Effect of Substrate Strain, Aluminum Thickness and Corona Pretreatment on the Electrical Resistance of Physical Vapor Deposited Aluminum Coatings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Corona Treatment

2.2. Measurement of Surface Energy

2.3. Physical Vapor Deposition

2.4. 180° Ethylene Acrylic Acid Copolymer Peel Test Applied to PET Samples

2.5. Tensile Test and Measurement of Electrical Resistance

2.6. Atomic Force Microscopy

2.7. Statistical Methods

3. Results and Discussion

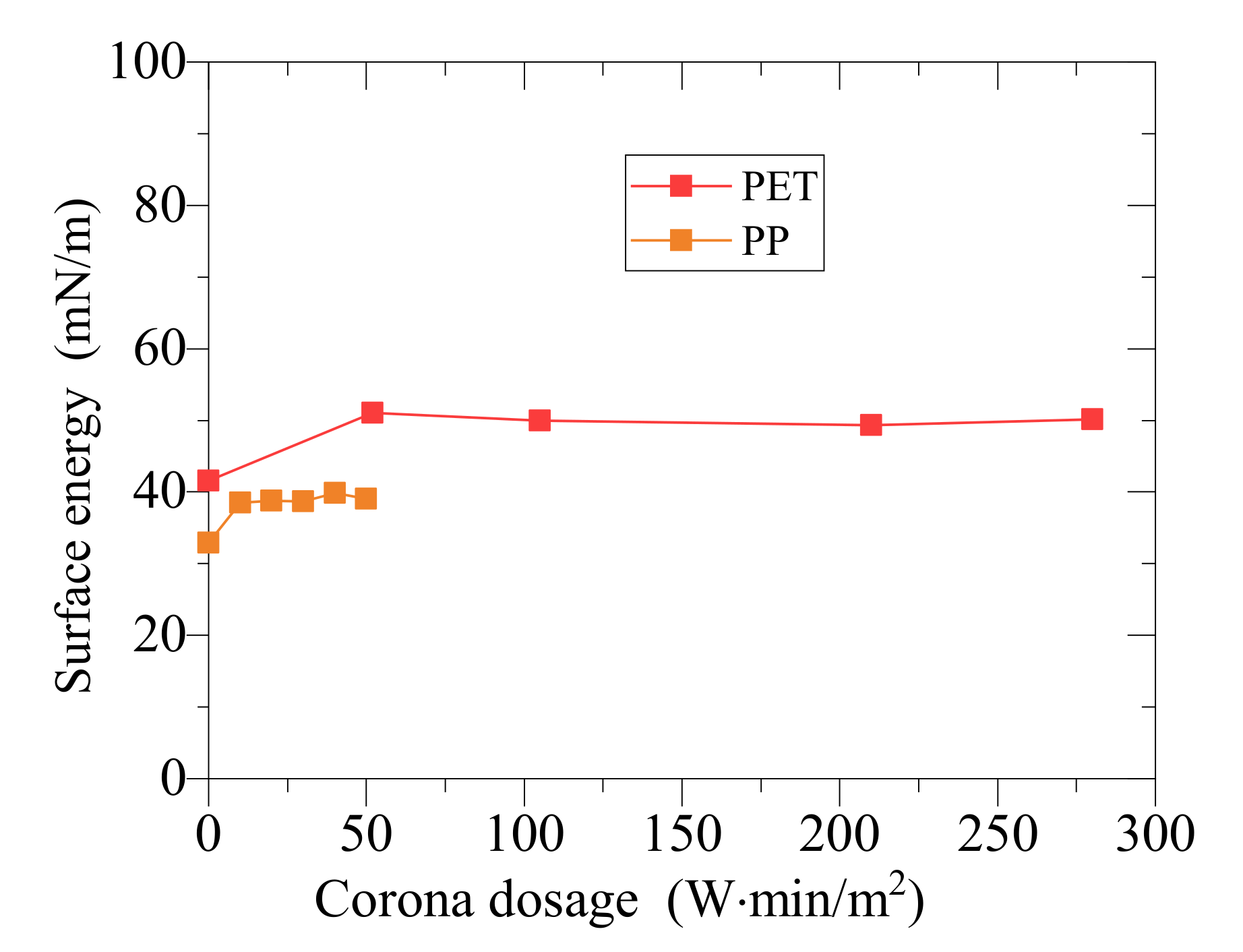

3.1. Surface Energy of PET and PP after Corona Treatment

3.2. Effect of Corona Dosage on the Adhesion of Aluminum to PET

