Research on Interface Characteristics and Mechanical Properties of 6061 Al Alloy and Q235a Steel by Hot Melt-Explosive Compression Bonding

Abstract

1. Introduction

2. Experimental

2.1. The Experimental Process

2.2. Experimental Parameters

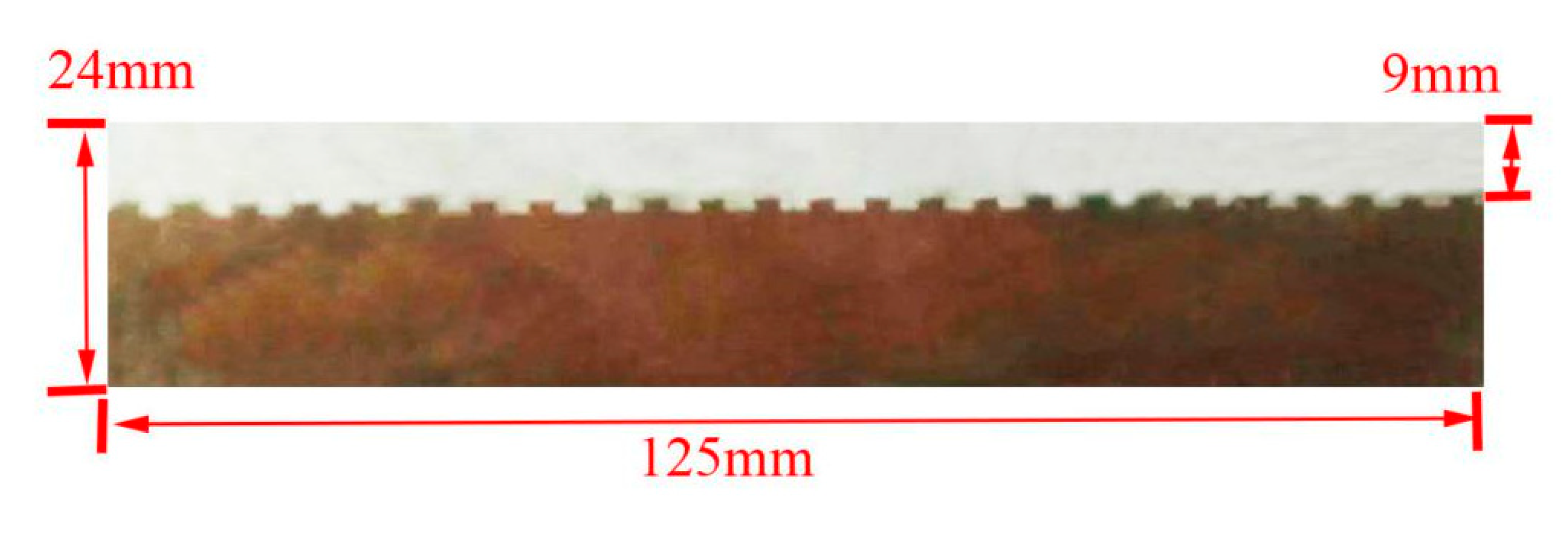

2.2.1. Hot-Melt Composite Plate

2.2.2. Explosive Compression Composite Plate

3. Experimental Results and Analysis

3.1. Welding Interface Structure Analysis

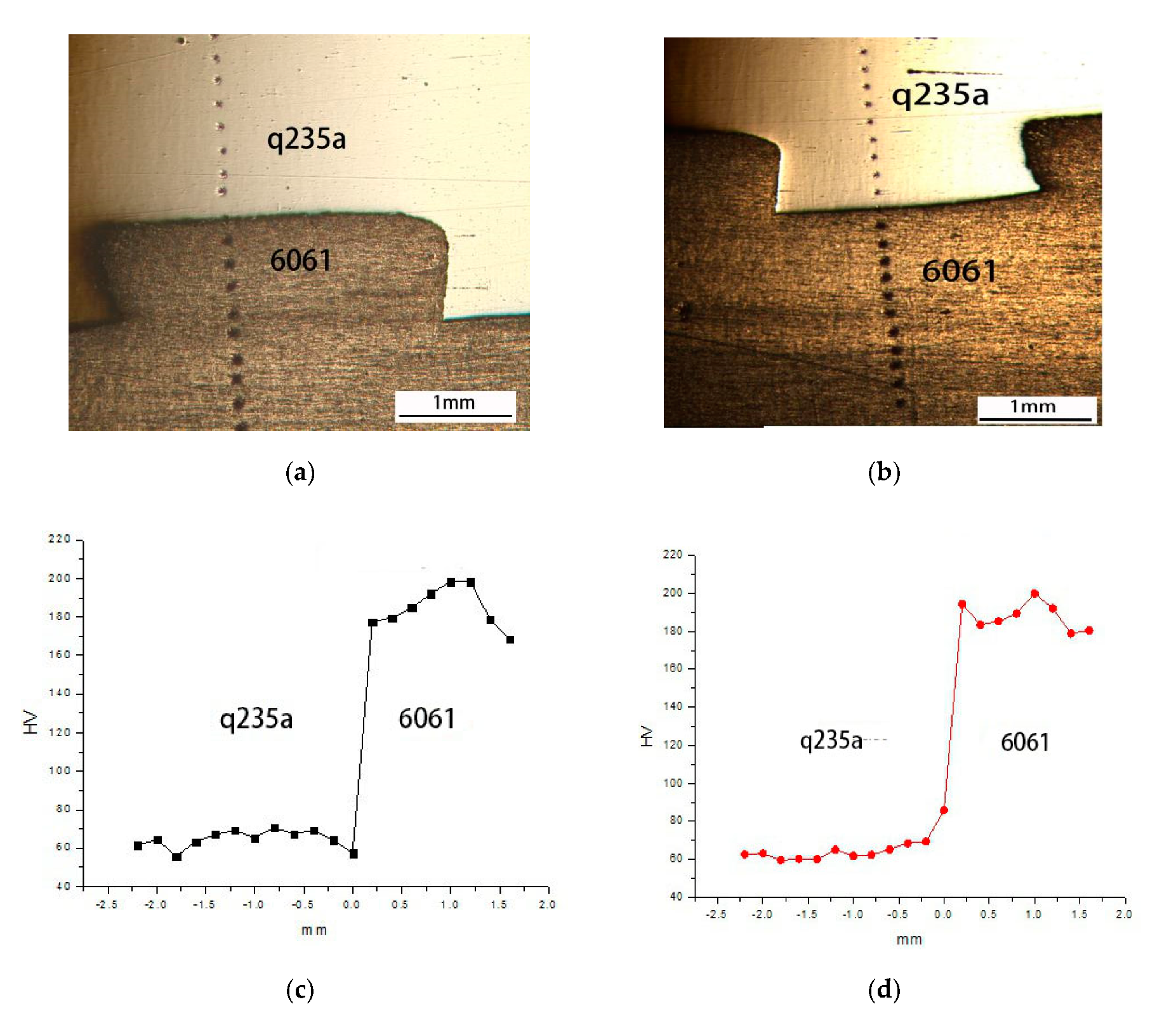

3.2. Observation of Interface Metallographic Structure

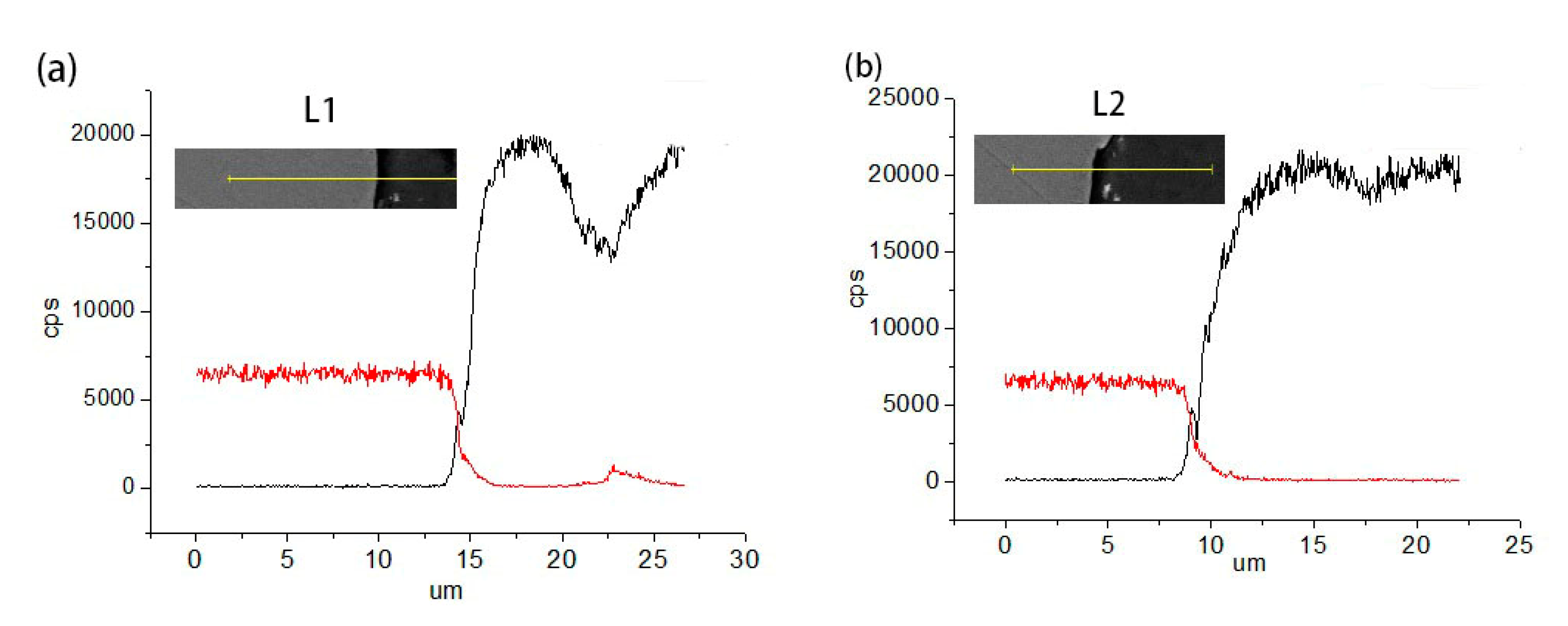

3.3. Interface Structure Analysis

3.4. Microhardness Analysis

