Gloss, Light Reflection and Iridescence in Ceramic Tile Enamels Containing ZrO2 and ZnO

Abstract

1. Introduction

1.1. Light Transmittance, Gloss and Luminescence in Ceramics

1.2. Iridescent and Pearl Techniques

1.3. Objectives

- To determine whether they have iridescent properties, due to light diffraction, or, conversely, whether they only present gloss effects and the reflection of light with elements in the surroundings.

- To determine the factors that produce the tiles’ high capacity for light reflection, reproduction and colour variety.

- To compare the colorimetric and gloss analysis to that of the ceramic pieces found on the façade of the Algueña Auditorium (MUCA).

2. Materials and Methods

- 1.

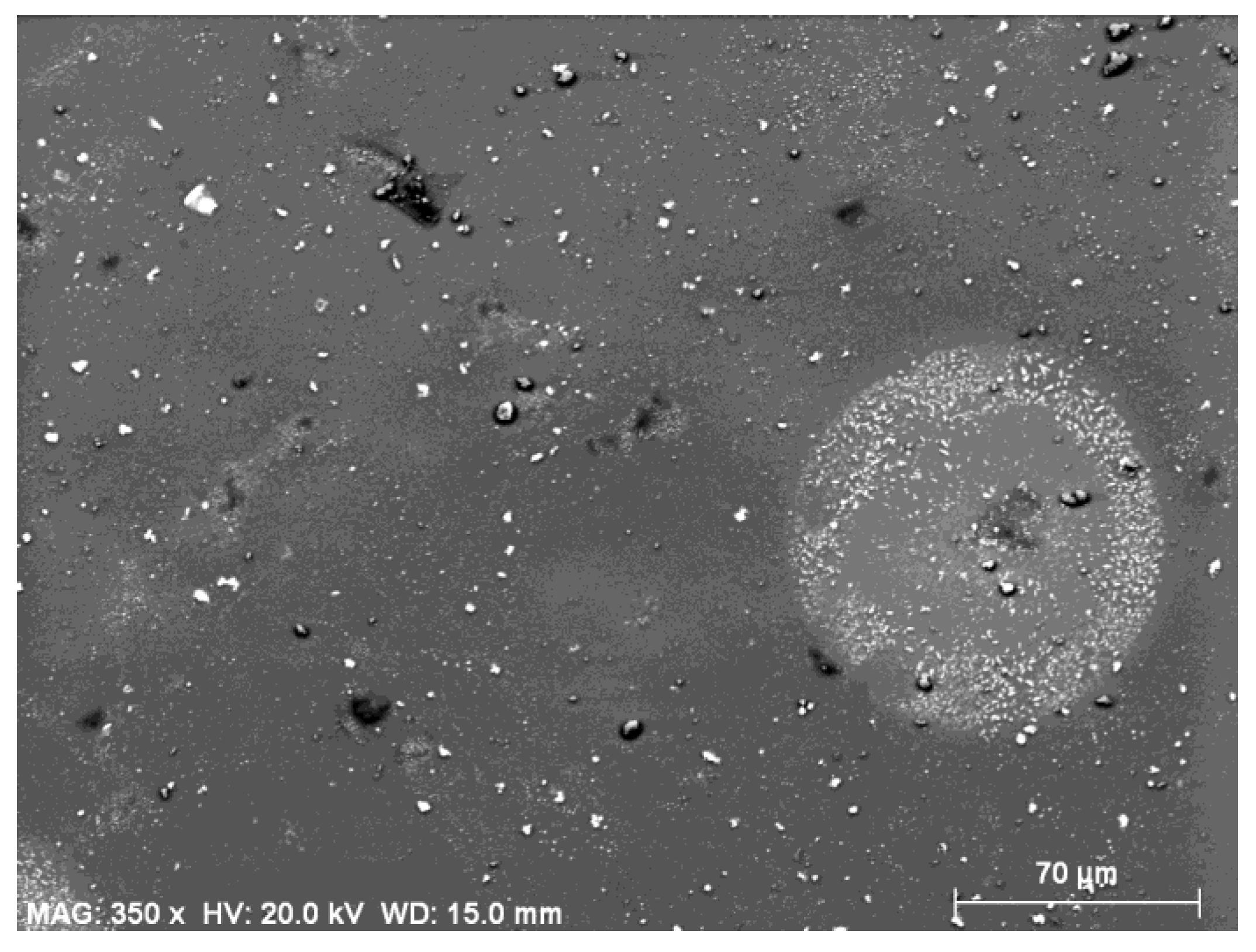

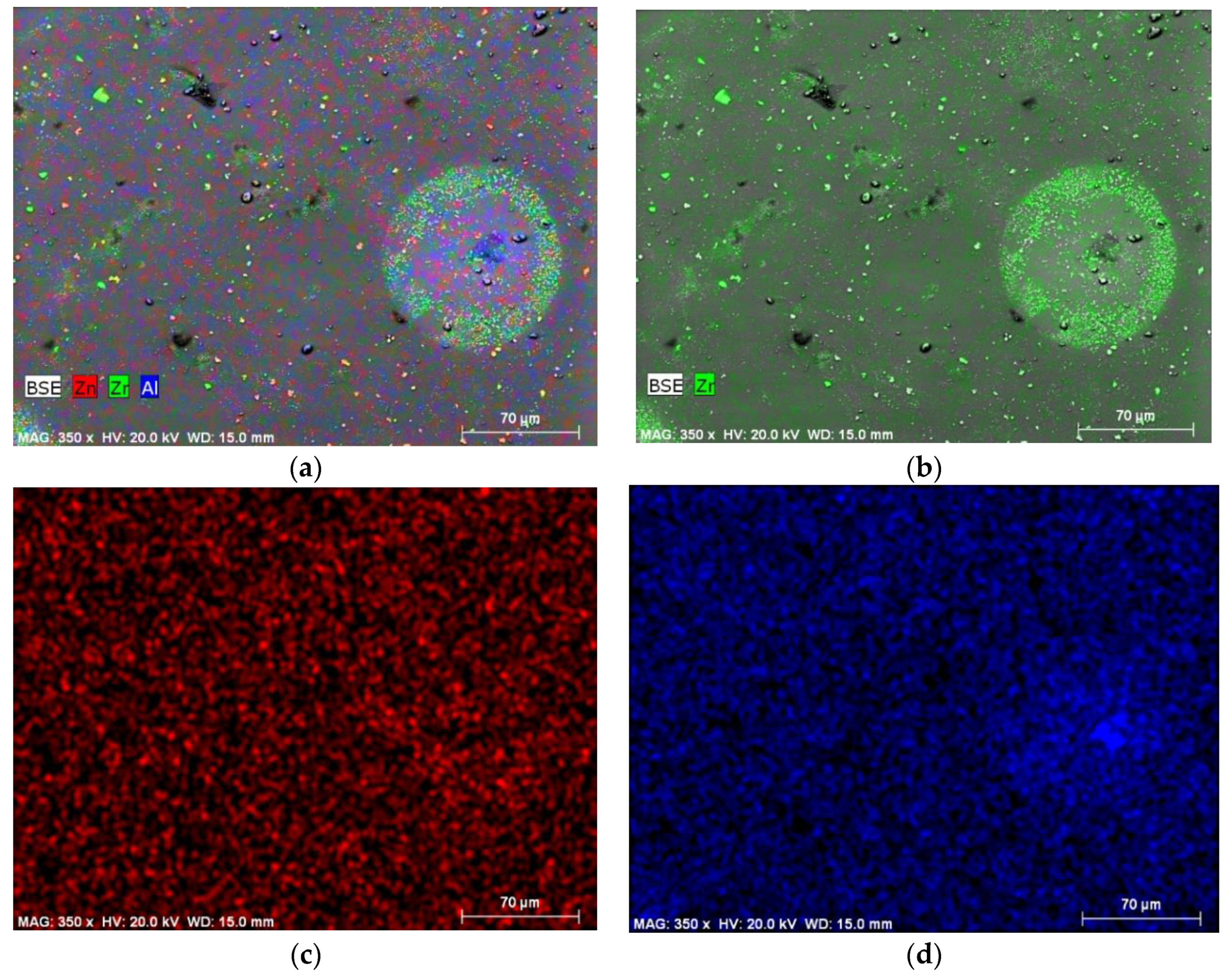

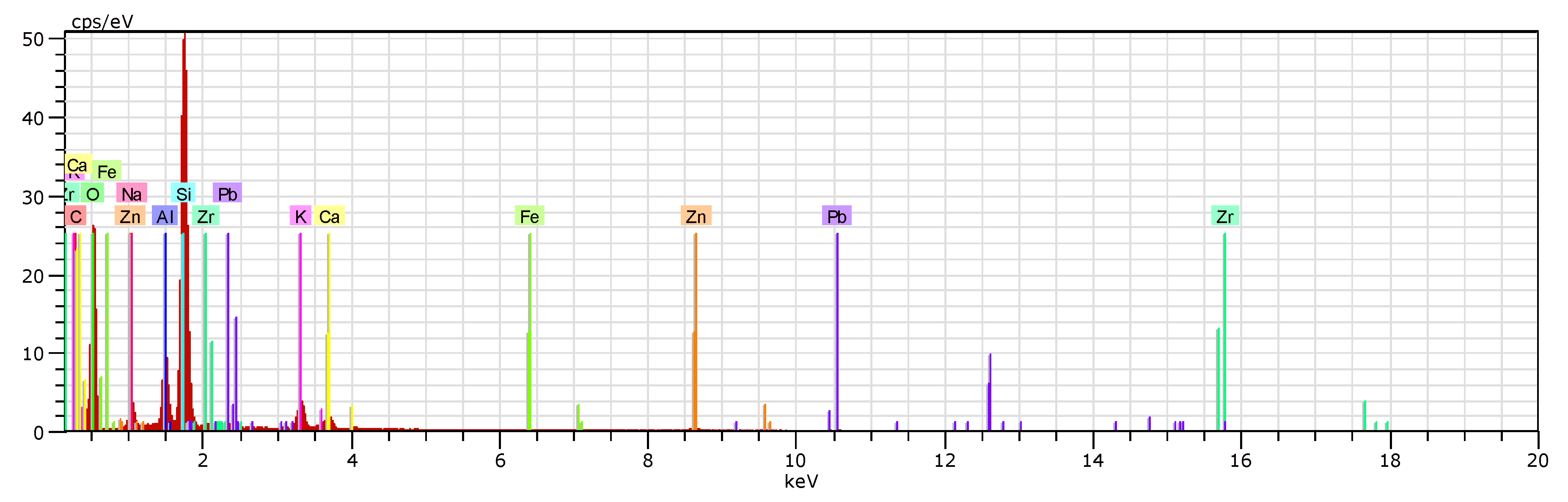

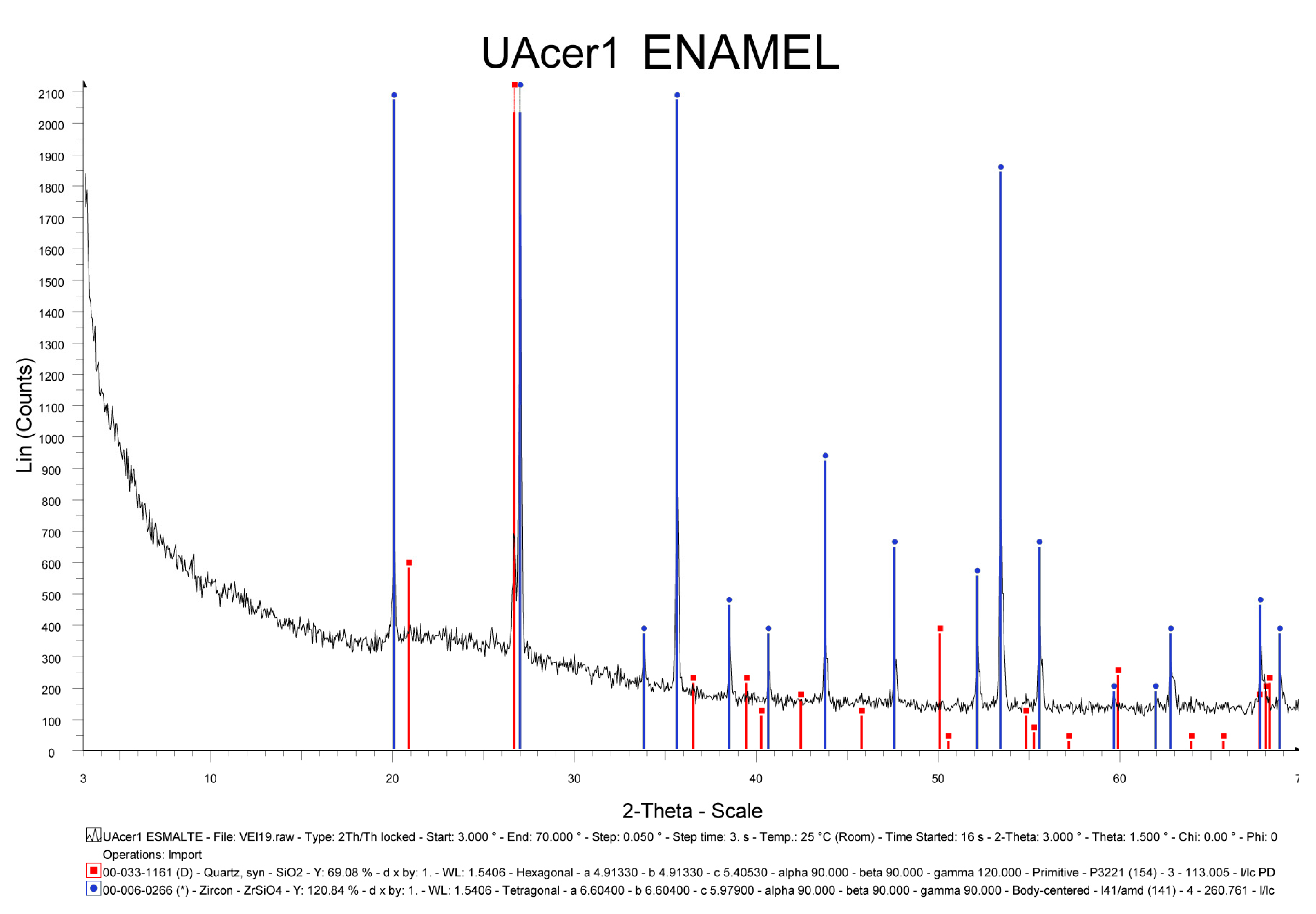

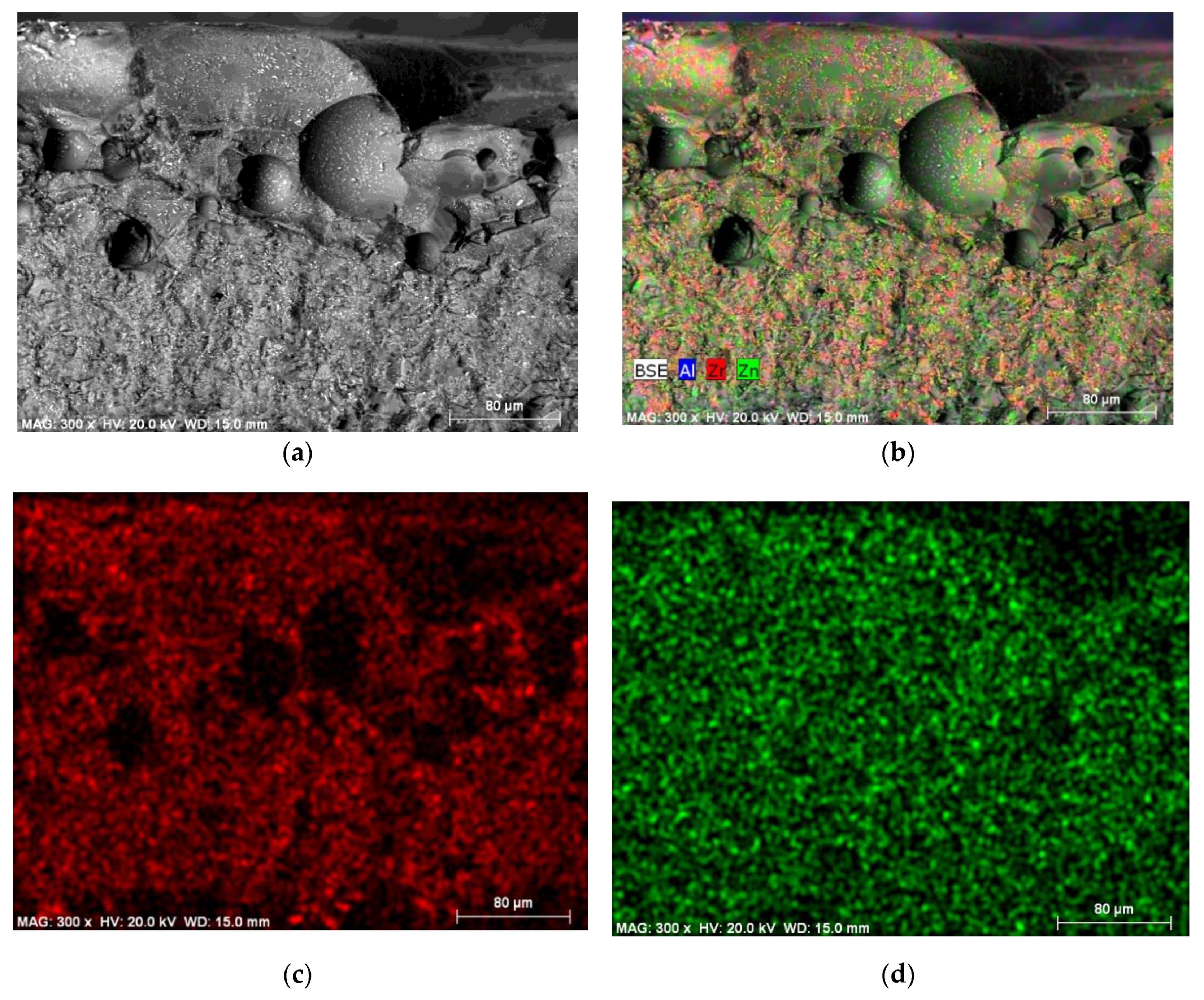

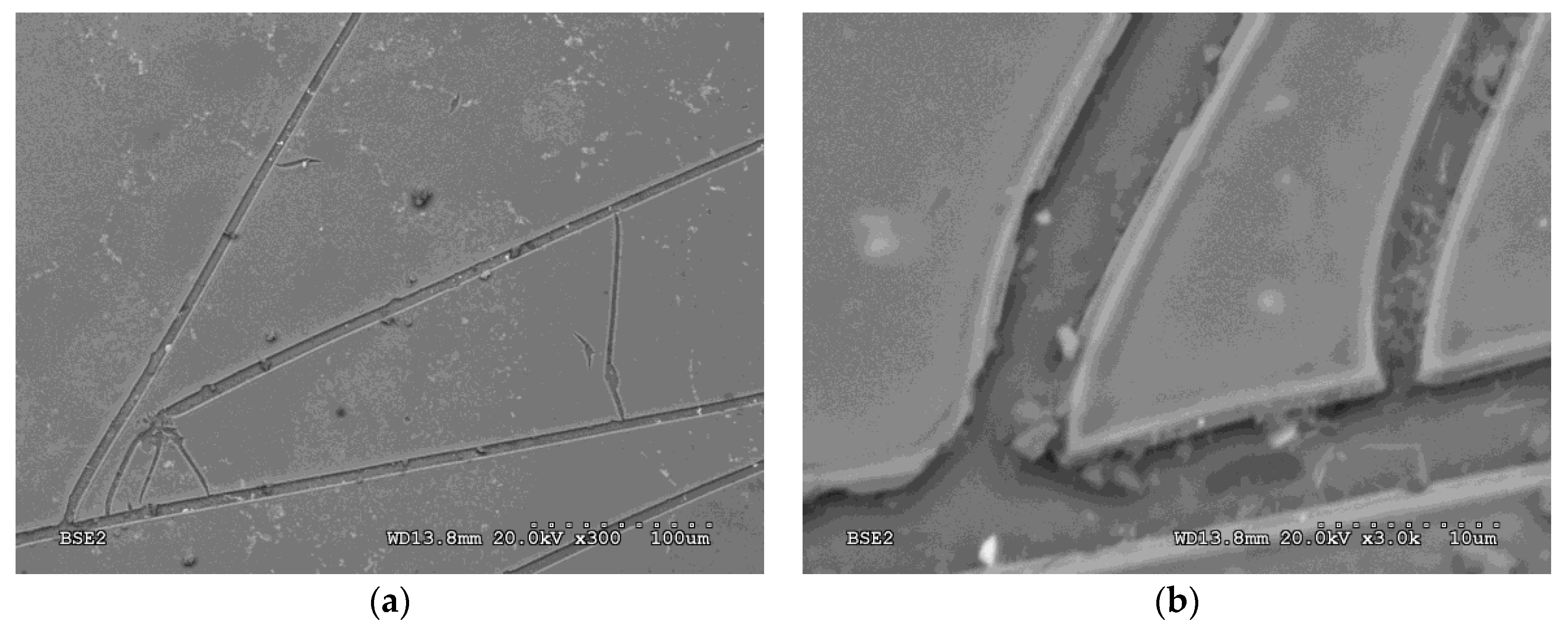

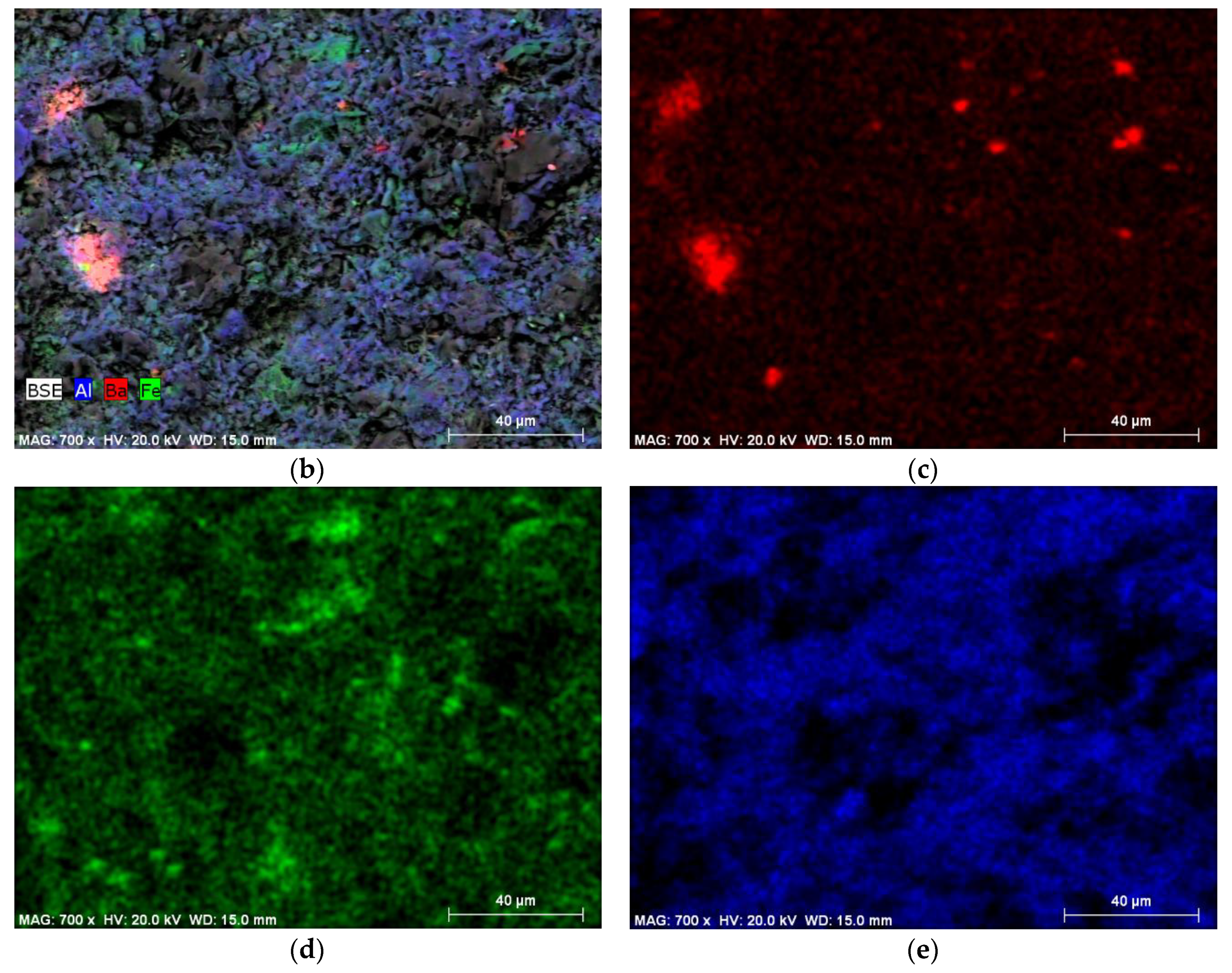

- Physico-chemical analysis of the bases and various enamel layers of the ceramic pieces. The goal was to determine the factors that produce the phenomena of gloss, reflection, iridescence and light diffraction. It was essential to characterise the layers’ various metals, distribution and possible microcracks. The physical-chemical characterisation of the analysed ceramic materials was performed using X-ray diffraction (XRD, Bruker D8-Advance, Alicante, Valencian State, Spain) and scanning electron microscopy (SEM, Hitachi S3000N, Alicante, Valencian State, Spain).

