Experimental Study on the Thickness-Dependent Hardness of SiO2 Thin Films Using Nanoindentation

Abstract

:1. Introduction

2. Theoretical Approach

3. Experimental Details

4. Results and Discussion

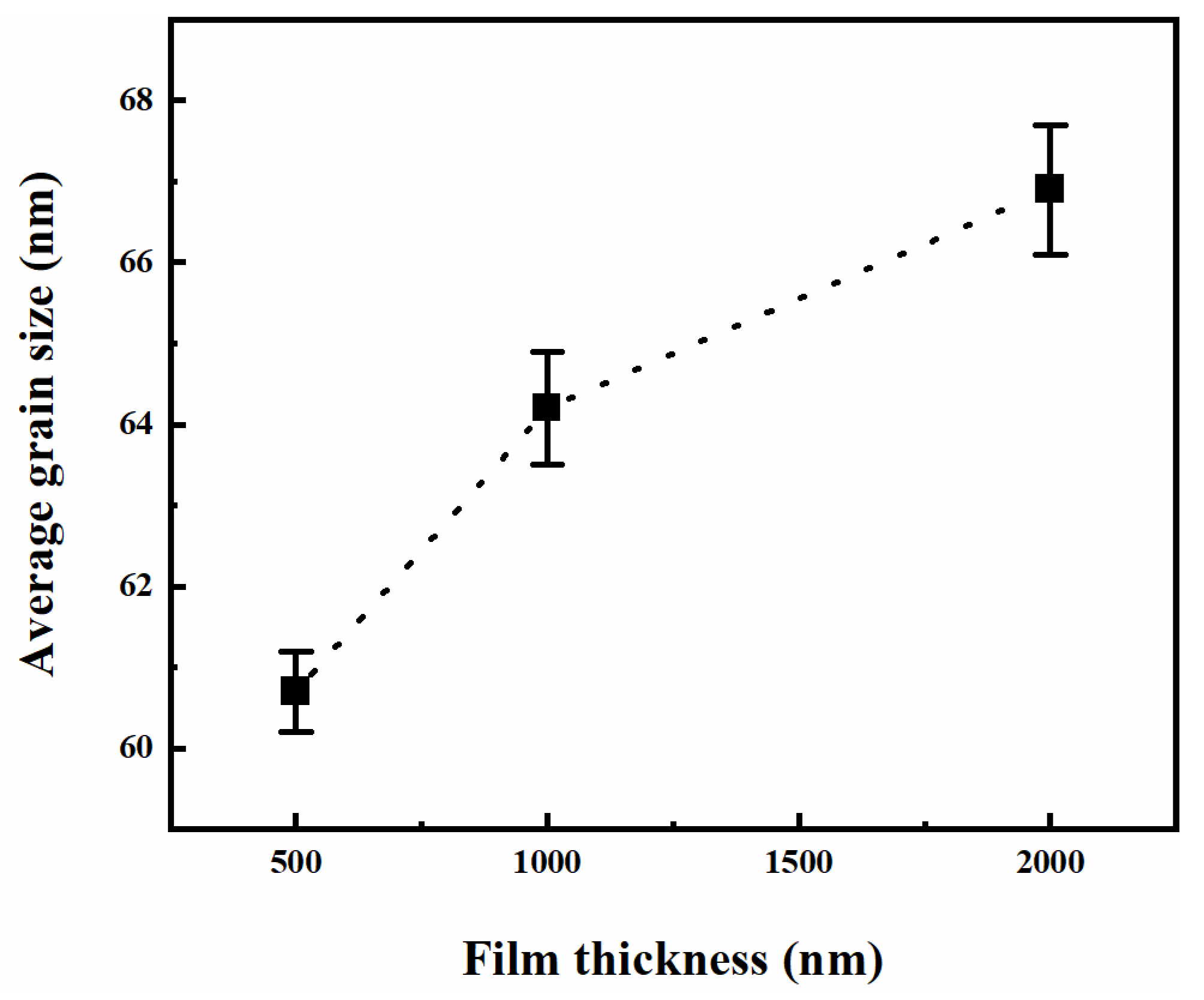

4.1. Morphology of the SiO2 Thin Films

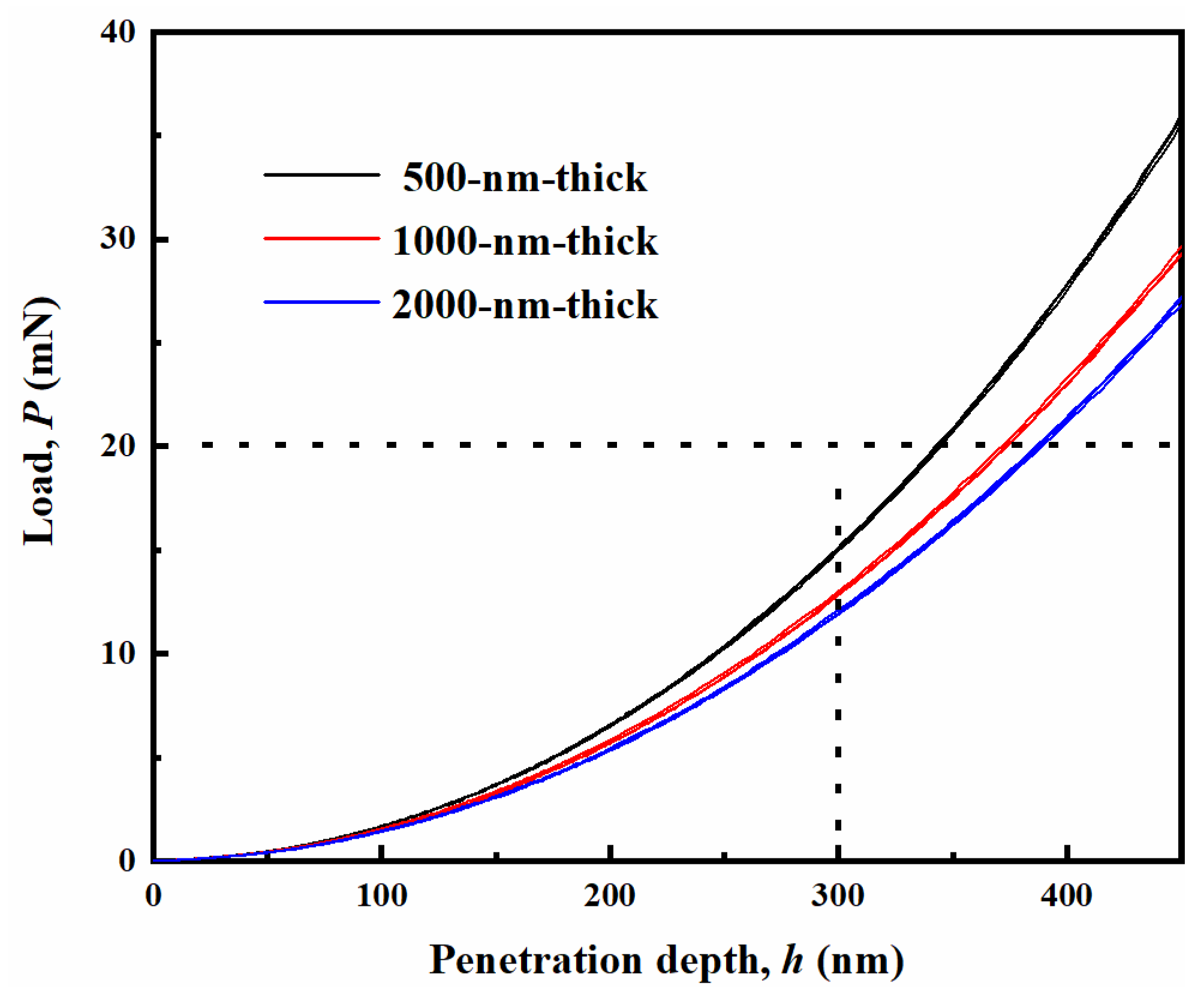

4.2. Load-Penetration Depth Curves of the SiO2 Thin Films

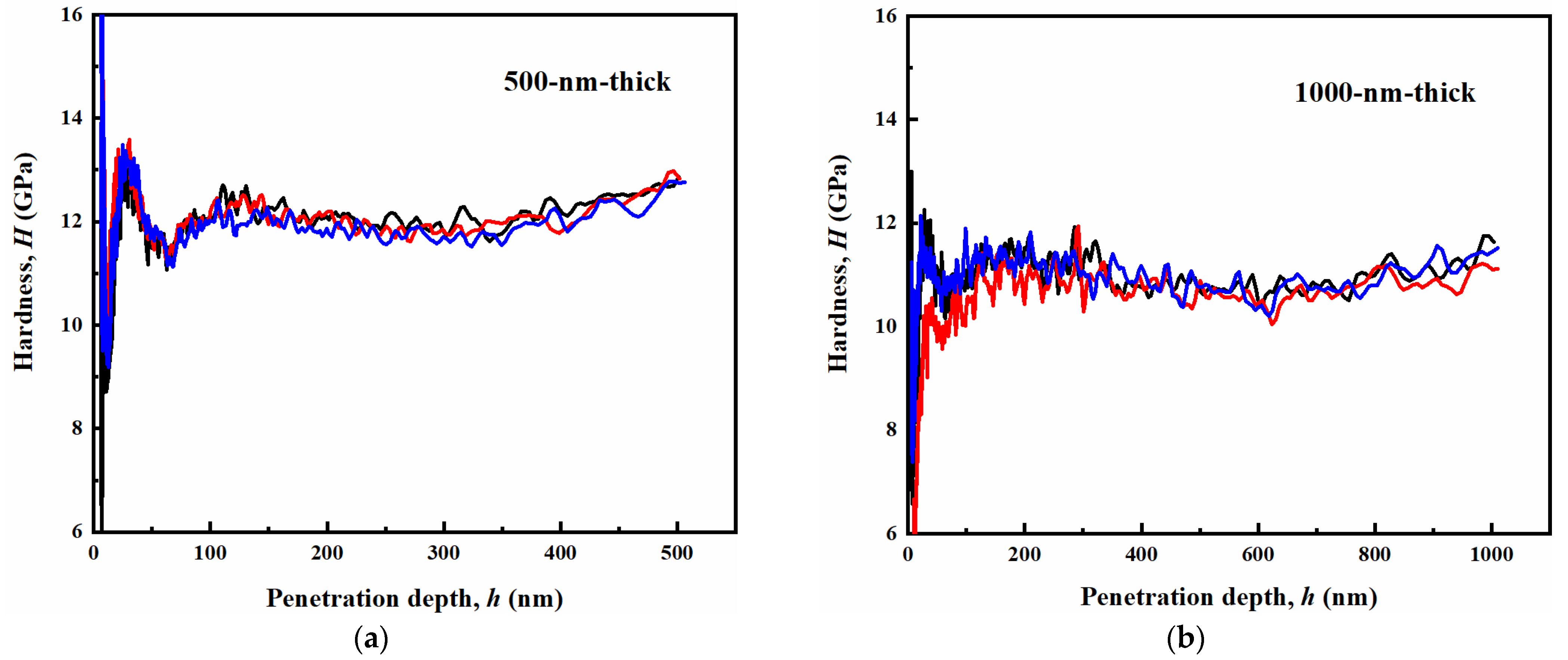

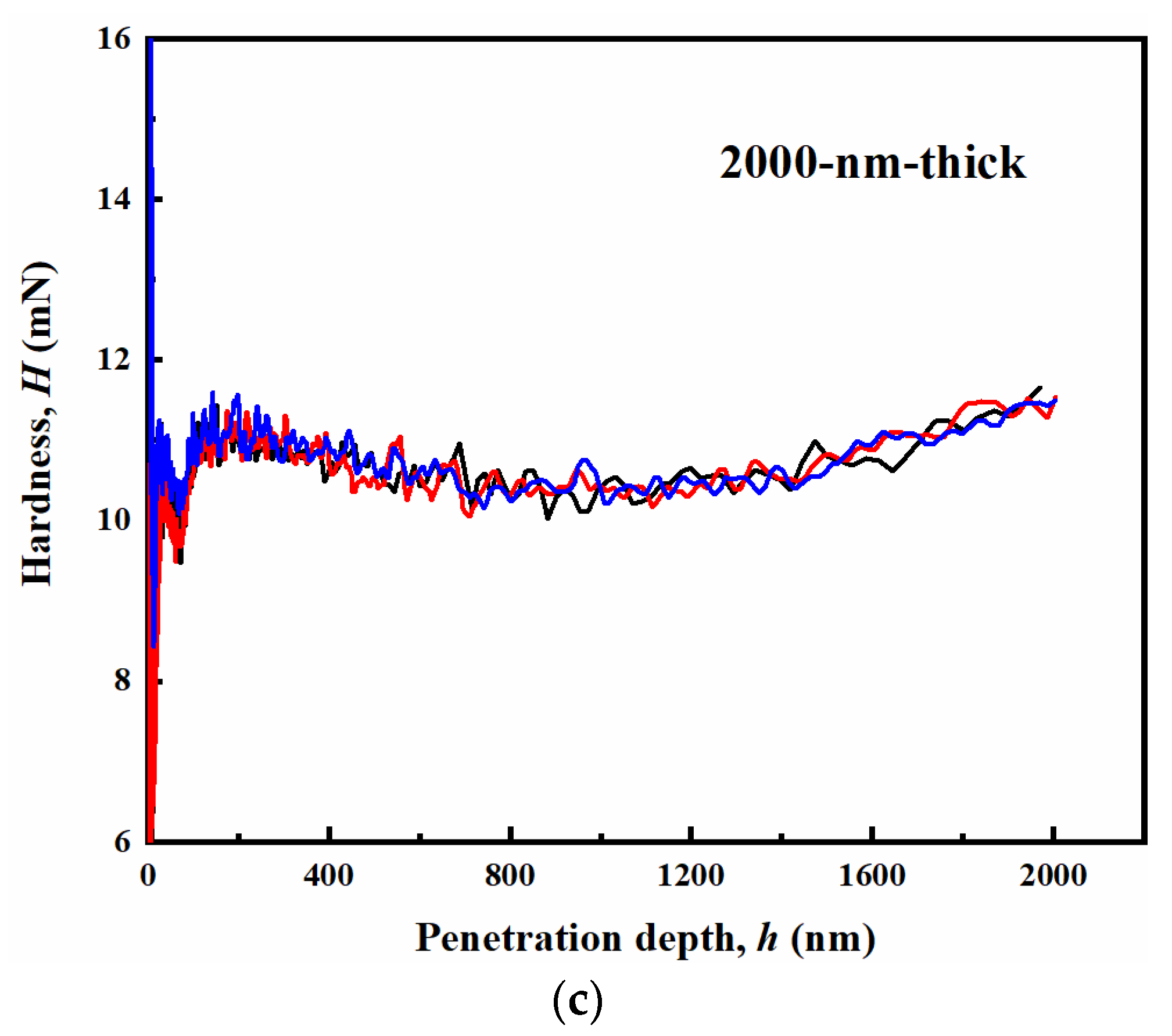

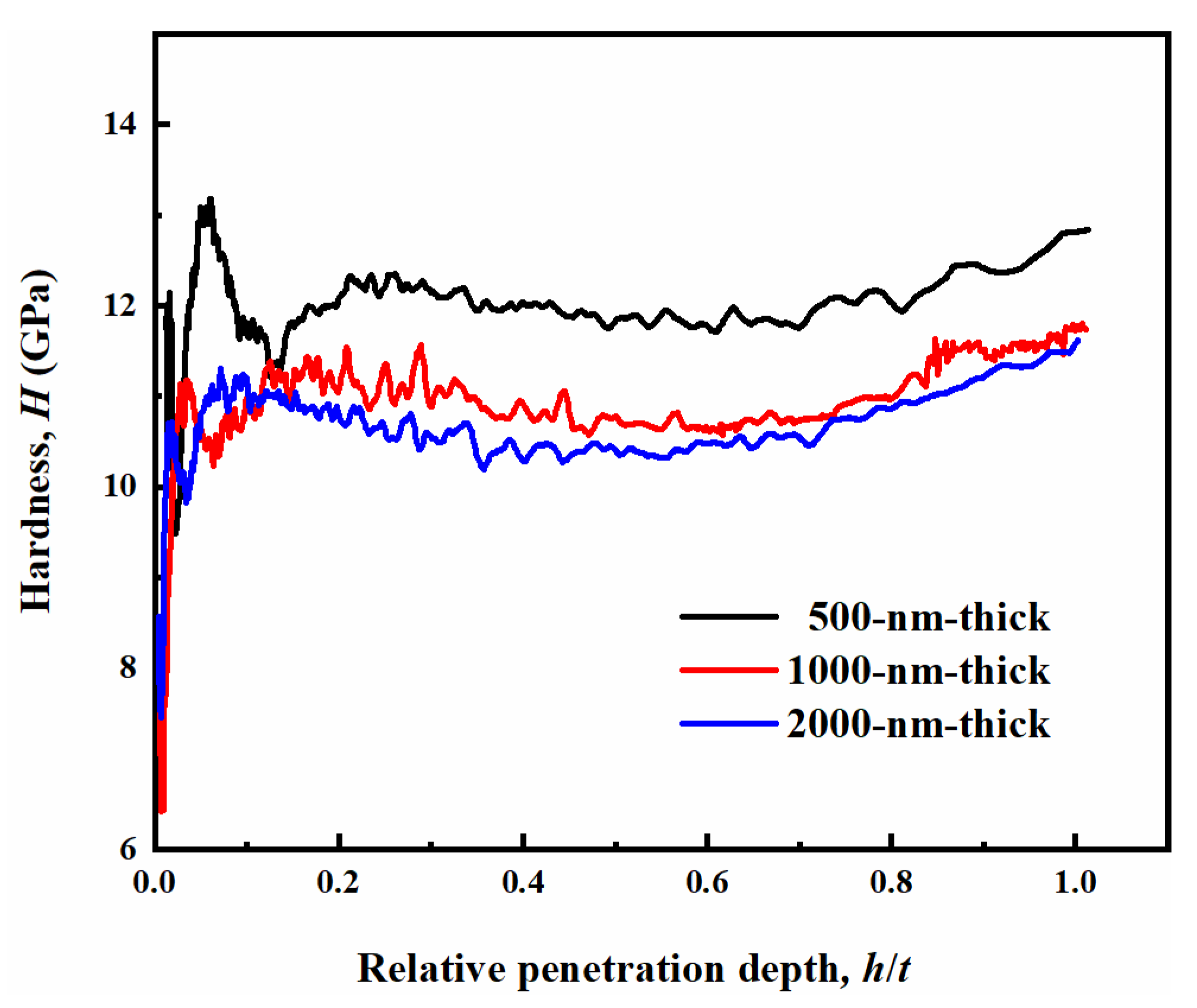

