Erosion Performance of Atmospheric Plasma Sprayed Thermal Barrier Coatings with Diverse Porosity Levels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coating Feedstock

2.2. Coating Deposition

- (a)

- Conventional porosity, low powder feed rate

- (b)

- Conventional porosity, medium powder feed rate

- (c)

- High porosity, high powder feed rate

- (d)

- High porosity with high feed rate and shorter standoff distance

2.3. Coating Characterization

3. Results and Discussion

3.1. Accuraspray Results

3.2. Microstructural Analysis

3.2.1. Conventional Porosity—Low Powder Feed Rate (LD-L and HOSP-L)

3.2.2. Conventional Porosity—Medium Powder Feed Rate (LD-M and HOSP-M)

3.2.3. High Porosity—Higher Feed Rates and Longer Standoff Distance (LD-H, A&S-H)

3.2.4. High Porosity—Higher Feed Rates and Shorter Standoff Distance (LD-H.S, A&S-H.S)

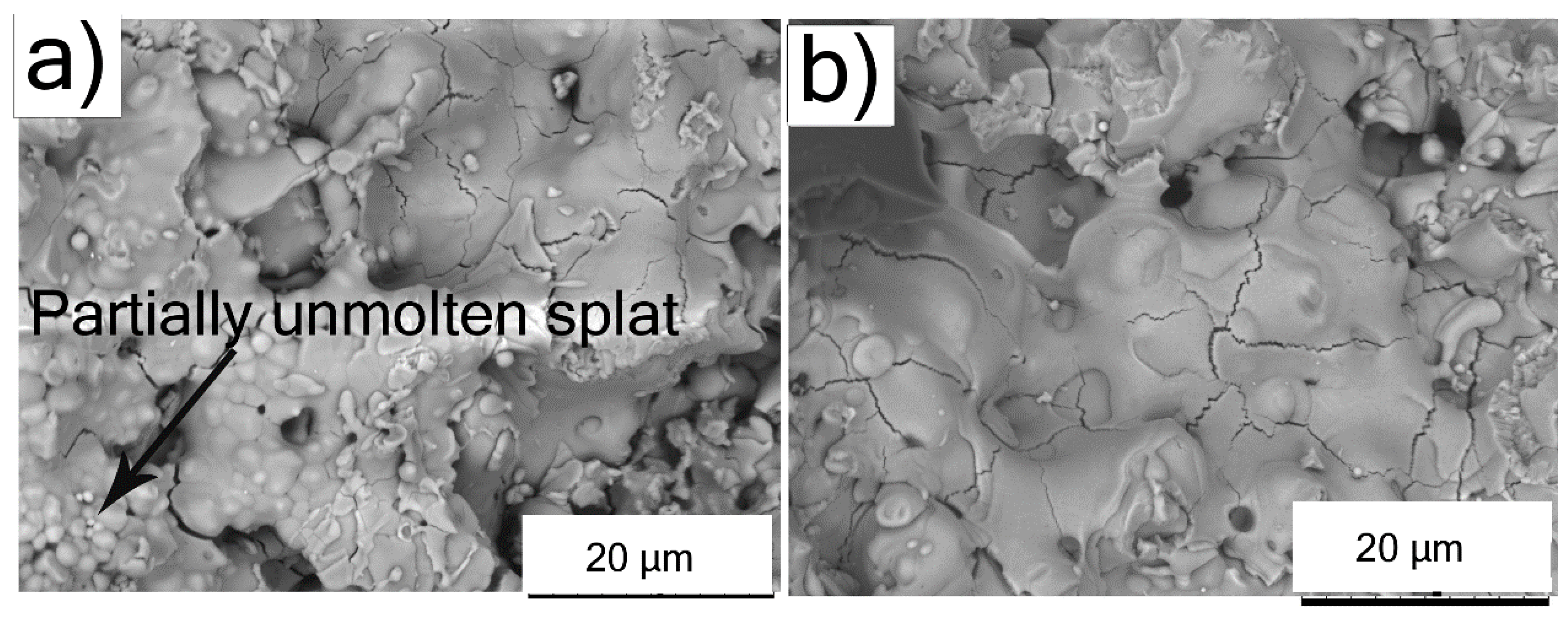

