High-Porosity Thermal Barrier Coatings from High-Power Plasma Spray Equipment—Processing, Performance and Economics

Abstract

1. Introduction

2. Materials and Methods

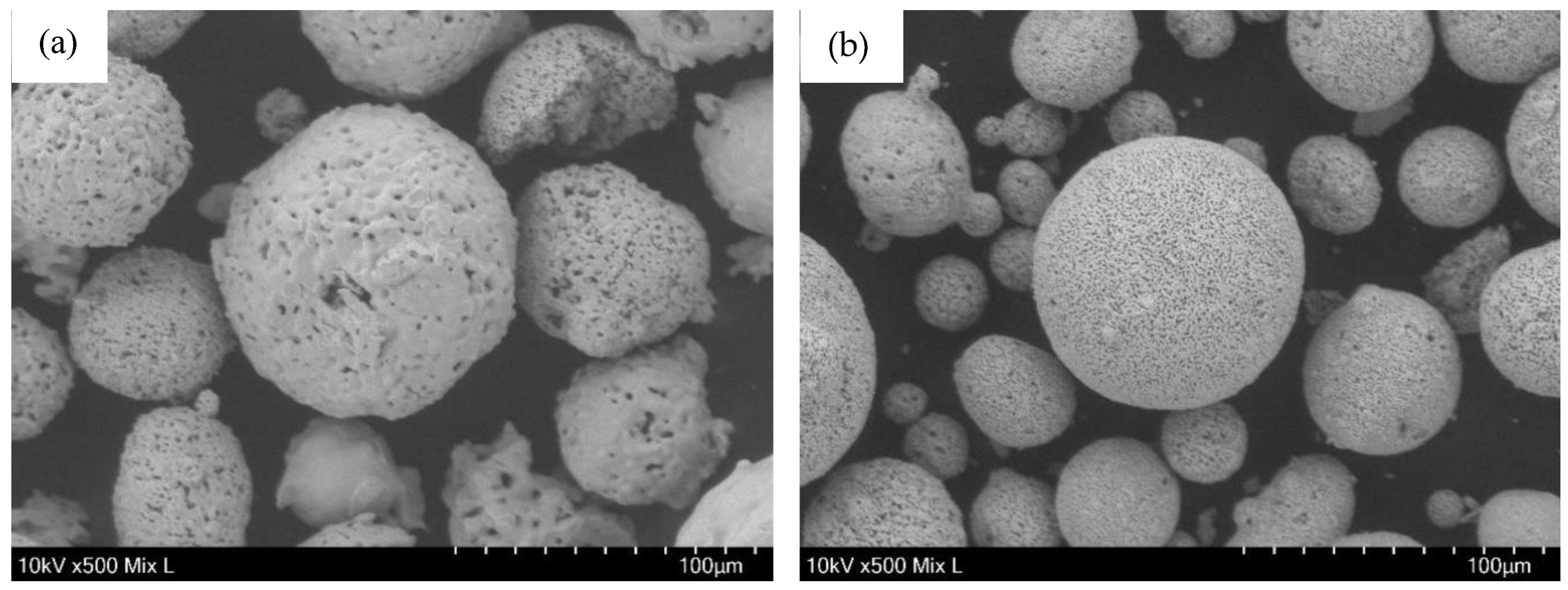

2.1. Spray Powders

2.2. Coating Conditions

2.3. Deposition Efficiency

2.4. Microstructure Preparation and Porosity Evaluation

2.5. Adhesion Testing

2.6. Thermal Conductivity Evaluation

2.7. Furnace Cycle Fatigue Evaluation

3. Results and Discussion

3.1. Coating Diagnostics

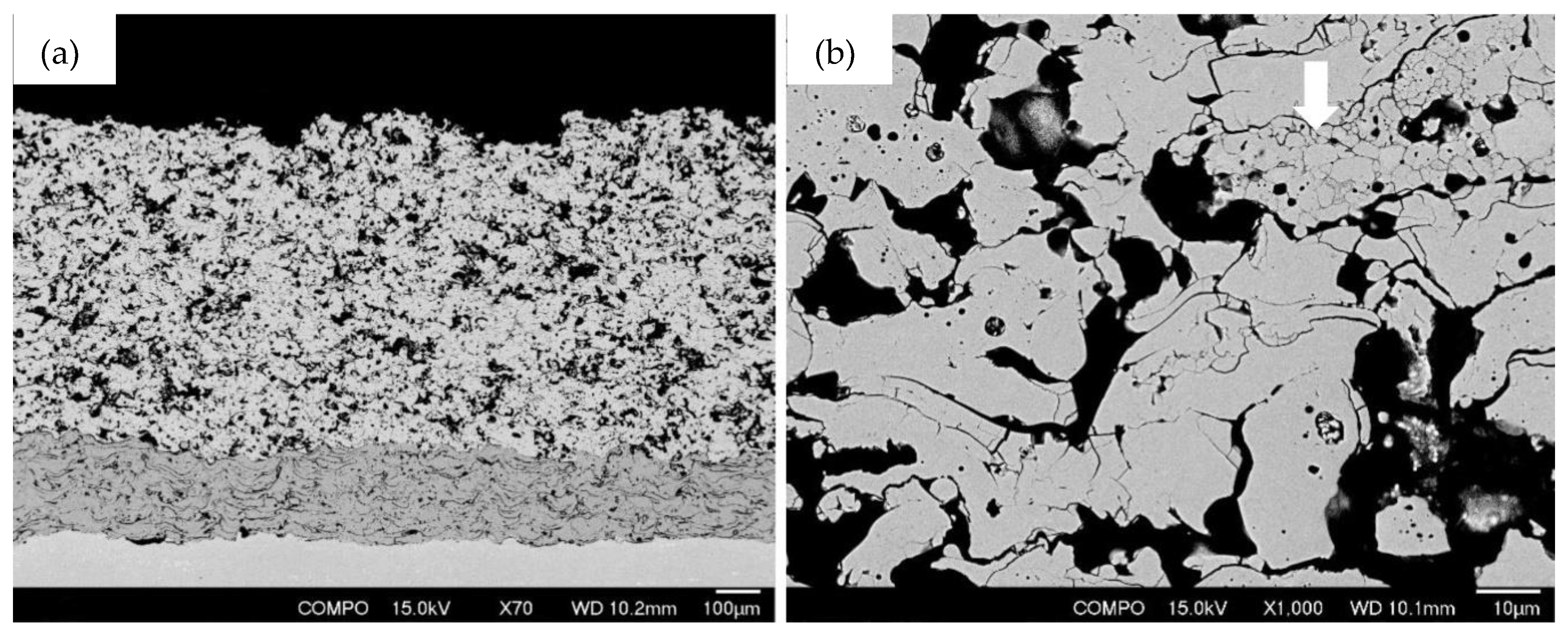

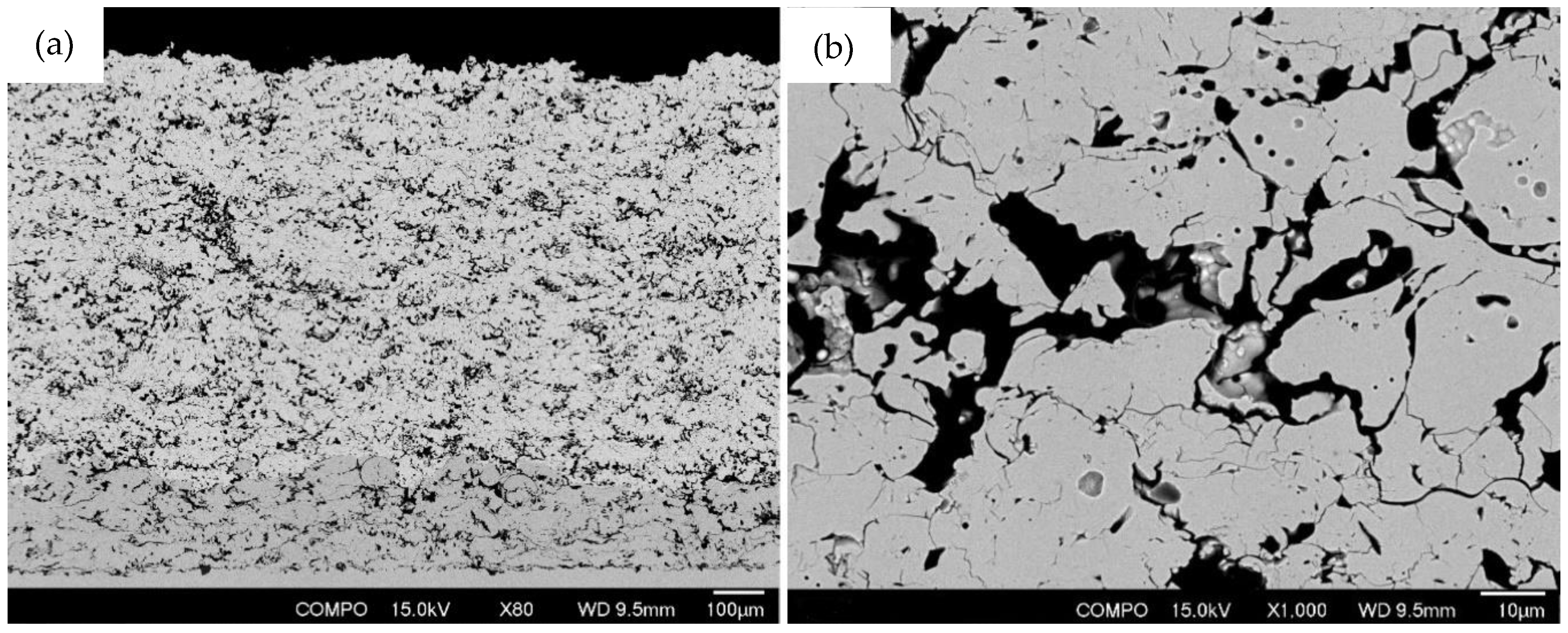

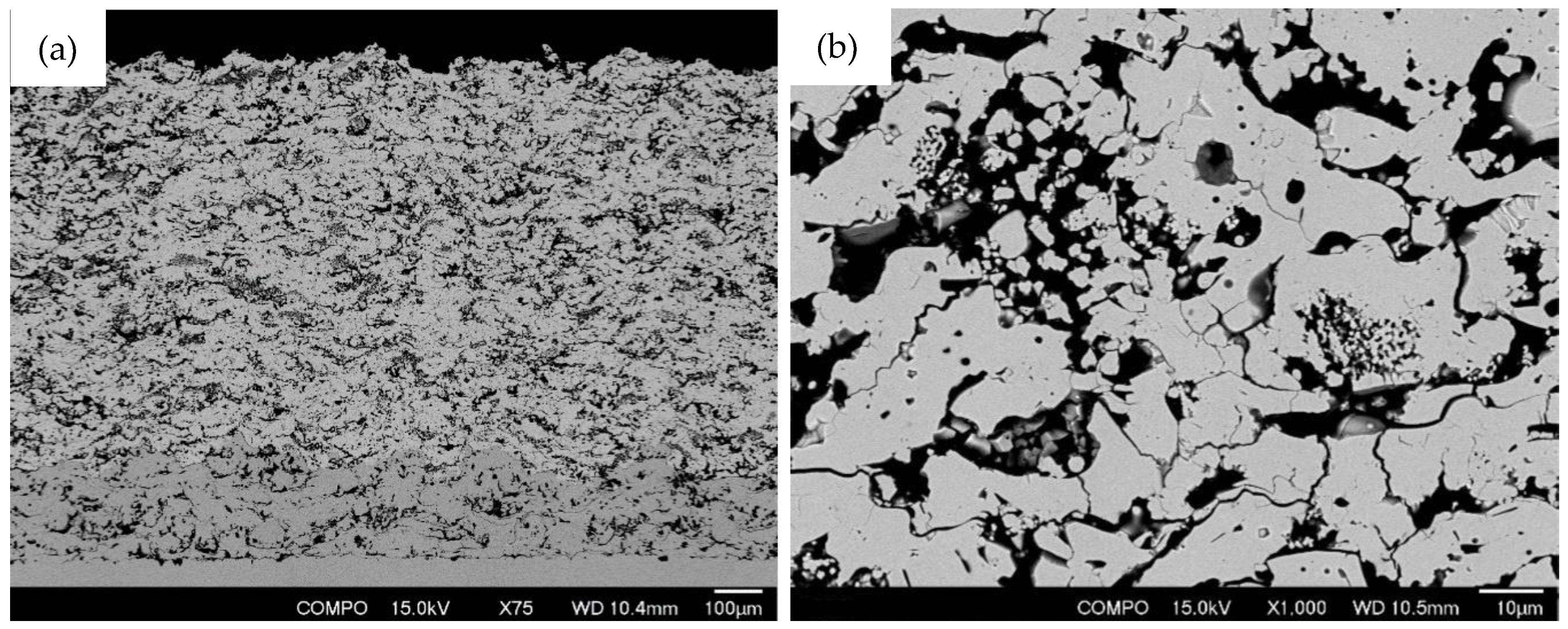

3.2. Coating Microstructures

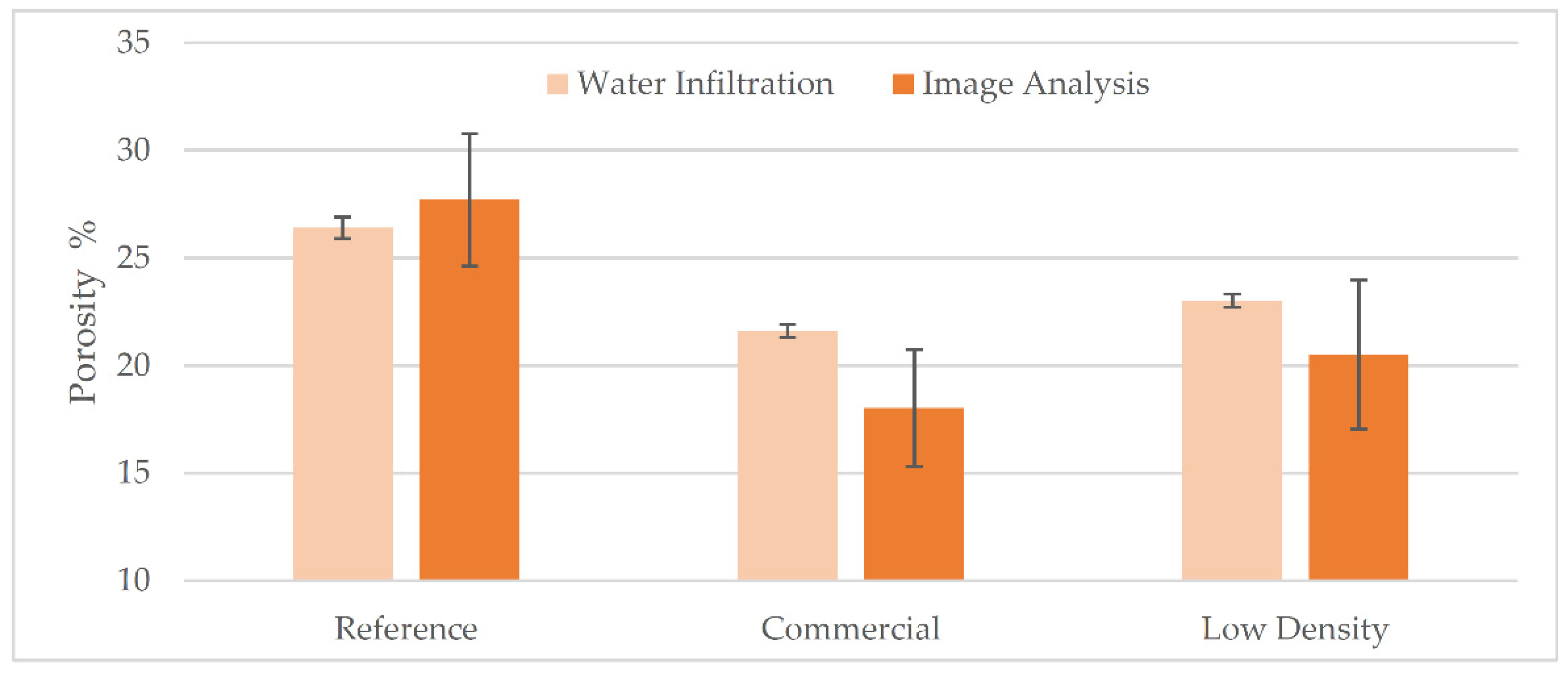

3.3. Porosity Evaluation

3.4. Adhesion Testing

3.5. Furnace Cyclic Fatigue Lifetime

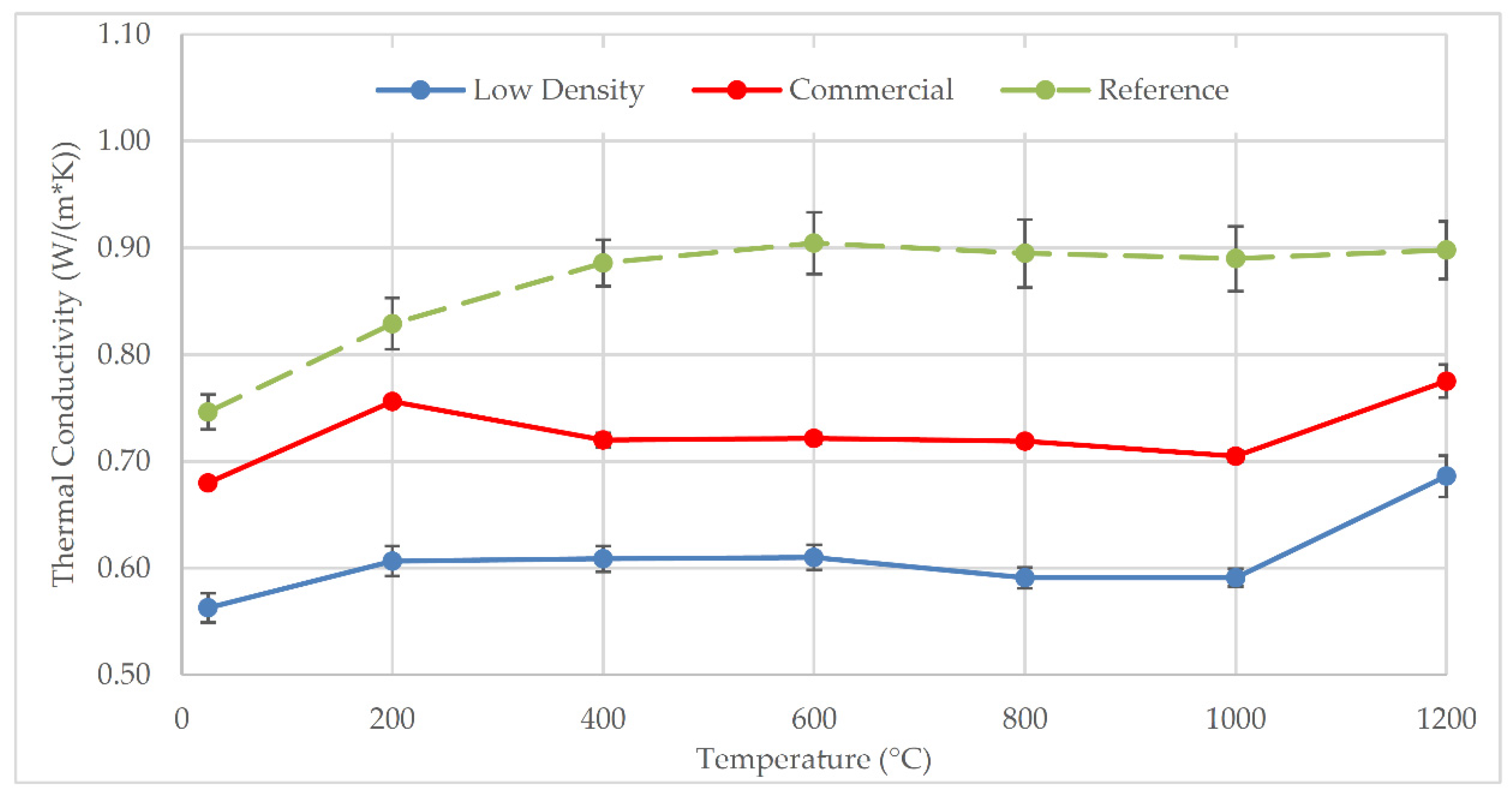

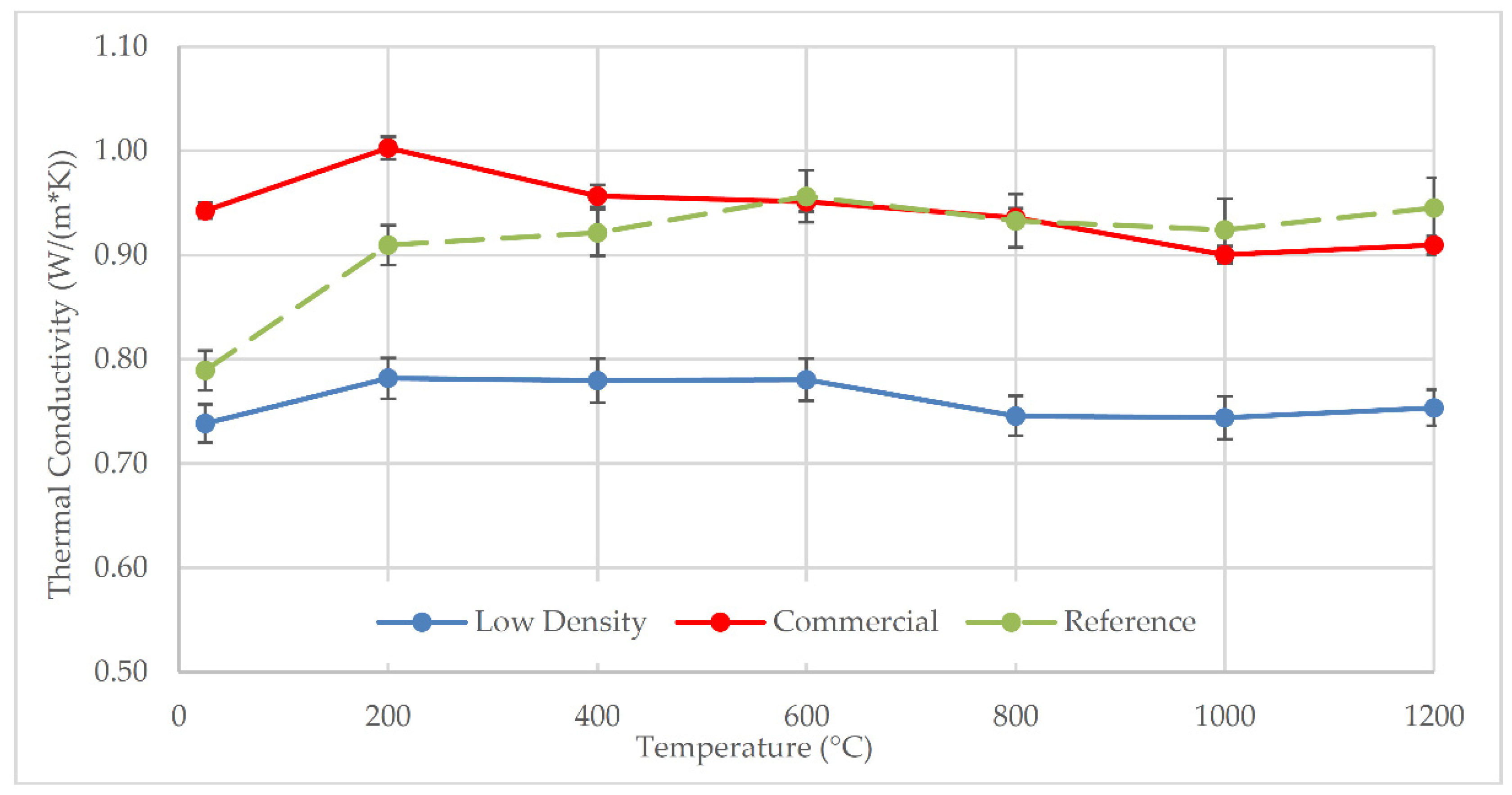

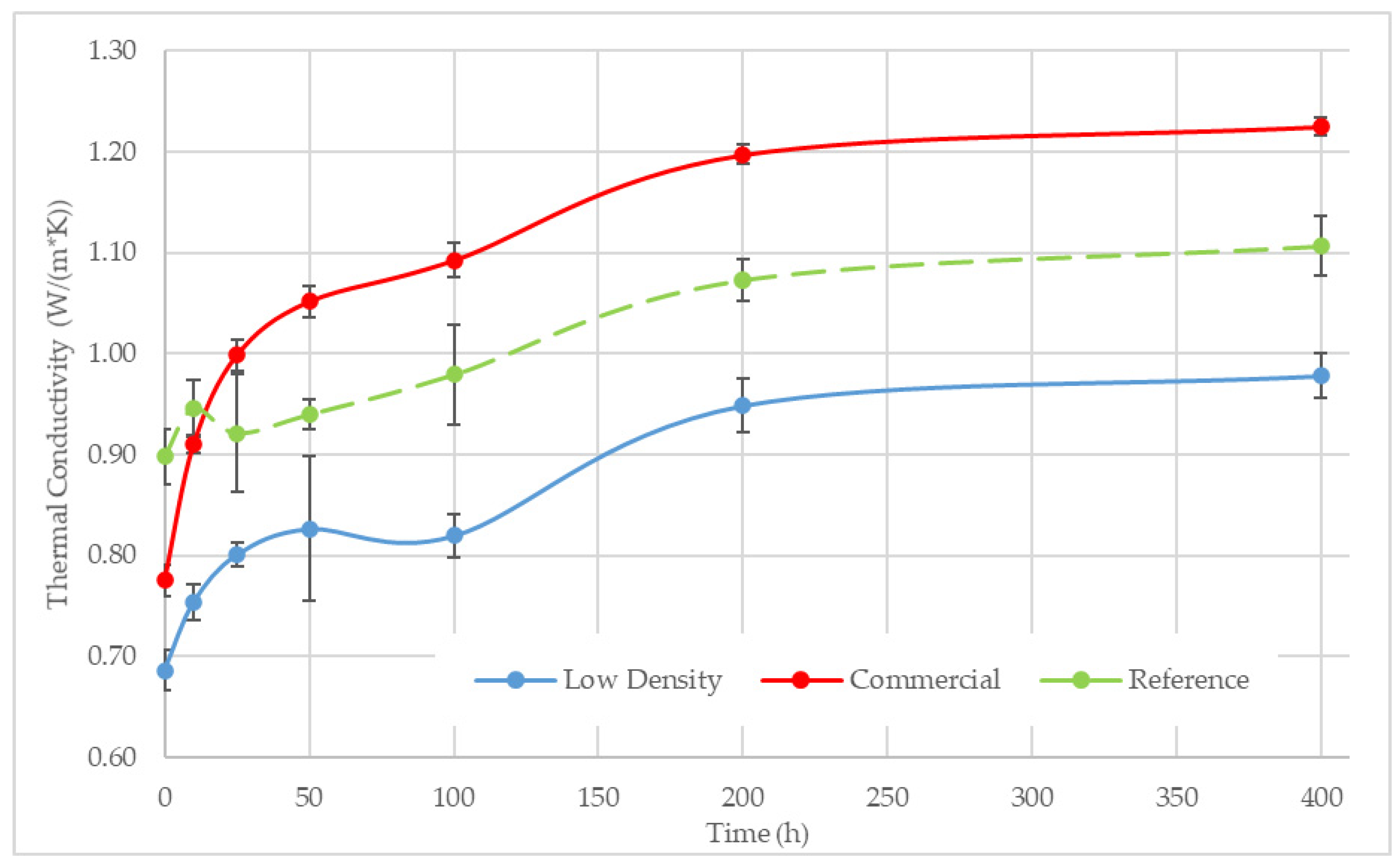

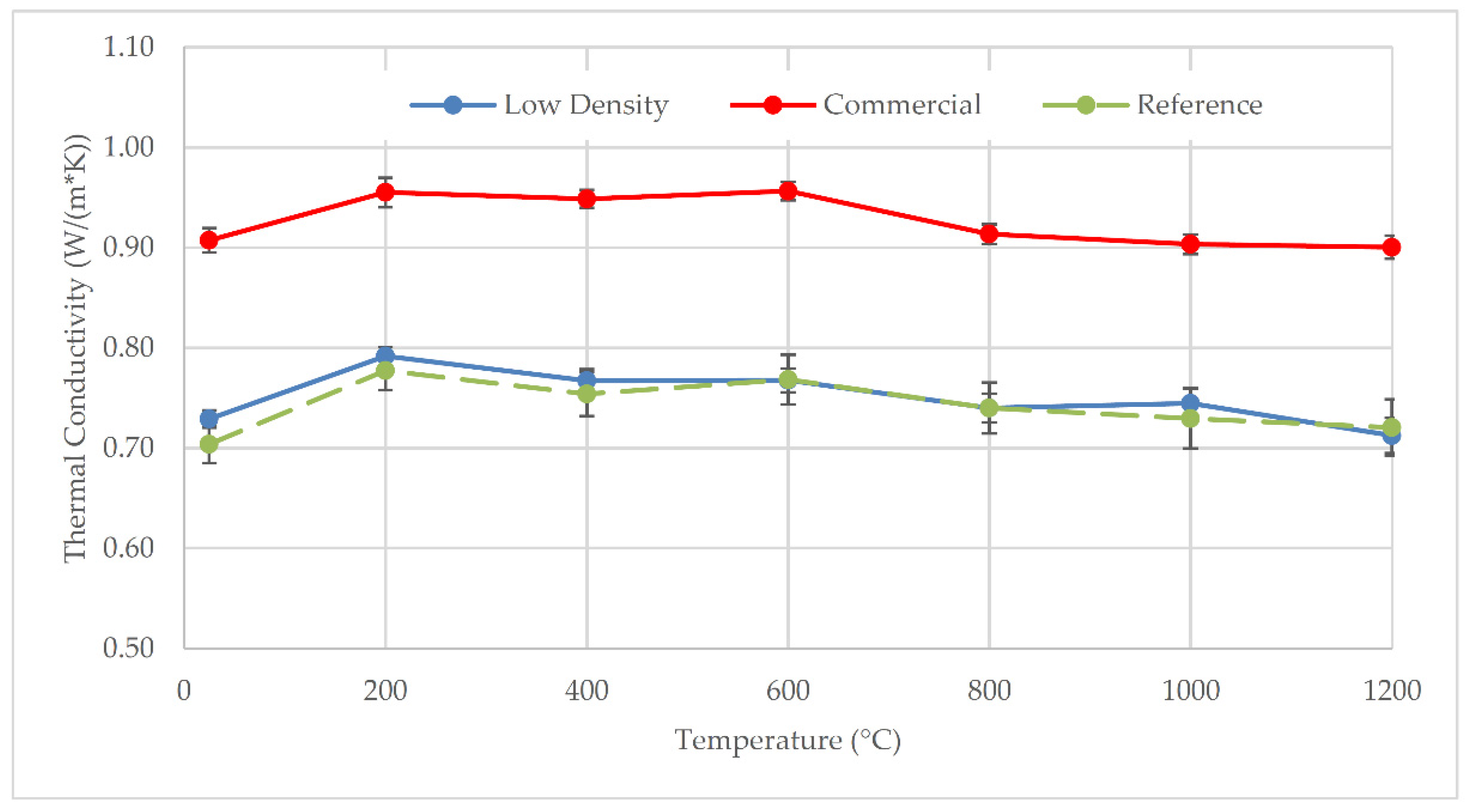

