A Flexible Pressure Sensor Based on Silicon Nanomembrane

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Principle

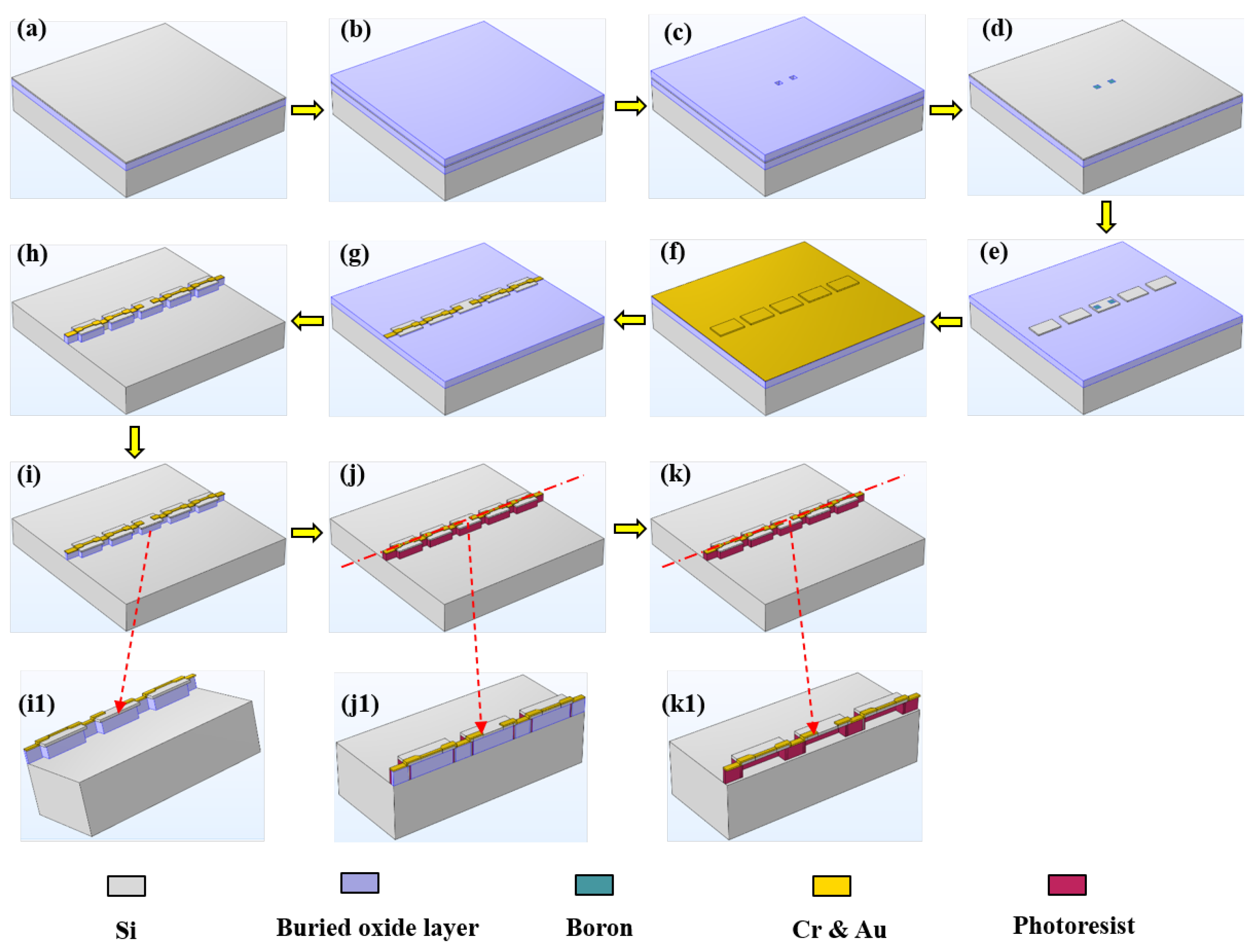

2.2. Fabrication of Silicon Nanomembrane

- (a)

- Cleaning wafers. Standard cleaning was performed on a 4 inch SOI wafer followed by drying with N2 to ensure that the wafer surface was clean;

- (b)

- Plasma-enhanced chemical vapor deposition (PECVD). PECVD was performed. The SOI wafer was placed in an SI500D plasma-enhanced chemical vapor deposition apparatus produced by SENTECH company (Berlin, Germany), and 1μm thick SiO2 was deposited on the wafer surface;

- (c)

- Photoetching the ohmic contact zone and etching SiO2. The SOI wafer was placed in a TATUNG vacuum oven to deposit hexamethyldisilazane (HMDS) adhesive at 130 °C for 1800 s and enhance the adhesion between the photoresist and the SOI wafer. The AZ6130 positive photoresist was spin-coated at 3000 rpm and then pre-baked on a hot plate at 100 °C for 75 s; then, a contact lithography machine (EVG-610TB) produced by the EVG company (St. Florian, Austria) was used for exposure. The fabricated specimen was exposed to a dose of 100 mJ/cm2. Then, the specimen was placed in a plasma degumming machine (ION Wave 10) at a power of 300 W for 2 min to remove the bottom film. Finally, it was placed on a drying table at 120 °C and hardened for 900 s. The SOI wafer was then placed in a reactive ion etching machine (RIE-10NR) produced by the SPTS company (Newport, England) to etch SiO2 at an etching rate of 20 nm/min for an estimated etching time of 50 min. After the etching was complete, the unetched silicon oxide was rinsed using the buffered oxide etch (BOE) solution. Then, an RTS-8 four-probe test system was used to measure the test area of the SOI wafer, which helped confirm whether the etched position reached the top silicon layer;

- (d)

- Doping boron and eroding impurities. The SOI wafer was cleaned and placed in a diffusion furnace (HQ100A-3DF10) produced by Qingdao Huaqi (Qingdao, China) at 1000 °C, and concentrated boron diffusion was carried out over an ohmic contact area for 10 min. Impurities, such as silicon oxide and borosilicate glass, were formed on the surface of the top-layer silicon after the doping. Then, the wafer was placed in the BOE solution to erode at 40 °C for 480 s. After erosion, the four-probe test system was used to further confirm whether the impurities were completely corroded;

