Mechanical Investigations of ASTM A36 Welded Steels with Stainless Steel Cladding

Abstract

:1. Introduction

2. Materials and Methods

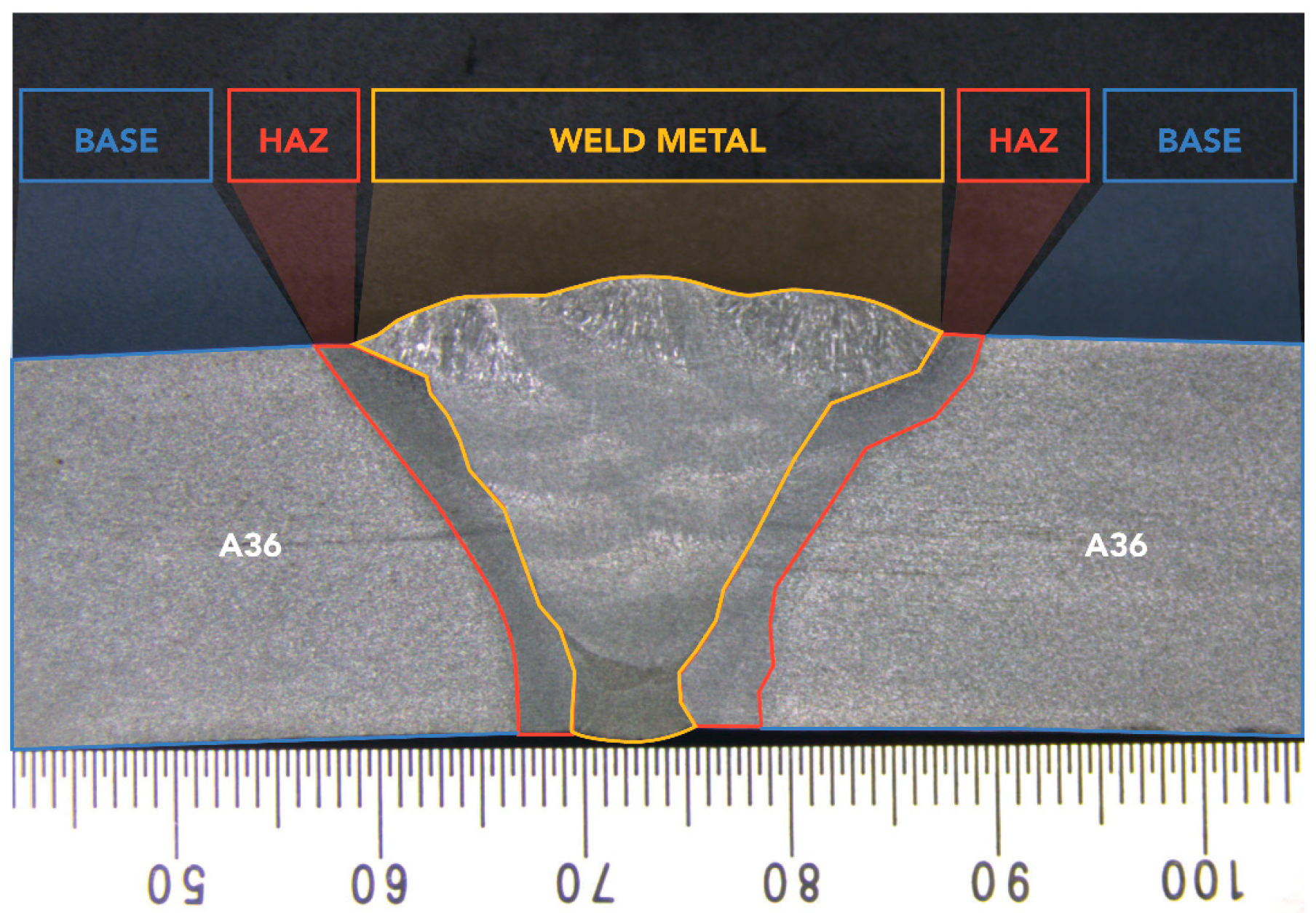

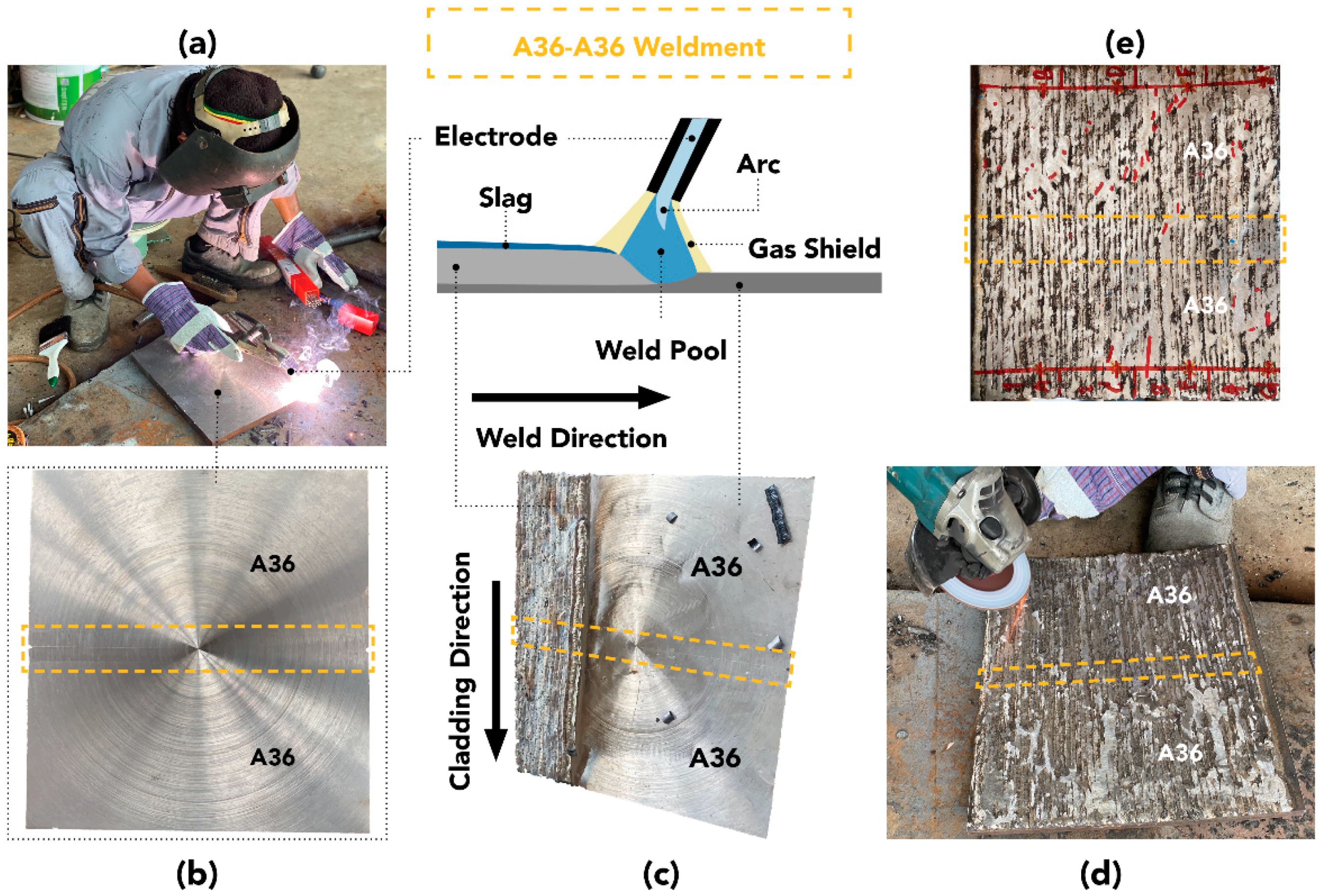

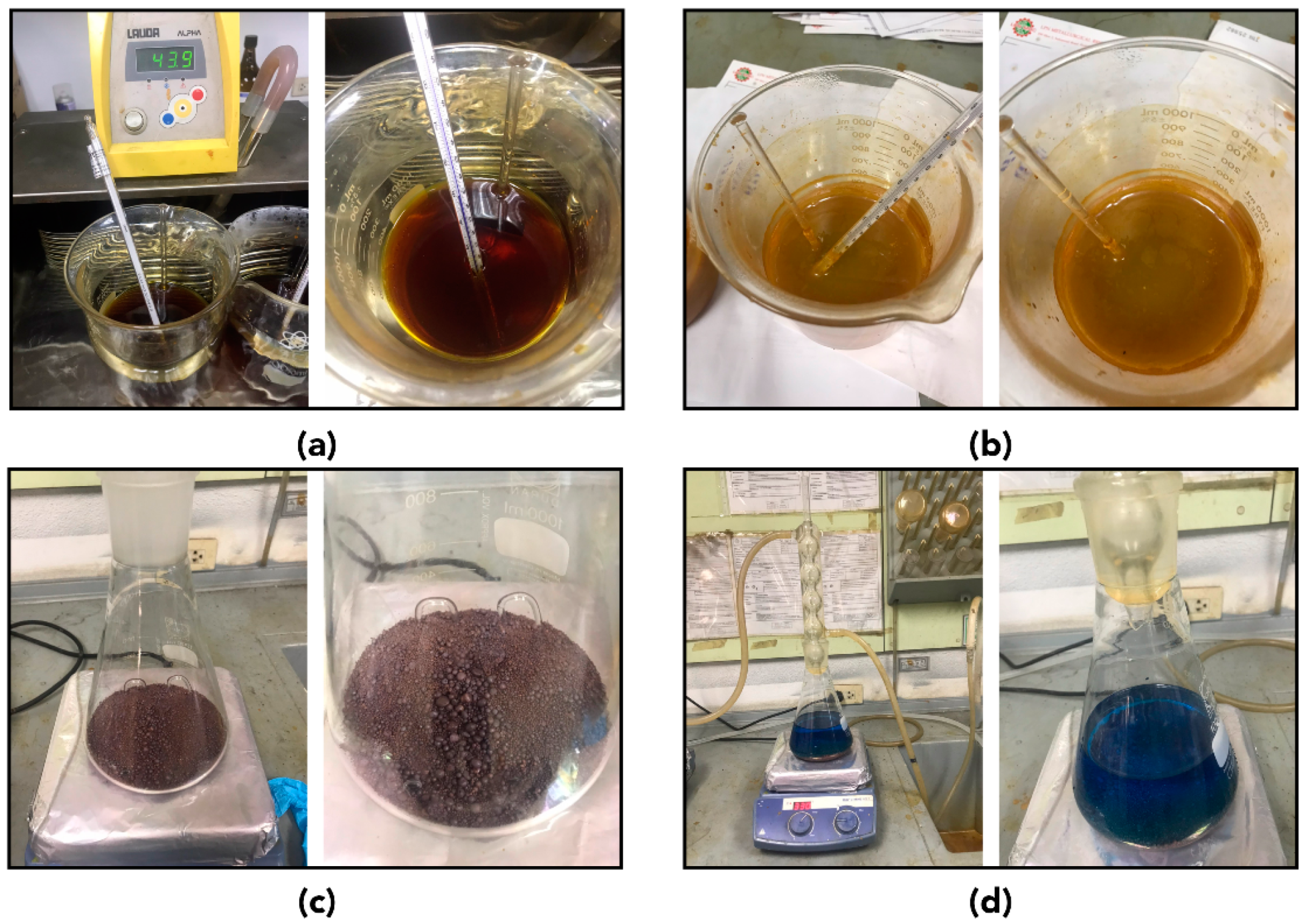

2.1. Weld Materials Preparation

2.2. Cladding Process and Residual Stress Measurements

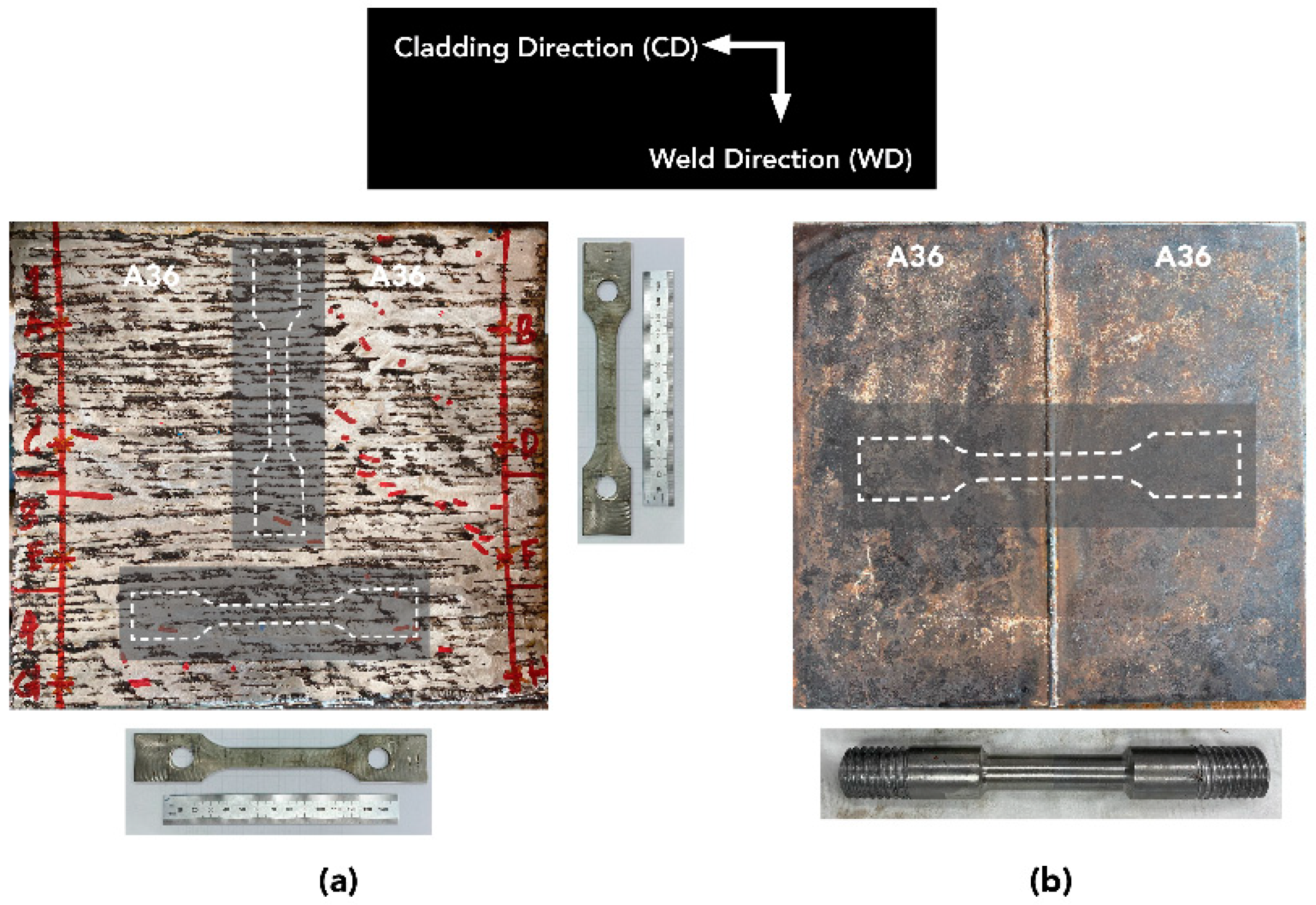

2.3. Tensile Tests

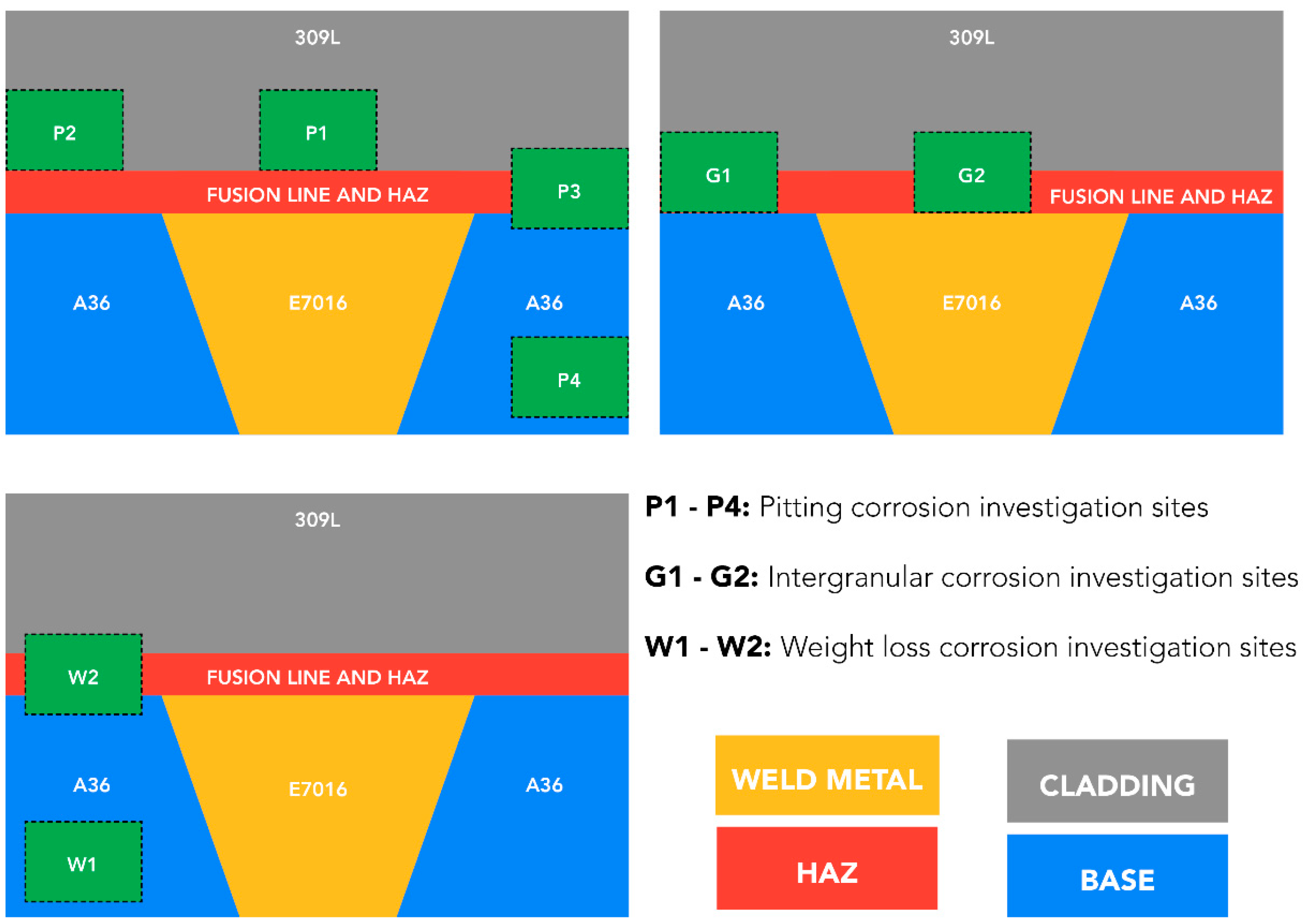

2.4. Corrosion Tests

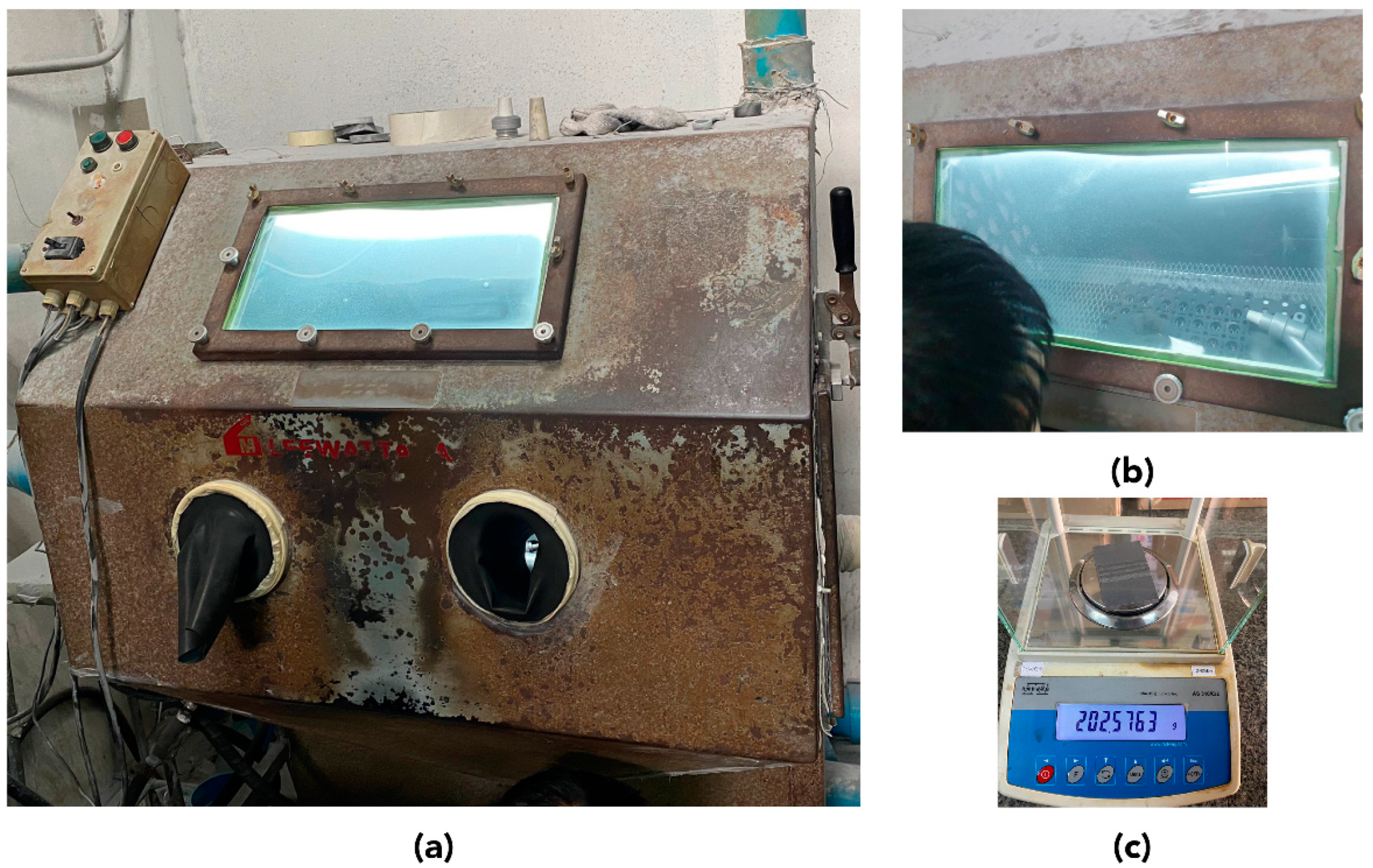

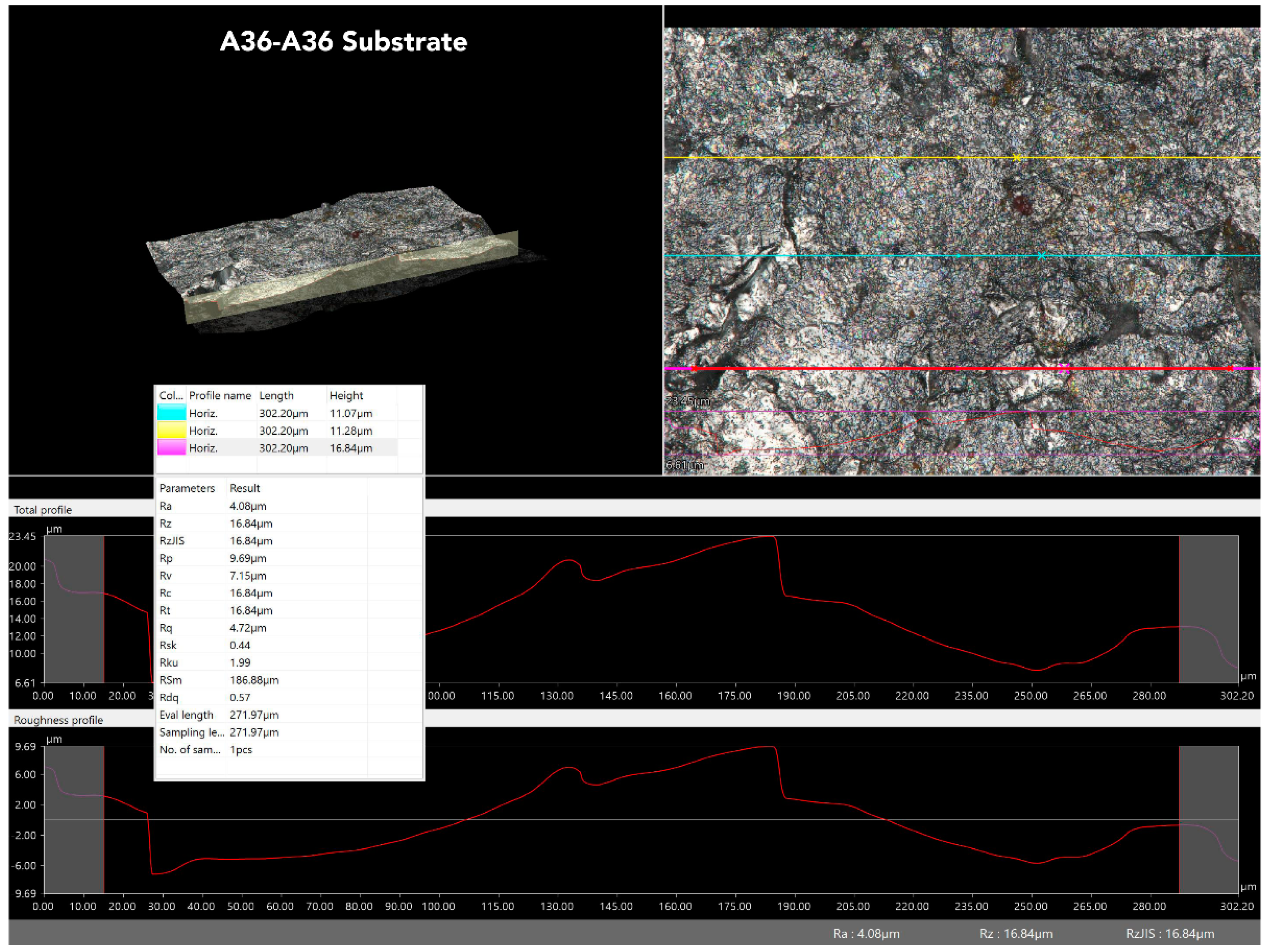