- 1.1.

- X-ray diffraction (XRD) is based on optical interference that occurs when monochrome radiation passes through a slit that has a thickness similar to that of the radiation wavelength. When irradiated over the sample to be analysed, the X-rays diffract at various angles depending on interatomic distances, thus allowing to identify the mineralogical composition of the crystalline samples. The equipment used in Alicante university’s technical services is a Bruker D8-Advance with a high temperature camera (up to 900 °C), and a KRISTALLOFLEX K 760-80F X-ray generator, equipped with an RX tube with a copper anode. The analysis was conducted in two phases, the first for a 2θ angle scanning between 25°–113°, and the second between 3°–70°, and a step of 0.05°.

- 1.2.

- Scanning electron microscopy (SEM) allows to identify the elements present in the sample and establish their concentration through the X-rays generated after electronic bombardment. The equipment used at the University of Alicante is a Hitachi S3000N model scanning electron microscope, which features a Bruker XFlash 3001 X-ray detector for microanalysis (EDS) and mapping. This SEM is equipped with an energy-dispersive X-ray spectrometry (EDX), a dispersive energy detector that allows you to collect the X-rays generated by the sample and perform various analyses. This allows obtaining images of the element distribution on polished surfaces.

- 2.

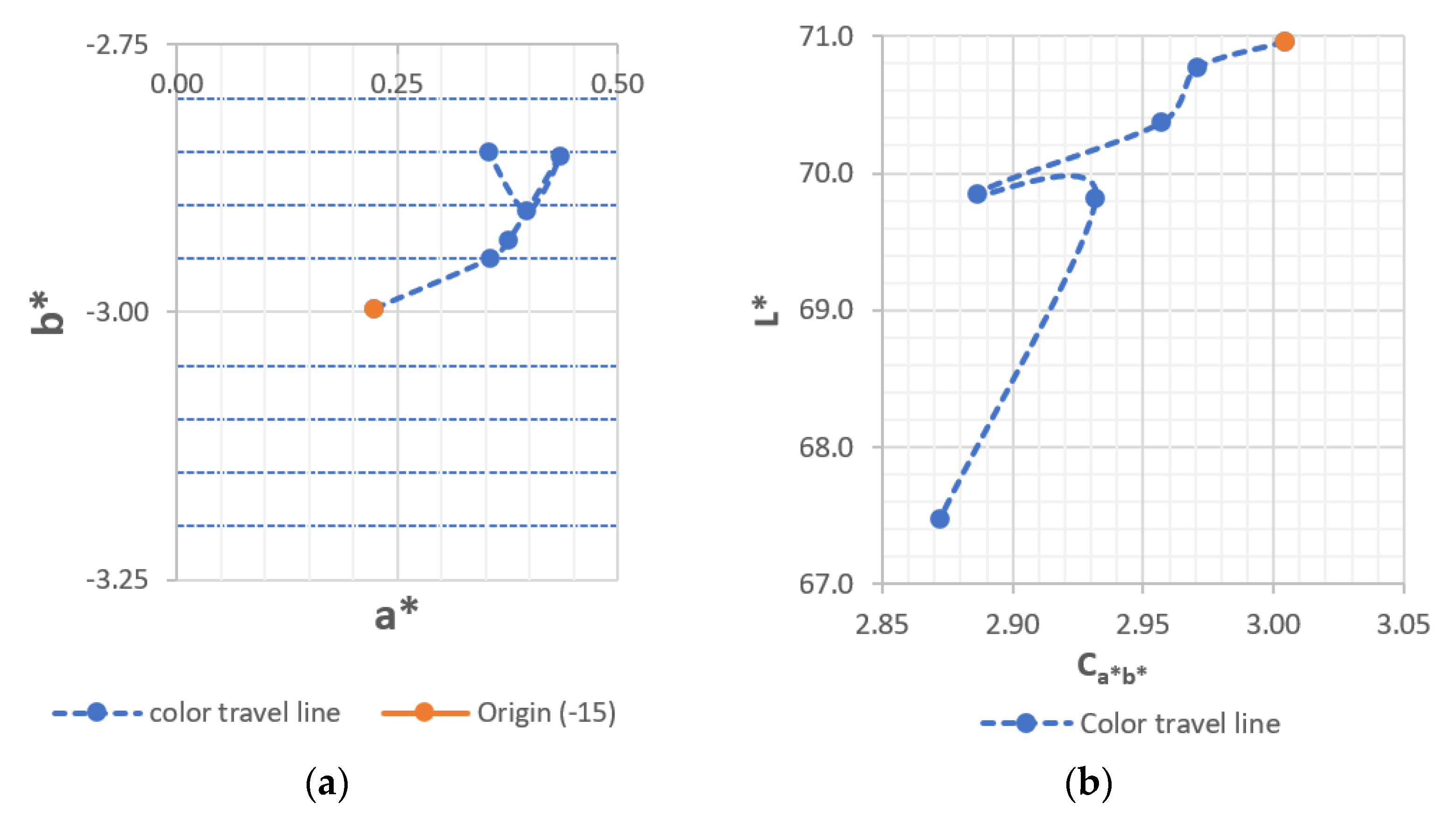

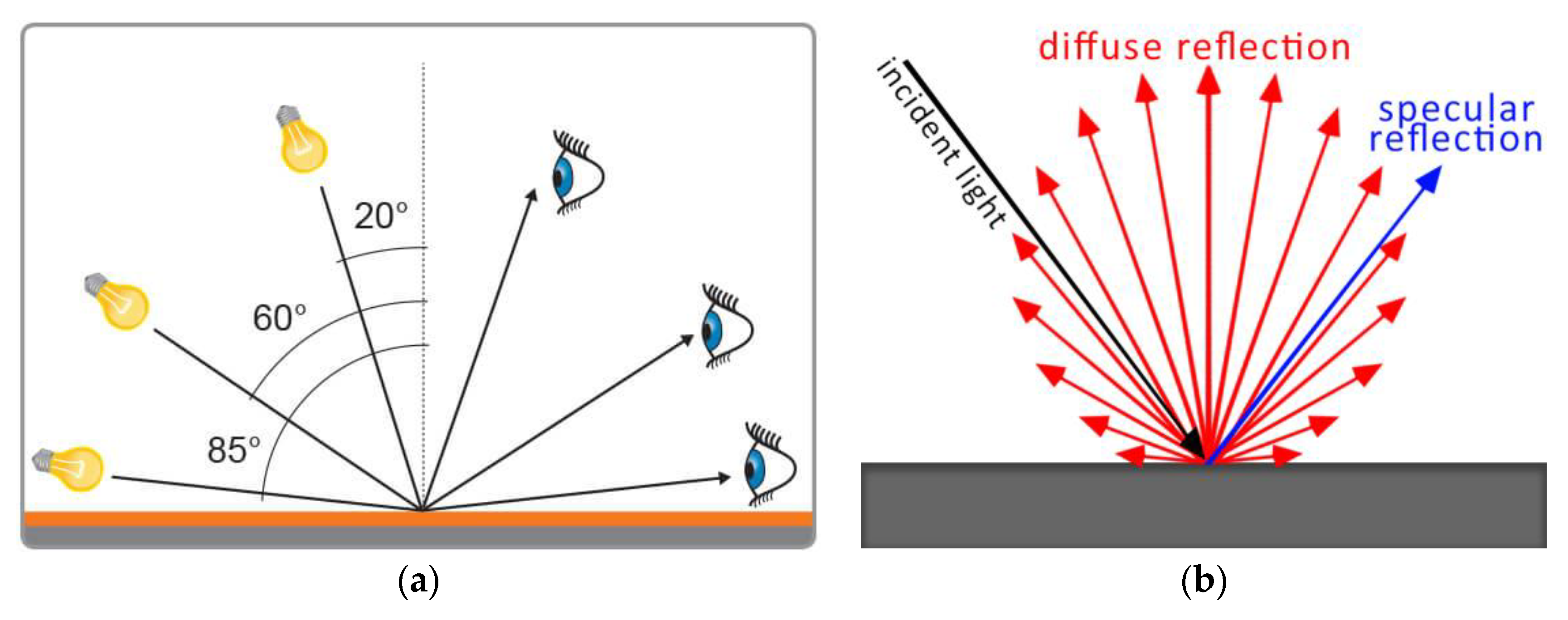

- Colorimetric characterisation. The objective was to analyse the goniochromatic colours and the various colour ranges on the enamelled faces of the ceramic tiles under study when subjected to light. The characterisation was performed based on observer perceptions according to viewing position and angle. We thus aimed at assessing the results of the gloss and iridescence effect pursued during the manufacturing of the ceramic pieces.