3.6. Thermal Conductivity Evaluation

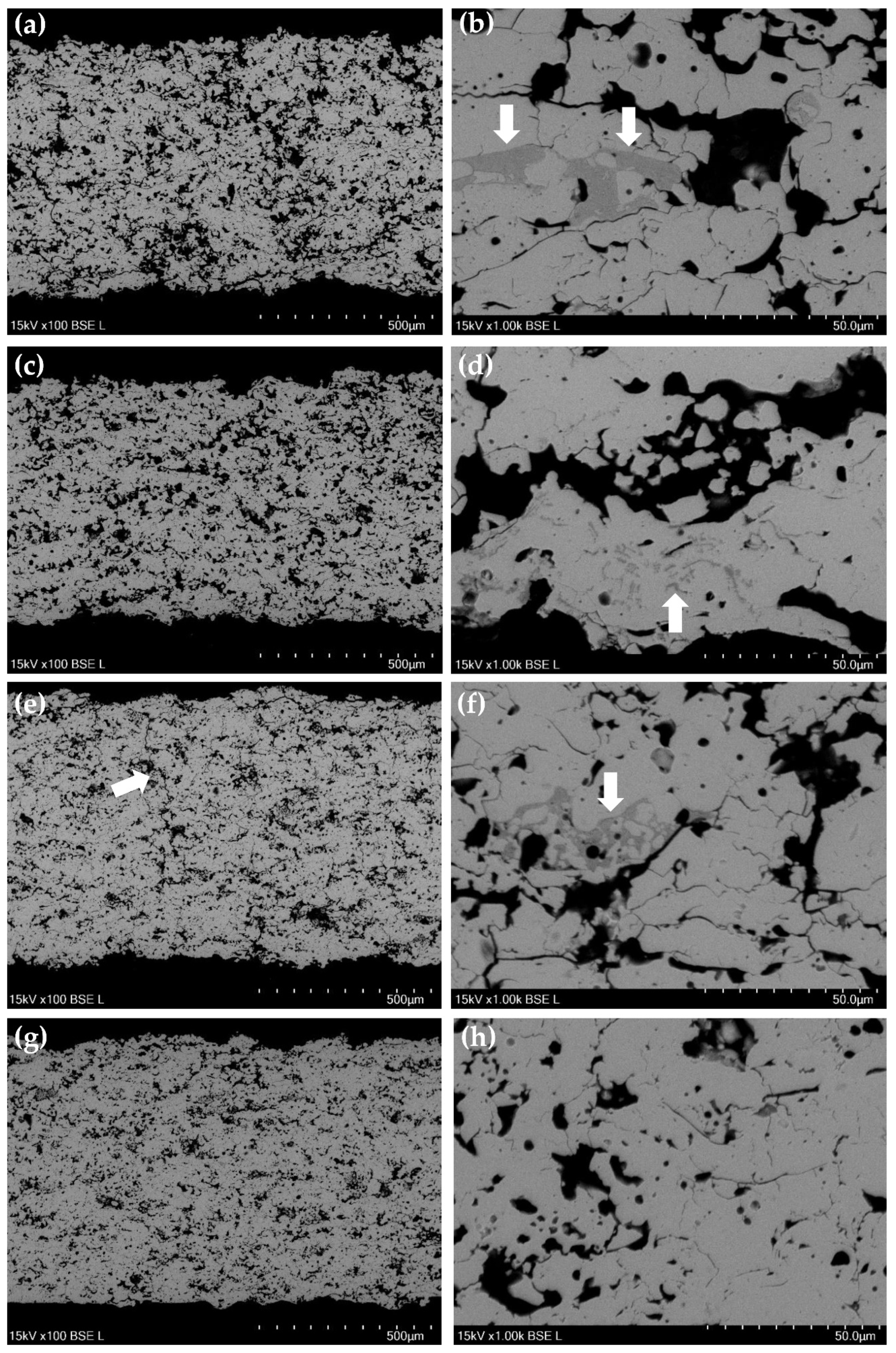

3.7. Microstructures after Thermal Exposure

3.8. Coating Economics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Boissonnet, G.; Bonnet, G.; Pasquet, A.; Bourhila, N.; Pedraza, F. Evolution of thermal insulation of plasma-sprayed thermal barrier coating systems with exposure to high temperature. J. Eur. Ceram. Soc. 2019, 39, 2111–2121. [Google Scholar] [CrossRef]

- Feuerstein, A.; Knapp, J.; Taylor, T.; Ashary, A.; Bolcavage, A.; Hitchman, N. Technical and economical aspects of current thermal barrier coating systems for gas turbine engines by thermal spray and EBPVD: A review. J. Therm. Spray Technol. 2008, 17, 199–213. [Google Scholar] [CrossRef]

- Lima, R.S. Perspectives on thermal gradients in porous ZrO2-7–8 wt.% Y2O3 (YSZ) thermal barrier coatings (TBCs) manufactured by air plasma spray (APS). Coatings 2020, 10, 812. [Google Scholar] [CrossRef]

