1. Introduction

Laser surface hardening is a heat treatment process that uses a high energy density laser in a localized heating zone [

1,

2]. Applying this process on steel parts and coupling it with a fast quenching technique, called martensitic quenching, allow improving fatigue life and limit the distortion of steel parts [

3,

4,

5]. The laser beam is capable of rapidly increasing the surface temperature to above the austenitizing temperature (Ac

3). This intense heating process makes it possible to transform the existing microstructure of the surface to austenite, and then to generate a very fine martensitic microstructure with high hardness [

6]. In order to obtain a uniform hardness profile on parts with complex geometries, specific tuning on the parameters of laser hardening processes, such as laser power and scanning speed, is required [

7,

8,

9]. This uniform hardness profile is recommended to uniformly distribute the mechanical loads. This layer is obtained by a uniform martensitic layer at the surface of hardened parts. This uniform hardened layer avoids stress concentration on the hard surface layer of parts and limits crack propagation under periodic loads, which improves the fatigue resistance of parts [

10,

11,

12]. In the case of splines, a uniform hardness profile on teeth geometry can effectively reduce the wearing caused by abrasion [

13].

To achieve this uniform hardness profile, it is important to calibrate parameters such as laser power, scanning speed, and rotational speed. Sun et al. [

14] proposed an experimental approach supported with an analysis of variance (ANOVA) to develop a model for optimizing laser cladding parameters. This approach allows demonstrating an optimal combination of process parameters to obtain a high-quality microstructure with laser coating applied to Ti6Al4V. Lambiase et al. [

15] proposed a prediction method that can determine the temperature distribution profile based on laser hardening process parameters using an artificial neural network technique. The artificial neural network model allows for a better understanding of laser heating process behavior and the validation of simulated data. Bailey et al. [

16] carried out tests to optimize the laser hardening processes of industrial parts with complex geometries by developing a predictive model. Their approach can estimate the amount of heat generated during the process and transferred to the surface of a splined shaft. Thus, it can predict the hardness profile based on the heated area on the surface layer of parts. Babu et al. [

17] carried out experimental studies on the microstructure of low alloy steels wherein the durability after laser hardening is studied. Their approach allows optimizing the hardness profile of EN25 steel and obtaining a surface hardness twice as high as the core hardness by varying the laser power and sweeping speed. Lusquinos et al. [

18] carried out theoretical and experimental studies of laser heat treatment applied to 1045 steel using a high-power diode laser source. The results of their study demonstrate that obtaining a greater degree of hardness can be archived by maintaining a relatively constant surface temperature during the process.

Most of the previous research works were carried out on simple geometries. However, in this paper, we present a comprehensive set of experimental tests on a complex geometry of a splined shaft and present a statistical approach to evaluate the effect of the laser hardening process and geometrical parameters on the case depth of splines. To this end, the first step is to plan experimental tests by varying different parameters of laser hardening procedures and geometrical parameters of splines. The second step involves defining the variation range of each independent parameter. The third step consists of acquiring the experimental results and analyzing these data using ANOVA analysis [

19,

20]. The final step is dedicated to developing a reliable statistical model to estimate the case depth hardness of splines, according to their geometry.

This article is organized as follows.

Section 2 presents the experimental planning, the methodology, and a description of the proposed approach toward using statistical analysis to determine the effect of laser hardening parameters on splined shafts. Results of experimental tests as well as statistical and sensitivity analyses are presented in

Section 3. The paper ends with a conclusion and ideas for future works on this domain in

Section 4.

2. Methodology and Experimentations

The experimental tests presented in this article are carried out on AISI 4340 steel splines. The chemical composition of AISI 4340 Steel and its mechanical characteristics are given in