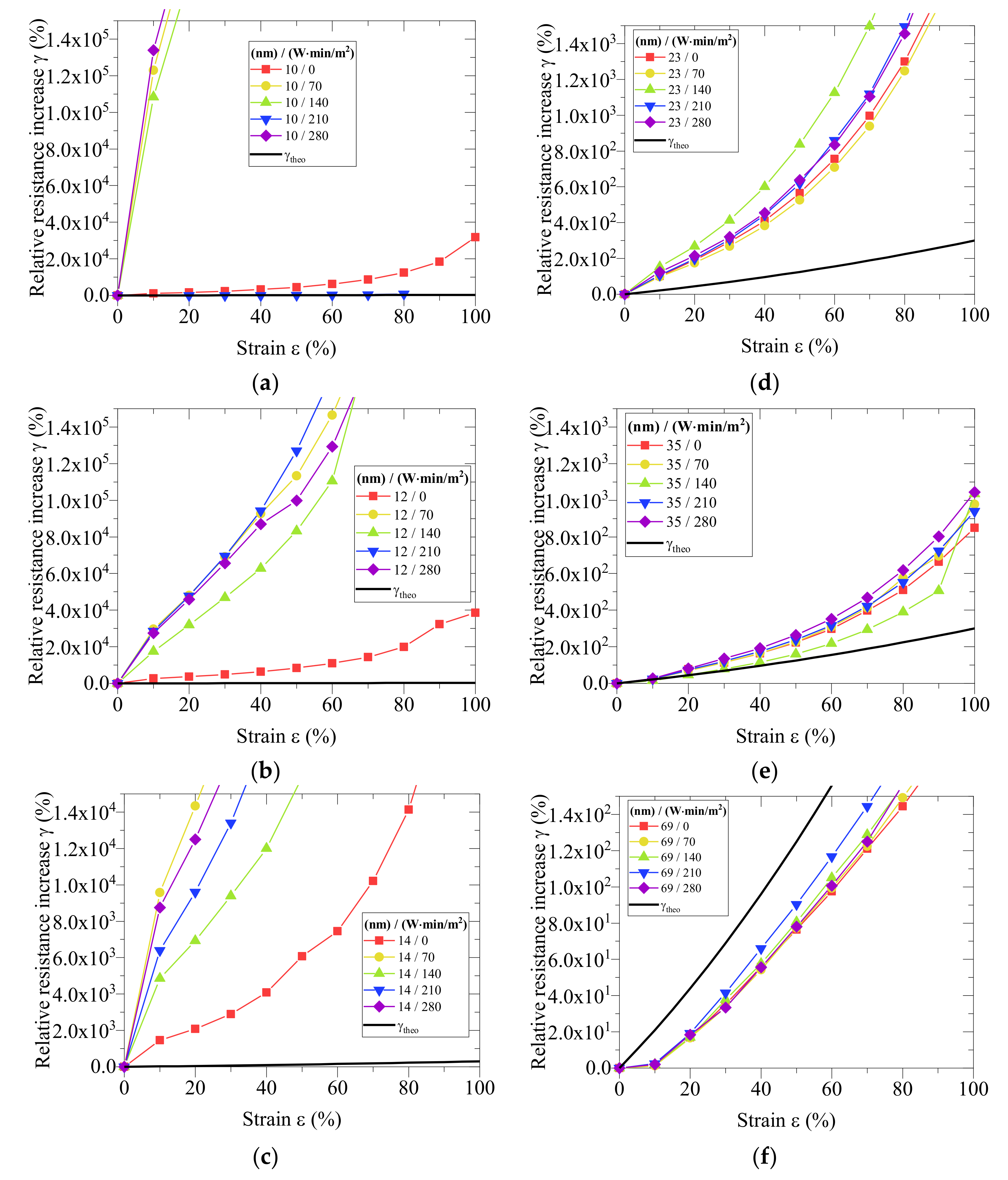

3.3. Effect of Corona Dosage on the Percentage Increase in Resistance of Aluminum-Coated PET under Strain

3.4. Effect of Aluminum Thickness on the Percentage Increase in Resistance of Aluminum-Coated PET under Strain

3.5. Effect of Corona Dosage on the Percentage Increase in Resistance of Aluminum-Coated PP under Strain

