Enhancing Biocide Safety of Milk Using Biosensors Based on Cholinesterase Inhibition

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Determination of Cholinesterase Enzyme Activity

2.2.2. Fabrication of Screen-Printed Electrodes

2.2.3. Enzyme Immobilization

2.2.4. Biosensor Measurements

2.2.5. Sample Pretreatment Using Liquid–Liquid Extraction

3. Results and Discussion

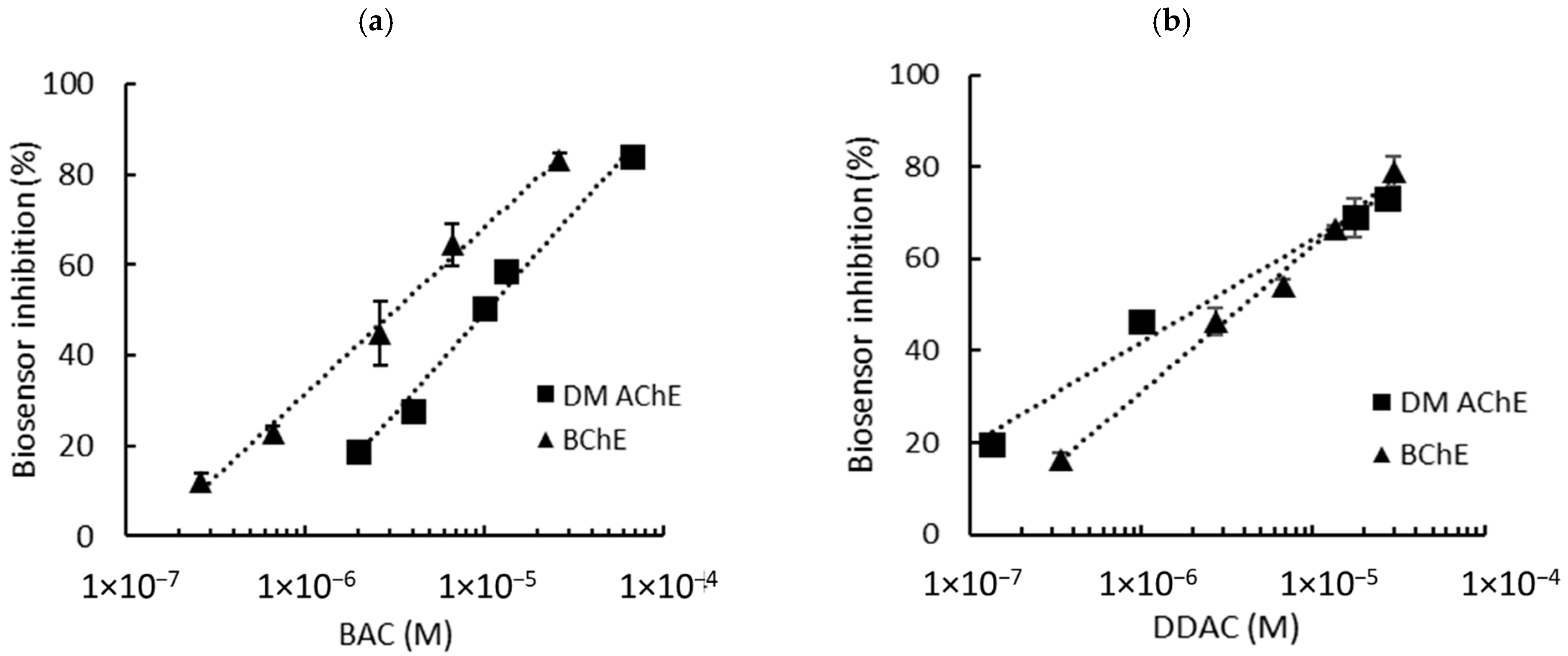

3.1. Tests and Optimization of DM AChE- and BChE-Based Biosensors Operating in PBS

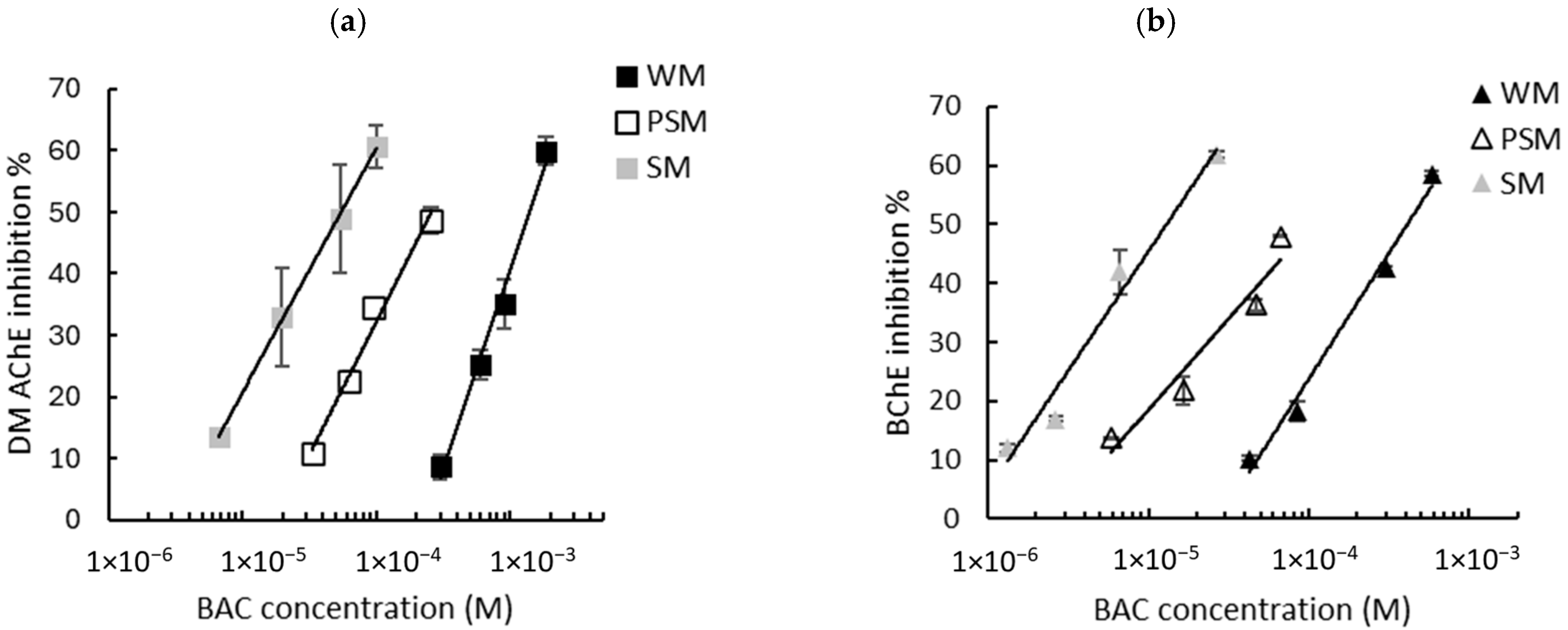

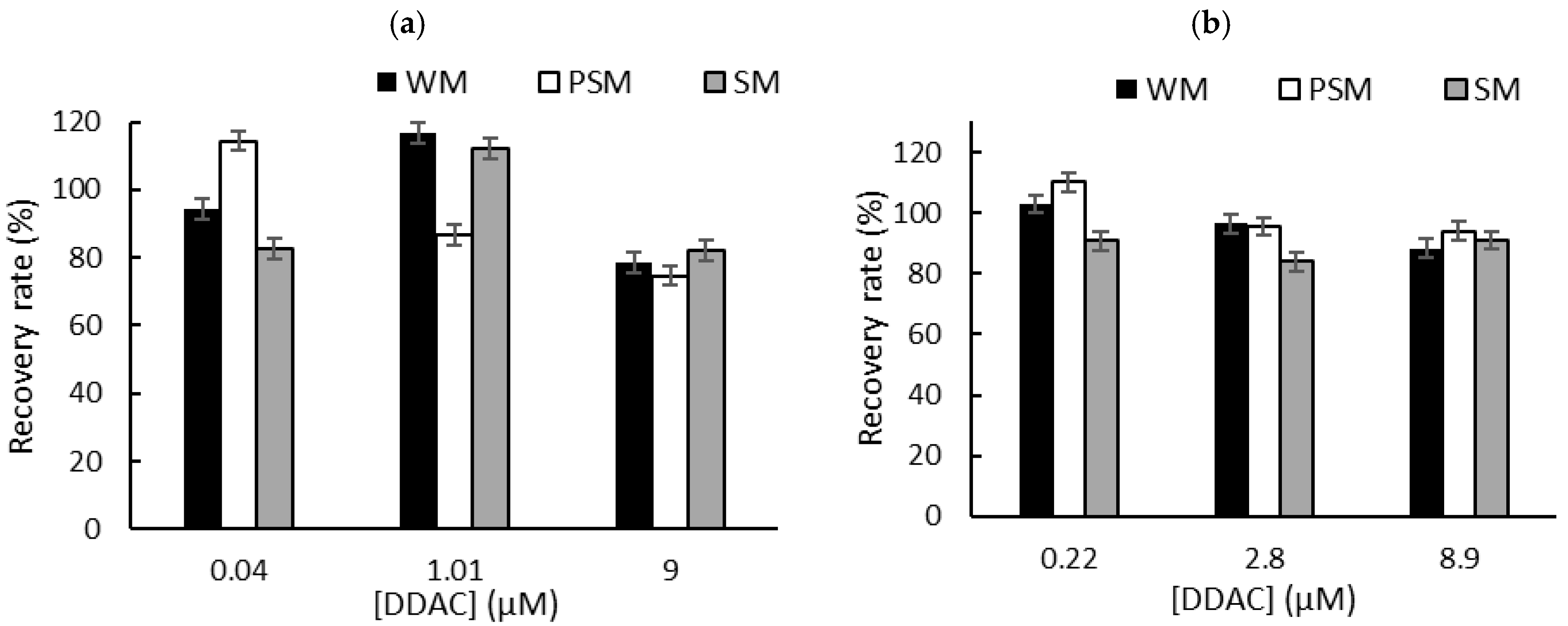

3.2. Detection of BAC and DDAC in Milk

3.2.1. Direct Detection in Milk and the Effect of Fat Content

3.2.2. Detection in PBS After Milk Treatment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DM AChE | Acetylcholinesterase from Drosophila melanogaster |

| ANSES | Agency for Food, Environmental and Occupational Health & Safety |

| BAC | Benzalkonium chloride |

| BChE | Butyrylcholinesterase from horse serum |

| PVA | Biosurfine-MRH photopolymer |

| CoPC | Cobalt phthalocyanine |

| ChE | Cholinesterase |

| DDAC | Didecyldimethylammonium chloride |

| DTNB | 5,5′-dithiobis-2-nitrobenzoic acid |

| EU | European Union |

| EC | European Commission |

| LOD | Limits of detection |