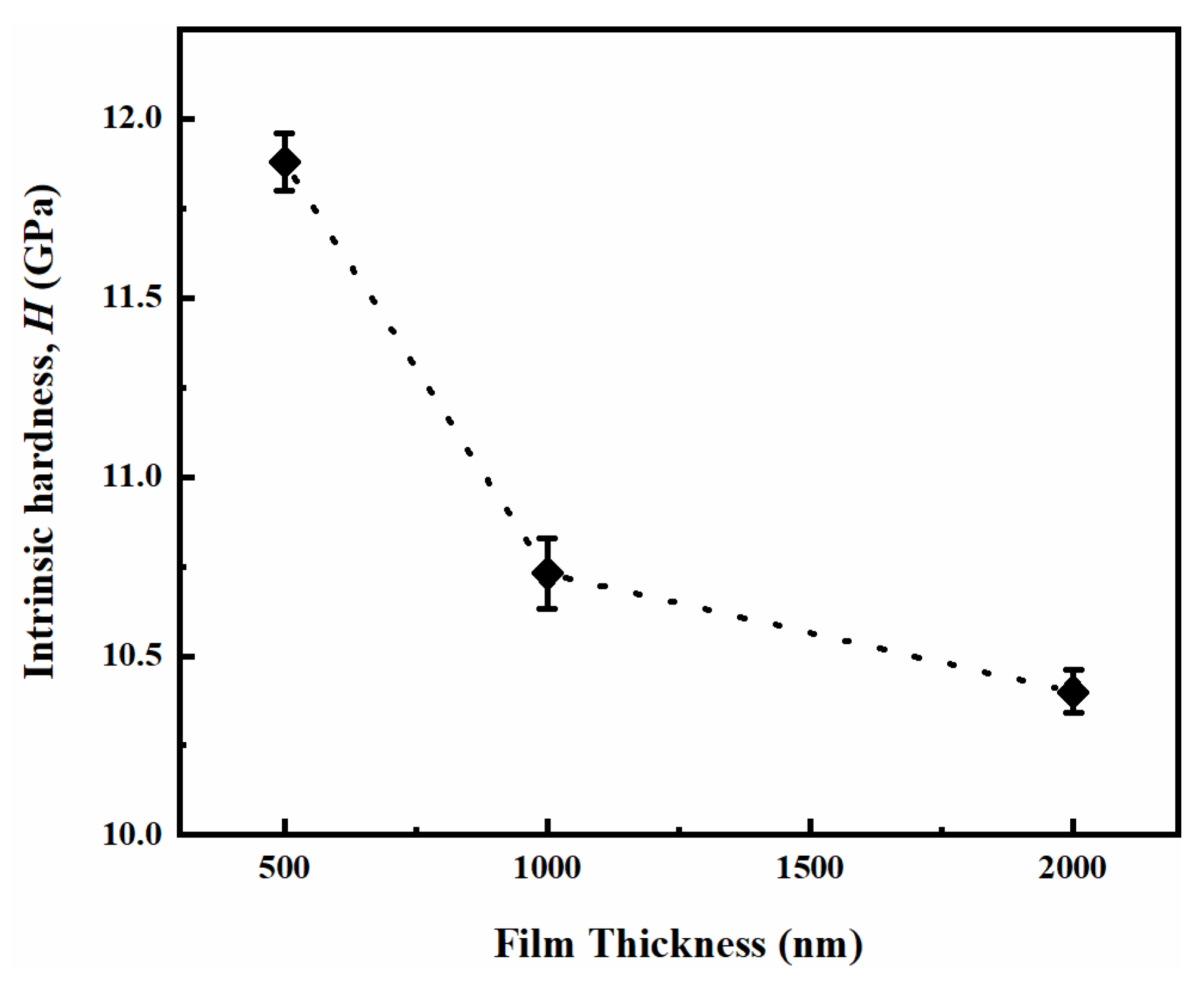

4.3. Hardness of the SiO2 Thin Films

5. Conclusions

- (1)

- The values of surface roughness parameters (Ra, RMS and Rz) of the three SiO2 thin films with different thicknesses were in the order of nanometer, indicating that the three SiO2 thin films with different thicknesses had good smoothness, ensuring the accuracy and consistency of the nanoindentation experimental results. The average grain sizes of the 500-, 1000- and 2000-nm-thick SiO2 thin films were measured to be 60.7, 64.2 and 