- Helminiak, M.A.; Yanar, N.M.; Pettit, F.; Taylor, T.; Meier, G.H. The behavior of high-purity, low-density air plasma sprayed thermal barrier coatings. Surf. Coat. Technol. 2009, 204, 793–796. [Google Scholar] [CrossRef]

- Bengtsson, P.; Ericsson, T.; Wigren, J. Thermal shock testing of burner cans coated with a thick thermal barrier coating. J. Therm. Spray Technol. 1998, 7, 340–348. [Google Scholar] [CrossRef]

- Steffens, H.D.; Babiak, Z.; Gramlich, M. Some aspects of thick thermal barrier coating lifetime prolongation. J. Therm. Spray Technol. 1999, 8, 517–522. [Google Scholar] [CrossRef]

- Taylor, T.A. Thermal Barrier Coating for Substrates and Process for Producing It. U.S. Patent 5073433A, 17 December 1991. [Google Scholar]

- Schwingel, D.; Taylor, R.; Haubold, T.; Wigren, J.; Gualco, C. Mechanical and thermophysical properties of thick PYSZ thermal barrier coatings: Correlation with microstructure and spraying parameters. Surf. Coatings Technol. 1998, 108, 99–106. [Google Scholar] [CrossRef]

- Guo, H.; Vaßen, R.; Stöver, D. Thermophysical properties and thermal cycling behavior of plasma sprayed thick thermal barrier coatings. Surf. Coatings Technol. 2005, 192, 48–56. [Google Scholar] [CrossRef]

- Curry, N.; VanEvery, K.; Snyder, T.; Markocsan, N. Thermal conductivity analysis and lifetime testing of suspension plasma-sprayed thermal barrier coatings. Coatings 2014, 4, 630–650. [Google Scholar] [CrossRef]

- Scrivani, A.; Rizzi, G.; Bardi, U.; Giolli, C.; Miranda, M.M.; Ciattini, S.; Fossati, A.; Borgioli, F. Thermal fatigue behavior of thick and porous thermal barrier coatings systems. J. Therm. Spray Technol. 2007, 16, 816–821. [Google Scholar] [CrossRef]

- Curry, N.; Donoghue, J. Evolution of thermal conductivity of dysprosia stabilised thermal barrier coating systems during heat treatment. Surf. Coat. Technol. 2012, 209, 38–43. [Google Scholar] [CrossRef]

