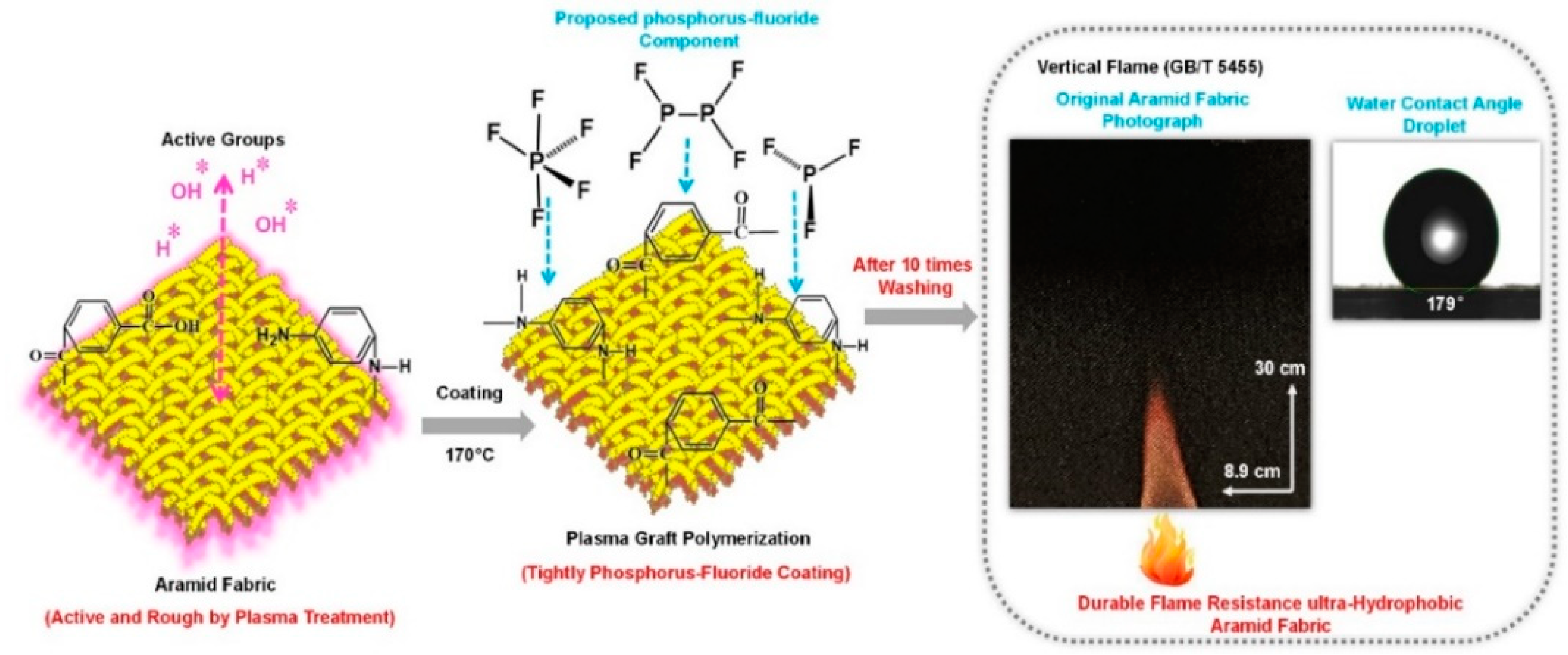

Durable Flame-Resistant and Ultra-Hydrophobic Aramid Fabrics via Plasma-Induced Graft Polymerization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plasma Surface Modification

