Preparation and Characterization of Bio-Nanocomposites Film of Chitosan and Montmorillonite Incorporated with Ginger Essential Oil and Its Application in Chilled Beef Preservation

Abstract

:1. Introduction

2. Results and Discussion

2.1. FT-IR Analysis of the Bio-Nanocomposites Film

2.2. Thickness and Mechanical Properties of Films

2.3. Water Vapor Permeability of Films

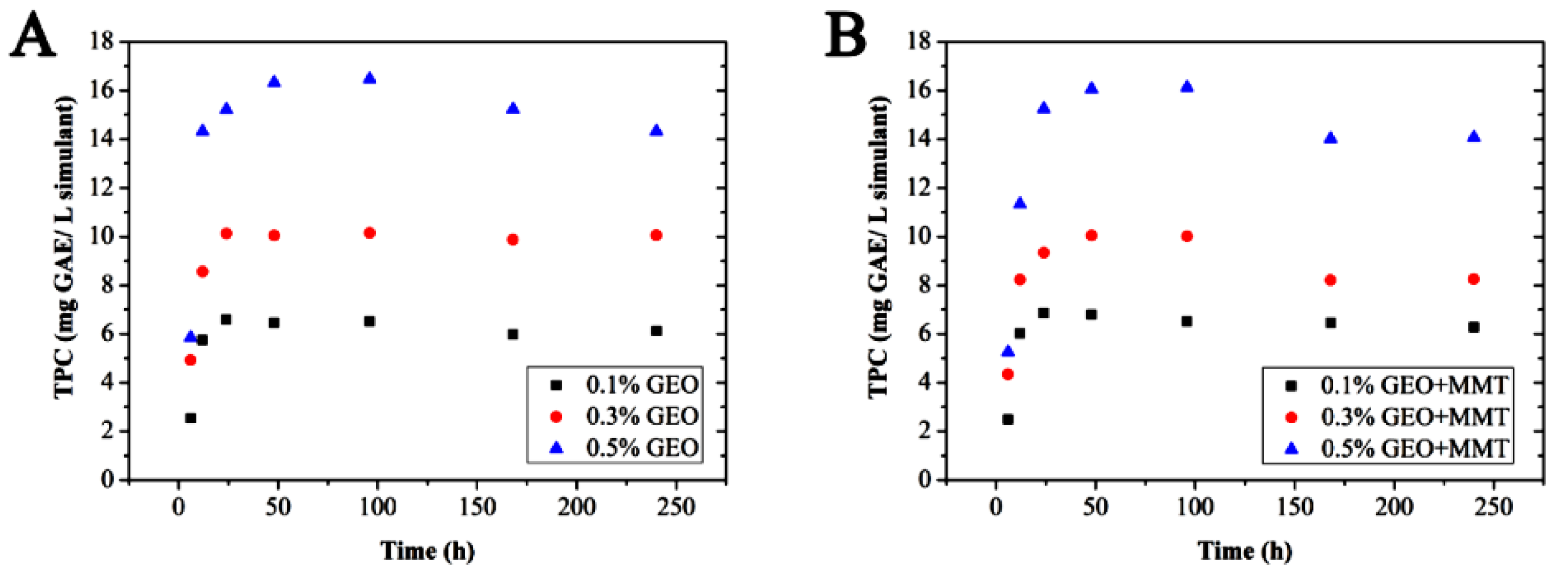

2.4. Migration of Phenolic Components of Films

2.5. Physicochemical Index of Chilled Beef Preserved by Bio-Composite Films

2.6. Lipid Oxidation Value of Chilled Beef Preserved by Bio-Composite Films

2.7. Total Mesophilic Aerobic Bacteria of Chilled Beef Preserved by Bio-Composite Films

3. Materials and Methods

3.1. Materials and Reagents

3.2. Preparation of Bio-Nanocomposite Films

3.3. Characterization of Bio-Nanocomposite Films

3.3.1. Fourier Transform Infrared Spectroscopy (FT-IR)

3.3.2. Thickness and Mechanical Properties of Films

3.3.3. Determination of Water Vapor Permeability of Bio-Nanocomposite Films

3.3.4. Migration Determination of Active Components in Films

3.4. Characterization of Chilled Beef

3.4.1. Fresh Beef Pretreatment

3.4.2. Physicochemical Index

3.4.3. Determination of Lipid Oxidation Value

3.4.4. Determination of Total Mesophilic Aerobic Bacteria (TMAB)

3.5. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gomez, I.; Garcia-Varona, C.; Curiel-Fernandez, M.; Ortega-Heras, M. Effects of an Extract from Olive Fruits on the Physicochemical Properties, Lipid Oxidation and Volatile Compounds of Beef Patties. Foods 2020, 9, 1728. [Google Scholar] [CrossRef]

