Influence of AlN and GaN Pulse Ratios in Thermal Atomic Layer Deposited AlGaN on the Electrical Properties of AlGaN/GaN Schottky Diodes

Abstract

:1. Introduction

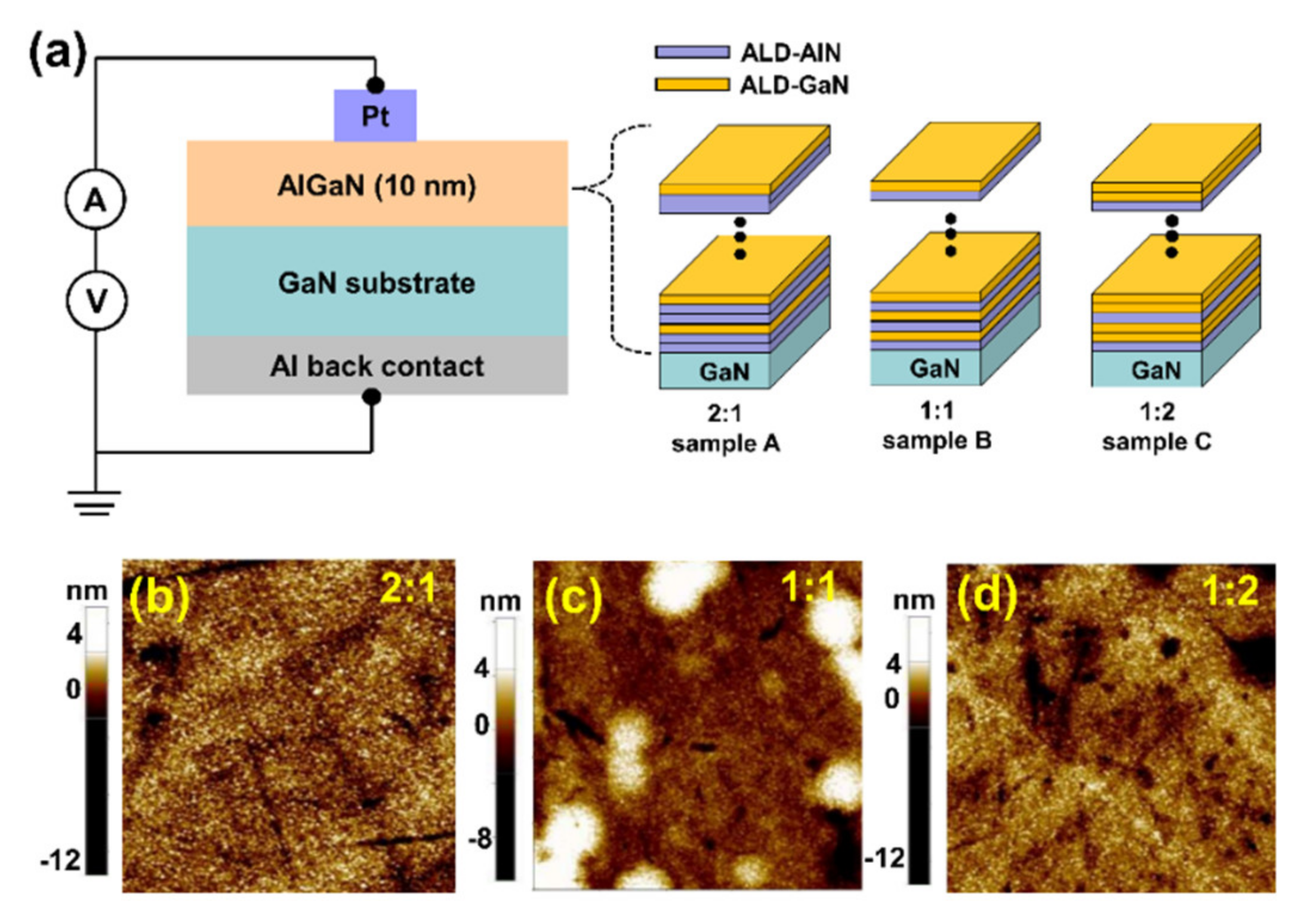

2. Materials and Methods

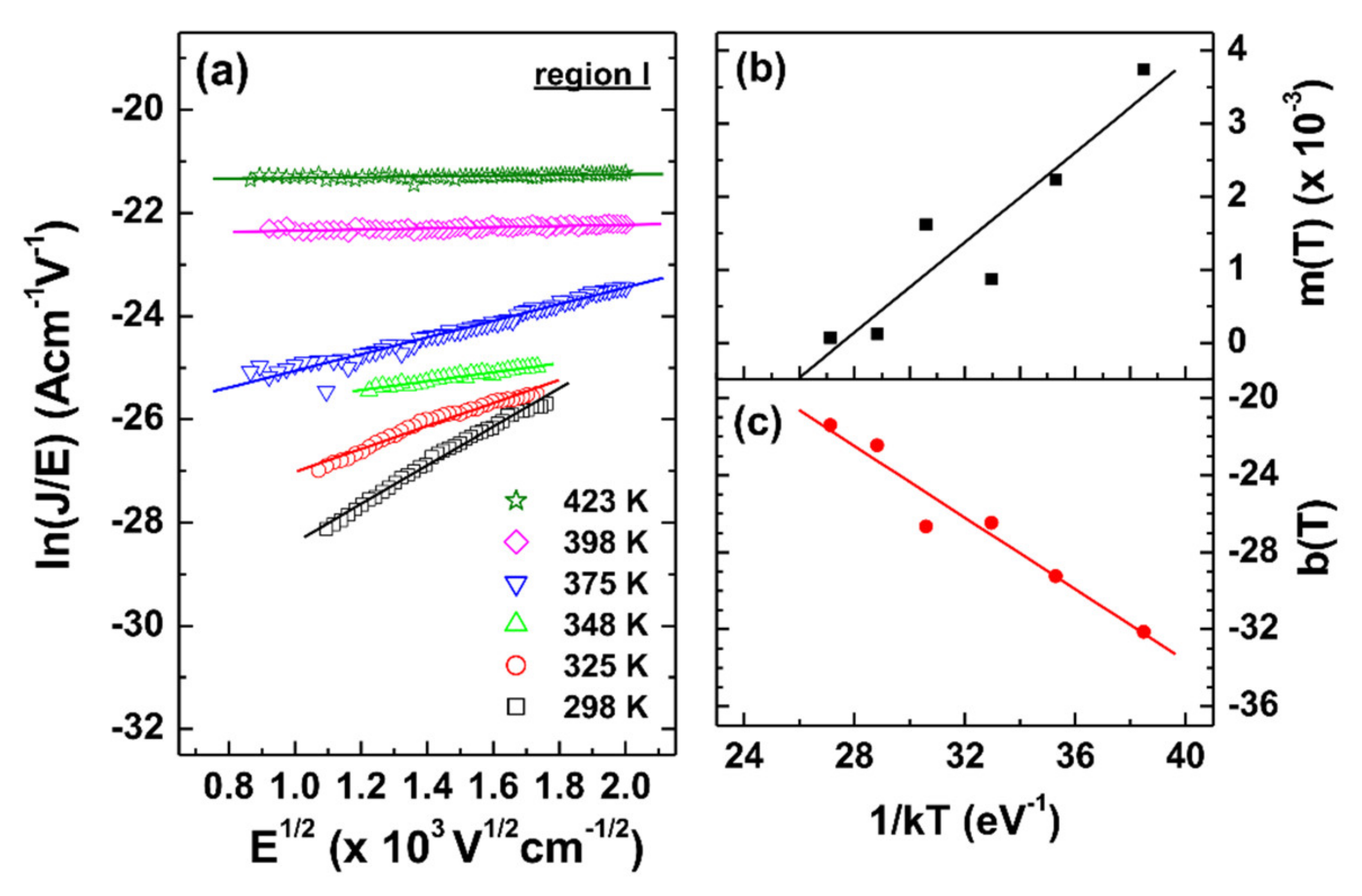