Table 1 and

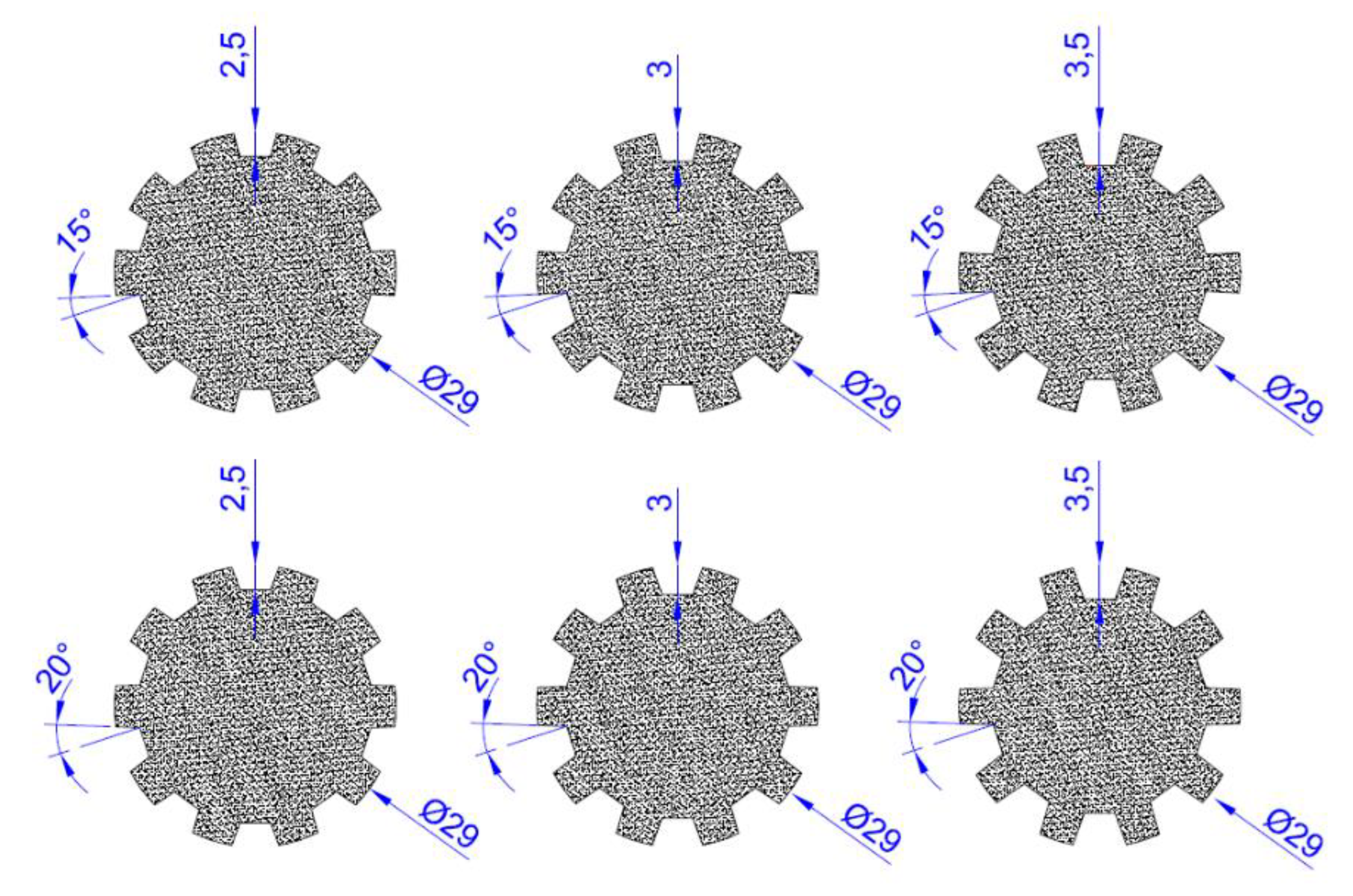

Table 2, respectively. The geometrical parameters of these splines, as shown in

Figure 1, consist of a diameter of 29 mm, flank tilt angles of 15° and 20°, and the tooth depth of splines, which varies in three different depths: 2.5, 3, and 3.5 mm.