- Keska, P.; Wójciak, K.M.; Stasiak, D.M. Influence of Sonication and Taraxacum Officinale Addition on the Antioxidant and Anti-ACE Activity of Protein Extracts from Sous Vide Beef Marinated with Sour Milk and after In Vitro Digestion. Molecules 2020, 25, 4692. [Google Scholar] [CrossRef] [PubMed]

- Xi, B.; Gao, Y.; Guo, T.; Li, W.; Yang, X.; Du, T.; Jiao, T. Study on Preservation of Chilled Beef with Natural Essential Oil Nanocapsules. J. Chem. 2020, 2020, 8126254. [Google Scholar] [CrossRef]

- McSharry, S.; Koolman, L.; Whyte, P.; Bolton, D. The microbiology of beef from carcass chilling through primal storage to retail steaks. Curr. Res. Food Sci. 2021, 4, 150–162. [Google Scholar] [CrossRef] [PubMed]

- Mizi, L.; Cofrades, S.; Bou, R.; Pintado, T.; López-Caballero, M.E.; Zaidi, F.; Jiménez-Colmenero, F. Antimicrobial and antioxidant effects of combined high pressure processing and sage in beef burgers during prolonged chilled storage. Innov. Food Sci. Emerg. 2019, 51, 32–40. [Google Scholar] [CrossRef] [Green Version]

- Sorrentino, A.; Gorrasi, G.; Vittoria, V. Potentilal perspectives of bionanocomposites for food packaging applications. Trends Food Sci. Technol. 2007, 18, 84–95. [Google Scholar] [CrossRef]

- Arora, A.; Padua, G.W. Review: Nanocomposite in food packaging. J. Food Sci. 2010, 75, R43–R49. [Google Scholar] [CrossRef]

- Barbosa-Pereira, L.; Angulo, I.; Lagarón, J.M.; Paseiro-Losada, P.; Cruz, J.M. Development of new active packaging films containing bioactive nanocomposites. Innov. Food Sci. Emerg. 2014, 26, 310–318. [Google Scholar] [CrossRef]

- Ni, Z.J.; Wang, X.; Shen, Y.; Thakur, K.; Han, J.Z.; Zhang, J.G.; Hu, F.; Wei, Z.J. Recent updates on the chemistry, bioactivities, mode of action, and industrial applications of plant essential oils. Trends Food Sci. Technol. 2021, 110, 78–89. [Google Scholar] [CrossRef]

- Shen, Y.; Ni, Z.J.; Thakur, K.; Zhang, J.G.; Hu, F.; Wei, Z.J. Preparation and characterization of clove essential oil loaded nanoemulsion and pickering emulsion activated pullulan-gelatin based edible Film. Int. J. Biol. Macromol. 2021, 181, 528–539. [Google Scholar] [CrossRef]

- Pires, J.R.A.; de Souza, V.G.L.; Fernando, A.L. Chitosan/montmorillonite bionanocomposites incorporated with rosemary and ginger essential oil as packaging for fresh poultry meat. Food Packag. Shelf Life 2018, 17, 142–149. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Rodrigues, P.F.; Duarte, M.P.; Fernando, A.L. Antioxidant migration studies in chitosan films incorporated with plant extracts. J. Renew. Mater. 2018, 6, 548–558. [Google Scholar]

- Souza, V.G.L.; Pires, J.R.A.; Vieira, E.; Coelhoso, I.; Duarte, M.; Fernando, A. Shelf life assessment of fresh poultry meat packaged in novel bionanocomposite of chitosan/montmorillonite incorporated with ginger essential oil. Coatings 2018, 8, 177. [Google Scholar] [CrossRef] [Green Version]

- Souza, V.G.L.; Pires, J.R.A.; Vieira, É.; Coelhoso, I.; Duarte, M.; Fernando, A. Activity of chitosan-montmorillonite bionanocomposites incorporated with rosemary essential oil: From in vitro assays to application in fresh poultry meat. Food Hydrocolloids 2019, 89, 241–252. [Google Scholar] [CrossRef]