2.2. Phosphorus–Fluoride Coatings on Aramid Fabric Surface

2.3. Coating Durability Test

2.4. Fabric Surface Analysis

3. Results and Discussion

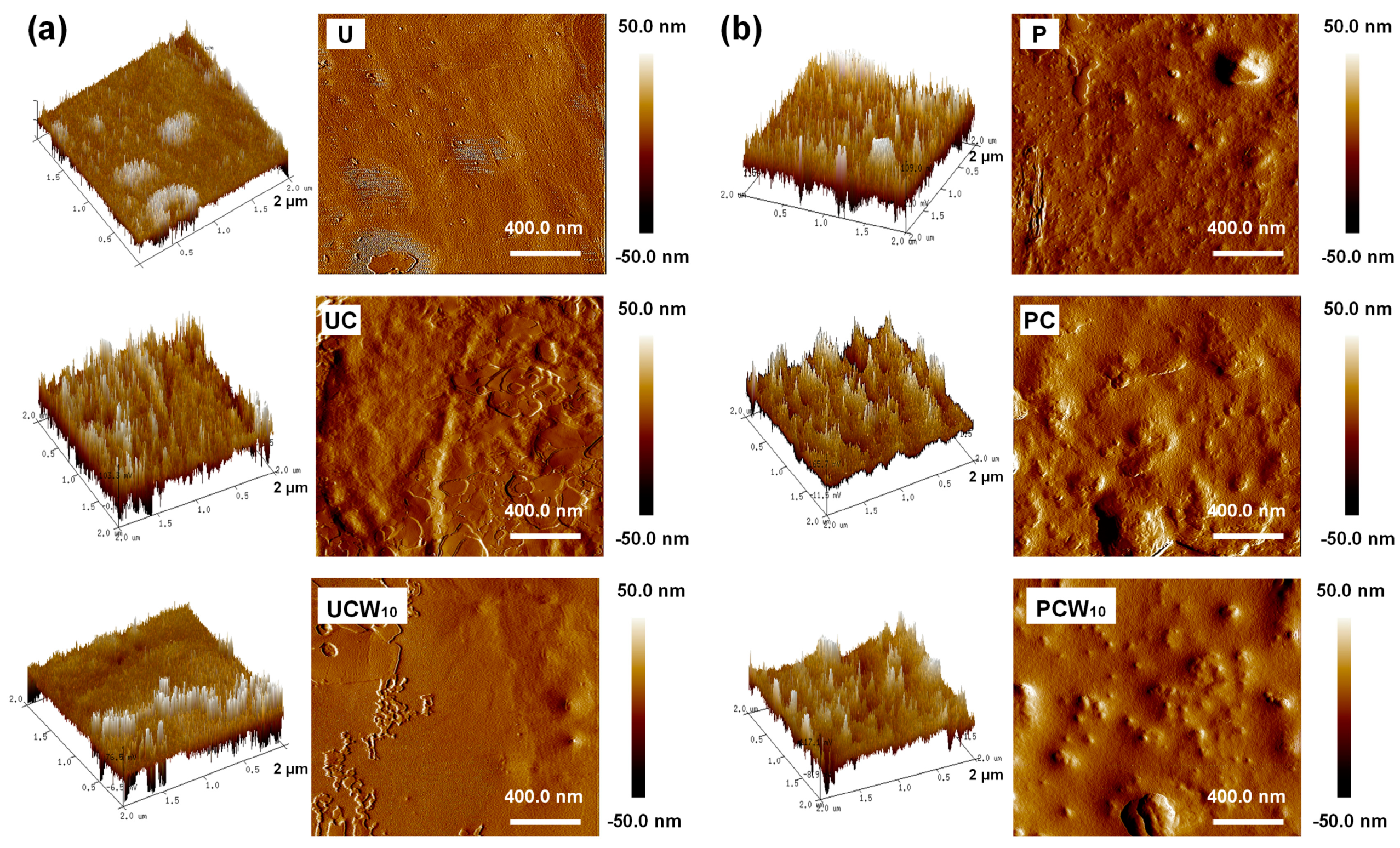

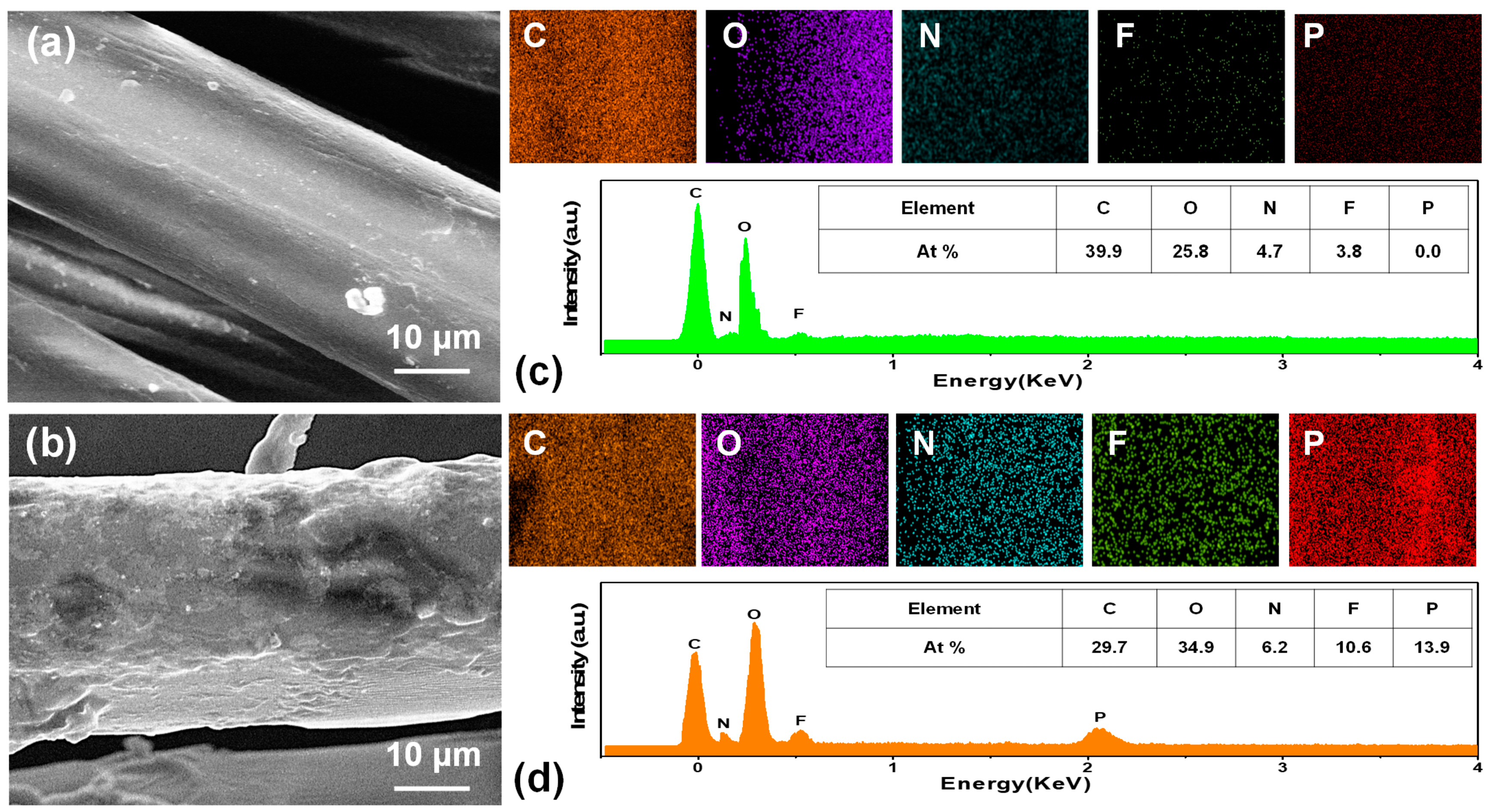