3.2.5. Top Surface SEM Analysis

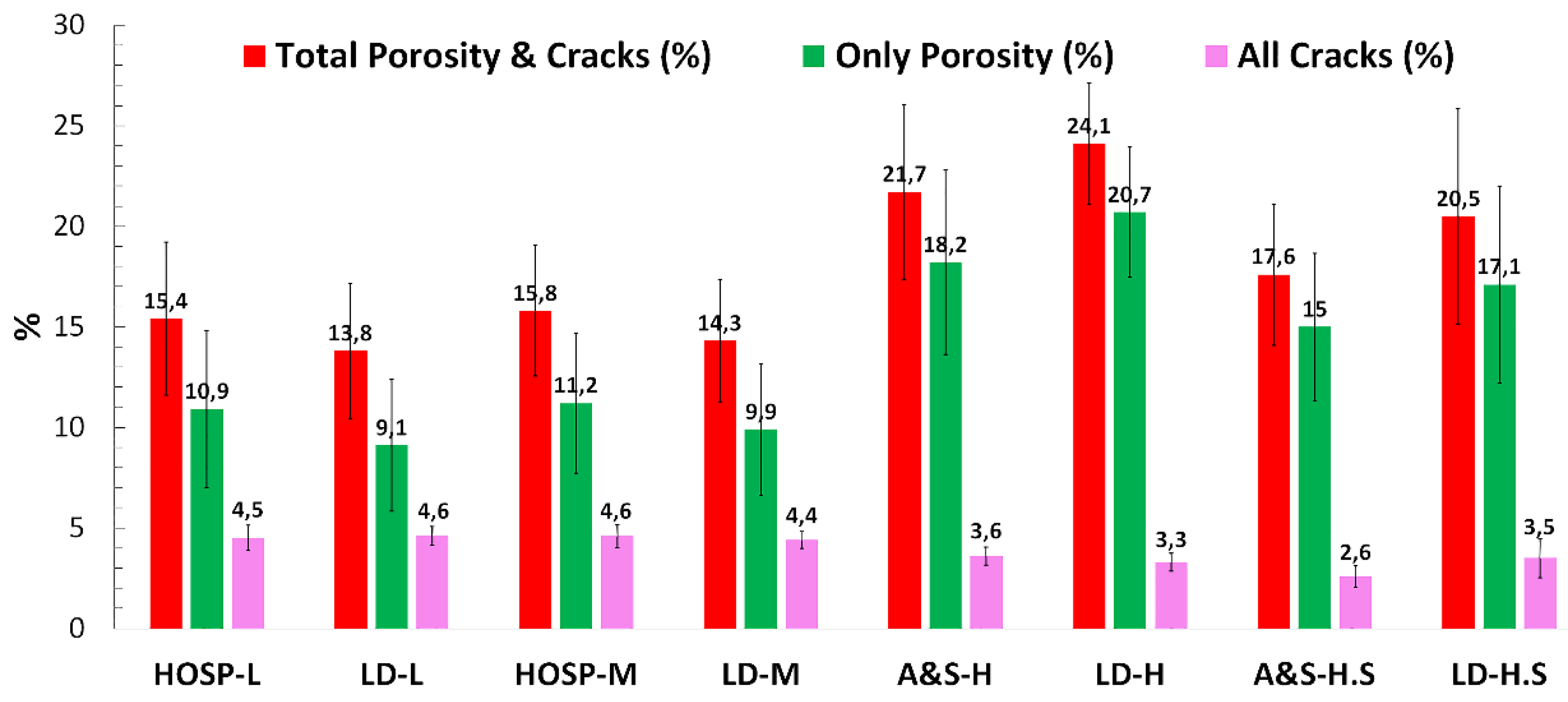

3.3. Quantification of Microstructural Features

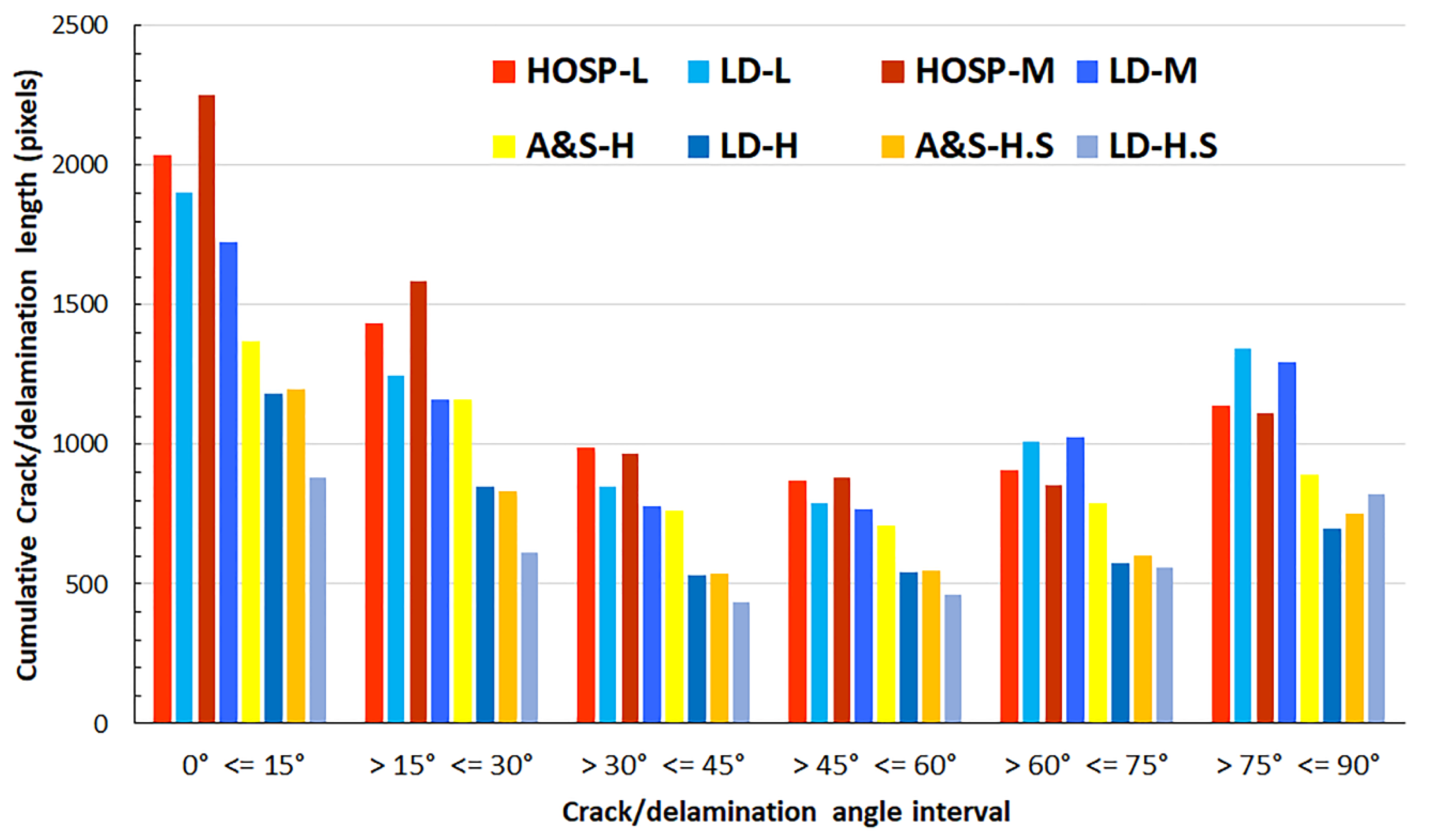

Inclination Angle of Cracks to the Substrate

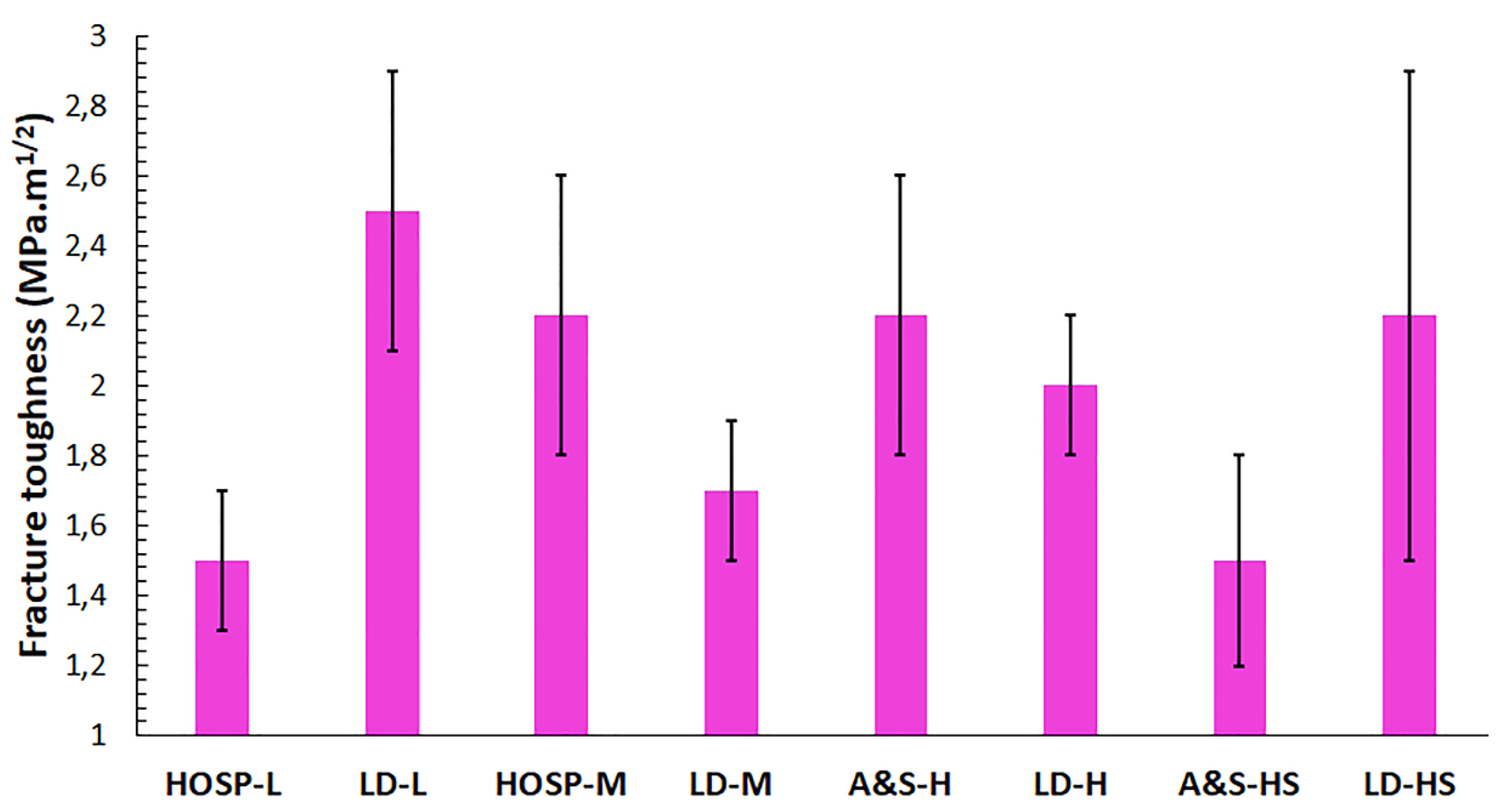

3.4. Hardness and Fracture Toughness

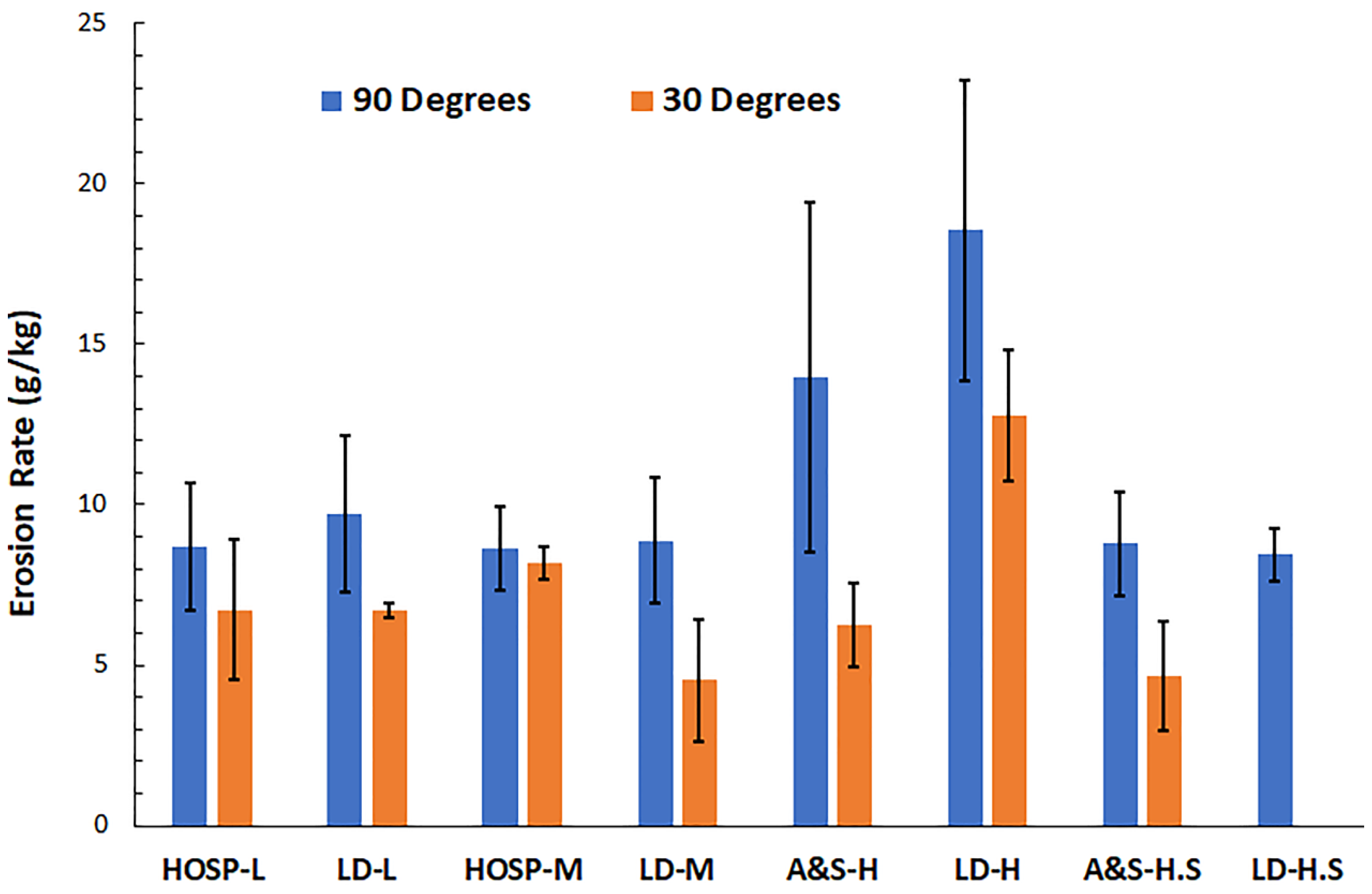

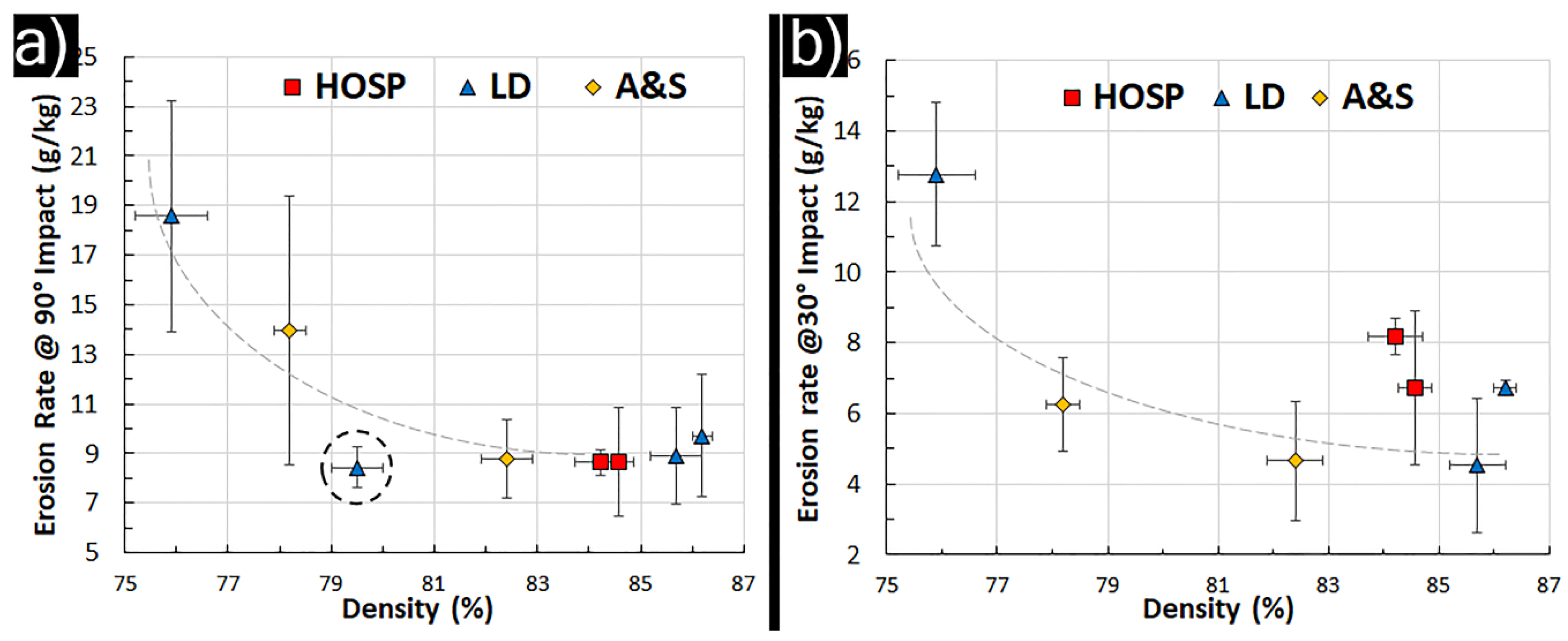

3.5. Erosion Rate at Different Impact Angles

3.6. Post-Erosion Analysis

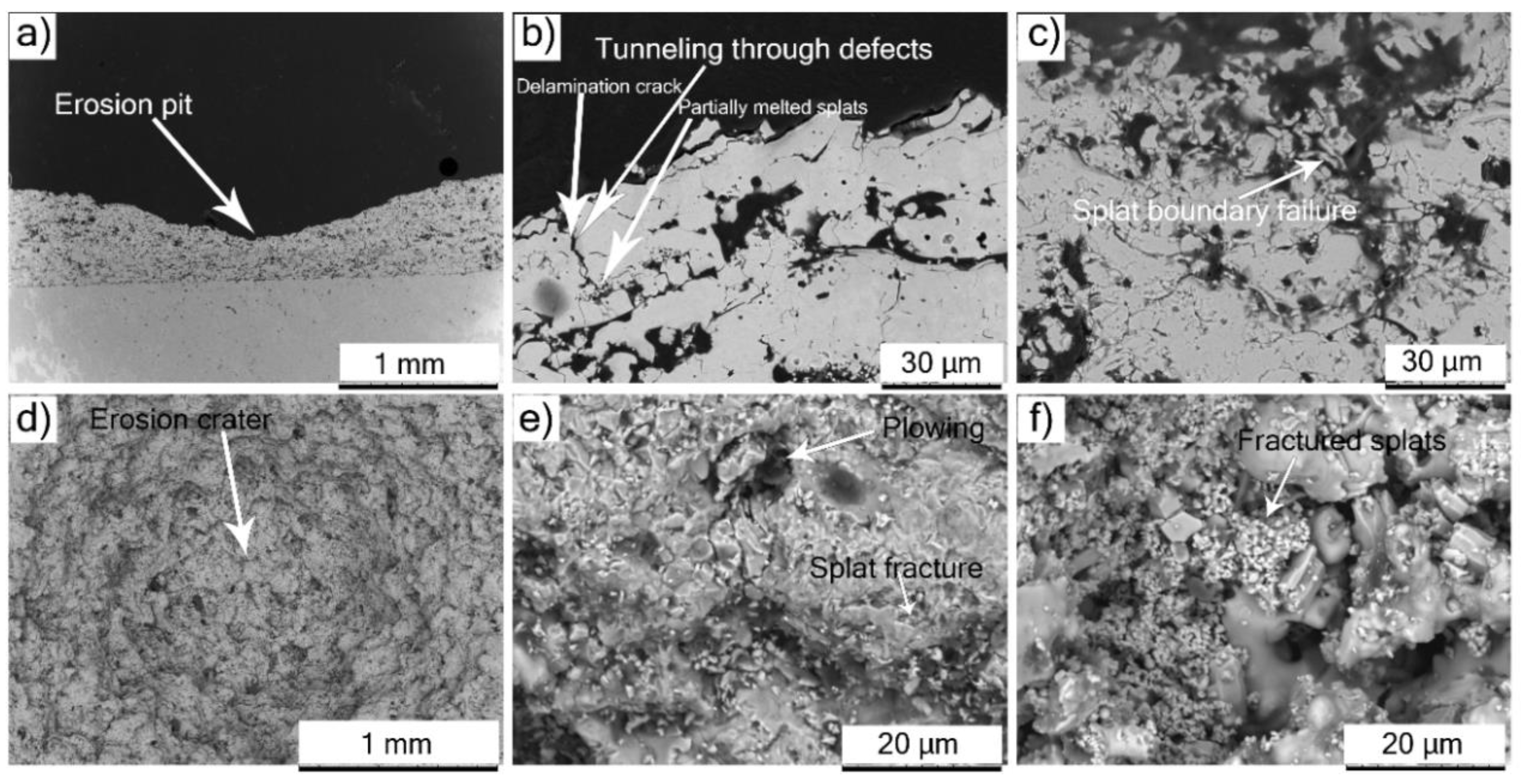

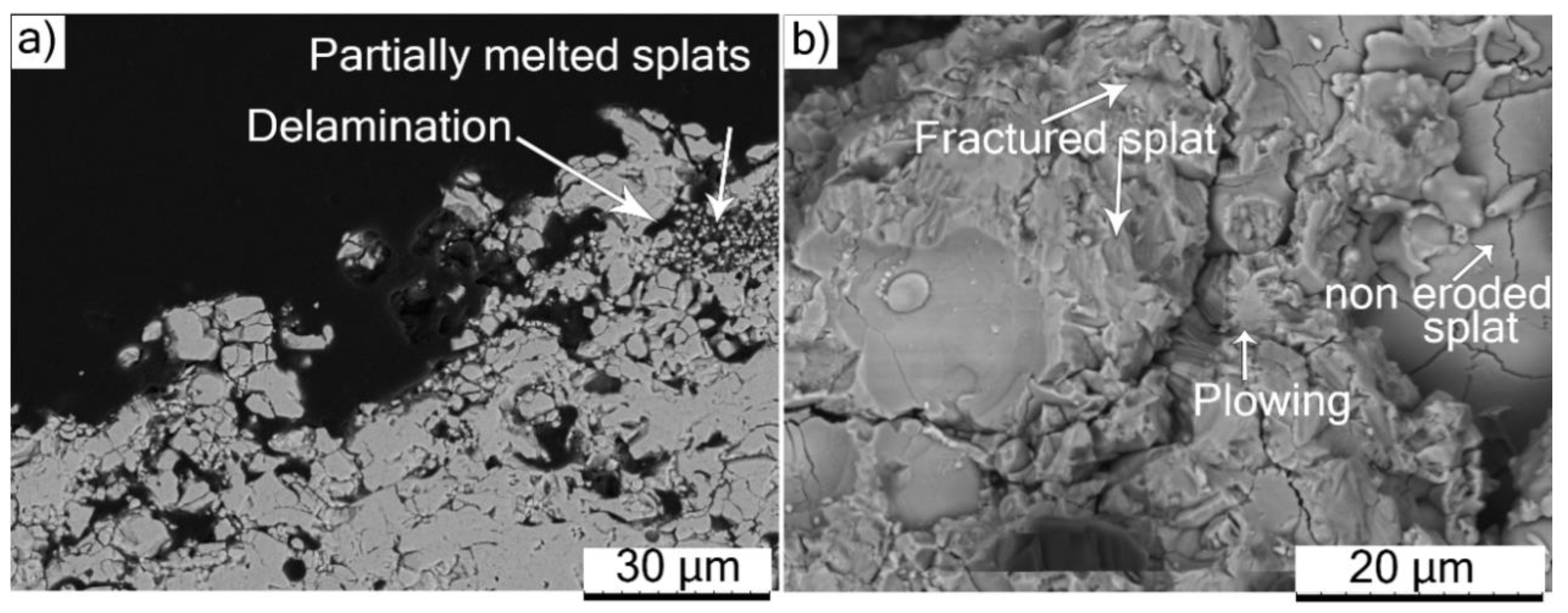

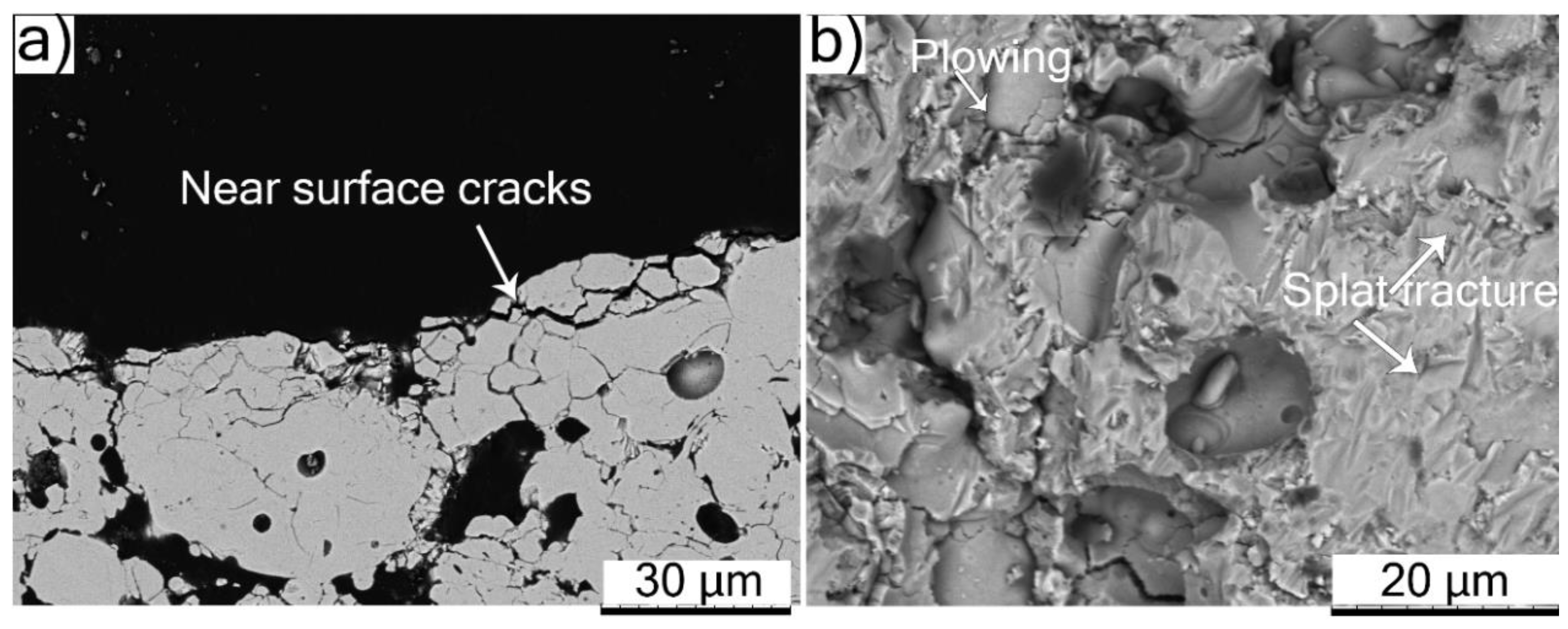

3.6.1. Erodent Impact at 90 Degrees

3.6.2. Erodent Impact at 30 Degrees

3.7. Correlating the Erosion Performance to Microstructure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miller, R. Thermal barrier coatings for aircraft engines: History and directions. J. Spray Technol. 1997, 6, 35–42. [Google Scholar] [CrossRef] [Green Version]