- Hamedi, H.; Kargozari, M.; Shotorbani, P.M.; Mogadam, N.B.; Fahimdanesh, M. A novel bioactive edible coating based on sodium alginate and galbanum gum incorporated with essential oil of Ziziphora persica: The antioxidant and antimicrobial activity, and application in food model. Food Hydrocolloids 2017, 72, 35–46. [Google Scholar] [CrossRef]

- Perdones, A.; Escriche, I.; Chiralt, A.; Vargas, M. Effect of chitosan lemon essential oil coatings on volatile profile of strawberries during storage. Food Chem. 2016, 197, 979–986. [Google Scholar] [CrossRef] [PubMed]

- Moradi, M.; Tajik, H.; Rohani, S.M.R.; Mahmoudian, A. Antioxidant and antimicrobial effects of zein edible film impregnated with Zataria multiflora Boiss. essential oil and monolaurin. LWT—Food Sci. Technol. 2016, 72, 37–43. [Google Scholar] [CrossRef]

- Wang, X.; Shen, Y.; Thakur, K.; Han, J.Z.; Zhang, J.G.; Hu, F.; Wei, Z.J. Antibacterial Activity and Mechanism of Ginger Essential Oil against Escherichia coli and Staphylococcus aureus. Molecules 2020, 25, 3955. [Google Scholar] [CrossRef]

- Silva-Weiss, A.; Bifani, V.; Ihl, M.; Sobral, P.J.A.; Gómez-Guillén, M.C. Structural properties of films and rheology of film-forming solutions based on chitosan and chitosan-starch blend enriched with murta leaf extract. Food Hydrocolloids 2013, 31, 458–466. [Google Scholar] [CrossRef] [Green Version]

- Woranuch, S.; Yoksan, R. Eugenol-loaded chitosan nanoparticles: II. Application in bio-based plastics for active packaging. Carbohydr. Polym. 2013, 96, 586–592. [Google Scholar] [CrossRef]

- Beigzadeh Ghelejlu, S.; Esmaiili, M.; Almasi, H. Characterization of chitosan-nanoclay bionanocomposite active films containing milk thistle extract. Int. J. Biol. Macromol. 2016, 86, 613–621. [Google Scholar] [CrossRef]

- Perdones, Á.; Vargas, M.; Atarés, L.; Chiralt, A. Physical, antioxidant and antimicrobial properties of chitosan-cinnamon leaf oil films as affected by oleic acid. Food Hydrocolloids 2014, 36, 256–264. [Google Scholar] [CrossRef]

- Tongnuanchan, P.; Benjakul, S.; Prodpran, T. Physico-chemical properties, morphology and antioxidant activity of film from fish skin gelatin incorporated with root essential oils. J. Food Eng. 2013, 117, 350–360. [Google Scholar] [CrossRef]

- Acevedo-Fani, A.; Salvia-Trujillo, L.; Rojas-Graü, M.A.; Martín-Belloso, O. Edible films from essential-oil-loaded nanoemulsions: Physicochemical characterization and antimicrobial properties. Food Hydrocolloids 2015, 47, 168–177. [Google Scholar] [CrossRef] [Green Version]

- Atarés, L.; Chiralt, A. Essential oils as additives in biodegradable films and coatings for active food packaging. Trends Food Sci. Technol. 2016, 48, 51–62. [Google Scholar] [CrossRef]

- Kurek, M.; Benbettaieb, N.; Šcetar, M.; Chaudy, E.; Repaji´c, M.; Klepac, D.; Vali´c, S.; Debeaufort, F.; Gali´c, K. Characterization of Food Packaging Films with Blackcurrant Fruit Waste as a Source of Antioxidant and Color Sensing Intelligent Material. Molecules 2021, 26, 2569. [Google Scholar] [CrossRef] [PubMed]

- Atarés, L.; Pérez-Masiá, R.; Chiralt, A. The role of some antioxidants in the HPMC film properties and lipid protection in coated toasted almonds. J. Food Eng. 2011, 104, 649–656. [Google Scholar] [CrossRef]

- Calatayud, M.; López-de-Dicastillo, C.; López-Carballo, G.; Vélez, D.; Hernández Muñoz, P.; Gavara, R. Active films based on cocoa extract with antioxidant, antimicrobial and biological applications. Food Chem. 2013, 139, 51–58. [Google Scholar] [CrossRef]