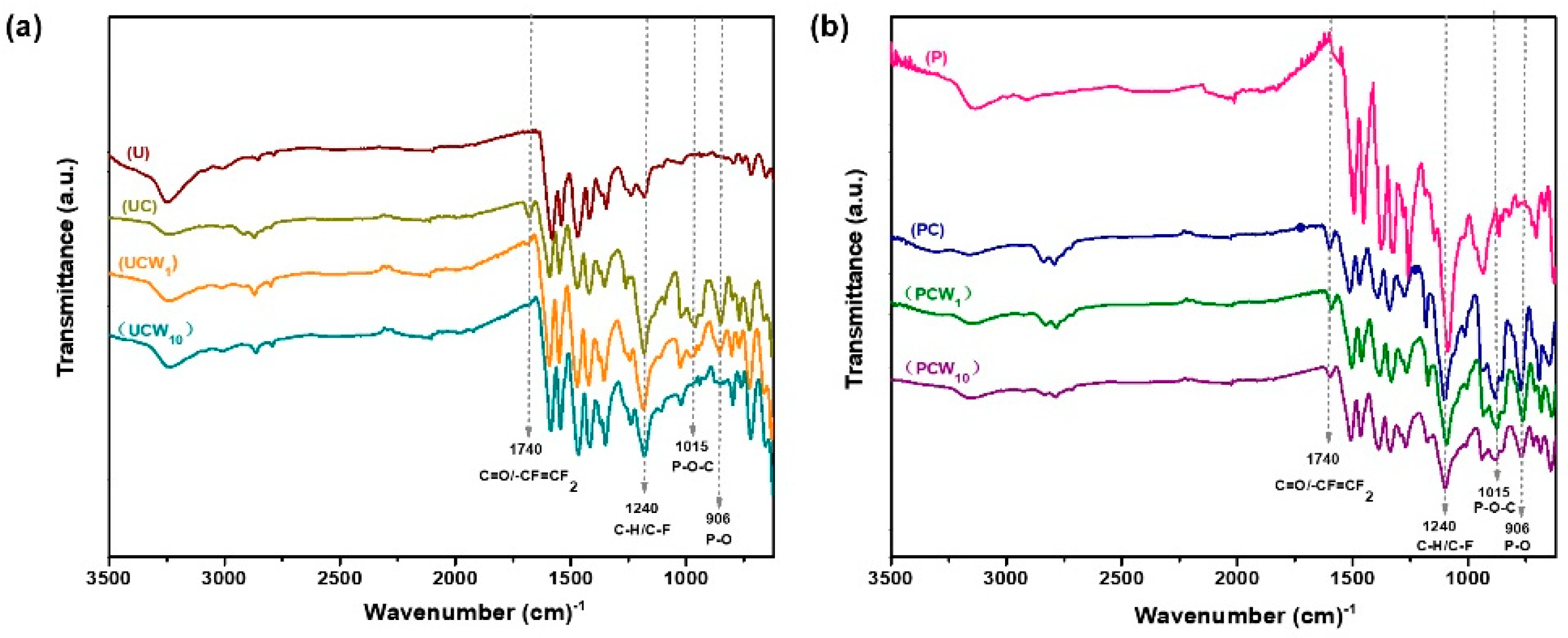

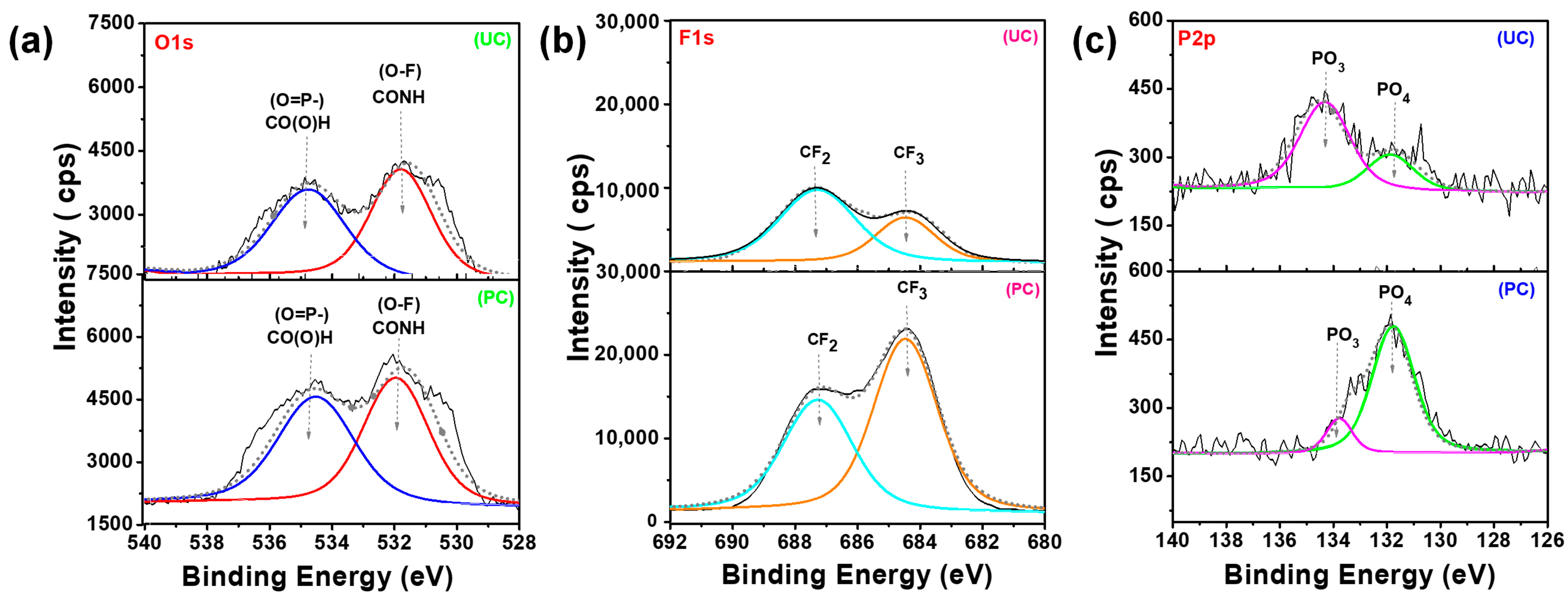

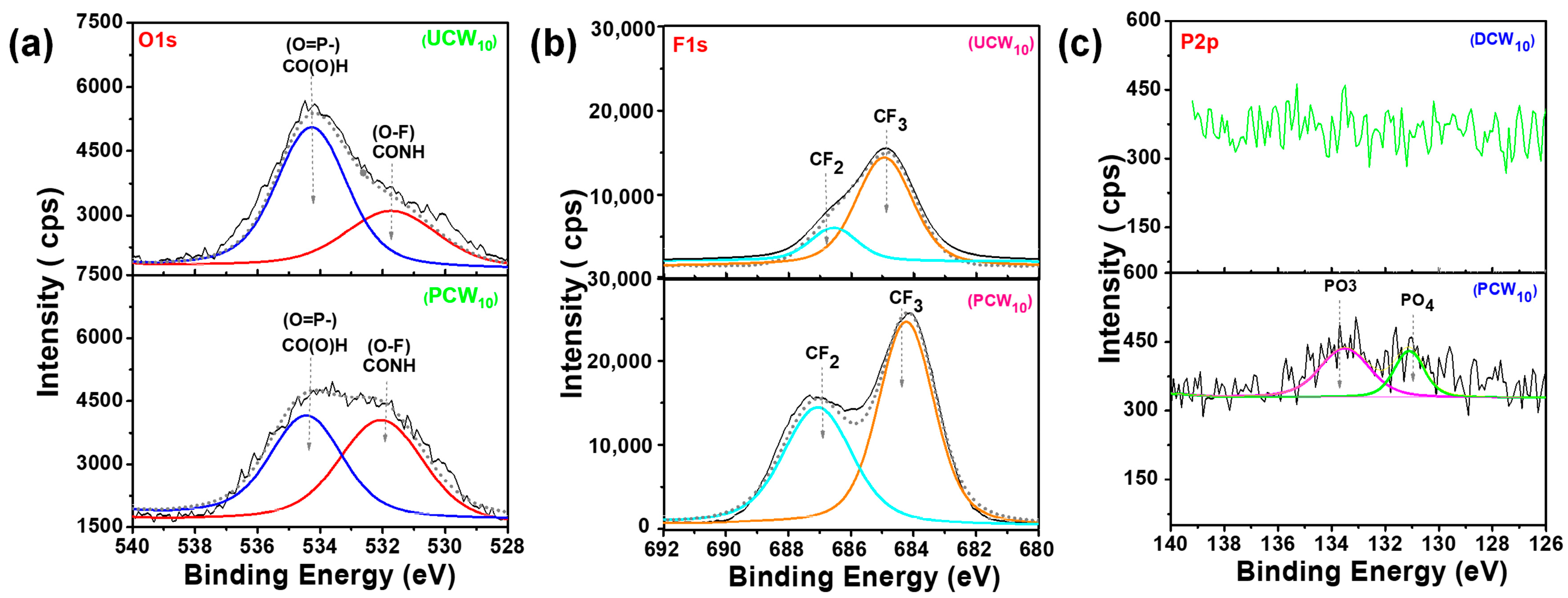

3.1. Surface Characterization

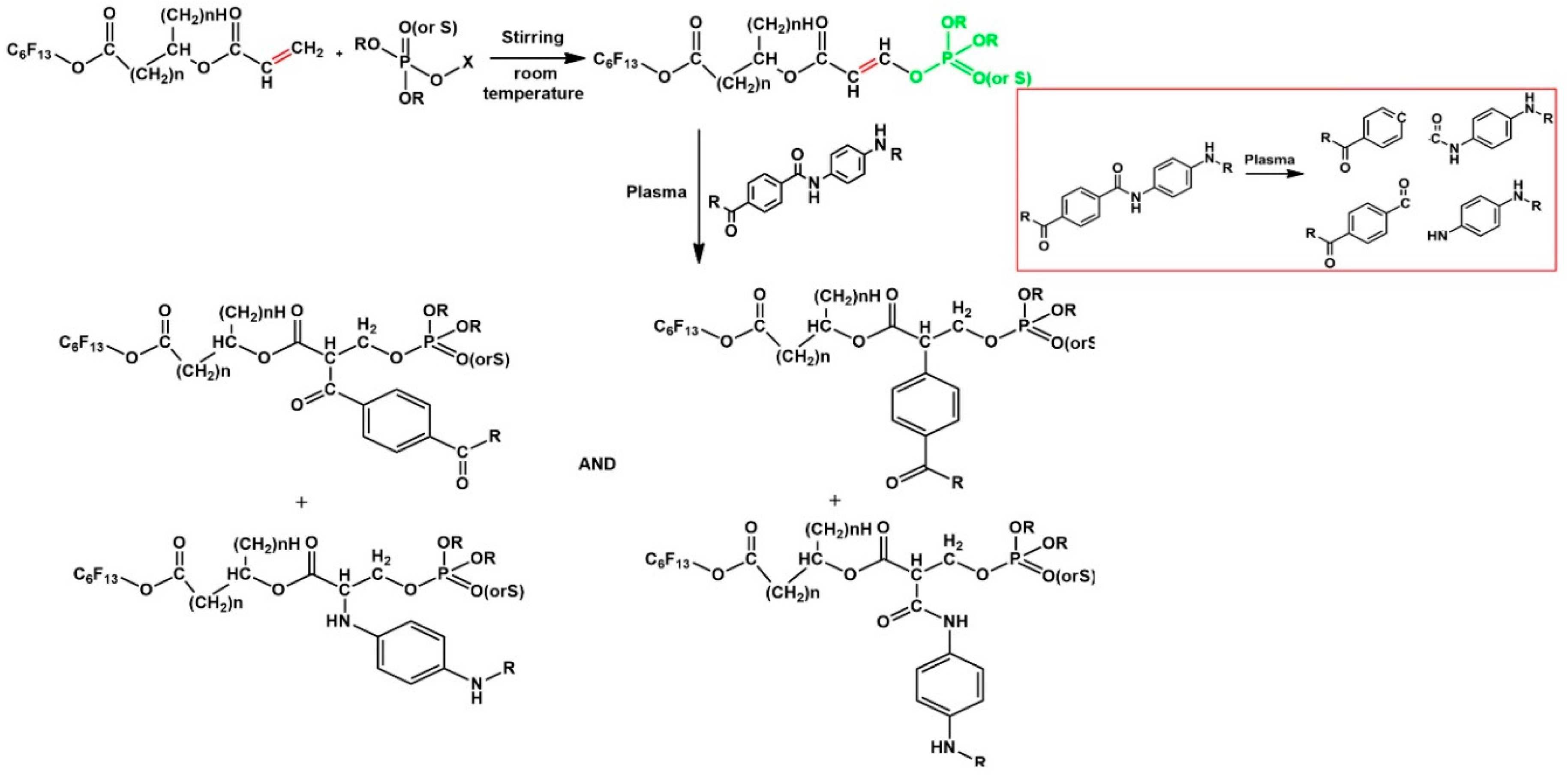