66.9 nm, respectively, indicating that the average grain size of SiO2 thin film increased with increasing film thickness.

- (2)

- The load–penetration depth curves of the three SiO2 thin films with different thicknesses demonstrate small variation and low noise, the experimental data have good repeatability, reliability and accuracy, and the three SiO2 thin films with different thicknesses have good uniformity. The SiO2 film with the thickness of 500 nm had the highest resistance to external pressure, while the SiO2 film with the thickness of 2000 nm had the lowest. Irreversible plastic deformation occurred in the three SiO2 thin films with different thicknesses during the nanoindentation process.

- (3)

- The average intrinsic hardnesses of the 500-, 1000- and 2000-nm-thick SiO2 thin films were 11.9, 10.7 and 10.4 GPa, respectively. The average intrinsic hardness of the SiO2 thin film decreased with increasing film thickness and average grain size, exhibiting a similar trend to the Hall-Petch type relationship.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, P.; Wang, C.; Li, C.; Yang, J.; Qiu, F.; Wang, R.; Yang, Y. Optical properties of the low-energy Ge-implanted and annealed SiO2 films. Opt. Mater. 2015, 46, 491–496. [Google Scholar] [CrossRef]

- Bose, S.; Cunha, J.M.V.; Suresh, S.; Wild, J.D.; Lopes, T.S.; Barbosa, J.R.S.; Silva, R.; Borme, J.; Fernandes, P.A.; Vermang, B.; et al. Optical lithography patterning of SiO2 layers for interface passivation of thin film solar cells. Sol. RRL 2018, 2, 1800212. [Google Scholar] [CrossRef]