- Golosnoy, I.O.; Cipitria, A.; Clyne, T. Heat transfer through plasma-sprayed thermal barrier coatings in gas turbines: A review of recent work. J. Therm. Spray Technol. 2009, 18, 809–821. [Google Scholar] [CrossRef]

- Smith, J.; Scheibel, J.; Classen, D.; Paschke, S.; Elbel, S.; Fick, K.; Carlson, D. Thermal barrier coating validation testing for industrial gas turbine combustion hardware. J. Eng. Gas. Turbines Power 2015, 138, 031508. [Google Scholar] [CrossRef]

- Scheibel, J.; Smith, J.S. Gas Turbine Low Conductivity Thermal Barrier Coating Validation and Demonstration; European Turbine Network: Brussels, Belgium, 2016; p. 10. [Google Scholar]

- Giolli, C.; Scrivani, A.; Rizzi, G.; Borgioli, F.; Bolelli, G.; Lusvarghi, L. Failure mechanism for thermal fatigue of thermal barrier coating systems. J. Therm. Spray Technol. 2009, 18, 223–230. [Google Scholar] [CrossRef]

- Nelson, W.A.; Orenstein, R.M. TBC experience in land-based gas turbines. J. Therm. Spray Technol. 1997, 6, 176–180. [Google Scholar] [CrossRef]

- Bolelli, G.; Righi, M.G.; Mughal, M.Z.; Moscatelli, R.; Ligabue, O.; Antolotti, N.; Sebastiani, M.; Lusvarghi, L.; Bemporad, E. Damage progression in thermal barrier coating systems during thermal cycling: A nano-mechanical assessment. Mater. Des. 2019, 166, 107615. [Google Scholar] [CrossRef]

- Mauer, G.; Vaßen, R.; Stöver, D. Preliminary study on the TriplexPro™-200 gun for atmospheric plasma spraying of yttria-stabilized zirconia. Surf. Coat. Technol. 2008, 202, 4374–4381. [Google Scholar] [CrossRef]

- Vaidya, A.; Srinivasan, V.; Streibl, T.; Friis, M.; Chi, W.; Sampath, S. Process maps for plasma spraying of yttria-stabilized zirconia: An integrated approach to design, optimization and reliability. Mater. Sci. Eng. A 2008, 497, 239–253. [Google Scholar] [CrossRef]

