Pulsed Magnetron Sputtering of Strongly Thermochromic VO2-Based Coatings with a Transition Temperature of 22 °C onto Ultrathin Flexible Glass

Abstract

:1. Introduction

2. Materials and Methods

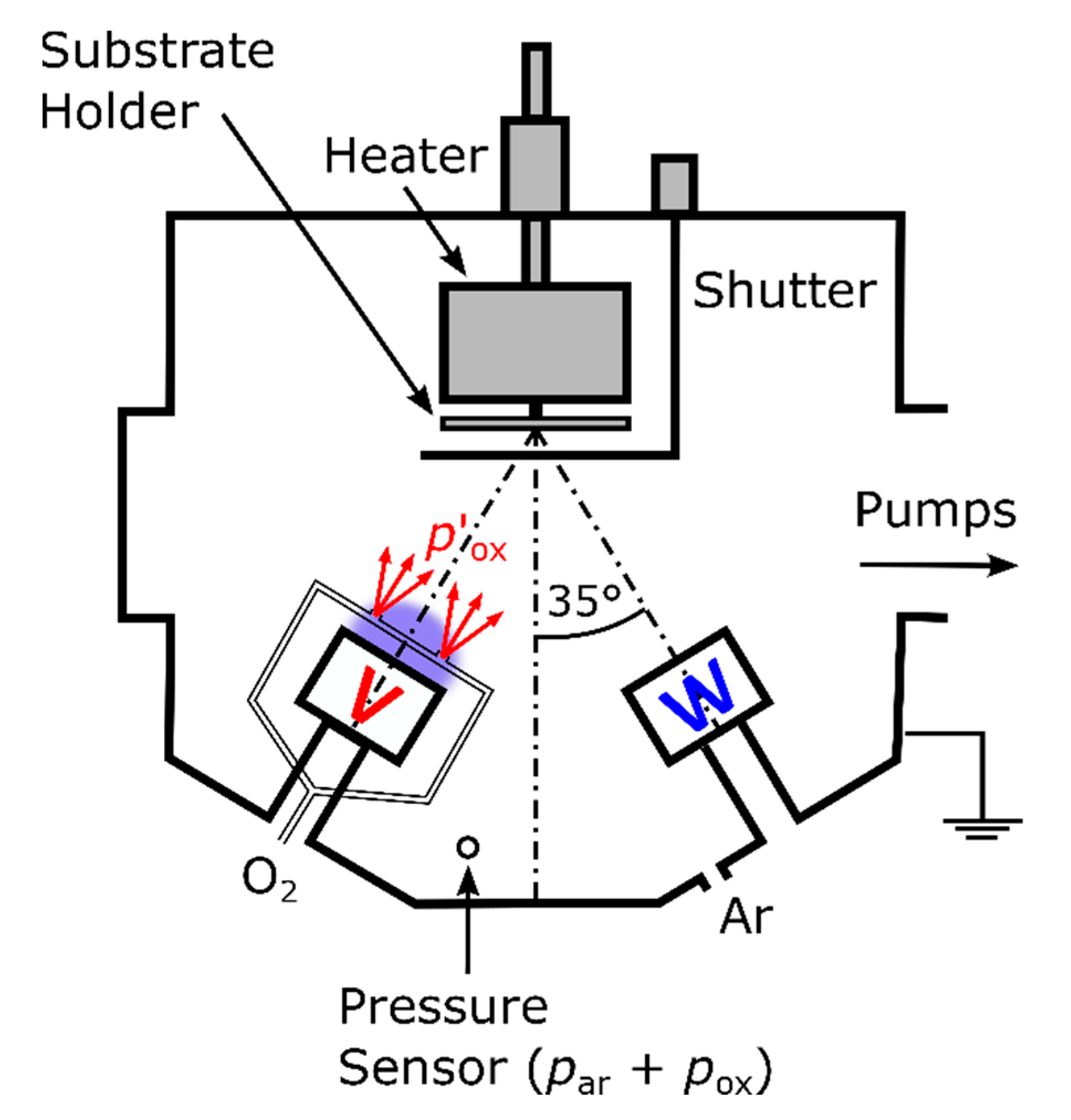

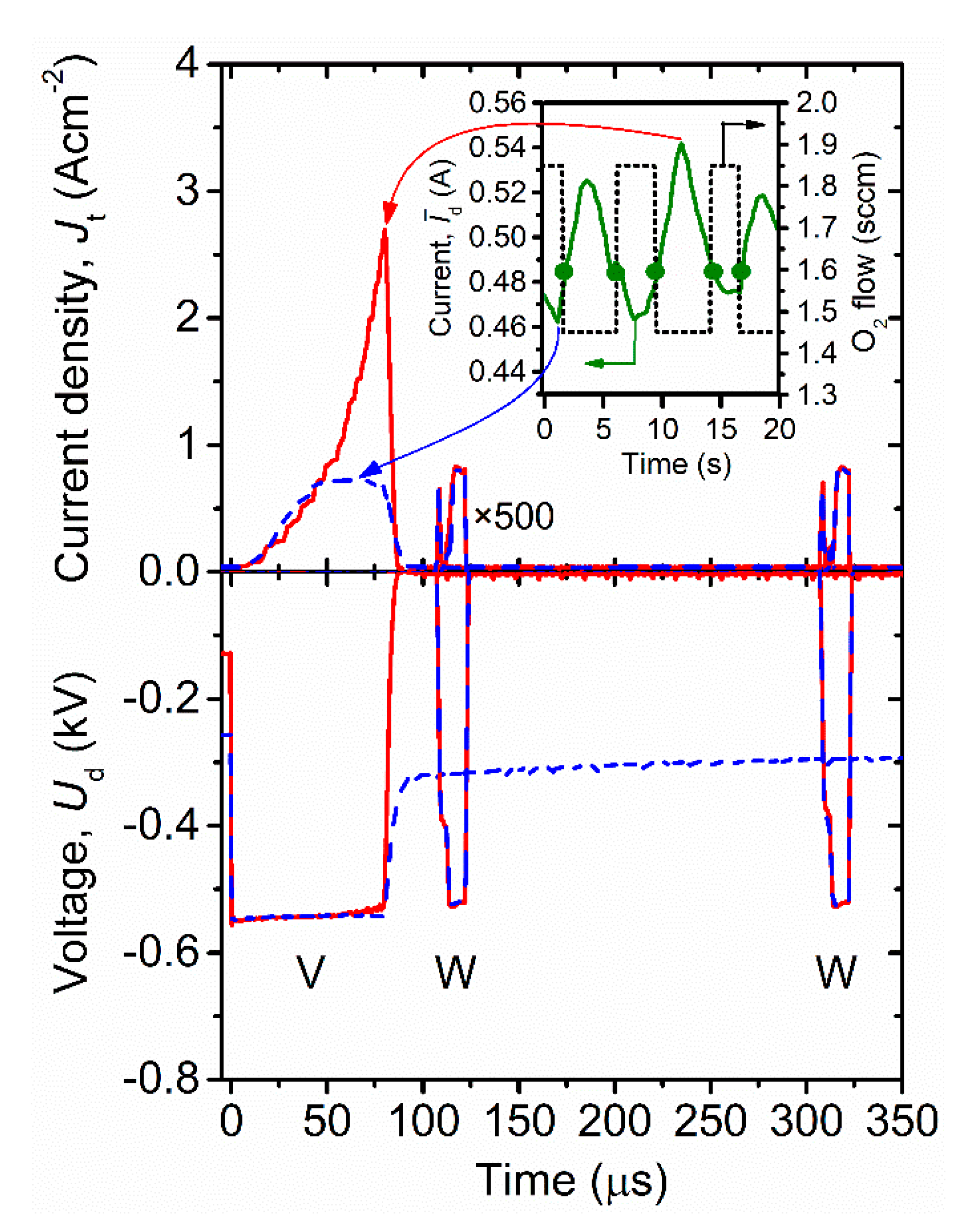

2.1. Coating Preparation

2.2. Coating Characterization

3. Results and Discussion

3.1. Coating Design