- Zukowski, P.; Koltunowicz, T.N.; Czarnacka, K.; Fedotov, A.; Tyschenko, I.E. Carrier transport and dielectric permittivity of SiO2 films containing ion-beam synthesized InSb nanocrystals. J. Alloys Compd. 2020, 846, 156482. [Google Scholar] [CrossRef]

- Huang, C.; Lin, Y. Surface properties of SiO2 with and without H2O2 treatment as gate dielectrics for pentacene thin-film transistor applications. Chem. Phys. Lett. 2018, 691, 141–145. [Google Scholar] [CrossRef]

- Li, W.; Mu, C. Charging effects of SiO2 thin film on Si substrate irradiated by penetrating electron beam. Micron 2021, 140, 102961. [Google Scholar] [CrossRef] [PubMed]

- Qin, F.; Jiang, L.; Long, P.; Xu, S.; Ling, Y.; Yu, Y.; Wei, G. Effect of deposition potential on preparation and corrosion resistance of SiO2 film on copper. Int. J. Electrochem. Sci. 2020, 15, 6478–6487. [Google Scholar] [CrossRef]

- Mazur, A.; Checmanowski, J.G.; Szczygiel, B. The effect of SiO2 thin films deposited on the sol-gel method on steel 316L on its corrosion resistance and bioactivity in artificial blood solution. Przem. Chem. 2017, 96, 1183–1188. [Google Scholar]

- Lu, J.; Xu, Y.; Zhang, Y.; Xu, X. The effects of SiO2 coating on diamond abrasives in sol-gel tool for SiC substrate polishing. Diam. Relat. Mater. 2017, 76, 123–131. [Google Scholar] [CrossRef]

- Chen, A.; Chen, Y.; Wang, Y.; Qin, J. Silica abrasives containing solid cores and mesoporous shells: Synthesis, characterization and polishing behavior for SiO2 film. J. Alloys Compd. 2016, 663, 60–67. [Google Scholar] [CrossRef]

- Vanheusden, K.; Warren, W.L.; Devine, R.A.B.; Fleetwood, D.M.; Schwank, J.R.; Shaneyfelt, M.R.; Winokur, P.S.; Lemnious, Z.J. Non-volatile memory device based on mobile protons in SiO2 thin films. Nature 1997, 386, 587–589. [Google Scholar] [CrossRef]

- Lin, Y.; Hung, C.; Huang, J.; Lin, S.; Chang, H. Electrical and surface properties of SiO2 films modified by ultraviolet irradiation and used as gate dielectrics for pentacene thin-film transistor applications. Chin. J. Phys. 2019, 61, 248–254. [Google Scholar] [CrossRef]

- Choi, Y.; Bae, S.; Kim, J.; Kim, E.; Hwang, H.; Park, J.; Yang, H.; Choi, E.; Hwang, J. Robust SiO2 gate dielectric thin films prepared through plasma-enhanced atomic layer deposition involving di-sopropylamino silane (DIPAS) and oxygen plasma: Application to amorphous oxide thin film transistors. Ceram. Int. 2018, 44, 1556–1565. [Google Scholar] [CrossRef]

- Wu, F.; Si, S.; Shi, T.; Zhao, X.; Liu, Q.; Liao, L.; Lv, H.; Long, S.; Liu, M. Negative differential resistance effect induced by metal ion implantation in SiO2 film for multilevel RRAM application. Nanotechnology 2018, 29, 054001. [Google Scholar] [CrossRef] [PubMed]

- Wostbrock, N.; Busani, T. Stress and refractive index control of SiO2 thin films for suspended waveguides. Nanomaterials 2020, 10, 2105. [Google Scholar] [CrossRef] [PubMed]

- Pfeiffer, K.; Shestaeva, S.; Bingel, A.; Munzert, P.; Ghazaryan, L.; Helvoirt, C.V.; Kessels, W.M.M.; Sanli, U.T.; Grévent, C.; Schütz, G.; et al. Comparative study of ALD SiO2 thin films for optical applications. Opt. Mater. Express 2016, 2, 660–670. [Google Scholar] [CrossRef] [Green Version]

- Ullah, A.; Wilke, H.; Memon, I.; Shen, Y.; Nguyen, D.T.; Woidt, C.; Hillmer, H. Stress relaxation in dual ion beam sputtered Nb2O5 and SiO2 thin films: Application in a Fabry-Pérot filter array with 3D nanoimprinted cavities. J. Micromech. Microeng. 2015, 25, 055019. [Google Scholar] [CrossRef]

- Sun, Q.; Sun, D.; Shang, H.; Yu, T.; Chang, L.; Sun, Z.; Xing, W.; Dong, M. Study of birefringence and stress distribution of SiO2 film optical waveguide on silicon wafer. Coatings 2019, 9, 316. [Google Scholar] [CrossRef] [Green Version]