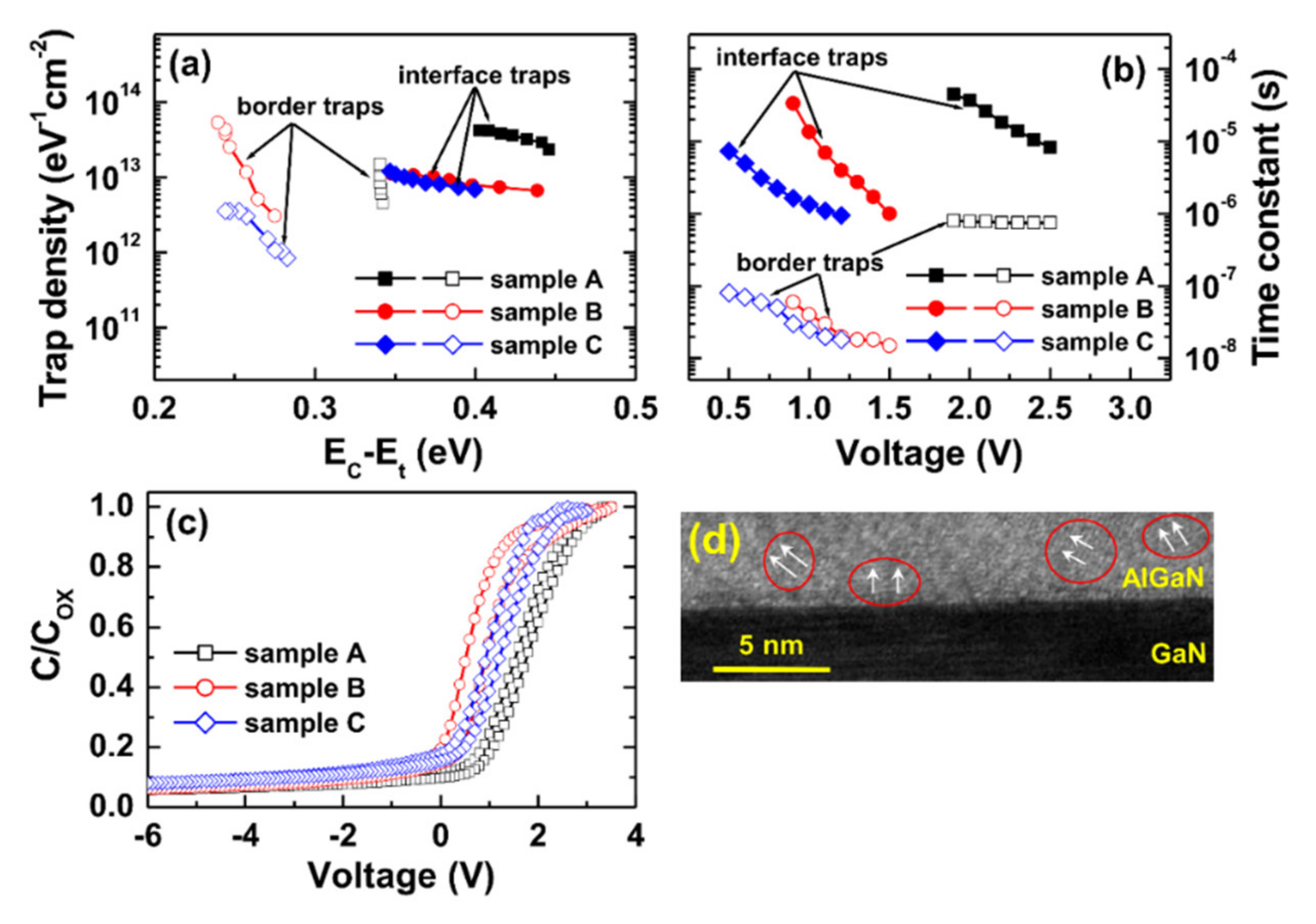

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Eastman, L.; Tilak, V.; Smart, J.; Green, B.; Chumbes, E.; Dimitrov, R.; Kim, H.; Ambacher, O.; Weimann, N.; Prunty, T.; et al. Undoped AlGaN/GaN HEMTs for microwave power amplification. IEEE Trans. Electron Dev. 2011, 48, 479–485. [Google Scholar] [CrossRef]

- Khandelwal, S.; Goyal, N.; Fjeldly, T. A physical-based analytical model for 2DEG charge density in AlGaN/GaN HEMT devices. IEEE Trans. Electron Dev. 2011, 58, 3622–3625. [Google Scholar] [CrossRef]