3.2. Phosphorus–Fluoride Graft Polymerization Reactions

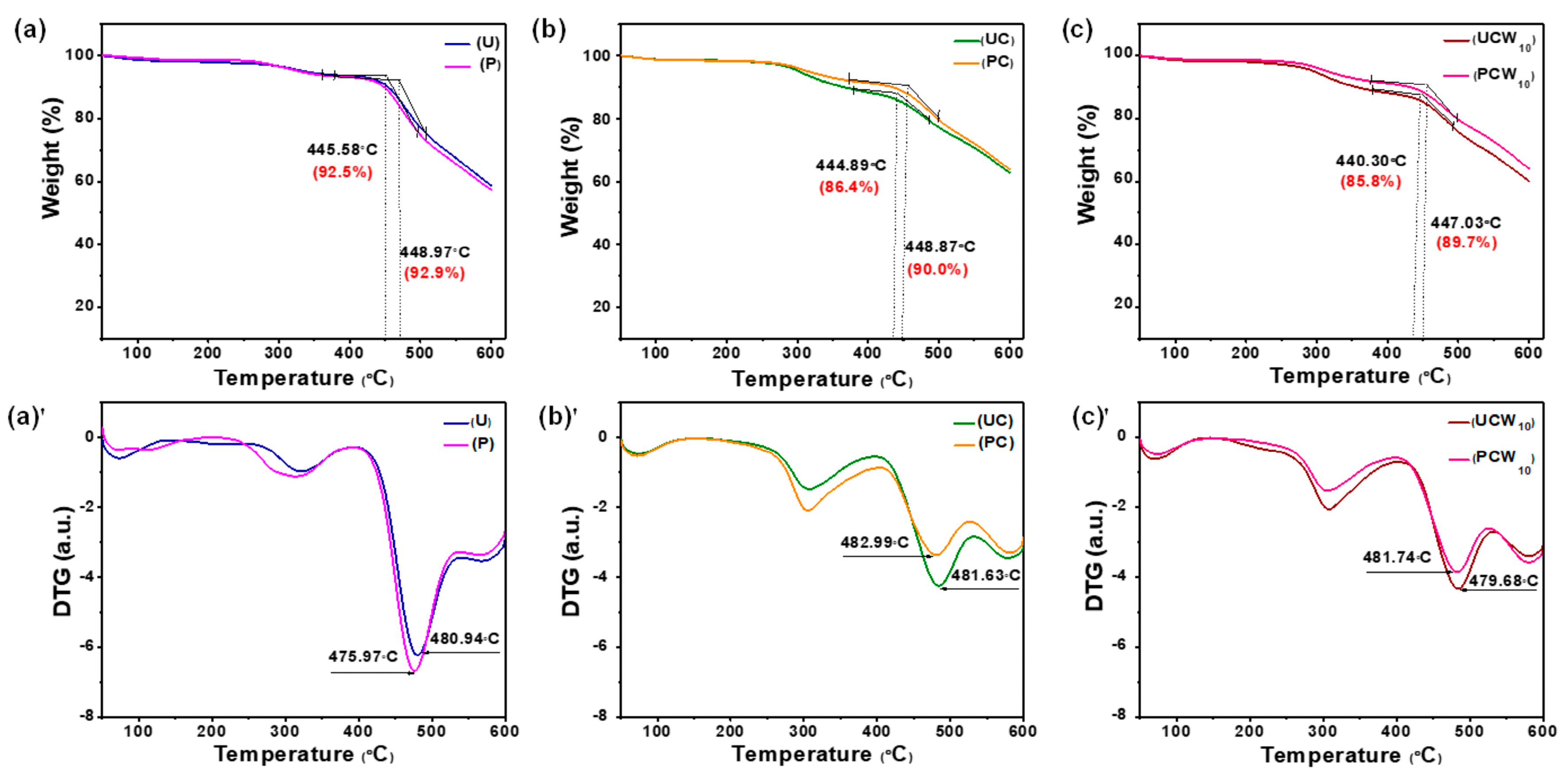

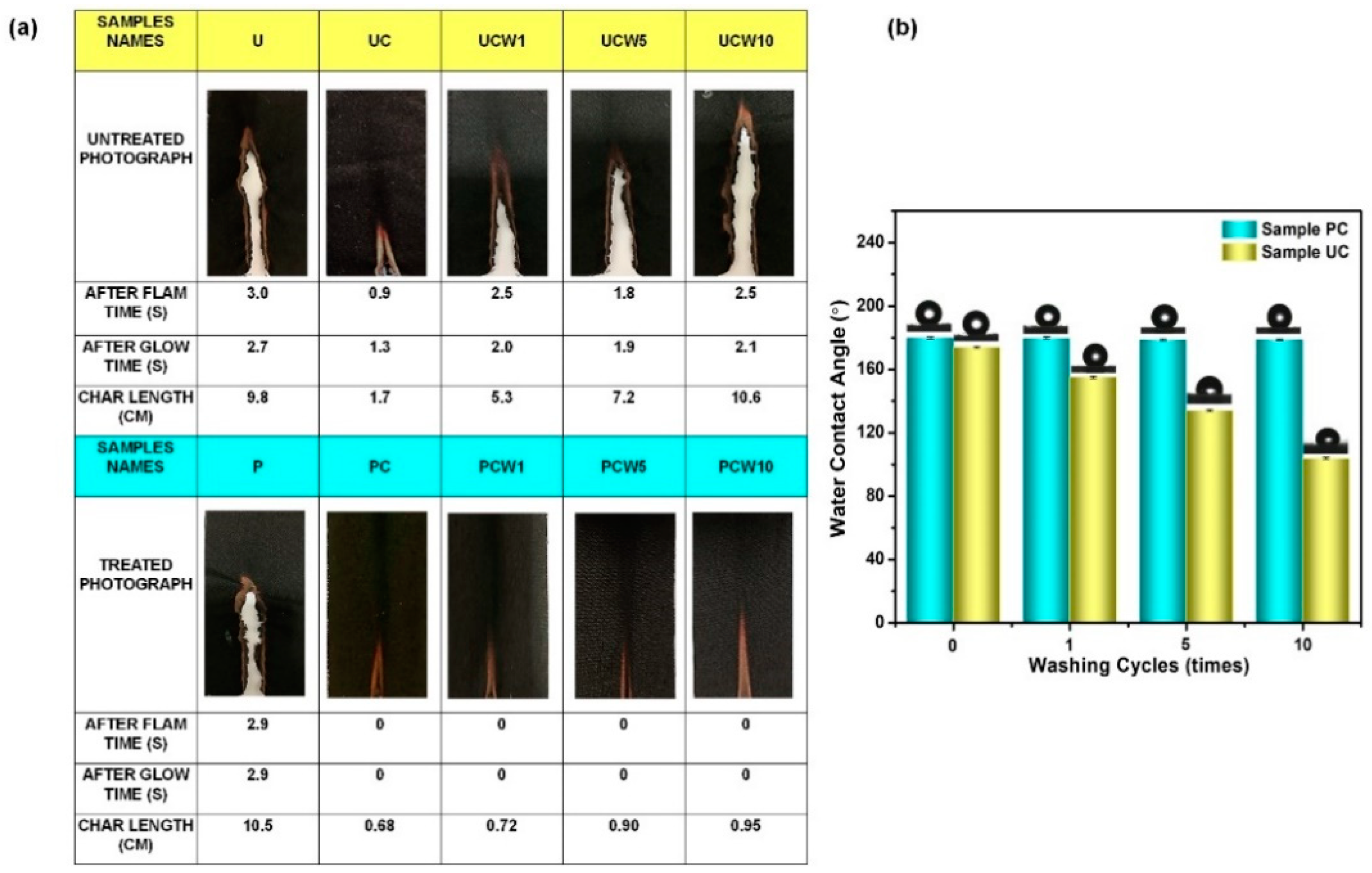

3.3. Durable Flame-Resistant Ultra-Hydrophobic Performance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Moiz, A.; Padhye, R.; Wang, X. Durable superomniphobic surface on cotton fabrics via coating of silicone rubber and fluoropolymers. Coatings 2018, 8, 104. [Google Scholar] [CrossRef] [Green Version]