- (e)

- Etching the piezoresistive region after photolithography. The positive photoresist was uniformly spin-coated. After exposure, the film was developed and hardened, and the piezoresistive region was retained. The reactive ion etching machine was used to etch the top-layer silicon (thickness = 340 nm) at an etching rate of 15 nm/min and etching time of approximately 23 min;

- (f)

- Sputtering metal and photolithography. The SOI wafer was placed in an EXPLORED magnetron sputtering coater produced by the Danton Vacuum company (Philadelphia, America) and sputtered with 30 nm Cr and 300 nm Au. Then, the photoresist was evenly spin-coated to finish the photolithography progress as before and the metal area was photoetched;

- (g)

- Corroding metal and annealing. The metals were successively corroded with the prepared gold and chromium etchants. After removing the photoresist, the SOI wafer was placed in a Hefei Kejing vacuum annealing furnace and annealed at 380 °C for 900 s so that the metal and the semiconductor formed an alloy, and the damage introduced during the diffusion process was repaired;

- (h)

- Etching the buried oxide layer after photolithography. Considering that the thickness of the buried oxide layer was 3 μm, an AZ4620 photoresist was selected. The speed was 3000 rpm, the thickness of the photoresist was approximately 6 μm, and the exposure dose was 200 mJ/cm2. The SOI wafer was placed in the RIE etching machine after photolithography, and the etching time was approximately 150 min. The buried oxide layer directly under the silicon nanomembrane and the metal strip was retained, and the rest of the buried oxide layer was completely etched away;

- (i)

- Wet-etching part of the buried oxide layer. The SOI wafer was placed in the BOE solution and eroded at room temperature. The progress in the corrosion was observed several times. After erosion, the SOI wafer was rinsed using deionized water and allowed to dry naturally. It was examined using a LEXTOLS4100 confocal microscope produced by OLYMPUS (Tokyo, Japan), and the measured corrosion depth was approximately 5 μm. A “roof structure” was formed under the piezoresistive area;

- (j)

- Photolithography and full exposure. Full exposure was performed with an exposure dose of 20 mJ/cm2 after spin-coating the photoresist on the SOI wafer. After development, the film was hardened and the photoresist under the “roof structure” was retained;

- (k)

- Eroding the buried oxide layer. The buried oxide layer was eroded using HF wet etching solution at room temperature. The progress in the corrosion was observed every few minutes. The wafer was examined under a confocal microscope after the etching was complete. The buried oxide layer was completely etched away, leaving behind the suspended silicon nanomembrane structure supported by the photoresist.