3.6. Effect of Aluminum Thickness the Percentage Increase in Resistance of Aluminum-Coated PP under Strain

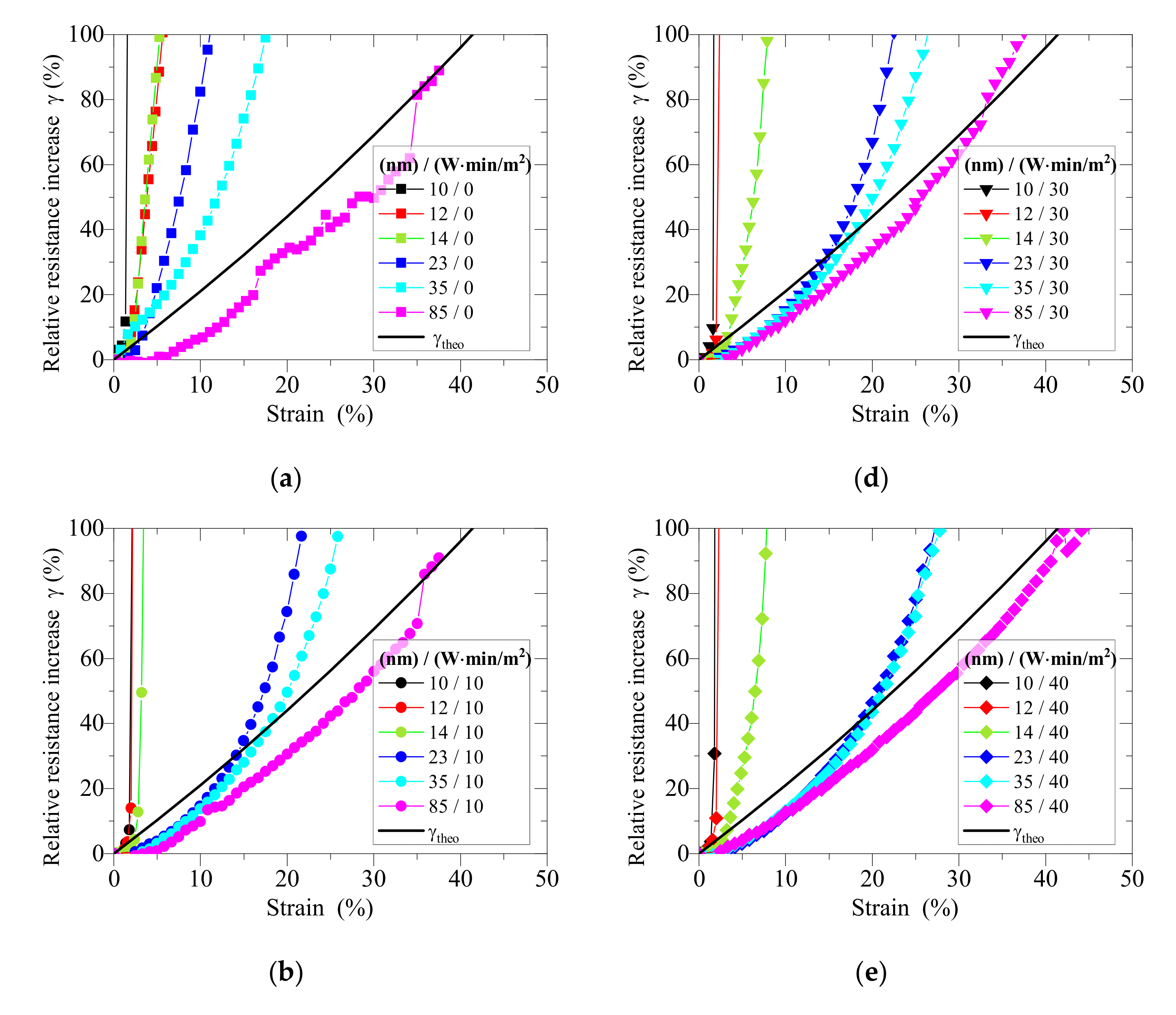

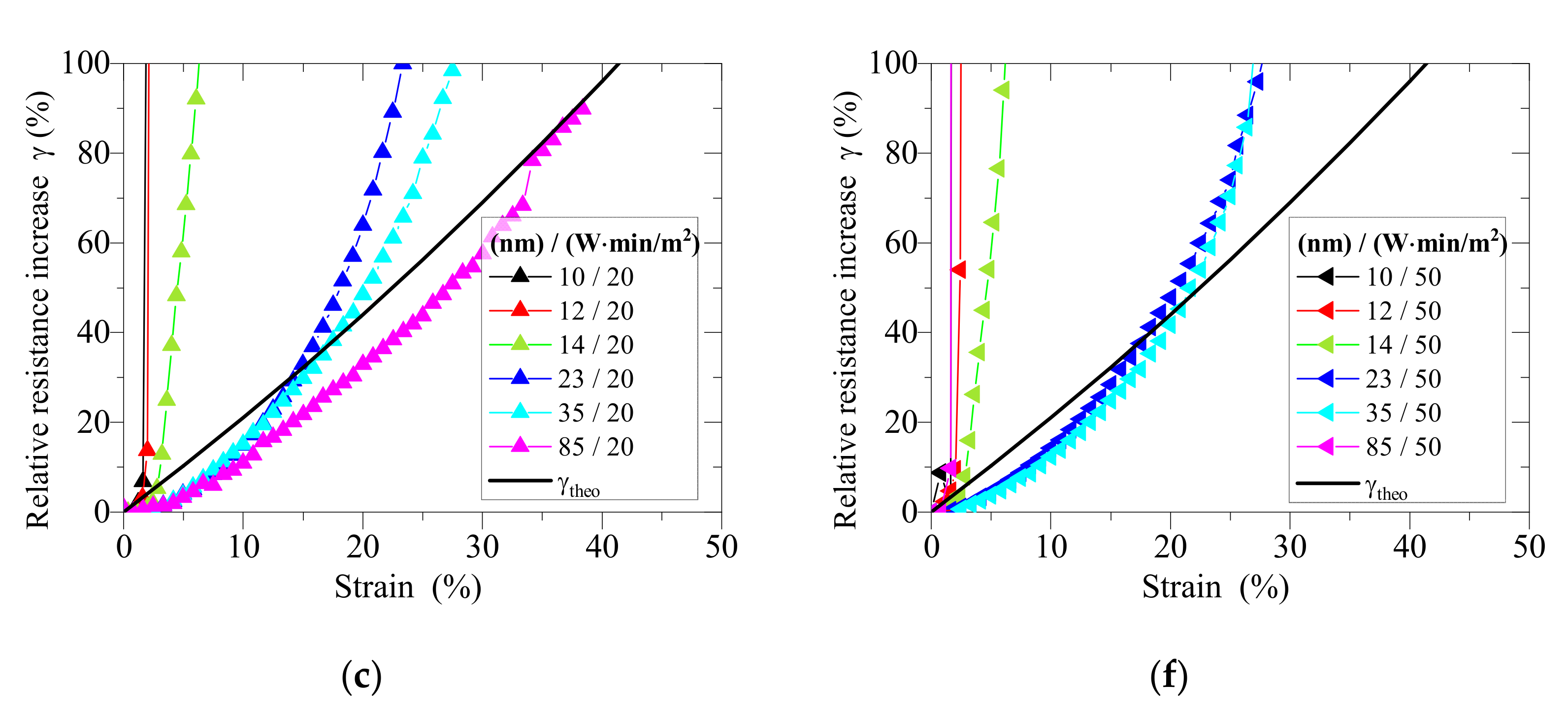

3.7. Combined Effect of Aluminum Thickness and Corona Dosage the Percentage Increase in Resistance of Aluminum-Coated PET and PP Films under Strain