- Tan, W.; Uren, M.; Fry, P.; Houston, P.; Balmer, R.; Martin, T. High temperature performance of AlGaN/GaN HEMTs on Si substrates. Solid State Electron. 2006, 50, 511–513. [Google Scholar] [CrossRef]

- Wang, X.; Hu, G.; Ma, Z.; Ran, J.; Wang, C.; Xiao, H.; Tang, J.; Li, J.; Wang, J.; Zeng, Y.; et al. AlGaN/AlN/GaN/SiC HEMT structure with high mobility GaN thin layer as channel grown by MOCVD. J. Cryst. Growth 2007, 298, 835–839. [Google Scholar] [CrossRef]

- Higashiwaki, M.; Matsui, T.; Mimura, T. AlGaN/GaN MIS-HFETs with fT of 163 GHz using cat-CVD SiN gate-insulating and passivation layers. IEEE Electron Device Lett. 2006, 27, 6–18. [Google Scholar]

- Xia, L.; Hanson, A.; Boles, T.; Jin, D. On reverse gate leakage current of GaN high electron mobility transistors on silicon substrate. Appl. Phys. Lett. 2013, 102, 113510. [Google Scholar] [CrossRef]

- Turuvekere, S.; DasGupta, A.; DasGupta, N. Effect of barrier layer thickness on gate leakage current in AlGaN/GaN HEMTs. IEEE Trans. Electron Dev. 2015, 62, 3449–3452. [Google Scholar] [CrossRef]

- Swain, R.; Jena, K.; Lenka, T. Modeling of forward gate leakage current in MOSHEMT using trap-assisted tunneling and Poole-Frenkel emission. IEEE Trans. Electron Dev. 2012, 63, 2346–2352. [Google Scholar] [CrossRef]

- Fiorenza, P.; Greco, G.; Giannazzo, F.; Nigro, R.; Roccaforte, F. Poole-Frenkel emission in epitaxial nickel oxide on AlGaN/GaN heterostructures. Appl. Phys. Lett. 2012, 101, 172901. [Google Scholar] [CrossRef]

- Zhu, J.; Ma, X.; Hou, B.; Chen, W.; Hao, Y. Investigation of gate leakage mechanism in Al2O3/Al0.55Ga0.45N/GaN metal-oxide-semiconductor high-electron-mobility transistors. Appl. Phys. Lett. 2014, 104, 153510. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Z.; Luo, W. Analysis of reverse gate leakage mechanism of AlGaN/GaN HEMTs with N2 plasma surface treatment. Solid State Electron. 2018, 144, 60–66. [Google Scholar] [CrossRef]

- Xu, X.; Beling, C.; Fung, S.; Zhao, Y.; Sun, N.; Sun, T.; Zhang, Q.; Zhan, H.; Sun, B.; Wang, J.; et al. Formation mechanism of a degenerate thin layer at the interface of a GaN/sapphire system. Appl. Phys. Lett. 2000, 76, 152–154. [Google Scholar] [CrossRef] [Green Version]

- Ozgit, C.; Donmez, I.; Alevli, M.; Biyikli, N. Atomic layer deposition of GaN at low temperatures. J. Vac. Sci. Technol. A 2013, 30, 01A124. [Google Scholar] [CrossRef]

- Shih, H.; Lin, M.; Chen, L.; Chen, M. Uniform GaN thin films grown on (100) silicon by remote plasma atomic layer deposition. Nanotechnology 2015, 26, 014002. [Google Scholar] [CrossRef]

- Kim, H.; Kim, N.; An, S.; Yoon, H.; Choi, B. Improved interfacial properties of thermal atomic layer deposited AlN on GaN. Vacuum 2019, 159, 379–381. [Google Scholar] [CrossRef]

- Sadeghpour, S.; Ceyssens, F.; Puers, R. Crystalline growth of AlN thin films by atomic layer deposition. J. Phys. Conf. Ser. 2016, 757, 012003. [Google Scholar] [CrossRef]

- Rontu, V.; Sippola, P.; Broas, M.; Glenn, R.; Sajavaara, T.; Lipsanen, H.; Paulasto-Kröckel, M.; Franssila, S. Atomic layer deposition of AlN from AlCl3 using NH3 and Ar/NH3 plasma. J. Vac. Sci. Technol. A 2018, 36, 021508. [Google Scholar] [CrossRef] [Green Version]