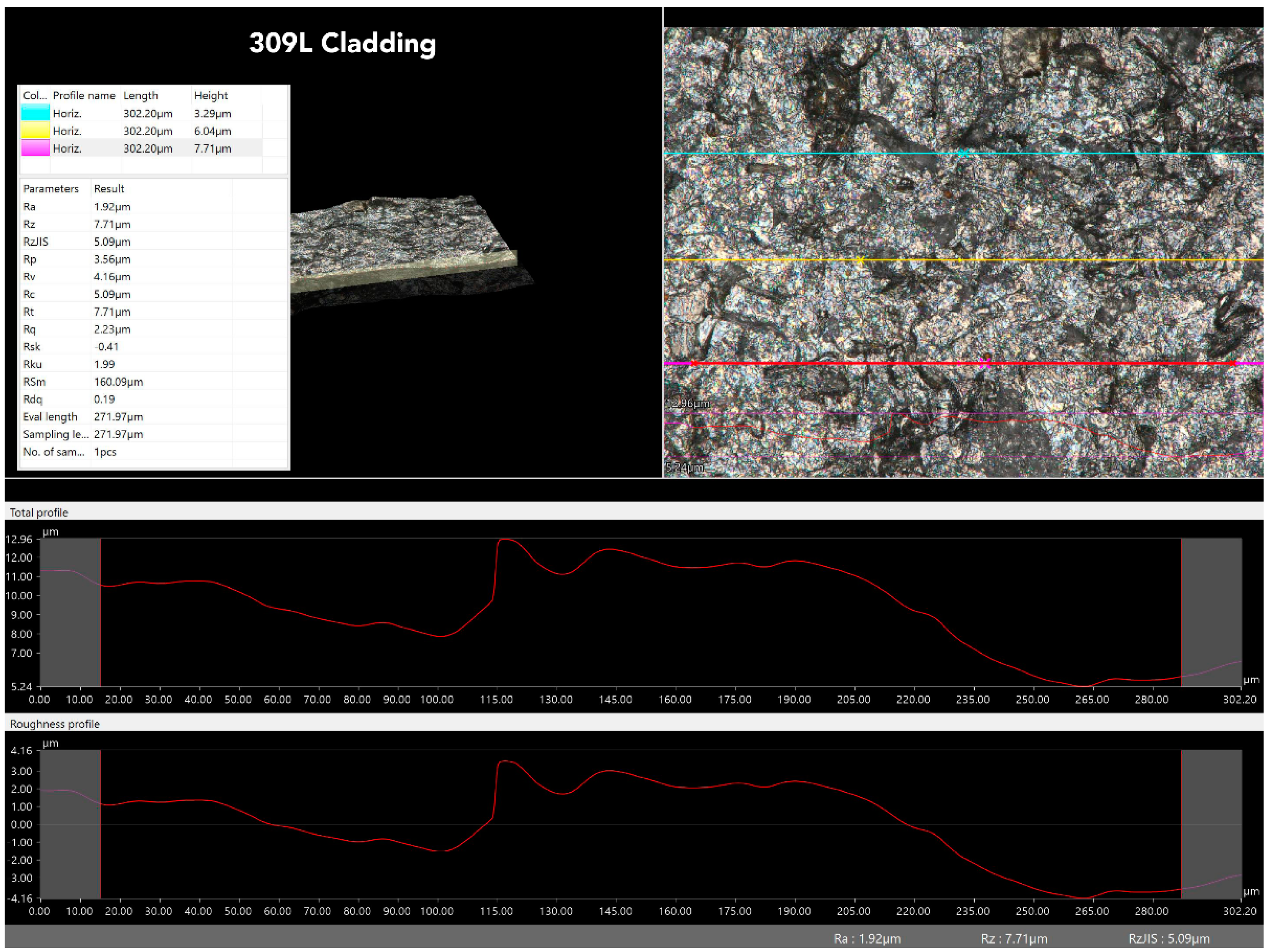

2.5. Wear Tests

3. Results

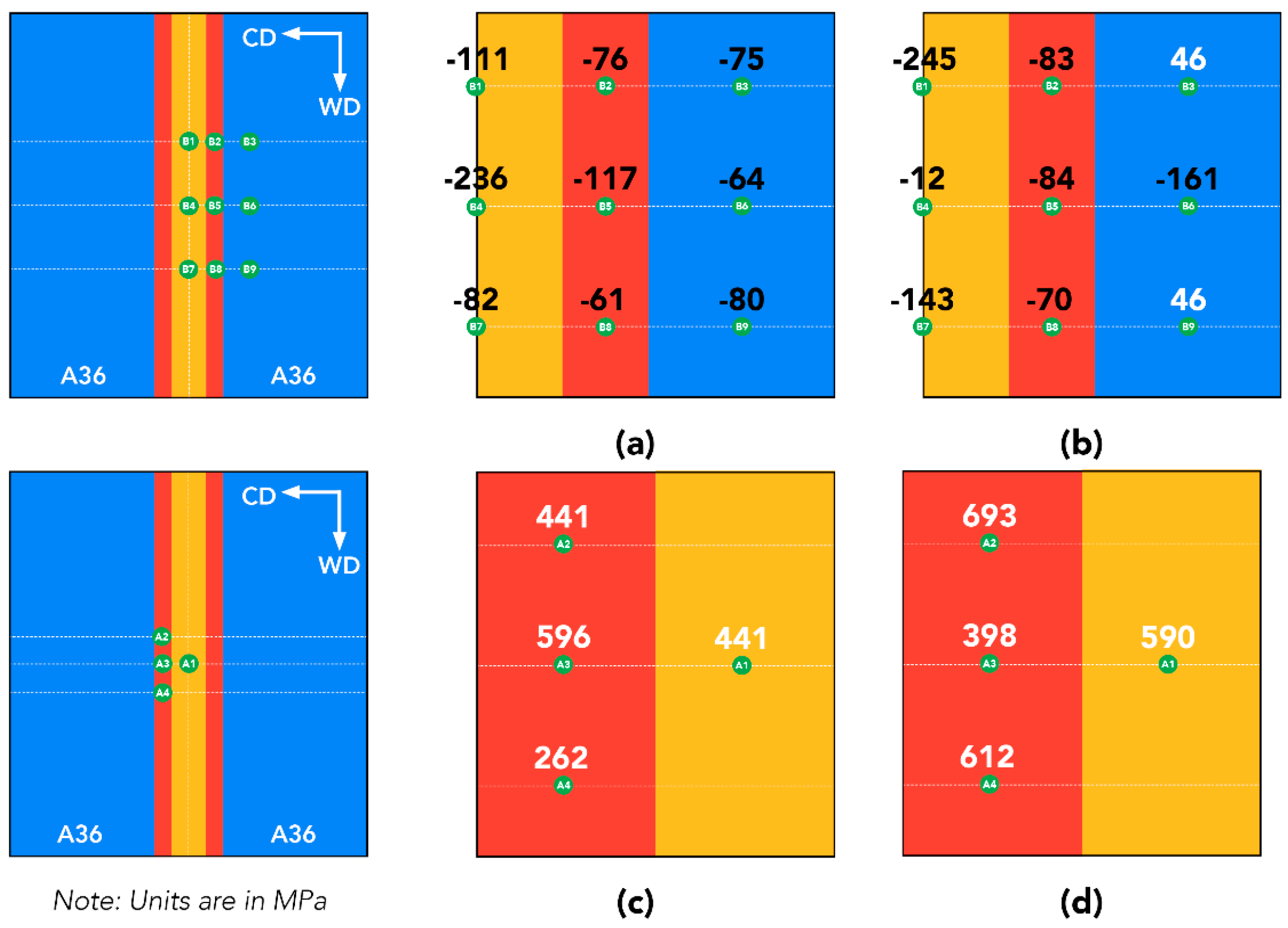

3.1. Residual Stress Measurement Results

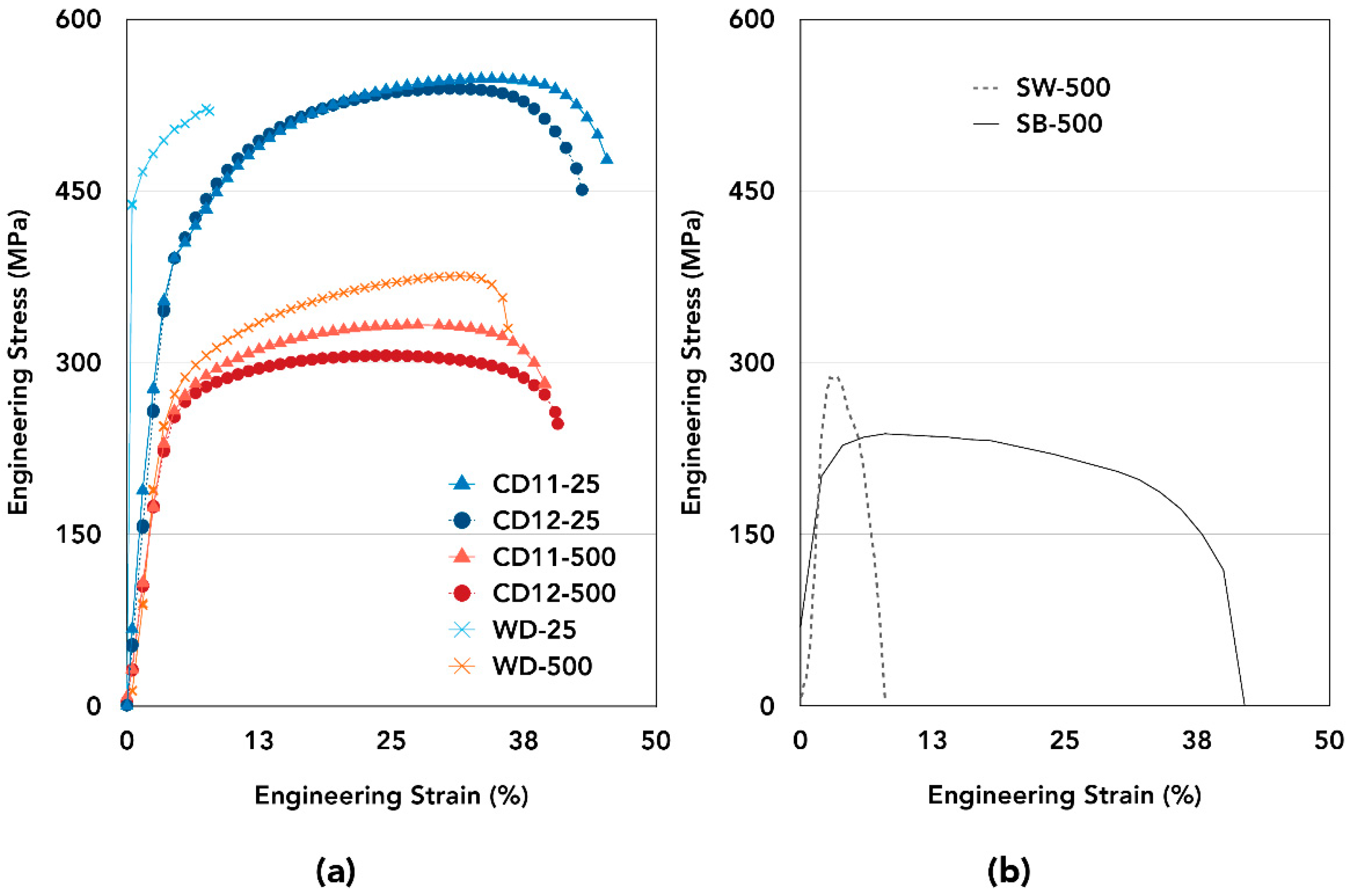

3.2. Tensile Testing Results

3.3. Corrosion Testing Results

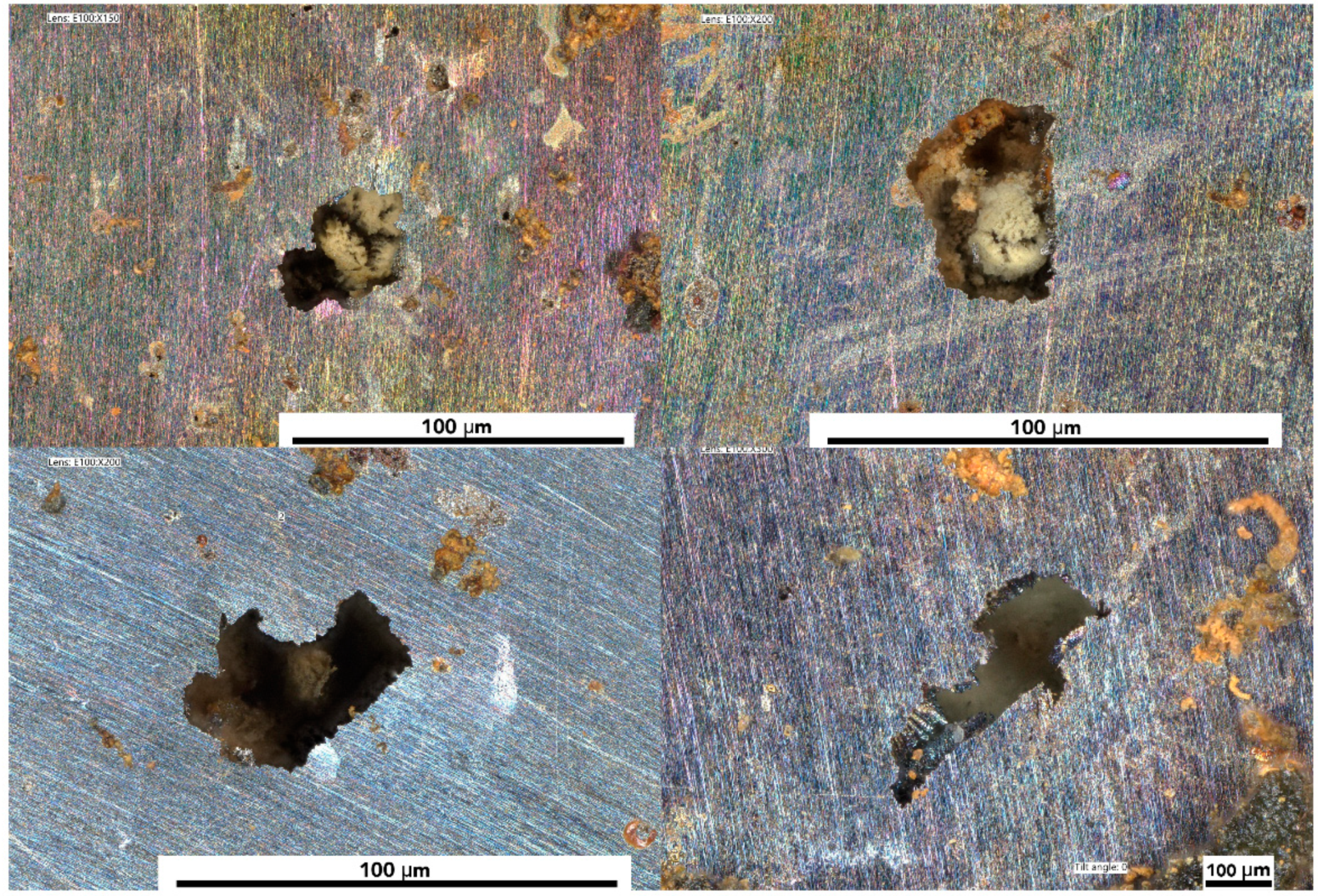

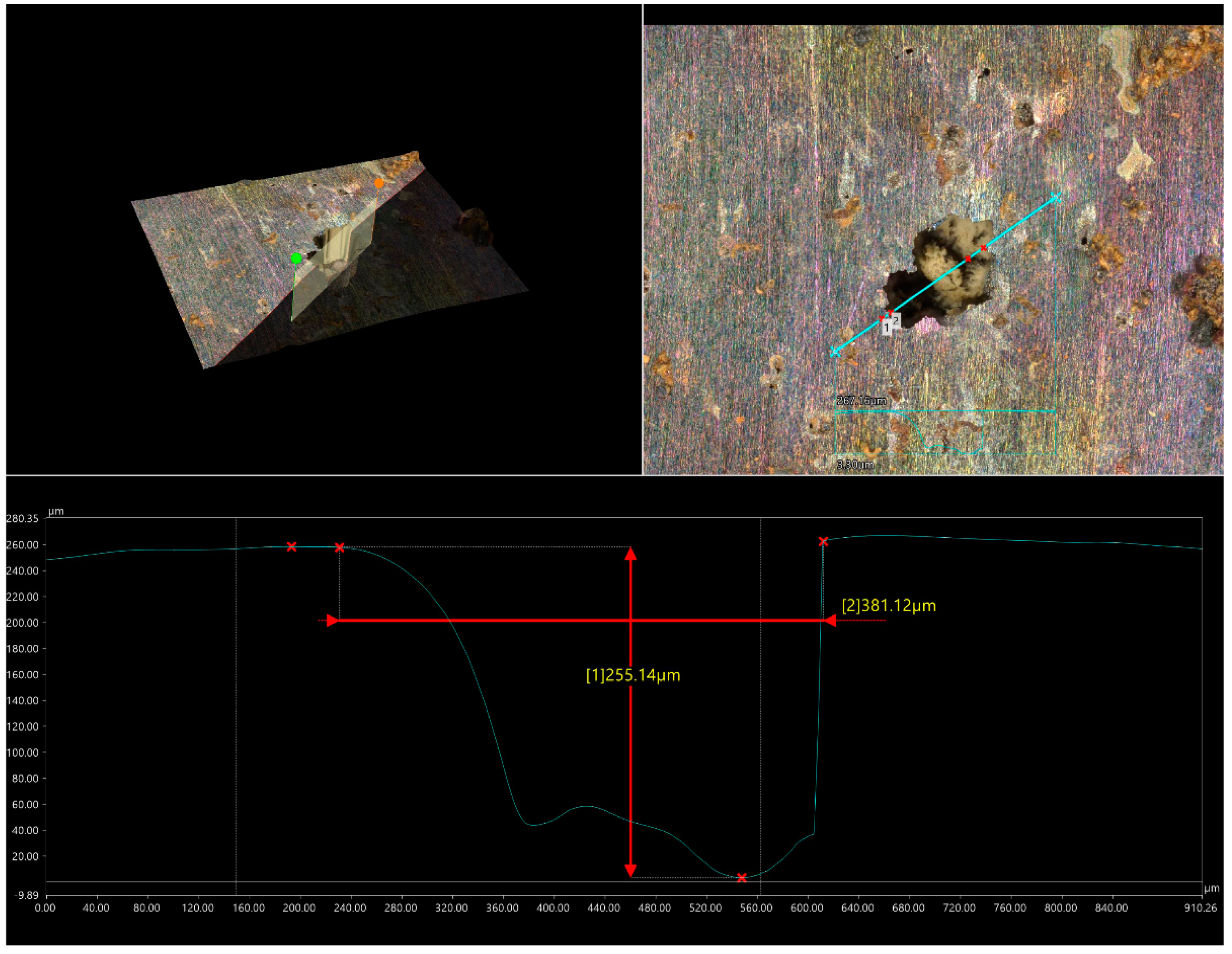

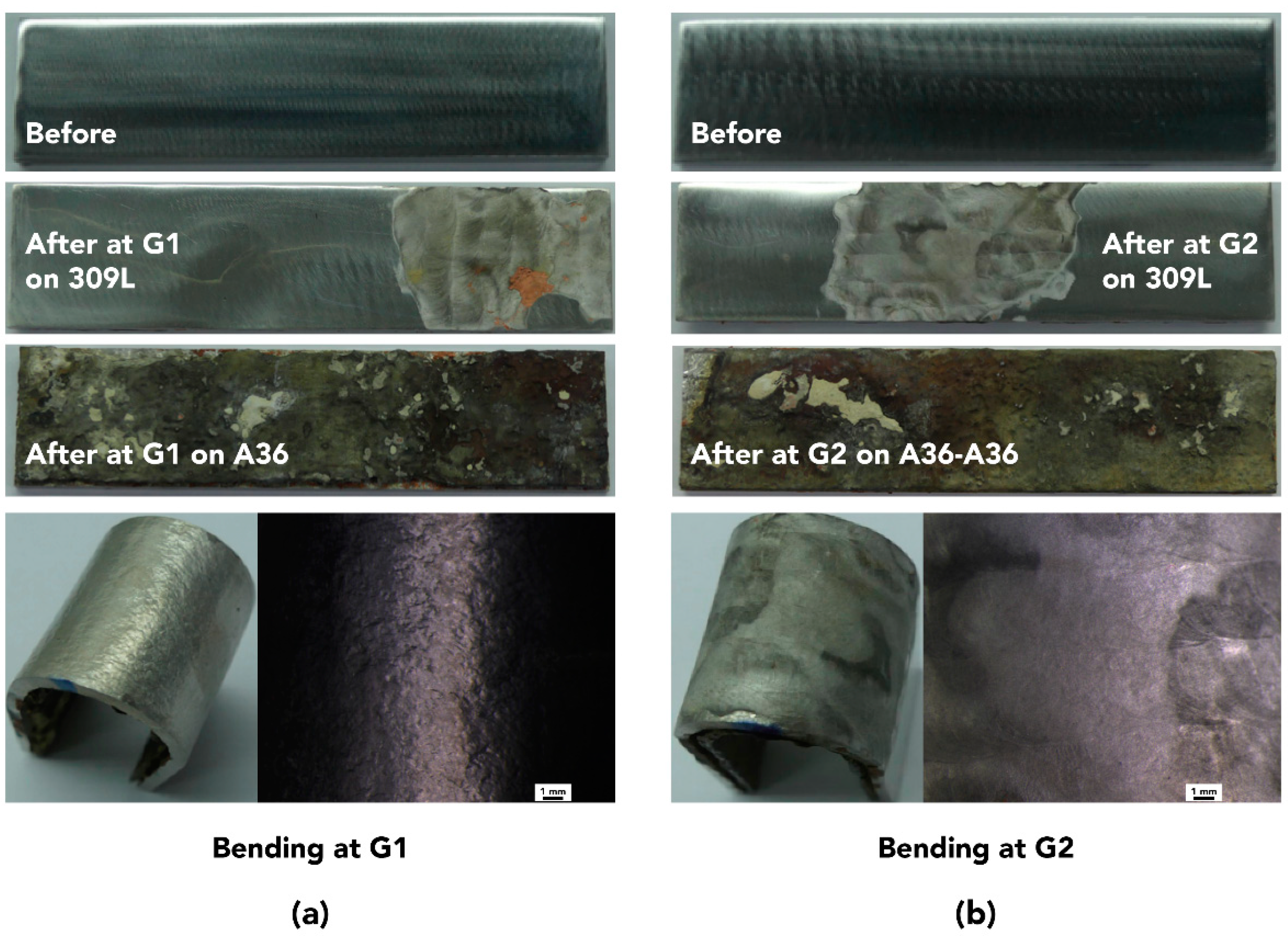

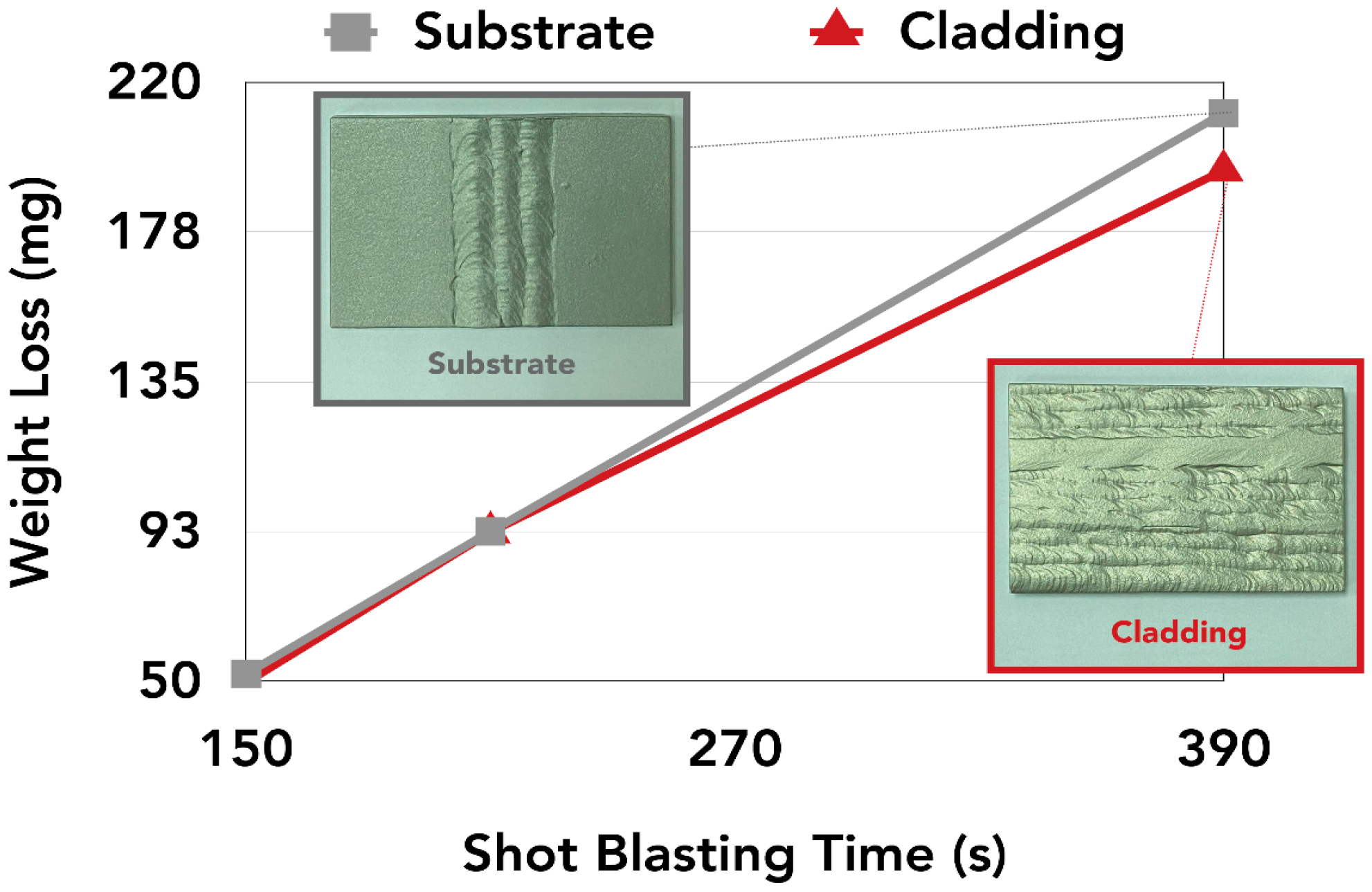

3.4. Wear Testing Results

4. Discussion

5. Conclusions

- The high compressive stress locations were mainly found in the Weld Metal and HAZ zones