- Seshadri, R.C.; Sampath, S. Characteristics of conventional and cascaded arc plasma spray-deposited ceramic under standard and high-throughput conditions. J. Therm. Spray Technol. 2019, 28, 690–705. [Google Scholar] [CrossRef]

- Lima, R.S.; Guerreiro, B.M.H.; Curry, N.; Leitner, M.; Körner, K. Environmental, economical, and performance impacts of Ar-H2 and N2-H2 plasma-sprayed YSZ TBCs. J. Therm. Spray Technol. 2019, 29, 74–89. [Google Scholar] [CrossRef]

- Marple, B.; Lima, R.; Moreau, C.; Kruger, S.; Xie, L.; Dorfman, M.R. Yttria-stabilized zirconia thermal barriers sprayed using N2-H2 and Ar-H2 plasmas: Influence of processing and heat treatment on coating properties. J. Therm. Spray Technol. 2007, 16, 791–797. [Google Scholar] [CrossRef]

- Solonenko, O.P.; Smirnov, A.V. Advanced oxide powders processing based on cascade plasma. J. Phys. Conf. Ser. 2014, 550, 012017. [Google Scholar] [CrossRef]

- Bobzin, K.; Ernst, F.B.G.; Zwick, J.B.; Richardt, K.R.M.; Sporer, D.; Molz, R. Triplex Pro 200: Potentials and advanced applications. In Global Coating Solutions; ASM International: Beijing, China, 2007. [Google Scholar]

- Mohanty, P.; George, A.; Pollard, L.; Snyder, D. A Novel single cathode plasma column design for process stability and long component life. J. Therm. Spray Technol. 2009, 19, 448–458. [Google Scholar] [CrossRef]

- Bisson, J.F.; Moreau, C.; Dorfman, M.; Dambra, C.; Mallon, J. Influence of hydrogen on the microstructure of plasma-sprayed yttria-stabilized zirconia coatings. J. Therm. Spray Technol. 2005, 14, 85–90. [Google Scholar] [CrossRef]

- Kucuk, A.; Lima, R.S.; Berndt, C. Influence of plasma spray parameters on formation and morphology of ZrO2−8 wt% Y2O3 deposits. J. Am. Ceram. Soc. 2001, 84, 693–700. [Google Scholar] [CrossRef]

- ImageJ. Available online: http://imagej.nih.gov/ij/ (accessed on 18 March 2009).

- ISO Standard 18754. Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Density and Apparent Porosity; International Organization for Standardization: Geneva, Switzerland, 2003. [Google Scholar]

- Wang, Z.; Kulkarni, A.; Deshpande, S.; Nakamura, T.; Herman, H. Effects of pores and interfaces on effective properties of plasma sprayed zirconia coatings. Acta Mater. 2003, 51, 5319–5334. [Google Scholar] [CrossRef]

- Tan, Y.; Longtin, J.P.; Sampath, S.; Wang, H. Effect of the starting microstructure on the thermal properties of as-sprayed and thermally exposed plasma-sprayed YSZ coatings. J. Am. Ceram. Soc. 2009, 92, 710–716. [Google Scholar] [CrossRef]

- Bacciochini, A.; Ilavsky, J.; Montavon, G.; Denoirjean, A.; Ben-Ettouil, F.; Valette, S.; Fauchais, P.; Wittmann-Teneze, K. Quantification of void network architectures of suspension plasma-sprayed (SPS) yttria-stabilized zirconia (YSZ) coatings using Ultra-small-angle X-ray scattering (USAXS). Mater. Sci. Eng. A 2010, 528, 91–102. [Google Scholar] [CrossRef]

- Ekberg, J.; Ganvir, A.; Klement, U.; Creci, S.; Nordstierna, L. The influence of heat treatments on the porosity of suspension plasma-sprayed yttria-stabilized zirconia coatings. J. Therm. Spray Technol. 2018, 27, 391–401. [Google Scholar] [CrossRef]

- ASTM C633. B08 committee test method for adhesion or cohesion strength of thermal spray coatings. ASTM Int. 2017. [Google Scholar] [CrossRef]

- Cernuschi, F.; Lorenzoni, L.; Ahmaniemi, S.; Vuoristo, P.; Mäntylä, T. Studies of the sintering kinetics of thick thermal barrier coatings by thermal diffusivity measurements. J. Eur. Ceram. Soc. 2005, 25, 393–400. [Google Scholar] [CrossRef]

- Shinoda, K.; Angulo, J.C.; Valarezo, A.; Sampath, S. Effect of deposition rate on the stress evolution of plasma-sprayed yttria-stabilized zirconia. J. Therm. Spray Technol. 2012, 21, 1224–1233. [Google Scholar] [CrossRef]

- Matsumoto, K.; Itoh, Y.; Kameda, T. EB-PVD process and thermal properties of hafnia-based thermal barrier coating. Sci. Technol. Adv. Mater. 2003, 4, 153–158. [Google Scholar] [CrossRef]

- Lee, P.H.; Lee, S.Y.; Kwon, J.Y.; Myoung, S.W.; Lee, J.H.; Jung, Y.G.; Cho, H.; Paik, U. Thermal cycling behavior and interfacial stability in thick thermal barrier coatings. Surf. Coatings Technol. 2010, 205, 1250–1255. [Google Scholar] [CrossRef]

- Lima, R.S.; Nagy, D.; Marple, B.R. Bond coat engineering influence on the evolution of the microstructure, bond strength, and failure of TBCS subjected to thermal cycling. J. Therm. Spray Technol. 2014. [Google Scholar] [CrossRef]

- Bolcavage, A.; Feuerstein, A.; Foster, J.; Moore, P. Thermal shock testing of thermal barrier coating/bondcoat systems. J. Mater. Eng. Perform. 2004, 13, 389–397. [Google Scholar] [CrossRef]

- Curry, N.; Markocsan, N.; Östergren, L.; Li, X.H.; Dorfman, M. Evaluation of the lifetime and thermal conductivity of dysprosia-stabilized thermal barrier coating systems. J. Therm. Spray Technol. 2013, 22, 864–872. [Google Scholar] [CrossRef]

- Patterson, T.; Leon, A.; Jayaraj, B.; Liu, J.; Sohn, Y.H. Thermal cyclic lifetime and oxidation behavior of air plasma sprayed CoNiCrAlY bond coats for thermal barrier coatings. Surf. Coat. Technol. 2008, 203, 437–441. [Google Scholar] [CrossRef]

- Cipitria, A.; Golosnoy, I.; Clyne, T. A sintering model for plasma-sprayed zirconia thermal barrier coatings. Part II: Coatings bonded to a rigid substrate. Acta Mater. 2009, 57, 993–1003. [Google Scholar] [CrossRef]

- Chi, W.; Sampath, S.; Wang, H. Microstructure-thermal conductivity relationships for plasma-sprayed yttria-stabilized zirconia coatings. J. Am. Ceram. Soc. 2008, 91, 2636–2645. [Google Scholar] [CrossRef]