- Ozgit-Akgun, C.; Goldenberg, E.; Okyay, A.; Biyikli, N. Hollow cathode plasma-assisted atomic layer deposition of crystalline AlN, GaN and AlxGa1−xN thin films at low temperatures. J. Mater. Chem. C 2014, 2, 2097–2284. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Yun, H.; Choi, S.; Choi, B. Atomic layer deposition of AlGaN on GaN and current transport mechanism in AlGaN/GaN Schottky diodes. Mater. Trans. 2020, 61, 88–93. [Google Scholar] [CrossRef]

- Tung, R. Recent advances in Schottky barrier concepts. Mater. Sci. Eng. R 2001, 35, 1–138. [Google Scholar] [CrossRef]

- Zhang, H.; Miller, E.; Yu, E. Analysis of leakage current mechanisms in Schottky contacts to GaN and Al0.25Ga0.75N∕GaN grown by molecular-beam epitaxy. J. Appl. Phys. 2006, 99, 023703. [Google Scholar] [CrossRef] [Green Version]

- Persano, A.; Pio, I.; Tasco, V.; Cuscun, M.; Passaseo, A.; Cola, A. Electrical properties of planar AlGaN/GaN Schottky diodes: Role of 2DEG and analysis of non-idealities. J. Appl. Phys. 2017, 121, 135701. [Google Scholar] [CrossRef]

- Hierro, A.; Arehart, A.; Heying, B.; Hansen, M.; Mishra, U.; DenBaars, S.; Speck, J.; Ringel, S. Impact of Ga/N flux ratio on trap states in n-GaN n-GaN grown by plasma-assisted molecular-beam epitaxy. Appl. Phys. Lett. 2002, 80, 805–807. [Google Scholar] [CrossRef]

- Fang, Z.; Farlow, G.; Claflin, B.; Look, D.; Green, D. Effects of electron-irradiation on electrical properties of AlGaN/GaN Schottky barrier diodes. J. Appl. Phys. 2009, 105, 123704. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Ng, G.; Arulkumaran, S.; Maung, Y.; Zho, H. Temperature-dependent forward gate current transport in atomic-layer-deposited Al2O3/AlGaN/GaN metal-insulator-semiconductor high electron mobility transistor. Appl. Phys. Lett. 2011, 98, 163501. [Google Scholar] [CrossRef]

- Jos, R. Reverse Schottky gate current in AlGaN-GaN high-electron-mobility-transistors. J. Appl. Phys. 2012, 112, 094508. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Liu, C.; Jiang, H.; Zou, X.; Zhang, A.; Lau, K. Ultralow reverse leakage current in AlGaN/GaN lateral Schottky barrier diodes grown on bulk GaN substrate. Appl. Phys. Exp. 2016, 9, 031001. [Google Scholar] [CrossRef] [Green Version]

- Saadaoui, S.; Salem, M.; Gassoumi, M.; Maaref, H.; Gaquière, C. Electrical characterization of (Ni/Au)/Al0.25Ga0.75N/GaN/SiC Schottky barrier diode. J. Appl. Phys. 2011, 110, 013701. [Google Scholar] [CrossRef]

- Weinstein, I.; Vokhmintsev, A.; Spiridonov, D. Thermoluminescence kinetics of oxygen-related centers in AlN single crystals. Diam. Relat. Mater. 2012, 25, 59. [Google Scholar] [CrossRef]

- Stampfl, C.; van de Walle, C. Theoretical investigation of native defects, impurities, and complexes in aluminum nitride. Phys. Rev. B 2002, 65, 1. [Google Scholar] [CrossRef] [Green Version]

- Tansley, T.; Egan, R. Point-defect energies in the nitrides of aluminum, gallium, and indium. Phys. Rev. B 1992, 45, 10942. [Google Scholar] [CrossRef] [PubMed]

- Sathaiya, D.; Karmalkar, S. Thermionic trap-assisted tunneling model and its application to leakage current in nitrided oxides and AlGaN∕GaN high electron mobility transistors. J. Appl. Phys. 2006, 99, 093701. [Google Scholar] [CrossRef]