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Lindner, M.; Reinelt, M.; Gilch, T.; Langowski, H.-C. Hygroexpansion, Surface roughness and porosity affect the electrical resistance of EVOH-aluminum-coated paper. Coatings 2019, 9, 295. [Google Scholar] [CrossRef] [Green Version]

- Kulachenko, A.; Gradin, P.; Westerlind, B. Analysis of paper web tension profiles. J. Graph. Technol. 2005, 2, 72–81. [Google Scholar]

- Glushko, O.; Cordill, M. Electrical resistance of metal films on polymer substrates under tension. Exp. Tech. 2016, 40, 303–310. [Google Scholar] [CrossRef]

- Naghdi, S.; Rhee, K.Y.; Hui, D.; Park, S.J. A review of conductive metal nanomaterials as conductive, transparent, and flexible coatings, thin films, and conductive fillers: Different deposition methods and applications. Coatings 2018, 8, 278. [Google Scholar] [CrossRef] [Green Version]

- Utz, H. Barriereeigenschaften Aluminiumbedampfter Kunststofffolien. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 1995. [Google Scholar]

- Kraker, P.T.; Glushko, O.; Cordill, M.J. Relationship between Cracking and Resistance Increase in Polymer-Supported Metal Films under Mechanical Load; Materials Science and Engineering Darmstadt, Germany; Montan Universität: Darmstadt, Germany, 2016. [Google Scholar]

- Glushko, O.; Kraker, P.; Cordill, M. Explicit relationship between electrical and topological degradation of polymer-supported metal films subjected to mechanical loading. Appl. Phys. Lett. 2017, 110, 191904. [Google Scholar] [CrossRef] [Green Version]

- Jörg, T.; Music, D.; Hauser, F.; Cordill, M.J.; Franz, R.; Köstenbauer, H.; Winkler, J.; Schneider, J.M.; Mitterer, C. Deformation behavior of Re alloyed Mo thin films on flexible substrates: In situ fragmentation analysis supported by first-principles calculations. Sci. Rep. 2017, 7, 7374. [Google Scholar] [CrossRef] [PubMed]

- Berger, J.; Glushko, O.; Marx, V.M.; Kirchlechner, C.; Cordill, M.J. Effect of microstructure on the electro-mechanical behaviour of Cu films on polyimide. J. Miner. Met. Mater. Soc. 2016, 68, 1640–1646. [Google Scholar] [CrossRef]

- Niu, R.; Liu, G.; Wang, C.; Zhang, G.; Ding, X.; Sun, J. Thickness dependent critical strain in submicron Cu films adherent to polymer substrate. Appl. Phys. Lett. 2007, 90, 161907. [Google Scholar] [CrossRef]

- Lu, N.; Wang, X.; Suo, Z.; Vlassak, J. Metal films on polymer substrates stretched beyond 50%. Appl. Phys. Lett. 2007, 91, 221909. [Google Scholar] [CrossRef]

- Polywka, A.; Stegers, L.; Krauledat, O.; Riedl, T.; Jakob, T.; Görrn, P. Controlled mechanical cracking of metal films deposited on polydimethylsiloxane (PDMS). Nanomaterials 2016, 6, 168. [Google Scholar] [CrossRef] [Green Version]

- Hamasha, M.M.; Alzoubi, K.; Switzer, J.C.; Lu, S.; Desu, S.B.; Poliks, M. A study on crack propagation and electrical resistance change of sputtered aluminum thin film on poly ethylene terephthalate substrate under stretching. Thin Solid Films 2011, 519, 7918–7924. [Google Scholar] [CrossRef]