- Eaton, H.; Novak, R. Sintering studies of plasma-sprayed zirconia. Surf. Coat. Technol. 1987, 32, 227–236. [Google Scholar] [CrossRef]

- Arfelli, M.; Ingo, G.M.; Mattogno, G. XPS investigation of impurity phase segregation in 25.5 wt.% CeO2−2.5 Y2O3−72 ZrO2 plasma-sprayed thermal barrier coatings. Surf. Interface Anal. 1990, 16, 452–456. [Google Scholar] [CrossRef]

- Vaßen, R.; Czech, N.; Malléner, W.; Stamm, W.; Stöver, D. Influence of impurity content and porosity of plasma-sprayed yttria-stabilized zirconia layers on the sintering behaviour. Surf. Coat. Technol. 2001, 141, 135–140. [Google Scholar] [CrossRef]

- Paul, S.; Cipitria, A.; Golosnoy, I.; Xie, L.; Dorfman, M.; Clyne, T. Effects of impurity content on the sintering characteristics of plasma-sprayed zirconia. J. Therm. Spray Technol. 2007, 16, 798–803. [Google Scholar] [CrossRef]

- Xie, L.; Dorfman, M.; Cipitria, A.; Paul, S.; Golosnoy, I.; Clyne, T. Properties and performance of high-purity thermal barrier coatings. J. Therm. Spray Technol. 2007, 16, 804–808. [Google Scholar] [CrossRef]

- Curry, N.; Janikowski, W.; Pala, Z.; Vilémová, M.; Markocsan, N. Impact of impurity content on the sintering resistance and phase stability of dysprosia- and yttria-stabilized zirconia thermal barrier coatings. J. Therm. Spray Technol. 2014, 23, 160–169. [Google Scholar] [CrossRef]

- Tsipas, S.; Golosnoy, I.O.; Damani, R.; Clyne, T. The effect of a high thermal gradient on sintering and stiffening in the top coat of a thermal barrier coating system. J. Therm. Spray Technol. 2004, 13, 370–376. [Google Scholar] [CrossRef]

- Lima, R.S.; Marple, B.R.; Marcoux, P. Thermal gradient behavior of TBCS subjected to a laser gradient test rig: Simulating an air-to-air combat flight. J. Therm. Spray Technol. 2016, 25, 282–290. [Google Scholar] [CrossRef]

- Lima, R.S.; Marple, B.R. Insights on the high-temperature operational limits of ZrO2-Y2O3 TBCs manufactured via air plasma spray. J. Mater. Eng. Perform. 2017, 26, 1272–1282. [Google Scholar] [CrossRef]

| Parameters | Powder | ||

|---|---|---|---|

| Commercial | Low Density | ||

| Particle Size (µm) | D10 | 16 | 21 |

| D50 | 50 | 54 | |

| D90 | 95 | 97 | |

| Specific Density | g/cc | 2.3 | 1.6 |

| Chemical Composition | - | - | |

| ZrO2 | wt.% | Balance | Balance |

| Y2O3 | 7.13 | 7.6 | |

| HfO2 | 1.57 | 1.86 | |

| SiO2 | 0.059 | <0.01 | |

| Al2O3 | 0.045 | <0.01 | |

| CaO | 0.035 | 0.04 | |

| TiO2 | 0.094 | 0.045 | |

| Fe2O3 | 0.011 | <0.01 | |

| Coating | Argon (SLM) | Nitrogen (SLM) | Hydrogen (SLM) | Current (A) | Voltage (V) | Power (kW) | Carrier Flow (SLM) |

|---|---|---|---|---|---|---|---|

| Commercial | 85 | 47 | 71 | 397 | 239.6 | 94.9 | 22 |

| Low Density | 398 | 239 | 95 | 18 |

| Coating ID | Spray System | Coating Thickness (µm) | Powder Feeding Rate (g/min) | Deposition Efficiency (%) |

|---|---|---|---|---|

| Reference | Cascade | 779 ± 10 | 270 | ~38 |

| Commercial | 100HE | 789 ± 8 | 280 | 39.4 |

| Low Density | 100HE | 816 ± 8 | 280 | 51.6 |

| Cascade | 100HE | |||

|---|---|---|---|---|

| Coating System | Reference | Commercial | Low Density | Low Density Optimised |

| Deposition Efficiency | 38% | 39.4% | 51.6% | |

| Coating thickness | 800 µm | 800 µm | 800 µm | 675 µm |

| Gas Cost | EUR 6.01 | EUR 14.00 | EUR 12.44 | EUR 10.54 |

| YSZ powder cost (@ EUR 35 per kg) | EUR 2475.49 | EUR 2322.55 | EUR 2058.76 | EUR 1737.08 |

| Powder saved (kg) | - | 4.4 | 11.9 | 21.1 |

| Electricity Cost | EUR 72.08 | EUR 87.12 | EUR 77.43 | EUR 65.61 |

| Labour Cost (@ €30 per hour) | EUR 139.98 | EUR 127.50 | EUR 114.04 | EUR 97.63 |

| Time (minutes) | 262 | 237 | 210 | 177 |

| Time Saving | - | 10% | 20% | 32% |

| Processing Cost | EUR 2693.55 | EUR 2551.16 | EUR 2262.66 | EUR 1910.85 |

| Cost Saving | - | 5% | 16% | 29% |

| Coating ID | Spray System | Thermal Conductivity @ 1200 °C (W·m/K) | Thermal Resistance (m2·K/W) (10−4) | Target Coating Thickness (µm) | Difference in Coating Thickness (%) |

|---|---|---|---|---|---|

| Reference | Cascade | 1.106 | 7.25 ± 0.26 | 800 | - |

| Commercial | 100HE | 1.225 | 6.68 ± 0.16 | 866 | +8.3% |

| Low Density | 100HE | 0.978 | 8.59 ± 0.31 | 674 | −15.8% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Curry, N.; Leitner, M.; Körner, K. High-Porosity Thermal Barrier Coatings from High-Power Plasma Spray Equipment—Processing, Performance and Economics. Coatings 2020, 10, 957. https://doi.org/10.3390/coatings10100957

Curry N, Leitner M, Körner K. High-Porosity Thermal Barrier Coatings from High-Power Plasma Spray Equipment—Processing, Performance and Economics. Coatings. 2020; 10(10):957. https://doi.org/10.3390/coatings10100957

Chicago/Turabian StyleCurry, Nicholas, Matthias Leitner, and Karl Körner. 2020. "High-Porosity Thermal Barrier Coatings from High-Power Plasma Spray Equipment—Processing, Performance and Economics" Coatings 10, no. 10: 957. https://doi.org/10.3390/coatings10100957

APA StyleCurry, N., Leitner, M., & Körner, K. (2020). High-Porosity Thermal Barrier Coatings from High-Power Plasma Spray Equipment—Processing, Performance and Economics. Coatings, 10(10), 957. https://doi.org/10.3390/coatings10100957