- Liang, J.; Lai, L.; Zhou, Z.; Zhang, J.; Zhang, J.; Xu, J.; Zhang, Y.; Liu, X.; Luo, W. Trap-assisted tunneling current of ultrathin InAlN/GaN HEMTs on Si (1 1 1) substrate. Solid State Electron. 2019, 160, 107622. [Google Scholar] [CrossRef]

- Arulkumaran, S.; Egawa, T.; Ishikawa, H.; Jimbo, T. Temperature dependence of gate–leakage current in AlGaN/GaN high-electron-mobility transistors. Appl. Phys. Lett. 2013, 82, 3110–3112. [Google Scholar] [CrossRef]

- Suemitsu, T.; Tomizawa, M.; Enoki, T.; Ishii, Y. Enhancement of weak impact ionization in InAlAs/InGaAs HEMTs induced by surface traps: Simulation and experiments, IWCE-6, Computational Electronics. In Extended Abstracts of 1998 Sixth International Workshop; IEEE: Piscataway, NJ, USA, 1998; pp. 250–253. [Google Scholar]

- Arulkumaran, S.; Egawa, T.; Ishikawa, H. Studies on the influences of i-GaN, n-GaN, p-GaN and InGaN cap layers in AlGaN/GaN high-electron-mobility transistors. Jpn. J. Appl. Phys. 2005, 44, 2953–2960. [Google Scholar] [CrossRef]

- Srivastava, S.; Hwang, S.; Islam, M.; Balakrishnan, K.; Adivarahan, V.; Khan, A. Ohmic contact to high-aluminum-content AlGaN epilayers. J. Electron. Mater. 2009, 38, 2348. [Google Scholar] [CrossRef]

- Ambacher, O.; Smart, J.; Shealy, J.; Weimann, N.; Chu, K.; Murphy, M.; Schaff, W.; Eastman, L.; Dimitrov, R.; Wittmer, L.; et al. Two-dimensional electron gases induced by spontaneous and piezoelectric polarization charges in N- and Ga-face AlGaN/GaN heterostructures. J. Appl. Phys. 1999, 85, 3222–3233. [Google Scholar] [CrossRef] [Green Version]

- Silvestri, M.; Uren, M.; Kuball, M. Iron-induced deep-level acceptor center in GaN/AlGaN high electron mobility transistors: Energy level and cross section. Appl. Phys. Lett. 2013, 102, 073501. [Google Scholar] [CrossRef] [Green Version]

- Ma, X.; Zhu, J.; Liao, X.; Yue, T.; Chen, W.; Hao, Y. Quantitative characterization of interface traps in Al2O3/AlGaN/GaN metal-oxide-semiconductor high-electron-mobility transistors by dynamic capacitance dispersion technique. Appl. Phys. Lett. 2013, 103, 033510. [Google Scholar] [CrossRef]

- Zeng, H.; Hao, L.; Luo, W.; Liao, X.; Huang, W.; Lin, Y.; Li, Y. Trapping properties of LiNbO3/AlGaN/GaN metal-ferroelectric-semiconductor heterostructure characterized by temperature dependent conductance measurements. J. Appl. Phys. 2010, 107, 084508. [Google Scholar] [CrossRef]

- Kordoš, P.; Stoklas, R.; Gregušová, D.; Novák, J. Characterization of AlGaN/GaN metal-oxide-semiconductor field-effect transistors by frequency dependent conductance analysis. Appl. Phys. Lett. 2009, 94, 223512. [Google Scholar] [CrossRef]

- Lin, J.; Gomeniuk, Y.; Monaghan, S.; Povey, I.; Cherkaoui, K.; O’Connor, E.; Power, M.; Hurley, P. An investigation of capacitance-voltage hysteresis in metal/high-k/In0.53Ga0.47As metal-oxide-semiconductor capacitors. J. Appl. Phys. 2013, 114, 144105. [Google Scholar] [CrossRef] [Green Version]

- Sang, L.; Ren, B.; Liao, M.; Koide, Y.; Sumiya, M. Suppression in the electrical hysteresis by using CaF2 dielectric layer for p-GaN MIS capacitors. J. Appl. Phys. 2018, 123, 161423. [Google Scholar] [CrossRef]