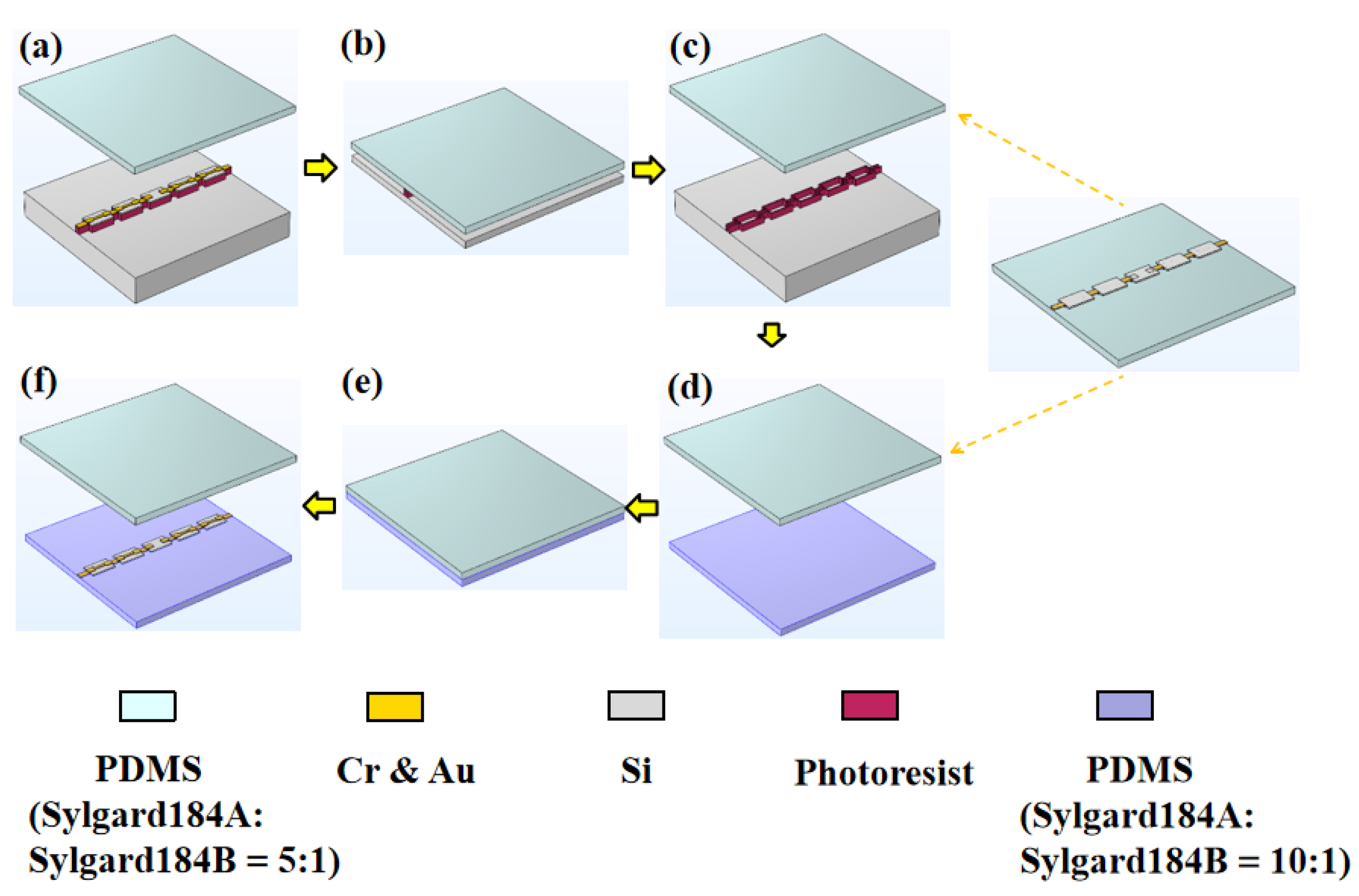

2.3. Transfer of Silicon Nanomembrane

2.4. Integration of the Sensor

3. Results and Discussion

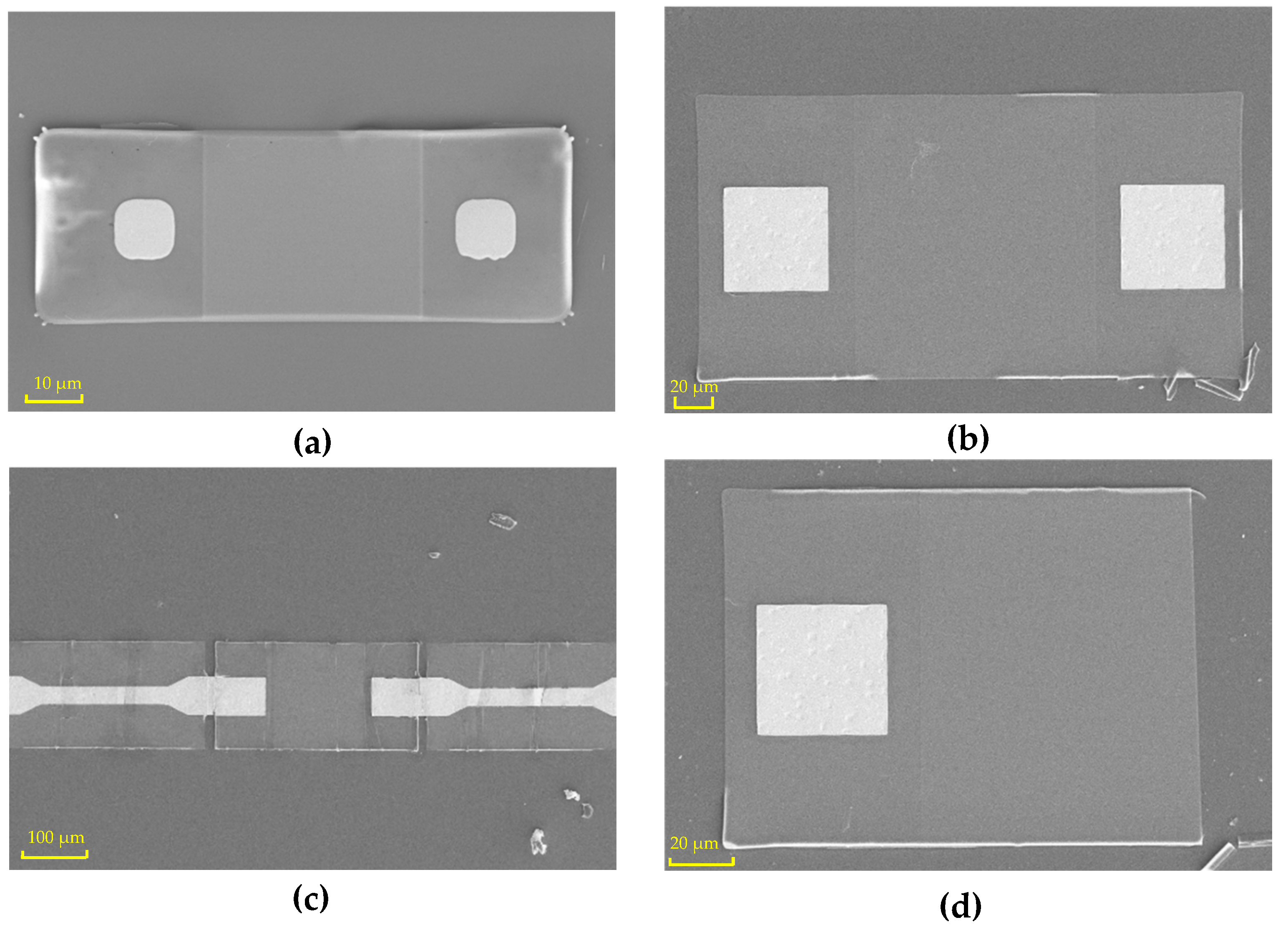

3.1. Characterizations of Silicon Nanomembrane

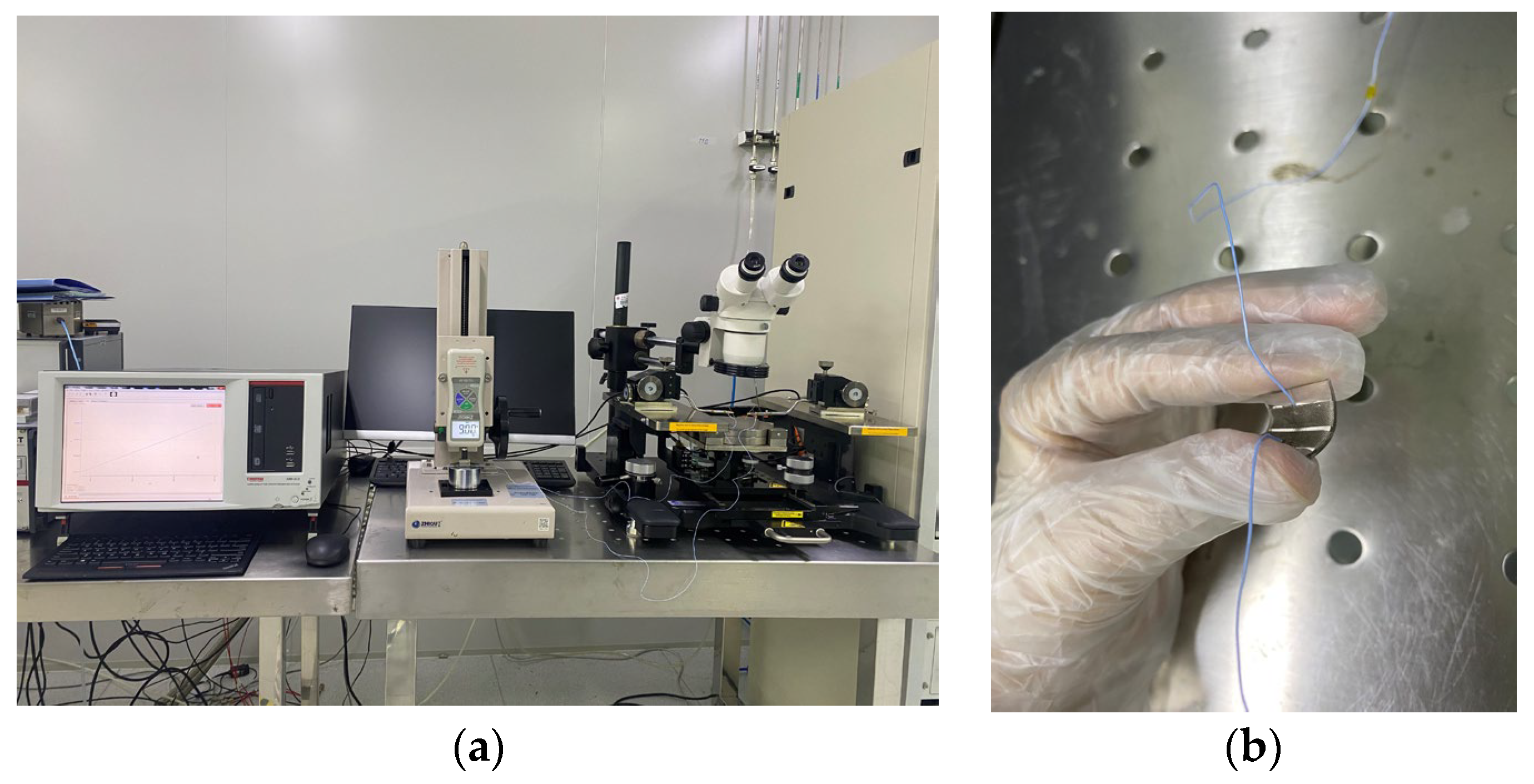

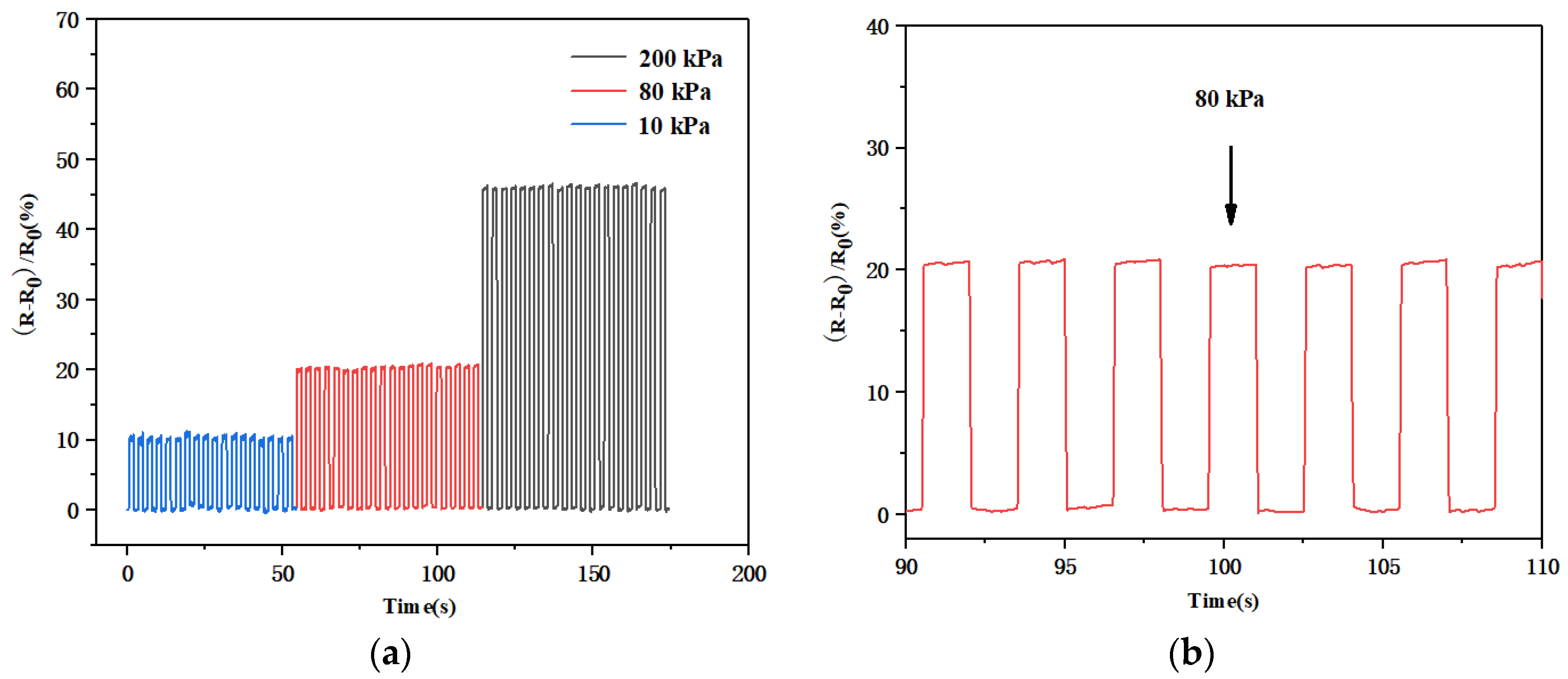

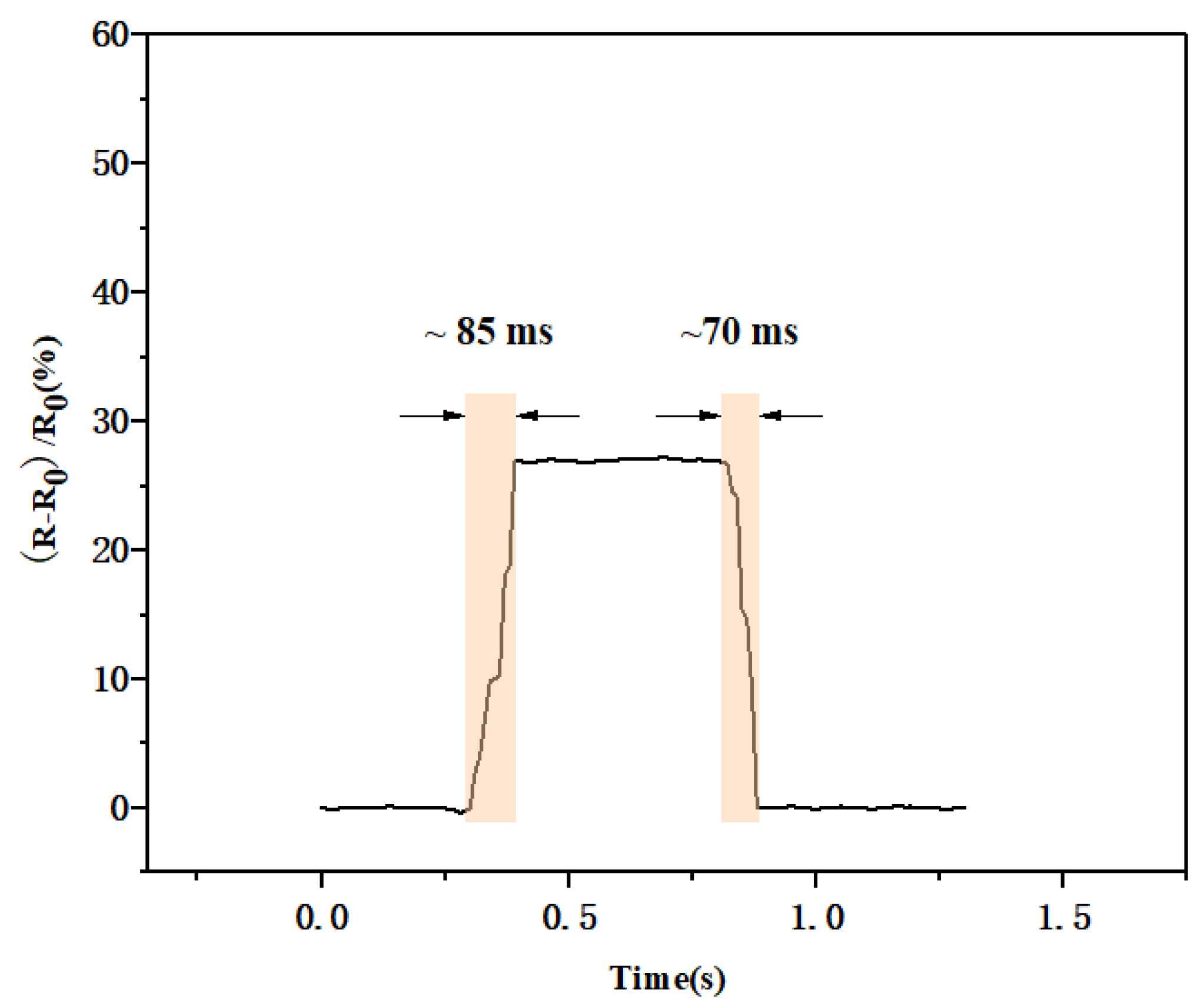

3.2. Sensing Performance of the Flexible Pressure Sensor

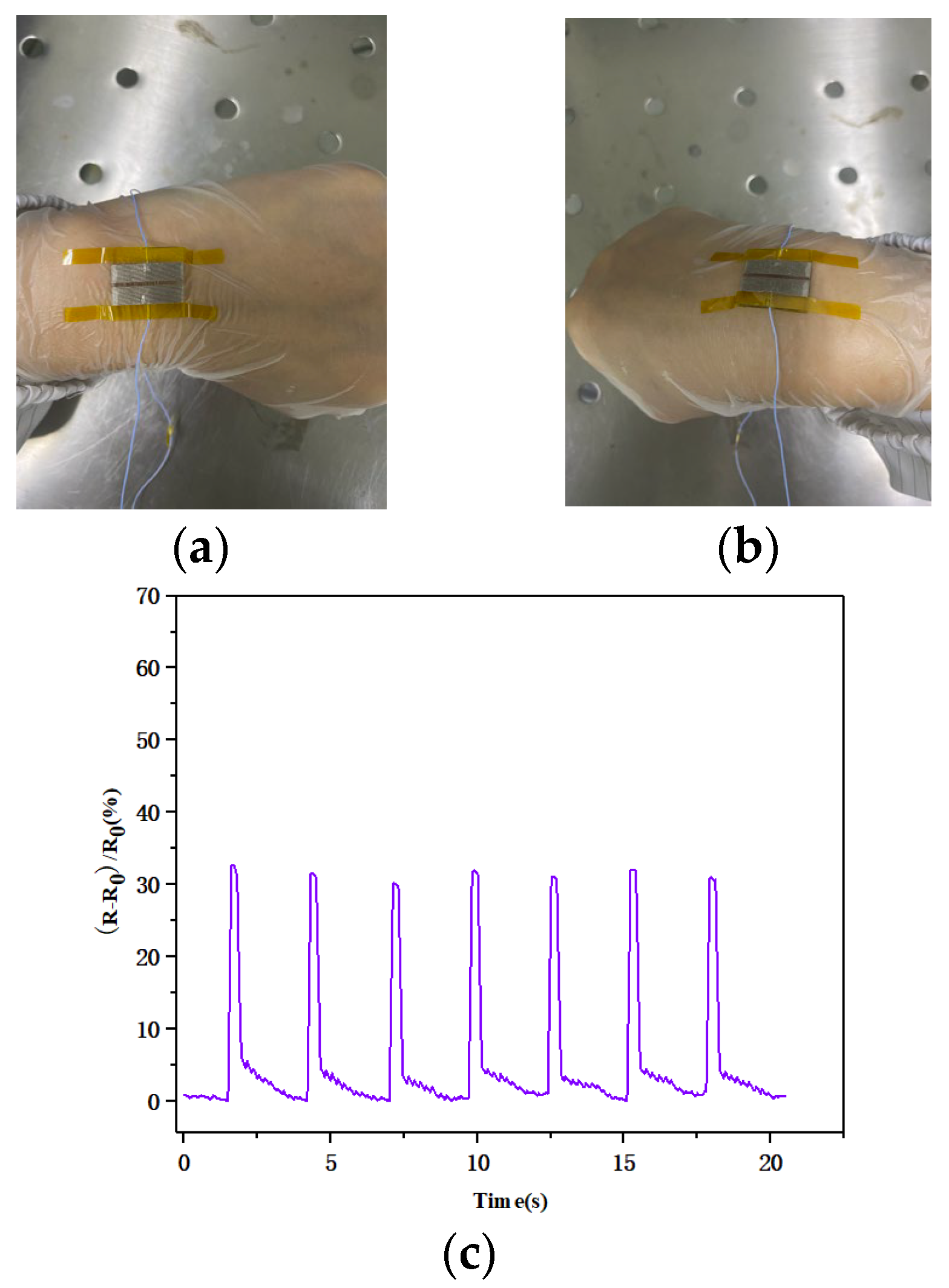

3.3. Application of the Flexible Pressure Sensor

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ganesh, R.S.; Yoon, H.J.; Kim, S.W. Recent Trends of Biocompatible Triboelectric Nanogenerators Toward Self-Powered E-Skin. EcoMater 2020, 2, 12065. [Google Scholar] [CrossRef]

- Yang, J.C.; Mun, J.; Kwon, S.Y.; Park, S.; Bao, Z.N.; Park, S. Electronic Skin: Recent Progress and Future Prospects for Skin-Attachable Devices for Health Monitoring, Robotics, and Prosthetics. Adv. Mater. 