.1. Fentanyl Detection on Microneedle Surface

3.2. Fentanyl Detection in Serum Sample

3.3. Sensor Selectivity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Armenian, P.; Vo, K.T.; Barr-Walker, J.; Lynch, K.L. Fentanyl, fentanyl analogs and novel synthetic opioids: A comprehensive review. Neuropharmacology 2018, 134, 121–132. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Claxton, A.R.; McGuire, G.; Chung, F.; Cruise, C. Evaluation of morphine versus fentanyl for postoperative analgesia after ambulatory surgical procedures. Anesth. Analg. 1997, 84, 509–514. [Google Scholar] [CrossRef] [PubMed]

- Bollella, P.; Sharma, S.; Cass, A.E.G.; Antiochia, R. Microneedle-based biosensor for minimally invasive lactate detection. Biosens. Bioelectron. 2019, 123, 152–159. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Riches, J.R.; Read, R.W.; Black, R.M.; Cooper, N.J.; Timperley, C.M. Analysis of Clothing and Urine from Moscow Theatre Siege Casualties Reveals Carfentanil and Remifentanil Use. J. Anal. Toxicol. 2012, 36, 647–656. [Google Scholar] [CrossRef] [Green Version]

- Barfidokht, A.; Mishra, R.K.; Seenivasan, R.; Liu, S.; Hubble, L.J.; Wang, J.; Hall, D.A. Wearable electrochemical glove-based sensor for rapid and on-site detection of fentanyl. Sensors Actuators B Chem. 2019, 296, 126422. [Google Scholar] [CrossRef] [PubMed]

- Slavova, S.; Costich, J.F.; Bunn, T.L.; Luu, H.; Singleton, M.; Hargrove, S.L.; Triplett, J.S.; Quesinberry, D.; Ralston, W.; Ingram, V. Heroin and fentanyl overdoses in Kentucky: Epidemiology and surveillance. Int. J. Drug Policy 2017, 46, 120–129. [Google Scholar] [CrossRef]

- Pandey, P.C.; Mitra, M.D.; Shukla, S.; Narayan, R.J. Organotrialkoxysilane-functionalized noble metal monometallic, bimetallic, and trimetallic nanoparticle mediated non-enzymatic sensing of glucose by resonance rayleigh scattering. Biosensors 2021, 11, 122. [Google Scholar] [CrossRef]

- Joshi, P.; Riley, P.; Goud, K.Y.; Mishra, R.K.; Narayan, R. Recent advances of boron-doped diamond electrochemical sensors toward environmental applications. Curr. Opin. Electrochem. 2022, 32, 100920. [Google Scholar] [CrossRef]

- Chen, K.I.; Li, B.R.; Chen, Y.T. Silicon nanowire field-effect transistor-based biosensors for biomedical diagnosis and cellular recording investigation. Nano Today 2011, 6, 131–154. [Google Scholar] [CrossRef]

- Pei, J.; Tian, F.; Thundat, T. Glucose Biosensor Based on the Microcantilever. Anal. Chem. 2004, 76, 292–297. [Google Scholar] [CrossRef] [PubMed]

- Ramachandran, A.; Wang, S.; Clarke, J.; Ja, S.J.; Goad, D.; Wald, L.; Flood, E.M.; Knobbe, E.; Hryniewicz, J.V.; Chu, S.T.; et al. A universal biosensing platform based on optical micro-ring resonators. Biosens. Bioelectron. 2008, 23, 939–944. [Google Scholar] [CrossRef] [PubMed]

- Kathuria, H.; Kochhar, J.S.; Kang, L. Micro and nanoneedles for drug delivery and biosensing. Ther. Deliv. 2018, 9, 489–492. [Google Scholar] [CrossRef] [Green Version]

- Riley, P.R.; Narayan, R.J. Recent advances in carbon nanomaterials for biomedical applications: A review. Curr. Opin. Biomed. Eng. 2021, 17, 100262. [Google Scholar] [CrossRef] [PubMed]

- Samant, P.P.; Prausnitz, M.R. Mechanisms of sampling interstitial fluid from skin using a microneedle patch. Proc. Natl. Acad. Sci. USA 2018, 115, 4583–4588. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schierenbeck, F.; Franco-Cereceda, A.; Liska, J. Accuracy of 2 Different Continuous Glucose Monitoring Systems in Patients Undergoing Cardiac Surgery. J. Diabetes Sci. Technol. 2017, 11, 108–116. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miller, P.R.; Taylor, R.M.; Tran, B.Q.; Boyd, G.; Glaros, T.; Chavez, V.H.; Krishnakumar, R.; Sinha, A.; Poorey, K.; Williams, K.P.; et al. Extraction and biomolecular analysis of dermal interstitial fluid collected with hollow microneedles. Commun. Biol. 2018, 1, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pires, L.R.; Vinayakumar, K.B.; Turos, M.; Miguel, V.; Gaspar, J. A Perspective on Microneedle-Based Drug Delivery and Diagnostics in Paediatrics. J. Pers. Med. 2019, 9, 49. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miller, P.R.; Skoog, S.A.; Edwards, T.L.; Wheeler, D.R.; Xiao, X.; Brozik, S.M.; Polsky, R.; Narayan, R.J. Hollow Microneedle-based sensor for multiplexed transdermal electrochemical sensing. J. Vis. Exp. 2012, 64, e4067. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, L.; Wen, Z.; Jiang, F.; Zheng, Z.; Lu, S. Silk/polyols/GOD microneedle based electrochemical biosensor for continuous glucose monitoring. RSC Adv. 2020, 10, 6163–6171. [Google Scholar] [CrossRef] [Green Version]

