Magnetic Properties of FeNi-Based Thin Film Materials with Different Additives

Abstract

:1. Introduction

2. Experiments

| Film material | Sputtering power (W) | |||

|---|---|---|---|---|

| FeNi | Mo | Al | B | |

| FeNi | 200 | - | - | - |

| FeNiMo-1 | 200 | 40 | - | - |

| FeNiMo-2 | 200 | 45 | - | - |

| FeNiMo-3 | 200 | 47 | - | - |

| FeNiAl-1 | 200 | - | 50 | - |

| FeNiAl-2 | 200 | - | 100 | - |

| FeNiAl-3 | 200 | - | 150 | - |

| FeNiB-1 | 225 | - | - | 150 |

| FeNiB-2 | 225 | - | - | 175 |

| FeNiB-3 | 225 | - | - | 200 |

3. Results and Discussion

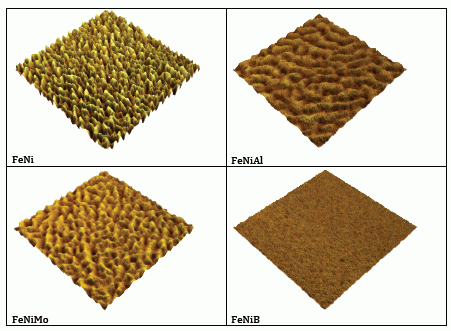

3.1. Synthesis and Microstructure of Thin Film Materials

| Film material | Thickness (nm) | Composition (at%) | Hc (kA/m) | Mr (kA/m) | Ms (kA/m) | |||

|---|---|---|---|---|---|---|---|---|

| FeNi | Mo | Al | B | |||||

| FeNi | 420 | 100 | 0 | 0 | 0 | 6.08 | 0.66 | 4.40 |

| FeNiMo-1 | 410 | 91.0 | 9.0 | 0 | 0 | 4.09 | 0.77 | 4.79 |

| FeNiMo-2 | 420 | 89.4 | 10.6 | 0 | 0 | 3.65 | 0.86 | 4.64 |

| FeNiMo-3 | 440 | 88.7 | 11.3 | 0 | 0 | 3.32 | 0.88 | 4.79 |

| FeNiAl-1 | 410 | 84.4 | 0 | 15.6 | 0 | 4.00 | 1.64 | 5.34 |

| FeNiAl-2 | 440 | 79.4 | 0 | 20.6 | 0 | 2.68 | 1.03 | 5.81 |

| FeNiAl-3 | 450 | 73.1 | 0 | 26.9 | 0 | 2.10 | 0.62 | 2.96 |

| FeNiB-1 | 540 | 90.8 | 0 | 0 | 9.2 | 0.16 | 0.51 | 7.80 |

| FeNiB-2 | 550 | 89.2 | 0 | 0 | 10.8 | 0.04 | 0.50 | 9.38 |

| FeNiB-3 | 580 | 87.4 | 0 | 0 | 12.6 | 0.08 | 0.49 | 10.54 |

3.2. In-Plane Magnetic Properties

3.3. Out-of-Plane Magnetic Properties

4. Conclusions

Acknowledgement

Author Contributions

Conflicts of Interest

References

- Grimes, C.A.; Ong, K.G.; Loiselle, K.; Stoyanov, P.G.; Kouzoudis, D.; Liu, Y.; Tong, C.; Tefiku, F. Magnetoelastic sensors for remote query environmental monitoring. Smart Mater. Struct. 1999, 8, 639–646. [Google Scholar] [CrossRef]

- Lakshmanan, R.S.; Guntupalli, R.; Hu, J.; Petrenko, V.A.; Barbaree, J.M.; Chin, B.A. Detection of Salmonella typhimurium in fat free milk using a phage immobilized magnetoelastic sensor. Sens. Actuator. B Chem. 2007, 126, 544–550. [Google Scholar] [CrossRef]

- Li, S.; Li, Y.; Chen, H.; Horikawa, S.; Shen, W.; Simonina, A.; Chin, B.A. Direct detection of Salmonella typhimurium on fresh produce using phage-based magnetoelastic biosensors. Biosens. Bioelectron. 2010, 26, 1313–1319. [Google Scholar]

- Viswanath, A.; Green, S.R.; Kosel, J.; Gianchandani, Y.B. Metglas-Elgiloy bi-layer, stent cell resonators for wireless monitoring of viscosity and mass loading. J. Micromech. Microeng. 2013, 23, 1–9. [Google Scholar]

- Kaniusas, E.; Pfützner, H.; Mehnen, L.; Kosel, J.; Varoneckas, G.; Alonderis, A.; Meydan, T.; Vázquez, M.; Rohn, M.; Merlo, A.M.; Marquardt, B. Magnetoelastic Skin Curvature Sensor for Biomedical Applications. In Proceeding of IEEE Sensors 2004, Vienna, Austria, 24–27 October 2004; pp. 1484–1487.