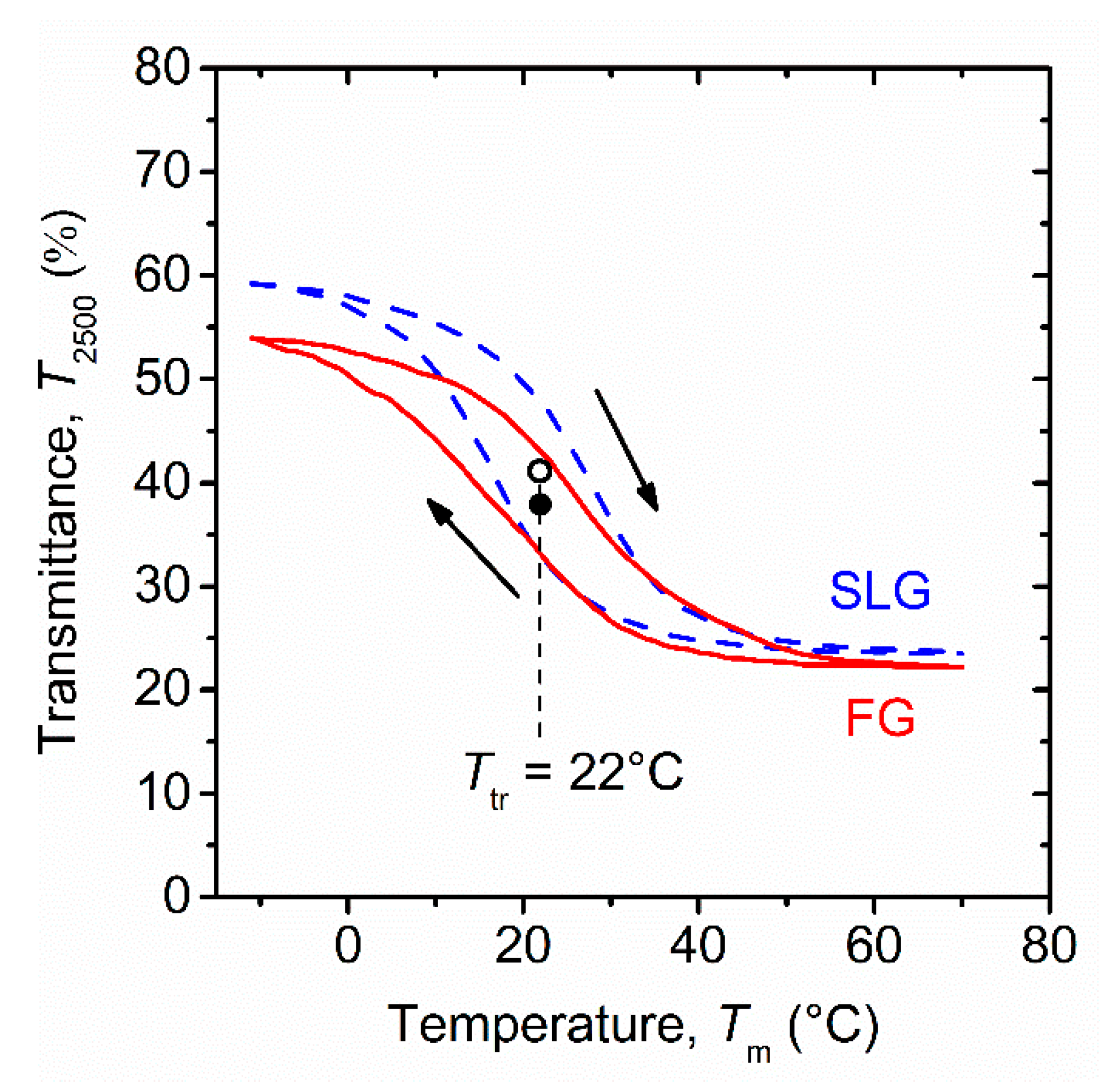

3.2. Transition Temperature

3.3. Coating Structure

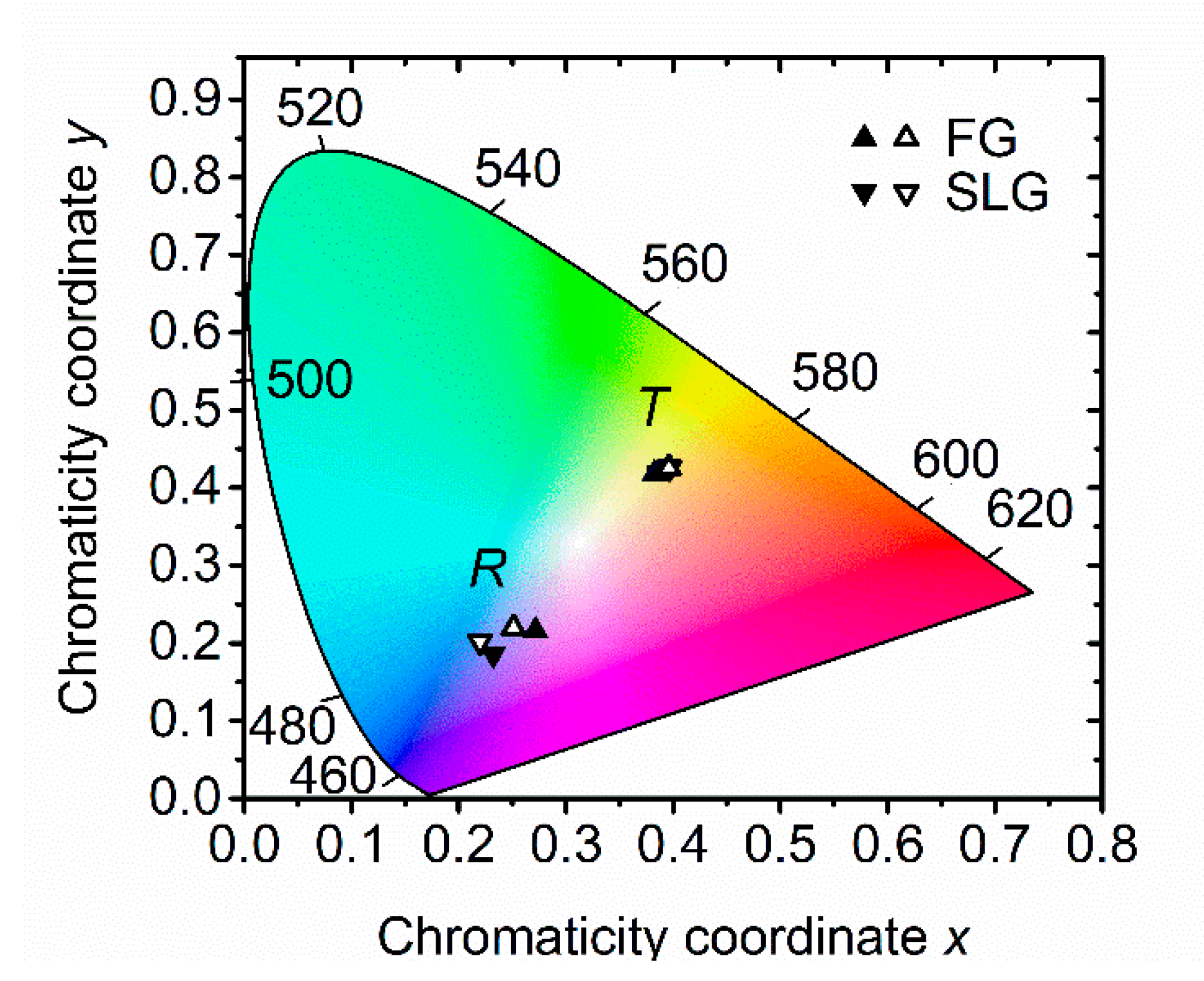

3.4. Optical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Omer, A.M. Energy, environment and sustainable development. Renew. Sust. Energ. Rev. 2008, 12, 2265–2300. [Google Scholar] [CrossRef]

- USA Department of Energy. 2011 Buildings Energy Data Book; USA Department of Energy: Washington, DC, USA, 2012.

- Granqvist, C.G. Recent progress in thermochromics and electrochromics: A brief survey. Thin Solid Films 2016, 614, 90–96. [Google Scholar] [CrossRef]

- Morin, F.J. Oxides Which Show a Metal-to-Insulator Transition at the Neel Temperature. Phys. Rev. Lett. 1959, 3, 34–36. [Google Scholar] [CrossRef]

- Gao, Y.; Luo, H.; Zhang, Z.; Kang, L.; Chen, Z.; Du, J.; Kanehira, M.; Cao, C. Nanoceramic VO2 thermochromic smart glass: A review on progress in solution processing. Nano Energy 2012, 1, 221–246. [Google Scholar] [CrossRef]

- Wang, S.; Liu, M.; Kong, L.; Long, Y.; Jiang, X.; Yu, A. Recent progress in VO2 smart coatings: Strategies to improve the thermochromic properties. Prog. Mater. Sci. 2016, 81, 1–54. [Google Scholar] [CrossRef]