- Hasunuma, R.; Kawamura, H.; Yamabe, K. Reliability factors of ultrathin dielectric films based on highly controlled SiO2 films. Jpn. J. Appl. Phys. 2018, 57, 06KB05. [Google Scholar] [CrossRef]

- Revilla, R.I.; Li, X.; Yang, Y.; Wang, C. Large electric field-enhanced-hardness effect in a SiO2 film. Sci. Rep. 2014, 4, 4523. [Google Scholar] [CrossRef] [Green Version]

- Jeffery, S.; Sofield, C.J.; Pethica, J.B. The influence of mechanical stress on the dielectric breakdown field strength of thin SiO2 films. Appl. Phys. Lett. 1998, 73, 172–174. [Google Scholar] [CrossRef]

- Yamabe, K.; Liao, K.; Minemura, H.; Murata, M. Nonuniform distribution of trapped charges in electron injection stressed SiO2 films. J. Electrochem. Soc. 2001, 148, F9–F11. [Google Scholar] [CrossRef]

- Yang, T.; Saraswat, K.C. Effect of physical stress on the degradation of thin SiO2 films under electrical stress. IEEE Trans. Electron Dev. 2000, 47, 746–755. [Google Scholar] [CrossRef]

- Guo, Y.; Staedler, T.; Fu, H.; Heuser, S.; Jiang, X. A novel way to quantitatively determine the mechanical properties of thin films from the initial-grown surface by nanoindentation. Appl. Surf. Sci. 2019, 479, 253–259. [Google Scholar] [CrossRef]

- Broitman, E.; Tengdelius, L.; Hangen, U.D.; Lu, J.; Hultman, L.; Hoögberg, H. High-temperature nanoindentation of epitaxial ZrB2 thin films. Scripta Mater. 2016, 124, 117–120. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Zhang, J.; Wu, K.; Liu, G.; Kiener, D.; Sun, J. Nanoindentation creep behavior of Cu–Zr metallic glass films. Mater. Res. Lett. 2018, 6, 22–28. [Google Scholar] [CrossRef] [Green Version]

- Haviar, S.; Kozák, T.; Meindlhumer, M.; Zitek, M.; Opatova, K.; Kučerová, L.; Keckes, J.; Zeman, P. Nanoindentation and microbending analyses of glassy and crystalline Zr(–Hf)–Cu thin-film alloys. Surf. Coat. Technol. 2020, 399, 126139. [Google Scholar] [CrossRef]

- Xiao, K.; Li, J.; Wu, X.; Liu, H.; Huang, C.; Li, Y. Nanoindentation of thin graphdiyne films: Experiments and molecular dynamics simulation. Carbon 2019, 144, 72–80. [Google Scholar] [CrossRef] [Green Version]

- Li, R.; Li, Y.; Yan, C.; Bao, Y.; Sun, H.; Hu, H.; Li, N. Thickness-dependent and tunable mechanical properties of CaTiO3 dielectric thin films determined by nanoindentation technique. Ceram. Int. 2020, 46, 22643–22649. [Google Scholar] [CrossRef]

- Grashchenko, A.S.; Kukushkin, S.A.; Osipov, A.V.; Redkov, A.V. Nanoindentation of GaN/SiC thin films on silicon substrate. J. Phys. Chem. Solids 2017, 102, 151–156. [Google Scholar] [CrossRef]

- Ozmetin, A.E.; Sahin, O.; Ongun, E.; Kuru, M. Mechanical characterization of MgB2 thin films using nanoindentation technique. J. Alloys Compd. 2015, 619, 262–266. [Google Scholar] [CrossRef]

- Chen, J.; Bull, S.J. On the factors affecting the critical indenter penetration for measurement of coating hardness. Vacuum 2009, 83, 911–920. [Google Scholar] [CrossRef]

- Qin, H.; Xiao, X.; Sui, X.; Qi, H. Influence of residual stress on the determination of Young’s modulus for SiO2 thin film by the surface acoustic waves. Jpn. J. Appl. Phys. 2019, 58, SHHG01. [Google Scholar] [CrossRef]

- Rakshit, S.; Tripuraneni, R.; Nadimpalli, S.P.V. Real-time stress measurement in SiO2 thin films during electrochemical lithiation/delithiation cycling. Exp. Mech. 2018, 58, 537–547. [Google Scholar] [CrossRef]

- Ho, C.; Alexis, J.; Dalverny, O.; Balcaen, Y.; Faure, B. Mechanical adhesion of SiO2 thin films onto polymeric substrates. Surf. Eng. 2018, 35, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; He, H.; Zhang, W. Substrate effects on the microstructure and mechanical properties of SiO2 thin films. J. Inorg. Mater. 2013, 28, 653–658. [Google Scholar] [CrossRef]

- Šimurka, L.; Čtvrtlik, R.; Tomaštík, J.; Bektaş, G.; Svoboda, J.; Bange, K. Mechanical and optical properties of SiO2 thin films deposited on glass. Chem. Pap. 2018, 72, 2143–2151. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiment. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Pharr, G.M.; Oliver, W.C. Measurement of thin film mechanical properties using nanoindentation. Mrs Bulletin. 1992, 17, 28–33. [Google Scholar] [CrossRef]