- Abdollahi, M.; Rezaei, M.; Farzi, G. Influence of chitosan/clay functional bionanocomposite activated with rosemary essential oil on the shelf life of fresh silver carp. Int. J. Food Sci. Technol. 2014, 49, 811–818. [Google Scholar] [CrossRef]

- Remya, S.; Mohan, C.O.; Bindu, J.; Sivaraman, G.K.; Venkateshwarlu, G.; Ravishankar, C.N. Effect of chitosan-based active packaging film on the keeping quality of chilled stored barracuda fish. J. Food Sci. Technol. 2016, 53, 685–693. [Google Scholar] [CrossRef] [Green Version]

- Melo, A.A.M.; De Geraldine, R.M.; Silveira, M.F.A.; Lopes, M.C.; Silva, C.; Fernandes, T.H.; De Oliveira, A.N. Microbiological quality and other characteristics of refrigerated chicken meat in contact with cellulose acetate-based film incorporated with rosemary essential oil. Braz. J. Microbiol. 2012, 43, 1419–1427. [Google Scholar] [CrossRef]

- Vilarinho, F.; Andrade, M.; Buonocore, G.G.; Stanzione, M.; Vaz, M.F.; Sanches Silva, A. Monitoring lipid oxidation in a processed meat product packaged with nanocomposite poly (lactic acid) film. Eur. Polym. J. 2018, 98, 362–367. [Google Scholar] [CrossRef]

- Dias, M.V.; Machado Azevedo, V.; Borges, S.V.; Soares, N.D.F.F.; de Barros Fernandes, R.V.; Marques, J.J.; Medeiros, E.A.A. Development of chitosan/montmorillonite nanocomposites with encapsulated α-tocopherol. Food Chem. 2014, 165, 323–329. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pola, C.C.; Medeiros, E.A.A.; Pereira, O.L.; Souza, V.G.L.; Otoni, C.G.; Camilloto, G.P.; Soares, N.F.F. Cellulose acetate active films incorporated with oregano (Origanum vulgare) essential oil and organophilic montmorillonite clay control the growth of phytopathogenic fungi. Food Packag. Shelf Life 2016, 9, 69–78. [Google Scholar] [CrossRef]

- GB/T 1040.3. Method for Plastics Determination of Tensile Properties; National Standards of the People’s Republic of China: Beijing, China, 2006. [Google Scholar]

- Fathi, N.; Almasi, H.; Pirouzifard, M.K. Effect of ultraviolet radiation on morphological and physicochemical properties of sesame protein isolate based edible films. Food Hydrocolloids 2018, 85, 136–143. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Fernando, A.L.; Pires, J.R.A.; Rodrigues, P.F.; Lopes, A.A.S.S.; Fernandes, F.M.B. Physical properties of chitosan films incorporated with natural antioxidants. Ind. Crop. Prod. 2017, 107, 565–572. [Google Scholar] [CrossRef]

- GB 5009.237. Method for Determination of pH Value of Food; National Standards of the People’s Republic of China: Beijing, China, 2016. [Google Scholar]

- GB 5009.3. Method for Determination of Moisture in Foods; National Standards of the People’s Republic of China: Beijing, China, 2016. [Google Scholar]

- Rosmini, M.R.; Perlo, F.; Pérez-Alvarez, J.A.; Pagán-Moreno, M.J.; Gago-Gago, A.; López-Santoveña, F.; Aranda-Catalá, V. TBA test by an extractive method applied to “paté”. Meat Sci. 1996, 42, 103–110. [Google Scholar] [CrossRef]

- GB4789.2. Food Microbiology Test—Method for Determination of Total Number of Colonies; National Standards of the People’s Republic of China: Beijing, China, 2016. [Google Scholar]