- Kaniusas, E.; Pfützner, H.; Mehnen, L.; Kosel, J.; Téllez-Blanco, J.C.; Varoneckas, G.; Alonderis, A.; Meydan, T.; Vázquez, M.; Rohn, M.; Merlo, A.M.; Marquard, B. Method for continuous non-disturbing monitoring of blood pressure by magnetoelastic skin curvature sensor and ECG. IEEE Sens. J. 2006, 6, 819–828. [Google Scholar] [CrossRef]

- Liang, C.; Morshed, S.; Prorok, B.C. Correction for longitudinal mode vibration in thin slender beams. Appl. Phys. Lett. 2007, 90, 221912–221913. [Google Scholar] [CrossRef]

- Johnson, M.L.; Wan, J.; Huang, S.; Cheng, Z.-Y.; Petrenko, V.A.; Kim, D.-J.; Chen, I.-H.; Barbaree, J.M.; Hong, J.; Chin, B.A. A wireless biosensor using microfabricated phage-interfaced magnetoelastic particles. Sens. Actuator. A Phys. 2008, 144, 38–47. [Google Scholar] [CrossRef]

- Liang, C. Development of Bulk-Scale and Thin Film Magnetostrictive Sensor. Ph.D. Thesis, Auburn University, Auburn, AL, USA, 20 December 2007. [Google Scholar]

- Liang, C.; Gooneratne, C.; Cha, D.-K.; Chen, L.; Gianchandani, Y.; Kosel, J. Development of FeNiMoB thin film materials for microfabricated magnetoelastic sensors. J. Appl. Phys. 2012, 112, 113912–113918. [Google Scholar] [CrossRef]

- Lenge, N.; Kronmuller, H. Low temperature magnetization of sputtered amorphous Fe-Ni-B films. Phys. Stat. Sol. 1986, 95, 621–633. [Google Scholar] [CrossRef]

- Morita, M.; Matsuoka, N.; Muramatsu, K.; Takeuchi, M.; Matsumura, Y. Magnetostrictive characteristics of Fe-Al films. J. Inst. Metals 2006, 70, 622–625. [Google Scholar] [CrossRef]

- Muramatsu, K.; Matsumura, Y. Preparation of magnetostrictive Fe-Al thin film using by plasma process. J. Adv. Sci. 2005, 17, 190–193. [Google Scholar] [CrossRef]

- Grössinger, R.; Turtelli, R.S.; Mehmood, N. Magnetostriction of Fe-X (X = Al, Ga, Si, Ge) intermetallic alloys. IEEE Trans. Magn. 2008, 44, 3001–3004. [Google Scholar] [CrossRef]

- Bertotti, G.; Fiorillo, F. Magnetic Properties of Metals; Landolt-Börnstein, Springer-Verlag: Berlin, Germany, 1994; Volume 19, p. 55. [Google Scholar]

- Metglas. Available online: http://metglas.com/products/magnetic_materials/2826mb.asp/ (accessed on 21 April 2014).

- Herzer, G. Grain-size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans. Magn. 1990, 26, 1397–1402. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Liang, C.; Gooneratne, C.P.; Wang, Q.X.; Liu, Y.; Gianchandani, Y.; Kosel, J. Magnetic Properties of FeNi-Based Thin Film Materials with Different Additives. Biosensors 2014, 4, 189-203. https://doi.org/10.3390/bios4030189

Liang C, Gooneratne CP, Wang QX, Liu Y, Gianchandani Y, Kosel J. Magnetic Properties of FeNi-Based Thin Film Materials with Different Additives. Biosensors. 2014; 4(3):189-203. https://doi.org/10.3390/bios4030189

Chicago/Turabian StyleLiang, Cai, Chinthaka P. Gooneratne, Qing Xiao Wang, Yang Liu, Yogesh Gianchandani, and Jurgen Kosel. 2014. "Magnetic Properties of FeNi-Based Thin Film Materials with Different Additives" Biosensors 4, no. 3: 189-203. https://doi.org/10.3390/bios4030189

APA StyleLiang, C., Gooneratne, C. P., Wang, Q. X., Liu, Y., Gianchandani, Y., & Kosel, J. (2014). Magnetic Properties of FeNi-Based Thin Film Materials with Different Additives. Biosensors, 4(3), 189-203. https://doi.org/10.3390/bios4030189