- Poobalan, B.; Moon, J.H.; Kim, S.; Job, S.; Bahng, W.; Kang, I.H.; Kim, N.; Cheong, K. Investigation of SiO2 film growth on 4H–SiC by direct thermal oxidation and postoxidation annealing techniques in HNO3 & H2O vapor at varied process durations. Thin Solid Film. 2014, 570, 138–149. [Google Scholar]

- Sobola, D.; Ramazanov, S.; Konečný, M.; Orudzhev, F.; Kaspar, P.; Papež, N.; Knápek, A.; Potocek, M. Complementary SEM-AFM of swelling Bi–Fe–O film on HOPG substrate. Materials 2020, 13, 2402. [Google Scholar] [CrossRef]

- Sobola, D.; Talu, S.; Sadovsky, P.; Papez, N.; Grmela, L. Application of AFM measurement and fractal analysis to study the surface the surface of natural optical structures. Adv. Electr. Electron. Eng. 2017, 15, 569–576. [Google Scholar] [CrossRef]

- Gao, Q.; Jiang, H.; Li, M.; Lu, P.; Lai, X.; Li, X.; Liu, Y.; Song, C.; Han, G. Improved mechanical properties of SnO2/F thin film by structural modification. Ceram. Int. 2014, 40, 2557–2564. [Google Scholar] [CrossRef]

- Cai, X.; Bangert, H. Hardness measurements of thin films-determining the critical ratio of depth to thickness using FEM. Thin Solid Film. 1995, 264, 59–71. [Google Scholar] [CrossRef]

- Bartali, R.; Vaccari, A.; Micheli, V.; Gottardi, G.; Pandiyan, R.; Collini, A.; Lori, P.; Coser, G.; Laidani, N. Critical relative indentation depth in carbon based thin films. Prog. Nat. Sci.-Mater. 2014, 24, 287–290. [Google Scholar] [CrossRef] [Green Version]

- Hakamada, M.; Nakamoto, Y.; Matsumoto, H.; Iwasaki, H.; Chen, Y.; Kusuda, H.; Mabuchi, M. Relationship between hardness and grain size in electrodeposited copper films. Mat. Sci. Eng. A 2007, 457, 120–126. [Google Scholar] [CrossRef]

- Yip, S. The strongest size. Nature 1998, 391, 532–533. [Google Scholar] [CrossRef]

- Ellis, E.A.I.; Chmielus, M.; Han, S.; Baker, S.P. Effect of sputter pressure on microstructure and properties of β-Ta thin films. Acta Mater. 2020, 183, 504–513. [Google Scholar] [CrossRef]

- Kumar, K.S.; Swygenhoven, H.V.; Suresh, S. Mechanical behavior of nanocrystalline metals and alloys. Acta Mater. 2003, 51, 5743–5774. [Google Scholar] [CrossRef]

- Cheng, S.; Spencer, J.A.; Milligan, W.W. Strength and tension/compression asymmetry in nanostructured and ultrafine-grain metals. Acta Mater. 2003, 51, 4505–4518. [Google Scholar] [CrossRef]

| SiO2 Film Thickness (nm) | Ra (nm) | RMS Roughness (nm) | Rz (nm) | Average Grain Size (nm) |

|---|---|---|---|---|

| 500 | 2.84 | 3.23 | 3.35 | 60.7 |

| 1000 | 2.92 | 3.52 | 3.39 | 64.2 |

| 2000 | 3.00 | 3.36 | 10.96 | 66.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Li, J.; Xing, Y.; Nie, X.; Lang, F.; Yang, S.; Hou, X.; Zhao, C. Experimental Study on the Thickness-Dependent Hardness of SiO2 Thin Films Using Nanoindentation. Coatings 2021, 11, 23. https://doi.org/10.3390/coatings11010023

Zhang W, Li J, Xing Y, Nie X, Lang F, Yang S, Hou X, Zhao C. Experimental Study on the Thickness-Dependent Hardness of SiO2 Thin Films Using Nanoindentation. Coatings. 2021; 11(1):23. https://doi.org/10.3390/coatings11010023

Chicago/Turabian StyleZhang, Weiguang, Jijun Li, Yongming Xing, Xiaomeng Nie, Fengchao Lang, Shiting Yang, Xiaohu Hou, and Chunwang Zhao. 2021. "Experimental Study on the Thickness-Dependent Hardness of SiO2 Thin Films Using Nanoindentation" Coatings 11, no. 1: 23. https://doi.org/10.3390/coatings11010023

APA StyleZhang, W., Li, J., Xing, Y., Nie, X., Lang, F., Yang, S., Hou, X., & Zhao, C. (2021). Experimental Study on the Thickness-Dependent Hardness of SiO2 Thin Films Using Nanoindentation. Coatings, 11(1), 23. https://doi.org/10.3390/coatings11010023