- 3.

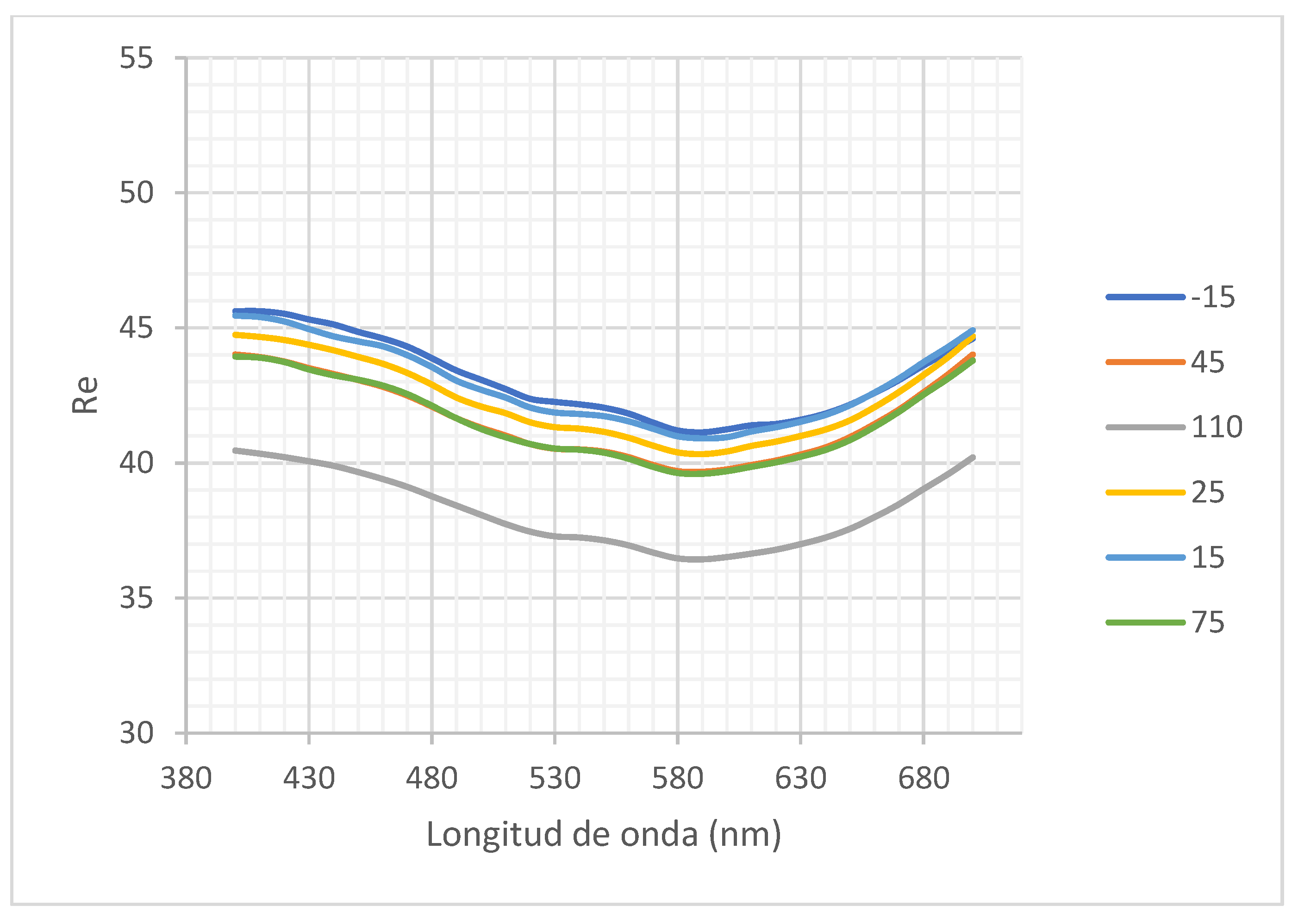

- Characterisation of the behaviour of gloss before the incidence of light, observers’ visual perception produced during the different daily and annual phases. The behaviour of the enamelled sides had to be measured according to the light coming from various angles, the quality of gloss of these enamels, the ability to reproduce the colour of elements or objects in the immediate surroundings of the enamel façade. For this purpose, the Minolta Multi-Gloss 268 equipment was made available by the University Institute of Physics Applied to Sciences and Technologies (IUFACyT) of the University of Alicante. The spectral radiance factor, or reflectance, was determined for each measurement geometry, and the chromatic coordinates in the CIE-L*a*b* space under D65 illumination (daylight) were calculated based on it. The reflectance of the ceramic samples could thus be displayed for the 6 different measurement geometries. Spectral measurements of characteristic colours [50] were analysed by tilting around the spectral profile and geometries closest to the direction of the gloss.

- 4.

- A comparative analysis of the results obtained in the previous test stages were made. It was important to evaluate the above parameters in each phase according to the manufacturing and enamel process of the ceramic tiles of both buildings. This way, it was possible to determine the factors that produce the effects of reflection, diffraction and iridescence of light making it possible to meet the study’s proposed objectives.