in the center area of the cladding surface. However, the overall stress distribution was considered typical and would not lead to lower fatigue resistance.

- The increased tensile strength of 16% at 500 °C could be obtained by cladding 309L stainless steel on the A36—A36 welded plate.

- No pitting and intergranular corrosions could be observed on A36 base material if coated with 309L stainless steel cladding. Also, the cladding layer improved weight loss corrosion by 24%.

- The 309L stainless steel cladding provided less volume loss of 9% compared to that of the A36—A36 welded plate with no coating under the shot blasting wear tests.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- ASTM International. ASTM A36/A36M-19, Standard Specification for Carbon Structural Steel; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Chen, H.; Pan, P.; Wang, Y.; Zhao, Q. Field study on the corrosion and ash deposition of low-temperature heating surface in a large-scale coal-fired power plant. Fuel 2017, 208, 149–159. [Google Scholar] [CrossRef]

- Chen, H.; Pan, P.; Shao, H.; Wang, Y.; Zhao, Q. Corrosion and viscous ash deposition of a rotary air preheater in a coal-fired power plant. Appl. Therm. Eng. 2017, 113, 373–385. [Google Scholar] [CrossRef]

- McEvily, A.J. Atlas of Stress-Corrosion and Corrosion Fatigue Curves; ASM International: West Conshohocken, PA, USA, 1990. [Google Scholar]

- Hussain, T.; Syed, A.U.; Simms, N.J. Trends in fireside corrosion damage to superheaters in air and oxy-firing of coal/biomass. Fuel 2013, 113, 787–797. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Kumar, M.; Handa, A. Combating hot corrosion of boiler tubes—A study. Eng. Fail. Anal. 2018, 94, 379–395. [Google Scholar] [CrossRef]

- Rahman Rashid, R.A.; Abaspour, S.; Palanisamy, S.; Matthews, N.; Dargusch, M.S. Metallurgical and geometrical characterisation of the 316L stainless steel clad deposited on a mild steel substrate. Surf. Coat. Technol. 2017, 327, 174–184. [Google Scholar] [CrossRef]

- Chen, C.X.; Liu, M.Y.; Liu, B.X.; Yin, F.X.; Dong, Y.C.; Zhang, X.; Zhang, F.Y.; Zhang, Y.G. Tensile shear sample design and interfacial shear strength of stainless steel clad plate. Fusion Eng. Des. 2017, 125, 431–441. [Google Scholar] [CrossRef]