- Widodo, M.; El-Shafei, A.; Hauser, P.J. Surface nanostructuring of kevlar fibers by atmospheric pressure plasma-induced graft polymerization for multifunctional protective clothing. J. Polym. Sci. Part B Polym. Phys. 2012, 50, 1165–1172. [Google Scholar] [CrossRef]

- Nabipour, H.; Wang, X.; Song, L.; Hu, Y. Graphene oxide/zeolitic imidazolate frameworks-8 coating for cotton fabrics with highly flame retardant, self-cleaning and efficient oil/water separation performances. Mater. Chem. Phys. 2020, 256, 123656. [Google Scholar] [CrossRef]

- Vasiljević, J.; Čolović, M.; Čelan Korošin, N.; Šobak, M.; Štirn, Ž.; Jerman, I. Effect of Different Flame-Retardant Bridged DOPO Derivatives on Properties of in Situ Produced Fiber-Forming Polyamide 6. Polymers 2020, 12, 657. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Serbezeanu, D.; Popa, A.M.; Stelzig, T.; Sava, I.; Rossi, R.M.; Fortunato, G. Preparation and characterization of thermally stable polyimide membranes by electrospinning for protective clothing applications. Text. Res. J. 2015, 85, 1763–1775. [Google Scholar] [CrossRef]

- Luo, L.; Wu, P.; Cheng, Z.; Hong, D.; Li, B.; Wang, X.; Liu, X. Direct fluorination of para-aramid fibers 1: Fluorination reaction process of PPTA fiber. J. Fluor. Chem. 2016, 186, 12–18. [Google Scholar] [CrossRef]

- Chen, X.; Wang, W.; Jiao, C. A recycled environmental friendly flame retardant by modifying para-aramid fiber with phosphorus acid for thermoplastic polyurethane elastomer. J. Hazard. Mater. 2017, 331, 257–264. [Google Scholar] [CrossRef]

- Fu, J.; Yang, F.; Chen, G.; Zhang, G.; Huang, C.; Guo, Z. A facile coating with water-repellent and flame-retardant properties on cotton fabric. New J. Chem. 2019, 43, 10183–10189. [Google Scholar] [CrossRef]

- Ipekci, H.H.; Arkaz, H.H.; Onses, M.S.; Hancer, M. Superhydrophobic coatings with improved mechanical robustness based on polymer brushes. Surf. Coat. Technol. 2016, 299, 162–168. [Google Scholar] [CrossRef]

- Qian, X.; Song, L.; Bihe, Y.; Yu, B.; Shi, Y.; Hu, Y.; Yuen, R.K. Organic/inorganic flame retardants containing phosphorus, nitrogen and silicon: Preparation and their performance on the flame retardancy of epoxy resins as a novel intumescent flame retardant system. Mater. Chem. Phys. 2014, 143, 1243–1252. [Google Scholar] [CrossRef]

- Chen, T.; Hong, J.; Peng, C.; Chen, G.; Yuan, C.; Xu, Y.; Zeng, B.; Dai, L. Superhydrophobic and flame retardant cotton modified with DOPO and fluorine-silicon-containing crosslinked polymer. Carbohydr. Polym. 2019, 208, 14–21. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Fan, H.; Tian, S.; Chen, Y.; Yan, J. Synergistic effect of phosphorus–nitrogen and silicon-containing chain extenders on the mechanical properties, flame retardancy and thermal degradation behavior of waterborne polyurethane. RSC Adv. 2016, 6, 72409–72422. [Google Scholar] [CrossRef]

- Wei, D.; Dong, C.; Chen, Z.; Liu, J.; Li, Q.; Lu, Z. A novel cyclic copolymer containing Si/P/N used as flame retardant and water repellent agent on cotton fabrics. J. Appl. Polym. Sci. 2019, 136, 47280. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, Y.; Gu, Y.; Zeng, Q. Flame retardant polyacrylonitrile fabrics prepared by organic-inorganic hybrid silica coating via sol-gel technique. Prog. Org. Coat. 2017, 112, 225–233. [Google Scholar] [CrossRef]

- Chen, X.; Wang, W.; Li, S.; Jiao, C. Fire safety improvement of para-aramid fiber in thermoplastic polyurethane elastomer. J. Hazard. Mater. 2017, 324, 789–796. [Google Scholar] [CrossRef]

- Zanini, S.; Freti, S.; Citterio, A.; Riccardi, C. Characterization of hydro-and oleo-repellent pure cashmere and wool/nylon textiles obtained by atmospheric pressure plasma pre-treatment and coating with a fluorocarbon resin. Surf. Coat. Technol. 2016, 292, 155–160. [Google Scholar] [CrossRef]

- Ding, X.; Fang, F.; Du, T.; Zheng, K.; Chen, L.; Tian, X.; Zhang, X. Carbon nanotube-filled intumescent multilayer nanocoating on cotton fabric for enhancing flame retardant property. Surf. Coat. Technol. 2016, 305, 184–191. [Google Scholar] [CrossRef]

- He, T.; Chen, X.; Wang, Y.; Cheng, Z.; Liu, Y.; Wang, X.; Luo, L.; Chen, Y.; Liu, X. Fabrication of durable superhydrophobic surfaces of polyester fabrics via fluorination-induced grafting copolymerization. Appl. Surf. Sci. 2020, 515, 146006. [Google Scholar] [CrossRef]