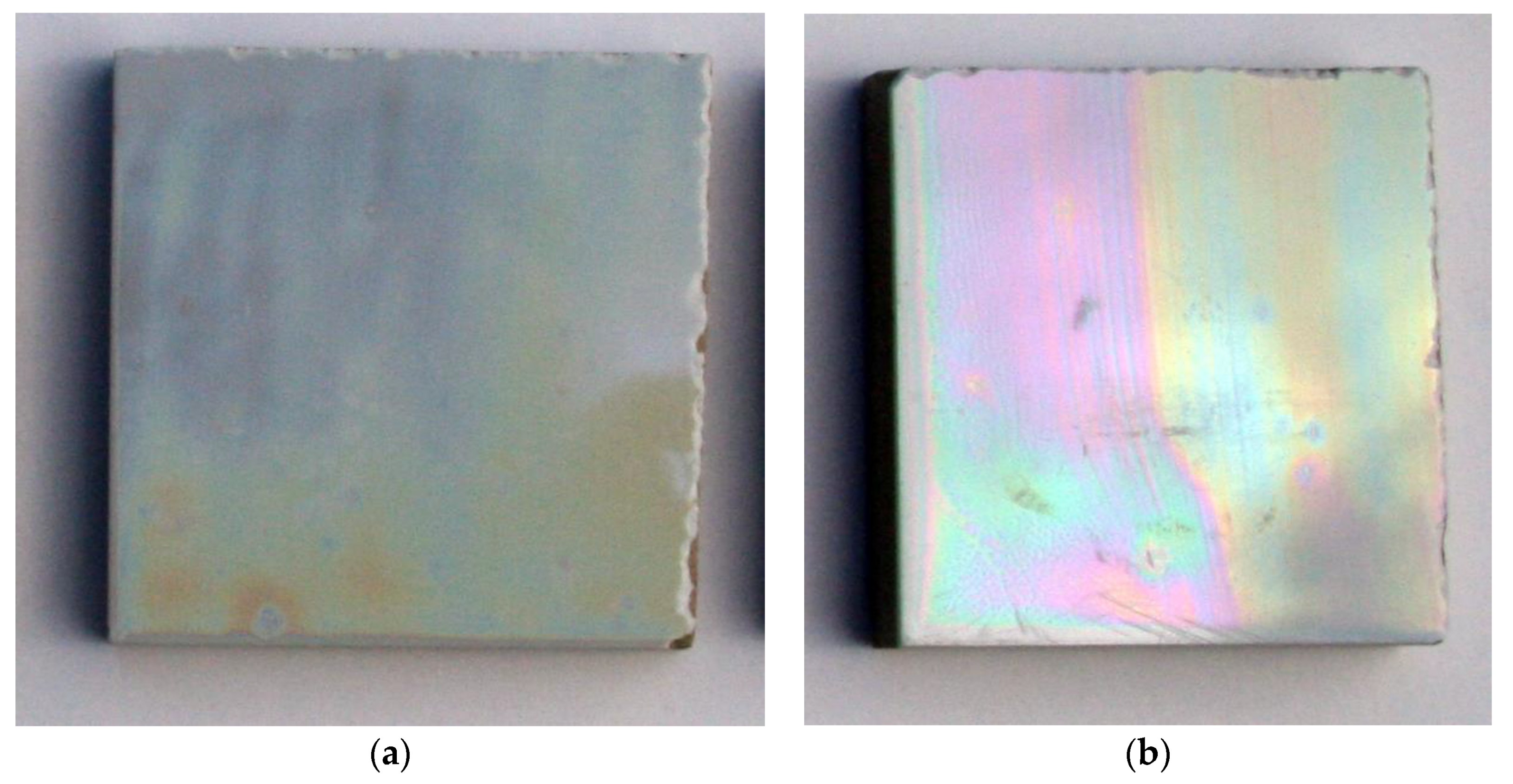

3. Faculty of Education of the University of Alicante: Ceramics and Reflection of Light

4. Description of the Manufacturing Process

5. Results

5.1. Physico-Chemical Analysis of the Ceramic Tiles

5.2. Colorimetric and Gloss Analysis

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Echarri Iribarren, V. Ceramics and energy efficiency: Passive and active conditioning systems. In Rhythms, Cycles, Performances-Ceramics in Architecture; Salazar, J., Sakamoto, T., Eds.; ASCER. ACTAR Publishers: Barcelona, Spain, 2010; pp. 92–95. [Google Scholar]

- Silva Moreno, G.; Mira Peidró, J. Innovative products in the ceramic sector. In Public Private Ephemeral: Ceramics in Architecture; Delbene, G., Ed.; ASCER. ACTAR Publishers: Barcelona, Spain, 2008; pp. 46–50. [Google Scholar]

- Ceramic Floor and Wall Tiles. Innovation, Avant-Garde and Sustainability in Public and Private Spaces. Report. Available online: http://www.promateriales.com/pdf/pm2209.pdf (accessed on 9 April 2019).

- Ahmad, I.; Yazdani, B.; Zhu, Y. Recent advances on carbon nanotubes and graphene reinforced ceramics nanocomposites. Nanomaterials 2015, 5, 90–114. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Guo, N.; Ji, L.; Xu, C. Synthesis of CaF2 nanoparticles coated by SiO2 for improved Al2O3/TiC self-lubricating ceramic composites. Nanomaterials 2019, 9, 1522. [Google Scholar] [CrossRef] [PubMed]

- Giuranno, D.; Bruzda, G.; Polkowska, A.; Nowak, R.; Polkowski, W.; Kudyba, A.; Sobczak, N.; Mocellin, F.; Novakovic, R. Design of refractory SiC/ZrSi2 composites: Wettability and spreading behavior of liquid Si-10Zr alloy in contact with SiC at high temperaturas. J. Eur. Ceram. Soc. 2020, 40, 953–960. [Google Scholar] [CrossRef]

- Villalba Weinberg, A.; Goeuriot, D.; Poirier, J.; Varona, C.; Chaucherie, X. Mullite–zirconia composite for the bonding phase of refractory bricks in hazardous waste incineration rotary kiln. J. Eur. Ceram. Soc. 2020, 13492. [Google Scholar] [CrossRef]

- Echarri Iribarren, V.; González Avilés, A.B.; Ródenas, M.; Olivares, J. Ceramics and reflected light new pearlescent and iridescent techniques and colorimetric characterization. Informes Constr. 2016, 68, e164. [Google Scholar] [CrossRef]

- Xu, Q.; Ma, H.M.; Zhang, Y.J.; Li, R.S.; Sun, H.Y. Synthesis of iridiscent Ni-containing anodic aluminium oxide films by anodization in oxalic acid. Opt. Mater. 2016, 52, 107–110. [Google Scholar] [CrossRef]

- Xu, Q.; Sun, C.X.; Wang, Z.J.; Liu, J.J.; Ren, Y.X.; Hao, S.Z.; Zhu, J.L.; Sun, Y.B.; Sun, H.Y. Preparation and characterization of iridescent Ni1−xCox-containing anodic aluminum oxide films. Dyes Pigment. 2017, 147, 313–317. [Google Scholar] [CrossRef]

- Wang, X.H.; Akahane, T.; Orisaka, H.; Kyotani, T. Brilliant and tunable color carbon-coated thin anodic aluminium oxide films. Appl. Phys. Lett. 2007, 91, 011908. [Google Scholar] [CrossRef]

- Li, F.; Tang, B.; Zhang, S. Iridescent structural colors from self-assembled polymer opal of polythiourethane microspheres. Dyes Pigment. 2017, 142, 371–378. [Google Scholar] [CrossRef]

- Song, L.; Chen, X.; Xie, Y.; Zhong, L.; Zhang, X.; Cheng, Z. Non-iridescent, crack-free, conductive structural colors enhanced by flexible nanosheets of reduced graphene oxide. Dyes Pigment. 2019, 164, 222–226. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, S.; Zhang, Y.; Wang, Z.; Zhou, G.; Wang, S. Crystal structure evolution and luminescence property of Ce3+-doped Y2O3–Al2O3–Sc2O3 ternary ceramics. J. Eur. Ceram. Soc. 2020, 40, 840–846. [Google Scholar] [CrossRef]

- Wu, H.; Hao, Z.; Pan, G.H.; Zhang, L.; Wu, H.; Zhang, X.; Zhang, L.; Zhang, J. Phosphor-SiO2 composite films suitable for white laser lighting with excellent color rendering. J. Eur. Ceram. Soc. 2020, 40, 2439–2444. [Google Scholar] [CrossRef]

- Rojas-Hernandez, R.E.; Rubio-Marcos, F.; Serrano, A.; Salas, E.; Hussainova, I.; Fernandez, J.F. Towards blue long-lasting luminescence of Eu/Nd-doped calcium-aluminate nanostructured platelets via the molten salt route. Nanomaterials 2019, 9, 1473. [Google Scholar] [CrossRef] [PubMed]

- Hříbalová, S.; Pabst, W. Light scattering and extinction in polydisperse systems. J. Eur. Ceram. Soc. 2020, 40, 867–880. [Google Scholar] [CrossRef]

- Qian, K.; Pan, Y.; Hu, Z.; Chen, X.; Shi, Y.; Liu, X.; Chen, H.; Nikl, M.; Li, J. Influence of co-doped alumina on the microstructure and radioluminescence of SrHfO3:Ce ceramics. J. Eur. Ceram. Soc. 2020, 40, 449–455. [Google Scholar] [CrossRef]

- Mirdali, N.K.; Daday, M.; Daday, M.T. Development and characterization of low temperature metallic glazes in Na2O–B2O3–SiO2 (NBS) system. Ceram. Int. 2019, 45, 21661–21667. [Google Scholar] [CrossRef]

- Pradell, T.; Pavlov, R.S.; Gutiérrez, P.C.; Climent-Font, A.; Molera, J. Composition, nanostructure, and optical properties of silver and silvercopper lusters. J. Appl. Phys. 2012, 112, 054307. [Google Scholar] [CrossRef]