- Goud, K.Y.; Moonla, C.; Mishra, R.K.; Yu, C.; Narayan, R.; Litvan, I.; Wang, J. Wearable Electrochemical Microneedle Sensor for Continuous Monitoring of Levodopa: Toward Parkinson Management. ACS Sens. 2019, 4, 2196–2204. [Google Scholar] [CrossRef] [PubMed]

- Pandey, P.C.; Shukla, S.; Skoog, S.A.; Boehm, R.D.; Narayan, R.J. Current Advancements in Transdermal Biosensing and Targeted Drug Delivery. Sensors 2019, 19, 1028. [Google Scholar] [CrossRef] [Green Version]

- Gill, H.S.; Denson, D.D.; Burris, B.A.; Prausnitz, M.R. Effect of microneedle design on pain in human volunteers. Clin. J. Pain 2008, 24, 585–594. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaushik, S.; Hord, A.H.; Denson, D.D.; McAllister, D.V.; Smitra, S.; Allen, M.G.; Prausnitz, M.R. Lack of pain associated with microfabricated microneedles. Anesth. Analg. 2001, 92, 502–504. [Google Scholar] [CrossRef] [Green Version]

- Gill, H.S.; Prausnitz, M.R. Coated microneedles for transdermal delivery. J. Control. Release 2007, 117, 227–237. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, J.H.; Allen, M.G.; Prausnitz, M.R. Biodegradable polymer microneedles: Fabrication, mechanics and transdermal drug delivery. J. Control. Release 2005, 104, 51–66. [Google Scholar] [CrossRef]

- Wang, P.M.; Cornwell, M.; Hill, J.; Prausnitz, M.R. Precise Microinjection into Skin Using Hollow Microneedles. J. Investig. Dermatol. 2006, 126, 1080–1087. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- McAllister, D.V.; Wang, P.M.; Davis, S.P.; Park, J.-H.; Canatella, P.J.; Allen, M.G.; Prausnitz, M.R. Microfabricated needles for transdermal delivery of macromolecules and nanoparticles: Fabrication methods and transport studies. Proc. Natl. Acad. Sci. USA 2003, 100, 13755–13760. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gittard, S.D.; Ovsianikov, A.; Monteiro-Riviere, N.A.; Lusk, J.; Morel, P.; Minghetti, P.; Lenardi, C.; Chichkov, B.N.; Narayan, R.J. Fabrication of Polymer Microneedles Using a Two-Photon Polymerization and Micromolding Process. J. Diabetes Sci. Technol. 2009, 3, 304. [Google Scholar] [CrossRef] [Green Version]

- Miller, P.R.; Gittard, S.D.; Edwards, T.L.; Lopez, D.M.; Xiao, X.; Wheeler, D.R.; Monteiro-Riviere, N.A.; Brozik, S.M.; Polsky, R.; Narayan, R.J. Integrated carbon fiber electrodes within hollow polymer microneedles for transdermal electrochemical sensing. Biomicrofluidics 2011, 5, 013415. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gittard, S.D.; Narayan, R.; Lusk, J.; Morel, P.; Stockmans, F.; Ramsey, M.; Laverde, C.; Phillips, J.; Monteiro-Riviere, N.A.; Ovsianikov, A.; et al. Rapid prototyping of scaphoid and lunate bones. Biotechnol. J. 2009, 4, 129–134. [Google Scholar] [CrossRef] [PubMed]

- Miller, P.R.; Skoog, S.A.; Edwards, T.L.; Lopez, D.M.; Wheeler, D.R.; Arango, D.C.; Xiao, X.; Brozik, S.M.; Wang, J.; Polsky, R.; et al. Multiplexed microneedle-based biosensor array for characterization of metabolic acidosis. Talanta 2012, 88, 739–742. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Joshi, P.; Mishra, R.; Narayan, R.J. Biosensing applications of carbon-based materials. Curr. Opin. Biomed. Eng. 2021, 18, 100274. [Google Scholar] [CrossRef]

- DEA Issues Nationwide Alert on Fentanyl as Threat to Health and Public Safety. Available online: https://www.dea.gov/press-releases/2015/03/18/dea-issues-nationwide-alert-fentanyl-threat-health-and-public-safety (accessed on 15 February 2022).

| Material | wt.% |

|---|---|

| Phenylbis(2,4,6 trimethylbenzoyl)-phosphine oxide photoinitiator | 0.5–1.5 |

| Propylated (2) neopentyl glycoldiacrylate | 15–30 |

| Urethane dimethacrylate | 60–80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Joshi, P.; Riley, P.R.; Mishra, R.; Azizi Machekposhti, S.; Narayan, R. Transdermal Polymeric Microneedle Sensing Platform for Fentanyl Detection in Biofluid. Biosensors 2022, 12, 198. https://doi.org/10.3390/bios12040198

Joshi P, Riley PR, Mishra R, Azizi Machekposhti S, Narayan R. Transdermal Polymeric Microneedle Sensing Platform for Fentanyl Detection in Biofluid. Biosensors. 2022; 12(4):198. https://doi.org/10.3390/bios12040198

Chicago/Turabian StyleJoshi, Pratik, Parand R. Riley, Rupesh Mishra, Sina Azizi Machekposhti, and Roger Narayan. 2022. "Transdermal Polymeric Microneedle Sensing Platform for Fentanyl Detection in Biofluid" Biosensors 12, no. 4: 198. https://doi.org/10.3390/bios12040198

APA StyleJoshi, P., Riley, P. R., Mishra, R., Azizi Machekposhti, S., & Narayan, R. (2022). Transdermal Polymeric Microneedle Sensing Platform for Fentanyl Detection in Biofluid. Biosensors, 12(4), 198. https://doi.org/10.3390/bios12040198