- Li, M.; Magdassi, S.; Gao, Y.; Long, Y. Hydrothermal Synthesis of VO2 Polymorphs: Advantages, Challenges and Prospects for the Application of Energy Efficient Smart Windows. Small 2017, 13, 1701147. [Google Scholar] [CrossRef]

- Xu, F.; Cao, X.; Luo, H.; Jin, P. Recent advances in VO2-based thermochromic composites for smart windows. J. Mater. Chem. C 2018, 6, 1903–1919. [Google Scholar] [CrossRef]

- Chang, T.-C.; Cao, X.; Bao, S.-H.; Ji, S.-D.; Luo, H.-J.; Jin, P. Review on thermochromic vanadium dioxide based smart coatings: From lab to commercial application. Adv. Manuf. 2018, 6, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Fortier, J.-P.; Baloukas, B.; Zabeida, O.; Klemberg-Sapieha, J.E.; Martinu, L. Thermochromic VO2 thin films deposited by HiPIMS. Sol. Energy Mater. Sol. Cells 2014, 125, 291–296. [Google Scholar] [CrossRef]

- Aijaz, A.; Ji, Y.-X.; Montero, J.; Niklasson, G.A.; Granqvist, C.G.; Kubart, T. Low-temperature synthesis of thermochromic vanadium dioxide thin films by reactive high power impulse magnetron sputtering. Sol. Energy Mater. Sol. Cells 2016, 149, 137–144. [Google Scholar] [CrossRef]

- Sun, G.; Cao, X.; Li, X.; Bao, S.; Li, N.; Liang, M.; Gloter, A.; Gu, H.; Jin, P. Low-temperature deposition of VO2 films with high crystalline degree by embedding multilayered structure. Sol. Energy Mater. Sol. Cells 2017, 161, 70–76. [Google Scholar] [CrossRef]

- Chang, T.; Cao, X.; Li, N.; Long, S.; Gao, X.; Dedon, L.R.; Sun, G.; Luo, H.; Jin, P. Facile and Low-Temperature Fabrication of Thermochromic Cr2O3/VO2 Smart Coatings: Enhanced Solar Modulation Ability, High Luminous Transmittance and UV-Shielding Function. ACS Appl. Mater. Interfaces 2017, 9, 26029–26037. [Google Scholar] [CrossRef] [PubMed]

- Saeli, M.; Piccirillo, C.; Parkin, I.P.; Binions, R.; Ridley, I. Energy modelling studies of thermochromic glazing. Energy Build. 2010, 42, 1666–1673. [Google Scholar] [CrossRef]

- Hu, L.; Tao, H.; Chen, G.; Pan, R.; Wan, M.; Xiong, D.; Zhao, X. Porous W-doped VO2 films with simultaneously enhanced visible transparency and thermochromic properties. J. Sol-Gel Sci. Technol. 2015, 77, 85–93. [Google Scholar] [CrossRef]

- Baloukas, B.; Loquai, S.; Martinu, L. VO2-based thermally active low emissivity coatings. Sol. Energy Mater. Sol. Cells 2018, 183, 25–33. [Google Scholar] [CrossRef]

- Wang, N.; Goh, Q.S.; Lee, P.L.; Magdassi, S.; Long, Y. One-step hydrothermal synthesis of rare earth/W-codoped VO2 nanoparticles: Reduced phase transition temperature and improved thermochromic properties. J. Alloy. Compd. 2017, 711, 222–228. [Google Scholar] [CrossRef]

- Dietrich, M.K.; Kuhl, F.; Polity, A.; Klar, P.J. Optimizing thermochromic VO2 by co-doping with W and Sr for smart window applications. Appl. Phys. Lett. 2017, 110, 141907. [Google Scholar] [CrossRef]

- Lu, L.; Wu, Z.; Ji, C.; Song, M.; Feng, H.; Ma, X.; Jiang, Y. Effect of Fe doping on thermochromic properties of VO2 films. J. Mater. Sci. Mater. Electron. 2018, 29, 5501–5508. [Google Scholar] [CrossRef]

- Loquai, S.; Baloukas, B.; Klemberg-Sapieha, J.E.; Martinu, L. HiPIMS-deposited thermochromic VO2 films with high environmental stability. Sol. Energy Mater. Sol. Cells 2017, 160, 217–224. [Google Scholar] [CrossRef]