| LOQ | Limits of quantification |

| MRL | Maximum residue limit |

| PBS | Phosphate-buffered saline |

| PSM | Partially skimmed milk |

| PVC | Poly (vinyl) chloride |

| QAs | Quaternary ammonium salts |

| SM | Skimmed milk |

| SPE | Screen printed electrode |

| TNB | 5-thio-2-nitrobenzoic acid |

| WM | Whole milk |

References

- Vereshchagin, A.N.; Frolov, N.A.; Egorova, K.S.; Seitkalieva, M.M.; Ananikov, V.P. Quaternary ammonium compounds (QACs) and ionic liquids (ILs) as biocides: From simple antiseptics to tunable antimicrobials. Int. J. Mol. Sci. 2021, 22, 6793. [Google Scholar] [CrossRef]

- Gaudin, V.; Soumet, C. Development of enzymatic biosensors to detect biocide disinfectants to strengthen self-monitoring in industry. Eng. Proc. 2021, 6, 36. [Google Scholar] [CrossRef]

- Choi, Y.; Kang, M.; Huh, D.; Chae, W.; Moon, K.W. Priority setting for management of hazardous biocides in Korea using chemical ranking and scoring method. Int. J. Environ. Res. Public Health 2020, 17, 1970. [Google Scholar] [CrossRef] [PubMed]

- Bertuzzi, T.; Pietri, A. Determination of benzalkonium homologues and didecyldimethylammonium in powdered and liquid milk for infants by hydrophilic interaction liquid Chromatography–Mass spectrometry. Food Anal. Methods 2014, 7, 1278–1284. [Google Scholar] [CrossRef]