2019, 31, 1904765. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, S.; Li, S.; Xia, Z.; Cai, K. A Review of Electronic Skin: Soft Electronics and Sensors for Human Health. J. Mater. Chem. B 2020, 8, 852–862. [Google Scholar] [CrossRef]

- Chou, H.H.; Nguyen, A.; Chortos, A.; To, J.W.; Lu, C.; Mei, J.; Kurosawa, T.; Bae, W.G.; Tok, J.B.; Bao, Z.N. A Chameleon-Inspired Stretchable Electronic Skin with Interactive Colour Changing Controlled by Tactile Sensing. Nat. Commun. 2015, 6, 8011. [Google Scholar] [CrossRef] [Green Version]

- Lee, Y.; Park, J.; Choe, A.; Cho, S.; Kim, J.Y.; Ko, H. Mimicking Human and Biological Skins for Multifunctional Skin Electronics. Adv. Funct. Mater. 2020, 30, 1904523. [Google Scholar] [CrossRef]

- Nie, P.; Wang, R.R.; Xu, X.J.; Cheng, Y.; Wang, X.; Shi, L.J.; Sun, J. High-Performance Piezoresistive Electronic Skin with Bionic Hierarchical Microstructure and Microcracks. ACS Appl. Mater. Interfaces 2017, 9, 14911–14919. [Google Scholar] [CrossRef]