- Mahade, S.; Jonnalagadda, K.; Curry, N.; Li, X.; Björklund, S.; Markocsan, N.; Nylén, P.; Peng, R. Engineered architectures of gadolinium zirconate based thermal barrier coatings subjected to hot corrosion test. Surf. Coat. Technol. 2017, 328, 361–370. [Google Scholar] [CrossRef]

- Drexler, J.; Shinoda, K.; Ortiz, A.; Li, D.; Vasiliev, A.; Gledhill, A.; Sampath, S.; Padture, N. Air-plasma-sprayed thermal barrier coatings that are resistant to high-temperature attack by glassy deposits. Acta Mater. 2010, 58, 6835–6844. [Google Scholar] [CrossRef]

- Bakan, E.; Mack, D.; Mauer, G.; Vaßen, R. Gadolinium Zirconate/YSZ Thermal Barrier Coatings: Plasma Spraying, Microstructure, and Thermal Cycling Behavior. J. Am. Ceram. Soc. 2014, 97, 4045–4051. [Google Scholar] [CrossRef]

- Cheng, B.; Zhang, Y.; Yang, N.; Zhang, M.; Chen, L.; Yang, G.; Li, C.; Li, C. Sintering-induced delamination of thermal barrier coatings by gradient thermal cyclic test. J. Am. Ceram. Soc. 2017, 100, 1820–1830. [Google Scholar] [CrossRef]

- Lima, R.; Guerreiro, B.; Aghasibeig, M. Microstructural Characterization and Room-Temperature Erosion Behavior of As-Deposited SPS, EB-PVD and APS YSZ-Based TBCs. J. Therm. Spray Technol. 2018, 28, 223–232. [Google Scholar] [CrossRef]

- Mahade, S.; Ruelle, C.; Curry, N.; Holmberg, J.; Björklund, S.; Markocsan, N.; Nylén, P. Understanding the effect of material composition and microstructural design on the erosion behavior of plasma sprayed thermal barrier coatings. Appl. Surf. Sci. 2019, 488, 170–184. [Google Scholar] [CrossRef]

- Brandon, J.; Taylor, R. Phase stability of zirconia-based thermal barrier coatings part I. Zirconia-yttria alloys. Surf. Coat. Technol. 1991, 46, 75–90. [Google Scholar] [CrossRef]