| Types of Film | Thickness (µm) | Ts (MPa) | EB (%) |

|---|---|---|---|

| Ch | 44 ± 1.2 a | 48.6 ± 1.5 A | 19.7% ± 1.8 a |

| Ch + MMT | 43 ± 0.8 a | 62.4 ± 3.1 B | 32.2% ± 4.2 b |

| Ch + 0.1% GEO | 56 ± 1.1 b | 46.5 ± 4.2 A | 24.5% ± 3.7 a |

| Ch + 0.3% GEO | 63 ± 2.1 bc | 33.4 ± 2.3 C | 22.1% ± 4.5 a |

| Ch + 0.5% GEO | 73 ± 2.3 c | 30.2 ± 1.1 C | 30.1% ± 2.5 b |

| Ch + MMT + 0.1% GEO | 53 ± 0.4 b | 42.4 ± 2.7 A | 32.1% ± 2.3 b |

| Ch + MMT + 0.3% GEO | 61 ± 2.1 bc | 30.6 ± 1.8 C | 30.3% ± 3.7 b |

| Ch + MMT + 0.5% GEO | 68 ± 2.5 c | 28.6 ± 3.1 C | 34.5% ± 6.2 b |

| Types of Film | WVP (10−7 g/m·h·Pa) |

|---|---|

| Ch | 9.18 ± 0.23 a |

| Ch + MMT | 9.82 ± 0.32 ab |

| Ch + 0.1% GEO | 10.32 ± 0.31 abc |

| Ch + MMT + 0.1% GEO | 10.97±0.33 abc |

| Ch + 0.3% GEO | 10.42 ± 0.46 abc |

| Ch + MMT + 0.3% GEO | 9.65 ± 0.49 ab |

| Ch + 0.5% GEO | 11.88 ± 0.74 abc |

| Ch + MMT + 0.5% GEO | 15.79 ± 0.84 c |

| Parameters | Days | Unwrapped | Ch | Ch + 0.1% G | Ch + 0.3% G | Ch + 0.5% G | Ch+MMT | Ch + MMT + 0.1% G | Ch + MMT + 0.3% G | Ch + MMT + 0.5% G |

|---|---|---|---|---|---|---|---|---|---|---|

| Hue angle (°) | 0 | 50.6 ± 1.8 a,A | 49.7 ± 1.2 a,A | 51.4 ± 1.8 a,A | 51.1 ± 1.2 a,A | 50.8 ± 1.5 a,A | 50.4 ± 1.3 a,A | 50.1 ± 1.4 a,A | 51.3 ± 2.1 a,A | 52.3 ± 2.1 a,A |

| 3 | 51.9 ± 1.6 a,A | 50.2 ± 1.1 a,A | 54.2 ± 2.0 b,B | 55.6 ± 0.9 b,BC | 58.7 ± 2.0 b,C | 46.1 ± 1.1 b,D | 47.3 ± 1.6 b,D | 57.7 ± 0.8 b,C | 58.9 ± 1.9 b,C | |

| 7 | 58.2 ± 2.1 b,A | 52.4 ± 1.6 b,B | 55.2 ± 1.7 b,AB | 56.1 ± 1.1 b,AB | 54.5 ± 1.9 ab,AB | 53.2 ± 0.9 c,AB | 58.2 ± 0.8 c,A | 58.3 ± 2.1 b,A | 55.3 ± 2.3 ab,AB | |

| 10 | 61.5 ± 2.6 c,A | 50.6 ± 1.4 a,B | 54.5 ± 2.2 b,C | 52.5 ± 1.5 a,BC | 53.6 ± 1.9 ab,BC | 53.9 ± 0.6 c,BC | 52.7 ± 1.2 a,BC | 49.8 ± 0.8 a,B | 50.5 ± 1.3 a,B | |

| 15 | 70.1 ± 1.1 d,A | 55.6 ± 1.5 c,B | 55.5 ± 1.5 b,B | 54.9 ± 0.8 b,B | 54.3 ± 1.3 ab,B | 54.3 ± 0.7 c,B | 53.3 ± 1.3 ac,B | 52.8 ± 1.1 a,B | 53.7 ± 1.4 a,B | |

| pH | 0 | 5.87 ± 0.8 a,A | 5.87 ± 0.4 a,A | 5.91 ± 0.2 a,A | 5.86 ± 0.8 a,A | 5.98 ± 0.4 a,A | 5.92 ± 0.3 a,A | 5.87 ± 0.0 a,A | 5.85 ± 0.2 a,A | 5.93 ± 0.4 a,A |

| 3 | 6.16 ± 0.5 ab,A | 6.02 ± 0.5 a,A | 5.95 ± 0.7 a,A | 5.96 ± 0.5 a,A | 6.04 ± 0.6 a,A | 6.01 ± 0.4 a,A | 5.93 ± 0.3 a,A | 5.92 ± 0.1 a,A | 5.96 ± 0.2 a,A | |