- Bobin, O.; Schvoerer, M.; Miane, J.L.; Fabre, J.F. Colored metallic shine associated to luster decoration of glazed ceramics: A theoretical analysis of the optical properties. J. Non Cryst. Solids 2003, 332, 28–34. [Google Scholar] [CrossRef]

- Jiang, W.; Xu, X.; Chen, T.; Liu, J.; Zhang, X. Preparation and chromatic properties of C@ZrSiO4 inclusion pigment via non-hydrolytic sol-gel method. Dyes Pigment. 2015, 114, 55–59. [Google Scholar] [CrossRef]

- Badenes, J.A.; Llusar, M.; Tena, M.A.; Calbo, J.; Monrós, G. Praseodymium-doped cubic Ca–ZrO2 ceramic stain. J. Eur. Ceram. Soc. 2020, 22, 1981–1990. [Google Scholar] [CrossRef]

- Yuan, L.; Han, A.; Ye, M.; Chen, X.; Ding, C.; Yao, L. Synthesis and characterization of novel non-toxic BiFe1−xAlxO3/mica-titania pigments with high NIR reflectance. Ceram. Int. 2017, 43, 16488–16494. [Google Scholar] [CrossRef]

- Kaya, S.Y.; Karasu, B. Process parameters determination of phosphorescent pigment added, frit-based wall tiles vetrosa decorations. Ceram. Int. 2012, 38, 2757–2766. [Google Scholar] [CrossRef]

- Gao, Y.F.; Zhao, F.; Liu, Y.; Luo, H.J. Synthesis and characterization of ZrO2 capsules and crystalline ZrO2 thin layers on Fe2O3 powders. CrystEngComm 2011, 13, 3511–3514. [Google Scholar] [CrossRef]

- Cavalcante, P.; Dondi, M.; Guarini, G.; Raimondo, M.; Baldi, G. Colour performance of ceramic nano-pigments. Dyes Pigm. 2009, 80, 226–232. [Google Scholar] [CrossRef]

- Jovaní, M.; Domingo, M.; Machado, T.R.; Longo, E.; Beltrán-Mir, H.; Cordoncillo, E. Pigments based on Cr and Sb doped TiO2 prepared by microemulsionmediated solvothermal synthesis for inkjet printing on ceramics. Dyes Pigm. 2015, 116, 106–113. [Google Scholar] [CrossRef]

- Fu, J.; Peng, Y.; Tian, X. Pigments Having Angle Dependence of the Interference Colours and Its Production Process. U.S. Patent US8066811B2, 29 November 2011. [Google Scholar]

- Cabrera, M.J.; Montins, V.; Solsona, D.; Sala, J.M. Obtención de efectos físico-ópticos para la decoración de baldosas cerámicas. Boletín Sociedad Española Cerámica y Vidrio 2012, 51, IX–XVI. [Google Scholar] [CrossRef]

- Tena, M.A.; Meseguer, S.; Gargori, C.; Forés, A.; Badenes, J.A.; Monrós, G. Study of Cr–SnO2 ceramic pigment and of Ti/Sn ratio on formation and coloration of these materials. J. Eur. Ceram. Soc. 2007, 27, 215–221. [Google Scholar] [CrossRef]

- Shen, Z.; Liu, L.; Xu, X.; Zhao, J.; Eriksson, M.; Zhong, Y.; Adolfsson, E.; Liu, Y.; Kocjan, A. Fractography of self-glazed zirconia with improved reliability. J. Eur. Ceram. Soc. 2017, 37, 4339–4345. [Google Scholar] [CrossRef]

- Cannio, M.; Bondioli, F. Mechanical activation of raw materials in the synthesis of Fe2O3–ZrSiO4 inclusion pigment. J. Eur. Ceram. Soc. 2012, 32, 643–647. [Google Scholar] [CrossRef]

- Hainschwang, T.; Notari, F. The cause of iridescence in rainbow andradite from Nara: Japan. Gems Gemol. 2006, 42, 248–258. [Google Scholar] [CrossRef]

- Sciau, P.; Noé, L.; Colomban, P. Metal nanoparticles in contemporary potters’ master pieces: Lustre and red “pigeon blood” potteries as models to understand the ancient pottery. Ceram. Int. 2016, 42, 15349–15357. [Google Scholar] [CrossRef]

- Liu, C.; Yen, M.; Han, A.; Li, J. Structural analysis and characterization of doped spinel Co2−xMxTiO4 (M = Mg2+, Mn2+, Ni2+, Cu2+, and Zn2+) coated mica composite pigments. Ceram. Int. 2015, 41, 5537–5546. [Google Scholar] [CrossRef]

- Jing, C.; Xiaobo, S.; Bing, H. The preparation and characteristics of cobalt blue colored mica titania pearlescent pigments by microemulsions. Dyes Pigment. 2007, 75, 766–769. [Google Scholar] [CrossRef]

- Bayat, N.; Baghshahi, S.; Alizadeh, P. Synthesis of white pearlescent pigments using the surface response method of statistical analysis. Ceram. Int. 2008, 34, 2029–2035. [Google Scholar] [CrossRef]

- Ryu, Y.C.; Kim, T.G.; Seo, G.-S.; Park, J.H.; Suh, C.S.; Park, S.-S.; Hong, S.-S.; Lee, G.D. Effect of substrate on the phase transformation of TiO2 in pearlescent pigment. J. Ind. Eng. Chem. 2008, 14, 213–218. [Google Scholar] [CrossRef]

- Siligardi, C.; Montecchi, M.; Montorsi, M.; Pasquali, L. Ceria-containing frit for luster in modern ceramic glaze. J. Am. Ceram. Soc. 2010, 93, 2545–2550. [Google Scholar] [CrossRef]

- Dondi, M.; Zanelli, C.; Ardit, M.; Cruciani, G.; Mantovani, L.; Tribaudino, M.; Andreozzi, G.B. Ni-free, black ceramic pigments based on Co—Cr—Fe—Mn spinels: A reappraisal of crystal structure, colour and technological behaviour. Ceram. Int. 2013, 39, 9533–9547. [Google Scholar] [CrossRef]

- He, X.; Wang, F.; Liu, H.; Niu, L.; Wang, X. Synthesis and color properties of the TiO2@CoAl2O4 blue pigments with low cobalt content applied in ceramic glaze. J. Am. Ceram. Soc. 2018, 101, 2578–2588. [Google Scholar] [CrossRef]

- Chen, S.; Cheng, M.; Lang, Y.; Wei, H.; Wang, C. Synthesis and chromatic properties of zircon encapsulated ceramic black pigment with carbon sphere as carbon source. J. Eur. Ceram. Soc. 2018, 38, 2218–2227. [Google Scholar] [CrossRef]

- Romero, M.; Rincón, J.M. Surface and bulk crystallization of glass-ceramic in the Na2O–CaO–ZnO–PbO–Fe2O3–Al2O3–SiO2 system derived from a goethite waste. J. Am. Ceram. Soc. 1999, 82, 1313–1317. [Google Scholar] [CrossRef]

- Montins Nebot, V.; Cabrera Ibáñez, M.J.; Solsona Monzonis, D.; Sala Iniesta, J.M. Recubrimiento Para Cuerpos Cerámicos. ES2415984B1, 20 May 2014. [Google Scholar]

- Echarri-Iribarren, V.; González-Avilés, A.B.; Viqueira-Pérez, V. Iridescent techniques in ceramics: Physico-chemical analysis and colorimetric characterization of the headquarters of the botín foundation in santander. Appl. Sci. 2019, 9, 1521. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Multiangle Color Measurement of Metal Flake Pigmented Materials; ASTM International: West Conshohocken, PA, USA, 2014; pp. E2194–E2214. Available online: http://www.astm.org (accessed on 17 March 2019).