- Chang, T.; Cao, X.; Dedon, L.R.; Long, S.; Huang, A.; Shao, Z.; Li, N.; Luo, H.; Jin, P. Optical design and stability study for ultrahigh-performance and long-lived vanadium dioxide-based thermochromic coatings. Nano Energy 2018, 44, 256–264. [Google Scholar] [CrossRef]

- Long, S.; Cao, X.; Li, N.; Xin, Y.; Sun, G.; Chang, T.; Bao, S.; Jin, P. Application-oriented VO2 thermochromic coatings with composite structures: Optimized optical performance and robust fatigue properties. Sol. Energy Mater. Sol. Cells 2019, 189, 138–148. [Google Scholar] [CrossRef]

- Shen, N.; Chen, S.; Chen, Z.; Liu, X.; Cao, C.; Dong, B.; Luo, H.; Liu, J.; Gao, Y. The synthesis and performance of Zr-doped and W–Zr-codoped VO2 nanoparticles and derived flexible foils. J. Mater. Chem. A 2014, 2, 15087–15093. [Google Scholar] [CrossRef]

- Dai, L.; Chen, S.; Liu, J.; Gao, Y.; Zhou, J.; Chen, Z.; Cao, C.; Luo, H.; Kanehira, M. F-doped VO2 nanoparticles for thermochromic energy-saving foils with modified color and enhanced solar-heat shielding ability. Phys. Chem. Chem. Phys. 2013, 15, 11723–11729. [Google Scholar] [CrossRef] [PubMed]

- Kolenatý, D.; Vlček, J.; Bárta, T.; Rezek, J.; Houška, J.; Haviar, S. High-performance thermochromic VO2-based coatings with a low transition temperature deposited on glass by a scalable technique. Sci. Rep. 2020, 10, 11107. [Google Scholar] [CrossRef]

- Houska, J.; Kolenaty, D.; Vlcek, J.; Barta, T.; Rezek, J.; Cerstvy, R. Significant improvement of the performance of ZrO2/V1−xWxO2/ZrO2 thermochromic coatings by utilizing a second-order interference. Sol. Energy Mater. Sol. Cells 2019, 191, 365–371. [Google Scholar] [CrossRef]

- Gudmundsson, J.T. On reactive high power impulse magnetron sputtering. Plasma Phys. Control. Fusion 2015, 58, 014002. [Google Scholar] [CrossRef] [Green Version]

- Junghähnel, M.; Westphalen, J. Processing on flexible glass—Challenges and opportunities. SVC Bull. Fall/Winter 2017, 31–39. [Google Scholar]

- Junghähnel, M.; Fahlteich, J. Thin-film deposition on flexible glass by plasma processes. In Flexible Glass: Enabling Thin, Lightweight, and Flexible Electronics, 1st ed.; Garner, S.M., Ed.; Scrivener Publishing LLC: Beverly, CA, USA, 2017; pp. 129–180. [Google Scholar]

- Fahland, M.; Zywitzki, O.; Modes, T.; Vondkar, K.; Werner, T.; Ottermann, C.; Berendt, M.; Pollack, G. Roll-to-roll sputtering of indium tin oxide layers onto ultrathin flexible glass. Thin Solid Films 2019, 669, 56–59. [Google Scholar] [CrossRef]

- Vlček, J.; Rezek, J.; Houska, J.; Kozak, T.; Kohout, J. Benefits of the controlled reactive high-power impulse magnetron sputtering of stoichiometric ZrO2 films. Vacuum 2015, 114, 131–141. [Google Scholar] [CrossRef]

- Kozák, T.; Vlček, J. A parametric model for reactive high-power impulse magnetron sputtering of films. J. Phys. D: Appl. Phys. 2016, 49, 055202. [Google Scholar] [CrossRef]

- Kozák, T.; Vlček, J. Dynamics of processes during the deposition of ZrO2 films by controlled reactive high-power impulse magnetron sputtering: A modelling study. J. Appl. Phys. 2017, 122, 043304. [Google Scholar] [CrossRef]

- Vlček, J.; Kolenatý, D.; Houška, J.; Kozák, T.; Čerstvý, R. Controlled reactive HiPIMS—Effective technique for low-temperature (300 °C) synthesis of VO2 films with semiconductor-to-metal transition. J. Phys. D: Appl. Phys. 2017, 50, 38LT01. [Google Scholar] [CrossRef] [Green Version]