| 7 | 6.72 ± 0.3 b,A | 6.20 ± 0.2 a,B | 6.12 ± 0.3 a,B | 6.05 ± 0.1 a,B | 5.99 ± 0.1 a,B | 6.32 ± 0.2 b,C | 6.22 ± 0.0 b,B | 6.07 ± 0.4 a,B | 6.04 ± 0.1 a,B | |

| 10 | 8.38 ± 0.2 c,A | 7.30 ± 0.1 b,B | 6.87 ± 0.2 b,C | 7.05 ± 0.4 b,BC | 6.63 ± 0.1 b,C | 7.22 ± 0.4 c,B | 7.04 ± 0.1 c,BC | 6.96 ± 0.4 b,BC | 6.49 ± 0.1 b,C | |

| 15 | 8.33 ± 0.1 c,A | 7.33 ± 0.3 b,A | 6.90 ± 0.5 b,A | 6.87 ± 0.3 b,A | 6.75 ± 0.3 b,A | 7.30 ± 0.1 c,A | 7.15 ± 0.4 c,A | 7.04 ± 0.3 b,A | 6.74 ± 0.3 c,A | |

| Moisture(%) | 0 | 74.6 ± 1.1 a,A | 74.6 ± 1.4 a,A | 74.5 ± 0.9 a,A | 74.6 ± 0.7 a,A | 74.3 ± 1.1 a,A | 74.5 ± 0.5 a,A | 74.6 ± 0.2 a,A | 74.5 ± 1.1 a,A | 74.5 ± 0.7 a,A |

| 3 | 73.6 ± 0.8 b,A | 72.6 ± 0.5 b,B | 72.5 ± 1.2 b,B | 72.4 ± 0.4 b,B | 71.2 ± 0.6 b,C | 72.3 ± 0.6 b,B | 71.3 ± 0.4 b,C | 69.7 ± 1.0 b,D | 69.8 ± 0.9 b,D | |

| 7 | 75.1 ± 1.3 a,A | 72.7 ± 1.1 b,B | 72.8 ± 0.8 b,B | 71.9 ± 0.2 b,B | 72.0 ± 0.4 b,B | 72.1 ± 0.3 b,B | 70.8 ± 0.3 bc,C | 69.4 ± 0.6 b,D | 69.6 ± 1.2 b,D | |

| 10 | 76.8 ± 1.6 c,A | 72.3 ± 0.8 b,B | 72.6 ± 0.7 b,B | 72.1 ± 0.9 b,B | 71.8 ± 1.4 b,B | 71.9 ± 0.3 b,B | 70.3 ± 0.5 c,C | 69.1 ± 0.8 b,D | 69.2 ± 1.1 b,D | |

| 15 | 76.9 ± 0.7 c,A | 72.0 ± 0.6 b,B | 72.4 ± 1.1 b,B | 71.8 ± 1.2 b,B | 71.6 ± 0.9 b,B | 71.7 ± 1.1 b,B | 70.4 ± 0.8 c,C | 68.9 ± 1.2 b,D | 69.3 ± 0.7 b,D |

| Parameters | Days | Unwrapped | Ch | Ch + 0.1% G | Ch + 0.3% G | Ch + 0.5% G | Ch + MMT | Ch + MMT + 0.1% G | Ch + MMT + 0.3% G | Ch + MMT + 0.5% G |

|---|---|---|---|---|---|---|---|---|---|---|

| TBARS (mg MDA/kg meat) | 0 | 0.24 ± 0.02 a,A | 0.24 ± 0.02 a,A | 0.24 ± 0.02 a,A | 0.24 ± 0.02 a,A | 0.24 ± 0.02 a,A | 0.24 ± 0.02 a,A | 0.24 ± 0.02 a,A | 0.24 ± 0.02 a,A | 0.24 ± 0.02 a,A |

| 3 | 0.28 ± 0.01 a,A | 0.27 ± 0.01 a,A | 0.31 ± 0.01 ab,A | 0.30 ± 0.02 a,A | 0.26 ± 0.02 a,A | 0.28 ± 0.03 a,A | 0.27 ± 0.03 a,A | 0.27 ± 0.03 a,A | 0.26 ± 0.01 a,A | |