- Webb, R.C.; Bonifas, A.P.; Behnaz, A.; Zhang, Y.H.; Yu, K.J.; Cheng, H.; Shi, M.; Bian, Z.; Liu, Z.; Kim, Y.S.; et al. Ultrathin Conformal Devices for Precise and Continuous Thermal Characterization of Human Skin. Nat. Mater. 2013, 12, 938–944. [Google Scholar] [CrossRef] [Green Version]

- Bianchi, C.; Loureiro, J.; Duarte, P.; Marques, J.; Figueira, J.; Ropio, I.; Ferreira, I. V2O5 Thin Films for Flexible and High Sensitivity Transparent Temperature Sensor. Adv. Mater. Technol. 2016, 1, 1600077. [Google Scholar] [CrossRef]

- Zhao, T.T.; Li, T.K.; Chen, L.L.; Yuan, L.; Li, X.F.; Zhang, J.H. Highly Sensitive Flexible Piezoresistive Pressure Sensor Developed Using Biomimetically Textured Porous Materials. ACS Appl. Mater. Interfaces 2019, 11, 29466–29473. [Google Scholar] [CrossRef]

- Li, T.K.; Chen, L.L.; Yang, X.; Chen, X.; Zhang, Z.H.; Zhao, T.T.; Li, X.F.; Zhang, J.H. A Flexible Pressure Sensor Based on An MXene–textile Network Structure. J. Mater. Chem. C 2019, 7, 1022–1027. [Google Scholar] [CrossRef]

- Xu, K.; Lu, Y.Y.; Takei, K. Multifunctional Skin-Inspired Flexible Sensor Systems for Wearable Electronics. Adv. Mater. Technol. 2019, 4, 1800628. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.H.; Yao, H.M.; Mo, J.Y.; Chen, S.Y.; Xie, Y.; Ma, S.L.; Chen, R.; Ling, W.S.; Qin, L.F.; Wang, Z.K.; et al. Finger-inspired Rigid-soft Hybrid Tactile Sensor with Superior Sensitivity at High Frequency. Nat. Commun. 2022, 13, 5076. [Google Scholar] [CrossRef] [PubMed]

- Vogt, D.M.; Park, Y.L.; Wood, R.J. Design and Characterization of a Soft Multi-axis Force Sensor Using Embedded Microfluidic Channels. IEEE Sens. J. 2013, 13, 4056–4064. [Google Scholar] [CrossRef] [Green Version]