3.5. Tension Shear Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Çelikyürek, İ.; Torun, O.; Baksan, B. Microstructure and strength of friction-welded Fe–28Al and 316 L stainless steel. Mater. Sci. Eng. A 2011, 528, 8530–8536. [Google Scholar] [CrossRef]

- Fan, M.; Domblesky, J.; Jin, K.; Qin, L.; Cui, S.; Guo, X.; Kim, N.; Tao, J. Effect of original layer thicknesses on the interface bonding and mechanical properties of TiAl laminate composites. Mater. Des. 2016, 99, 535–542. [Google Scholar] [CrossRef]

- HSFL Carvalho, G.; Galvão, I.; Mendes, R.; M Leal, R.; Loureiro, A. Aluminum-to-Steel Cladding by Explosive Welding. Metals 2020, 10, 1062. [Google Scholar] [CrossRef]

- Upadhyay, A.; Sherpa, B.B.; Kumar, S.; Srivastav, N.; Dinesh Kumar, P.; Agarwal, A. Experimental Investigation and Micro-Structure Study of Interface of Explosive Welded SS304 and AA6061 Plates. Mater. Sci. Forum 2015, 830, 261–264. [Google Scholar] [CrossRef]

- Elango, E.; Saravanan, S.; Raghukandan, K. Experimental and numerical studies on aluminum-stainless steel explosive cladding. J. Cent. South Univ. 2020, 27, 1742–1753. [Google Scholar] [CrossRef]

- Han, J.H.; Ahn, J.P.; Shin, M.C. Effect of interlayer thickness on shear deformation behavior of AA5083 aluminum alloy/SS41 steel plates manufactured by explosive welding. J. Mater. Sci. 2003, 38, 13–18. [Google Scholar] [CrossRef]