- Vaßen, R.; Jarligo, M.; Steinke, T.; Mack, D.; Stöver, D. Overview on advanced thermal barrier coatings. Surf. Coat. Technol. 2010, 205, 938–942. [Google Scholar] [CrossRef]

- Mauer, G.; Jarligo, M.; Mack, D.; Vaßen, R. Plasma-sprayed thermal barrier coatings: New materials, processing issues, and solutions. J. Therm. Spray Technol. 2013, 22, 646–658. [Google Scholar] [CrossRef]

- Vaßen, R.; Traeger, F.; Stöver, D. New thermal barrier coatings based on Pyrochlore/YSZ double-layer systems. Int. J. Appl. Ceram. Technol. 2005, 1, 351–361. [Google Scholar] [CrossRef]

- Fauchais, P.; Montavon, G.; Bertrand, G. From powders to thermally sprayed coatings. J. Therm. Spray Technol. 2009, 19, 56–80. [Google Scholar] [CrossRef] [Green Version]

- Tejero-Martin, D.; Rezvani Rad, M.; McDonald, A.; Hussain, T. Beyond traditional coatings: A review on thermal-sprayed functional and smart coatings. J. Therm. Spray Technol. 2019, 28, 598–644. [Google Scholar] [CrossRef] [Green Version]

- Nicholls, J.; Deakin, M.; Rickerby, D. A comparison between the erosion behaviour of thermal spray and electron beam physical vapour deposition thermal barrier coatings. Wear 1999, 233–235, 352–361. [Google Scholar] [CrossRef]

- Wellman, R.; Nicholls, J. A review of the erosion of thermal barrier coatings. J. Phys. D Appl. Phys. 2007, 40, R293–R305. [Google Scholar] [CrossRef]

- Cernuschi, F.; Lorenzoni, L.; Capelli, S.; Guardamagna, C.; Karger, M.; Vaßen, R.; von Niessen, K.; Markocsan, N.; Menuey, J.; Giolli, C. Solid particle erosion of thermal spray and physical vapour deposition thermal barrier coatings. Wear 2011, 271, 2909–2918. [Google Scholar] [CrossRef]

- Pawlowski, L. Finely grained nanometric and submicrometric coatings by thermal spraying: A review. Surf. Coat. Technol. 2008, 202, 4318–4328. [Google Scholar] [CrossRef]