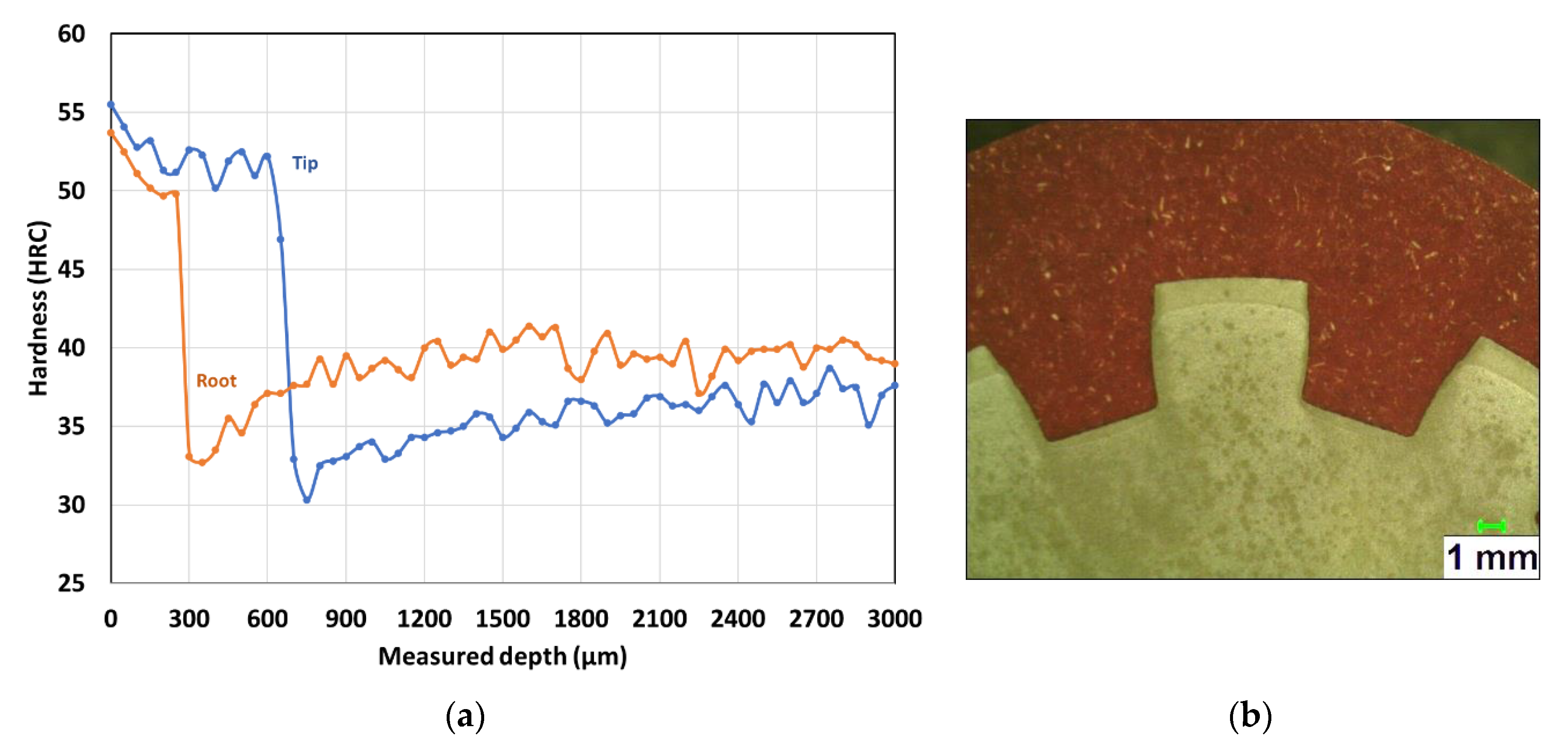

Before applying the laser hardening heat treatment, the spline shafts are quenched and tempered to achieve a uniform core hardness of approximately 45 HRC. The experimental laser hardening set-up, as illustrated in

Figure 2, is composed of a 3 kW fiber laser source and six degrees of freedom (DF) articulated FANUC robot, which supports the laser head. A rotating rig is also integrated into the experimental set-up, which provides a maximal rotation speed of 10,000 rpm. This experimental set-up is also equipped with a mixed mounting system, comprising central support with three jaws and a counter-head that moves along the z-axis. This mounting system allows centering the spline shafts during rotation. The laser spot is located in the median plane of splines, which are laser heat-treated. Following laser heat treatment, the samples are carefully prepared, polished, and etched using a Nital chemical solution (95% ethanol and 5% nitric acid). The hardness profiles are then characterized by micro-hardness measurements using a Clemex machine.