- Journal of the European Union, EU Law n° 1119/2014. Available online: www.eur-lex.europa.eu (accessed on 12 September 2024).

- Slimani, K.; Féret, A.; Pirotais, Y.; Maris, P.; Abjean, J.; Hurtaud-Pessel, D. Liquid chromatography-tandem mass spectrometry multiresidue method for the analysis of quaternary ammonium compounds in cheese and milk products: Development and validation using the total error approach. J. Chromatogr. A 2017, 1517, 86–96. [Google Scholar] [CrossRef] [PubMed]

- Van Dorst, B.; Mehta, J.; Bekaert, K.; Rouah-Martin, E.; De Coen, W.; Dubruel, P.; Blust, R.; Robbens, J. Recent advances in recognition elements of food and environmental biosensors: A review. Biosens. Bioelectron. 2010, 26, 1178–1194. [Google Scholar] [CrossRef]

- Mouawad, L.; Istamboulie, G.; Catanante, G.; Noguer, T. Acetylcholinesterase-and butyrylcholinesterase-based biosensors for the detection of quaternary ammonium biocides in food industry. Foods 2023, 13, 133. [Google Scholar] [CrossRef] [PubMed]

- Marangoni, F.; Pellegrino, L.; Verduci, E.; Ghiselli, A.; Bernabei, R.; Calvani, R.; Cetin, I.; Giampietro, M.; Perticone, F.; Piretta, L.; et al. Cow’s milk consumption and health: A health professional’s guide. J. Am. Coll. Nutr. 2019, 38, 197–208. [Google Scholar] [CrossRef] [PubMed]