- Ramachandran, C.; Balasubramanian, V.; Ananthapadmanabhan, P. Erosion of atmospheric plasma sprayed rare earth oxide coatings under air suspended corundum particles. Ceram. Int. 2013, 39, 649–672. [Google Scholar] [CrossRef]

- Dwivedi, G.; Viswanathan, V.; Sampath, S.; Shyam, A.; Lara-Curzio, E. Fracture Toughness of Plasma-Sprayed Thermal Barrier Ceramics: Influence of Processing, Microstructure, and Thermal Aging. J. Am. Ceram. Soc. 2014, 97, 2736–2744. [Google Scholar] [CrossRef]

- Li, C.; Yang, G.; Ohmori, A. Relationship between particle erosion and lamellar microstructure for plasma-sprayed alumina coatings. Wear 2006, 260, 1166–1172. [Google Scholar] [CrossRef]

- Nicholls, J.; Lawson, K.; Johnstone, A.; Rickerby, D. Methods to reduce the thermal conductivity of EB-PVD TBCs. Surf. Coat. Technol. 2002, 151–152, 383–391. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.S.; Tian, Z.J.; Yang, B.; Shen, L.D. Preparation and solid particle erosion behaviors of plasma-sprayed and laser-remelted ZrO2-7wt.% Y2O3 thermal barrier coatings. In Applied Mechanics and Materials; Wu, J., Xie, H., Eds.; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2012; Volume 159, pp. 191–197. [Google Scholar]

- Ghasemi, R.; Shoja-Razavi, R.; Mozafarinia, R.; Jamali, H. Laser glazing of plasma-sprayed nanostructured yttria stabilized zirconia thermal barrier coatings. Ceram. Int. 2013, 39, 9483–9490. [Google Scholar] [CrossRef]

- Ahmaniemi, S.; Vuoristo, P.; Mäntylä, T. Mechanical and elastic properties of modified thick thermal barrier coatings. Mater. Sci. Eng. A 2004, 366, 175–182. [Google Scholar] [CrossRef]

- Tsai, P.; Lee, J.; Chang, C. Improving the erosion resistance of plasma-sprayed zirconia thermal barrier coatings by laser glazing. Surf. Coat. Technol. 2007, 202, 719–724. [Google Scholar] [CrossRef]

- Planques, P.; Vidal, V.; Lours, P.; Proton, V.; Crabos, F.; Huez, J.; Viguier, B. Mechanical and thermo-physical properties of plasma-sprayed thermal barrier coatings: A literature survey. Oxid. Met. 2017, 88, 133–143. [Google Scholar] [CrossRef] [Green Version]

- Guo, H.; Kuroda, S.; Murakami, H. Microstructures and properties of plasma-sprayed segmented thermal barrier coatings. J. Am. Ceram. Soc. 2006, 89, 1432–1439. [Google Scholar] [CrossRef]

- Lima, R. Perspectives on thermal gradients in porous ZrO2-7–8 wt.% Y2O3 (YSZ) thermal barrier coatings (TBCs) manufactured by air plasma spray (APS). Coatings 2020, 10, 812. [Google Scholar] [CrossRef]

- Boissonnet, G.; Bonnet, G.; Pasquet, A.; Bourhila, N.; Pedraza, F. Evolution of thermal insulation of plasma-sprayed thermal barrier coating systems with exposure to high temperature. J. Eur. Ceram. Soc. 2019, 39, 2111–2121. [Google Scholar] [CrossRef]

- Smith, J.; Scheibel, J.; Classen, D.; Paschke, S.; Elbel, S.; Fick, K.; Carlson, D. Thermal barrier coating validation testing for industrial gas turbine combustion hardware. J. Eng. Gas Turbines Power 2015, 138. [Google Scholar] [CrossRef]

- Scrivani, A.; Rizzi, G.; Bardi, U.; Giolli, C.; Miranda, M.; Ciattini, S.; Fossati, A.; Borgioli, F. Thermal fatigue behavior of thick and porous thermal barrier coatings systems. J. Therm. Spray Technol. 2007, 16, 816–821. [Google Scholar] [CrossRef]

- Curry, N.; Leitner, M.; Körner, K. High-porosity thermal barrier coatings from high-power plasma spray equipment—processing, performance and economics. Coatings 2020, 10, 957. [Google Scholar] [CrossRef]

- Giolli, C.; Scrivani, A.; Rizzi, G.; Borgioli, F.; Bolelli, G.; Lusvarghi, L. Failure mechanism for thermal fatigue of thermal barrier coating systems. J. Therm. Spray Technol. 2009, 18, 223–230. [Google Scholar] [CrossRef]

- Lima, R.; Guerreiro, B.; Curry, N.; Leitner, M.; Körner, K. Environmental, economical, and performance impacts of Ar-H2 and N2-H2 plasma-sprayed YSZ TBCs. J. Therm. Spray Technol. 2019, 29, 74–89. [Google Scholar] [CrossRef]

- Mahade, S.; Curry, N.; Björklund, S.; Markocsan, N.; Nylén, P. Thermal conductivity and thermal cyclic fatigue of multilayered Gd2Zr2O7/YSZ thermal barrier coatings processed by suspension plasma spray. Surf. Coat. Technol. 2015, 283, 329–336. [Google Scholar] [CrossRef] [Green Version]

- Evans, A.; Charles, E. fracture toughness determinations by indentation. J. Am. Ceram. Soc. 1976, 59, 371–372. [Google Scholar] [CrossRef]

- ASTM G76—13 Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets; ASTM International: West Conshohocken, PA, USA, 2013. [CrossRef]

- Markocsan, N.; Nylén, P.; Wigren, J.; Li, X. Low thermal conductivity coatings for gas turbine applications. J. Therm. Spray Technol. 2007, 16, 498–505. [Google Scholar] [CrossRef]

- Mahade, S.; Curry, N.; Björklund, S.; Markocsan, N.; Nylén, P.; Vaßen, R. erosion performance of gadolinium zirconate-based thermal barrier coatings processed by suspension plasma spray. J. Therm. Spray Technol. 2016, 26, 108–115. [Google Scholar] [CrossRef]

- Viswanathan, V.; Dwivedi, G.; Sampath, S. Multilayer, multimaterial thermal barrier coating systems: Design, synthesis, and performance assessment. J. Am. Ceram. Soc. 2015, 98, 1769–1777. [Google Scholar] [CrossRef]