To evaluate the case depth at the tip and root of spline teeth, a series of experimental tests are carried out wherein the laser hardening process and splines’ geometrical parameters are varied. Adopting an experimental plan in which different parameters vary within their variation range, allow studying the effect of parameters on the case of depth. The efficiency and simplicity of factorial experiments make it the most commonly used model for choosing factor levels and the simultaneous mode of factor variation in order to study the effect of each factor on the process [

22]. In the case of laser hardening processes, it is important to define the experimental margins by allowing for minimal case depth transformation and excessive transformation. Maximal and minimal tuning is necessary before parameter levels can be established. The experimental strategy consists of investigating independent and controllable operational factors [

23]. The five factors that are used in these experiments are laser power (P), scanning speed (S), rotation speed (R), flank tilt angle (A), and tooth depth (D).

Table 3 shows the factors and their variation ranges in our experiments. Four factors with three variation levels were considered for laser power, scanning speed, rotation speed, and tooth depth. The remaining factor, flank tilt angle (A), had only two variation levels due to the non-availability of manufacturing tools. All the factors used in these experiments are continuous and interrelated. The average variation range of laser hardening parameters, which allows us to achieve an acceptable case depth in a laser heat treatment process that is determined as 2200 W, 4 mm/s, and 2000 rpm.

Each test consists of linear displacement of the spot in the spline’s medium plane. Using a micro-hardness measuring machine, the hardness of heat-treated splines is measured by examining their cross-section to determine the hardness profile (case depth). These results are then exploited using the contributions and average effects of each studied factor on the final response. To this end, the analysis of variance (ANOVA), a statistical model which analyzes the differences among group means in a sample, is used to determine the effect of each factor on the case hardening of splines. The percentage contribution of a single factor reflects the total variation observed in the experiments attributed to this factor and the interactions between factors [

24]. These analyses are then followed by performing a linear regression to obtain a mathematical model of case hardening as a function of independent variables and their interactions. This mathematical model can predict the case depth of spline shafts at the tip and root of splines’ teeth. Lastly, sensitivity analyses of case depths based on the response surfaces [

25] as a function of laser hardening process parameters is performed to obtain a more clear understanding of the estimated model responses. The sensitivity study is established to explore the effects of the laser hardening process parameters on the hardness profile. In fact, the response surfaces present contour plots of case depths at the tip and root of a splines’ tooth with respect to the variation of the process parameters.

In

Section 3, the results of case depth measurements are presented and supported with ANOVA analysis. These analyses allow evaluating the effect of laser treatment parameters on case depth. The predictive model of case depth at tip and root of spline shafts is then developed based on a linear regression method.

4. Conclusions

The effect of different parameters in a laser hardening process on the case depth of AISI 4340 steel splined shafts is studied in this article. Laser hardening is a heat treatment process that allows microstructural transformation on the surface layer of steel. This microstructural transformation generates martensite on the surface layer of AISI 4340 splines, which increases their surface hardness. This process, which is also known as case hardening, results in a hard and wear-resistant surface while maintaining a soft and ductile core. The study is based on developing experimental tests by varying the hardening process parameters as well as the geometry of splines. These tests are then analyzed using statistical approaches to define the effectiveness of each parameter on the case depth at the tip and root of splines’ tooth.

The influence of laser power, scanning speed, tooth depth, and flank tilt angle on the laser hardening process of spline shafts with different dimensions are studied and analyzed in this study. Performing experimental tests wherein test parameters are systematically varied and then using ANOVA analysis demonstrate that the case depth is mainly affected by the factors of laser power and scanning speed. These factors contribute to approximately 70% of case depth variability at the tip and root of splines’ tooth. In addition, a statistically estimated model of case depth at the tip and root of splines is proposed based on correlations between case depths and laser power, scanning speed, rotation speed, flank tilt angle, and tooth depth. These correlations estimate the case depth of splines with an accuracy in which the mean square error is less than 5%. The obtained results can be used to plan the modeling process and be served as a development guideline based on case depth predictions for AISI 4340 steel splines with studied geometries.

Even if the validation results of these predicted models are promising, they can be improved by performing additional tests outside the variation range of parameters presented in this study. This ensures the validation of our predictive models on a larger range of parameter variation. Applying an artificial neural network based on the results of these tests can also improve the estimation of predictive models. Lastly, a statistical approach based on validation and verification methods can be applied to evaluate quantitatively the precision of predictive models.