- Ellman, G.L.; Courtney, K.D.; Andres, V., Jr. Feather-Stone RM. A new and rapid colorimetric determination of acetylcholinesterase activity. Biochem. Pharmacol. 1961, 7, 88–95. [Google Scholar] [CrossRef] [PubMed]

- Istamboulie, G.; Sikora, T.; Jubete, E.; Ochoteco, E.; Marty, J.L.; Noguer, T. Screen-printed poly (3, 4-ethylenedioxythiophene)(PEDOT): A new electrochemical mediator for acetylcholinesterase-based biosensors. Talanta 2010, 82, 957–961. [Google Scholar] [CrossRef]

- Mohamad, N.R.; Marzuki, N.H.C.; Buang, N.A.; Huyop, F.; Wahab, R.A. An overview of technologies for immobilization of enzymes and surface analysis techniques for immobilized enzymes. Biotechnol. Biotechnol. Equip. 2015, 29, 205–220. [Google Scholar] [CrossRef]

- Reale, M.; Costantini, E.; Di Nicola, M.; D’Angelo, C.; Franchi, S.; D’Aurora, M.; Di Bari, M.; Orlando, V.; Galizia, S.; Ruggieri, S.; et al. Butyrylcholinesterase and Acetylcholinesterase polymorphisms in Multiple Sclerosis patients: Implication in peripheral inflammation. Sci. Rep. 2018, 8, 1319. [Google Scholar] [CrossRef] [PubMed]

- Štěpánková, Š.; Vorčáková, K. Cholinesterase-based biosensors. J. Enzym. Inhib. Med. Chem. 2016, 31, 180–193. [Google Scholar] [CrossRef] [PubMed]

- Mouawad, L.; Esque, J.; André, I.; Istamboulie, G.; Catanante, G.; Noguer, T. Evaluating cholinesterases inhibition by BAC and DDAC biocides: A combined experimental and theoretical approach. Biochim. Biophys. Acta (BBA)-Gen. Subj. 2024, 1898, 130726. [Google Scholar] [CrossRef]

- Tong, X.; Jiang, L.; Ao, Q.; Lv, X.; Song, Y.; Tang, J. Highly stable glucose oxidase polynanogel@MXene/chitosan electrochemical biosensor based on a multi-stable interface structure for glucose detection. Biosens. Bioelectron. 2024, 248, 115942. [Google Scholar] [CrossRef]

| DM AChE | BChE | |||

|---|---|---|---|---|

| 0.3 mU | 0.9 mU | 0.3 mU | 0.9 mU | |

| BAC | 0.98 | 1.3 | 0.21 | 0.26 |

| DDAC | 0.04 | 0.04 | 0.1 | 0.22 |

| PBS | WM | PSM | SM | ||

|---|---|---|---|---|---|

| Relative response (%) | DM AChE biosensor | 100 | 99.4 | 106.2 | 89.1 |

| BChE biosensor | 100 | 105.6 | 101 | 90.5 |

| DM AChE | BChE | |||

|---|---|---|---|---|

| BAC | DDAC | BAC | DDAC | |

| Whole milk | 335.1 | 65.8 | 47.5 | 119.2 |

| Partially skimmed milk | 30.7 | 13.6 | 5.3 | 50.4 |

| Skimmed milk | 5.4 | 5.0 | 1.3 | 8.1 |

| PBS (0.1 M pH7) | 1.3 | 0.04 | 0.26 | 0.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mouawad, L.; Istamboulie, G.; Catanante, G.; Noguer, T. Enhancing Biocide Safety of Milk Using Biosensors Based on Cholinesterase Inhibition. Biosensors 2025, 15, 26. https://doi.org/10.3390/bios15010026

Mouawad L, Istamboulie G, Catanante G, Noguer T. Enhancing Biocide Safety of Milk Using Biosensors Based on Cholinesterase Inhibition. Biosensors. 2025; 15(1):26. https://doi.org/10.3390/bios15010026

Chicago/Turabian StyleMouawad, Lynn, Georges Istamboulie, Gaëlle Catanante, and Thierry Noguer. 2025. "Enhancing Biocide Safety of Milk Using Biosensors Based on Cholinesterase Inhibition" Biosensors 15, no. 1: 26. https://doi.org/10.3390/bios15010026

APA StyleMouawad, L., Istamboulie, G., Catanante, G., & Noguer, T. (2025). Enhancing Biocide Safety of Milk Using Biosensors Based on Cholinesterase Inhibition. Biosensors, 15(1), 26. https://doi.org/10.3390/bios15010026