- Zhang, Y.; Long, B.; Meng, K.; Gohkman, A.; Cuia, Y.; Zhang, Z. Diffusion bonding of Q345 steel to zirconium using an aluminum interlayer. J. Mater. Process. Technol. 2020, 275, 116352. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Yang, J. First principle calculations and mechanical properties of the intermetallic compounds in a laser welded steel/aluminum joint. Opt. Laser Technol. 2020, 122, 105875. [Google Scholar] [CrossRef]

- Tanaka, T.; Nezu, M.; Uchida, S.; Hirata, T. Mechanism of intermetallic compound formation during the dissimilar friction stir welding of aluminum and steel. J. Mater. Sci. 2020, 55, 3064–3072. [Google Scholar] [CrossRef]

- Li, L.; Xia, H.; Tan, C.; Ma, N. Influence of laser power on interfacial microstructure and mechanical properties of laser welded-brazed Al/steel dissimilar butted joint. J. Manuf. Process. 2018, 32, 160–174. [Google Scholar] [CrossRef]

- Wang, X.; Li, F.; Huang, T.; Wang, X.; Liu, H. Experimental and numerical study on the laser shock welding of aluminum to stainless steel. Opt. Lasers Eng. 2019, 115, 74–85. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, J.; Cheng, Z.; Ye, Z.; Chi, H.; Peng, L.; Chen, S. Study on MIG-TIG double-sided arc welding-brazing of aluminum and stainless steel. Mater. Lett. 2016, 172, 146–148. [Google Scholar] [CrossRef]

- Babu, S.; Panigrahi, S.K.; Ram, G.J.; Venkitakrishnan, P.V.; Kumar, R.S. Cold metal transfer welding of aluminium alloy AA 2219 to austenitic stainless steel AISI 321. J. Mater. Process. Technol. 2019, 266, 155–164. [Google Scholar] [CrossRef]

- Matsuda, T.; Adachi, H.; Sano, T.; Yoshida, R.; Hori, H.; Ono, S.; Hirose, A. High-frequency linear friction welding of aluminum alloys to stainless steel. J. Mater. Process. Technol. 2019, 269, 45–51. [Google Scholar] [CrossRef]

- Murugan, B.; Thirunavukarasu, G.; Kundu, S.; Kailas, S.V. Influence of Tool Traverse Speed on Structure, Mechanical Properties, Fracture Behavior, and Weld Corrosion of Friction Stir Welded Joints of Aluminum and Stainless Steel. Adv. Eng. Mater. 2019, 21, 1800869. [Google Scholar] [CrossRef]

- Thomä, M.; Gester, A.; Wagner, G.; Fritzsche, M. Analysis of the Oscillation Behavior of Hybrid Aluminum/Steel Joints Realized by Ultrasound Enhanced Friction Stir Welding. Metals 2020, 10, 1079. [Google Scholar] [CrossRef]

- Chitturi, V.; Pedapati, S.R.; Awang, M. Challenges in dissimilar friction stir welding of aluminum 5052 and 304 stainless steel alloys. Materialwissenschaft und Werkstofftechnik 2020, 51, 811–816. [Google Scholar] [CrossRef]

- Li, P.; Chen, S.; Dong, H.; Ji, H.; Li, Y.; Guo, X.; Yang, G.; Zhang, X.; Han, X. Interfacial microstructure and mechanical properties of dissimilar aluminum/steel joint fabricated via refilled friction stir spot welding. J. Manuf. Process. 2020, 49, 385–396. [Google Scholar] [CrossRef]

- Kapil, A.; Mao, Y.; Vivek, A.; Cooper, R.; Hetrick, E.; Daehn, G. A new approach for dissimilar aluminum-steel impact spot welding using vaporizing foil actuators. J. Manuf. Process. 2020, 58, 279–288. [Google Scholar] [CrossRef]

- Wang, J.; Lu, X.; Cheng, C.; Li, B.; Ma, Z. Improve the quality of 1060Al/Q235 explosive composite plate by friction stir processing. J. Mater. Res. Technol. 2020, 9, 42–51. [Google Scholar] [CrossRef]

- Singh, P.; Deepak, D.; Brar, G.S. Comparative evaluation of aluminum and stainless steel dissimilar welded joints. Mater. Today. in press. [CrossRef]