- Pan, L.J.; Chortos, A.; Yu, G.H.; Wang, Y.Q.; Isaacson, S.; Allen, R.; Shi, Y.; Dauskardt, R.; Bao, Z.N. An U ltra-sensitive Resistive Pressure Sensor Based on Hollow-sphere Microstructure Induced Elasticity in Conducting Polymer Film. Nat. Commun. 2014, 5, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Ge, J.; Wang, X.; Drack, M.; Volkov, O.; Liang, M.; Bermudez, G.S.C.; Illing, R.; Wang, C.G.; Zhou, S.Q.; Fassbender, J.; et al. A Bimodal Soft Electronic Skin for Tactile and Touchless Interaction in Real Time. Nat. Commun. 2019, 10, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Park, Y.L.; Majidi, C.; Kramer, R.; Berard, P.; Wood, R.J. Hyperelastic Pressure Sensing with a Liquid-embedded Elastomer. Micromech. Microeng. 2010, 20, 125029. [Google Scholar] [CrossRef] [Green Version]

- Chun, S.; Kim, Y.; Oh, H.; Bae, G.; Park, W. Highly Sensitive Pressure Sensor Using a Double-layered Graphene Structure for Tactile Sensing. Nanoscale 2015, 7. [Google Scholar] [CrossRef]

- Yuan, H.; Lei, T.M.; Qin, Y.; Yang, R.S. Flexible Electronic Skins Based on Piezoelectric Nanogenerators and Piezotronics. Nano Energy 2019, 59, 84–90. [Google Scholar] [CrossRef]

- Ha, M.; Lim, S.; Cho, S.; Lee, Y.; Na, S.; Baig, C.; Ko, H. Skin-inspired Hierarchical Polymer Architectures with Gradient Stiffness for Spacer-free, Ultrathin, and Highly Sensitive Triboelectric Sensors. ACS Nano 2018, 12, 3964–3974. [Google Scholar] [CrossRef]

- Tien, N.T.; Jeon, S.H.; Kim, D.; Trung, T.Q.; Jang, M.; Hwang, B.; Byun, K.; Bae, J.; Lee, E.; Tok, J.B.; et al. A flexible Bimodal Sensor Array for Simultaneous Sensing of Pressure and Temperature. Adv. Mater. 2014, 26, 796–804. [Google Scholar] [CrossRef]

- Wu, W.Z.; Wen, X.N.; Wang, Z.L. Taxel-addressable Matrix of Vertical-nanowire Piezotronic Transistors for Active and Adaptive Tactile Imaging. Science 2013, 340, 952–957. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.T.; Song, Y.; Guo, H.; Miao, L.M.; Chen, X.X.; Su, Z.M.; Zhang, H.X. Hybrid Porous Micro Structured Finger Skin Inspired Self-powered Electronic Skin System for Pressure Sensing and Sliding Detection. Nano Energy 2018, 51, 496–503. [Google Scholar] [CrossRef]

- Chen, H.T.; Miao, L.M.; Su, Z.M.; Song, Y.; Han, M.D.; Chen, X.X.; Cheng, X.L.; Chen, D.M.; Zhang, H.X. Fingertip-inspired Electronic Skin Based on Triboelectric Sliding Sensing and Porous Piezoresistive Pressure Detection. Nano Energy 2017, 40, 65–72. [Google Scholar] [CrossRef]

- Cao, Y.D.; Li, T.; Gu, Y.; Luo, H.; Wang, S.Q.; Zhang, T. Fingerprint-inspired Flexible Tactile Sensor for Accurately Discerning Surface Texture. Adv. Sci. News 2018, 1703902. [Google Scholar] [CrossRef] [PubMed]

- Kuang, J.; Dai, Z.H.; Liu, L.Q.; Yang, Z.; Jin, M.; Zhang, Z. Synergistic Effects from Graphene and Carbon Nanotubes Enable Ordered Hierarchical Structure Foams with Combination of Compressibility, Super- elasticity and Stability, and Their Potential Application as Pressure Sensors. Nanoscale 2015, 7, 9252–9260. [Google Scholar] [CrossRef]

- Tian, H.; Shu, Y.; Cui, Y.L.; Mi, W.T.; Yang, Y.; Xie, D.; Ren, T.L. Scalable Fabrication of High-performance and Flexible Graphene Strain Sensors. Nanoscale 2014, 6, 699–705. [Google Scholar] [CrossRef]

- Park, J.J.; Hyun, W.J.; Mun, S.C.; Park, Y.T.; Park, O.O. Highly Stretchable and Wearable Graphene Strain Sensors with Controllable Sensitivity for Human Motion Monitoring. ACS Appl. Mater. Interfaces 2015, 7, 6317–6324. [Google Scholar] [CrossRef]

- Yang, T.T.; Wang, W.; Zhang, H.Z.; Li, X.M.; Shi, J.D.; He, Y.J.; Zheng, Q.S.; Li, Z.H.; Zhu, H.W. Tactile Sensing System Based on Arrays of Graphene Woven Microfabrics: Electromechanical Behavior and Electronic Skin Application. ACS Nano 2015, 9, 10867–10875. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Vosgueritchian, M.; Tee, B.C.; Hellstrom, S.L.; Lee, J.A.; Fox, C.H.; Bao, Z.N. Skin-like Pressure and Strain Sensors Based on Transparent Elastic Films of Carbon Nanotubes. Nat. Nanotech. 2011, 6, 788–792. [Google Scholar] [CrossRef]

- Fu, X.; Ramos, M.; Al-Jumaily, A.M.; Meshkinzar, A.; Huang, X.Y. Stretchable Strain Sensor Facilely Fabricated Based on Multi-wall Carbon Nanotube Composites with Excellent Performance. Mater Sci. 2019, 54, 2170–2180. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.F.; Song, H.N.; Huang, H.L.; Gou, J. Highly Stretchable and Wearable Strain Sensor Based on Printable Carbon Nanotube Layers/Polydimethylsiloxane Composites with Adjustable Sensitivity. ACS Appl. Mater. Interfaces 2018, 10, 7371–7380. [Google Scholar] [CrossRef]

- Ma, L.F.; Yang, W.; Wang, Y.S.; Chen, H.; Xing, Y.F.; Wang, J.C. Multi-dimensional Strain Sensor Based on Carbon Nanotube Film with Aligned Conductive Networks. Compos. Sci. Technol. 2018, 165, 190–197. [Google Scholar] [CrossRef]