- Kim, H.; Kwon, Y.; Choi, B. AlN passivation effect on Au/GaN Schottky contacts. Thin Solid Film. 2019, 670, 41–45. [Google Scholar] [CrossRef]

- Qin, X.; Dong, H.; Kim, J.; Wallace, R. A crystalline oxide passivation for Al2O3/AlGaN/GaN. Appl. Phys. Lett. 2014, 105, 141604. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Yoon, H.; Choi, B. Thickness dependence on interfacial and electrical properties in atomic layer deposited AlN on c-plane GaN. Nanoscale Res. Lett. 2008, 13, 232. [Google Scholar] [CrossRef] [Green Version]

- Bosund, M.; Sajavaara, T.; Laitinen, M.; Huhtio, T.; Putkonen, M.; Airaksinen, V.; Lipsanen, H. Properties of AlN grown by plasma enhanced atomic layer deposition. Appl. Surf. Sci. 2011, 257, 7827–7830. [Google Scholar] [CrossRef]

- Nguyen, H.; Tang, H.; Huang, W.; Lin, M. Mechanisms for reactions of trimethylaluminum with molecular oxygen and water. Comput. Theor. Chem. 2014, 1035, 39–43. [Google Scholar] [CrossRef]

- Lee, Y.; Kang, S. Growth of aluminum nitride thin films prepared by plasma-enhanced atomic layer deposition. Thin Solid Film. 2004, 446, 227. [Google Scholar] [CrossRef]

- Raja, L.; Nguyen, C.; Lee, C.; Balaji, N.; Chatterjee, S.; Jang, K.; Kim, H.; Yi, J. Improved data retention of InSnZnO nonvolatile memory by H2O2 treated Al2O3 tunneling layer: A cost-effective method. IEEE Electron Dev. Lett. 2016, 37, 1272. [Google Scholar] [CrossRef]

- Irokawa, Y. Hydrogen-induced change in the electrical properties of metal-insulator-semiconductor Pt–GaN diodes. J. Appl. Phys. 2010, 108, 094501. [Google Scholar] [CrossRef]

- Irokawa, Y.; Matsuki, N.; Sumiya, M.; Sakuma, Y.; Sekiguchi, T.; Chikyo, T.; Sumida, Y.; Nakano, Y. Anomalous capacitance-voltage characteristics of Pt-AlGaN/GaN Schottky diodes exposed to hydrogen. Phys. Status Solidi C 2010, 7, 1928. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Liu, Y.; Liao, X.; En, Y.; Fang, W.; Huang, Y. Effect of hydrogen on defects of AlGaN/GaN HEMTs characterized by low-frequency noise. IEEE Trans. Electron Dev. 2018, 65, 1321. [Google Scholar] [CrossRef]

- Hasegawa, H.; Inagaki, T.; Ootomo, S.; Hashizume, T. Mechanisms of current collapse and gate leakage currents in AlGaN/GaN heterostructure field effect transistors. J. Vac. Sci. Technol. B 2013, 21, 1844. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.; Choi, S.; Choi, B.J. Influence of AlN and GaN Pulse Ratios in Thermal Atomic Layer Deposited AlGaN on the Electrical Properties of AlGaN/GaN Schottky Diodes. Coatings 2020, 10, 489. https://doi.org/10.3390/coatings10050489

Kim H, Choi S, Choi BJ. Influence of AlN and GaN Pulse Ratios in Thermal Atomic Layer Deposited AlGaN on the Electrical Properties of AlGaN/GaN Schottky Diodes. Coatings. 2020; 10(5):489. https://doi.org/10.3390/coatings10050489

Chicago/Turabian StyleKim, Hogyoung, Seok Choi, and Byung Joon Choi. 2020. "Influence of AlN and GaN Pulse Ratios in Thermal Atomic Layer Deposited AlGaN on the Electrical Properties of AlGaN/GaN Schottky Diodes" Coatings 10, no. 5: 489. https://doi.org/10.3390/coatings10050489

APA StyleKim, H., Choi, S., & Choi, B. J. (2020). Influence of AlN and GaN Pulse Ratios in Thermal Atomic Layer Deposited AlGaN on the Electrical Properties of AlGaN/GaN Schottky Diodes. Coatings, 10(5), 489. https://doi.org/10.3390/coatings10050489