- Hokamoto, K.; Chiba, A.; Fujita, M.; Izuma, T. Single-shot explosive welding technique for the fabrication of multilayered metal base composites: Effect of welding parameters leading to optimum bonding condition. Compos. Eng. 1995, 5, 1069–1079. [Google Scholar] [CrossRef]

- Aceves, S.M.; Espinosa-Loza, F.; Elmer, J.W.; Huber, R. Comparison of Cu, Ti and Ta interlayer explosively fabricated aluminum to stainless steel transition joints for cryogenic pressurized hydrogen storage. Int. J. Hydrog. Energy 2015, 40, 1490–1503. [Google Scholar] [CrossRef]

- Li, X.; Ma, H.; Shen, Z. Research on explosive welding of aluminum alloy to steel with dovetail grooves. Mater. Des. 2015, 87, 815–824. [Google Scholar] [CrossRef]

- Lysak, V.I.; Kuzmin, S.V. Energy balance during explosive welding. J. Mater. Process. Technol. 2015, 222, 356–364. [Google Scholar] [CrossRef]

- Ming, Y.A.; Shen, Z.W.; Chen, D.G.; Deng, Y.X. Microstructure and mechanical properties of Al-Fe meshing bonding interfaces manufactured by explosive welding. Trans. Nonferr. Met. Soc. China 2019, 29, 680–691. [Google Scholar]

- GB/T 6386-2008 Test Method Clad Steel Plates-Mechanical and Technological Test; China National Standardization Management Committee: Beijing, China, 2008.

- Fan, Z.; Yu, H.; Li, C. Interface and grain-boundary amorphization in the Al/Fe bimetallic system during pulsed-magnetic-driven impact. Scr. Mater. 2016, 110, 14–18. [Google Scholar] [CrossRef]

| Element | Cu | Mn | Mg | Zn | Cr | Ti | Si | Fe | Al |

|---|---|---|---|---|---|---|---|---|---|

| Content | 0.15–0.4 | 0.15 | 0.8–1.2 | 0.25 | 0.04–0.35 | 0.15 | 0.4–0.8 | 0.7 | Bal. |

| Element | C | Mn | Si | S | P | Fe |

|---|---|---|---|---|---|---|

| Content | 0.14–0.22 | 0.30–0.65 | 0.30 | 0.05 | 0.045 | Bal. |

| Parameters | Density of Explosive/g·cm−3 | Charge Mass/g | Layout Thickness/mm | Charge at Unit Area/g·cm−2 | Mass Ratio |

|---|---|---|---|---|---|

| Parameter values | 0.9 | 275 | 10 | 0.9 | 0.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.-l.; Ma, H.-h.; Yang, M.; Shen, Z.-w.; Luo, N.; Wang, L.-q. Research on Interface Characteristics and Mechanical Properties of 6061 Al Alloy and Q235a Steel by Hot Melt-Explosive Compression Bonding. Coatings 2020, 10, 1031. https://doi.org/10.3390/coatings10111031

Sun Y-l, Ma H-h, Yang M, Shen Z-w, Luo N, Wang L-q. Research on Interface Characteristics and Mechanical Properties of 6061 Al Alloy and Q235a Steel by Hot Melt-Explosive Compression Bonding. Coatings. 2020; 10(11):1031. https://doi.org/10.3390/coatings10111031

Chicago/Turabian StyleSun, Yu-ling, Hong-hao Ma, Ming Yang, Zhao-wu Shen, Ning Luo, and Lu-qing Wang. 2020. "Research on Interface Characteristics and Mechanical Properties of 6061 Al Alloy and Q235a Steel by Hot Melt-Explosive Compression Bonding" Coatings 10, no. 11: 1031. https://doi.org/10.3390/coatings10111031

APA StyleSun, Y.-l., Ma, H.-h., Yang, M., Shen, Z.-w., Luo, N., & Wang, L.-q. (2020). Research on Interface Characteristics and Mechanical Properties of 6061 Al Alloy and Q235a Steel by Hot Melt-Explosive Compression Bonding. Coatings, 10(11), 1031. https://doi.org/10.3390/coatings10111031