- Cai, L.; Song, L.; Luan, P.S.; Zhang, Q.; Zhang, N.; Gao, Q.Q.; Zhao, D.; Zhang, X.; Tu, M.; Yang, F.; et al. Super-stretchable Transparent Carbon Nanotube-Based Capacitive Strain Sensors for Human Motion Detection. Sci. Rep. 2013, 3, 3048. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chun, S.; Son, W.Y.; Choi, C.S. Flexible Pressure Sensors Using Highly-oriented and Free-standing Carbon Nanotube Sheets. Carbon 2018, 139, 586–592. [Google Scholar] [CrossRef]

- Lei, M.; Feng, K.; Ding, S.; Wang, M.R.; Dai, Z.Y.; Liu, R.L.; Gao, Y.B.; Zhou, Y.N.; Xu, Q.S.; Zhou, B.P. Breathable and Waterproof Electronic Skin with Three-Dimensional Architecture for Pressure and Strain Sensing in Nonoverlapping Mode. ACS Nano 2022, 7. [Google Scholar] [CrossRef] [PubMed]

- Diem, B.; Rey, P.; Renard, S.; Bosson, S.V.; Bono, H.; Michel, F.; Delaye, M.T.; Delapierre, G. SOI ‘SIMOX’; from bulk to surface micromachining, a new age for silicon sensors and actuators. Sens. Actuators A Phys. 1995, 46, 8–16. [Google Scholar] [CrossRef]

- Hwang, G.S.; Giapis, K.P. On the origin of the notching effect during etching in uniform high density plasmas. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 1997, 15, 70–87. [Google Scholar] [CrossRef] [Green Version]

- Woo, J.C.; Kim, G.H.; Kim, J.G.; Kim, C.I. Etching characteristic of ZnO thin films in an inductively coupled plasma. Surf. Coat. Technol. 2008, 202, 5705–5708. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, L.J.; Zhang, H.M.; Zhao, Z.X.; Dong, S.L.; Wei, S.; Zhao, J.; Wang, Z.L.; Guo, B.; Hu, P.A. Highly Sensitive Flexible Three-axis Tactile Sensors Based on The Interface Contact Resistance of Microstructured Graphene. Nanoscale 2018, 10, 7387–7395. [Google Scholar] [CrossRef]

- Smith, A.D.; Niklaus, F.; Paussa, A.; Vaziri, S.; Fischer, A.C.; Sterner, M.; Forsberg, F.; Delin, A.; Esseni, D.; Palestri, P.; et al. Electromechanical Piezoresistive Sensing in Suspended Graphene Membranes. Nano Lett. 2013, 13, 3237–3242. [Google Scholar] [CrossRef]

| Number | Low Speed (rpm) | Constant Time (s) | High Speed (rpm) | Constant Time (s) | Measured Thickness (μm) |

|---|---|---|---|---|---|

| 1 | 500 | 10 | 1500 | 15 | 83 |

| 2 | 500 | 10 | 1200 | 15 | 103 |

| 3 | 500 | 10 | 1000 | 10 | 159 |

| 4 | 500 | 10 | 800 | 10 | 169 |

| 5 | 500 | 10 | 750 | 10 | 193 |

| 6 | 200 | 10 | 0 | 0 | 350 |

| 7 | 100 | 10 | 0 | 0 | 402 |

| 8 | 10 | 3 | 0 | 0 | 502 |

| Source | Substrate | Sensitive Material | Transduction Principle | Sensitivity (GF) | Range |

|---|---|---|---|---|---|

| Chun, S. et al. [17] | PET | Double-layered graphene | Piezoresistivity | 0.24 kPa−1 (<250 Pa) | 0.3 Pa–10 kPa |

| 0.039 kPa−1 (>700 Pa) | |||||

| Lei, M. et al. [35] | PDMS/CIP | Carbon-based conductive materials | Piezoresistivity | 0.0198 kPa−1 (<3 kPa) | 0 Pa–200 kPa |

| 0.0008 kPa−1 (3 kPa–200 kPa) | |||||

| Zhang, J. et al. [39] | Micro-pyramid PDMS | Reduced graphene oxide (RGO) | Piezoresistivity | −1.71 kPa−1 (<2 kPa) | 0 Pa–5 kPa |

| −0.02 kPa−1 (2–5 kPa) | |||||

| Smith., A.D. et al. [40] | Cavities etched into a SiO2 film on a silicon substrate | Graphene membranes | Piezoresistivity | 2.25 × 10−3 kPa−1 | 0 Pa–100 kPa |

| Zhang, J.H. et al. [12] | PDMS/epoxy pillars | PVDF | Piezoelectricity | 346.9 pCN−1 | 0.009–4.3 N |

| Chun, S. et al. [34] | PEN | CNT sheets | Capacitance | 0.06–0.13% (<20 kPa) | 1 Pa–40 kPa |

| 0.02–0.04% (20–40 kPa) | |||||

| This work | PDMS | Silicon nanofilm | Piezoresistivity | 0.0185 kPa−1 (<5 kPa) | 0–200 kPa |

| 0.0023 kPa−1 (5–200 kPa) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, L.; Hao, X.; Liu, G.; Zhang, W.; Cui, J.; Zhang, G.; Yang, Y.; Wang, R. A Flexible Pressure Sensor Based on Silicon Nanomembrane. Biosensors 2023, 13, 131. https://doi.org/10.3390/bios13010131

Cheng L, Hao X, Liu G, Zhang W, Cui J, Zhang G, Yang Y, Wang R. A Flexible Pressure Sensor Based on Silicon Nanomembrane. Biosensors. 2023; 13(1):131. https://doi.org/10.3390/bios13010131

Chicago/Turabian StyleCheng, Lixia, Xiaojian Hao, Guochang Liu, Wendong Zhang, Jiangong Cui, Guojun Zhang, Yuhua Yang, and Renxin Wang. 2023. "A Flexible Pressure Sensor Based on Silicon Nanomembrane" Biosensors 13, no. 1: 131. https://doi.org/10.3390/bios13010131