- Lindner, M.; Rodler, N.; Jesdinszki, M.; Schmid, M.; Sängerlaub, S. Surface energy of corona treated PP, PE and PET films, its alteration as function of storage time and the effect of various corona dosages on their bond strength after lamination. J. Appl. Polym. Sci. 2017, 135. [Google Scholar] [CrossRef]

- Bishop, C. Some considerations on fine-line patter metallization. Convert. Q. 2018, 8, 30–32. [Google Scholar]

- Bishop, C.A. Vacuum Deposition onto Webs, Films and Foils, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Izdebska, J. Corona Treatment. In Printing on Polymers; Ebnesajjad, S., Ed.; William Andrew Publishing: Chadds Ford, PA, USA, 2016; pp. 123–142. [Google Scholar]

- Sun, C.; Zhang, D.; Wadsworth, L.C. Corona treatment of polyolefin films—A review. Adv. Polym. Technol. 1999, 18, 171–180. [Google Scholar]

- Sherman, P.B. Adhesion and corona treatment. In Proceedings of the SPE National Technical Conference: Plastic in Packaging and Acrylonitrile—A Dual Meet, Chicago, IL, USA, 13–15 November 1978; pp. 184–189. [Google Scholar]

- Pascual, M.; Calvo, O.; Sanchez-Nácher, L.; Bonet, M.A.; Garcia-Sanoguera, D.; Balart, R. Optimization of adhesive joints of low density polyethylene (LDPE) composite laminates with polyolefin foam using corona discharge plasma. J. Appl. Polym. Sci. 2009, 114, 2971–2977. [Google Scholar] [CrossRef]

- Cramm, R.H.; Bibee, D.V. Theory and Practice of Corona Treatment for Improving Adhesion; Tappi: Peachtree Corners, GA, USA, 1982; pp. 75–78. [Google Scholar]

- Zhang, D.; Sun, Q.; Wadsworth, L.C. Mechanism of corona treatment on polyolefin films. Polym. Eng. Sci. 1998, 38, 965–970. [Google Scholar] [CrossRef]

- Guimond, S.; Wertheimer, M.R. Surface degradation and hydrophobic recovery of polyolefins treated by air corona and nitrogen atmospheric pressure glow discharge. J. Appl. Polym. Sci. 2004, 94, 1291–1303. [Google Scholar] [CrossRef]

- Zenkiewicz, M. Investigation on the oxidation of surface layers of polyolefins treated with corona discharge. J. Adhes. Sci. Technol. 2001, 15, 63–70. [Google Scholar] [CrossRef]

- Strobel, M.; Lyons, C.S.; Strobel, J.M.; Kapaun, R.S. Analysis of air-corona-treated polypropylene and poly(ethylene terephthalate) films by contact-angle measurements and X-ray photoelectron spectroscopy. J. Adhes. Sci. Technol. 1992, 6, 429–443. [Google Scholar] [CrossRef]

- Sapieha, S.; Cerny, J.; Klemberg-Sapieha, J.E.; Martinu, L. Corona versus low pressure plasma treatment: Effect on surface properties and adhesion of polymers. J. Adhes. 1993, 42, 91–102. [Google Scholar] [CrossRef]

- Pascual, M.; Sanchis, R.; Sánchez, L.; García, D.; Balart, R. Surface modification of low density polyethylene (LDPE) film using corona discharge plasma for technological applications. J. Adhes. Sci. Technol. 2008, 22, 1425–1442. [Google Scholar] [CrossRef]

- Owens, D.K. The mechanism of corona and ultraviolet light-induced self-adhesion of poly(ethylene terephthalate) film. J. Appl. Polym. Sci. 1975, 19, 3315–3326. [Google Scholar] [CrossRef]

- Novák, I.; Chodák, I. Adhesion of poly(propylene) modified by corona discharge. Angew. Makromol. Chem. 1998, 260, 47–51. [Google Scholar] [CrossRef]

- Lynch, J.B.; Spence, P.D.; Baker, D.E.; Postlethwaite, T.A. Atmospheric pressure plasma treatment of polyethylene via a pulse dielectric barrier discharge: Comparison using various gas compositions versus corona discharge in air. J. Appl. Polym. Sci. 1999, 71, 319–331. [Google Scholar] [CrossRef]