| 7 | 1.03 ± 0.08 b,A | 0.42 ± 0.02 ab,B | 0.36 ± 0.07 b,B | 0.32 ± 0.03 a,B | 0.31 ± 0.01 a,B | 0.48 ± 0.01 b,B | 0.29 ± 0.06 a,B | 0.38 ± 0.03 b,B | 0.35 ± 0.04 b,B | |

| 10 | 1.62 ± 0.06 c,A | 0.46 ± 0.01 ab,B | 0.38 ± 0.05 b,B | 0.33 ± 0.04 a,B | 0.31 ± 0.01 a,B | 0.52 ± 0.06 b,B | 0.32 ± 0.01 a,B | 0.36 ± 0.02 b,B | 0.34 ± 0.01 b,B | |

| 15 | 2.05 ± 0.03 d,A | 0.51 ± 0.05 b,BC | 0.41 ± 0.06 b,B | 0.32 ± 0.05 a,C | 0.33 ± 0.06 a,C | 0.69 ± 0.05 c,B | 0.48 ± 0.06 b,BC | 0.43 ± 0.05 b,B | 0.38 ± 0.06 b,B | |

| TMAB (Log10CFU/g meat) | 0 | 4.6 ± 0.1 a,A | 4.6 ± 0.1 a,A | 4.6 ± 0.1 a,A | 4.6 ± 0.1 a,A | 4.6 ± 0.1 a,A | 4.6 ± 0.1 a,A | 4.6 ± 0.1 a,A | 4.6 ± 0.1 a,A | 4.6 ± 0.1 a,A |

| 3 | 6.2 ± 0.2 b,A | 6.0 ± 0.2 b,A | 6.0 ± 0.2 b,A | 6.0 ± 0.2 b,A | 5.9 ± 0.1 b,A | 6.0 ± 0.2 b,A | 5.5 ± 0.1 b,B | 5.9 ± 0.1b,A | 5.9 ± 0.2 b,A | |

| 7 | 9.1 ± 0.4 c,A | 8.4 ± 0.3 c,B | 7.9 ± 0.3 c,BC | 7.3 ± 0.2 c,C | 7.1 ± 0.5 c,C | 8.6 ± 0.4 c,B | 8.2 ± 0.6 c,B | 8.1 ± 0.2 c,B | 7.8 ± 0.2 c,BC | |

| 10 | 9.6 ± 0.3 c,A | 8.7 ± 0.4 c,B | 8.0 ± 0.3 c,B | 7.6 ± 0.1 c,BC | 7.3 ± 0.1 c,C | 8.9 ± 0.3 c,B | 8.4 ± 0.7 c,B | 8.3 ± 0.1 c,B | 8.0 ± 0.2 c,B |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.-P.; Wang, X.; Shen, Y.; Thakur, K.; Zhang, J.-G.; Hu, F.; Wei, Z.-J. Preparation and Characterization of Bio-Nanocomposites Film of Chitosan and Montmorillonite Incorporated with Ginger Essential Oil and Its Application in Chilled Beef Preservation. Antibiotics 2021, 10, 796. https://doi.org/10.3390/antibiotics10070796

Zhang Y-P, Wang X, Shen Y, Thakur K, Zhang J-G, Hu F, Wei Z-J. Preparation and Characterization of Bio-Nanocomposites Film of Chitosan and Montmorillonite Incorporated with Ginger Essential Oil and Its Application in Chilled Beef Preservation. Antibiotics. 2021; 10(7):796. https://doi.org/10.3390/antibiotics10070796

Chicago/Turabian StyleZhang, Yin-Ping, Xin Wang, Yi Shen, Kiran Thakur, Jian-Guo Zhang, Fei Hu, and Zhao-Jun Wei. 2021. "Preparation and Characterization of Bio-Nanocomposites Film of Chitosan and Montmorillonite Incorporated with Ginger Essential Oil and Its Application in Chilled Beef Preservation" Antibiotics 10, no. 7: 796. https://doi.org/10.3390/antibiotics10070796

APA StyleZhang, Y.-P., Wang, X., Shen, Y., Thakur, K., Zhang, J.-G., Hu, F., & Wei, Z.-J. (2021). Preparation and Characterization of Bio-Nanocomposites Film of Chitosan and Montmorillonite Incorporated with Ginger Essential Oil and Its Application in Chilled Beef Preservation. Antibiotics, 10(7), 796. https://doi.org/10.3390/antibiotics10070796