- Xu, L.; Lai, Y.; Liu, L.; Yang, L.; Guo, Y.; Chang, X.; Shi, J.; Zhang, R.; Yu, J. The Effect of Plasma Electron Temperature on the Surface Properties of Super-Hydrophobic Cotton Fabrics. Coatings 2020, 10, 160. [Google Scholar] [CrossRef] [Green Version]

- Ramamoorthy, A.; El-Shafei, A.; Hauser, P. Plasma induced graft polymerization of C6 fluorocarbons on cotton fabrics for sustainable finishing applications. Plasma Process. Polym. 2013, 10, 430–443. [Google Scholar] [CrossRef]

- Shao, Z.-B.; Tang, Z.-C.; Lin, X.-Z.; Jin, J.; Li, Z.-Y.; Deng, C. Phosphorus/sulfur-containing aliphatic polyamide curing agent endowing epoxy resin with well-balanced flame safety, transparency and refractive index. Mater. Des. 2020, 187, 108417. [Google Scholar] [CrossRef]

- Zhang, S.-H.; He, G.-Q.; Liang, G.-Z.; Cui, H.; Zhang, W.; Wang, B. Comparison of F-12 aramid fiber with domestic armid fiber III on surface feature. Appl. Surf. Sci. 2010, 256, 2104–2109. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, Y.; He, T.; Ding, K.; Huang, X.; Li, H.; Shi, J.; Guo, Y.; Zhang, J. The Effects of Thermal and Atmospheric Pressure Radio Frequency Plasma Annealing in the Crystallization of TiO2 Thin Films. Coatings 2019, 9, 357. [Google Scholar] [CrossRef] [Green Version]

- Carosio, F.; Alongi, J.; Frache, A. Influence of surface activation by plasma and nanoparticle adsorption on the morphology, thermal stability and combustion behavior of PET fabrics. Eur. Polym. J. 2011, 47, 893–902. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, W.; Yang, D.; Zhou, X.; Zhao, Z.; Zhang, L.; Wang, S.; Feng, J. Hydrophilicity modification of aramid fiber using a linear shape plasma excited by nanosecond pulse. Surf. Coat. Technol. 2018, 344, 614–620. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Wu, J.-Y.; Tsai, C.-S.; Hsieh, K.-H.; Yeh, J.-T.; Chen, K.-N. Effects of argon plasma treatment on the adhesion property of ultra high molecular weight polyethylene (UHMWPE) textile. Surf. Coat. Technol. 2013, 231, 507–511. [Google Scholar] [CrossRef]

- Siddig, E.A.; Yu, X.; Tao, H.; Ming, G.; Baojing, Y.; Tianshu, W.; Zhang, J. Plasma-induced graft polymerization on the surface of aramid fabrics with improved omniphobicity and washing durability. Plasma Sci. Technol. 2020, 22, 055503. [Google Scholar] [CrossRef]

- Gasi, F.; Petraconi, G.; Bittencourt, E.; Lourenço, S.R.; Castro, A.H.R.; Miranda, F.d.S.; Essiptchouk, A.M.; Nascimento, L.; Petraconi, A.; Fraga, M.A. Plasma Treatment of Polyamide Fabric Surface by Hybrid Corona-Dielectric Barrier Discharge: Material Characterization and Dyeing/Washing Processes. Mater. Res. 2020, 23. [Google Scholar] [CrossRef]

- Amel, E.E.; Ying, G.; Jianjun, S.; Ke, D.; Jing, Z. Synergistic Effect of Atmospheric Pressure Plasma Pre-Treatment on Alkaline Etching of Polyethylene Terephthalate Fabrics and Films. Plasma Sci. Technol. 2016, 18, 346. [Google Scholar] [CrossRef] [Green Version]

- Molina, J.; Fernández, J.; Fernandes, M.; Souto, A.P.; Esteves, M.; Bonastre, J.; Cases, F. Plasma treatment of polyester fabrics to increase the adhesion of reduced graphene oxide. Synth. Met. 2015, 202, 110–122. [Google Scholar] [CrossRef]

- Dinçmen, M.G.; Hauser, P.J.; Gürsoy, N.Ç. Plasma induced graft polymerization of a fluorocarbon monomer on polyamide 6, 6 fabrics. J. Text. Appar. Tekst. Konfeksiyon 2017, 27, 38–45. [Google Scholar]

- Jeong, E.; Lee, B.H.; Doh, S.J.; Park, I.J.; Lee, Y.-S. Multifunctional surface modification of an aramid fabric via direct fluorination. J. Fluor. Chem. 2012, 141, 69–75. [Google Scholar] [CrossRef]

- Malshe, P.; Mazloumpour, M.; El-Shafei, A.; Hauser, P. Multi-functional military textile: Plasma-induced graft polymerization of a C6 fluorocarbon for repellent treatment on nylon–cotton blend fabric. Surf. Coat. Technol. 2013, 217, 112–118. [Google Scholar] [CrossRef]

- Zhang, D.; Williams, B.L.; Shrestha, S.B.; Nasir, Z.; Becher, E.M.; Lofink, B.J.; Santos, V.H.; Patel, H.; Peng, X.; Sun, L. Flame retardant and hydrophobic coatings on cotton fabrics via sol-gel and self-assembly techniques. J. Colloid Interface Sci. 2017, 505, 892–899. [Google Scholar] [CrossRef]

- Kamlangkla, K.; Hodak, S.K.; Levalois-Grützmacher, J. Multifunctional silk fabrics by means of the plasma induced graft polymerization (PIGP) process. Surf. Coat. Technol. 2011, 205, 3755–3762. [Google Scholar] [CrossRef]

- Wang, S.; Liu, X.; Wang, L.; Wen, Q.; Du, N.; Huang, J. Formation mechanism and properties of fluoride–phosphate conversion coating on titanium alloy. RSC Adv. 2017, 7, 16078–16086. [Google Scholar] [CrossRef] [Green Version]

- Luo, J.; Wu, Q.; Huang, H.-C.; Chen, J.-J. Studies of fluorinated methylacrylate copolymer on the surface of cotton fabrics. Text. Res. J. 2011, 81, 1702–1712. [Google Scholar]

- Zhao, F.-G.; Zhao, G.; Liu, X.-H.; Ge, C.-W.; Wang, J.-T.; Li, B.-L.; Wang, Q.-G.; Li, W.-S.; Chen, Q.-Y. Fluorinated graphene: Facile solution preparation and tailorable properties by fluorine-content tuning. J. Mater. Chem. A 2014, 2, 8782–8789. [Google Scholar] [CrossRef]