- Bablyuk, E.B.; Popov, O.N.; Segueikin, G.I. Adhesion Properties of Polyethylene Terephtalate (PET) Film Treated with Corona Discharge. In Proceedings of the IS&T 49th Annual Conference, Minneapolis, MN, USA, 19–24 May 1996; pp. 556–558. [Google Scholar]

- Weber, R. Saturation phenomena in conjunction with corona treatment on different substrates. In Proceedings of the TAPPI PLACE Conference, Las Vegas, NV, USA, 25–29 September 2005; pp. 1213–1224. [Google Scholar]

- Steinhauser, H.; Ellinghorst, G. Corona treatment of isotactic polypropylene in nitrogen and carbondioxide. Macromol. Mater. Eng. 1984, 120, 177–191. [Google Scholar]

- Tuominen, M.; Lavonen, J.; Lahti, J.; Kuusipalo, J. Atmospheric plasma treatment in extrusion coating: Part 2—Surface modification of LDPE and PP coated papers. In Atmospheric Pressure Plasma Treatment of Polymers; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 355–381. [Google Scholar]

- Law, K.Y.; Zhao, H. Surface Wetting: Characterization, Contact Angle, and Fundamentals; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Kaelble, D. Dispersion-polar surface tension properties of organic solids. J. Adhes. 1970, 2, 66–81. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Rabel, W. Einige aspekte der benetzungstheorie und ihre anwendung auf die untersuchung und veränderung der oberflächeneigenschaften von polymeren. Farbe Lack 1971, 77, 997–1006. [Google Scholar]

- Fowkes, F.M. Determination of interfacial tensions, contact angles, and dispersion forces in surfaces by assuming additivity of intermolecular interactions in surfaces. J. Phys. Chem. 1962, 66, 382. [Google Scholar] [CrossRef]

- Lindner, M.; Höflsauer, F.; Heider, J.; Reinelt, M.; Langowski, H.-C. Comparison of thickness determination methods for physical-vapor-deposited aluminum coatings in packaging applications. Thin Solid Films 2018, 666, 6–14. [Google Scholar] [CrossRef]

- Kucukpinar, E.; Jesdinszki, M.; Rodler, N.; Struller, C.; Noller, K.; Blondin, D.; Cassio, V.; Langowski, H.-C. Determination of metal adhesion strength of metallized films by peel tests. In Proceedings of the Web Coating and Handling Conference, Myrtle Beach, SC, USA, 19–22 October 2014. [Google Scholar]

- Jesdinszki, M.; Struller, C.; Rodler, N.; Blondin, D.; Cassio, V.; Kucukpinar, E.; Langowski, H.-C. Evaluation of adhesion strength between thin aluminum layer and poly (ethylene terephthalate) substrate by peel tests—A practical approach for the packaging industry. J. Adhes. Sci. Technol. 2012, 26, 2357–2380. [Google Scholar] [CrossRef]