- Vlček, J.; Kolenatý, D.; Kozák, T.; Houška, J.; Čapek, J.; Kos, Š. Ion-flux characteristics during low-temperature (300 °C) deposition of thermochromic VO2 films using controlled reactive HiPIMS. J. Phys. D: Appl. Phys. 2019, 52, 025205. [Google Scholar] [CrossRef]

- Aiempanakit, M.; Aijaz, A.; Lundin, D.; Helmersson, U.; Kubart, T. Understanding the discharge current behavior in reactive high power impulse magnetron sputtering of oxides. J. Appl. Phys. 2013, 113, 133302. [Google Scholar] [CrossRef]

- Bechhoefer, J. Feedback for physicists: A tutorial essay on control. Rev. Mod. Phys. 2005, 77, 783–836. [Google Scholar] [CrossRef] [Green Version]

- Available online: http://rredc.nrel.gov/solar/spectra/am1.5/; http://hyperphysics.phy-astr.gsu.edu/hbase/vision/efficacy.html; (accessed on 14 June 2016).

- Oberste-Berghaus, J.; Van Nuffel, R.; Gobin, G.; De Jaeger, K.; Das, A.; De Bosscher, W. Film properties of zirconium oxide top layers from rotatable targets. In Proceedings of the 58th Annual Technical Conference Proceedings of SVC 2015, Santa Clara, CA, USA, 25–30 April 2015; pp. 228–234. [Google Scholar]

- Chen, Z.; Gao, Y.; Kang, L.; Cao, C.; Chen, S.; Luo, H. Fine crystalline VO2 nanoparticles: Synthesis, abnormal phase transition temperatures and excellent optical properties of a derived VO2 nanocomposite foil. J. Mat. Chem. A 2014, 2, 2718–2727. [Google Scholar] [CrossRef]

- The International Centre for Diffraction Data. PDF-4+ Database; The International Centre for Diffraction Data: Newtown Square, PA, USA, 2015. [Google Scholar]

| Substrate | Tlum (Tms) (%) | Tlum (Tmm) (%) | ΔTlum (%) | Tsol (Tms) (%) | Tsol (Tmm) (%) | ΔTsol (%) |

| FG | 45.7 | 42.2 | 3.5 | 39.6 | 30.0 | 9.6 |

| SLG | 48.6 | 45.5 | 3.1 | 43.1 | 32.4 | 10.7 |

| Substrate | Rlum (Tms) (%) | Rlum (Tmm) (%) | ΔRlum (%) | Rsol (Tms) (%) | Rsol (Tmm) (%) | ΔRsol (%) |

| FG | 8.2 | 8.3 | −0.1 | 16.6 | 18.9 | −2.3 |

| SLG | 6.4 | 7.1 | −0.7 | 15.1 | 16.9 | −1.8 |

| Substrate | Alum (Tms) (%) | Alum (Tmm) (%) | ΔAlum (%) | Asol (Tms) (%) | Asol (Tmm) (%) | ΔAsol (%) |

| FG | 46.1 | 49.5 | −3.4 | 43.8 | 51.1 | −7.3 |

| SLG | 45.0 | 47.4 | −2.4 | 41.8 | 50.7 | −8.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bárta, T.; Vlček, J.; Houška, J.; Haviar, S.; Čerstvý, R.; Szelwicka, J.; Fahland, M.; Fahlteich, J. Pulsed Magnetron Sputtering of Strongly Thermochromic VO2-Based Coatings with a Transition Temperature of 22 °C onto Ultrathin Flexible Glass. Coatings 2020, 10, 1258. https://doi.org/10.3390/coatings10121258

Bárta T, Vlček J, Houška J, Haviar S, Čerstvý R, Szelwicka J, Fahland M, Fahlteich J. Pulsed Magnetron Sputtering of Strongly Thermochromic VO2-Based Coatings with a Transition Temperature of 22 °C onto Ultrathin Flexible Glass. Coatings. 2020; 10(12):1258. https://doi.org/10.3390/coatings10121258

Chicago/Turabian StyleBárta, Tomáš, Jaroslav Vlček, Jiří Houška, Stanislav Haviar, Radomír Čerstvý, Jolanta Szelwicka, Matthias Fahland, and John Fahlteich. 2020. "Pulsed Magnetron Sputtering of Strongly Thermochromic VO2-Based Coatings with a Transition Temperature of 22 °C onto Ultrathin Flexible Glass" Coatings 10, no. 12: 1258. https://doi.org/10.3390/coatings10121258