- Siow, K.S.; Britcher, L.; Kumar, S.; Griesser, H.J. Deposition and XPS and FTIR analysis of plasma polymer coatings containing phosphorus. Plasma Process. Polym. 2014, 11, 133–141. [Google Scholar] [CrossRef]

- Peng, B.; Xu, Y.; Liu, K.; Wang, X.; Mulder, F.M. High-Performance and Low-Cost Sodium-Ion Anode Based on a Facile Black Phosphorus−Carbon Nanocomposite. ChemElectroChem 2017, 4, 2140–2144. [Google Scholar] [CrossRef]

- Li, J.; Tong, W.; Yi, L. Flame-retardant composite coatings for cotton fabrics fabricated by using oxygen plasma-induced polymerization of vinyl phosphonic acid/cyclotetrasiloxane. Text. Res. J. 2019, 89, 5053–5066. [Google Scholar] [CrossRef]

- Jesuarockiam, N.; Jawaid, M.; Zainudin, E.S.; Thariq Hameed Sultan, M.; Yahaya, R. Enhanced thermal and dynamic mechanical properties of synthetic/natural hybrid composites with graphene nanoplateletes. Polymers 2019, 11, 1085. [Google Scholar] [CrossRef] [Green Version]

- Villar-Rodil, S.; Martínez-Alonso, A.; Tascón, J. Studies on pyrolysis of Nomex polyaramid fibers. J. Anal. Appl. Pyrolysis 2001, 58, 105–115. [Google Scholar] [CrossRef] [Green Version]

- Shen, M.-Y.; Chen, W.-J.; Kuan, C.-F.; Kuan, H.-C.; Yang, J.-M.; Chiang, C.-L. Preparation, characterization of microencapsulated ammonium polyphosphate and its flame retardancy in polyurethane composites. Mater. Chem. Phys. 2016, 173, 205–212. [Google Scholar] [CrossRef]

- Edwards, B.; El-Shafei, A.; Hauser, P.; Malshe, P. Towards flame retardant cotton fabrics by atmospheric pressure plasma-induced graft polymerization: Synthesis and application of novel phosphoramidate monomers. Surf. Coat. Technol. 2012, 209, 73–79. [Google Scholar] [CrossRef]

- Cheng, X.-W.; Guan, J.-P.; Yang, X.-H.; Tang, R.-C. Improvement of flame retardancy of silk fabric by bio-based phytic acid, nano-TiO2, and polycarboxylic acid. Prog. Org. Coat. 2017, 112, 18–26. [Google Scholar] [CrossRef]

- Khattab, T.A.; Mohamed, A.L.; Hassabo, A.G. Development of durable superhydrophobic cotton fabrics coated with silicone/stearic acid using different cross-linkers. Mater. Chem. Phys. 2020, 249, 122981. [Google Scholar] [CrossRef]

- Wang, Y.; Lan, Y.; Shi, X.; Sheng, Y.; Yang, Y.; Peng, S.; Xu, J. Highly efficient fabrication of self-extinguished flame-retardant and underwater superoleophobic coatings through layer-by-layer method. Mater. Chem. Phys. 2020, 256, 123590. [Google Scholar] [CrossRef]

- Taherkhani, A.; Hasanzadeh, M. Durable flame retardant finishing of cotton fabrics with poly (amidoamine) dendrimer using citric acid. Mater. Chem. Phys. 2018, 219, 425–432. [Google Scholar] [CrossRef]

- Möncke, D.; Eckert, H. Review on the structural analysis of fluoride-phosphate and fluoro-phosphate glasses. J. Non-Cryst. Solids X 2019, 3, 100026. [Google Scholar] [CrossRef]

| Experimental Conditions | Treatment Formulas | Coating Formulas | Washing Cycles Formulas | ||

|---|---|---|---|---|---|

| 1 (Time) | 5 (Time) | 10 (Time) | |||

| Untreated | U | UC | UCW1 | UCW5 | UCW10 |

| Plasma treated | P | PC | PCW1 | PCW5 | PCW10 |

| Samples Names | Atomic Ratio (%) | |||

|---|---|---|---|---|

| C1s | O1s | F1s | P2p | |

| UC | 43.2 | 9.8 | 54.5 | 1.6 |

| UCW10 | 37.9 | 5.7 | 41.7 | 0.3 |

| PC | 36.5 | 10.5 | 79.7 | 3.1 |

| PCW10 | 33.8 | 9.6 | 76.9 | 2.9 |

| Sample Name | TGA (°C) | Weight (%) | DTG (°C) |

|---|---|---|---|

| U | 448.97 | 92.9 | 480.94 |

| UC | 444.89 | 86.4 | 481.63 |

| UCW10 | 440.30 | 85.8 | 479.68 |

| P | 445.58 | 92.5 | 475.97 |

| PC | 448.87 | 90.0 | 482.99 |

| PCW10 | 447.03 | 89.7 | 481.74 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siddig, E.A.A.; Zhang, Y.; Yang, B.; Wang, T.; Shi, J.; Guo, Y.; Xu, Y.; Zhang, J. Durable Flame-Resistant and Ultra-Hydrophobic Aramid Fabrics via Plasma-Induced Graft Polymerization. Coatings 2020, 10, 1257. https://doi.org/10.3390/coatings10121257

Siddig EAA, Zhang Y, Yang B, Wang T, Shi J, Guo Y, Xu Y, Zhang J. Durable Flame-Resistant and Ultra-Hydrophobic Aramid Fabrics via Plasma-Induced Graft Polymerization. Coatings. 2020; 10(12):1257. https://doi.org/10.3390/coatings10121257

Chicago/Turabian StyleSiddig, Eshraga A. A., Yu Zhang, Baojing Yang, Tianshu Wang, Jianjun Shi, Ying Guo, Yu Xu, and Jing Zhang. 2020. "Durable Flame-Resistant and Ultra-Hydrophobic Aramid Fabrics via Plasma-Induced Graft Polymerization" Coatings 10, no. 12: 1257. https://doi.org/10.3390/coatings10121257

APA StyleSiddig, E. A. A., Zhang, Y., Yang, B., Wang, T., Shi, J., Guo, Y., Xu, Y., & Zhang, J. (2020). Durable Flame-Resistant and Ultra-Hydrophobic Aramid Fabrics via Plasma-Induced Graft Polymerization. Coatings, 10(12), 1257. https://doi.org/10.3390/coatings10121257