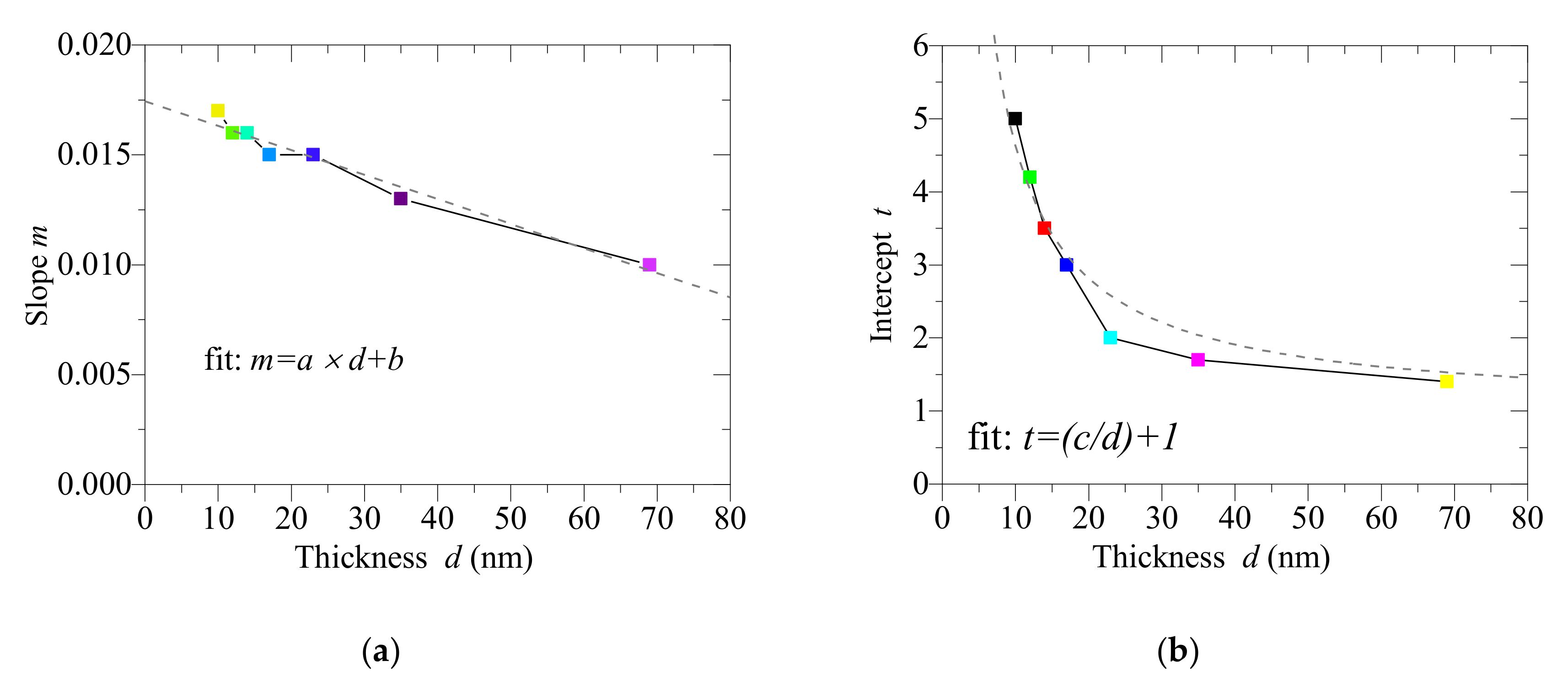

| Aluminum Thickness d (nm) | Slope m | Intercept t |

|---|---|---|

| 10 | 0.017 | 5.0 |

| 12 | 0.016 | 4.2 |

| 14 | 0.016 | 3.5 |

| 17 | 0.015 | 3.0 |

| 23 | 0.015 | 2.0 |

| 35 | 0.013 | 1.7 |

| 69 | 0.010 | 1.4 |

| Fit Factor | Value |

|---|---|

| a | 1.11591 × 10−4 |

| b | 0.01744 |

| c | 36.31374 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lindner, M. Effect of Substrate Strain, Aluminum Thickness and Corona Pretreatment on the Electrical Resistance of Physical Vapor Deposited Aluminum Coatings. Coatings 2020, 10, 1245. https://doi.org/10.3390/coatings10121245

Lindner M. Effect of Substrate Strain, Aluminum Thickness and Corona Pretreatment on the Electrical Resistance of Physical Vapor Deposited Aluminum Coatings. Coatings. 2020; 10(12):1245. https://doi.org/10.3390/coatings10121245

Chicago/Turabian StyleLindner, Martina. 2020. "Effect of Substrate Strain, Aluminum Thickness and Corona Pretreatment on the Electrical Resistance of Physical Vapor Deposited Aluminum Coatings" Coatings 10, no. 12: 1245. https://doi.org/10.3390/coatings10121245

APA StyleLindner, M. (2020). Effect of Substrate Strain, Aluminum Thickness and Corona Pretreatment on the Electrical Resistance of Physical Vapor Deposited Aluminum Coatings. Coatings, 10(12), 1245. https://doi.org/10.3390/coatings10121245