- Liu, B.X.; Wang, S.; Fang, W.; Ma, J.L.; Yin, F.X.; He, J.N.; Feng, J.H.; Chen, C.X. Microstructure and mechanical properties of hot rolled stainless steel clad plate by heat treatment. Mater. Chem. Phys. 2018, 216, 460–467. [Google Scholar] [CrossRef]

- Kono, D.; Maruhashi, A.; Yamaji, I.; Oda, Y.; Mori, M. Effects of cladding path on workpiece geometry and impact toughness in Directed Energy Deposition of 316L stainless steel. CIRP Ann. 2018, 67, 233–236. [Google Scholar] [CrossRef]

- Farias, F.W.C.; Filho, J.C.P.; de Azevedo, L.M.B. Microstructural and mechanical characterization of the transition zone of 9% Ni steel cladded with Ni-based superalloy 625 by GTAW-HW. Metals 2018, 8, 1007. [Google Scholar] [CrossRef] [Green Version]

- Xue, J.; Bouchard, J.; Chen, X.; Fan, Z.; Zhou, Y. Anisotropic elastic constants calculation of stainless steel cladded layers of pressure vessel steel plate. Int. J. Press. Vessel. Pip. 2019, 177, 103991. [Google Scholar] [CrossRef]

- Li, C.A.; Qin, G.; Tang, Y.; Zhang, B.; Lin, S.; Geng, P. Microstructures and mechanical properties of stainless steel clad plate joint with diverse filler metals. J. Mater. Res. Technol. 2020, 9, 2522–2534. [Google Scholar] [CrossRef]

- Ban, H.; Zhu, J.; Shi, G. Cyclic loading tests on welded connections of stainless-clad bimetallic steel and modelling. J. Constr. Steel Res. 2020, 171, 106140. [Google Scholar] [CrossRef]

- Ban, H.; Bai, R.; Chung, K.-F.; Bai, Y. Post-fire material properties of stainless-clad bimetallic steel. Fire Saf. J. 2020, 112, 102964. [Google Scholar] [CrossRef]

- Kim, Y.; Nam, H.; Lee, J.; Park, C.; Moon, B.; Nam, D.-G.; Lee, S.H.; Kang, N. Hot-cracking resistivity of dissimilar clads using Inconel 52 and 308L stainless steel on carbon steel. J. Nucl. Mater. 2020, 533, 152103. [Google Scholar] [CrossRef]

- Gomes, J.H.F.; Paiva, A.P.; Costa, S.C.; Balestrassi, P.P.; Paiva, E.J. Weighted multivariate mean square error for processes optimization: A case study on flux-cored arc welding for stainless steel claddings. Eur. J. Oper. Res. 2013, 226, 522–535. [Google Scholar] [CrossRef]

- Kumar, G.S.; Saravanan, S.; Balan, A.V.; Oscar, J.; Ragunath, R.; Ramesh, M. Influence of FCAW process parameters in super duplex stainless steel claddings. Mater. Today Proc. 2020, 21, 63–65. [Google Scholar] [CrossRef]

- Eghlimi, A.; Shamanian, M.; Raeissi, K. Effect of current type on microstructure and corrosion resistance of super duplex stainless steel claddings produced by the gas tungsten arc welding process. Surf. Coat. Technol. 2014, 244, 45–51. [Google Scholar] [CrossRef]

- Shihab, S.K.; Mohamed, R.H.; Mubarek, E.M. Optimization of process parameters in cladding of stainless steel over mild steel. Mater. Today Proc. 2019, 16, 816–823. [Google Scholar] [CrossRef]

- Singhal, T.S.; Jain, J.K. GMAW cladding on metals to impart anti-corrosiveness: Machine, processes and materials. Mater. Today Proc. 2020, 26, 2432–2441. [Google Scholar] [CrossRef]

- Padhiar, S.A.; Vincent, S. Effect of hard facing processes on mild steel A-36 by arc welding. Mater. Today Proc. 2020, 28, 526–531. [Google Scholar] [CrossRef]

- Kang, K.; Kawahito, Y.; Gao, M.; Zeng, X. Effects of laser-arc distance on corrosion behavior of single-pass hybrid welded stainless clad steel plate. Mater. Des. 2017, 123, 80–88. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Shoja-Razavi, R.; Abdollah-Pour, H.; Mohammadian-Semnani, H. Influence of using electroless Ni–P coated WC–Co powder on laser cladding of stainless steel. Surf. Coat. Technol. 2018, 348, 41–54. [Google Scholar] [CrossRef]

- Murkute, P.; Pasebani, S.; Isgor, O.B. Production of corrosion-resistant 316L stainless steel clads on carbon steel using powder bed fusion-selective laser melting. J. Mater. Process. Technol. 2019, 273, 116243. [Google Scholar] [CrossRef]

- Segura, I.A.; Murr, L.E.; Terrazas, C.A.; Bermudez, D.; Mireles, J.; Injeti, V.S.V.; Li, K.; Yu, B.; Misra, R.D.K.; Wicker, R.B. Grain boundary and microstructure engineering of Inconel 690 cladding on stainless-steel 316L using electron-beam powder bed fusion additive manufacturing. J. Mater. Sci. Technol. 2019, 35, 351–367. [Google Scholar] [CrossRef]

- Li, G.; Gan, Y.; Liu, C.; Shi, Y.; Zhao, Y.; Kou, S. Corrosion and wear resistance of Fe-based amorphous coatings. Coatings 2020, 10, 73. [Google Scholar] [CrossRef] [Green Version]

- Yu, J.; Sun, W.; Huang, H.; Huang, Y. Study on the deformation control and microstructures of thin-walled parts repaired by laser cladding. Coatings 2020, 10, 369. [Google Scholar] [CrossRef] [Green Version]

- Li, B.; Zhu, H.; Qiu, C.; Gong, X. Laser cladding and in-situ nitriding of martensitic stainless steel coating with striking performance. Mater. Lett. 2020, 259, 126829. [Google Scholar] [CrossRef]

- Mahmoud, E.R.I.; Khan, S.Z.; Ejaz, M. Laser surface cladding of mild steel with 316L stainless steel for anti-corrosion applications. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Liu, B.X.; Wang, S.; Fang, W.; Yin, F.X.; Chen, C.X. Meso and microscale clad interface characteristics of hot-rolled stainless steel clad plate. Mater. Charact. 2019, 148, 17–25. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Liu, J.; Chen, Y.; Zhang, F.; Wu, L.; Hao, J.; Liu, L. Microstructure evolution and properties of laser cladding CoCrFeNiTiAlx high-entropy alloy coatings. Coatings 2020, 10, 373. [Google Scholar] [CrossRef] [Green Version]

- Li, B.C.; Zhu, H.M.; Qiu, C.J.; Zhang, D.K. Development of high strength and ductile martensitic stainless steel coatings with Nb addition fabricated by laser cladding. J. Alloys Compd. 2020, 832, 154985. [Google Scholar] [CrossRef]

- Moskal, G.; Niemiec, D.; Chmiela, B.; Kałamarz, P.; Durejko, T.; Ziętala, M.; Czujko, T. Microstructural characterization of laser-cladded NiCrAlY coatings on Inconel 625 Ni-based superalloy and 316L stainless steel. Surf. Coat. Technol. 2020, 387, 125317. [Google Scholar] [CrossRef]

- Shen, F.; Tao, W.; Li, L.; Zhou, Y.; Wang, W.; Wang, S. Effect of microstructure on the corrosion resistance of coatings by extreme high speed laser cladding. Appl. Surf. Sci. 2020, 517, 146085. [Google Scholar] [CrossRef]

- Venkatesh, B.; Sriker, K.; Prabhakar, V.S.V. Wear characteristics of hard facing alloys: State-of-the-art. Procedia Mater. Sci. 2015, 10, 527–532. [Google Scholar] [CrossRef] [Green Version]

- Shi, Q.; Zhu, H.; Li, C. The effects of the addition of Ti3SiC2 on the microstructure and properties of laser cladding composite coatings. Coatings 2020, 10, 498. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, W.; Peng, Y.; Zhang, M.; Liu, S.; Liu, Y. Microstructures and wear resistance of FeCoCrNi-Mo high entropy alloy/diamond composite coatings by high speed laser cladding. Coatings 2020, 10, 300. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Li, M.; Wang, S.; Chi, J.; Ren, L.; Fang, M.; Zhou, C. Enhanced wear resistance and new insight into microstructure evolution of in-situ (Ti,Nb)C reinforced 316 L stainless steel matrix prepared via laser cladding. Opt. Lasers Eng. 2020, 128, 106043. [Google Scholar] [CrossRef]

- Singh, J.; Thakur, L.; Angra, S. An investigation on the parameter optimization and abrasive wear behaviour of nanostructured WC–10Co–4Cr TIG weld cladding. Surf. Coat. Technol. 2020, 386, 125474. [Google Scholar] [CrossRef]

- Singh, J.; Thakur, L.; Angra, S. Abrasive wear behavior of WC–10Co–4Cr cladding deposited by TIG welding process. Int. J. Refract. Met. Hard Mater. 2020, 88, 105198. [Google Scholar] [CrossRef]

- Singh, J.; Singh Chatha, S.; Singh Sidhu, B. Effect of surface alloying on wear behaviour of En-47 steel. Mater. Today Proc. 2020, 21, 1340–1349. [Google Scholar] [CrossRef]