- Klein, G.A. Industrial Color Physics; Springer: New York, NY, USA, 2010. [Google Scholar]

- Chorro, E.; Perales, E.; Burgos, F.J.; Gómez, O.; Vilaseca, M.; Viqueira, V.; Pujol, J.; Martínez-Verdú, F.M. The minimum number of measurements for colour, sparkle, and graininess characterisation in gonio-apparent panels. Coloration Technol. 2015, 131, 303–309. [Google Scholar] [CrossRef]

- Ferrero, A.; Perales, E.; Rabal, A.; Campos, J.; Martínez-Verdú, F.M.; Chorro, E.; Pons, A. Color representation and interpretation of special effect coatings. J. Opt. Soc. Am. A 2014, 32, 436–447. [Google Scholar] [CrossRef] [PubMed]

- Pastor, J.Y.; Poza, P.; LLorca, J.; Peña, J.I.; Merino, R.I.; Orera, V.M. Mechanical properties of directionally solidified Al2O3–ZrO2(Y2O3) Eutectics. Mater. Sci. Eng. A 2001, 308, 241–249. [Google Scholar] [CrossRef]

- Merino, R.I. Cerámicas eutécticas solidificadas direccionalmente para fotónica y electrocerámica. Rev. Real Acad. Cienc. 2006, 61, 47–86. [Google Scholar]

- Dahl, G.T.; Krueger, J.D.; Döring, S.; Weller, H.; Vossmeyer, T. Seeded growth synthesis of Zirconia@Gold particles in aqueous solution. Nanomaterials 2020, 10, 1197. [Google Scholar] [CrossRef]

- Solís Pinargote, N.W.; Smirnov, A.; Peretyagin, N.; Seleznev, A.; Peretyagin, P. Direct Ink writing technology (3D printing) of graphene-based ceramic nanocomposites: A review. Nanomaterials 2020, 10, 1300. [Google Scholar] [CrossRef]

- Gajadhur, M.; Łuszczyńska, A. Influence of pearlescent pigments on light-fastness of water-based flexographic inks. Dyes Pigment. 2017, 138, 119–128. [Google Scholar] [CrossRef]

- Florez Miguel, R.; Crespillo, L.; He, X.; White, T.W.; Hilmas, G.; Fahrenholtz, W.; Graham, J. The irradiation response of ZrC ceramics under 10 MeV Au3+ ion irradiation at 800 °C. J. Eur. Ceram. Soc. 2020, 40, 1791–1800. [Google Scholar] [CrossRef]

- Lei, B.; Qin, W.; Kang, G.; Peng, C.; Wu, J. Modeling and evaluation for encapsulation efficiency of zircon-based heteromorphic encapsulation pigments. Dyes Pigment. 2015, 112, 245–254. [Google Scholar] [CrossRef]

| C Norm. (wt.%) Outer Enamel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Element | C | O | Na | Al | Si | K | Ca | Fe | Zn | Zr | Pb | - |

| Average % | 4.77 | 52.35 | 2.71 | 5.42 | 25.32 | 3.12 | 1.91 | 0.18 | 1.87 | 1.43 | 0.92 | 100% |

| Average Values of C Norm. (wt.%) | |||||

|---|---|---|---|---|---|

| Element | Sample Enamel 1 | Sample Enamel 2 | Sample Interior 1 | Sample Interior 2 | Sample Interior Profile |

| C | 4.93 | 4.16 | - | - | 13.28 |

| O | 52.00 | 52.65 | 50.14 | 51.13 | 45.52 |

| Na | 2.51 | 2.72 | 0.67 | - | 1.33 |

| Al | 5.29 | 5.53 | 9.93 | 11.25 | 6.08 |

| Si | 25.32 | 25.32 | 19.17 | 18.11 | 18.02 |

| K | 3.50 | 3.17 | - | 3.39 | 2.36 |

| Ca | 2.00 | 1.89 | 8.64 | 8.26 | 4.29 |

| Fe | 0.20 | - | 4.78 | 4.62 | 0.70 |

| Zn | 1.95 | 1.78 | - | - | 2.11 |

| Zr | 1.29 | 1.59 | - | - | 4.46 |

| Pb | 1.02 | 0.97 | - | - | - |

| Mg | - | 0.22 | 2.01 | 1.68 | 0.37 |

| S | - | - | 0.74 | 0.74 | - |

| Cl | - | - | 0.18 | - | - |

| Ti | - | - | 0.71 | 0.83 | - |

| Ba | - | - | - | - | - |

| Ni | - | - | - | - | 0.10 |

| Mo | - | - | - | - | 1.37 |

| Total | 100% | 100% | 100% | 100% | 100% |

| Param2 STD: Sample FEUA | ||||||

|---|---|---|---|---|---|---|

| Angle | L* | a* | b* | C* | h° | Angle |

| −15 | 70.97 | 0.22 | −3.00 | 3.00 | 274.25 | −15 |

| 15 | 70.77 | 0.36 | −2.95 | 2.97 | 276.87 | 15 |

| 25 | 70.37 | 0.38 | −2.93 | 2.96 | 277.31 | 25 |

| 45 | 69.85 | 0.43 | −2.85 | 2.89 | 278.67 | 45 |

| 75 | 69.82 | 0.40 | −2.90 | 2.93 | 277.79 | 75 |

| 110 | 67.47 | 0.35 | −2.85 | 2.87 | 277.07 | 110 |

| Measure | Angle (Deg) | ||

|---|---|---|---|

| 20° | 60° | 85° | |

| Number | GU (Gloss Units) | ||

| 1 | 67.30 | 80.30 | 84.60 |

| 2 | 67.40 | 80.20 | 84.70 |

| 3 | 67.30 | 80.20 | 84.80 |

| 4 | 67.40 | 80.20 | 84.70 |

| 5 | 67.60 | 80.10 | 85.20 |

| 6 | 67.90 | 80.30 | 85.70 |

| 7 | 68.00 | 80.20 | 85.20 |

| 8 | 68.20 | 80.30 | 84.90 |

| 9 | 67.70 | 80.10 | 84.60 |

| 10 | 68.20 | 80.50 | 84.80 |

| Average | 67.6 | 80.2 | 84.9 |

| Standard deviation | 0.4 | 0.1 | 0.3 |

| Measure | Angle (Deg) | ||

|---|---|---|---|

| 20° | 60° | 85° | |

| GU (Gloss Units) | |||

| Point 1 | - | - | - |

| Average | 62.1 | 81.1 | 82.3 |

| Standard deviation | 0.0 | 0.1 | 1.0 |

| Point 2 | - | - | - |

| Average | 68.8 | 81.4 | 84.1 |

| Standard deviation | 0.1 | 0.1 | 0.1 |

| Point 3 | - | - | - |

| Average | 62.5 | 81.0 | 81.9 |

| Standard deviation | 0.7 | 0.0 | 0.1 |

| Media Global | 64.5 | 81.2 | 82.7 |

| Standard deviation | 3.2 | 0.2 | 1.2 |

| Measure | Angle (Deg) | ||

|---|---|---|---|

| 20° | 60° | 85° | |

| GU (Gloss Units) | |||

| Point 1 | - | - | - |

| Average | 0.0 | 0.0 | 97.2 |

| Standard deviation | 0.0 | 0.0 | 0.1 |

| Point 2 | - | - | - |

| Average | 0.0 | 0.0 | 97.1 |

| Standard deviation | 0.0 | 0.0 | 0.1 |

| Point 3 | - | - | - |

| Average | 0.0 | 0.0 | 97.4 |

| Standard deviation | 0.0 | 0.0 | 0.2 |

| Media Global | 0.0 | 0.0 | 97.2 |

| Standard deviation | 0.0 | 0.0 | 0.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Echarri-Iribarren, V.; Rizo-Maestre, C. Gloss, Light Reflection and Iridescence in Ceramic Tile Enamels Containing ZrO2 and ZnO. Coatings 2020, 10, 854. https://doi.org/10.3390/coatings10090854

Echarri-Iribarren V, Rizo-Maestre C. Gloss, Light Reflection and Iridescence in Ceramic Tile Enamels Containing ZrO2 and ZnO. Coatings. 2020; 10(9):854. https://doi.org/10.3390/coatings10090854

Chicago/Turabian StyleEcharri-Iribarren, Víctor, and Carlos Rizo-Maestre. 2020. "Gloss, Light Reflection and Iridescence in Ceramic Tile Enamels Containing ZrO2 and ZnO" Coatings 10, no. 9: 854. https://doi.org/10.3390/coatings10090854

APA StyleEcharri-Iribarren, V., & Rizo-Maestre, C. (2020). Gloss, Light Reflection and Iridescence in Ceramic Tile Enamels Containing ZrO2 and ZnO. Coatings, 10(9), 854. https://doi.org/10.3390/coatings10090854