- Quinn, G.; Bradt, R. On the vickers indentation fracture toughness test. J. Am. Ceram. Soc. 2007, 90, 673–680. [Google Scholar] [CrossRef]

- Zhou, D.; Guillon, O.; Vaßen, R. Development of YSZ thermal barrier coatings using axial suspension plasma spraying. Coatings 2017, 7, 120. [Google Scholar] [CrossRef] [Green Version]

- Murray, J.; Rance, G.; Xu, F.; Hussain, T. Alumina-graphene nanocomposite coatings fabricated by suspension high velocity oxy-fuel thermal spraying for ultra-low-wear. J. Eur. Ceram. Soc. 2018, 38, 1819–1828. [Google Scholar] [CrossRef]

- Marinis, A.; Aquilino, S.; Lund, P.; Gratton, D.; Stanford, C.; Diaz-Arnold, A.; Qian, F. Fracture toughness of yttria-stabilized zirconia sintered in conventional and microwave ovens. J. Prosthet. Dent. 2013, 109, 165–171. [Google Scholar] [CrossRef]

- Eaton, H.; Novak, R. Particulate erosion of plasma-sprayed porous ceramic. Surf. Coat. Technol. 1987, 30, 41–50. [Google Scholar] [CrossRef]

- Janos, B.; Lugscheider, E.; Remer, P. Effect of thermal aging on the erosion resistance of air plasma sprayed zirconia thermal barrier coating. Surf. Coat. Technol. 1999, 113, 278–285. [Google Scholar] [CrossRef]

- Mahade, S.; Zhou, D.; Curry, N.; Markocsan, N.; Nylén, P.; Vaßen, R. Tailored microstructures of gadolinium zirconate/YSZ multi-layered thermal barrier coatings produced by suspension plasma spray: Durability and erosion testing. J. Mater. Process. Technol. 2019, 264, 283–294. [Google Scholar] [CrossRef]

- Schmitt, M.; Stokes, J.; Gorin, B.; Rai, A.; Zhu, D.; Eden, T.; Wolfe, D. Effect of Gd content on mechanical properties and erosion durability of sub-stoichiometric Gd2Zr2O7. Surf. Coat. Technol. 2017, 313, 177–183. [Google Scholar] [CrossRef] [Green Version]

- Algenaid, W.; Ganvir, A.; Calinas, R.; Varghese, J.; Rajulapati, K.; Joshi, S. Influence of microstructure on the erosion behaviour of suspension plasma sprayed thermal barrier coatings. Surf. Coat. Technol. 2019, 375, 86–99. [Google Scholar] [CrossRef]

- Yu, Q.; He, Q.; Ning, F. Influence of interface morphology on erosion failure of thermal barrier coatings. Ceram. Int. 2018, 44, 21349–21357. [Google Scholar] [CrossRef]

- Steinberg, L.; Mikulla, C.; Naraparaju, R.; Toma, F.; Großmann, H.; Schulz, U.; Leyens, C. Erosion resistance of CMAS infiltrated sacrificial suspension sprayed alumina top layer on EB-PVD 7YSZ coatings. Wear 2019, 438–439, 203064. [Google Scholar] [CrossRef]

- Zhang, P.; Li, F.; Zhang, X.; Zhang, Z.; Tan, C.; Ren, L.; Wang, Y.; Ma, W.; Liu, M. Effect of bionic unit shapes on solid particle erosion resistance of ZrO2–7wt%Y2O3 thermal barrier coatings processed by laser. J. Bionic Eng. 2018, 15, 545–557. [Google Scholar] [CrossRef]

| Sample ID | Powder | Gun Power (kW) | Spray Distance (mm) | Feed Rate (g/min) | Thickness (µm) | µm Per Pass | Porosity % | Deposition Efficiency |

|---|---|---|---|---|---|---|---|---|

| Conventional Porosity, Low (L) powder feed rate | ||||||||

| HOSP-L | HOSP Commercial | 100kW | 150 | 90 | 452 | 12.2 | 15.4 | 43.6% |

| LD-L | Low-Density | 90kW | 150 | 90 | 469 | 12.7 | 13.8 | 68.9% |

| Conventional Porosity, Medium (M) powder feed rate | ||||||||

| HOSP-M | HOSP Commercial | 100kW | 150 | 150 | 470 | 13.4 | 15.8 | 35.8% |

| LD-M | Low-Density | 95kW | 150 | 150 | 438 | 17.5 | 14.3 | 66.3% |

| High Porosity, High (H) powder feed rate | ||||||||

| A&S-H | A&S Commercial | 95kW | 175 | 280 | 804 | 20.1 | 21.8 | 39.4% |

| LD-H | Low-Density | 95kW | 175 | 280 | 840 | 16.2 | 24.1 | 51.6% |

| High Porosity, High (H) powder feed rate, short (S) standoff distance | ||||||||

| A&S-H.S | A&S Commercial | 95kW | 150 | 280 | 981 | 20.4 | 17.6 | 56.4% |

| LD-H.S | Low-Density | 95kW | 150 | 280 | 834 | 22.5 | 20.5 | 60.7% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahade, S.; Venkat, A.; Curry, N.; Leitner, M.; Joshi, S. Erosion Performance of Atmospheric Plasma Sprayed Thermal Barrier Coatings with Diverse Porosity Levels. Coatings 2021, 11, 86. https://doi.org/10.3390/coatings11010086

Mahade S, Venkat A, Curry N, Leitner M, Joshi S. Erosion Performance of Atmospheric Plasma Sprayed Thermal Barrier Coatings with Diverse Porosity Levels. Coatings. 2021; 11(1):86. https://doi.org/10.3390/coatings11010086

Chicago/Turabian StyleMahade, Satyapal, Abhilash Venkat, Nicholas Curry, Matthias Leitner, and Shrikant Joshi. 2021. "Erosion Performance of Atmospheric Plasma Sprayed Thermal Barrier Coatings with Diverse Porosity Levels" Coatings 11, no. 1: 86. https://doi.org/10.3390/coatings11010086

APA StyleMahade, S., Venkat, A., Curry, N., Leitner, M., & Joshi, S. (2021). Erosion Performance of Atmospheric Plasma Sprayed Thermal Barrier Coatings with Diverse Porosity Levels. Coatings, 11(1), 86. https://doi.org/10.3390/coatings11010086