- Sekhar, B.R.; Nayak, R.K.; Rout, S.R.; Masanta, M. Wear characteristic of TiC coated AISI 1020 mild steel fabricated by TIG cladding method. Mater. Today Proc. 2020, 26, 3288–3291. [Google Scholar] [CrossRef]

- Labiapari, W.S.; Ardila, M.A.N.; Costa, H.L.; de Mello, J.D.B. Micro abrasion-corrosion of ferritic stainless steels. Wear 2017, 376–377, 1298–1306. [Google Scholar] [CrossRef]

- Zhang, Z.; Kovacevic, R. Laser cladding of iron-based erosion resistant metal matrix composites. J. Manuf. Process. 2019, 38, 63–75. [Google Scholar] [CrossRef]

- Ni, X.; Wang, S.; Zhao, Y.; Li, W.; Jiao, X. Investigation on Microstructure, Hardness, and Corrosion Resistance of Mo–Ni–B Coatings Prepared by Laser Cladding Technique. Coatings 2019, 9, 856. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Zhang, L.; Zhang, B.; Zhang, Q. Effect of substrate on metallographic corrosion of cladding in stainless/carbon steel bimetal plate. Results Phys. 2020, 16, 102925. [Google Scholar] [CrossRef]

- Lima, C.R.C.; Belém, M.J.X.; Fals, H.D.C.; Rovere, C.A.D. Wear and corrosion performance of Stellite 6® coatings applied by HVOF spraying and GTAW hotwire cladding. J. Mater. Process. Technol. 2020, 284, 116734. [Google Scholar] [CrossRef]

- Li, Y.; Tan, N.; Jin, G.; Cui, X.; Li, Q. Thermal fatigue failure behavior of surface/interface of plasma cladding layer. Coatings 2019, 9, 646. [Google Scholar] [CrossRef] [Green Version]

- Latha, S.; Nandagopal, M.; Parameswaran, P.; Reddy, G.V.P. Effect of P and Si on creep induced precipitation in 20% CW Ti-modified 14Cr-15Ni stainless steel fast reactor clad. Mater. Sci. Eng. A 2019, 759, 736–744. [Google Scholar] [CrossRef]

- Meng, Y.; Kang, K.; Gao, M.; Zeng, X. Microstructures and properties of single-pass laser-arc hybrid welded stainless clad steel plate. J. Manuf. Process. 2018, 36, 293–300. [Google Scholar] [CrossRef]

- Mohammed, R.; Kumar, E.N.; Ram, G.D.J.; Kamaraj, M.; Reddy, G.M.; Rao, K.S. Microstructure, mechanical and corrosion behaviour of weld overlay cladding of DMR 249A steel with AISI 308L. Mater. Today Proc. 2019, 15, 2–10. [Google Scholar] [CrossRef]

- Varghese, P.; Vetrivendan, E.; Dash, M.K.; Ningshen, S.; Kamaraj, M.; Kamachi Mudali, U. Weld overlay coating of Inconel 617 M on type 316 L stainless steel by cold metal transfer process. Surf. Coat. Technol. 2019, 357, 1004–1013. [Google Scholar] [CrossRef]

- Luz, F.S.D.; Pinheiro, W.A.; Monteiro, S.N.; Candido, V.S.; Silva, A.C.R.D. Mechanical properties and microstructural characterization of a novel 316L austenitic stainless steel coating on A516 Grade 70 carbon steel weld. J. Mater. Res. Technol. 2020, 9, 636–640. [Google Scholar] [CrossRef]

- ASTM International. ASTM E8/E8M-16ae1, Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM International. ASTM G48-03, Standard Test Methods for Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys by Use of Ferric Chloride Solution; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- ASTM International. ASTM A262-15, Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Wang, Z.; Xu, J.; Shoji, T.; Takeda, Y.; Yuya, H.; Ooyama, M. Microstructure and pitting behavior of the dissimilar metal weld of 309L cladding and low alloy steel A533B. J. Nucl. Mater. 2018, 508, 1–11. [Google Scholar] [CrossRef]

| Welding Process | Number of Layers | Filler Metal | Current Type and Polarity | Current (Amp) | Voltage (V) | Travel Speed (mm/min) |

|---|---|---|---|---|---|---|

| GTAW | 1–2 | ER70S-6 (2.4 mm Diameter) | DCEN | 90–140 | 10–15 | 50–100 |

| SMAW | 3–13 | E7016 (3.2 mm Diameter) | DECP, AC | 90–130 | 22–30 | 60–120 |

| Chemical Composition (wt.%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Material | C | Mn | Cr | Si | Mo | Ni | Cu | S | P |

| ASTM A36 | 0.250 max. | 0.850–1.350 | – | 0.400 max. | – | – | – | 0.030 | 0.030 |

| ER70S-6 | 0.100 | 1.560 | 0.020 | 0.860 | <0.010 | 0.010 | 0.240 | 0.012 | 0.012 |

| E7016 | 0.080 | 0.940 | 0.020 | 0.600 | <0.100 | 0.010 | – | 0.006 | 0.004 |

| E309L-16 | 0.040 | 0.500–2.500 | 22.000–25.000 | 1.000 | 0.750 | 12.000–14.000 | 0.750 | 0.030 | 0.040 |

| Mechanical Properties | |||

|---|---|---|---|

| Material | Yield Strength (N/mm2) | Tensile Strength (N/mm2) | Elongation (%) |

| ASTM A36 | 250 | 400–550 | 23 |

| ER70S-6 | 420 | 550 | 35 |

| E7016 | 420 | 520 | 33 |

| E309L-16 | 420 | 520 | 30 |

| Welding Process | Number of Layers | Filler Metal | Current Type and Polarity | Current (Amp) | Voltage (V) | Travel Speed (mm/min) |

|---|---|---|---|---|---|---|

| SMAW | 1 | E309L-16 (3.2 mm diameter) | DECP, AC | 80–86 | 20–24 | 144–174 |

| Test Numbers | Layers | Orientations | Materials | Thickness (mm) | Temperatures (°C) |

|---|---|---|---|---|---|

| CD11-25 | Cladding | Cladding Direction | 309L Stainless Steel | 2.5 | 25 |

| A36 Steel | 2.5 | ||||

| CD12-25 | Cladding | Cladding Direction | 309L Stainless Steel | 2.5 | 25 |

| A36 Steel | 5.0 | ||||

| CD11-500 | Cladding | Cladding Direction | 309L Stainless Steel | 2.5 | 500 |

| A36 Steel | 2.5 | ||||

| CD12-500 | Cladding | Cladding Direction | 309L Stainless Steel | 2.5 | 500 |

| A36 Steel | 5.0 | ||||

| WD-25 | Cladding | Weld Direction | 309L Stainless Steel | 2.8 | 25 |

| WD-500 | Cladding | Weld Direction | 309L Stainless Steel | 2.8 | 500 |

| SB-500 | Substrate | Rolling Direction | A36 Steel (Base Material) | 8.0 (diameter) | 500 |

| SW-500 | Substrate | Welding Direction | A36—A36 Welded Steel | 8.0 (diameter) 1 | 500 |

| Tests | Standards | Layers | Materials |

|---|---|---|---|

| Pitting Corrosion | ASTM G48 A [56] | Cladding Layer over Weldment (P1) | 309L Stainless Steel |

| Cladding Layer (P2) | 309L Stainless Steel | ||

| Cladding-Substrate Layer (P3) | 309L Stainless Steel—A36 Steel | ||

| Substrate Layer (P4) | A36 Steel | ||

| Intergranular Corrosion | ASTM 262 E [57] | Cladding Layer over Weldment (G1) | 309L Stainless Steel |

| Cladding-Substrate Layer over Weldment (G2) | 309L Stainless Steel—A36 Steel | ||

| Weight Loss Corrosion | None | Substrate Layer (W1) | A36 Steel |

| Cladding Layer (W2) | 309L Stainless Steel—A36 Steel |

| Parameters | Considered Conditions |

|---|---|

| Materials | Substrate (A36—A36 welded plate), Cladding (309L stainless steel) |

| Shot blasting time (s) | 150, 270, 390 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Preedawiphat, P.; Mahayotsanun, N.; Sa-ngoen, K.; Noipitak, M.; Tuengsook, P.; Sucharitpwatskul, S.; Dohda, K. Mechanical Investigations of ASTM A36 Welded Steels with Stainless Steel Cladding. Coatings 2020, 10, 844. https://doi.org/10.3390/coatings10090844

Preedawiphat P, Mahayotsanun N, Sa-ngoen K, Noipitak M, Tuengsook P, Sucharitpwatskul S, Dohda K. Mechanical Investigations of ASTM A36 Welded Steels with Stainless Steel Cladding. Coatings. 2020; 10(9):844. https://doi.org/10.3390/coatings10090844

Chicago/Turabian StylePreedawiphat, Pavaret, Numpon Mahayotsanun, Keerati Sa-ngoen, Mai Noipitak, Pongsak Tuengsook, Sedthawatt Sucharitpwatskul, and Kuniaki Dohda. 2020. "Mechanical Investigations of ASTM A36 Welded Steels with Stainless Steel Cladding" Coatings 10, no. 9: 844. https://doi.org/10.3390/coatings10090844

APA StylePreedawiphat, P., Mahayotsanun, N., Sa-ngoen, K., Noipitak, M., Tuengsook, P., Sucharitpwatskul, S., & Dohda, K. (2020). Mechanical Investigations of ASTM A36 Welded Steels with Stainless Steel Cladding. Coatings, 10(9), 844. https://doi.org/10.3390/coatings10090844